Abstract

A range of dairy products are consumed on a regular basis as sources of macronutrients (fats and proteins) and micronutrients such as minerals and fat-soluble vitamins. Among these, there are products such as butter and cheese that form a part of daily diets and then there are others such as whipped cream and ice-creams that are usually considered as indulgence products. From colloid science point of view, these products could be broadly classified as structured emulsions (butter and butter spreads), coagulated gels (various cheese types) and foamed emulsions (ice-creams and whipped creams). These products have different microstructures (Fig. 13.1), all of them containing a significant proportion of milk fat distributed either in the bulk or dispersed phases. Milk fat is composed primarily of triglycerides (TAGs) with a significantly high proportion of saturated fatty acids (Table 13.1). Palmitic acid, the main fatty acid in milk fat, is known to increase the risk of cardiovascular disease (CVD) (Wang et al., 2017). And it has been consistently suggested by health agencies that replacing dairy fats with vegetable oils rich in polyunsaturated fatty acids reduces the risk of CVD (Chen et al., 2016; Nettleton, Brouwer, Geleijnse, & Hornstra, 2017). However, the high melting fraction of milk fat (composed of TAGs rich in long-chain fatty acids) is responsible for providing the underlying colloidal network of crystalline particles, which in turn governs the macrostructure and organoleptic properties of dairy fat products. Such properties include spreadability of butter and cheese spreads, plasticity of baking butter, hardness of cooking butter, voluminous body of whipped cream, texture of cheese, creaminess of ice-cream and melt-in-mouth effect of most dairy fat products. In addition, the stabilizing effect provided by bulk crystallization of milk fat in butter and interfacial stabilization of partially coalesced fat globules in whipped cream and ice cream is also dependent on the high melting TAGs in milk fat. Due to this broad range of functionality provided by milk fat, it is a challenging prospect to replace high melting milk fat with liquid vegetable oils rich in polyunsaturated fatty acids without compromising on the product attributes of reformulated dairy fat products.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

A range of dairy products are consumed on a regular basis as sources of macronutrients (fats and proteins) and micronutrients such as minerals and fat-soluble vitamins. Among these, there are products such as butter and cheese that form a part of daily diets and then there are others such as whipped cream and ice-creams that are usually considered as indulgence products. From colloid science point of view, these products could be broadly classified as structured emulsions (butter and butter spreads), coagulated gels (various cheese types) and foamed emulsions (ice-creams and whipped creams). These products have different microstructures (Fig. 13.1), all of them containing a significant proportion of milk fat distributed either in the bulk or dispersed phases. Milk fat is composed primarily of triglycerides (TAGs) with a significantly high proportion of saturated fatty acids (Table 13.1). Palmitic acid, the main fatty acid in milk fat, is known to increase the risk of cardiovascular disease (CVD) (Wang et al., 2017). And it has been consistently suggested by health agencies that replacing dairy fats with vegetable oils rich in polyunsaturated fatty acids reduces the risk of CVD (Chen et al., 2016; Nettleton, Brouwer, Geleijnse, & Hornstra, 2017). However, the high melting fraction of milk fat (composed of TAGs rich in long-chain fatty acids) is responsible for providing the underlying colloidal network of crystalline particles, which in turn governs the macrostructure and organoleptic properties of dairy fat products. Such properties include spreadability of butter and cheese spreads, plasticity of baking butter, hardness of cooking butter, voluminous body of whipped cream, texture of cheese, creaminess of ice-cream and melt-in-mouth effect of most dairy fat products. In addition, the stabilizing effect provided by bulk crystallization of milk fat in butter and interfacial stabilization of partially coalesced fat globules in whipped cream and ice cream is also dependent on the high melting TAGs in milk fat. Due to this broad range of functionality provided by milk fat, it is a challenging prospect to replace high melting milk fat with liquid vegetable oils rich in polyunsaturated fatty acids without compromising on the product attributes of reformulated dairy fat products.

Representative microstructures of dairy fat products such as butter (water droplets dispersed in oil continuous phase containing fat crystals), cheese (fat droplets embedded in protein matrix), and ice-cream (air bubbles stabilized by partially coalesced fat droplets dispersed in water continuous phase containing ice crystals)

From a general perspective, there has been a growing trend in the lipid community to identify alternative routes for structuring liquid vegetable oils in order to reformulate a broad range of lipid-based products (including dairy-related products) owing to a combination of factors including (1) recent policy changes in United States with regards to removal of trans-fats from food products, (2) raising concerns among consumers about the negative effect of saturated fat consumption and (3) the ecological damage caused by palm oil usage. These have together provided new motivations for food material scientists to focus on innovations in formulating lipid-based products with the aim of improving their nutritional profiles (trans fat- free, low in saturated fats, and high in unsaturated fats) and decreasing the over-reliance on palm oil (Patel & Edible, 2017).

Over the last decade, the field of oil structuring has seen a rapid advancement. Different approaches and structuring agents identified so far, may find applications in commercial settings very soon. In the following section, first, the basic concept of fat crystallization is introduced followed by a general overview of the field of oil structuring. The section concludes with a brief review of some of the examples of the applications of structured oil in dairy fat and related products.

2 Crystallization Behaviour of Milk TAGs

As discussed in the previous section, the network of crystalline particles affect a range of macrostructure and organoleptic properties of dairy fat products; hence, it is very important to first understand the crystallization behaviour of TAGs in milk fat. This knowledge can lay a foundation for exploring alternative ways for oil structuring.

Due to the broad TAGs profile, milk fat displays a broad melting range instead of a discrete melting point. Being a mixture of high and low melting TAGs, the crystallization behaviour is a combination of both melt crystallization as well as crystallization from a supersaturated solution where low melting TAGs can be considered to act as solvents for high melting TAGs. In general, fat crystallization behaviour can be broadly defined by three phenomena: nucleation, crystal growth and polymorphism. In addition to these basic phenomenon, the final development of bulk fat also involves a range of structural reorganization at different length scales as shown in Fig. 13.2 (Patel & Dewettinck, 2015).

