Abstract

Potato tubers are living, respiring, biologically active organisms that require optimal storage conditions to maintain the quality entering the storage at harvest. Successful storage requires an understanding of the factors that affect tuber health and quality. Proper storage conditions depend on the crop’s growing and storing environment, time in storage, variety, use of the potatoes, and knowledge of key characteristics of the potatoes placed in storage.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Potato tubers are living, respiring, biologically active organisms that require optimal storage conditions to maintain the quality entering the storage at harvest. Successful storage requires an understanding of the factors that affect tuber health and quality. Proper storage conditions depend on the crop’s growing and storing environment, time in storage, variety, use of the potatoes, and knowledge of key characteristics of the potatoes placed in storage.

Storage Principles

The overall objective of storage is to help maintain quality and minimize further quality reductions. Storage basics for potatoes include: a dark facility; store only sound potatoes and at the proper maturity; maintain desired temperature and relative humidity (RH); and provide adequate, well-distributed ventilation. Potatoes are constantly respiring and, therefore, require oxygen. In turn, they produce carbon dioxide, water, and energy in the form of heat. Heat and carbon dioxide need to be exhausted from the storage. Many storage objectives revolve around the need to maintain quality, minimize loss, and address the nature of respiration.

Managers make many important decisions as the potatoes come into storage. Decisions should be made regarding storage volume needed; contract or end use(s); and facility disinfection, conditions, and management to maintain desired quality, method of sprout control, and length of storage before any potatoes are brought into the storage facility.

This chapter describes the basic principles associated with potato storage and provides information for application of these principles. Chap. 15 contains information about using sugar monitoring techniques in making harvest and storage decisions. The information in Chap. 15, in conjunction with this chapter, will provide the storage manager with an effective arsenal of storage management ideas and tools. If the intended crop is for organic certification, additional storage information can be found in Chap. 6.

Storage Structures

This chapter will not provide detailed information on building and equipping a potato storage. Several companies design and build modern potato storages, and any one of these businesses can provide the latest information on construction. These specifications will vary depending upon the environment and location of the storage facility. Outside temperature, humidity, and weather extremes will impact the design and function of the storage facility. Growers also may successfully use many types of storages, of different ages and designs, to maintain the intended quality (Figs. 17.1 and 17.2). General types of structures include partially underground, straight-walled, Quonset/curvette, and slant or inclined walls.

All facilities need a strong foundation, insulation, protection from the elements, climate controls, ventilation system, and temperature controls to provide a suitable environment for potatoes. Modern storage facilities integrate air and humidification systems that allow year-round storage with minimal loss

To provide optimum storage conditions for potatoes, certain essential design and equipment characteristics must be present. These include:

-

Sufficiently strong foundation and lateral wall support to hold the weight of the pile and roof support for weight of any snow load.

-

Adequate insulation and moisture barrier.

-

An air circulation system capable of providing a uniform supply of air to the entire storage.

-

A method for raising or lowering air temperature, or maintaining it within a desired range. This is accomplished by bringing in outside cooling air and/or use of refrigeration.

-

Equipment for supplying moisture (humidity) to the circulation air.

-

Adequate sensors and controllers to allow maintenance of optimal conditions.

-

Ability to easily clean and disinfect.

-

Convenient access and handling of the potatoes.

When building a storage, it is important to keep in mind that its capacity should match the volume of the projected crop, and the air and humidity equipment should be adequate for maximum capacity. The storage will be designed and built based upon the intended capacity of the storage. Storing more or less than the intended amount will alter the environmental conditions provided to the stored crop. The following formula can be used to determine the capacity of a storage facility:

Example:

General layout or design of a storage facility will differ depending upon need and location. A simplified description of a typical North American-style storage is as follows. Walls and ceilings are built with insulation (r-value) and strength appropriate for the region. Outside air is brought in when louvers or doors are opened to the outside. The incoming outside air is mixed with return air (if required; return air is recirculated), humidified via evaporative cooling pads or supplemental humidification systems, and fans force the air down a centralized plenum. In order to distribute air to the potatoes, the plenum supplies air to lateral ducts (Fig. 17.3.) This can be accomplished with aboveground lateral ducts on top of soil or concrete floors with built-in lateral ventilation ducts. Each of those ducts provide the desired amount of air to the bulk potatoes above the ducts (Fig. 17.4). The air is pushed through the bulk pile of potatoes (bottom to top), and the air is either recirculated, mixed with in-coming fresh air, or exhausted. The ventilation system is controlled to a desired temperature and humidity set point utilizing sophisticated electronic control panels that takes into account the outside air temperature and humidity, rate of airflow, and temperature and humidity near the potatoes.

