Abstract

So far Ba scandate cathodes have shown the highest emission capability of all thermionic cathodes and are promising for future applications, e.g., in thermionic converters, in high-power high-frequency tubes, especially in vacuum terahertz devices. They are essentially based on Ba dispenser matrix cathodes modified with differently distributed additions of scandia. In this review, the historical development of different types of Ba scandate cathodes is addressed. Then the Philips activities on Laser ablation deposition (LAD) top-layer scandate cathodes with Re and Ba scandates are presented, which were mainly aimed at increasing ion bombardment resistivity and hence lifetime, but also led to record saturated pulsed emission of up to 400 A/cm2. Finally, the activities on nanosized-Scandia Doped Dispenser cathodes (SDD cathode) carried out more recently at Beijing University of Technology (BJUT) and Beijing Vacuum Electronics Research Institute (BVERI) in China, which mainly focused on application in high current density, long life advanced vacuum electron devices, are introduced. The outstanding emission capability and lifetime tested at both diodes and electron guns are presented and also basic investigations on the emission model are discussed. A further motivation for this review is to derive guidelines for more robust highly emissive Ba scandate cathodes suitable for future tube applications.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

3.1 Introduction: Historical Development of Different Types of Ba Scandate Dispenser Cathodes and Application Perspectives

As we have already seen in Chap. 1, vacuum electron sources or cathodes are the crucial components of a wide range of vacuum electron devices (VEDs) such as cathode-ray tubes (CRTs), X-ray tubes, or microwave tubes [1, 2]. Despite the decline of CRTs, advanced microwave and terahertz devices with applications ranging from civilian communication and scientific research to military and space-based technologies are being continuously improved [1,2,3]. One of the development challenges for advanced high power VEDs are electron sources with high current densities and long lifetime. VEDs operating at millimeter-wave and in THz range require cathodes that provide space charge limited (SCL) current densities up to 100 A/cm2 with good emission uniformity and more than 10,000 h of a lifetime at reasonable operating temperatures [3,4,5].

Since in high power microwave devices also substantial currents are needed, thermionic cathodes are the only candidates for this task at present. Among the currently available thermionic cathodes, Ba dispenser cathodes, including mixed matrix and M-type cathodes, have long lifetimes >20,000 h with current densities of 5–10 A/cm2 [2, 5]. However, at current densities of >20 A/cm2 their practicality becomes problematic, due to the high temperatures and excessive evaporation of cathode materials and hence shorter lifetime. Alloy cathodes such as Ir2La and Ir5Ce can provide pulsed current densities of 50–100 A/cm2, but at very high operating temperatures of 1600–1800 °C and a lifetime in the order of 1000 h [6, 7]. Ba scandate cathodes, which are Ba dispenser cathodes with scandium oxide additions, also referred to as scandate cathodes, have attracted great attention in recent years thanks to their low work function and capability of providing high current densities at operating temperatures lower than that of Ba dispenser cathodes [8,9,10]. In the following, we will call impregnated cathodes without scandium Ba dispenser cathodes (also known as I or impregnated cathodes) and cathodes with scandium Ba scandate dispenser cathodes (or Ba scandate cathodes for short). The development of emission capabilities versus time has already been shown in Chap. 1, Fig. 1.12.

Since the discovery of the Ba scandate cathode by Figner et al. [11] in 1967, the first rapid development of this kind of cathode was for high-resolution CRTs, which required cathodes with DC current densities of more than 10 A/cm2 and an operating temperature lower than that of Ba dispenser cathodes. To meet the demands, several types of Ba scandate cathodes, including impregnated, mixed matrix, pressed top-layer, and thin-film top-layer types, had been developed in 1970s–1990s [9, 12,13,14,15,16,17,18,19,20,21,22]. However, none of the above cathodes has found applications in CRTs before the decline of this industry.

Yet it is instructive to study the different types of Ba scandate cathodes with their respective peculiarities in the sequence of their introduction, which can be found in more detail in [2, 9]. Starting with the pressed scandate cathode, which is based on a patent of Figner from 1967 [11], van Oostrom et al. [12] in 1979 realized i0 = 10 A/cm2 at 950 °C(Mo-brightness) operating temperature (1017 °C true temperature). Comparable emission was achieved with the impregnated scandate cathode invented by Philips (van Stratum et al. [13]) in 1977, where Sc2O3 was added to the impregnant. Mixed-matrix scandate cathodes were first introduced by S. Yamamoto (Hitachi) in 1983 [14], where the matrix consisted of a mixture of tungsten and Sc203: J. Hasker (Philips) improved this in 1989 by using W + ScH2 as a starting powder mixture [16], yielding about 100 A/cm2 at the standard operating temperature. In 1986 Hasker had also pioneered the top-layer scandate cathode [15], where a 5 µm layer on top of the porous W body consisted of a mixed matrix of W + Sc2O3, but was still prepared via powder metallurgy. Further variants of top-layer scandate cathodes were then introduced by sputter coating the W-base with W + Sc2O3 (1986) [17, 18] and later on with W + Sc2W3O12 (1989) by Yamamoto et al. (Hitachi) [19]. This approach was also continued by R. Longo et al. from Hughes and by Y. Wang using pulsed laser depositing at BVERI (1996) [20, 21], but the results of Hasker were not surpassed. G. Gaertner et al. (Philips) also investigated top-layer scandate cathode preparation by plasma-activated CVD of W and Sc2O3 from WF6/H2 and Sc(C5H7O2)3/O2 starting compounds in alternate layers. They managed to reduce the inevitable C and F content of the top layer significantly by modifications of the DC glow discharge CVD process and by further thermal treatment and realized about 60 A/cm2 pulsed emission, which also was no real improvement [22]. U. van Slooten and P. Duine from Philips reported improved ion bombardment resistivity of a ee-coated mixed matrix scandate cathode in 1996 [23]. A common feature of all these types of Ba scandate cathodes was their nonuniformity and the low robustness under ion bombardment. From all these variants only impregnated scandate cathodes based on a Philips license are still produced by Spectra-Mat and others and were used in some microwave tubes [13, 24].

In the following subchapter we will first address LAD top-layer scandate cathodes as investigated by Philips for CRT applications, which were mainly aimed at increasing ion bombardment resistivity, but also led to record saturated pulsed emission of up to 400 A/cm2 [9]. These cathodes differ from other variants, since the top layer coating prepared by laser ablation deposition (LAD) in the form of nanoparticles consisted of Re, scandia, and (411) impregnants doped with scandia. The details given here may help to trigger new research also with reference to cheaper production methods of this type.

In the next part the activities on a new type of Ba scandate cathode, the nanosized-Scandia Doped Dispenser cathodes (in short SDD cathode) developed about two decades ago first by Beijing University of Technology (BJUT) and Beijing Vacuum Electronics Research Institute (BVERI) and later continuously carried out at BJUT in China, which mainly focused on application in high current density, long life advanced vacuum electron devices, are presented [10]. They are now the current workhorse for new device applications. More recently, in the US a new initiative on Ba scandate cathode research has been started [25].

3.2 LAD Top-Layer Ba Scandate Dispenser Cathodes with Re on W Base Matrix (G. Gaertner)

3.2.1 Motivation

The main aims for developing top-layer LAD cathodes with Re and Ba scandate at Philips Research Aachen (PRA) were to increase ion bombardment resistivity and emission uniformity with operating time and hence lifetime. In order to also overcome disadvantages of I cathodes such as high operating temperature (high Ba production!) and limited current density, Philips Research realized a top-layer scandate cathode by laser ablation deposition (LAD), which reached unprecedented pulsed emission (saturated) current density of up to 400 A/cm2 at the same operating (true) temperature as for I cathodes of 1030 °C [9]. Thus, a reduction of the LAD scandate cathode operating temperature and also new high-end applications become feasible. The top-layer scandate cathodes were prepared by Excimer LAD of ultrafine particles of W or Re and of Sc2O3 or Ba, Sc containing materials from respective targets on 411-impregnated W–I cathode bases, usually already mounted in Philips 0.65 W cathode units. The top layer of typically 100–500 nm thickness had a very fine-grained structure after activation, which is favorable for fast resupply of Ba and Sc to the surface. The preparation conditions will be presented in more detail in the next paragraph. The robustness under ion bombardment [28] and also the emission uniformity of this cathode was strongly improved over previous scandate cathode types. Methods for accelerated ion bombardment are presented and the superposition model is discussed. Further topics are emission properties such as lifetime, poisoning sensitivity, emission dependence on temperature [9], and roll-off in diode and gun configuration. Cathode surface investigations by SEM/EDX and SAM and elemental depth profiles have been carried out and are correlated to the emission properties.