Different structural levels (from molecular to macroscale level) involved in bulk fat development. Reproduced with permission from Patel & Dewettinck, Current update on the influence of minor lipid components, shear and presence of interfaces on fat crystallization. Current Opinion in Food Science 2015, 3:65–70

2.1 Nucleation

Nucleation is described as the formation of the crystalline phase from the liquid phase through the organization of TAGs into a crystal lattice. Three types of nucleation that can generally occur in fats include:

Primary homogeneous nucleation which occurs in the absence of any foreign materials. This process is very rare in milk fat because of the requirement of a very deep supercooling which is practically difficult to attain.

Primary heterogeneous nucleation which is initiated at the surfaces of catalytic impurities such as dust, seed particles or templates of high melting lipid components such as partial glycerides etc. In milk fat, micelles formed by monoacylglycerides may act as catalytic impurities for heterogeneous nucleation (Huppertz, Kelly, & Fox, 2009).

Secondary nucleation occurs when small pieces break from existing crystals and act as nuclei and is also important in milk fat.

2.2 Crystal Growth

Crystal growth is caused by the inclusion of other TAGs from bulk liquid in the existing crystal lattice. The TAG molecules can incorporate on either of the flat, kinked or stepped surfaces. The crystal growth involves firstly the diffusion of TAG molecules from the bulk phase to the crystal site and secondly the proper orientation to align with the existing packing of the molecules.

2.3 Polymorphism

Polymorphism governs the order of the packing of TAG molecules in the crystals. Polymorphic forms are solid phases of the same chemical composition that differ among themselves in crystalline structures. Milk fats like other fats are known to display monotropic polymorphism wherein one phase is stable, and others are metastable under all conditions, regardless of the external conditions such as temperature and pressure. The three polymorphic forms of milk fat crystals include α and β´ (metastable) and β (stable) forms. Fat crystallization follows the Ostwald’s step rule which states that the least stable polymorphs (α, in this case) is first to crystallize on cooling followed by step-wise transition to the most stable form. In milk fat, the majority of crystals are known to remain in the metastable β´ form, even after prolonged storage (Wright & Marangoni, 2006).

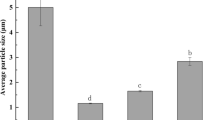

Fat crystals can grow into spherulitic or needle-shaped structures. In milk fat spherulitic crystal structures are predominant, these crystals have a very dense centre with decreasing density as the distance from the crystal centre increases. Spherulites continue to grow and aggregate into a three-dimensional network to take the form of bulk fat. Since the whole crystallization process of fats is rather ‘slow’, processing parameters like rapid (quenching) and deep cooling (supercooling) along with application of shear and incorporation of surface-active species is commonly employed to obtain the desired product (Patel, 2015). Generally, a faster cooling rate with deep cooling ensures that a large number of formed nuclei do not get enough time to grow, hence resulting in the formation of larger population of smaller crystals. Smaller size of crystals provide a higher overall effective surface area leading to stronger crystal-crystal interactions in the network. The crystalline network with immobilized liquid oil constitutes conventional route of oil structuring.

For a colloid scientist, this structured system is more akin to a particle-filled gel where a sufficiently high mass fraction of crystalline particles is required to obtain physical gels of liquid oil. Typically, a mass fraction of at least 0.2–0.25 is need for firm gels. Alternatively, such physical gels could be prepared using oleogelators instead of solid fats at relatively lower mass fraction (as low as 0.005 in some case). In the following section, different approaches of oil structuring is briefly discussed with specific emphasis on oleogelation through direct dispersion of structuring materials.

3 Different Approaches for Oil Structuring

There are different ways of categorizing oil structuring approaches, e.g., based on the molecular characteristics of structuring agents (low molecular weight organic compounds, polymeric compounds and inorganic compounds), their chemical types (lipid and non-lipid based oleogelators), and the molecular assemblies formed by the agents (crystalline particles, self-assembled structures, agglomerated inorganic particles and polymeric strands) (Patel & Dewettinck, 2016). The above mentioned ways of categorizing oil structuring approaches suitably covers oleogels which are fabricated by direct dispersion of gelling agent(s) but leaves out many unconventional approaches which may be considered more practical for use in commercial settings. Alternatively, a more comprehensive way of classifying structuring approaches is based on the processing steps involved in creating the structured oil systems as shown in Fig. 13.3.

Various approaches used for edible oil structuring. EC and CSD = Ethyl cellulose and colloidal silicon dioxide respectively. Reproduced with permission from Patel & Dewettinck, Edible oil structuring: an overview and recent updates. Food & Function, 2016, 7, 20–29. Published by The Royal Society of Chemistry

3.1 Direct Dispersion of Structuring Agents in Oil Phase

Almost all molecular gels are created by direct dispersion of structuring agent at elevated temperature followed by cooling down to ambient or cool temperature to trigger precipitation/crystallization/self-assembly of molecules into building blocks such as fine crystalline units, fibres, micelles etc. that can further associate via non-covalent interactions to form a space-filling continuous network. The solvent is then physically trapped into this network leading to a ‘gel-like’ state.

This is the most common approach used for preparing edible gels, lipid-based structuring agents such as partial glycerides, fatty acids, fatty alcohols, sorbitan esters and waxes are first dispersed above their melting points in liquid oils to create a clear molecular (supersaturated) solution followed by lowering of temperature to trigger crystallization (undercooling). Steps of nucleation, crystal growth, aggregation and network formation (as seen with high melting TAGs) are involved in oil structuring with lipid-based gelators as this approach is similar to fat-based structuring. However, the type and the morphology of crystals formed, the tendency of their unidirectional growth and limited aggregation of the formed crystals, differentiates them from the conventional crystals of TAGs, resulting in a continuous network (that shows high oil binding capacity) at much lower mass fraction of crystalline phase (as low as 0.5 wt%). The formed network from these lipid-based gelators display thermoreversible properties as seen with the conventional fat. This ability of lipid-based gelators to structure oil reversibly at very low concentrations is quite appealing to the food industry. Accordingly, this category of structuring agents has been studied extensively for edible applications (discussed further in the text).