Storage Cleaning and Maintenance

Cleaning of the storage facility is a good practice for all storages and is essential for seed producers. The first step is to clear all debris associated with the previous year’s operation. The second step is to clean facilities and equipment with a detergent and warm/hot water (Fig. 17.5). These procedures are particularly effective in eliminating bacterial problems that may have developed from a previous contamination. The third step is to rinse and apply a registered, labeled disinfectant. In most potato producing states, the Department of Agriculture maintains a current listing of available registered products that can be used for storage disinfection.

Off-season care of the potato storage facility is important to maintain its functionality and ensure long-term storage of high-quality potatoes. The period between storage crops is also a good opportunity for managers to repair equipment or add modifications that will improve efficiency and effectiveness of the storage. A short list of maintenance procedures is presented in the checklist at the end of this chapter.

Pre-harvest Decisions

Freshly harvested potatoes are extremely vulnerable to diseases (see Chap. 9) and physiological disorders (see Chap. 14), and evaluation must be made of best management practices for each incoming lot. Potatoes affected by temperature extremes, disease, nutrient excesses or deficiencies, water stress, physical damage, or other unfavorable growing conditions during the growing season may not respond to storage environments equally, and management can be altered to maintain quality as much as possible.

Harvest and handling operations also affect the storability of the crop (Fig. 17.6; Chap. 16). Potatoes that are bruised or damaged during any part of the harvesting, hauling, piling, or storing operations may require additional consideration for proper storage management (Fig. 17.7). Bruising creates entry points for diseases and increases tuber respiration and evaporation rates. Thus, specific storage conditions are needed to handle these situations. Be aware that tuber conditions vary with variety, growing location within or between fields, time of day harvested, and other factors that can add to the variability of the crop to be stored.

The first storage decision is whether to store potatoes from a particular field. Sampling potatoes from a field will provide the information needed to make an educated decision. Some tuber decay diseases, such as pink rot, late blight, soft rot, and bacterial ring rot, may be present in the crop before harvest. Most modern storages can provide conditions that will allow the presence of some decay at the beginning of storage. Unfortunately, some diseases, such as Fusarium dry rot and leak, will not commonly appear until after the potatoes are in storage. As little as 1–3% decay at harvest can make potatoes difficult to store. As a general rule, potatoes in a modern storage facility with up to 5% wet rot can be successfully stored if proper procedures are employed to minimize free and excess moisture and supply an aggressive ventilation program. The same is true for tubers damaged by frost. Other problems should be evaluated while potatoes are still in the field. This includes presence of potato virus Y, tobacco rattle virus, and potato mop-top virus that could cause tuber necrotic disorders, pink eye, and premature death. Symptoms associated with a virus or pink eye may or may not become more severe over time in storage, but if they cause any break in the skin they can become an entry point for other pathogens to enter (Fig. 17.8).

Potatoes with severe stress-related problems, such as sugar ends, jelly ends, or high overall sugar levels, should also be considered for immediate delivery. Potatoes with these problems can exhibit a rapid, unmanageable degradation of quality—especially processing quality—during the first few weeks of storage. Sugar monitoring can help with early detection of problems that may become serious later in the storage period. See Chap. 15, for details on sugar monitoring.

Once the decision is made to store potatoes, an understanding of the quality status of the crop will help with early management decisions. More information on this topic is available throughout this chapter and in Chap. 15.

Filling the Storage

Harvest potatoes with pulp temperatures between 45 and 65 °F. This range may change depending upon variety and harvest conditions. See Chap. 16. Attempt to minimize the amount of rocks, dirt, and debris entering the storage with the potatoes, while also minimizing bruise damage. This can be accomplished by the following practices:

-

Use well-maintained unloading, even-flow bins, and/or sorting equipment for delivery of potatoes from trucks to the storage.

-

Keep all drops to 6 in or less, and pad all sharp or hard surfaces on handling equipment.

-

Keep all equipment running smoothly and full to capacity with potatoes.

-

Use roll prevention belts on pilers and steep elevators.

-

Eliminate dirt, rock, debris, and rotten potatoes.

-

Pile the potatoes using a tier system. Start the piler low and to the front of the pile, then work up and back in a tiered fashion. Avoid rollback and bruising. Bulk pile no higher than the designed capacity of the building, typically 18–20 ft. (Fig. 17.9).

-

Use only well-trained personnel to operate piling equipment.

-

Ensure lateral ducts are properly aligned, connected, and sealed before piling potatoes over the ducts.

-

Keep records of incoming tuber pulp temperatures and conditions, along with location of the crop within the storage facility.

