Abstract

The grafting of copolymers has received significant attention due to the successful integration of their properties, both the backbone and graft chain polymers. The matter becomes even more interesting when the reactive/stimuli responsive polymeric chains are grafted onto backbone polymer, which offers unique physical properties such as crystallization or optoelectronic properties, etc. Such graft copolymer materials are very promising for the opening of new horizons of applications both in industry and academia. The grafting of reactive/responsive polymer chains onto commercially available polymers for greater manipulation of their properties is an attractive field of research. Grafting onto commercially available membrane-forming polymers such as poly(vinyledene fluoride) (PVDF) has aroused significant interest due to the possibilities of stimuli dependent membrane pore size modulation, supramolecular interactions have boosted its applications for affinity-based chromatography. Similarly, graft copolymers based on conjugated polymer backbones are also very much interesting, since interactions of the grafted chains with the external chemical or physical stimuli (such as pH, photoirradiation, salts, surfactants, temperature changes, etc.) significantly affect the conformation of the backbone chain, both in the solution state, gel state and solid state. This leads to changes in the optical response of the backbone polymers which are very useful in sensor applications, since the photo-responsivity of polymer systems is much stronger than small molecules due to signal amplification even under tiny perturbation. In most cases, grafting is done following an uncontrolled free radical-driven polymerization protocol, which associates threats to backbone degradation, the formation of high molecular weight graft chains, which affect the native properties of the backbone irreversibly. However, in order to keep the native properties of the backbone polymer intact, the grafting of polymeric chains must be performed in a controlled manner. In the present chapter, different strategies for the controlled grafting of neutral or ionic polymeric chains onto electroactive polymers and impact of the reactivity of the grafted chains onto the polymer property will be discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

10.1 Introduction

In order to make polymeric materials useful, two types of processes are generally used: (i) physical mixing of two polymers or by formation of composites and (ii) by chemical modification, e.g. copolymer or graft copolymer formation. The greatest difficulty in the former method is the limited miscibility between the two polymers, however, it is sometimes found that the microphase separation improves some properties (Parameswaranpillai et al. 2014). The composites, especially nanocomposites, greatly improve the mechanical and physical properties for commodity applications, but none of the physical mixing processes can tune the molecular properties of polymers and this can be achieved by chemical modification of polymers. Among the different chemical processes (copolymerization), the grafting is superior because it does not affect the properties of the main chain, rather it imparts new properties to the polymer coming from the pendent chains. Polymers are mainly insulator due to the difficulty in generating charge and its flow. A new class of polymers called electroactive polymers (EAPs) are very useful for this purpose. EAPs are those kinds of polymers which can generate charges under special conditions and, sometimes, charges can flow along the chain under an external field. They have good optoelectronic properties which can be modulated by varying their structure by grafting and varying external conditions. Grafting is a process that attaches pendent oligomers/polymers keeping intact the properties of main chain and providing new properties from the grafted chains. They have aroused great interest due to their possible applications as smart materials in the areas of actuators, batteries, membranes, sensors and also in the biomedical field.

However, among all known EAPs, poly(vinylidene fluoride) (PVDF) is the center of scientific attraction because of its highest known piezo- and pyro-electric properties (Gallantree 1983, Lang and Muensit 2006). In addition, this semi-crystalline fluoropolymer has excellent membrane formation capacity, chemical and weather resistance, biocompatibility and durability (Kuila et al. 2017a). There are five different crystalline forms of PVDF (α, β, γ, δ and ε) (Lovinger 1982). Among these, α-polymorph is mostly produced in melting crystallization, which have monoclinic unit cell with \( TGT\overline{G} \) chain conformation (Lovinger 1982, Kim et al. 2009, Martins et al. 2012). β-polymorph has an orthorhombic unit cell with an all trans conformation and exhibits the most important piezo- and pyro-electric properties (Morra and Stein 1982). γ phase has an orthorhombic unit cell with a \( {T}_3G{T}_3\overline{G} \) chain conformation (Doll and Lando 1970). The δ and ε polymorphs are polar and antipolar analogs of α and γ form, respectively (Lando et al. 1966, Weinhold et al. 1979). The grafting of this polymer with a different polymer is interesting since the crystallinity, electrical and mechanical properties, membrane forming ability, miscibility, structure, etc., can be tuned.

Poly(thiophene) (PT) is another interesting EAP, which has a conjugated double bond along the chain and can conduct electricity and also exhibits optoelectronic properties (McCullough and Lowe 1992, Maity et al. 2018). The main drawback of this polymer is that it is infusible and insoluble in both hydrophilic and hydrophobic solvents (Das et al. 2015, Jaymand et al. 2015). It is thus difficult to process and grafting of short or long polymer chain overcomes this difficulty since the pendent chains prevent the strong π-stacking interaction between the thiophene units of the PT chain (Das et al. 2015, Jaymand et al. 2015). The grafted PT chains showing chromic response is an interesting candidate for the manufacture of smart materials (Le’vesque et al. 2000). The optoelectronic properties of PT-graft copolymer can be tuned effectively by varying the biomolecules, ions, light, pH, temperature, etc. (Maity et al. 2018). The fascinating area of application of these graft copolymers is the development of sensors for biological analytes, energy devices, logic gate and molecular thermometers (Das et al. 2015, Jaymand et al. 2015, Das et al. 2017, Maity et al. 2018). They are better than the small molecular analogues due to their mechanical superiority and the cooperative amplified response of each segment through the conjugated chain, even for a very small perturbation (Das et al. 2015, Das et al. 2017). In the following sections, the different methods of synthesis, characterization, properties and application from graft copolymers of the above EAPs, made so far will be discussed.

10.2 Grafting of Poly(Vinyledene Fluoride) (PVDF)

In view of the significant piezo- and pyro-electric properties (Lovinger 1982), good biocompatibility (Bagchi et al. 2016), excellent membrane forming capability (Hester et al. 2002, Chen et al. 2003), graft modification of PVDF is very desirable in order to exhibit improved antistaticity, biocompatibility and surface properties.

10.2.1 Conventional Approach

It has been a general practice to employ free radical polymerization for graft modification of commercial polymers. Free radical centers are generated into polymer backbone after exposing them to ionizing radiation, free radical initiators (Hester et al. 2002) or the introduction of peroxide groups onto the original polymer backbone by ozone treatment (Boutevin et al. 1992, Fargere et al. 1994, Kang et al. 1997, Wang et al. 1998, Liu et al. 2001). The radical centers so produced initiate polymerization of several desired comonomers. However, such uncontrolled polymerizations, mainly generate a significant amount of homopolymer together with the desired graft copolymer. In addition, commercial polymers such as PVDF are usually of high molecular weights (Mw), initial viscosity of the polymerization mixture remains high. Therefore, under uncontrolled polymerization conditions, there is a significant threat of gel formation or backbone degradation (Wang et al. 1999). An acceptable remedy for these problems is to use a controlled polymerization reaction during the synthesis of the grafted chains following the ‘grafting from’ strategy.

10.2.2 Grafting From Approach

In this respect, atom transfer radical polymerization (ATRP) technique is very acceptable due to its robust nature (with respect of the tolerance to various functional groups of monomers or solvents etc.), at relatively simple and profitable polymerization conditions. A schematic representation of the ATRP mechanism is given below (Scheme 10.1), where an alkyl halide R-X (or halogen-capped polymer chain Pn-X, X = Cl, Br) reversibly generates radical centers R● (or Pn●) by reacting with transition metal complex of lower oxidation state.

The radical centers produced react with vinyl monomers during chain propagation and are reversibly deactivated by the transition metal complex of higher oxidation state, which plays the role of ‘persistent radical’. Different transition metal complexes have been used as ATRP catalysts (Coessens et al. 2001; Matyjaszewski, & Xia 2001). However, the copper-based complexes have the most efficient performance. The main requisite in controlled radical polymerization is the initiation rate, which must be faster than propagation rate. However, due to very high bond strength of C-F bond and the relatively poor radical stabilization in the secondary carbon atom, this condition can never be achieved. Therefore, controlled polymerization initiated from the PVDF backbone is undoubtedly a challenge.

Hester et al. (2002) used for the first time ATRP of oxyethylene methacrylate (OEM) and tert-butyl methacrylate (tBMA) initiated from the PVDF backbone in homogeneous solution of N-methyl-2-pyrilidone (NMP) using CuCl/4,4′-dimethyl-2,2′-dipyridyl (DMDP) as catalysts. The initiation of the polymerization occurred from the secondary fluorine atoms present in the PVDF backbone. However, in view of the very high C-F bond strength (486 KJ/mole) and the appreciable stabilization of F-CuIIL bond (Lanzalaco et al. 2017), neither the activation nor the deactivation occurred at a faster rate. This significantly affected the control over polymerization. The polymerization performance also recorded a significantly low yield, reaching ~42% tBMA conversion after 20 h and 20% OEM conversion after 19 h. The 1H-NMR analysis indicated the presence of the poly(methacrylate) chains together with PVDF and the size exclusion chromatography (SEC) analysis exhibited a clean sweep of Mw distribution trace towards a lower elution volume compared to the PVDF macroinitiator. 1H-NMR analysis is generally used to determine the graft chain Mw by using Eq. 10.1 (Expression for measuring Mw of graft copolymer).

where x is the molar ratio of the comonomer units measured from nuclear magnetic resonance (NMR).