Waxes

Among lipid-based gelators that form crystalline particles, natural waxes are by far the most studied group of materials for structuring edible oils. Chemically, waxes are composed of multiple chemical entities, the four major components are wax esters (WEs), fatty acids (FAs), fatty alcohols (Falcs) and linear hydrocarbons (HCs). Because of the presence of molecular units with linear structures, crystals formed by waxes show predominantly higher one-dimensional (1D) and two-dimensional (2D) growth resulting in needle-like to plate-like structures which are more efficient at gelling liquid oil at a concentration as low as 0.5 wt% (Patel, Babaahmadi, Lesaffer, & Dewettinck, 2015a). In addition to oil gelation, waxes are also known to stabilize oil continuous emulsions by a combination of bulk and interfacial crystallization (Fig. 13.4) (Patel, 2015). Owing to their oil structuring and colloid stabilization properties, a wide range of natural waxes have been explored so far for oil structuring. However, the results obtained with respect to critical gelling concentrations and rheological behaviour differ widely in different studies which makes it difficult to select suitable waxes for food applications. Recently, a comprehensive study was conducted to first elucidate the compositional characterization (percentage and chain length of each chemical class) of a set of waxes and further understand their role in the structuring of liquid oil (Doan et al., 2017). Using a set of waxes and a common solvent (rice bran oil), it was found that WEs result in strong and brittle gels with high modulus and yield stress, while HCs and long-chain FAs (above C16) contribute to stability and consistency of gels (high critical stress and consistency index) (Doan et al., 2017).

(On left) Needle-like crystals of wax (sunflower wax) seen under cryo-SEM (scale bar = 20 μm); (on right) Confocal image (taken in reflectance mode) of oleogel-based emulsion clearly showing the accumulation of fine wax crystals (shellac wax) at water-oil interface (Pickering stabilization; scale bar = 30 μm). Reproduced from Patel A. R., Alternative Routes to Oil Structuring, Springer International Publishing, 2015, UK

Partial Glycerides

Partial glycerides- mono and di- glycerides (MAGs and DAGs) are comparatively more polar than TAGs due to their structural features. Their crystallization behaviour is thus quite different from TAGs although they all belong to the acylglycerol family (i.e. fatty acid esters of glycerol). The advantage of using these partial glycerides (particularly, DAGs) over TAGs is that, while, they can mimic the crystal network formation and temperature induced texture reversibility shown by TAGs, their digestion in the gastro intestinal tract is quite different from that of TAGs and does not follow the usual mucosal resynthesize of TAGs, resulting in decreased body fat accumulation (Osaki et al., 2005). Both MAGs and DAGs are known to form a crystalline network in liquid oils which results in gel formation. In particular, MAGs with saturated long-chain fatty acids have been extensively studied for oil gelation (Ojijo, Neeman, Eger, & Shimoni, 2004). Since these partial glycerides are already being used in food industry as direct additives without any specified maximum limits (quantum satis), they can be considered to have a better acceptance compared to the other lipidic structurants. In addition, due to the interesting phase behaviour displayed by MAGs in oil-water mixtures, a range of oil-water gelled systems can be easily produced (Batte, Wright, Rush, Idziak, & Marangoni, 2007a, 2007b).

Sphingolipids

Sphingolipids are a class of biologically relevant lipids containing a sphingosine (a type of aliphatic amino alcohol) backbone with either one hydroxyl group esterified to a fatty acid side chain (ceramides) or both hydroxyl group substituted with a fatty acid and a non-fatty acid group (sphingomyelin, cerebroside and ganglioside). Ceramides, which are the simplest of sphingolipids have been studied for their oil gelling properties, it has been reported that certain short-chain ceramides are effective oleogelators. The increase in the fatty acid chain length adversely affects the success of ceramide as a gelator. The shorter fatty acid chain lengths are known to promote fibril growth, while longer chain lengths promote spherulite or platelet structures (Wang & Rogers, 2015).

Shellac

Shellac is a resin purified from the secretion of lac insects, Laccifer Lacca. It is not a single compound, but a complex mixture of polar and non-polar components consisting of polyhydroxy polycarboxylic esters, acids and alkanes. Being a complex mixture of fatty esters and alcohols, shellac has a lipophilic nature and tends to self-assemble into colloidal structures based on the solvent properties (Patel, Schatteman, De Vos, & Dewettinck, 2013a).

Shellac shows good miscibility with oil at temperatures above its melting range and forms an oleogel when the dispersion of shellac in liquid oil is cooled to room temperature. These oleogel samples could be obtained even after several cycles of heating and cooling, indicating their thermo-reversible nature. Figure 13.5 shows a comparative picture of samples prepared by heating the shellac dispersions at different concentrations in rapeseed oil followed by cooling to room temperature. As seen from Fig. 13.5, a concentration of 2 wt% is sufficient to create an oleogel. The microscopy studies revealed the formation of crystalline particles which forms a continuous network that entraps the liquid oil into a gel-like phase.

(a) Photograph of oleogels prepared at varying concentrations of shellac. (a) From left to right: 1, 2, 4, 5 and 6 wt% shellac in rapeseed oil and (b) optical microscopy image of an oleogel with 5 wt% shellac (scale bar = 200 mm). Reproduced with permission from Patel et al., Shellac as a natural material to structure a liquid oil based thermo reversible soft matter system. RSC Adv., 2013, 3, 5324–5326. Published by The Royal Society of Chemistry

Phytosterol-Oryzanol Mixtures

Mixed component oleogels of phytosterols and oryzanol are one of the most studied structured oil systems. When mixed at certain proportions, they co-assemble to form nanoscale tubular structures, and depending on the concentration, these nanoscale tubules aggregate to form a 3-D network that can physically immobilize liquid oil through capillary forces to form a viscoelastic gel. The building blocks in these oleogels are self-assembled tubules of nanoscale dimensions (Bot et al., 2012). These tubules have a complex helical, ribbon-like structure which is mediated by the intermolecular hydrogen bonding between the hydroxyl group of phytosterol and carbonyl group of oryzanol. Beta-sitosterol and other related phytosterols such as dihydrocholesterol, cholesterol and stigmasterol can also produce gels with oryzanol. Structurally, the presence and position of hydroxyl was found to be critical for gel formation while the composition of alkyl group did not appear to have any major impact on the gelling properties of phytosterols (Bot & Agterof, 2006). Although the combination is able to form clear (or slightly hazy) oil gels, the effectiveness of structuring in the presence of water becomes less because of the formation of thicker sitosterol monohydrate fibres (microscale dimensions) (den Adel, Heussen, & Bot, 2010).