Early Storage Management and Wound Healing Period

Freshly harvested potatoes can exhibit potential problems that are not apparent in the field. The first few days of storage are the time to recognize and address these problems. The first issue is elimination of field heat. Potatoes harvested at pulp temperatures above 65 °F can be much more prone to disease development and quality problems than cooler potatoes, unless the warm potatoes can be cooled immediately. The heat given off due to rapid respiration in freshly dug tubers can increase temperatures further. Every effort should be made to rapidly cool freshly harvested potatoes to 55–60 °F as soon as possible (within 2 or 3 days of harvest). This is accomplished by moving a maximum amount of cooling air through the pile. Use refrigeration or evaporative cooling to extend cooling time in these situations.

Unless there is a significant amount of wet rot present in the potato pile, high humidity (>95%) should be maintained during the early part of storage. If diseased or wet potatoes are present coming out of the field or a post-harvest problem with decay occurs (e.g., leak), it may be appropriate to dry the tubers during this early storage management period to prevent rapid development of disease problems. This is accomplished by moving a high volume of air through the pile with reduced humidity. Reducing humidity can have consequences of increased weight loss (and pressure bruise), and this risk needs to be weighed when deciding on reducing humidification.

Potatoes coming from the field into storage usually go through a period of wound healing (curing period) before storage holding temperatures are attained. This is to promote healing of bruises, cuts, scrapes, and skinning damage. This wound-healing period may take from 2 to 3 weeks at 50–55 °F depending on the variety, disease presence, sugar content, and available cooling air. Wound healing occurs at a faster rate at warmer temperatures. Temperatures below 50 °F may reduce the rate of wound healing, thereby extending the length of storage periods required to provide adequate protection to the tubers. Temperatures above 60 °F may increase disease development before the wound healing process can be completed.

Wound healing is an extremely important component in reducing disease development and minimizing weight loss during storage (Fig. 17.10). However, it is also important to avoid keeping the tubers too warm for an extended period of time, because most disease organisms can multiply faster at warm temperatures. The storage manager must balance wound healing with slowing disease development and weight loss. Warmer temperatures promote greater evaporation and respirational losses. There are varietal differences in wound healing ability; therefore, wound healing temperature and duration may need to be modified during this early storage period. Usually, the best practice is to provide wound-healing conditions for an appropriate period of time, then reduce the temperature (ramp) to the desired holding temperature (0.1–0.5 °F/day). See the section on Storage Temperature for guidelines on ramping down the temperature.

The early storage and wound healing period is also an important time to assess and solve preexisting conditions that may lead to poor processing quality due to high sugar content. See Chap. 15. Sugar levels can be reduced by adjusting the temperature or length of the early storage period (preconditioning).

Holding Period and Removal from Storage

The holding period comprises the majority of the storage duration where potatoes are held at the desired temperature and humidity by modifying ventilation rates and air supply. Holding temperatures will vary with variety and desired end use. The holding period can last a few weeks to several months depending upon the time to market. Potatoes should be at least 45 °F prior to removal from storage to minimize the potential for damage when unloading, handling, and transporting. Below are additional specifics to the three basics of storage requirements: ventilation, temperature, and RH used during early storage and holding period management.

Ventilation

Storage managers are usually only able to control the supply air temperature, RH, and ventilation rate. However, by using these control features properly, adjustments can be made to the environmental conditions to provide optimum storage conditions. The ventilation system controls the temperature and distributes the humidity in the storage building and is a critical functioning system for maintaining quality in storage.

Proper storage management requires some specific knowledge of potato physiology and storage facility operation. Ventilation will provide conditions for the desired temperatures to the bulk pile, supply humidity to the potatoes, provide oxygen to the potatoes, and exhaust heat and carbon dioxide. Ventilation also provides conditions to dry out wet or decayed potatoes and a means for applying sprout control products. Some storages, particularly those holding process potatoes, are often ventilated to maintain carbon dioxide levels below the range of 1500–5000 ppm due to the potential for reducing sugar accumulation and/or changes in taste. Potatoes stored under refrigeration need periodic purging of carbon dioxide by bringing in outside air.

A consistent rate of forced-air supply is critical for maintaining tuber quality in potato storages. Most modern North American style storage air systems have been designed to supply 10–25 cubic ft. per minute (cfm) per ton of stored potatoes. In general, a storage design of 20+ cfm/ton air supply is required for handling potatoes that have been stressed or harvested in wet conditions. The ability of the storage facility to dry out “wet spots” or to remove free moisture is critical for preventing disease development in harvested potatoes. It is also important to have a sufficient air supply to remove water from decaying tubers. After the field heat and wound healing periods, ventilation rates are typically reduced.