3.2.2 Experimental Conditions

3.2.2.1 Cathode Preparation by LAD

A common idea of nearly all concepts and structures of scandate cathodes is to provide Sc sources near the cathode or on the cathode surface, since the Sc diffusion length is much smaller than the diffusion length for Ba, the other component needed for a Ba scandate cathode. Several groups at Hitachi [17, 19] and at Hughes [20] had studied the preparation of top-layer scandate cathodes by sputter-deposition of Scandia on impregnated cathode bases. The cathodes obtained showed saturated emission current densities of 100 A/cm2 at 1030 °C true temperature, but only limited ion bombardment resistivity and were not really an improvement over the other types discussed in the historical section. This was partly due to the fact that the composition was not really suited. At Philips Research, therefore, a more controlled approach was used by laser ablation deposition (LAD) of thin layers of ultrafine particles and also the composition of these layers was varied [29]. This approach insured that Sc sources were in several nm distances to the emitting surface.

The LAD of top-layer scandate cathodes was carried out with a KrF Excimer laser (type EMG 202MSC, Lambda Physik; λ = 248 nm) of about 60 W average power and maximum pulse energy of 6 J, which is well suited not only for LAD of refractory metals such as W due to electronic instead of thermal excitation, but also for oxides. This setup had been used before for preparation of nanosized phosphor particles, e.g., consisting of yttria doped with Pr [26, 27] and was modified for the new task. The Excimer laser beam was guided into a stainless steel ablation chamber (UHV flanges) through a UV quartz window and hit a rotating cylindrical target. In Fig. 3.1 also a multi-target arrangement with 3 targets in a row is seen. A plasma plume with ablated nanoparticles formed above the target and the nanoparticles (also called ultrafine particles or UFPs, in the LAD case typically of 5–10 nm size) were carried by the carrier gas to the substrates. In the initial setup, the deposition was static with low yields [26, 27]. In a later stage a scale-up of deposition rates and efficiency was carried out by the addition of a nozzle above the substrate (see Fig. 3.2) and a meander scanning movement of the substrate relative to the nozzle. Also, LAD parameters such as gas flow, gas composition, and total pressure were adjusted in order to obtain improved uniformity. Thus, a UFP deposition yield of up to 60% of the ablated material was achieved. In the case of W-LAD, a major problem was the formation of W-oxide phases in the UFPs due to oxygen contaminations, despite using an inert carrier gas. During activation of the cathode, this leads to unwanted side effects such as WOx loss by evaporation and/or formation of BaWO4 (of negligible emission!) by reaction with atomic Ba. By several measures comprising the use of high purity argon (Ar 6.0: 99.9999% purity), the addition of hydrogen (Ar/H2 mixture), and heating of the cathode units during W deposition, the WOx (x ≥ 2) content could be reduced from 70% to about 20%, yet a much stronger improvement was obtained by replacing W by Re (Re-oxide content about 1%) [30].

Schematic view of the Excimer—LAD setup (first stage, static substrate); see [26].

A careful investigation of the I cathode bases (entry control) by SEM/EDX and STM [34] prior to the LAD coating revealed a varying contamination of the supplied W bases with BaO nanoparticles. These particles were remnants from the washing procedure of the pills and originated from the impregnant. After Re + Sc2O3 LAD it turned out, that there was a positive correlation between improved emission performance/fast ion bombardment recovery of the scandate cathodes thus obtained and the BaO nanoparticle base contamination in the range around 1.5 % Ba as determined by EDX. In conclusion G. Gaertner et al. at PRA introduced a similar artificial interface layer by LAD and investigated several Ba-oxide compounds [29–31], from targets not only such as BaO2, BaCO3, and also Ba3Sc4O9, Ba2Sc2O5, but also Sc2W3O12, 4BaO2·CaAlO4, 8BaCO3·2CaCO3·1/2 Sc2O3. Yet the emission properties of all these layer variants were minor to the BaO-contaminated cathodes. By the way, the beneficial effect of an intermediate sputtered W + BaO layer below a sputtered W + Sc2W3O12 layer on emission and its uniformity was later also shown by Sasaki et al. [35]. Therefore targets were directly prepared from the 411 impregnant melt, but with different additions of Scandia [30,31,32,33]. This approach resulted in a major breakthrough in emission capability and also in IB resistivity. It turned out that the optimum 411x target composition was about 4BaO·CaO·Al2O3·1/3 Sc2O3 with acceptable performance also for the interval between x = 1/4 and 1/2. Yet there was the tendency to get more stable targets for x ≥ ½ and better emission performance for x ≤ 1/3. As an alternative the same target compositions were prepared by sintering of pressed powder targets, but again stable targets were only obtained for x ≥ ½. Table 3.1 shows the influence of the target composition on the average emission results

Figure 3.3 shows some steps of the evolution of LAD layer structures as schematic views of the deposition sequence/layer structure of LAD top-layer scandate cathodes with alternate layers of Scandia and Re. The common porous tungsten base is impregnated with 4BaO·CaO·Al2O3 (411). Figure 3.3b has an inverted layer structure compared to Fig. 3.3a, but here also the beneficial BaO surface contamination on W is shown schematically. A typical LAD top-layer deposition sequence (in a structural numbering #Cd0122_3, in short CG1_3, one of the first cathode series with top emission) is listed below and is also schematically shown in Fig. 3.3: about 4000 pulses of 411.1/4 (target C), then 6000 pulses Re, 2000 pulses Sc2O3, 6000 pulses Re, 2000 pulses Sc2O3, with the general conditions 0.4 slm Ar 6.0 carrier gas flow and a chamber pressure of 2.5–5 mbar depending on the target [29, 31]. The meander movement over the substrate was restricted to a total area of 16 mm × 16 mm. The whole process was computer controlled. The laser pulse energy was 400–460 mJ, with 4–6 Hz repetition frequency. The whole deposition then lasted about 75 min. The effective coating thickness (for 100% density) was calculated from EDX analysis referenced to the deposited mass. For CG1_3 one thus obtained about 120 nm for the 411x layer, 140 nm of Re, and 25 nm Sc2O3 mass equivalent layer thickness in total (assuming 100% density). Of course the layers are very porous and not 100% dense. After LAD smaller pores are covered and others are partly closed, as can be later seen in Fig. 3.21, they get open again after activation, when the structures become coarser due to grain growth. We achieved similar emission results with “132” top-layer structures (G2), where a top Re sub-layer was added, and with inverted structures, where the sequence of Sc2O3 and Re was inverted. The idea behind doubling the Re and Sc2O3 layers was to create a reservoir for ion bombardment. A doubling of the 411x layer only makes sense, if additionally a neighboring W layer is added, which implies an extension to a fourfold target arrangement.

Evolution of LAD layer structures: schematic views of the deposition sequence/layer structure of LAD top-layer scandate cathodes. The porous tungsten base is impregnated with 4BaO·CaO·Al2O3 (411). In the following, we simply call <022>=:G0, <122>=:G1, <132>=:G2, and <132> with double thickness d0<132>2d0 = G2 + (structures see [29,30,31,32,33])

Further improvements especially in ion bombardment resistivity were achieved by the “132” structure and by the so-called 2d0 layers, where the thickness of every sub-layer was increased by doubling the number of laser ablation pulses (e.g., #D2d0132_1 = :DG2+). With the first cathode DG2+_1.2 of this series 27% of the specified ILD (ion lifetime dose) was reached!

We can see from Table 3.1, where cathodes have been classified with reference to the 411x target, disregarding their layer structure as in Fig. 3.3, that the lowest scandia content in 411x gave the best results. Yet we could not lower x further below 1/4, because the targets became mechanically unstable. The rather large scatter in the overall emission results, as judged from the jmax(1.7 kV) values at operating temperature shown in Table 3.1, is partly artificial, since not only variations of layer sequence and sub-layer thickness, but also changes in activation are contained in the respective groups. The sintered S targets showed less scatter, but could only be prepared for x > 0.5. For comparison in the table also results without 411x layer, only with LAD top layers of Re and ScOx are given (G0 type), illustrating the strong improvement by introduction of this “magic” interlayer. In this reference case an average jmax of 106 A/cm2 was obtained, where the saturated emission density j10% is only about 40 A/cm2. But also when all conditions were kept constant, there was still some scattering of results. Possible reasons are the target composition and the target properties (such as stability and porosity) and also changes of the target surfaces during subsequent ablations can contribute, since the same surface parts are hit several times by the laser beam in a spiraling movement, influencing the size distribution of nanoparticles. But also variations in the rest gas composition dependent on pumping down conditions can play a role or drift in the laser fluence due to internal window contamination or variation of the cathode base properties and some other not directly controlled conditions. Best conditions were achieved when the LAD setup was run continuously with 2–3 deposition runs per week and intermittent pumping-down cycles. Technically the relevant parameters can be controlled better by improvements in the setup.