Fatty Acid-Fatty Alcohol Mixtures

Fatty acid and fatty alcohol systems (stearic acid/stearyl alcohol, in particular) were among the first mixed component oleogels studied for potential use in edible fields (Gandolfo, Bot, & Flöter, 2004). The synergistic effect in these systems was explained based on mixed crystal formation. It was hypothesized that the mixed crystals displayed finer crystal sizes as well as an altered crystal morphology (needle-like for combination versus platelet-like for mono components) (Schaink, van Malssen, Morgado-Alves, Kalnin, & van der Linden, 2007). However, it has recently been reported that the synergistic effect is rather linked to an increase in the crystalline mass as well as the spatial distribution of the crystalline mass (Blach et al., 2016).

Unlike phytosterol-oryzanol system, oleogels can be formed individually by both fatty acids and fatty alcohols (Schaink et al., 2007). However, the mixed oleogels display relatively higher firmness and also provides the possibility of tuning the rheological properties by altering the proportion of individual components.

Phytosterol-Monoglyceride Mixtures

Both phytosterols (PS) and saturated monoglycerides (MAGs) are able to gel liquid oil on their own. However, these mono-component oleogels suffer from certain stability issues on storage. For instance, crystals of PS tend to agglomerate and settle to the bottom resulting in a contraction of the crystalline phase (Vaikousi, Lazaridou, Biliaderis, & Zawistowski, 2007). Oleogels prepared with MAGs also suffer from storage stability issues owing to the slow polymorphic transition that leads to the formation of gritty β-crystals on aging (Da Pieve, Calligaris, Panozzo, Arrighetti, & Nicoli, 2011). In addition, mono component gels made using MAGs are sensitive to processing conditions especially shear (Da Pieve, Calligaris, Co, Nicoli, & Marangoni, 2010). Moreover, the high concentration of MAGs required for the formation of mono-component gels may also affect the sensorial quality of the oleogels due to the surface-active nature of MAGs. Surprisingly by combining MAGs with PS at certain proportions, a synergistic enhancement in the rheological properties of oleogels was observed due to the formation of finer crystalline particles with completely different morphology compared to MAG and PS crystals (Bin Sintang, Rimaux, Van de Walle, Dewettinck, & Patel, 2017a). In addition, based on a four-week storage study, it was confirmed that the contraction of crystalline phase and consequent phase separation were also prevented. This was a first such demonstration of identifying synergistic combination that can overcome drawbacks associated with individual structurants (Bin Sintang, Rimaux, et al., 2017a; Patel, 2015).

Mixed Systems Containing Lecithin as an Additive

The above mentioned example of mixed gel systems are all based on a combination of components that can individually form structured material phases or combine together to form such material in-situ in the solvent (Patel, 2017a). In addition to these two classes, oleogel systems can also be created by combining a structured material forming component with a non-crystallizing additive (that can impact either the self-assembling properties of gelator or promote an effective spatial distribution of building blocks formed by gelator or strengthen the network linkages among the formed building blocks) (Buerkle & Rowan, 2012; Patel, 2017a). Lecithin is the most common surfactant used in these type of oleogels. Lecithin on its own cannot gel oils unless a small amount of polar solvent (such as water or glycerol) is introduced into the mix. But due to its amphiphilic properties, it can be combined together with other components such as sorbitan tristearate, α-tocopherol and sucrose esters to form oleogel where lecithin can contribute as crystal modifier, network strengthener (formation of weak junctions between crystals) and stabilization of complex micellar structure (Bin Sintang et al., 2017b; Han et al., 2014; Nikiforidis & Scholten, 2014; Patel, 2017b; Pernetti, van Malssen, Kalnin, & Flöter, 2007).

Ethylcellulose Oleogels

Ethyl cellulose (EC) is a hydrophobic cellulose derivative synthesize chemically from cellulose through substitution of hydroxyl group on monomeric glucose units which forms the backbone of cellulose. Like other cellulose derivatives, the properties of EC is dependent on the degree of polymerization (DP) and degree of substitution (DS). DP gives a measure of the molecular weight of the polymer whereas DS provides information about the average number of hydroxyl groups substituted on the cellulose backbone. Since glucose monomers have 3-hydroxyl groups that can be substituted, the DS for cellulose derivatives vary between zero to three. A DS of approximately 2.4–2.5 (with approximately 47–48% ethoxy content) results in a hydrophobic polymer that is immiscible in water and miscible in various apolar solvents (Koch, 1937). Commercially, EC polymers are supplied in specific viscosity grades which can be correlated to their molecular weight (Davidovich-Pinhas, Barbut, & Marangoni, 2014).

EC-based oleogels are usually prepared by dispersing polymer powder in liquid oil at temperatures above the glass transition temperature of polymer (Tg ≈ 130 °C) followed by cooling to lower temperatures. At high temperatures, the polymer chains are unfolded and on subsequent cooling, the unfolded polymer chains form a backbone for cross-linked gel network. The gel is stabilized by hydrogen bonding among polymer chains along with some hydrophobic interactions between acyl chains of oil and the side chains of EC. The minimum gelling concentration (Cg) of EC required for gelation is strongly affected by the molecular weight of polymer and the type of oil used. For instance, the Cg of EC 45 cP is 4 and 6 wt% in soybean and canola oil respectively (Zetzl, Marangoni, & Barbut, 2012).