Storage managers typically use variable speed fans, or control the number of operating fans, to alter ventilation rates to fine tune temperature differences between the top and bottom of the pile (Fig. 17.11). This differential, called delta-T or ∆T, should be maintained between 0.5 and 2 °F. Minimizing air flow when the ∆T is within the desired range is a good management tool for maintaining tuber quality, lowering risk for pressure bruise development, and reducing energy costs.

Basic principles of managing ventilation systems in a potato storage include the following: Ventilation fans should be operated to cool the pile, maintain the ∆T in the desired range, or provide fresh air. Use ventilation air at least 1–2 degrees cooler than the tubers at the bottom of the pile to avoid condensation within the pile. Operate humidifiers whenever bringing in outside air unless there is a need to remove excess moisture from the pile. Keep circulation air at or near 95 to 98 % RH.

Storage Temperatures

Optimal holding temperatures for potatoes in storage depend on the potato variety and its intended end use. Processing potatoes are generally stored between 45 and 50 °F to limit the concentration of reducing sugars in the tuber tissue. See Chap. 15, for more information. By comparison, potatoes intended for the fresh market are typically stored between 40 and 45 °F, while those intended for seed are usually stored at 38–40 °F. It is best to store potatoes at the lowest temperature specific to the variety, use, and desired quality. Storage temperatures are maintained with the use of outside cooling air mixed with recirculated air or refrigeration, if available or necessary.

Storage temperatures are also used to minimize weight losses caused by respiration and evaporation. Respiratory losses are often minimal near 45 °F (Fig. 17.12). Typical total weight loss over an 8–10-month storage season is 5–8%. Of that total, theoretically weight loss due to respiration alone can be 1.5%. The remaining loss is due to evaporation and decay. High rates of respiration can also reduce the amount of carbohydrates in tubers, with a potential change in product texture and quality. Consequently, it is important for managers to consider minimum respiration rates for the variety when maintaining long-term storage.

Rate of respiration of potatoes at various storage temperatures. (Source: Burton 1978)

An increase or decrease in storage temperatures can be used to minimize disease development. By reducing holding temperature, disease development and spread can be retarded, especially due to secondary infection from soft rot. However, managing storage temperature to control or prevent the spread of a disease may affect the tuber quality needed for processing or fresh market uses.

Sugar content is also an important consideration for potatoes stored for processing. Sugar monitoring can help establish appropriate early-storage conditions. See Chap. 15, for a discussion of this topic. Pre- and reconditioning refer to the use of elevated pile temperatures to help lower reducing sugar level in tubers. Higher temperatures increase the tuber respiration rate and allow for carbohydrate conversions, thereby decreasing reducing sugar concentrations so that the processed potatoes meet industry requirements. Preconditioning refers to using elevated storage temperatures at the beginning of the storage season compared to reconditioning, which is used before removal of the potatoes. Reconditioning, or increasing the temperature of potatoes in storage, is also used to stimulate sprouting of seed potatoes. Some varieties stored for seed at the normal temperatures of 38–40 °F may be very slow to sprout. Increasing the temperature of the seed potatoes in storage can help promote more consistent sprout development before planting, although there is the risk of too much sprout development, which alters the desired physiological age of the seed.

Standard guidelines for potato storage temperatures include many of the above-mentioned considerations. Temperatures outside of the optimal ranges may result in physical damage to stored potatoes. For example, potato tissue may freeze at temperatures below 30 °F. Also, a non-pathological breakdown of the tissue (chilling injury) may occur as the potato tissue approaches the freezing point. Most of the physical damage to potatoes at high temperatures is a result of increased disease activity. Blackheart, a physiological condition as a result of oxygen deprivation, may also increase as pulp temperatures rise above normal handling temperatures. See Chap. 14, for additional information.

Temperature changes in storage should be gradual and not exceed recommendations for various product uses. The rate of downward ramping of storage temperature for potatoes intended for processing should follow guidelines established by the processing industry. The typical rate of ramping is 0.1–0.5 °F per day to specified holding temperatures and will depend upon available outside cooling air. This gradual temperature reduction helps eliminate changes in the sugar content of tubers that can affect processed product quality. Guidelines for proper holding temperatures in storage may vary with the variety. However, storage managers should try to maintain a minimum temperature differential of less than 2 °F between the bottom and top of the pile.

For processing potatoes, it is critical that minimal sugar accumulation occurs. Cold sweetening is not the only concern with respect to sugar accumulation. Because potato tubers are alive, they age with time; a process that can be accelerated due to storage conditions. Higher temperatures result in more rapid aging.