Hester et al. (2002) revealed through the use of dynamic scanning calorimetric (DSC) analysis that the melting temperature (Tm) and crystallinity were reduced after graft modification. However, the loss was more pronounced in the case of POEM graft chains, perhaps due to its greater flexibility and compatibility with the polar groups (>CF2) of the PVDF backbone. Despite the lower degree of control over polymerization, the synthesized graft copolymers imparted the desired level of hydrophilicity to the PVDF backbone, which exhibited improved permeability towards aqueous analytes and protein antifouling properties when used in a 5% load with PVDF before membrane preparation by immersion precipitation technique.

The growth of hydrophilic chains on the surface of the PVDF membrane has been an acceptable strategy to impart hydrophilicity or antifouling property, retaining primarily the native properties of PVDF and the membrane framework. However, this is quite difficult to carry out the cleavage of C-F bond under heterogeneous conditions. With this in mind, Chen et al. (2006) reported a similar approach where surface-initiated atom transfer radical polymerization of poly(ethylene glycol) methyl ether methacrylate (PEGMA) or 2-dimethylaminoethyl methacrylate (DMAEMA) was carried out in water medium using CuCl/bipyridine (bpy) or CuBr/hexamethyltriethylenetetramine (HMTETA) complexes as catalysts. These authors performed a successful surface-initiated ATRP reaction from heterogeneous PVDF surface as a macroinitiator (Chen et al., 2006). Subsequently, the ‘living’ character of the surface grafted PPEGMA chains or poly(2-dimethylamino)ethyl methacrylate (PDMAEMA) has been established by a block copolymer with poly(styrene) (PS).

In view of the very high bond strength of C-F bond (486 kJ/mol compared to 339 kJ/mol for C-Cl bond) and the relatively poor stability of the secondary radical center in PVDF backbone compared to the tertiary/α-ester group stabilized radical canters produced on monomer residues by C-Cl bond cleavage (during propagation). Thus, a slower initiation rate can be expected compared to the propagation rate. This should result in fairly poor control over the polymer chains and the ‘non-living’ character compared to any ATRP model system. It can also be expected that the control will be even lower during the surface initiated ATRP. Nevertheless, the work done by Chen et al. (2006) demonstrated a successful block copolymer formation with PS, which was established by 1H-NMR analysis. Similarly, an appreciable antifouling property of the surface of hydrophilic polymer modified PVDF membrane with respect to the aqueous bovine serum albumin (BSA) solution was demonstrated.

Zhai et al. (2002) and Cen et al. (2004) reported a surface modification technique for modifying the surface of the PVDF membrane to impart antibacterial properties. Radiation-induced grafting of 4-vinylpyridine was carried out by Cen et al. (2004) on PVDF surface. Plasma pretreatment followed by exposure to air could create oxide or peroxide groups, and then graft copolymerization can be induced from them. The pyridine rings in the grafted chains were subsequently quaternized with hexyl bromide to generate n-hexylbromide groups onto the grafted poly(4-vinylpyridine) (P4VP) chains. A significant antibacterial property of the graft modified PVDF membrane was demonstrated by Cen et al. (2004) using Escherichia coli test compared to pristine PVDF membrane. The scanning electron microscopy (SEM) images showed numerous E. coli cells distributed on the upper fibers and interstitial spaces in contrast to the surface-modified membrane (PVDF-10) where no bacterial cells are found (Fig. 10.1a and b) (Cen et al. 2004).

SEM images of (a) Pristine PVDF and (b) modified PVDF-10 membrane. Reproduced with permission from Cen et al. (2004)

In a fascinating approach, Singh et al. (2005) reported a methodology to convert commercially available PVDF microporous membranes into ion exchange membranes by grafting from primary anchoring poly(glycidyl methacrylate) (PGMA) monolayers. In order to avoid the ATRP initiation through a very strong C-F bond cleavage, PGMA layers were initially deposited on a plasma-pretreated microporous PVDF surface, where covalent anchoring with the PVDF surface was expected through reactive epoxy groups. Subsequently, the residual epoxide rings were opened with bromoacetic acid, and therefore, ATRP initiating sites were placed. The ATRP of 4-vinylpyridine was then carried out from these initiating sites using CuBr/Me4Cyclam as catalysts in acetonitrile medium. The ion exchange capacities of the functionalized membrane were measured by generating titration curves of the pyridine groups on the membrane surface against 0.01 (M) HCl.

Pandey et al. (2003) also found that static ion exchange capacity was increased with the polymerization time during P4VP grafting, since a longer polymerization time had the introduction of a greater number of pyridine moieties onto the grafted chains. However, the ion exchange capacity observed was lower by the surface modified PVDF membrane compared to the commercially available ion exchange membranes (Table 10.1).

PDMAEMA is very interesting polymer due to its amphiphilic nature, thermo (lower critical solution temperature (LCST) at ~50 °C in neutral water) and pH responsive character. Most of the PDMAEMA’s unique properties are due to their pendant tertiary amine groups (-NMe2), which are very reactive. The easier availability of alone electron pair of the nitrogen atom can also induce supramolecular interactions with the positively charged carbon centers of PVDF (>CF2) groups, and therefore, interesting bulk properties can be obtained. Apart from this, bulk modification of PVDF chains with PDMAEMA grafted chains was achieved, and therefore, the fabrication of membranes resulted in an improved affinity-based separation of the compounds from the analytes. In addition, given the hydrophilicity of the PDMAEMA chains, the membranes fabricated from bulk modified PVDF after the grafting solution phase of the PDMAEMA chains showed a better antifouling and antibacterial activity.

Xue et al. (2008) reported ATRP of DMAEMA initiated from the PVDF macroinitiator in N,N-dimethylformamide (DMF) medium using CuBr/pentamethyldiethylenetriamine (PMDETA) complex at 90 °C. The membrane fabrication was subsequently carried out using immersion precipitation technique. The analysis of the membrane surface composition was thoroughly performed by X-ray photoelectron spectra (XPS) analysis. The morphology of the membrane surface showed a significant dependence on external stimuli such as pH or temperature (Fig. 10.2). The PVDF-g-PDMAEMA synthesized by Xue et al. (2008) exhibited a significant antifouling property when studied in aqueous BSA solution. These materials also demonstrated a significant antibacterial property against Staphylococcus aureus compared to membranes fabricated from pristine PVDF (Fig. 10.3). In addition, the relatively low value of formation constant of CuBr/PMDETA complex resulted in a significant deactivation of the complex structure, particularly in reactive DMF solvent at elevated temperature as high as 90 °C. Therefore, a relatively poor degree of control over the graft chain polymer molecules is expected. Nevertheless, this work represents a significantly ‘living’ character of the grafted PDMAEMA chains, which is further established by the synthesis of the PDMAEMA-b-poly(napthyl methacrylate) (PNM) block copolymer with fluorescent polymer PNM in the graft chains. Xue et al. (2008) also indicated that the initiation step during the synthesis of the block copolymer occurs from the fluoro-capped PDMAEMA graft chains and excludes any initiation from the residual backbone VDF moieties, as the temperature during the synthesis of the block copolymer with the same ATRP catalyst was maintained at 25 °C instead of 90 °C, and the fluorescence spectra of the PVDF-g-P(DMAEMA-b-NM) membrane casted from deionized water at 25 °C and pH 7 exhibited photoemission at ~364 nm when excited at 268 nm. Nevertheless, SEC analysis in support of the block copolymer synthesis was not given. Apart from providing hydrophilicity or antibacterial properties, the significantly reactive pendant tertiary amine (-NMe2) groups of PDMAEMA graft chains can interact supramolecularly with the (>CF2) dipole of VDF units. This could result in a significant development of the bulk properties of the PVDF-g-PDMAEMA graft copolymer. However, in order to achieve this, a significant amount of PDMAEMA chains is required to be grafted onto PVDF backbone.

SEM images of the surface (top) view and cross-sectional view of the PVDF-g-PDMAEMA copolymer membrane (from 2 h of ATRP fused at (a) 25 °C and (b) 70 °C in aqueous medium at pH 7. Reproduced with permission from Xue et al. (2008)

SEM images of (a) the pristine PVDF membrane and the PVDF-g-PDMAEMA membranes from the copolymers with (b) 2 h and (c) 12 h of ATRP, after exposure to the S. aureus culture medium for 24 h. Reproduced with permission from Xue et al. (2008)

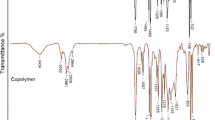

Samanta et al. (2009) reported solution phase grafting of PDMAEMA chains onto PVDF macroinitiator in NMP medium at 80 °C using CuCl/DMDP catalyst. Unlike the CuBr/PMDETA catalyst used previously, CuCl/DMDP forms a much more stable catalytic complex having much greater efficiency to drive ATRP equilibrium. The polymerization kinetics was carefully monitored by gravimetric method, which exhibited about 39% monomer conversion for 24 h during grafting. The kinetic analysis showed a first order linear plot for the disappearance of monomers with a monomer conversion time of up to ~36%, and the evolution of Mw of the grafted chains with monomer conversion exhibited a linear relationship, as well as the SEC analysis confirmed the controlled nature of the polymerization through the clean sweep of the Mw distribution traces corresponding to the graft copolymers with increasing DMAEMA conversion, while the 1H-NMR analysis proved to be quite useful for determining the exact Mw of the graft copolymers, graft length and graft density.