The industrialization prospects for top-layer scandate cathodes by using Excimer LAD are good in view of the deposition yield in the order of 50%. Excimer lasers are commercially available and—equipped with commercial chambers—are used for low-pressure LAD of thin compact layers. A change to a pressure range of several mbar as used here leads to the formation of UFP layers instead of compact layers. In the experiments 10–20 years ago at Philips Research Aachen, a KrF Excimer laser type EMG 202MSC of Lambda Physik with about 60 W average power was used. Yet only about 3 W were needed for the above deposition conditions for a top layer of about 300 nm thickness in total. Since the ablation rates scale with power, nowadays commercial Excimer lasers with 600 W average power and a maximum pulse repetition frequency of 600 Hz are available. Of course price predictions of LAD scandate I cathodes will strongly depend on the number of cathodes to be produced. As an alternative, the same layer structures as above could also be prepared by sputtering, since the subsequent thermal activation treatment will anyway change and roughen the surface structures as prepared.

3.2.2.2 Thermionic Emission Measurements

In the initial static stage of the LAD experiments a substrate plate with 32 circular holes was used, where impregnated cathode pills with 1 mm diameter Dc were sitting in the holes, see Fig. 3.1. This implied that these pills after LAD had to be mounted in 0.65 W Philips cathode units with heaters as shown in Fig. 3.4. In order to avoid possible damage to the LAD layer during mounting and processing, in the second stage of LAD experiments, four complete 0.65 W Philips I-cathode units were directly mounted (of course without Os/Ru layer, only W–I cathodes) under respective holes in a new substrate plate, with an additional central circular Mo reference substrate of 3 mm diameter used for layer characterization.

Philips 0.65 W I-cathode unit; cathode pill diameter 1 mm; from [2], G. Gaertner, H. Koops, chapter 10 of “Vacuum Electronics, Components and Devices”, Springer 2008, p. 440

Electron emission measurements were carried out in either closed-spaced diode or electron gun configuration in a UHV (ultra-high vacuum) chamber, as can be seen in Fig. 3.5. In the close-spaced diode configuration the typical cathode to anode distance dCA was 0.2–0.3 mm. Close-spaced diode implies that dCA < ¼ Dc (see Hasker [38]), where Dc is the diameter of the cathode disk.

Schematic longitudinal section of an electron gun (one electron beam). The electrons ionize the rest gas and ions (mainly Ar, N2) are accelerated back to the cathode surface through the grid apertures: locally peaked ion beam profile! (see X. Zhang, G. Gaertner, presentation at IVESC 2002 and [44]; copyright Royal Philips N.V)

The cathode pill was mounted in a Mo cap, the side of which could be observed through a glass window for pyrometric determination of cathode temperature. The temperature could be adjusted by control of the heater voltage of 0.65 W unit. A typical setting for an operating temperature of 965 °C(Mo-brightness) or 1030 °C true temperature is a heater voltage of 6.4 V and a heater current of 103 mA. Despite heater calibration curves, the Mo-brightness temperature was determined in every measurement and corrected for window absorption.

The massive anode typically consisted of high melting Ta, in order to stand continuous heating by the electron current. The measurement of a current-voltage characteristic was done by starting with DC measurements from 10 to 100 V, then continuing with pulsed measurements in order to avoid excessive heating of the anode at higher voltages. Pulses were either delivered by a sawtooth pulser of up to 1.75 kV voltage and up to 3 A emission current, the pulse length being varied from 5 µs to 15, 50 or 100 µs, with a repetition frequency of 50 Hz, or by a rectangular pulser of up to 2 kV pulse height (pulse length 10 µs, repetition frequency 50 Hz, stepping up the voltage). In the original version (later on in parallel) of the sawtooth pulser the pulsed current–voltage characteristic could be observed as a stationary triggered sweep on an oscilloscope. During the whole project all emission measurements were computer controlled, the electronics being assembled in test racks. This implied an averaging of the pulsed sawtooth measurements over a chosen time interval. During the 25-year duration of several cathode projects, Philips Research Aachen (PRA) was equipped with up to 10 UHV chambers (32 diode test positions), including two chambers with Ar ion guns for ion bombardment investigations (see Fig. 3.6), additional dummy glass tubes for gun testing, and 4 emission test racks for measuring, e.g., current-voltage characteristics at a given temperature (status at PRA visit of IVESC 1996 participants). Cooling or heating effects under a given DC load were in most cases compensated via the heater voltage of the cathode.

Schematic diagram of the diode configuration with the differentially pumped Ar ion gun (Perkin-Elmer Φ 04): dCA = 0.3 mm; the anode aperture has 2 mm diameter; the cathode can be translated to a planar diode test position (compare [44])

Since scandate cathodes show anomalous behavior in the saturation range with only a small gradual deviation from the space charge limit (SCL) especially at higher temperatures, from the current voltage I(U) characteristics the 10% deviation point from SCL I10% is used [9] as a good approximation of saturated emission current Isat (see Manenschijn et al. [39]). For I cathodes I10% is about 10% larger than Isat obtained by fitting [39]. It has to be noted that the slope in a lgI /lgU plot in the SCL range is not 1.5, but according to Child-Langmuir theory (see formula (10.9), p. 433 in [2] and the calculation of diode characteristics by Hasker [40] and Scott [37]) varying between 1.35 and 1.45. The higher values of x are obtained for current densities in the range around 100 A/cm2 [39]. For determination of I10%, it is then required that the slope x in the SCL range is above 1.4. The current density limit j10% is also a reasonable measure of electron emission capability for the typical applications in the space charge limited range as in CRTs [36, 39]. Interestingly, the saturation region of scandate cathodes can also be described by a power law with slopes lower than the SCL slope. This lends support to the superposition theory of scandate patch fields, where their contribution is reduced by prolonged sputtering as in [28]. In this context one should keep in mind that also for standard Ba dispenser cathodes a theoretical description for the complete I(U) characteristic is missing. It only exists for the space charge limited range and at much higher voltages for the Schottky range. In the intermediate range in between a theoretical description in closed form is missing, apart from the approximation by Hasker [40] and the numerical solution by Scott [37].

In the electron gun configuration usually 3 cathodes (for red, green, and blue) were mounted in a Philips 45AX CRT gun, as can be seen in Fig. 3.5, where the distance to grid 1 typically was 80 µm. In the diode mode of the gun, only the emission to grid 1 outside the rectangular hole of 0.5 × 0.7 mm2 size was measured. This was compared to roll-off measurements in the gun mode. The gun could either be mounted in a vacuum chamber or in a dummy tube (just the neck, without phosphor screen). The path of one electron beam in gun operation is also shown in Fig. 3.5, with a beam crossover in grid 1 region, which also gives a peaked ion beam hitting back onto the cathode surface. A potential distribution for such a gun was given by T. Spanjer et al. in Fig. 8, p. 353 of Philips Technical Review 44 [42].

Since a theoretical description of the I(U) characteristics of Ba scandate cathodes in the saturation range is still missing and hence zero field emission cannot be derived from a curve fit, the group at BJUT of Yiman Wang uses the deviation point Idev, where deviation from SCL just starts [43]. These values are lower than the I10% values. In a further method, the intersection point of the straight line fits (power law slopes) in SCL range and saturation range is determined in a double logarithmic plot of the characteristic. The projected point Iis on the characteristic is a good approximation of zero field emission, which is more in line with the I10% value. Yet this method cannot be applied, if the voltage range is not reaching far enough into the “saturation” region. In this case, a clear recipe is needed for marking the transition from SCL to saturation. This problem does not occur for I(U) characteristics at lower temperatures, where there are only small deviations between I10% and Iis, as we will see later during the evaluation of temperature-dependent I(U) characteristics.

It should be noted that the type of equipment used for emission measurements was also used at Philips Research Eindhoven and by Philips Display Components. The 45 AX guns in the tests were applied in several commercial Philips CRTs and their design was based on electron optical calculations (see [41, 42] and other articles in Philips Research Reports or Philips Technical Review). With this equipment all types of thermionic cathodes, including thoriated tungsten, oxide cathodes, and various types of impregnated and scandate cathodes, have been tested, results have been published and are consistent with the literature. The message is that the record emission is not due to peculiarities of the test equipment, as one might speculate, since quite regularly top emission of the same cathodes was ruined by accelerated ion bombardment or by deterioration during operation (see [28, 47]) and it took some years to reach the state of the art in 1994 and then improve further.