One of the symptoms of aging is an uncontrollable increase in tuber sugar content. This is known as senescent sweetening. Once senescent sweetening begins to occur, the potatoes can no longer be warmed (reconditioned) to reduce sugar levels. See Chap. 15, for more discussion about senescent sweetening. Determination of optimum holding temperature consists of finding a balance between the temperatures at which cold sweetening becomes an issue and minimizing aging.

Relative Humidity (RH)

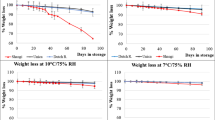

The impact of RH on storage weight losses can be substantial. Most of the tuber weight loss that occurs during the first month of storage results from water lost and tuber respiration. This early weight loss has the greatest impact on the overall total weight loss for the storage season. Maintaining high RH in storage lowers the vapor pressure deficit between the tuber and the surrounding air and helps control the total water loss during the storage season (Fig. 17.13).

Percent weight loss (shrinkage) of potatoes stored at various supply air humidity levels. (Source: Waelti 1989)

Weight loss in storage is directly proportional to the length of the storage season and increases with time in storage. The rate of weight loss is inversely proportional to the RH conditions maintained within that storage, with lower RH promoting greater weight loss. The current recommendation is to maintain 95% RH or above (typical range is 90–98% RH). Equipment to maintain high RH is a standard part of the infrastructure of modern potato storages and can be constructed to maintain nearly any range of RH (Fig. 17.14). The necessary level to humidify the air will be dependent upon the humidity of the outside air. Arid conditions in the Pacific Northwest (PNW) mean that there are fewer grains of moisture in the air compared to the more humid conditions of the Canadian Maritimes; therefore, storage facilities in the PNW require greater water input via humidification to reach 95% RH.

Another aspect of managing RH is to prevent condensation and free moisture on the potatoes. Free moisture on the surface of the potatoes can significantly contribute to disease breakdown in storage. Condensation can become a problem when it occurs directly on the tubers or on any inside surface of the storage. Condensation occurs when temperature differentials occur in the air circulating within the storage facility. If any of the air drops below the dew point, condensation will be the inevitable result. The “dew point “is defined as the temperature at which water vapor condenses at the same rate that it evaporates, which is just a more complicated way of saying the air is saturated with moisture or is at 100% RH. This means that the air simply cannot hold any more water vapor, and any further cooling of the air means that condensation will be the result. Localized areas within a storage facility where some of the air becomes cooled below the dew point can occur. Condensation on the tubers can also result when supplying moist circulation air that is warmer than the tubers at the bottom of the pile. As this air comes into contact with the tubers, the air rapidly cools, the RH reaches 100%, and moisture condenses on the tubers. Condensation on building surfaces usually results from inadequate insulation. If building surfaces are cooler than the air inside the storage, moisture condenses on the surface then drips onto the potatoes. This can be especially damaging if the moisture is on the ceiling of the storage and, therefore, becomes free moisture on the potatoes (Fig. 17.15).

Maintaining circulation air slightly cooler than the bottom of the pile will help prevent condensation directly onto the tubers. Likewise, condensation on building surfaces can be minimized by providing adequate insulation and making sure there is enough air movement to keep surfaces warm and to evaporate the moisture that collects before it drips onto the potatoes. By placing extra fans on top of the potato pile in strategic locations, condensation problems can be minimized in storages with historical problems or during extremely cold weather.

In any situation where there is a significant difference in potato or surface temperature (i.e., wall, ceiling, structural element, etc.) and air temperature within a humid storage, there is the potential for condensation to occur. This potential makes it very important to monitor and integrate the temperature of the crop into your ventilation system operation and storage management plans. Condensation that occurs on the interior of the storage, especially ceilings, beams, or walls, can drip free water onto the stored potatoes below. Warmer air holds more water vapor than cooler air, so if the warm air around the surface is quickly cooled, water may condense out if the temperature of the surface is below the dew point of the surrounding air.

Sprout Inhibition

Modern North American style potato storages are designed to store from 50,000 to more than 500,000 hundredweight (cwt) of potatoes in bulk piles. Successful long-term storage of fresh and process potatoes requires using a sprout inhibitor in combination with proper storage management to ensure control of sprouting. Cooler storage temperatures will slow down sprout development. Utilize temperature along with a sprout control program to successfully suppress sprout development and store potatoes to the preferred length of time. Decisions on what product to use will depend upon variety, the market use of the potatoes, if seed will also be stored in the same facility, and desired outcome. Each variety may react differently to sprout inhibitors. Knowledge of varietal differences in dormancy length is important for successful long-term storage (Table 17.1). This information will allow the appropriate timing of a sprout inhibitor.