Very interesting, Samanta et al. (2009) also found that defect sites (H-H) of PVDF chains play a preferential role during the ATRP initiation. The 19F-NMR analysis of the graft copolymer with maximum DMAEMA conversion (39% monomer conversion in PD24) exhibited about 60% of the defective sites (H-H) responsible for the ATRP initiation, despite its abundance of only ~4.33% in the PVDF backbone, which of course is rich in (H-T) bonds (95.67%). The bulk modification of PVDF after grafting with hydrophilic PDMAEMA chains (as in PD24) was produced significantly, which is evident from the first-time report of PVDF-based graft copolymer being water soluble. The analysis of the thermal properties of the graft copolymer exhibited significant interactions between PDMAEMA graft chains and the PVDF backbone, resulting in a significant loss of crystallinity and a decrease in the Tm and degradation temperature of the graft copolymer. These effects were more pronounced by increasing graft conversion. Samanta et al. (2009) also suggested supramolecular interactions between the lone electron pairs on -NMe2 group and the positively charged carbon atoms of > CF2 groups, which results in the formation of ‘fringed micelle’ like crystallites for PVDF domains throughout the graft copolymer matrix (Scheme 10.2). The proposed supramolecular interactions are also supported from small angle X-ray scattering (SAXS), wide angle X-ray scattering (WAXS) and Fourier transform infrared (FTIR) analyses. The nanophases of the graft copolymer allow sufficient interaction between the components due to the increase in surface area. Samanta et al. (2009) also observed a dramatic increase in the toughness of the graft copolymer (~1970%) compared to PVDF, which was attributed to the unwinding of supramolecularly-organized rubbery PDMAEMA chains when stress is applied. In addition, the graft copolymer shows significant activity as an adhesive, which was able to withstand ~16 kg load when a pair of aluminum plates were fused using a thin film of PVDF-PDMAEMA (0.05 mm thickness and a square centimeter area). These authors indicated that this tremendous adhesive strength was caused by filler action of the nano dispersed PVDF crystallites, and possibly in some degree of crosslinking by PDMAEMA chains during heating at 180 °C, before sealing the plates.

Schematic model of PVDF-g-PDMAEMA graft chains with supramolecular interactions. Reproduced with permission from Samanta et al. (2009)

In another work, Samanta et al. (2010) carried out the ATRP grafting of poly(n-butyl methacrylate) (PnBMA) onto PVDF backbone under similar conditions to those considered for tert-butyl methacrylate (Hester et al., 2002). The polymerization kinetics exhibited first-order linear plot of almost 80% monomer conversion when the polymerization reaction was conducted in the presence of ~5% CuCl2/DMDP complex with respect to CuCl/DMDP. The 19F-NMR analysis demonstrated defect sites (H-H) on the synthesized graft copolymer, which were the preferred site for ATRP initiation, while supramolecular interactions between the carbonyl ester group (>C=O) of the PnBMA chains and the (>CF2) groups of PVDF were established by the FTIR analysis. The graft copolymer synthesized also shows appreciable mechanical properties, which were attributed to the supramolecular interactions between the ester carbonyl groups of grafted PnBMA chains and > CF2 groups present on PVDF backbone. In addition, the graft copolymer showed appreciable solubility in low boiling organic solvent tetrahydrofuran (THF). Interestingly, honeycomb-like porous membranes were manufactured when film casting was done from the solution of the polymer in THF, following ‘breath figure’ mechanism (Scheme 10.3).

A schematic model representing the pore formation of PB graft copolymers through ‘breath figure’ mechanism. Reproduced with permission from Samanta et al. (2010)

Samanta et al. (2010) also indicated that the graft copolymeric membrane casted from its THF solution exhibited a beautiful honeycomb-like morphology (Fig. 10.4) formed due to operation of the ‘breath figure’ mechanism. While the crystallinity of PVDF in the PVDF-g-PnBMA graft copolymer makes it a potential candidate to be used as a solid-state electrolyte in a Li+ ion battery. In fact, the graft copolymer film when doped with 5% Li+ ion (LiOTf), showed much an increased conductivity, as high as 1.04 × 10−5 S/cm compared to 2.0 × 10−10 S/cm dc conductivity of melt cooled Li+ ion doped PVDF film (Fig. 10.5) because of porosity of the film.

Field emission scanning electron microscopy (FESEM) micrograph of (a) pure PnBMA, (b) PVDF-g-PnBMA films and (c) top: cross-section morphology of the PVDF-g-PnBMA film and bottom: high resolution micrograph of top. All films were cast from a THF solution in air at 30 °C. Reproduced with permission from Samanta et al. (2010)

Plot of dc conductivity vs. Li+ ion concentration of doped PVDF-g-PnBMA graft copolymer with porous and non-porous morphology. Reproduced with permission from Samanta et al. (2010)

Another acceptable strategy for the synthesis of EAPs is graft copolymer based on PVDF keeping the reactive functional pendant groups, and subsequently modify for the introduction of desired moieties before or after membrane fabrication. In this sense, Cai et al. (2011) reported on grafting of propargyl methacrylate (PMA) by thermal polymerization onto ozone pretreated PVDF backbone. This was followed by the manufacture of membranes by the phase inversion technique. Subsequently, the alkyne moieties present on the surface of the membrane were used for thiol-yne ‘click’ reaction with 3-mercapto-1-propansulphonic acid sodium salt. Alternatively, alkyne-azide click reaction was performed to introduce β-cyclodextrin (β-CD) moieties to obtain mono(6-azido-6-deoxy)-β-cyclodextrin membrane surface. These moieties acted as hosts for the formation of inclusion complexes with diadamentyl-poly(ethylene oxide) (AD-PEO). Thus, polar PEO moieties were introduced on the membrane surface to impart significant antifouling properties. In fact, the PEO tethered membrane surface showed less than 25% γ-globulin absorption compared to the PVDF-g-PPMA precursor graft copolymer membrane. The high efficiency and the almost universal nature of the alkyne-azide click reaction allows additional extrapolation of the strategy developed for anchoring azide end capped polymeric chains of PEO monomethyl ether (azido-MPEO), poly[2-(N,N-dimethylamino)ethyl methacrylate](azido-PDMAEMA) and poly(N-isopropyl acrylamide) (azido-PNIPAM) on PVDF-g-PPMA membranes for the production of antifouling, pH and temperature responsive membranes.

Materials having a combination of orthogonal properties such as ferroelectricity and semi conductivity generate a significant interest in applications such as nonvolatile data storage. Normally different inorganic materials are used for such applications. The ferroelectric properties of the β-phase of PVDF can be valuable in such applications if the semiconductor organic substances can be united with it. In this regard, poly(3-hexyl)thiophene (P3HT) has received significant attention as an organic semiconductor material, however, it is very difficult to covalently connect ferroelectric PVDF and semiconductor P3HT. With this in mind, Samanta et al. (2012a) designed a novel synthetic strategy for the preparation of covalently attached ferroelectric PVDF and semiconductor P3HT in a graft copolymer. In this work, the PGMA chains were first grown up via ATRP from the PVDF macroinitiator and then the 3-thiopheneacetic acid molecules were anchored after opening the epoxide rings. In the next step, the oxidative polymerization of 3-hexylthiophene was carried out with FeCl3 in nitromethane medium in the presence of the above thiophene ring anchored PVDF graft copolymer (Scheme 10.4). The ATRP of glycidyl methacrylate (GMA) is quite difficult because of its tremendous susceptibility to acidic or basic impurities during the polymerization reaction which can lead to the epoxide ring opening and finally to irreversible gelation. The ATRP of GMA was conducted by Samanta et al. (2012a) in ethylene carbonate (EC) solvent with PVDF macroinitiator using CuCl/DMDP catalyst at 90 °C. However, Mw evolution, polymerization kinetics and SEC analysis indicated a fairly controlled ATRP, which achieved a very poor monomer conversion of about 33% after 6 h. The epoxy rings of the PGMA graft chains were subsequently opened by heating with thiophene 3-acetic acid and then oxidative polymerization of 3-hexylthiophene was carried out in the presence of the modified graft copolymer to synthesize PVDF-g-PGMA-g-P3HT (PGHT). The FTIR and crystallographic analysis indicated the presence of PVDF α-polymorph state in the PVDF-g-PGMA, which subsequently became β-phase in PGHT. The TEM micrograph of melt quenched PGMA samples exhibited a spherulitic structure of PVDF (Fig. 10.6), which disappears after the formation of PGHT showing the development of P3HT nanospheres. However, the analysis of dc conductivity shows an appreciably poor value of PGHT compared to P3HT, which was attributed to the largest energy barrier for hopping of the charge carriers through the conductive P3HT nanospheres dispersed into the non-conducting PVDF-g-PGMA matrix.