3.2.3 Summary of Emission Results

3.2.3.1 Top-Layer Scandate Cathode Activation

It is well known that impregnated dispenser cathodes need an activation process in vacuum, in order to start the Ba supply to the surface, where Ba is generated via a reaction of the impregnant with the tungsten of the pore walls. A typical activation scheme of an I cathode consists of some preheating steps and activation by heating at 1100 °CMo-Br for half an hour. It turned out, that this scheme is not really suited for LAD top-layer scandate cathodes. Of course also some preheating steps are needed for degassing of the deposited layer. A typical preactivation sequence used was 5 min at 850 °CMo-Br, then followed by 5 min at 965 °CMo-Br, under the condition that the total pressure in the chamber is kept below 10−7 mbar. Yet the high-temperature activation needs to happen at 40–60 °C lower temperature than for I cathodes, otherwise lifetime and survived ion dose are strongly reduced. The optimum activation conditions are obtained under the action of an electric field (typically 75 V at dCA = 0.25 mm) at a temperature of about 1060 °CMo-Br. with a duration of 60–120 min. Figure 3.7 shows the activation curves of cathode CG1_3.2 at an average temperature of about 1060 °C(Mo-Br.) with a constant electric field of 75 V/0.25 mm. Shown is current in log scale, either DC or pulsed, versus time in log scale. The dotted line is an estimation of activation continuing in the pulsed range; see [45]. During operation of the cathode at 965 °CMo-Br. following the activation interval in Fig. 3.7, one can still observe a slow further increase in the emission current.

Activation of cathode CG1_3.2 at an average temperature of about 1060 °CMo-Br. with constant electric field of 75 V/0.25 mm. Shown is current in log scale, either DC or pulsed versus time in log scale; data based on [45]

The influence of the electric field on activation of LAD scandate cathodes of type BG1 at an activation temperature of about 1060 °C is shown in Fig. 3.8. Here we see that the lower the field strength the longer the activation time needed, but tact (1 mA) has the character of a delay time, which is also dependent on the thickness of the LAD layer. It should be noted here, that for W–I, Re–I, or mixed matrix scandate cathodes, the initial delay is less than 2 min. Once a level around 0.1–1 mA has been reached, the further increase is at about the same rate as in Fig. 3.7. The influence of the electric field, especially in the higher voltage range of the I(U) characteristic, is consistent with the higher mobility of Sc shown in Auger experiments by J. Crombeen, where the application of a diode voltage of about 200 V would strongly increase the Sc/W signal ratio [16, 45]; he has also shown a strong influence of the oxygen concentration on activation. The advantageous action of an electric field is also known from the activation of oxide cathodes (see Chap. 4).

Activation time (delay) to DC current level of 1 mA at a temperature of about 1060 °C for LAD scandate cathodes (BG1) as a function of applied voltage (dCA = 0.25 mm); data based on [45]

Of course, Ba supply during activation and on life can also be monitored by emission measurements. Here emission activation energy can be determined from the temperature dependence of activation times (e.g., time to reach half of the maximum or plateau value). Figure 3.9 shows results obtained for LAD Ba scandate cathodes with Re and uncoated impregnated (W–I) cathodes. It has to be noted that in the case of scandate cathodes two activation times can be observed, namely a fast activation—typical for Ba supply—to space charge limited emission in the low voltage range (DC-emission; Re–I characteristic!), and a slower activation to the final scandate I(U) characteristics in the high voltage range (pulsed emission) belonging to Ba-scandate complex formation (‘Sc’). The Ba activation energy Eact (Ba) = 3.12 ± 0.1 eV is the same for both types of Ba dispenser cathodes. The activation times to the scandate characteristic are a factor 6 prolonged, but Eact (‘Sc’) = 3.35 ± 0.2 eV is (within the limits of accuracy) still consistent with Ba generation being the limiting factor [46, 47].

Inverse activation times as a function of inverse true temperature for LAD Ba scandate cathodes with Re (series BG1, here denominated as Sc-I; with constant electric field), and B-type Ba dispenser cathodes (W–I); from [46] and [47], G. Gaertner et al., “Supply and Loss Mechanisms of Ba Dispenser Cathodes”, Appl. Surf. Sci. 146, 22–30 (1999), with permission from Elsevier

The activation times needed are dependent not only on temperature and electric field, but also on the layer thickness, the degree of oxidation of W or Re and other impurity contents, and may be prolonged by 1–2 orders of magnitude depending on the conditions, but we will not go into further details here.

3.2.3.2 Thermionic Emission Properties

The motivation for the investigation of scandate cathodes was to overcome the disadvantages of the I cathode such as high operating temperature (high Ba production!) and limited current density. Yet one of the common features of the development of different types of scandate cathodes was that they did not show a clear transition to saturation and a continuing current increase with voltage in this region instead. Since an accepted theoretical description is missing, more phenomenological practical approaches have been used, as we have already discussed in Sect. 3.2.2, namely the different transition criteria I10%, Iis and Idev, where Idev is marking the lower boarder of the transition range. The differences between these criteria get smaller at lower temperatures.

In Fig. 3.10 the current density versus voltage characteristics of a LAD top-layer scandate cathode type DG2, an Os/Ru–I cathode, and a W–I cathode at 965 °C Mo-brightness temperature (1030 °Ctrue), as determined in the diode mode in an electron gun configuration (45AX), are compared. The onset of saturation is given as a 10% deviation from the space charge limitation (slope 1.46 with second-order corrections) [57, 58]. For the Os/Ru–I cathode, the SCL slope is about 1.35 (compare [39]) and the saturation slope is 0.4. For the W–I cathode, the SCL slope is about 1.30 and the saturation slope is also 0.4. The gun data are consistent with diode measurements and the literature with reference to both types of I cathodes. In this plot also, practically no significant differences between the j10% values and jdev (of Wang et al. [43]) can be seen. We will discuss the correlations between gun and diode measurements later.

Current density versus voltage characteristics of a LAD top-layer scandate cathode type DG2, an Os/Ru–I or M cathode and a W–I cathode at 965 °C Mo-brightness temperature, as determined in the diode mode in an electron gun configuration (dca ~ 80 µm). The onset of saturation is given as 10% deviation from the space charge limitation (slope 1.46 for DG2). For the Os/Ru–I cathode, the SCL slope is about 1.35 and the saturation slope 0.4. The graph is based on a re-evaluation of data presented in [57, 59]

In Fig. 3.11 the emission current densities j of a BG1-type cathode are depicted versus diode voltage U in a double logarithmic plot at different temperatures [9]. These characteristics have been measured in a close-spaced diode configuration and are consistent with characteristics in the diode mode of a 45AX gun, where higher electric field strengths can be reached in pulsed measurements. There (Fig. 3.10) the emitting cathode area Acath for determination of current density from current is Acath = (π × 0.52–0.35) mm2 compared to Acath = π × 0.52 mm2 = 0.7854 mm2 in a planar diode. The power law slopes in saturation are shown at the right side of the curves. The respective j10% values for the temperatures from 600 °C to 915 °C are given in Table 3.2. Saturation cannot be determined at an operating temperature of 965 °CMo-Br., since the maximum pulsed voltage is not high enough to see a deviation from space charge limit.

lg j/lg U characteristics of BG1_2 cathode for different Mo-brightness temperatures in diode configuration (dca ~ 200 µm). The power law slopes xs in the double logarithmic plot in saturation are shown at the right side of the curves. The graph is based on a re-evaluation of data presented in [9]

a Saturation current density versus true temperature. A general feature of all Ba scandate cathodes prepared by LAD is the work function of about 1.15 eV, whereas the Richardson constant AR is varying between 3 and 8 A/(cm2K2). For comparison, also the saturated emission density curves for work functions of 1.52 eV and 1.42 eV with the Richardson constant being the thermionic constant are shown. Results of [47, 59] are contained in this graph. b Temperature versus heater voltage for Philips I-cathode unit. The blue curve is the Mo-brightness temperature in °C and the red curve the true temperature in K. Measured Mo-brightness temperatures of individual units may deviate in the region of the working point 6.3 Vf by about +15 °C. During continuous DC load also, emission cooling has to be taken into account. These calibration curves are basis for the results given in [47, 59]

In a plot of saturation current density versus true temperature as in Fig. 3.12a, one can obtain a good overview of the optimization of LAD scandate cathodes. Here j10% has been chosen as a good approximation for zero field emission or “saturation” current density. A general feature of all Ba scandate cathodes prepared by LAD is the work function of about 1.15 eV, as one can also derive from the Richardson plots of Fig. 3.13. The same holds also for SDD cathodes of Y. Wang and for sputtered top-layer scandate cathodes of S. Yamamoto. Only the Richardson constant AR is varying between 3 and 8 A/(cm2K2), which is a measure of increasing coverage of the surface area (see Gilmour, p. 44 in [48]) and is also consistent with increasing ion bombardment resistivity when Ar = 8 A/(cm2K2) is approached. For comparison also the saturated emission density curves for work functions of 1.52 eV and 1.42 eV with the Richardson constant being the thermionic constant are shown in Fig. 3.12a, but they do not deliver a good fit over a larger temperature interval. One can also see that only tungsten-based LAD cathodes without Re, namely BG(W)1_1 and G0(W), are located around AR = 3 A/(cm2K2) at the lower boarder. In this context a Ba scandate cathode on W base has also been obtained by metal Sc-LAD on a W–I base with js in the same range (not shown here, literally Sc/W–I), where the W base is usually decorated with BaO nanoparticles as already mentioned [34]. Activation then leads to oxidation and scandate formation on a W–I base.