Chlorpropham, or CIPC, is the most effective and commonly used post-harvest sprout inhibitor registered for use in potato storages in the U.S. This product has been used successfully as a sprout inhibitor for more than 60 years. CIPC inhibits sprout development by interfering with cell division. Cell division is not only important for sprout growth, but it is necessary to form the wound periderm during wound healing. Consequently, CIPC must be applied after the wound-healing period is over, but before dormancy break or initiation of sprout growth. Commercial applicators apply the CIPC aerosol formulation to bulk potatoes in storage. Other sprout inhibitor products are available in the U.S. and include maleic hydrazide, essential oils, naphthalenes, 3-decen-2-one, 1-Octanol. Others are currently under development.

Maleic hydrazide is applied as a foliar spray treatment during the growing season. Timing of application is important since the product alters cell division and can impact tuber development. Potatoes treated with maleic hydrazide have an approximate 30-day delay in dormancy break depending upon variety as well as rate and timing of application. Maleic hydrazide applications can be used alone for short-term sprout control or in combination with other sprout control products.

Several essential oils extracted from plant materials are effective potato sprout suppressants. They suppress sprouting by physically damaging the developing sprouts or buds before they can elongate. Repeated or continuous application of many of these essential oil-based sprout suppressants are necessary to achieve the desired sprout control. Carvone, the oil from caraway seed, is marketed in several countries as a potato sprout inhibitor. It is efficacious and can be applied to potato storages using both cold aerosol application and conventional thermal aerosol fogging. Clove, spearmint, and peppermint oils have been used successfully to suppress sprouting in potatoes for extended storage periods. These oils, which are derived and extracted from plants, are effective in suppressing sprouting in stored potatoes as long as the material is present in sufficient quantities in the head space of the potato storage. Essential oils can be applied in several ways. Conventional thermal fogging may not be quite as effective as a cold aerosol application or forced evaporation for spearmint and peppermint oils, but is the most effective way to apply clove oil (Fig. 17.16). A disadvantage to using essential oils is their high volatility. Normal air circulation can vent the material from the storage, and repeated or continuous applications are necessary to achieve the desired result. See Chap. 6, for additional information on the use of essential oils in organic potato production.

Substituted naphthalenes have been successfully used to suppress sprout development. Two products have been registered for application to potatoes; 1,4-dimethyl naphthalene and diisopropylnaphthalene. The naphthalenes probably assist in sprout suppression by hormonal action and act quite differently from the cell division inhibitor, CIPC. 1,4-dimethyl naphthalene is also registered and labeled for use on seed potatoes as a mild sprout suppressant. An unsaturated ketone, 3-decen-2-one, can be applied to potatoes in storage as a thermal aerosol. The product physically damages the emerging sprout, and repeated applications are necessary depending upon variety, storage temperature, and storage duration.

Occasionally, inadequate sprout inhibition occurs after treatment, and several factors may have caused the sprouting problems in storage: (1) Improperly designed air systems can cause the potato pile to have a temperature differential from top to bottom, with the top being 3 or more degrees warmer. This temperature differential causes increased respiration of the tubers, which may induce earlier sprouting; (2) Improper sizing, spacing, or placement of air ducts may result in non-uniform pile temperatures and uneven air circulation, which can produce poor sprout inhibitor distribution within the storage; (3) Hot spots in the pile caused by disease, excess dirt restricting air flow, and/or plugged air vents can cause elevated pile temperatures that may result in premature sprouting (Fig. 17.17). This sprouting may occur in a small spot or, if undetected, may spread to larger areas of the pile; (4) Field-stressed potatoes may respond differently to sprout inhibitor application in storage than potatoes grown under non-stressed conditions. Field stress conditions (e.g., disease, water balance, nutrition, temperature) may also reduce sprout inhibitor effectiveness; (5) Potatoes stored under fluctuating temperatures and humidity may physiologically age faster than those stored under more uniform conditions; (6) Late-season application (usually after dormancy break) of CIPC produces mixed results, ranging from adequate sprout inhibition to complete failure. In comparison, some sprout control products are effective at damaging an emerging sprout and can be used at this later date.

Internal sprouting is a disorder in which a lateral sprout grows inward into the tuber or outward into an adjacent tuber. This tuber defect occurs mainly in long-term storage, and then only occasionally. The causes of this disorder are not well understood, but appear to be related to a lack of sprout inhibitor on or around tightly packed tubers. See Chap. 14. Environmental factors, such as storage temperature and pile pressure on tubers, can have significant effects on internal sprouting. Insufficient sprout inhibitor concentrations caused by pile settling or excess soil and debris in the pile, or late application, can accentuate the problem.