Synthesis of the PVDF-g-PGMA-g-P3HT copolymer using ATRP and oxidative polymerization techniques. Reproduced with permission from Samanta et al. (2012a)

TEM micrograph of PVDF-g-PGMA after 1 and 6 h of ATRP (PG1 and PG6). Corresponding samples after P3HT bonding (PGHT1 and PGHT6). Reproduced with permission from Samanta et al. (2012a)

On the other hand, Lanzalaco et al. (2017) reviewed the mechanism of PVDF backbone initiated ATRP, and evidenced that the slower initiation through the highly stable (C-F) bond breakage was the principal reason behind the poor control over the synthesized graft chains. These authors also suggested that the structure of the activator and deactivator catalyst complexes under the polymerization conditions was [CuI(DMDP)2]+[CuCl2]− and [CuII(DMDP)2Cl2], respectively. Therefore, after initiation through the PVDF macroinitiator, the expected structure of the deactivator complex should be [CuII(DMDP)2ClF]Cl−. In this situation, Cl− ions should provide a faster deactivation rate, although the relatively slow transfer of F− (due to the greater CuII-F bond force) (Lanzalaco et al. 2017). Lanzalaco et al. (2017) also reported that the greater thermodynamic stability of C-F bond is decided on the propagating poly(methacrylate) graft chain ends. The last possibility must present a condition of slower chain reinitiation compared to the first, which results in poorly controlled polymerization. According to Lanzalaco et al. (2017) a greater monomer conversion in such polymerization can still be achieved due to the presence of a large number of initiation sites distributed throughout the PVDF backbone. Therefore, a potential reason behind a relatively lower conversion, particularly in the case of monomers containing reactive pendant functional groups, should be catalyst deactivation. In line with this, the appreciably good nucleophilicity of the pendant -NMe2 groups can replace the Cl atom from the primary valence sphere of the deactivator complex during polymerization of DMAEMA, resulting in the formation of deactivator complex such as [CuII(DMDP)2(DMAEMA)F]Cl. This deactivator complex does not contain any Cl atom for providing deactivation, thus a very low deactivation rate can be expected for F− ions. Under these conditions, the activator concentration decreases sharply due to non-establishment of the ATRP equilibrium, resulting in a poor monomer conversion until the end, even after an appreciable period of time (Lanzalaco et al. 2017).

In order to alleviate this problem and obtain a well-controlled polymerization from PVDF backbone, Kuila et al. (2014) introduced for the first time an approach for tethering model ATRP initiator onto the PVDF backbone, and therefore, to drive the polymerization. In this work, the first 4-hydroxyTEMPO moieties were anchored onto PVDF backbone using atom transfer radical coupling (ATRC) reaction based on CuCl/DMDP (Kuila et al. 2014). This allowed the presence of hydroxyl groups distributed randomly onto PVDF backbone and then model ATRP initiators for various (meth)acrylate and acrylamide monomers were coupled to these sites by simple ester coupling reactions. All these strategies are presented in Scheme 10.5. The strategy applied presents a complete solution to the problem of slow initiation related with the cleavage of the C-F bond from PVDF backbone.

Synthetic scheme of different graft copolymers using the coupled ATRC and ATRP approach. Reproduced with permission from Kuila et al. (2014)

Many monomers have been successfully grafted from the PVDF backbone, which could not be done through direct ATRP. Table 10.2 shows many monomers having different reactivity. The highest polymerization rate of methyl methacrylate (MMA) using modified PVDF initiator compared to unmodified PVDF initiator is also given in Fig. 10.7a. As expected, Kuila et al. (2014) reported that during modified PVDF initiated polymerizations, the graft chain lengths were relatively longer compared to PVDF initiated graft chains. This was very evident by the relatively pronounced increase in the graft Mw with the conversion during the modified PVDF-initiated polymerization of MMA. Interestingly, the degrafted poly(methyl methacrylate) (PMMA) chains from the PVDF backbone of the modified PVDF-initiated graft copolymer, showed a linear increase in Mw with the conversion, thus maintaining an appreciably low Mw distribution (MWD or polydispersity index - PDI = weight-average apparent molecular weight (Mw)/number-average apparent molecular weight (Mn)), which shows an additional decrease as the conversion increases. In addition, the ‘living’ nature of the grafted PMMA chains when initiated from modified PVDF initiator is established by block copolymer synthesis with poly(methoxyethoxy)ethyl methacrylate (PMeO2MA). According to Kuila et al. (2014) the superposition of SEC traces confirmed the ability to restart grafted PMMA chains of the grafted PMMA chains through clean sweep to reduce elution volume after block copolymer formation (Fig. 10.7b).

(a) Disappearance of monomer with polymerization time and (b) SEC traces in THF of PVDF-g-PMMA and PVDF-g-P(MMA-b-MeO2MA) block copolymer. Reproduced with permission from Kuila et al. (2014)

PVDF is highly hydrophobic in nature, initial attempts for attaching hydrophilic graft chains onto PVDF backbone have been aimed at imparting hydrophilicity to the membrane surface to improve antifouling properties and water permeation. A successful application of the strategy developed was demonstrated by Kuila et al. (2015) during the preparation of PVDF-g-PMeO2MA with almost 70% monomer conversion when the polymerization was conducted at 60 °C. The appreciable graft conversion during the synthesis of the hydrophilic PMeO2MA chains made the water-soluble graft copolymer at low concentration. Kuila et al. (2015) also reported that the thermo-responsive character of the grafted PMeO2MA chains in aqueous solution was reflected on the temperature-dependent aggregation/disaggregation behavior of the graft copolymer, and therefore, in its aqueous solubility (Fig. 10.8). The thermo-responsive character of the PMeO2MA grafted chains was also performed by Kuila et al. (2015) for the demonstration of the antifouling character of the graft copolymer membranes casted by the ‘breath figure’ technique (Fig. 10.9). A digital image for the filtering configurations used for demonstrating the previous antifouling properties is shown in Fig. 10.10.

Z average size vs. temperature plot of the PD-24 graft copolymer obtained from the study of dynamic light scattering (DLS) in aqueous solution (0.1% w/v). Reproduced from with permission Kuila et al. (2015)

Fluorescence spectra of aqueous solution of BSA before and after filtration through the graft copolymer film at (a) 15 °C and (b) 37 °C. Reproduced with permission from Kuila et al. (2015)

The development of the ATRP grafting from the PVDF surface in the last two decades has finally made the PVDF soluble in water or other protic solvents. Water soluble PVDF-g-PDMAEMA or PVDF-g-P(DMAEMA-alt-MeO2MA) have been used for stabilization of gold nanoparticles (Au NPs) (Samanta et al. 2009) or silver NPs (Ag NPs) (Kuila et al. 2017b), respectively, in aqueous medium. A similar study was done by Kuila et al. (2016) by synthesizing PVDF-g-PMeO2MA (PD) copolymer, demonstrating simultaneous presence of LCST and upper critical solution temperature (UCST) in water/methanol (40–60%) medium (Fig. 10.11).

(a) Comparison of the area of methylene peaks of grafted PMeO2MA from 1H NMR in MeOD-D2O (1:1) and Z-average sizes of PD in methanol/water (1:1) at different temperature which show both UCST and LCST and (b) Quasi binary phase diagram of PD in methanol/water solution (1:1 v/v). Reproduced with permission from Kuila et al. (2016)

Interestingly, He et al. (2014) with the objective of increasing the cytocompatibility of PVDF, studied the covalent bonding of the arginine-glycine-aspartic acid tripeptide (RGD) on the PVDF backbone, thus exploiting reactive epoxy groups of grafted PGMA chains onto PVDF. The synthesis of the material was carried out by coupled application of ATRP and alkyne-azide click chemistry, where the PGMA chains were directly grafted from the PVDF backbone by ATRP, subsequently, click coupling of the tripeptide was carried out after opening of the epoxide rings by azide ions (Scheme 10.6). The superior mechanical and physicochemical properties of these materials allow them to be applied to replace the defective function of a tissue or part of an organ. He et al. (2014) also found that the surfaces of the synthesized graft copolymeric materials improved cell attachment and proliferation of adipose derived stem cells (ASC) compared to the pristine PVDF or PVDF-g-PGMA film surfaces.