Very important for establishing a reliable plot as in Fig. 3.12a and also as a basis for the Richardson plots of Fig. 3.13 a + b is the determination of true temperature, which is not trivial. Such a calibration curve is given in Fig. 3.12b as a function of the heater voltage of the I-cathode unit. Of course the measured Mo-brightness temperatures of individual units may deviate, which can be about + 15 °C in the region around the working point 6.3 Vf. During continuous DC load also electron emission cooling has to be taken into account. Thus at certain intervals during continuous runs or before/after I(U) characteristic measurements, the cathode temperature needs to be determined usually by optical pyrometry (visible or infrared). In regular intervals (<1 year) the pyrometer needs to be calibrated with either a tungsten ribbon lamp or a black body radiator. If the brightness temperature of the Mo cap is measured, not only the Mo emissivity as a function of temperature and observation wavelength has to be taken into account, but also the transmission of the viewing window. In case the observation spot is located on the part of the uncovered tungsten, W emissivity determines the correction.

We know from Chaps. 1 and 2 that the dependence of saturated electron emission current density on temperature is given by the Richardson–Dushman equation [2, 48], which is usually written in the form

where AR is the Richardson constant, which for real cathodes in most cases is smaller or much smaller than the thermionic constant Ath = 120.4 Acm−2 K−2 for the ideal case. eΦR [eV] is the Richardson work function in the form written by S. Dushman, Herring and Nichols, Nottingham, Scott [37], Hasker [40], and others [2], where within this book eΦ = ϕ is used. js is the saturated emission current density in Acm−2. From the measured dependence of js on true temperature T [K], one can determine work function and Richardson constant from a so-called Richardson plot [48] of log (js/T2) versus 1/T, where the physical quantities have been divided by their respective units

It should be noted, that the Richardson constant AR can also be expressed as a temperature dependence of work function eΦ = eΦR + αT, with the coefficient α = k ln (Ath/AR). This of course only makes sense for uniform emitter surfaces. Figure 3.13 a shows Richardson plots of LAD top-layer scandate cathodes of type G0 (without 411x layer, ϕ = 1.16 eV, ARrel = 2.8), CG1_1 (x = 1/4, ϕ = 1.17 eV, ARrel = 6.3), CG1_2 (x = 1/4, ϕ = 1.14 eV, ARrel = 6.2), and BG1 (x = 1/2, ϕ = 1.15 eV, ARrel = 7.0). The Richardson work function of about 1.16 + 0.02 eV and a Richardson constant of AR = 6 to 7 Acm−2K−2 gives a better fit to the experimental ‘Sc’-I data than an effective work function of 1.4–1.45 eV (AR = Ath = 120.4 Acm−2K−2). This illustrates the superior emission of the LAD scandate cathodes down to temperatures of 500 °C with about constant work function.

Here in Fig. 3.13a again as in Fig. 3.12a, the only tungsten-based LAD scandate cathode without Re, namely G0(W), is characterized by AR of about 3 A/(cm2K2), hence in the lower range.

In order to check the validity of this interpretation of the Richardson constants of scandate-type cathodes, it should be compared with the respective results for impregnated Ba dispenser cathodes, namely the W–I or Re–I cathode bases, which in general exhibit more uniform emission than scandate cathodes. Therefore in Fig. 13b Richardson plot data of Os/Ru–I, Ir–I, and W–I cathodes from Philips and a W–I cathode from Thomson have been evaluated. The results are listed in Table 3.3.

Unfortunately respective data for Re–I have not been published; from the comparison at the operating temperature at 965 °C(Mo-Br), the Re–I line is expected in the emission range 30–40% lower than Os/Ru–I cathodes. In conclusion much higher Richardson constants for Ba dispenser cathodes are obtained from this new evaluation compared to older references. The range of AR for Os/Ru–I and Ir–I shows a rather good agreement. Reasons for disagreement with the older literature are mainly due to the systematic errors in the determination of zero field emission current density j0 induced by Schottky extrapolation used at that time, especially at higher temperatures, as pointed out by Hasker [38, 40]. To some extent, it may also be due to rather small temperature intervals and to problems in determining true temperature. Especially the results of Manenschijn et al. for Os/Ru–I [39] are very reliable, since they have determined j0 by application of the theory of Hasker for the transition range between space charge limited and Schottky emission [39, 40]. The values for the W–I cathodes should be checked again, despite that a value of the Richardson constant higher than the thermionic constant is not uncommon for certain crystal faces of pure metals and corresponds in the alternate picture to a negative temperature dependence of work function. In case of the values of Shroff, the Richardson plot exhibited a slight curvature. One has to keep in mind that the results for AR and eΦR will also change with operation time.

3.2.3.3 Features of an Emission Model

One of the models to describe the current–voltage characteristics in this range is the semiconductor model of Raju and Maloney [50]. We do not doubt the usefulness of this model, but it was applied to very nonuniform scandate cathodes of minor emission performance. From simulation and from continuing ion bombardment experiments [28, 49], we found that scandate cathodes can be better described by a patch or superposition model, where the ideal scandate surface portion is in first approximation only space charge-limited, but with a lot of I cathode (in our case Re–I) patches in between. Depending on the relative fractions of the Ba scandate and Re–I part, the slope in a double logarithmic plot of I versus U is increasing from about 0.4–1.46 (space charge slope or power) with increasing scandate part. This behavior at operating temperature or below is linked to the fact that the Ba-scandate surface complex has a very low work function of about 1.15 eV compared to 2.02 eV for W–I and 1.93 eV for Re–I [51,52,53]. This superposition model is also backed by measurements of the local nonuniform emission distribution by Hasker [16] and by measurements of the local work function of sputtered top-layer scandate cathodes by Yamamoto with the field emission retarding potential (FERP) method, yielding 1.15 eV [54]. Also, the investigation of a model system by Zagwijn et al. [55] with Sc and Ba monolayers (ML) on W(001) surface with medium energy ion scattering (MEIS) resulted in a work function of 1.18 eV for O concentrations between 1 and 1.5 ML. It is consistent with the observation that the slope is increasing during activation, which takes longer for the Ba-scandate complex than for the I cathode parts. The same happens in the reverse direction after successive ion bombardment and during emission decline at the end of life, where the I cathode area portions now increase. Yet it has to be kept in mind, that the superposition model does not imply the simple addition of contributions, since there is also a mixed term by enlargement of the Ba scandate portion by space charge expansion within the space charge coupling length, which is also called the beamlet effect by Hasker [38]. In the first approximation, this coupling length is estimated to be related to the distance dm of the space charge maximum in front of the cathode. For a cathode temperature of 1300 K and a current density of j = 100 A/cm2, one obtains dm = 0.6 µm and for j = 10 A/cm2, dm = 1.6 µm [56]. Due to this space charge leakage and the low Schottky saturation contribution of the I cathode portions, one can observe a space charge like behavior with lower power (slope in log-log plot below the space charge limit slope of about 1.45). A complete theory of this “coupled superposition” still has to be established. Surface analysis of Sc-I cathodes after activation and during life typically shows spots with Sc and Ba enrichment with an extension below the grain sizes of about 3 µm on the average. It should be noted that the superposition model is not in contradiction with a still to be established emission model of the emitting (Ba, Sc, O) complex, eventually via a semiconductor type theory of a Ba–Sc mixed oxide compound with a Ba monolayer on top, but here in the form of patches.

3.2.3.4 Low-Temperature Thermionic Emission and Field Emission

Due to the low work function, thermionic emission could be measured down to about 200 °C, where the temperature was measured with an infrared pyrometer. Field emission (FE) was observed at room temperature and under moderate heating up to 1.5Vf (about 300 °C) for ‘Sc’/Re–I, Re–I, and W–I cathodes. The threshold field strengths (reference level 1 nA) were 3.2 V/µm for ‘Sc’/Re–I, 9 V/µm for Re–I and 11 V/µm for W–I [59]. In the range from 250 to 350 °C, thermal-assisted field emission is observed and the threshold vanishes [59–61, 63] as can be seen for the respective upper curves in Fig. 3.14. These results are discussed in more detail in [59]. Unfortunately for stable field emission of scandate cathodes a very good UHV with chamber pressures in the order of 10−10 mbar is needed, including the baking of the chamber after cathode mounting. K. Jensen gives a theoretical description of the superposition of thermal and field emission in Chap. 8.