Colloidal Silicon Dioxide (CSD) Oleogels

The use of inorganic particles such as clay as structuring agents to from organogels is well-documented in the cosmetics field where bentonite clays have been extensively studied for their gelation functionalities. In foods domain, CSD has been studied for oil structuring as mono component gelator as well as in combination with fat crystals (Chauhan, Dullens, Velikov, & Aarts, 2017; Patel, Mankoc, Bin Sintang, Lesaffer, & Dewettinck, 2015b). Gelation mechanism in colloidal silicon dioxide oleogels involves a long-range organization of colloidal particles into mesoscopic agglomerated structures. When used together with fat, a composite network of fat crystals and aggregated silica particles is obtained. As recently demonstrated by Chauhan et al., this could be a useful strategy to create reduced solid fat alternatives with similar rheological behaviour and thermal properties as the full-fat systems (Chauhan et al., 2017).

3.2 Indirect Methods of Using Hydrophilic Polymers for Oil Structuring (Emulsion Templates)

Using polymers for oil structuring is a promising strategy because there are many polymers that are approved for use in foods and most of them have been well-characterized. However, as most of the food polymers are inherently hydrophilic in nature, they show limited dispersion in oil which makes them ineffective in structuring oils. In order to use hydrophilic polymers for oil structuring, it is important to first pre-hydrate them in aqueous phase and arrest these hydrated conformations in dehydrated form such that they can be used for physical entrapment of liquid oils. Food polymers such as proteins and modified polysaccharides are surface-active and a conformational framework of these components can be created from their aqueous dispersions by first inducing their adsorption at the oil-water interfaces followed by removal of water to obtain dried microstructures with entrapped/embedded oil phase. As demonstrated in various studies, using this technique a range of structured oil systems such as oil powders, gels and soft solids can be created from emulsion templates (Adelmann, Binks, & Mezzenga, 2012; Liu, Chen, Guo, Yin, & Yang, 2016; Mezzenga & Ulrich, 2010; Patel et al., 2015c; Romoscanu & Mezzenga, 2006; Tavernier, Patel, Van der Meeren, & Dewettinck, 2017). Success of this approach is dependent on the formation of a stable interfacial layer that is elastic enough to withstand the dehydration during drying. This has been achieved through three different ways: (a) by stabilizing interfaces using surface active protein and subsequently crosslinking it through thermal or chemical means, (b) using protein particles followed by complexation with lipid additive, and (c) using a combination of surface and non-surface active food polymers that can increase the viscoelasticity of the interface (Patel & Dewettinck, 2016).

3.3 Structuring Aided by Physical Sorption of Liquid Oil

In the last few years, there has been a rising interest in developing porous materials that can take up a large quantity of hydrophobic oil in the presence of water. Such porous structures with high oil absorption functionality can find important applications in the management of oil spill accidents. Related concept could also be used to create porous materials from food-grade components such as cellulose derivatives (hydroxyl propyl methyl cellulose and methylcellulose), these porous cryogel show exceptional oil sorption properties and could be used for creating structured oleogels containing as high as 98 wt% of liquid oil (Patel, Schatteman, Lesaffer, & Dewettinck, 2013b).

Other materials such as carrageenan aerogels, cellulose fibres and porous starch have also been explored for their oil-absorbing properties (Manzocco et al., 2017; Patel & Dewettinck, 2016).

3.4 Structured Biphasic Systems

The three different types of structured biphasic systems used in food structuring are depicted using simple schematics in Fig. 13.6. In the case of structured emulsions, the interfaces around the dispersed oil droplets are structured with the help of water-swollen, crystallized monoglyceride layers. In the oil bulking systems, the dispersed oil droplets are embedded in the matrix of water phase which is gelled using network of polymers, and the gelled emulsions are formed by tightly packed dispersed water droplets gelled using synergistic combination of hydrocolloids such as locust bean gum and carrageenan.

Schematic representation of three different types of structured biphasic systems: structured emulsions, oil bulking system and gelled emulsion with structured interface, bulk phase and continuous phase, respectively. Structured emulsion and oil bulking system have oil droplets dispersed in water continuous phase whereas the gelled emulsion is composed of tightly packed gelled water droplets dispersed in oil continuous phase. Reproduced with permission from Patel & Dewettinck, Edible oil structuring: an overview and recent updates. Food & Function, 2016, 7, 20–29. Published by The Royal Society of Chemistry

4 Functionality of Milk Fat and Possible Applications of Structured Oil in Dairy Fat and Related Products

Partial or complete replacement of milk fat has always been a focus for many food manufacturing industries dealing with dairy products. Traditionally, the main reason was to reduce the cost of products by replacing expensive milk fat (due to competitive market and changes in seasonal availability) with cheaper alternatives like tailor-made vegetable fat blends. In order to find a suitable replacement, a thorough consideration has to be given to functionalities which are specific to milk fat. These functionalities include:

Crystallization Behaviour

Milk fat is known to crystallise and be stable in the β´ polymorph. This gives milk fat some desirable characteristics such as relatively high crystallisation rate, smaller crystals and good foam stabilising properties. Hence, when partially replacing milk fat with β-tending vegetable fats, a due consideration needs to be given to their crystallization pattern.

Melting Properties

Milk fat displays good melting properties, being quite hard at lower temperatures and melting completely at body temperature. This melting behaviour is important for the mouthfeel and flavour release when eating the finished product. The melting profile further affects the consistency of milk fat, influencing, for example, the texture and eating properties of products such as butter and butter spreads and cheese. In addition, when air is incorporated into the products, such as whipped cream and ice-cream, the ratio between the solid fat and liquid oil (measured through solid fat content) becomes very important for the stability, texture and creaminess of the product.

Unique Taste

Due to its unique fatty acid composition (high amount of short-chain fatty acids), milk fat has a strong but desirable creamy/buttery flavour. The compounds responsible for this typical flavour are formed when the short-chain fatty acids undergo reactions such as lactonization and oxidation. In addition, butter also lacks a strong off-flavour which is generally associated with other animal fats.