Schematic illustration of the surface-initiated ATRP process of GMA from the PVDF film to give the PVDF-g-PGMA film surface, subsequent addition of azide groups via ring opening reaction of the epoxy groups on the PGMA brushes with sodium azide to produce PVDF-g-PGMA-N3 surface and the conjugation of the RGD peptide to the PGMA brushes via alkyne-azide click reaction. Reproduced with permission from He et al. (2014)

Given the technological importance and biocompatibility of PVDF, water-soluble PVDF-based polymeric materials are very desirable. In this respect, PVDF grafted with ampholytic graft chains with hydrophilicity or aqueous solubility is receiving considerable attention. With this in mind, Pakhira et al. (2019) synthesized a PVDF-based zwitterionic graft copolymer. The two-step strategy for synthesis is shown in Scheme 10.7, where at first, the PDMAEMA chains were grafted onto PVDF backbone by ATRP and then the pendant tertiary amine groups (-NMe2) of the PDMAEMA chains were quaternized with 1,3-propane sultone. This was further fractionated by water to obtain the aqueous solution having much better optical clarity and emission properties with a quantum yield of 8%. This approach was very interesting since the molecule does not contain any conjugated fluorophoric moiety. The origin of such fluorescence emission with nonconjugated chromophores was attributed to the clustering of carbonyl groups.

Synthesis of PVDF-based ampholytic graft copolymer. Reproduced with permission from Pakhira et al. (2019)

Thus, great steps are made in the grafting of the technologically important PVDF using the ATRP technique with different polymeric chains to produce innumerable new functional materials. The works in this field has allowed the successful use of the ATRP in the controlled grafting of PVDF, where the C-F bond has a very high bond energy too difficult to activate (Kuila et al. 2014). In addition, after the initial attempt to carry out ATRP from the PVDF macroinitiator through C-F bond cleavage, the introduction of tethering model ATRP initiating sites onto PVDF backbone using ATRC to form a modified macroinitiator has thrown light for easier graft polymerization of different monomers with a substantial degree of polymerization. This could lead to producing interesting properties which can produce different functional materials, biomaterials, sensors, etc., in the near future.

10.3 Poly(Thiophene) (PT)

Up to three quarters of the twentieth century nobody would have believed that polymers could conduct electricity as metals. Polymers have been considered as insulators of electricity. About 40 years ago a new class of organic polymers was discovered whose have the remarkable ability to conduct electricity, classified as ‘electrically conducting polymers’ or ‘synthetic metals’ (Walton 1990). The discovery of poly(acetylene) by Hideki Shirakawa’s group opened a new window before us in the field of electroactive polymer due to its unique conjugated system (Shirakawa et al. 1977). The conjugated polymers (CPs) are organic macromolecules, characterized by a backbone chain of alternating double and single bonds, their overlapping π-orbitals create a system of delocalized π-electrons, which result in interesting and useful optical and electronic properties (Barford 2005). They also have a conductivity similar to metal with the following advantages: corrosion resistance, easy processing and recyclability, grater workability, lighter weight and low cost (Mac Diarmid 2001, Ignatyev et al. 2014).

After this advance, many new conjugated polymers such as poly(aniline) (PANI), poly(p-phenylene vinylene), poly(p-phenylene), poly(pyrrole), PT, etc. have been discovered, which have demonstrated an appreciably high value of electrical conductance (sometimes even greater than metallic copper). Among all conducting polymers, PT is a well-known electroactive polymer showing tuneable fluorescence properties, Forster resonance energy transfer (FRET) and tunable electrical conductivity (Liu et al. 2002, Rasmussen et al. 2015, Westenhoff et al. 2005). The solubility in common organic solvents and in water is the greatest difficulty of pristine PT for its technological application (Das et al. 2015). Now, the processable materials in solution are always profitable and handier for technological applications. To overcome the processability problem, the attachment of flexible pendent groups onto the conjugated PT backbone is necessary (Das et al. 2015, Jaymand et al. 2015). Substituted PTs are semiconducting materials which have various technological applications particularly in the fields of field effect transistor (FETs), polymer light emitting diodes (PLEDs), solar cells and other optoelectronic devices due to its easy fabrication and tuneable optoelectronic properties (Andersson et al. 1999, Ong et al. 2004, Perepichka et al. 2005, Kim et al. 2006).

The attachment of different types of polar ionic pendent (anionic, cationic, zwitterionic) or the grafting of flexible polymers onto the PT backbone makes it stretchy enough to be solubilized in common organic solvents as well as in water (Das et al. 2015, Jaymand et al. 2015, Das et al. 2017). To achieve the water solubility of conventional PT, a widely used approach is to attach ionic ammonium, phosphate or sulfonate side groups onto hydrophobic π-conjugated backbones (Das et al. 2017). Ionic systems sometimes require adjusting the pH of the solution to avoid the aggregation of the polymers. In addition, the ion attached on the CP can migrate into the organic active layers of organic semiconductor devices and degrade their long-term stability. To overcome the drawbacks of ionic water-soluble CPs, another approach is to use some small non-ionic, highly polar, but neutral side groups to conjugate backbones, such as ethylene glycol and hydroxyl (Das et al. 2015). The grafting of polymer chains on PT backbone is more advantageous than the binding of small molecules due to the cooperative response of the graft polymers even in the presence of a small perturbation of the local environment (Das et al. 2015).

10.3.1 Grafting of PT

The idea of grafting flexible polymer chains onto the PT backbone is a fascinating way to produce processable PTs in solution. This approach is a useful tool to alter the solubility and mechanical properties of PT, and can also be used to introduce additional functional groups. The grafted chains can also introduce a controlled switching behavior in the main PT backbone, which leads to changes in the conformation, solubility, electrical and optical properties, which can be triggered by external stimuli, such as ion concentrations, pH changes, temperature or applied electrical potential (Maity et al. 2018). There are three approaches to grafting flexible polymer chains onto rigid backbone: (1) ‘grafting from’ when initiating sites located on the main polymer backbone initiate the polymerization of another monomer, (2) ‘grafting to’ when a growing polymer or a preformed polymer with reactive end groups reacts with pendant functional groups located on another polymer and (3) ‘grafting through’, involves the synthesis of macromonomers, and then a low Mw monomer is radically copolymerized with the macromonomer.

10.3.1.1 ‘Grafting From’ Technique

Recently, grafting has emerged as a very common and important technique for polymer brush synthesis. The ‘grafting from’ method is the most widely reported and popular among the three methodologies due to the commercial availability of functionalized monomers, which can be readily linked from initiating sites. Here, an end-functionalized PT can be used as a macroinitiator for the chain polymerization of another monomer. The ‘grafting from’ technique includes the ATRP, reversible addition-fragmentation chain transfer (RAFT) and single-electron transfer living radical polymerization (SET-LRP) (Lee et al. 2010, Foster et al. 2017, Lligadas et al. 2017). Among these techniques, the ATRP is very robust, as it tolerates many functional groups such as allyl, amino, epoxy, hydroxy and vinyl groups present in the monomer or in the initiator (Lee et al. 2010).

Costanzo and Stokes (2002) presented for the first time an idea to incorporate highly dense poly(methyl acrylate) chains from PT macroinitiator using this technique. These authors first prepared a regioregular PT using the McCullough’s polymerization method (McCullough and Lowe 1992) of thiophene monomer containing a protected alcohol group, then the backbone was functionalized by incorporating 2-bromo-propionyl bromide (ATRP initiator) into the regioregular PT backbone. From these initiator sites, the methyl acrylate monomer was polymerized to produce well-defined polymer brushes (Scheme 10.8). Although the synthesized polymer was insoluble in water due to the hydrophobicity of poly(methyl acrylate) chains, the solubility and processability of the graft polymer in common organic solvents was increased. The graft segment also helped the backbone to obtain an extended conformation, thus avoiding π-stacking interactions of thiophene units. Thus, the non-radiative decay paths of PT excitations were decreased, which led to a 20-fold increase in fluorescence intensity relative to the PT macroinitiator with a quantum yield of 40% in solid state (Costanzo and Stokes 2002).