Disease Management

One of the most challenging storage management problems is controlling tuber diseases (Fig. 17.18). Some post-harvest disease decay problems are associated with field locations where disease pressure was high or soil saturation occurs. These areas need to be identified before harvest so that the resulting tubers are stored only if the facility is capable of handling problem lots, and is in a location where they can be easily removed from storage. Initially it is very important to properly identify the disease causing issues in storage to direct management to that specific disease. See Chap. 9, for information on properly identifying the casual disease.

Storage diseases that cause a wet decay are difficult to control unless the storage facility is equipped to supply high volumes of air. Most storage diseases that cause tuber decay or rot will release large volumes of moisture that must be removed before it contributes to the spread of soft rot. Generally, a 1% tuber loss in a 100,000 cwt storage will release 10,000 gallons of water over a rather short period of time. Engineers must design modern storages that can deal with this level of decay by providing high ventilation rates, along with proper temperature and humidity control. Soft rot, leak, pink rot, late blight, and dry rot, and are the most common and problematic diseases in storages. Additional diseases, such as silver scurf, can impact quality of the crop, but will not cause loss due to decay. See Chap. 9, for additional information on causal organisms and management recommendations. In general, disease management in storage utilizes temperature, ventilation, humidity, and, if appropriate, post-harvest product application. Post-harvest products include spray applications going into storage, such as phosphite-based products or disinfectants, or applied via the humidification system or thermally as some disinfectants are currently. Regardless, ensure the product you are using targets the disease of concern. Not all products are effective against all storage diseases.

Potato soft rot, caused by several species of both Pectobacteria and Dickeya, is a serious storage disease due to the opportunistic nature of these bacterial pathogens. This disease will spread rapidly from tuber to tuber if the conditions are appropriate. These bacteria are present in tuber lenticels and can also infect the tuber skin at harvest when bruises, scrapes, and cracks occur. However, the most common way for infection to occur is where fungal diseases, such as dry rot, pink rot, leak, or late blight, are already present. Soft rot enters as the secondary invader after the initial infection and is often associated with “hot spots” or “sink holes” in the pile due to the rapid breakdown of the tubers. Storage management includes use of cooler temperatures and high airflow to those infected areas to prevent spread. For more information, see Chap. 9.

Wet spots that appear in the pile at the beginning of storage season are often associated with leak (caused by Pythium ultimum), pink rot (caused by Phytophthora erythroseptica), and late blight (caused by Phytophthora infestans). The initial diseases may result in greater breakdown, depending upon the level of the disease and if secondary soft rot infection occurs. Late blight-infected tubers will decay slower in storage compared to leak and pink rot, but can become infected with soft rot that will accentuate tuber decay and allow the soft rot to spread rapidly in storage. Control measures include constant fan operation to dry out the infected tubers before they can become a problem and the use of cooler storage temperatures to keep the tubers in marketable condition.

Dry rot, caused by Fusarium sambucinum, can be a serious storage disease of potatoes, especially when susceptible varieties are grown, excessive bruising and wounding occurs at harvest, and if they are stored under sub-optimal storage conditions for wound healing. Fusarium sambucinum need an entry point to infect, such as a wound, which occurs mainly during harvest or handling. Disease progression is relatively slow and may not be evident for several months into storage. Some varieties, such as Clearwater Russet and Umatilla Russet, may be especially susceptible to dry-rot infection. Having knowledge of varietal susceptibility can help identify management conditions to minimize wounding at harvest and provide proper wound healing conditions specific to the variety.

Silver scurf, caused by the fungus Helminthosporium solani, is a disease that causes silvery blotches on the surface of the tuber. Although this disease is mainly considered a cosmetic problem with fresh market potatoes, it can cause problems during processing because of the thicker, corky periderm that results from the surface infection sites. This disease can also spread in storage if conditions are right for spore germination. Research has shown reduced infection from Helminthosporium solani when storage humidity was lowered to below 85% RH. Lowering humidity is not generally a recommended practice for managing silver scurf in storage. Crop shrinkage will be greater at lower RH conditions. Making these decisions requires knowledge of the intended market, the history and severity of potential problems, and the economic balance between determining factors.

Checklist for Storage Management

1–3 Months Before Harvest

-

Repair all insulation materials to minimize the potential for condensation.

-

Clean plenum and duct ports thoroughly.

-

Replace worn humidity equipment and high-pressure nozzles.

-

Check for corrosion on all surfaces that may limit the life of the storage facility.

-

Service the air system and check all fans for proper balance. Check the air-delivery system by adjusting all ports or ducts for optimum, consistent air flow.

-

Repair or replace worn components on air louvers, both fresh air and exhaust.

-

Calibrate all computerized sensors that are used for control functions.

