Abstract

An overview of the dropwise condensation process is presented in the preceding chapters. It involves vapor-to-liquid phase change in the form of discrete drops on or underneath horizontal and inclined substrates. The process is hierarchical, in the sense that it occurs over a wide range of length and timescales. A mathematical model of dropwise condensation underneath textured surfaces, horizontal and inclined, is discussed in the text. The model starts from the formation of drops at the atomic scale at randomized nucleation sites, and follows its growth by direct condensation and coalescence, till individual drops are large enough to fall off or slide away. Fresh nucleation commences on the exposed surface devoid of drops and the cycle continues in a quasi-steady state. Predictions of numerical simulation are compared against experimentally derived condensation patterns and heat fluxes. The significance of droplet level details including statics, spreading, and coalescence is revealed in the text. Additional discussion related to surface preparation and measurement of heat fluxes on the drop-scale and the device-scale are presented. This final chapter closes with newer directions that are likely to be explored in the future.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Droplet statics

- Spreading and coalescence

- Dropwise condensation model

- Comparison with experiments

- Surface preparation

- Heat flux measurement

- Future work

1 Droplet Statics

Dropwise condensation is a multiscale process; small-scale processes impact the macroscopically observed drop distribution and heat transfer rates. The smallest drop that is nucleated over the substrate arises from a balance of internal pressure and drop curvature superimposed over the thermodynamic phase behavior. Subsequently, it grows by direct condensation of vapor over the liquid-vapor interface. In this connection, static considerations of a liquid drop resting over a textured surface are discussed in the text. The governing equation arising from force balance is the Young-Laplace equation, with surface characteristics specified in terms of the contact angle distribution around the three-phase contact line of the drop. Methods of solving this equation, mainly for the drop shape, are discussed. The contact line and the contact angle are shown to be important factors in fixing the drop shape.

2 Droplet Spreading

For a given volume of the drop and prescribed surface properties and inclination, the drop attains an equilibrium shape. Of course, the shape tends to become a part of a sphere for increasing levels of hydrophobicity and diminishing contact hysteresis. Any departure from equilibrium leads to drop spreading, namely a process in which fluid velocity arises from non-equilibrium conditions. Spreading itself is a multiscale process in time during which droplet oscillations may be observed, but is ultimately followed by a viscous dissipation controlled, asymptotic decay of the transience. The spreading process is intricate and is rich in details. In the text, a contact line model that is free of modeling approximations is presented. It is shown to match experiments quite well.

3 Coalescence Dynamics

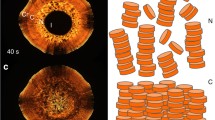

The coalescence model adopted in most studies approximates the nuances of the overall merger process, by requiring that it occurs instantaneously, moving from one equilibrium shape to the next. Preliminary experiments highlight the subtleties of the process and reveal complex flow patterns including oscillations of the free surface and large instantaneous wall shear stresses and wall heat fluxes. Specifically, drop coalescence commences when two droplets approach each other and contact either at the three-phase contact line or above the surface, depending on the degree of hydrophobicity of the surface. A tiny liquid bridge is immediately formed, induced by the van der Waals forces. The coalescence process gets initiated by the extra surface energy released in the process. The difference in internal pressure between the two drops drives fluid motion. Immediately afterward, the coalescence process tends to get limited by viscous and inertia forces. In typical water droplets, free surface oscillation can last ~20–40 ms, depending on their size, substrate orientation, and thermophysical properties. Long-term relaxation can occur over 40–100 ms. Rapid transients in the early stage of coalescence will induce large shear stresses over the substrate, further accompanied by enhancement of the wall heat fluxes. To address this issue, experiments on coalescence of sessile and pendant drops were carried out on a hydrophobic surface. The phenomenon was imaged using a high-speed camera. The length, velocity, and timescales of coalescence were determined and compared with analytical estimates. This data was subsequently integrated with the dropwise condensation model to incorporate finite time effects in the simulation.