Grafting of highly dense poly(methyl acrylate) chains from PT backbone. Conditions: (a) N-bromosuccinimide (NBS)/THF, (b) Me3SiCl/NEt3/THF; (c) dichloro(1,3-bis(diphenylphosphino)propane)nickel (Ni(dppp)Cl2), lithium diisopropylamide (LDA)/THF or ZnCl2, (d) THF/NEt3/tetra-n-butylammonium fluoride (TBAF)/2-bromopropionyl bromide, (e) ATRP conditions and (f) H2SO4/THF/MeOH. Reproduced with permission from Costanzo and Stokes (2002)

Balamurugan et al. (2005) adopted another technique in which the thiophene initiator, (3-[1-ethyl-2-(2-bromoisobutyrate)]thiophene, TI) was first prepared from thiophene-3-ethanol by coupling with the ATRP initiator moiety 2-bromoisobutyryl bromide in the presence of triethylamine. The PT macroinitiator was then synthesized by polymerization of the initiator containing thiophene monomer by oxidative polymerization using FeCl3 as an oxidant. Finally, grafting of hydrophilic N-isopropylacrylamide (NIPAAm) monomer by ATRP from the initiator containing PT backbone was performed to obtain a highly water-soluble and thermally responsive poly(thiophene-g-NIPAAm) molecular brush (Scheme 10.8). These authors then demonstrated the temperature-induced structural transition of the graft polymer in water. At LCST, poly(N-isopropylacrylamide) (PNIPAAm) underwent a rapid and reversible conformational change from an extended hydrated coil to a collapsed hydrophobic globule, which led to a change in the effective conjugation length of the PT backbone with abrupt and reversible color and absorption intensity changes at 30–35 °C (Balamurugan et al. 2005). Following this typical protocol, many other researchers have successfully grafted several types of flexible monomer onto rigid PT backbone by ATRP. For example, Wang et al. (2008) grafted another hydrophilic monomer N,N-dimethyl aminoethyl methacrylate (DMAEMA) onto the PT backbone following the same protocol used by Balamurugan et al. (2005), and provided direct evidence of the molecular mechanism that drives the pH-induced conformational changes of PT, and optical properties. At low pH due to the repulsive interactions between the protonated PDMAEMA side chains, the PT backbone adopts a less folded and twisted conformation than at high pH. This caused a color change of the solution from yellow (deprotonated condition) to dark orange (protonated condition) with an increase in emission intensity. In this same line, Samanta et al. (2012b) developed a fully polymeric fluorescent molecular logic gate using the same graft polymer (PT-g-poly(dimethylaminoethyl methacrylate) (PT-g-PDMA, PD)) doped on methyl cellulose (MC) based hydrogel, in which found that fluorescence property of PT had as an output and, on the other hand, temperature and pH were used as inputs with maximum sensitivity under basic condition and at high temperatures (45 °C) (Fig. 10.12).

Synthesis of poly(thiophene-g-NIPAAm). Reproduced from Balamurugan et al. (2005)

Grande et al. (2011) grafted homopolymer of PMMA, poly(carbazole ethyl methacrylate), poly(tert-butylacrylate) (PtBA), PS and block copolymer brushes of PMMA-b-PS and PMMA-b-poly(pentafluorostyrene) from PT backbone using a surface-initiated RAFT (SI-RAFT) polymerization. These authors forwarded an idea of electropolymerization of a terthiophene monomer with a dithiobenzoate moiety: 2-(thiophen-3-yl)ethyl 4-cyano-4-(phenylcarbonothioylthio)pentanoate 2-(2,5-di(thiophen-2-yl)thiophen-3-yl)ethanol, and subsequent deposition using poly(terthiophene) or PTs on flat electrode surfaces (Scheme 10.10). These films were then subjected to SI-RAFT polymerization to obtain surface-anchored polymers (Grande et al. 2011).

General route for preparing homopolymer and block copolymers from electrochemically deposited terthiophene CTA. Reproduced with permission from Grande et al. (2011)

Following Das et al. (2013a) a series of water-soluble thermosensitive poly(ethylene glycol) (PEG)-based PT graft copolymers using grafting of PT macroinitiator were obtained by means of the protocol of Balamurugan et al. (2005). These authors successfully tuned the physical (LCST-type phase transition) and optical properties with systematic variations of the copolymer composition (Das et al. 2013a). The π-π* absorption band of the backbone showed a red shift in PT-g-poly[oligo(ethylene glycol) methyl ether methacrylate] (PTDO) copolymers from that of PT-g-poly[(diethylene glycol) methyl ether methacrylate] (PTD) due to the extension of the length of PT conjugation from the uncoiling state by the more hydrophilic poly[oligo(ethylene glycol) methyl ether methacrylate] (POEGMA). Das et al. (2013a) also noted a strong increase in the emission of PTD solution at the LCST due to the collapse of the radiating poly[(diethylene glycol) methyl ether methacrylate] (PMeO2MA) fibrils which formed a shell on the PT nanosphere. PTD showed LCST at 21 °C, which was gradually increased from 31 to 43 °C with increasing OEGMA concentration.

Das et al. (2013b) also grafted pH responsive PDMAEMA chains and temperature responsive PMeO2MA onto PT backbone. This graft copolymer was used as a polymeric AND logic gate where pH and temperature were used as inputs and the fluorescence intensity was obtained as output. This graft copolymer was also used for the detection of nitroaromatics in solid/solution state, which is originated from the quenching of the PT excitons by the electron-poor nitro-substituted aromatic rings. This concept was further expanded by Das et al. (2014a) to obtain the maximum sensitivity of the logic operation under a lower pH by simple increasing the hydrophobicity of the grafted segments in which a N,N-dimethylamino ethyl methacrylate monomer was used.

Routh et al. (2012) successfully synthesized and stabilized Au NPs in water and tuned its morphological and electronic properties with ribonucleic acid (RNA) depending upon its assembled structure using the reducing capacity of PTDMA. The Au NPs embedded into PT-based polymer showed a dc-conductivity 6 times greater than that of the pure polymer due to the hopping process for charge carriers via Au NPs. This system also showed symmetric negative differential resistance (NDR) with a maximum NDR ratio of 64. This was possibly due to the fact that during the preparation of Au NPs, a large amount of charges were adsorbed on Au NPs, thus causing a hindrance to charge flow to reach a higher voltage when it releases the trapped charges completely, thereby giving almost zero current.

Lin et al. (2012) successfully grafted the PT backbones containing nitroxide radicals. These authors used a macroinitiator 2,5-poly(3-[1-ethyl-2-(2-bromoisobutyrate)]thiophene) (PEBBT) synthesized from 3-[1-ethyl-2-(2-bromoisobutyrate)]thiophene (EBBT) to be grafted onto poly(2,2,6,6-tetramethylpiperidin-4-yl methacrylate) (PTMPM) via ATRP, and then oxidized the PTMPM side chain with m-chloroperoxybenzoic acid (mCPBA) to produce a high Mw PEBBT-g-poly(2,2,6,6-tetramethylpiperidin-1-oxyl-4-yl methacrylate) (PEBBT-g-PTMA) (Scheme 10.11). The electrochemical properties in the batteries of organic radicals showed that the polymer had a good cyclic and electrochemical stability, since it inhibited the dissolution into the electrolyte solvents. Thus, PEBBT-g-PTMA has potential as a cathode-active material in a rechargeable organic radical battery.

Grafting of nitroxide radical-containing polymer onto PT backbone via ATRP. Reproduced with permission from Lin et al. (2012)

According to Fantin et al. (2016) direct grafting of methacrylic acid chains onto PT backbone is one of the biggest challenges for ATRP due to the intramolecular cyclization reaction, which leads to the loss of the carbon-halide chain-end functionality, thus resulting in the partial termination of the growing polymer chains. In this sense, Malmström et al. (2013) grafted poly(acrylic acid) (PAA) brushes from poly(3,4-ethylenedioxythiophene) (PEDOT). These authors first attached an ATRP initiator (2-bromopropionyl bromide) to the monomer 3,4-ethylenedioxythiophene (EDOT). The modified monomer (3,4-ethylenedioxythiophene)methyl 2-bromo-propanoate - BrEDOT) was then electropolymerized on large area gold-coated electrodes, and tert-butyl acrylate (tBA) brushes were grafted from the backbone by ATRP, followed by acid hydrolysis to give pH-responsive PAA brushes (Scheme 10.12).

Grafting of PAA brushes from the PBrEDOT backbone. Conditions: (i) acetone/CuBr/PMDETA/tBA at 60 °C and (ii) 1% methanesulfonic acid in dichloromethane (DCM). Reproduced with permission from Malmström et al. (2013)

Zhao et al. (2013) also forwarded a general approach of electropolymerization of EDOT to form an initiator group containing PEDOT. Neutral poly[oligo(ethylene glycol) methacrylate], POEGMA, poly(sulfobetaine methacrylate) (PSBMA) and zwitterionic poly([2-(methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide) were grafted by SI-ATRP from the conducting polymer deposited on the surface. These grafted polymers prevented the binding of proteins and also showed the adhesion of the cells on the surface. In another work, Das et al. (2014b) also successfully grafted methacrylic acid chains onto a PT backbone by ATRP of tBMA followed by hydrolysis of tert-butyl groups using trifluoroacetic acid. The synthesized PT-g-PTMA polymer can be used as a template or a dopant for the synthesis of PANI nanostructures with motivational morphological and electronic properties. PTMA-doped PANI (PTPA) hybrids can be self-assembled in non-helical or single-handed helical nanorod with some morphology of small-sized spheroids depending on the amount of PANI ratio. The PTMA itself has a spheroidal morphology, while PTPA hybrids have a nanorod morphology. By increasing the aniline concentration with respect to PTMA, the nanorod becomes helical in nature, along with some spheroids. The PTPA hybrid has a maximum of 4.1 × 10-2 S/cm of dc-conductivity, while the PTMA has only a conductivity value of 5.6 × 10-7 S/cm. The PTPA hybrid exhibited reproducible photoconductivity by alternating between ‘on’ and ‘off’ switching of white light illumination with a semiconducting nature, and this photocurrent generation is a property of only PTPA hybrids, since no appreciable photocurrent is observed for the PT macroinitiator nor for the PMA-doped PANI. The core-shell type structure of PTMA with a conducting PANI coating was responsible for the good electrical conduction, because the doped-PANI produces an additional electrical conduction path. The molecular arrangement of PANI and PT in the PTPA samples can be attributed to the charges stored through resonance stabilization, thus producing a moderate capacitance value. The single semicircle in the Cole-Cole plot of real and imaginary parts of complex impedance can thus be obtained.