-

Service the RH supply cell decks. Check for mineral deposits and eliminate clogged flow paths.

1 Week Before Storage

-

Inspect the crop and look for preexisting conditions that may impact storability. Know the quality of incoming potatoes and the potential problems that might arise in storage. If potatoes are destined for processing, consider sampling fields and determining sugar levels as an indicator for physiological maturity.

-

Condition the storage by operating the air circulation, humidity, and temperature equipment before delivery begins.

-

If needed, wet the soil floor surfaces of the storage to help minimize dehydration of the tubers at the bottom of the pile.

At Potato Delivery

-

Harvesting and handling operations should deliver the least amount of bruise and wounds as possible.

-

Check and record pulp temperatures of potatoes going into storage. A minimum temperature of 45 °F to a maximum of 65 °F should be maintained. When possible, suspend harvest operations until pulp temperatures are within this temperature range.

-

Limit potato pile height to 18–20 ft., or to the specifications of the storage design, to minimize pressure bruise (remember that pressure bruise can be variety dependent) and deliver the proper volume of air per cwt.

-

Tape all duct seams to improve system performance. Open seams will reduce air delivery consistency.

-

Operate fan and humidity systems as soon as the first few ducts are covered. Early fan operation helps to remove field heat and standardize pulp temperature differences that are inherent between fields, truckloads, and time of day.

-

Remove clods, loose dirt, and debris from the incoming loads. This is critical to achieve optimum air circulation performance from the mechanical system.

-

Fill each storage structure with potatoes destined for similar end uses. Close storages as soon as filled to achieve rapid temperature equilibration of the pile.

During the First 2 Months

-

Immediately remove field heat and stabilize potatoes to 55 °F as soon as possible.

-

Maintain pulp temperatures between 50 and 55 °F for 2–3 weeks for proper wound healing. Relative humidity of 95% is recommended for the wound-healing period and for continued storage.

-

Reduce pile temperatures slowly (also known as ramping) approximately 2–3 degrees per week, to a general recommended holding temperature of 38–40 °F for seed, 40–45 °F for fresh pack, and 45–50 °F for processing (all variety dependent).

-

If appropriate, sample and test for sugars and adjust conditions to minimize future problems.

-

Shorter dormancy varieties may require a sprout inhibitor application.

-

Observe pile for any hot spots, odors, or areas of wetness that may indicate breakdown due to disease.

During the Holding Stage

-

Continue to monitor the storage daily for operational continuity and any problem that might occur.

-

Ventilation should be set to maintain pile temperature variation of 0.5 to 2 °F from bottom to top. Continuous fan operation at reduced airflow or speed is capable of maintaining the desired temperature control of the pile.

-

When appropriate, use sugar monitoring for early detection of deterioration in processing quality.

-

Watch for condensation on walls and ceilings dripping onto potatoes. Increase air circulation in these areas, if necessary.

-

Note any odors, sunken areas, or hot spots that may indicate breakdown due to disease.

-

Make a timely decision on the length of storage period. If necessary, have a certified applicator make applications of sprout inhibitor. The type of inhibitor or time of application may change with different varieties, storage temperatures, and expected length of time in sprout control.

Before and During Removal

-

In a situation where potatoes are destined for processing and sugar levels are too high, recondition the pile by raising the temperature to 55–60 °F for 3–4 weeks. During the reconditioning period, test samples to confirm an improvement in color and ensure that senescent sweetening is not contributing to the sugar problems. Sprouting and disease development are more likely to occur at these warmer temperatures; therefore, ensure adequate sprout inhibition and watch for any breakdown. Only sound potatoes can withstand reconditioning.

-

Maintain storage air supply during unloading to minimize quality losses. Remember that good storage management during the unloading operation includes adjustment of duct airflow to maintain consistent supply to all areas of the remaining pile.

-

Make sure pulp temperatures are at least 45 °F before handling to minimize damage.

-

Operate the storage under optimum conditions until the last potatoes are removed.

References

Burton WG (1978) The physics and physiology of storage. In: Harris P (ed) The potato crop—the scientific basis for improvement. Chapman and Hall, London

Waelti H (1989) Potato storage and ventilation in the Pacific northwest. In: Potato storage technology and practice. American Society of Agricultural Engineers, St. Joseph, pp 1–89

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Olsen, N., Kleinkopf, G. (2020). Storage Management. In: Stark, J., Thornton, M., Nolte, P. (eds) Potato Production Systems. Springer, Cham. https://doi.org/10.1007/978-3-030-39157-7_17

Download citation

DOI: https://doi.org/10.1007/978-3-030-39157-7_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39156-0

Online ISBN: 978-3-030-39157-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)