Field emission characteristics at room temperature and low temperature I(U) characteristics for top-layer Re-Scandate = ‘Sc’/Re–I, Re–I, and W–I cathodes; from G. Gaertner et al. [59], Copyright 2002, with permission from Elsevier

3.2.3.5 Life-Limiting Mechanisms and Experimental Results

As shown in [46, 47], the Ba evaporation rate for ’Sc’/Re–I (Scandate with Re) cathodes is lower than that of standard impregnated or I cathodes (metal matrix: W and metal surface: W or Os or Ir or Re …), at least during the initial 1000 h. Figure 2 of [47] shows that Ba evaporation from the I cathodes is higher than that of the two top-layer ‘Sc’-I cathodes. An exponential fit of the data yields activation energy for Ba evaporation Eact = 3.15 eV for all 4 cathodes, which is due to the same generation mechanism. An explanation for the lower rates for ‘Sc’-I cathodes could be that Ba is needed for buildup and replenishment of the Ba–Sc–O surface complex.

In conclusion, one limiting mechanism is the Ba generation and evaporation, which is mainly dependent on the design of the I cathode base. According to Aida et al. [65], the life end is above all determined by the exhaust of the Ba supply reaction of the impregnant with W (pore walls). Hence, it depends on the total amount of impregnant in the porous W matrix, i.e., for 20% porosity, and also on the thickness of the cathode pill. Aida et al. [65] have measured Ba and BaO evaporation over life (see Fig. 6 of [47]). They observed a clear correlation: end of life has been reached when the Ba evaporation (linked to Ba generation) falls below BaO evaporation. A detailed quantitative description of I cathode life-limiting mechanisms has also been given by Roquais et al. [68].

Due to the addition of Re, which is also more persistent during ion bombardment, the base emission is that of the Re–I cathode, which is about 10 A/cm2 at Top = 965 °C(Mo-Br) or about 1030 °C true operating temperature. This ensures that despite the possible loss of the Ba–Sc–O complex, the saturated emission current density or transition from space charge limited to temperature limited regime remains at this level at least for the guaranteed lifetime of the (W)-I cathode base [66, 67].

An essential mechanism of life limitation of ‘Sc’-I cathodes is the loss of Sc not by evaporation, but by ion bombardment. Hence also due to the short diffusion length of Sc, a rather thick reservoir containing Sc of some 100 nm is needed below the outer surface. This is ensured by the LAD top-layer coating containing BaO and ScOx.

In Fig. 3.15 lifetime data of LAD top-layer scandate cathode type CG1 are depicted, showing pulsed results at 1.7 kV and 200 V and also DC results for 75 V (see [9]). The time of operation was 17,328 h, with a continuous DC load of 4 A/cm2 (75 V) applied. It has to be noted that due to electron emission cooling, the operating temperature under load is about 25 °C lower than that given above for the no-load condition. This effect will also depend on the design of the I cathode base.

Lifetime data of LAD top-layer scandate cathode type CG1, operated at 940 °C(Mo-Br) and 4 A/cm2 continuous DC load in planar diode configuration. The graph is based on re-evaluated data of [9] plus additional data

A series of CG1- and BG1-type LAD scandate cathodes have been operated under UHV at operating times between 1400 to 4000 h at DC levels of 2–3 A/cm2, with Idc(100 V) remaining constant at about 5 A/cm2. Here the general conclusion for ‘Sc’/Re–I cathodes is that a DC operation base level of 15 A/cm2 should be maintained for the designed lifetime of the I cathode base, (in our case of 0.65 W Philips I-cathode units of about 20,000 h; pill diameter 1 mm, pill thickness 0.4 mm), due to the persistence of the Re surface. For operation at higher pulse test levels of, e.g., 100–200 A/cm2, not only the surface adjacent reservoir of Sc (more specifically the amount of the Ba–Sc–O complex) will be decisive, as one can see from the ion bombardment investigations, but also a low UHV pressure level during operation is important.

3.2.3.6 Correlation Between Planar Diode and Electron Gun Emission Measurements

Since the final aim of the project was to apply the LAD scandate cathodes in CRT guns, their behavior in guns needed to be studied and correlated to planar diode results, which were of course much easier to obtain via directly mounting in UHV chambers. Moreover, the real ion bombardment happened in guns via ionization of the rest gas and had to be correlated to bombardment with Ar ions in a diode configuration [28, 44, 49], as we will discuss in the next subchapter.

The main difference between electron gun and planar diode is that in the gun for the electron beam one can only measure roll-off curves (also under-heating curves: electron current versus heater voltage) or activity curves (versus temperature) at a specific grid voltage setting for judging the emission capability of the cathode. It should be noted that there is a direct correlation between heater voltage and temperature via calibration curves (see Fig. 3.12b). In a diode, of course, it is no problem also to measure activity curves besides the I(U) characteristics at a set of temperatures. In the operation mode of the electron gun grid 1 usually has the same potential as the cathode (or a slight blocking voltage is applied) and the beam electrons are only extracted from the central region under the grid hole. The other grids have accelerating voltages. Yet there is the possibility to operate also the gun in a diode mode, where grid 1 serves as the anode and at the other more distant grids higher extraction voltages are applied, so that the electrons from the central part below the hole are still extracted to the other grids. In this diode mode of the gun, the emitting area is now the cathode surface area without the area of the grid opening. Yet it is required, that the correlation is investigated just after activation at the beginning of life, before any damage in the central beam region can happen (see Fig. 3.21a, b). For well-activated cathodes from the same batch, we found good consistency between the I(U) characteristics in the planar diode and the diode mode in the gun and also between roll-off curves measured in the planar diode or under so-called half-drive conditions in a gun (see Fig. 3.16a, b).

Consistency between gun and diode measurements: a Electron emission current density j[A/cm2] versus dimensionless “reduced space charge voltage coordinates” of (U/V)1.5/(dca/mm)2 for 3 Philips Os/Ru–I cathodes mounted in 0.65 W cathode units at an operating temperature of 965 °CMo-br.; based on data from [57, 59, 62]. Copyright of Fig. 3.16a: Georg Gaertner, Aachen, Germany.

b Roll-off measurements of a LAD scandate cathode type DG1 in diode mode (blue circles) and “half”-drive beam mode (red triangles) in 45AX electron gun.

c Roll-off measurements of LAD scandate cathodes type DG2 in “half” drive beam mode (red triangles) and in diode mode (blue circles) in 45AX electron gun versus j10% measured in the diode mode at 965 °C Mo-br. The temperatures in brackets are the true temperatures for the respective heater voltages. The theoretical values are also given for AR varying from 3 to 8 A/(cm2K2) and a work function of 1.15 eV

The good consistency of cathode emission data obtained in a diode or in the diode mode of a gun is shown in Fig. 3.16a. A comparison of emission characteristic measurements in planar diode and in diode mode of a 45AX gun configuration was carried out for different Philips Os/Ru–I cathodes mounted in 0.65 W cathode units at the standard operating temperature of 965 °CMo-br. The results are shown in a double logarithmic diagram of the electron emission current density j[A/cm2] versus dimensionless “reduced space charge voltage coordinates” of (U/V)1.5/(dca2/mm2). The cathode to anode distances were 70 µm in case of the diode mode of the gun, 190 µm for diode 1, and 250 µm for diode 2. The I cathodes tested were all standard Os/Ru I cathodes of Philips with 411 impregnants, mounted in 0.65 W cathode units. The agreement between the different Os/Ru I cathodes in the plot with reduced space-charge ordinate in the saturation range is remarkable. The small deviation in the space charge limited range is probably due to the fact that the lowest four data points at 25, 50, 75, and 100 V in the diode case are DC measurements of about 10–20 s duration (with some emission cooling), whereas the gun measurements and the diode saturation data are from pulsed measurements (pulse duration gun: 12 µs, pulse duration diode 5 µs). Also, a better determination of diode distance could result in still better consistency.

Since one can calculate activity curves from I(U) characteristics at different temperatures, one may also correlate j10% at operating temperature and the knee of roll-off curves. The figure of merit is now the knee of the roll-off curve, defined as Uf−10%, i.e., the heater voltage value of the 10% deviation from the slightly inclined I(Uf) line (see Fig. 3.16b). Via work function and j10%(T) there exists a correlation between the roll-off knee and the electron emission current density j10% after IB [28, 49] (compare Fig. 3.16c). The correlation between the roll-off knee and the electron emission current density j10% exists via the Richardson equation (via work function and Richardson constant), since from the half-drive condition of 1.2 mA or 2.5 A/cm2 (a criterium used for I cathodes) the knee temperature can be determined or can be read from a plot such as in Fig. 3.12a. For example, Uf−10% = 4.5 Vf corresponds to j10% = 40 A/cm2 at 6.3 Vf. Hence high pulse emission at high temperature is directly correlated with the roll-off knee at very low temperature. If ion bombardment reduces emission at high temperature in the diode, the roll-off measurement in the gun will show an increase of the knee temperature.