Colloidal Instability

Partial coalescence is one of the colloidal instability displayed by milk fat when used in emulsified products such as whipped cream and ice-cream. Partially coalesced fat droplets form a three dimensional network which is responsible for stabilizing air bubbles and in turn providing the creamy texture of the final product. This property is dependent on both temperature (suggesting a reliance on the solid fat content) and the aeration conditions.

Based on the above mentioned functionalities, it is quite clear that a complete replacement of milk fat will result in a severe loss of product attributes. Hence, the best case scenario is to replace only a part of milk fat with non-dairy fat to obtain products with enhanced nutritional profile. However, these non-dairy fat-containing analogue end up having a relatively higher amount of saturated fats. Structured oil could thus be used in these products to lower the amount of solid fat while simultaneously improving the nutritional profile of the products. As this field is still in its infancy, the reported literature on applications of structured oil in dairy related products are rather scarce, few examples of such published results are discussed below.

Wax-Based Oleogels in Structuring of Reduced-Fat Ice-Cream

Wax-based oleogels were evaluated in ice-cream formulations in two separate studies done by the same group. The initial study compared the properties of ice-cream formulations prepared using rice bran wax (RBW) oleogel, liquid oil and butter as fat sources in presence of a commercial emulsifier which was a mixture of mono diglyceride and polysorbate 80 (Zulim Botega, Marangoni, Smith, & Goff, 2013a). Authors observed that 10 wt% RBW oleogel performed comparatively better than liquid oil in terms of overrun, fat globule and air bubble sizes. Further, the fat droplet aggregation at the air cell interface seen in oleogel sample in contrast to oil spreading seen with HOSO suggested that RBW oleogel behaved more as crystallized fat droplets than like liquid oil. However, the overrun of oleogel samples were comparatively lower than milk fat and the fat structure that was formed by the oleogel droplets was not sufficient to cause the expected delay in structural collapse (Zulim Botega et al., 2013a).

In the follow-up study, candelilla wax (CDW) and carnauba wax (CBW) were included in addition to RBW along with glycerol mono oleate as emulsifier and formulations were prepared using continuous and batch freezing (Zulim Botega, Marangoni, Smith, & Goff, 2013b). The authors found that the RBW performed better than CDW and CBW oleogels in terms of higher meltdown stabilization and fat aggregation. The inclusion of GMO as an emulsifier was found to have an influence on wax crystal morphology resulting in the formation of large protruding crystals that facilitated fat droplet agglomeration. In addition, they found that continuous freezing and using a relatively higher concentration of oleogel (15 wt%) showed a better shape retention (Zulim Botega et al., 2013b).

Results from these two studies strongly suggest that there is a potential for replacing milk fat with wax structured vegetable oils.

Oleogels in Cream Cheese Spreads

RBW and EC oleogels were used in the formulation of reduced fat cream cheese spreads with an aim of nutritional enhancement of the fatty acid profile (Bemer, Limbaugh, Cramer, Harper, & Maleky, 2016). Oleogels at 10 wt% gelator concentration using high oleic soybean oil and soybean oil as the solvents were simultaneously prepared during the cream cheese manufacturing process instead of preparing them beforehand. Results from microstructure analysis suggested a successful incorporation of oleogels in the formulation matrix resulting in a network structure and fat globule size which were similar to the control sample. Textural evaluation revealed that oleogel cream cheese samples (OCC) showed comparable hardness, spreadability, and stickiness with the full-fat cream cheese control. The samples were also subjected to sensorial evaluation to compare the organoleptic properties of OCC with that of full-fat control and the results suggested that the palatability of OCC could be improved to reduce its strong flavour and bitterness (Bemer et al., 2016).

Oleogels Based on Hydrophilic Cellulose Derivatives in Sandwich Cookie Creams

Tanti et al. recently evaluated the possibility of replacing icing shortening with structured oil (based on hydroxyl propyl methylcellulose and methylcellulose) in recipes of sandwich cookie creams (Tanti, Barbut, & Marangoni, 2016). Formulations were prepared by combining 40% fat (icing shortening or structured oil or in several combinations) with 60% icing sugar, the icing shortening was replaced at 50, 75 and 100% levels. A complete replacement of icing shortening resulted in a hard, unacceptable product but 50 and 75% replacement of icing shortening led to products which had comparable textural properties to commercial benchmark (Tanti et al., 2016).

Although the fat replaced in this study was non-dairy in nature, the strategy used in this study could benefit replacement of conventional icing shortening which is based on butter.

Oleogels as Spreadable Fat and Butter Alternatives

Yilmaz and Ogutcu carried out sensory and consumer tests to evaluate the possibility of using wax-based oleogel of hazelnut oil (aromatized with 0.5 wt% diacetyl as butter flavor) as butter alternative. Based on the Hedonic attributes (such as appearance, odor, flavour and spreadability) tested by the consumers, oleogel products showed potential as butter alternatives. When tested with consumers (among 120 consumers) for their buying decisions, around 43% and 57% indicated that they would definitely buy the product while 24–29% indicated that they would try once and then decide.options to be explored for future commercial applications in reduced fat products.

Anhydrous Milk Fat–Sunflower Oil Wax Blends

Hybrid systems which are structured oil systems that rely on combining fat hardstocks with oleogelators are considered as one of the options to be explored for future commercial applications in reduced-fat products (Patel, 2017c; Patel & Edible 2017).

Combining of one of the several oleogelators with anhydrous milk fat (AMF) could be useful in developing hybrid systems which could be used in the formulation of dairy fat products.

Kerr et al. studied the effect of sunflower oil wax on the crystallization behaviour and functional properties of anhydrous milk fat (Kerr, Tombokan, Ghosh, & Martini, 2011). The incorporation of wax resulted in a decrease in the induction times of nucleation and smaller crystal formation of AMF. The smaller size of crystal ensured a stronger network formation and an increase in the hardness. These results indicate that there is a potential to develop hybrid systems using AMF as the fat hardstock.