4 Dropwise Condensation

Dropwise condensation, the primary application of interest, is vapor-to-liquid phase change in the form of discrete drops on or underneath horizontal and inclined substrates. The process is hierarchical in the sense that it occurs over a wide range of length and timescales. A mathematical model of dropwise condensation underneath textured surfaces, horizontal (with or without wettability gradient) and inclined, is reported. The model starts from the formation of drops at the atomic scale at randomized nucleation sites and follows its growth by direct condensation and coalescence, till the drop is large enough to fall off or slide away. The atomic model shows that the largest stable cluster size in the atomic scale matches the minimum drop radius estimated from thermodynamic considerations. The drops of minimum radius are insensitive to surface texturing and do not provide controllability at large length and timescales. In the model, nucleation sites are randomly distributed over the substrate. Growth rate at each nucleation site is derived, on the basis that vapor condenses on the free surface of the drop, and releases latent heat, that is transferred through the liquid drop to the cold substrate. The stability criterion is developed as a force balance equation at the level of a drop. Transport parameters of a sliding drop are determined using a CFD model and presented in the form of correlations. Fluids considered are water, and liquid metals such as mercury and sodium, representing a wide range of Prandtl numbers. Performing simulation of the complete cycle of dropwise condensation, the spatio-temporal distribution of drops is obtained, from which local and area-averaged heat transfer rates, as a function of time are predicted.

An experimental study of water vapor condensation underneath a chemically textured substrate is carried out for validation of the complete dropwise condensation model. Substrate preparation involves coating the glass surface using chemical vapor deposition of silane molecules. The spatio-temporal drop distribution recorded during the experiment and observed in simulation underneath an inclined chemically textured substrate show fair to good agreement. Heat transfer rates are also validated against experiment data of water vapor and mercury available in the literature. Specific conclusions arrived at in the present study are listed below.

4.1 Drop Instability

The critical drop radius at which commencement of sliding takes place is a function of the thermophysical properties of the fluid, inclination of the substrate and contact angle hysteresis. Fluids with higher surface tension show larger size at instability. Reduction in contact angle hysteresis reduces the critical size, for a given angle of inclination.

4.2 Modeling Fluid Motion Inside a Moving Drop

During motion, a circulation pattern is set up within the drop volume. The center of the circulation pattern moves towards the solid surface at higher Reynolds numbers. Pressure and wall shear stress are nearly uniform at the base of the drop, except at the periphery, where large gradients prevail. Heat transfer in drops of high Prandtl numbers is characterized by the appearance of thermal boundary layers. Temperature distribution across the drop shows large gradients near the walls while temperature inversion is seen in the core. At lower Prandtl numbers, diffusive transport governs heat transfer rates and a near-linear variation of the temperature profile is obtained.

4.3 Macroscopic Modeling

The overall condensation model includes the effect of contact angle, hysteresis, inclination of the substrate, thermophysical properties of fluids, nucleation site density, degree of subcooling, saturation temperature, promoter layer thickness, and wettability gradient. Simulation for various fluids and substrate inclinations shows the following trends.

-

1.

Dropwise condensation is necessarily a quasi-cyclic process from which the average drop size, distribution, and cycle time as well as overall heat transfer coefficient and wall shear can be computed.

-

2.

Two distinct phases of droplet growth are observed: growth due to direct condensation and growth primarily due to coalescence.

-

3.

Increase of static contact angle (decrease in wettability of the substrate) reduces the droplet area coverage. Reduction of coverage is also observed by increasing the substrate inclination.

-

4.

Decrease in wettability results in earlier fall-off (horizontal substrate) and earlier slide-off (inclined substrate).

-

5.

The critical radius of droplet at which commencement of sliding takes place is a function of the thermophysical properties of the fluid, inclination of the substrate and contact angle hysteresis. Fluids with higher surface tension show larger critical radius. Reduction in contact angle hysteresis reduces the critical radius of the droplet for a given angle of inclination.

-

6.

Inclining the substrate results in larger number of small drops and hence in higher heat transfer coefficient.

-

7.

Heat transfer coefficient increases with an increase in the degree of subcooling, saturation temperature, and is a strong function of the Prandtl number.

-

8.

Providing wettability gradient serves the purpose of passively destabilizing drops in a manner similar to inclined surfaces in a gravity field. It results in a larger number of small drops and hence will lead to a higher average heat transfer coefficient.

-

9.

Nucleation sites density is an uncertain parameter that can be determined only indirectly but has a definite effect on the heat transfer coefficient. A high nucleation density leads to frequent drop mergers and instability followed by fresh nucleation, thus reducing the average drop size. Hence, it leads to a high overall heat transfer coefficient.