Figure 3.16b shows a comparison of roll-off measurements of a LAD scandate cathode type DG1 in the diode mode (blue circles) and in the “half”-drive beam mode (red triangles) in 45AX electron gun for the same Uf−10% = 3.6 Vf for both cases The Uf−10% was determined as −10% deviation from the fitted saturation slope as a measure of the knee. The beam measurements have been carried out in the so-called half-drive mode with grid 1 at the ground, grid 2 at +1 kV, and grid 3 at +3 kV, so that the beam current is 1.2 mA at the working point of 6.3 Vf or 965 °C(Mo-br.), which corresponds to 2.5 A/cm2 peak beam current density according to the electron optical calculations. Based on this density the equivalent current in the diode mode was calculated (Igun times 9.06) and is shown as blue circles in Fig. 3.16b for a direct comparison. In the diode mode, the current density calculated from cathode area minus hole projection is 2.8 A/cm2. The plot illustrates the good consistency between half-drive and diode mode measurements. But it can also be used for an estimation of the maximum error, since it could mean that the relevant cathode area is about 12% larger than the geometrical projection. This would imply a diode mode correction in a gun of j10% by −12%.

In Fig. 3.16c roll-off measurements of a series of LAD scandate cathodes type DG2 in “half”-drive beam mode (red triangles) and in diode mode (blue circles) in 45AX electron gun are depicted as a function of j10% measured in the diode mode at 965 °C Mo-br. The temperatures in brackets are the true temperatures for the respective heater voltages. The theoretical values are also given for AR varying from 3 to 8 A/(cm2K2) and a work function of 1.15 eV. The measurements were all carried out directly after activation (“0 h”) and hence further emission increase in the following several hundred hours is not contained in this diagram.

A reliable comparison between gun and diode mode can only be carried out in the beginning, before deterioration in the central beam emitting area starts. Yet also the scatter in the beam mode may be larger, since the beam originates from a much smaller area than the diode part. In conclusion, one can see that the high emission capability of LAD top-layer scandate cathodes in guns at operating temperature is correlated with very low roll-off knee temperature.

3.2.3.7 Ion Bombardment Investigations

In cathode-ray tube applications, an important loss mechanism for Ba is ion bombardment (IB). The ions are generated by the interaction of the electron beam with the residual gas in the tube and are accelerated back to the cathode surface (see Fig. 3.5). The emerging ion beam has a strongly peaked density profile and hence sputter damage is strongly localized [28, 44, 49, 69, 70] in the central emitting area of the cathode (about 6% of the effective emitting beam area of 0.23 × 0.32 mm2 dimensions of 45AX gun). Most electron gun experiments were done with 45AX guns in UHV chambers with a controlled gas admission valve. In this configuration, the ion life dose (ILD) is proportional to the electron current times the integral of pressure over time (average pressure times lifetime) and was specified as

for 1.2 mA “half-drive”conditions in a Philips CRT. This corresponds to a leveling off of the initially higher pressure to nearly constant 2×10−9 mbar over a tube life of 20,000 h. The effect of ion bombardment in a gun is measured via the “roll-off” curve of the beam current, as we have seen above, starting at 1.2 mA (measured at grid 3) for 6.3 Vf, at given voltage settings (grid 1: 0 V; grid 2: 1 kV; grid 3: 3 kV) as a function of temperature, i.e., heater voltage Uf. The figure of merit is now the knee of the roll-off curve Uf −10% which is correlated to the electron emission current density j10% after IB [28, 49].

Accelerated ion bombardment experiments conducted in an electron gun configuration (Fig. 3.5) with controlled gas admission were then correlated with experiments in a diode configuration (Fig. 3.6) using an ion gun with a uniform ion density profile. Accelerated life testing of cathodes in the diode configuration has a number of advantageous aspects: the ions are generated externally in an ion gun and the ion current applied to the cathode is measurable, so that the number of ions hitting the surface is really known. The ion current density is constant over the cathode surface, which enables the examination of fundamental behavior and material properties of the cathodes without the influence due to the electron and ion optics in the electron gun, which in case of the gun cause a very sharply peaked ion density profile (hole burning into the emitting electron area, see Fig. 3.23a, b. Since the ion current generated by the electron beam is proportional to electron current and rest gas pressure, the effective ion dose ILD in the electron gun in units of mA*mbar*sec can be scaled to the absolute ion dose (charge) via the relation [28, 49]:

This relation was mainly established via correlation of initial decay in gun and diode. In the case of the gun, the real ion dose can be determined from the specific ionization, where gas composition and electron energy need to be known, and from the path length of ionization. Most of the accelerated ion bombardment experiments were done in the diode configuration, using a moveable anode with a circular hole and a differentially pumped Ar ion gun (PerkinElmer Φ 04–303; typical Ar+ energy 3 keV; see Fig. 3.6). In the first step, the sputter ablation rates of pure and multilayered VSP materials were determined. This gives the correlation between ion dose (ion energy 3 keV) and layer thickness removed (sputter yield Y). For W and Sc2O3 VSP-layers, yields of 1.1 and 0.4 atoms/ion were determined. Secondly, IB was applied to the surface of LAD cathodes and the emission recovery was investigated as a function of time, temperature, and ion dose. Qualitative main results were the following: in the W + Sc2O3 system emission recovery after IB is inferior and already at low doses (about 1017 ions/cm2), emission falls back to a W–I characteristic. Better IB resistivity is achieved by Re + Sc2O3 LAD I cathodes, but the best results were obtained after further addition of the 411x intermediate layer and about 25% of the total life dose of 1700 µAs were achieved for the best variant DG2 + , where additionally the LAD scandate cathodes were not fully activated = under-activated (ua). This is depicted in Fig. 3.17, where the percentage of ILD that survived at a level of 40 A/cm2 is related to the LAD scandate cathode type. This improvement of scandate cathode types in time scale continued from 1993 to 1997. Since these tests were accelerated tests, the shielding factor related to the dose rate has to be taken into account. With this correction the top value of 25% ILD corresponds to 63% of the reference lifetime dose. In consequence by an improvement of vacuum by a factor of 2 (reduction of average tube pressure by ½ or tube pressure 1×10−9 mbar), emission-induced ion bombardment in a CRT during life will be survived at a level of 40 A/cm2. Figure 3.18 shows the degradation of the I(U) characteristic as a function of IB dose: the total emission can be described qualitatively as the superposition of area fractions of Scandate-I (only space charge limited) and Re–I, with some extra space charge leakage into the Re fraction, where the Re–I fraction increases with increasing ion dose [28, 49].

Degradation of I(U) characteristic as function of IB dose in diode with Ar ion gun (ILD = 1700 µAs): Dashed lines: perfect ‘Sc’/Re–I and Re–I cathodes. Total emission is superposition of area fractions of Scandate (only space charge limited) and Re–I; see [2, 28, 49], G. Gaertner, H. Koops, Chap. 10 of “Vacuum Electronics, Components and Devices”, Springer 2008, p. 442

During IB, two processes are competing, namely sputter removal of surface atoms and Ba resupply from the interior. The time change of emission current I can be formally described [16, 28, 49] by the sum of a destruction term (τIB) and a regeneration term (τrec):

With respect to emission, this initially leads to a fast decline (time constant proportional to inverse ion current) followed by a slow bending to a dynamic equilibrium which is determined by the ratio between destruction and resupply rates. This is illustrated in Fig. 3.19 showing half-drive beam currents of LAD scandate cathodes type DG2 before, during, and after ion bombardment in a 45AX gun for different levels of Ar gas admission. Duration of IB is 15 min for Ar gas admission of 4×10−6 mbar (blue circles) and 60 min for 6.7×10−6 mbar Ar (red squares). Ar was introduced via a leak valve, since it has no poisoning effect on emission and hence only acts via ionization and ion bombardment of the cathode surface. The longer poisoning interval corresponds to an ion dose of 5.4×10−5 mA*mbar*h or 12% of the IB life dose. Similar curves are obtained for ion bombardment in a diode configuration with an Ar ion gun, as shown in Fig. 1 in [28], Fig. 5 of [49] or Fig. 6 of [44], which are not shown here.

Compared to an ILD extrapolation in diode configuration at high IB dose rates (1 µA), the ILD extrapolation at more realistic low dose rates (10 nA) will hence yield an increase in extrapolated IB life of up to a factor of 8 due to the dynamic shielding effect [28, 49].

A further requirement is a short recovery time after IB: as specified this should be 1 min. Best time constants achieved for Sc-recovery were 8 min at 965 °C Mo-br. Yet this requirement is only relevant in the initial phase of high tube pressures, which are continuously decreasing, equivalent to an initial dose of 4×10−7 mA*mbar*h.