5 Conclusion

Although a lot of progress has been made in the recent few years, the field of oleogelation is still in its growing phase. Different structuring agents including lipidic materials (waxes, partial glycerides, fatty acids/alcohols etc.), polymers and inorganic particles have been extensively investigated for their role in oil structuring both for fundamental exploration and application-oriented work. They have also been studied in a range of food products mainly including chocolates, spreads & bakery products. As demonstrated in few reported studies, incorporation of structured oil systems could also be beneficial in the reformulation of a broad category of dairy fat and related products. Milk fat has many unique properties which makes it quite challenging to completely replace it with structured oil systems. However, the hybrid system created by combining milk fat and oleogelators could pave way for a new range of dairy products with healthier lipid profiles while still maintaining the characteristics of conventional products.

References

Adelmann, H., Binks, B. P., & Mezzenga, R. (2012). Oil powders and gels from particle-stabilized emulsions. Langmuir, 28, 1694–1697.

Batte, H. D., Wright, A. J., Rush, J. W., Idziak, S. H. J., & Marangoni, A. G. (2007a). Phase behavior, stability, and mesomorphism of monostearin–oil–water gels. Food Biophysics, 2, 29–37.

Batte, H. D., Wright, A. J., Rush, J. W., Idziak, S. H. J., & Marangoni, A. G. (2007b). Effect of processing conditions on the structure of monostearin–oil–water gels. Food Research International, 40, 982–988.

Bemer, H. L., Limbaugh, M., Cramer, E. D., Harper, W. J., & Maleky, F. (2016). Vegetable organogels incorporation in cream cheese products. Food Research International, 85, 67–75.

Bin Sintang, M. D., Rimaux, T., Van de Walle, D., Dewettinck, K., & Patel, A. R. (2017a). Oil structuring properties of monoglycerides and phytosterols mixtures. European Journal of Lipid Science and Technology, 119, 1500517.

Bin Sintang, M. D., et al. (2017b). Mixed surfactant systems of sucrose esters and lecithin as a synergistic approach for oil structuring. Journal of Colloid and Interface Science, 504, 387–396.

Blach, C., et al. (2016). Revisiting the crystallization behavior of stearyl alcohol: Stearic acid (SO: SA) mixtures in edible oil. RSC Advances, 6, 81151–81163.

Bot, A., & Agterof, W. G. M. (2006). Structuring of edible oils by mixtures of γ-oryzanol with β-sitosterol or related phytosterols. Journal of the American Oil Chemists’ Society, 83, 513–521.

Bot, A., et al. (2012). Elucidation of density profile of self-assembled sitosterol + oryzanol tubules with small-angle neutron scattering. Faraday Discussions, 158, 223–238.

Buerkle, L. E., & Rowan, S. J. (2012). Supramolecular gels formed from multi-component low molecular weight species. Chemical Society Reviews, 41, 6089–6102.

Chauhan, R. R., Dullens, R. P. A., Velikov, K. P., & Aarts, D. G. A. L. (2017). The effect of colloidal aggregates on fat crystal networks. Food & Function, 8, 352–359.

Chen, M., et al. (2016). Dairy fat and risk of cardiovascular disease in 3 cohorts of US adults. The American Journal of Clinical Nutrition, 104, 1209–1217.

Da Pieve, S., Calligaris, S., Co, E., Nicoli, M. C., & Marangoni, A. G. (2010). Shear nanostructuring of monoglyceride organogels. Food Biophysics, 5, 211–217.

Da Pieve, S., Calligaris, S., Panozzo, A., Arrighetti, G., & Nicoli, M. C. (2011). Effect of monoglyceride organogel structure on cod liver oil stability. Food Research International, 44, 2978–2983.

Davidovich-Pinhas, M., Barbut, S., & Marangoni, A. G. (2014). Physical structure and thermal behavior of ethylcellulose. Cellulose, 21, 3243–3255.

den Adel, R., Heussen, P. C., & Bot, A. (2010). Effect of water on self-assembled tubules in β-sitosterol + γ-oryzanol-based organogels. Journal of Physics: Conference Series, 247, 12025.

Doan, C. D., et al. (2017). Chemical profiling of the major components in natural waxes to elucidate their role in liquid oil structuring. Food Chemistry, 214, 717–725.

Gandolfo, F. G., Bot, A., & Flöter, E. (2004). Structuring of edible oils by long-chain FA, fatty alcohols, and their mixtures. Journal of the American Oil Chemists’ Society, 81, 1–6.

Han, L., et al. (2014). Structure and physical properties of organogels developed by sitosterol and lecithin with sunflower oil. Journal of the American Oil Chemists’ Society, 91, 1783–1792.

Huppertz, T., Kelly, A. L., & Fox, P. F. (2009). Dairy fats and related products (pp. 1–27). Chichester: Wiley-Blackwell. https://doi.org/10.1002/9781444316223.ch1

Kerr, R. M., Tombokan, X., Ghosh, S., & Martini, S. (2011). Crystallization behavior of anhydrous milk fat–sunflower oil wax blends. Journal of Agricultural and Food Chemistry, 59, 2689–2695.

Koch, W. (1937). Properties and uses of ethylcellulose. Industrial and Engineering Chemistry, 29, 687–690.

Liu, X., Chen, X.-W., Guo, J., Yin, S.-W., & Yang, X.-Q. (2016). Wheat gluten based percolating emulsion gels as simple strategy for structuring liquid oil. Food Hydrocolloids, 61, 747–755.

Manzocco, L., et al. (2017). Exploitation of κ-carrageenan aerogels as template for edible oleogel preparation. Food Hydrocolloids, 71, 68–75.

Mezzenga, R., & Ulrich, S. (2010). Spray-dried oil powder with ultrahigh oil content. Langmuir, 26, 16658–16661.

Nettleton, J. A., Brouwer, I. A., Geleijnse, J. M., & Hornstra, G. (2017). Saturated fat consumption and risk of coronary heart disease and ischemic stroke: A science update. Annals of Nutrition & Metabolism, 70, 26–33.