Ghosh et al. (2015) synthesized cationic PT-g-poly[(N,N,N-trimethylamino iodide)ethyl methacrylate with iodide counter anion (CPT-I) from PTDMA, followed by quaternization of PDMAEMA segments using methyl iodide. The CPT-I has a lower fluorescence intensity than that of PTDMA due to the transfer of excitonic energy from the PT backbone to iodide ions. When the iodide anions were substituted by cyanide ions, the fluorescence intensity showed a huge rise depending on its concentration. Ghosh et al. (2016) also synthesized a PT-g-poly(ampholyte) (PTP) and studied the aggregation-disaggregation behavior with ionic surfactants with different charges at different pHs of the medium. For this purpose, the PTP was synthesized using N,N-dimethylaminoethyl methacrylate and tBMA monomers by grafting from the PT backbone, followed by hydrolysis. The PTP exhibited a reversible fluorescence on and off response in both acidic (Scheme 10.13) and basic medium with the sequential addition of ionic surfactants with different charge through self-assembly and de-assembly of the ionic aggregates, repeatedly.

Reversible turn ‘on’ and ‘off’ plot of fluorescence intensity of PTP in aqueous solution with increasing amounts of sodium dodecylbenzenesulfonate (SDBS) then cetyltrimethylammonium bromide (CTAB) sequentially at pH 2.7. Reproduced with permission from Ghosh et al. (2016)

An ampholytic PT (PT-g-poly[(N,N,N-trimethylamino iodide)ethyl methacrylate-co-methacrylic acid], APT) was also synthesized by Ghosh et al. (2017) synthesized in order to tune the optoelectronic properties of the PT chains depending on the position of Hofmeister iodide (I-) ion at different pH values. The APT was synthesized by copolymerization of tBMA and DMAEMA monomers from the PT backbone by ATRP technique (Scheme 10.14). The hydrolysis of the tBMA residues and the quaternization of the DMAEMA residues of the graft copolymer were then performed to produce the desired polymer. Under acidic conditions, the absorption and emission signals of the PT chromophore exhibited an appreciable blue shift in the presence of I− only as a counter anion. The cooperative effect of non-dissociated -COOH and quaternary ammonium groups immobilized I- near the apolar PT chain, causing the threading of grafted chains, and therefore, twisting of the backbone was attributed to the blue shift. The dethreading of PT backbone was produced as medium pH increased, due to the ionization of -COOH groups, thus releasing quencher iodide ions from the vicinity of the PT chains, resulting in a red shift in absorption and a sharp increase in fluorescence intensity. The dethreading was also found when APT interacts with RNA, which shows a significant increase of fluorescence for displacing iodide ions forming the nanofibrillar network morphology. Threading and dethreading also affected the capacitance (C), resistance (R2) and Warburg’s impedance (W) values of APT. The threading and dethreading of the grafted chains in APT also influenced the electrical properties of the system as follows from the impedance spectra (Nyquist plot, Fig. 10.13). APT at pH 2 and pH 4.5 showed a semicircle in the impedance spectra due to the presence of an equivalent circuit containing C and R2 in parallel with each other, while at pH 9 a semicircle and a linear hike corresponds to the presence of the W in the lower frequency region, whereas at a lower pH, the loss of planarity of the PT chain and the shield resisting the interchain hopping of charge carriers for the threaded nonconducting grafted chain caused a hindrance to the charge flow. APT has a maximum C value at pH 2, since the vesicle surface can easily store the charges at pH 4.5, due to the creation of partial negative charges, which leads to the charge annihilation, resulting in the lowest C value. At pH 9, APT showed an increase in C with W which arose for mass transfer because complete dethreading caused the I− ions free to move into the nano-fibrillar network. So, the influence of Hofmeister I− ion was established for tuning the optoelectronic properties of a novel PT-based polyampholyte by changing the pH or by conjugating with RNA (Ghosh et al. 2017).

Synthetic procedure for the preparation of ampholytic PT from 3-thiophene ethanol. Reproduced with permission from Ghosh et al. (2017)

Nyquist plots of APT under conditions of (a) pH 2 and pH 4.5 and (b) from pH 9 with their corresponding equivalent circuit. Reproduced with permission from Ghosh et al. (2017)

Recently, Ghosh et al. (2018) anchored uracil moiety on PT backbone to modulate the electronic structure of a π-CP from the stimulus-sensitive side chains to obtain the desired optoelectronic properties. For this purpose, PT-g-poly-[N-(6-methyluracilyl)-N,N-dimethylamino chloride)] ethyl methacrylate (PTDU) was synthesized by ATRP of the DMAEMA monomer from PT backbone followed by quaternization reaction with 6-chloromethyl uracil. The uracil moiety of the grafted chains when exposed to diffuse sunlight caused the absorption maximum of PTDU solution, showing a gradual blue shift of 87 nm and a gradual blue shift in emission maximum (46 nm) quenching its fluorescence (~7 times) with time. These effects occurred only in the absorption range of PT chromophore when exposed to direct exposure of light of different wavelengths, and the optimum wavelength was 420 nm. The uracil moieties after being exposed to visible light, these were moved towards the backbone to facilitate the photoinduced electron transfer (PET) between the PT and the uracil moieties, which was attributed to the variation of optoelectronic and phase transition properties. The transparent orange colored PTDU solution become cloudy with an increase in emission intensity when sodium halides were added and become reversibly transparent or cloudy when heated or cooled to a certain temperature. The screening of cationic centers of PTDU by varying halide anion concentration tuned the phase transition temperature. Thus, the light-induced variation of the backbone conformation was responsible for tuning the optoelectronic properties and regulates the thermal response capacity of the PTDU solution in the presence of halide ions (Ghosh et al. 2018).

10.3.1.2 ‘Grafting to’ Technique

In case of ‘grafting to’ technique at first, different polymer chains are synthesized separately and these pre-synthesized polymer chains are then linked onto the PT backbone. The Cu-catalyzed click chemistry and azide-alkyne cycloaddition are the simplest and most popular reaction procedures for the ‘grafting to’ process with high yield (Lutz et al. 2005). This method also avoids situations in which the ‘grafting from’ approach does not fit well. Although this method has not gained much popularity and has not been widely as ‘grafting from’ process due to the introduction of click chemistry and the steric hindrance has limited the chain growth of the polymer. Keeping this in view, Li et al. (2011) synthetized an amphiphilic rod-coil diblock copolymer (P3HT-b-PAA) using click reaction under the ‘grafting to’ approach between ethynyl-end regioregular P3HT with azide-end poly(tert-butyl acrylate) followed by acidolysis of PtBA (Scheme 10.15). Thus, Li et al. (2011) forwarded an idea to facilitate the synthesis and development of new block copolymers with high purity. In the same year, Wu et al. (2011) also reported on the synthesis of self-assembled P3HT-b-poly(g-benzyl-L-glutamate), which was the first report of PT/polypeptide-based diblock copolymer using Cu-catalyzed click chemistry. This copolymer could be self-assembled into hierarchal structures in solution and in solid state, and depending on the aggregation of the P3HT chains, the color of the THF solution of the polymer changes from orange to purple (the absorption peak shifts from 442 to 484 nm) by the slow addition of dimethyl formamide. Wei et al. (2015) reported the thiolated PEG binding to an alkene-functionalized poly(3,4-propylenedioxythiophene) (PProDOT) through thiol-ene click chemistry.

Synthesis of P3HT-b-PtBA and P3HT-b-PAA using grafting-to approach. Reproduced with permission from Li et al. (2011)

Recently, Mohamed et al. (2014) also reported water-soluble amphiphilic P3HT-g-PEO rod-coil conjugated random copolymers using the simple oxidative polymerization followed by simple click chemistry between azido-grafted random P3HT copolymers and ethynyl-end PEO (hydrophilic side chain). These authors stated that such P3HT polymers presenting PEO units on side chains are promising materials for a variety of bioengineering and biomedical applications (Mohamed et al. 2014). Kumari et al. (2015) also reported a new class of amphiphilic rod-coil conjugated block copolymer composed of regioregular P3HT and thermo-sensitive PNIPAAm by a Cu-catalyzed click reaction. The polymer exhibited LCST type thermo response capability and the luminescence and optical property of this block copolymer was different from its pure analogue and depended largely on the nature of the solvent or composition in a mixed solvent (Fig. 10.14) (Kumari et al. 2015).