3.2.3.8 Emission Poisoning

From emission poisoning investigations, one can conclude that Ba scandate cathodes are about an order of magnitude less sensitive to poisoning than I cathodes. The figure of merit p (ΔI = − 10%) = f {gas, cathode type, T, dCA, i, t} is defined by a 10% current decrease when increasing pressure in the UHV chamber by controlled gas admission through a UHV gas leak. The poisoning threshold p (0.9 I0) for air admission of 1×10−5 mbar for LAD scandate cathodes is about a factor of 10 higher than that of Os/Ru–I, as can be seen from Fig. 3.20. In this case the experiments have been conducted with Re+ScOx LAD top-layer scandate cathodes (type G0). According to the literature [71,72,73,74,75] and also our own experiments for scandate and I cathodes, the poisoning insensitivity for different gases can be ranked in the sequence (hierarchy): O2 < CO2 < air < CH4 < CO < H2 (most insensitive). For I cathodes water vapor poisoning is less sensitive than O2 poisoning. Concerning the other parameters, one finds decreasing poisoning sensitivity with increasing temperature and increasing poisoning sensitivity with increased diode spacing (less pumping effect of evaporant!) up to 1.5 mm. The mechanism of emission poisoning is based on gas molecule adsorption on the cathode surface and hence the change of the work function.

Emission poisoning of LAD scandate cathode of type G0 (Re) and a Os/Ru—I cathode by air introduced at 965 °C Mo-Br. Depicted is the normalized emission (relative emission decline) after 1 min as a function of total pressure increased from UHV by controlled admission of air through a leak valve. The figure of merit is given by I = 0.9 I0 and is 1×10−6 mbar for the Os/Ru–I and 1×10−5 mbar for the Ba scandate cathode

A further important property of these Ba scandate cathodes is that, e.g., after air admission they can be reactivated in vacuum again to j10% > 100 A/cm2, if they had reached that level before: there is no significant deterioration of emission capability.

3.2.4 High-Resolution Cathode Characterization

High-resolution characterization of LAD top-layer scandate cathodes as prepared and after a certain time of operation was carried out by SEM, EDX, and SAM. Typical SAM analysis conditions and quantification parameters are given in Table 3.4 (sample angle = 0°).

Maps were made at a primary beam voltage of 10 kV, to improve lateral resolution. All spectra were made at a primary beam voltage of 5 kV. For quantification the high energy Auger lines for AI, W, and Re were used. The low energy line for AI interferes with low Ba-lines and the low energy lines of W and Re coincide at 179 eV and cannot be used to discriminate these elements. The same holds for the W-line at 1798 eV and the Re-line at 1799 eV. For that reason, the weaker Re-line on 1858 eV was used for the quantification. The high energy lines are quite insensitive, but there was no alternative for reasonable quantification. The sensitivity data given by Physical Electronics do not give sensitivities for all these Auger lines. Sensitivities for some lines were calculated by using the ratio with other Auger lines. So sensitivities can differ from the elemental sensitivities given by Physical Electronics. So semi-quantitative values of atomic concentrations of the elements present can be obtained. For a quantitative evaluation a correction for the matrix effect and chemical binding effects needs to be carried out and also gauge samples have to be used for the specific elements present. The above conditions are similar to the conditions given by Philips Research in [23, 77].

The information depth in Auger electron spectroscopy (AES) is approximately 2 nm (0.5–5 nm), whereas the lateral resolution depends on the fine-focused electron beam and at best it is about 30 nm, but usually it is averaged over the larger area investigated. A sputter depth profile can be performed to monitor the elemental concentrations as a function of depth. Ar+ ions are used for sputtering, while the sputter conditions have been calibrated using a known SiO2 layer thickness on Si. The measured sputter rate for SiO2 was 9.3 nm/min (at raster 1.5 × 1.5 mm2, 30° tilt angle, 3 keV Ar+, 15.5 nA). This sputter rate may, however, differ for the various elements and elemental compositions. For Sc2O3, a sputter rate of 6 nm/min was calculated under these conditions.

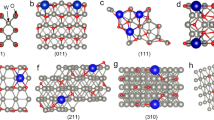

Figure 3.21a shows an SEM micrograph of part of cathode surface SG2 + type after LAD. The surface structures of other cathodes after LAD look similar and will coarsen and shrink on the grains during operation. The result of grain growth and roughening is depicted in the SEM micrograph in Fig. 3.21b for CG1 cathode after gun operation of 750 h. It is a surface area outside the grid hole region, where practically no ion bombardment has taken place, at a magnification of 10,000. Figure 3.21c, d show elemental maps of O(c) and Sc (d) by SAM of the same surface area as in b. The composition here should be similar to the composition after activation, whereas in the sputtered region under the grid hole Sc and Ba concentrations are much lower (not shown here). It is striking that the Sc and O distributions are very similar, indicating that Sc is present as oxide. As can be judged from other elemental maps of LAD cathode surfaces, Ba is more uniformly distributed and usually covers a larger surface area than Sc, which partly is concentrated, and is also found outside ScOx patches. This is due to its resupply from the pores and its longer diffusion lengths. Hence there are two portions of Ba, the one diffusing over the whole cathode surface as a monolayer (including over the complex) and the portion bound in the Ba–Sc–O complex. The elemental composition at room temperature over the surface area at a magnification of 168x was 7% Sc, 15.9% Ba, 24% O, 11.7% Re, and 20.2% W (+4.8% Al). In the area outside the grid of Fig. 3.21b the composition was 8.5% Sc, 14.2% Ba, 20.2% O, and 7.8% W/Re. We can compare this with a similar cathode #CG1_2.1, which also reached a saturated emission current density of 293 A/cm2 at operating temperature. There we obtain (flocky structure) 7.9% Sc, 17.2% Ba, 20.0% O, 13.5% Re, and 23.9% W (+ 3.1% Al). These results are quite similar.

a SEM micrograph of surface of SG2 + type cathode after LAD; structures will first coarsen and later on shrink on the grains during operation. b SEM micrograph of surface of CG1-type cathode outside grid hole region after gun operation; magnification 10,000x. c O elemental map by SAM of cathode surface of CG1-type after gun operation; same area as in 3.21b; magnification 10,000x. d Sc elemental map by SAM of cathode surface of CG1-type after gun operation; same area as in 3.21b; magnification 10,000x

A sputter depth profile of DG1 cathode (also after gun test) is given in Fig. 3.22a of an area of 200 × 200 µm2 outside the grid hole region. For comparison the LAD preparation conditions for this cathode were 411_0.35: 8400 pulses, Re: 12,500 pulses, ScOx: 8300 pulses (i10% (under-activated) = 230 A/cm2). Averaging the Ba:Sc:O ratio from 0 to 6 min of sputtering, which corresponds to n Sc sputter depth of 36 nm, one obtains Ba:Sc:O = 1.78: 1: 1.26. Here oxygen associated with W was not taken into account. Figure 3.22b shows another sputter depth profile now of a DG2 + cathode of a surface area of 500 × 500 µm2. This cathode was mounted in a diode and reached a maximum saturated emission current density of 267 A/cm2, but with an early deterioration. The LAD preparation conditions for this cathode were 411_0.35: 16,500 pulses, Re: 25,000 pulses, ScOx: 8400 pulses. Since more Re has been ablated, a higher Re concentration of 55% was reached. Here the averaging over an Sc sputter depth of 36 nm results in Ba:Sc:O = 2.44: 1: 1.4.

The average value from the surface analysis is Ba:Sc:O = 2.04: 1: 2.78. Since Ba as a monolayer on W or Re is independent of the position of the complex, the Ba to Sc ratio of the complex is probably a bit lower.

Figure 3.23a, b show SAM analysis results of a CG1 cathode after life test in a 45AX gun. The Sc elemental map under the rectangular grid opening of 0.7 mm × 0.5 mm illustrates the final removal of Sc by ion bombardment caused by the electron beam, whereas the Ba map is more uniform due to the resupply from the pores.

The micrographs of Fig. 3.21 were first shown by G. Gaertner in a presentation at RWTH Aachen in 2000 and again at South East University Nanjing in 2004; see also [67].

We can compare these data also with the literature. van Veen by XPS [76] and Hasker by AES [77] found a Ba/Sc ratio of 1 for scandate cathodes with emission <100 A/cm2. According to the investigations of Y. Wang and her coworkers of improved Sc–I cathodes, the emissive surface of the scandate cathodes investigated consists of an active surface multilayer containing (Ba, Sc, O) with a ratio of Ba:Sc:O around 1.9: 1: 2.2 [10]. It is interesting that J. Hasker already presented a depth profile in [15] after activation for a scandate cathode prepared with W and ScH2 in the top layer, which looks quite similar to Fig. 3.22, Ba and Sc decreasing within the first 6 min of sputtering. The signal ratio Sc/Ba = 2 is consistent with the lower emission capability of this cathode type.