4.4 Water Versus Bismuth

The dropwise condensation model has been first simulated with water, and the condensation characteristics are then compared with that of bismuth. Differences arise mainly from those in thermophysical properties. Relative to water, liquid bismuth has a higher density, higher thermal conductivity, higher surface tension with vapor, higher viscosity but a much smaller latent heat of vaporization, thus generating several contrasts with it. Cycle time, minimum radius of drop, holdup, and vapor-liquid interfacial resistance of liquid bismuth are larger than water for both horizontal and vertical surfaces. Maximum radius of drop, average radius of drop, conductance resistance, and average heat transfer coefficient of liquid bismuth are smaller than water for both horizontal and vertical surfaces. As a result, wall heat flux based on direct condensation as well as coalescence is substantially larger for water than liquid bismuth for both horizontal and vertical surfaces. The average heat transfer coefficient in bismuth is smaller than for water. Fluctuations in heat fluxes in water are small but frequent while in bismuth, the local peaks arising from drop instability are larger and occasional. Wall shear stresses generated during coalescence as well as sliding of drops are larger for liquid bismuth than water for both horizontal and vertical surfaces.

4.5 Surface Texturing

For laboratory-scale experiments on dropwise condensation, small patches of a surface can be chemically textured to generate the required level of hydrophobicity. Such techniques have been summarized in the text. Tools required for surface characterization in terms of equilibrium contact angle and contact angle hysteresis are also presented. For larger surface areas, surface patterning such as micro-grooves and nanoscale pillars are recommended. Texturing tubular surfaces is an ongoing part of research.

4.6 Measurement of Wall Heat Flux

Wall heat fluxes during dropwise condensation are large and show considerable variation in both space and time. Even on a scale of a single drop, the variation can go from small values at the center to a large value along the three-phase contact line. Heat fluxes will be large under drops that have just nucleated and small under those subject to incipient instability. An experiment involving liquid crystal thermography for measuring heat flux distribution under a single drop is discussed in the text. Since the space-averaged heat flux can also exhibit strong time dependence, an inverse methodology for estimation of the instantaneous heat flux from single thermocouple data is also discussed.

5 Future Work

Opting for dropwise condensation in advanced engineering systems involves not only an understanding of the fundamental thermo-fluidic transport phenomena but also the microscale issues associated with the individual drops and the surface characteristics of the substrate. Hence, future research should address the following concerns:

-

1.

Surface hydrophobicity is essential for realizing the dropwise condensation cycle. However, forces generated during spreading, coalescence, and movement of drops lead to surface damage. Hence, chemical texturing is limited by factors such as leaching that tend to peal out surface coatings. In this context, pillared or patterned surfaces are to be preferred.

-

2.

Creating physical textures by patterning that will ensure sustained hydrophobicity is a long-standing problem in surface engineering. The connection of a surface pattern with contact angle and hysteresis is unresolved. Specifically, the modeling of drop-level dynamics such as spreading and coalescence and the dropwise condensation cycle for a pillared surface are topics of importance.

-

3.

It is desirable that shear stresses experienced by the wall be small while wall heat fluxes are large. While models are helpful in determining these quantities, experimental validation is important. However, experimental determination of local and instantaneous wall shear stress and heat transfer coefficient is a challenge. The statistical nature of droplet distribution in the ensemble further contributes to the intricacy of analysis and interpretation.

-

4.

The mathematical model presented captures the major constituents of dropwise condensation process quite satisfactorily. There are local discrepancies, however. Looking at the experiments closely, the three-dimensional geometry of the growing drops, highly localized three-phase contact line motion and the 3D dynamics of coalescence need deeper investigation.

-

5.

Information gathered on dropwise condensation calls for its utilization in applications as diverse as water harvesting from atmospheric moist air and distillation of precious metals.

-

6.

Discussion on the behavior of small liquid drops will be useful in designing microfluidic switches, bio-MEMS devices, lab-on-chip, and electro-locomotion of liquid drops on dielectric surfaces.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Khandekar, S., Muralidhar, K. (2020). Closing Remarks and Prospects. In: Drop Dynamics and Dropwise Condensation on Textured Surfaces. Mechanical Engineering Series. Springer, Cham. https://doi.org/10.1007/978-3-030-48461-3_16

Download citation

DOI: https://doi.org/10.1007/978-3-030-48461-3_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-48460-6

Online ISBN: 978-3-030-48461-3

eBook Packages: EngineeringEngineering (R0)