Nikiforidis, C. V., & Scholten, E. (2014). Self-assemblies of lecithin and [small alpha]-tocopherol as gelators of lipid material. RSC Adv, 4, 2466–2473.

Ojijo, N. K. O., Neeman, I., Eger, S., & Shimoni, E. (2004). Effects of monoglyceride content, cooling rate and shear on the rheological properties of olive oil/monoglyceride gel networks. Journal of the Science of Food and Agriculture, 84, 1585–1593.

Osaki, N., et al. (2005). Metabolities of dietary triacylglycerol and diacylglycerol during the digestion process in rats. Lipids, 40, 281.

Patel, A. R. (2015). In A. R. Patel (Ed.), Alternative routes to oil structuring (pp. 1–14). Cham: Springer. https://doi.org/10.1007/978-3-319-19138-6_1

Patel, A. R. (2017a). A colloidal gel perspective for understanding oleogelation. Current Opinion in Food Science, 15, 1. https://doi.org/10.1016/j.cofs.2017.02.013

Patel, A. R. (2017b). Stable ‘arrested’ non-aqueous edible foams based on food emulsifiers. Food & Function, 8, 2115. https://doi.org/10.1039/C7FO00187H

Patel, A. R. (2017c). Methylcellulose-coated microcapsules of Palm stearine as structuring templates for creating hybrid oleogels. Materials Chemistry and Physics, 195, 268–274.

Patel, A. R., & Dewettinck, K. (2015). Current update on the influence of minor lipid components, shear and presence of interfaces on fat crystallization. Current Opinion in Food Science, 3, 65–70.

Patel, A. R., & Dewettinck, K. (2016). Edible oil structuring: An overview and recent updates. Food & Function, 7, 20–29.

Patel, A., & Edible, R. (2017). ‘Oleocolloids’: The final frontier in food innovation? Journal of Agricultural and Food Chemistry, 65, 3432–3433.

Patel, A. R., Schatteman, D., De Vos, W. H., & Dewettinck, K. (2013a). Shellac as a natural material to structure a liquid oil-based thermo reversible soft matter system. RSC Advances, 3, 5324–5327.

Patel, A. R., Schatteman, D., Lesaffer, A., & Dewettinck, K. (2013b). A foam-templated approach for fabricating organogels using a water-soluble polymer. RSC Advances, 3, 22900–22903.

Patel, A. R., Babaahmadi, M., Lesaffer, A., & Dewettinck, K. (2015a). Rheological profiling of organogels prepared at critical gelling concentrations of natural waxes in a triacylglycerol solvent. Journal of Agricultural and Food Chemistry, 63, 4862–4869.

Patel, A. R., Mankoc, B., Bin Sintang, M. D., Lesaffer, A., & Dewettinck, K. (2015b). Fumed silica-based organogels and ‘aqueous-organic’ bigels. RSC Advances, 5, 9703–9708.

Patel, A. R., et al. (2015c). Biopolymer-based structuring of liquid oil into soft solids and oleogels using water-continuous emulsions as templates. Langmuir, 31, 2065–2073.

Pernetti, M., van Malssen, K., Kalnin, D., & Flöter, E. (2007). Structuring edible oil with lecithin and sorbitan tri-stearate. Food Hydrocolloids, 21, 855–861.

Romoscanu, A. I., & Mezzenga, R. (2006). Emulsion-templated fully reversible protein-in-oil gels. Langmuir, 22, 7812–7818.

Schaink, H. M., van Malssen, K. F., Morgado-Alves, S., Kalnin, D., & van der Linden, E. (2007). Crystal network for edible oil organogels: Possibilities and limitations of the fatty acid and fatty alcohol systems. Food Research International, 40, 1185–1193.

Tanti, R., Barbut, S., & Marangoni, A. G. (2016). Hydroxypropyl methylcellulose and methylcellulose structured oil as a replacement for shortening in sandwich cookie creams. Food Hydrocolloids, 61, 329–337.

Tavernier, I., Patel, A. R., Van der Meeren, P., & Dewettinck, K. (2017). Emulsion-templated liquid oil structuring with soy protein and soy protein: κ-carrageenan complexes. Food Hydrocolloids, 65, 107–120.

Vaikousi, H., Lazaridou, A., Biliaderis, C. G., & Zawistowski, J. (2007). Phase transitions, solubility, and crystallization kinetics of phytosterols and phytosterol–oil blends. Journal of Agricultural and Food Chemistry, 55, 1790–1798.

Wang, T.-M., & Rogers, M. A. (2015). Biomimicry – An approach to engineering oils into solid fats. Lipid Technology, 27, 175–178.

Wang, Y., et al. (2017). Saturated palmitic acid induces myocardial inflammatory injuries through direct binding to TLR4 accessory protein MD2. Nature Communications, 8, 13997.

Wright, A. J., & Marangoni, A. G. (2006). In P. F. Fox & P. L. H. McSweeney (Eds.), Advanced dairy chemistry volume 2 lipids (pp. 245–291). Boston: Springer. https://doi.org/10.1007/0-387-28813-9_7

Zetzl, A. K., Marangoni, A. G., & Barbut, S. (2012). Mechanical properties of ethylcellulose oleogels and their potential for saturated fat reduction in frankfurters. Food & Function, 3, 327–337.

Zulim Botega, D. C., Marangoni, A. G., Smith, A. K., & Goff, H. D. (2013a). The potential application of rice bran wax oleogel to replace solid fat and enhance unsaturated fat content in ice cream. Journal of Food Science, 78, C1334–C1339.

Zulim Botega, D. C., Marangoni, A. G., Smith, A. K., & Goff, H. D. (2013b). Development of formulations and processes to incorporate wax oleogels in ice cream. Journal of Food Science, 78, C1845–C1851.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Patel, A.R. (2020). Oil Structuring in Dairy Fat Products. In: Truong, T., Lopez, C., Bhandari, B., Prakash, S. (eds) Dairy Fat Products and Functionality. Springer, Cham. https://doi.org/10.1007/978-3-030-41661-4_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-41661-4_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-41660-7

Online ISBN: 978-3-030-41661-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)