(a) Variation in the PL intensity at different temperatures of the P3HT-b-PNIPAM solution in water and (b) emission color of P3HT-b-PNIPAM in various solvents under ultra-violet (UV) radiation. Reproduced with permission from Kumari et al. (2015)

10.3.1.3 ‘Grafting Through’ Technique

The macromonomer method or ‘grafting through’ method is one of the oldest and easiest ways to synthesize graft copolymers with very good control over graft chain length and PDI. Normally, a low Mw monomer can be radically copolymerized with an acrylate or methacrylate-functionalized macromonomer to avoid the steric effect of the macromonomers which can make polymerization difficult. In this sense, Le’vesque et al. (2000) reported a new regioregular PT derivative (poly(3-methylhexa(oxyethylene)oxy-4-methylthiophene) - PHEGMT) with side chains having exactly six oxyethylene units in each thiophene unit. The macromonomer (3-methylhexa(oxyethylene)oxy-4-methylthiophene) was first synthesized from 3-hexa(oxyethylene)oxy-4-methylthiophene. The PHEGMT was then obtained via chemical polymerization of the monomer with iron trichloride as an oxidizing agent. Due to the thermochromic and ionochromic behavior of this polymer, it was concluded that the hexa(oxyethylene) side chains induce a more planar conformation of the PT backbone than random length oxyethylene side chains with an average of seven oxyethylene units. Brustolin et al. (2002) also reported water-soluble regioregular PT (poly-{3-[(2S)-2-methyl-3,6,9,12,15-pentaoxahexadecyloxy]-4-methylthiophene} - PMPT), bearing enantiomerically pure oligo(ethylene oxide) side chains. The thiophene-based macromonomer (3-[(2S)-2-methyl-3,6,9,12,15-pentaoxahexadecyloxy]-4-methylthiophene) was first obtained by the transetherification of 3-methoxy-4-methylthiophene with (2S)-2-methyl-3,6,9,12,15-pentaoxahexadecanol using p-toluenesulfonic acid as a catalyst. The chemical polymerization of the macromonomer was performed to obtain the PMPT using iron trichloride as an oxidizing agent (Scheme 10.16).

Synthesis of water soluble regioregular PMPT. Reproduced with permission from Brustolin et al. (2002)

Qi et al. (2006) synthesized thiophene copolymers and their derivatives with PEO side chains by chemical oxidation with FeCl3 and electropolymerization. The starting monomers were 3-hexylthiophene and 2-(3-thienyl)ethanol with PEO grafted onto the side chains. Shao et al. (2013) also reported the synthesis of a water-soluble non-ionic PT derivative (poly(3-(2-(2-(2-methoxyethoxy)ethoxy)ethoxy)methylthiophene) - P3TEGT) with a hydrophilic tri-ethylene glycol side group on the backbone. The PT derivative was synthesized from 2-bromo-5-iodo-3-(2-(2-(2-methoxy-ethoxy)ethoxy)ethoxy)methylthiophen using Kumada catalyst-transfer polymerization. P3TEGT films after thermal annealing exhibited a well-organized nano-fibrillar lamellar nanostructure which was originated from the strong π-π stacking of the backbones. p-type organic field-effect transistors (OFET) were fabricated from this water-soluble PT derivative, presenting the possibility of an environment friendly solvent for applications based on low-cost green solvent-processed devices.

Zhao et al. (2012) successfully synthesized a series of methyl- or benzyl-capped oligoethylene glycol-functionalized thiophene monomers, and also successfully polymerized the macromonomer by Grignard metathesis polymerization or reductive coupling polymerization following the ‘grafting through’ approach. The synthesized polymers showed high electroactivity and stability in aqueous solution and exhibited different colors depending on the doping state. In this same line, Bendrea et al. (2013) synthesized organic hybrid materials consisting of graft copolymers with a PT backbone and well-defined chains of PEG grafted onto the backbone by anodic polymerization of chemically synthesized pentathiophene macromonomers with methyl-capped PEG chains linked to the central thiophene. The synthesized polymer exhibited greater cell viability than steel and culture plate controls, thus suggesting that PEDOT films could be used as a promising tool for biomedical applications. Thus, the main bottleneck for PT application is its insolubility and rigidity in the backbone structure, which can be overcome by grafting a suitable polymer. These systems promise applications in manufacture of molecular logic gates, molecular thermometer, sensing of different toxic ions, sensors for biological molecules, surfactants, etc. The efficiency of these systems can be further tuned by changing the density of functional groups or by changing the graft density, graft Mw, co-grafting with different monomers, etc.

10.4 Summary and Outlook

In summary, this chapter presented the chronological development of graft copolymers of poly(thiophene) (PT) and poly(vinyledene fluoride) (PVDF), which are technologically very important as evidenced by their different uses. However, there is still much to be developed for its potential technological applications. A perspective for the future development of electroactive graft copolymers was given here, paying special attention to PVDF and PT.

Although PVDF has been grafted with a good number of acrylates, methacrylates and acrylamide-based monomers with several functional groups. There are still different monomer systems which have not been possible to graft from PVDF. Thus, different strategies of ATRP or RAFT polymerization can be designed to obtain new PVDF graft copolymers. However, the grafting of stimuli-responsive block copolymers onto PVDF has not yet been explored. This could help in the strategic design for producing smart polymers, both from its piezoelectric property and for making ion-selective, antibactarial and antifouling membranes. The introduction of thermo-sensitive and pH sensitive graft copolymers could also help to tune their electrical and piezoelectric properties under different conditions of ions, pH and temperature (Zarrintaj et al. 2019).

Another strategy for introducing desired complementary functionalities can be subsequent modification of PVDF graft copolymers, since the grafted chains have active functionalities. This strategy can be effective for producing materials combining orthogonal properties, e.g. PVDF piezoelectricity and semiconducting properties of organic or inorganic materials. For example, the conjugation of these copolymers with carbon nanotubes, CdS, CdSe and graphene quantum dots, as well as metal ions are very promising. This could help the manufacture of magneto-electric, multi-ferroic and data storage materials. PVDF graft copolymers can also act as compatibilizers, and reactive grafted groups could also help the manufacture of self-healing PVDF-based materials suitable for specific biological applications.

On the other hand, the increase in signal intensity for the cooperative response of the of grafted PT chain segments makes it attractive for sensor application, developing sensors for toxic ions, surfactants, biological analytes, logic gates, etc. The efficiency can be further improved by introducing more responsive functionalities such as changing graft density and length, polymer grafts, etc. require new ATRP or RAFT polymerization reaction conditions. The modification of PT backbone by grafting with stimulus sensitive polymers also causes a significant change in the properties by changing external stimuli, e.g. biomolecules, ions, light, pH, surfactants, temperature, etc. The modification in PT-graft copolymer morphologies causes a change into the PT backbone conformations, which could change optical and electrical properties of PT. Thus, the grafting of liquid crystalline polymer onto PT backbone could allow to couple the optoelectronic properties of PT with the anisotropic properties of the liquid crystalline systems, thus opening new application possibilities, particularly in electronic displays with improved response.

The grafting of stimuli-responsive block copolymers onto PT backbone by ‘grafting from’ approach has not yet been well explored, which could help generate new optoelectronic properties that can be tuned with the composition and length of the block, among others. The preparation of covalently/noncovalently-linked bio-conjugates with stimuli-responsive PT-based graft copolymer using different biomolecules (e.g. nucleic acids, peptides, proteins, etc.) may be suitable for applications in biological assays in the understanding of detailed structure of biomolecules from the chromic properties of PT chains. Thus, the grafting of functional polymers onto electroactive polymers could help material engineers and scientists such as biotechnologists, device engineers and nanotechnologists, to manufacture different functional materials for applications in biomaterials, electronic appliances, energy devices, sensors, etc. Undoubtedly, it will stimulate collaborative research between this new field of polymer chemistry with the cutting edge of materials science and engineering for developing new technological devices.

References

Andersson, M. R., Thomas, O., Mammo, W., Svensson, M., Theander, M., & Inganäs, O. (1999). Substituted polythiophenes designed for optoelectronic devices and conductors. Journal of Materials Chemistry, 9, 1933–1940. https://doi.org/10.1039/a902859e.

Bagchi, B., Banerjee, S., Kool, A., Thakur, P., Bhandary, S., Hoque, N. A., & Das, S. (2016). Synthesis of eucalyptus/tea tree oil absorbed biphasic calcium phosphate–PVDF polymer nanocomposite films: A surface active antimicrobial system for biomedical application. Physical Chemistry Chemical Physics, 18(25), 16775–16785. https://doi.org/10.1039/c6cp03493d.

Balamurugan, S. S., Bantchev, G. B., Yang, Y., & McCarley, R. L. (2005). Highly water-soluble thermally responsive poly(thiophene)-based brushes. Angewandte Chemie, International Edition, 44(31), 4872–4876. https://doi.org/10.1002/anie.200500867.

Barford, W. (2005). Electronic and optical properties of conjugated polymers. New York: Oxford U. Press.

Bendrea, A. D., Fabregat, G., Cianga, L., Estrany, F., del Valle, L. J., Cianga, I., & Alemán, C. (2013). Hybrid materials consisting of an all-conjugated polythiophene backbone and grafted hydrophilic poly(ethylene glycol) chains. Polymer Chemistry, 4(9), 2709–2723. https://doi.org/10.1039/c3py00029j.