Abstract

Potato yield and quality are sensitive to both excess and deficit soil water. This sensitivity, coupled with a relatively shallow root zone and medium- to coarse -textured soils common in many production areas, makes economically efficient irrigated potato production challenging. Potato is grown under all types of irrigation systems worldwide, but irrigation systems capable of light, frequent, uniform water application are best. Optimum potato irrigation management requires a working knowledge of soil water relations and irrigation system characteristics. This chapter introduces both in the context of potato production in arid areas of the Pacific Northwest U.S. General guidelines and irrigation management aids are presented along with examples for implementing quantitative irrigation management of potato in an arid environment.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Potato yield and quality are sensitive to both excess and deficit soil water. This sensitivity, coupled with a relatively shallow root zone and medium- to coarse -textured soils common in many production areas, makes economically efficient irrigated potato production challenging. Potato is grown under all types of irrigation systems worldwide, but irrigation systems capable of light, frequent, uniform water application are best. Optimum potato irrigation management requires a working knowledge of soil water relations and irrigation system characteristics. This chapter introduces both in the context of potato production in arid areas of the Pacific Northwest U.S. General guidelines and irrigation management aids are presented along with examples for implementing quantitative irrigation management of potato in an arid environment.

The Benefits of Using Irrigation in Potato Cropping Systems

Irrigation is required for profitable commercial potato production in many areas worldwide. To maximize production efficiency, soil moisture must be effectively maintained within rather narrow limits throughout the growing season. Potato is one of the most sensitive crops to both excess and deficit soil water due to its relatively shallow root system and because it is often grown on soils with low to medium water-holding capacity. These conditions necessitate that reliable irrigation systems capable of light, frequent, uniform water applications be used to optimally control soil water availability throughout the growing season. These conditions also dictate that an effective potato irrigation management program include: (1) regular monitoring of soil water content, (2) quantitative irrigation scheduling according to crop water use and soil water-holding capacity, and (3) a water supply and irrigation system capable of providing frequent, uniform water application.

The sensitivity of potato yield to irrigation management is depicted in Fig. 13.1. The results were obtained from a 1995 research study of water management practices on 45 commercial potato fields in Idaho (Stark 1996). Potato yield is reduced by both over- and under-irrigation. A mere 10% deviation from optimum water application for the growing season may begin to decrease yield. This marked response to water management is attributable to the sensitivity of potato plants to moderate water deficits and excess soil water, coupled with a very small margin for error in irrigation scheduling resulting from limited soil moisture storage in the root zone. This is due, in part, to a relatively shallow root zone. Yield reductions due to over-irrigation can be attributed to poor soil aeration, increased disease problems, and leaching of nitrogen from the shallow crop root zone. Quantitative irrigation management can increase marketable yield while reducing production costs by conserving water, energy, and nitrogen fertilizer as well as reducing potential groundwater contamination. Quantitative irrigation management, therefore, is a prerequisite for maximizing production efficiency from irrigated potato production.

Potato Growth and Soil Water Availability

Potato root system development is relatively shallow, 18–24 in, with the majority of roots in the upper 12 in soil profile. The shallow rooting depth is largely attributable to the inability of the relatively weak root system to penetrate tillage pans or other restrictive layers. Soil compaction by field vehicle traffic can greatly restrict potato root penetration. High soil moisture content at the time of tillage operations typically increases the degree of compaction resulting from field traffic. Potato rooting depth can also be restricted by weakly cemented calcium carbonate layers in the top 2 ft of soil in arid regions, which restrict potato root penetration, but not necessarily water movement. Field determination of actual potato plant rooting depth is of primary importance in developing an effective irrigation management program.

The first physiological response of potato to water deficits is closure of the leaf stomata; the small pores in the leaf that control gas exchange between internal leaf cells and the environment. Evaporation of water from the leaves cools the plant canopy temperature below air temperature under well-watered conditions. The stomata in the leaf close under plant water deficits as a defense against further water loss. One of the first physical indications of water stress is an increase in canopy temperature because of reduced evaporative cooling of the leaves.

While stomatal closure reduces water loss through the leaves, it also reduces carbon dioxide diffusion into the leaf. This slows photosynthesis, reducing the production of photosynthetic products (starch and sugars) by the plant and their translocation from the leaves to the tubers. Potato yield and quality depend upon maximizing the steady accumulation of photosynthetic products in the tubers. When production of these products exceeds that needed for respiration and continued plant growth, they are stored in the tubers.

Another physiological response affected by plant water deficits is the expansion of leaves, stems, and tubers. Water deficits reduce plant growth by reducing the internal water pressure in plant cells (turgor pressure), which is necessary for expansion. Reduced vine and leaf growth limits total photosynthetic capacity, while reduced root development limits the plant’s ability to take up water and nutrients. Water deficits also disrupt normal tuber growth patterns by reducing or temporarily stopping tuber expansion. Tuber growth resumes following relief of plant water deficits, but the disruption of the normal tuber expansion rate may result in tuber malformations such as pointed ends, dumbbells, bottlenecks, and knobs. Widely fluctuating soil moisture levels create the greatest opportunity for developing these tuber defects. Growth cracks are also associated with wide fluctuations in soil water availability and corresponding changes in tuber turgidity and volume of internal tissues.

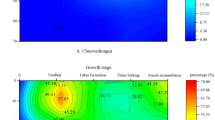

Potato is particularly sensitive to water stress during tuber initiation and early tuber development. Water deficits at this time can substantially reduce U.S. No. 1 yields by increasing the proportion of rough, misshapen tubers. Early-season water stress can also reduce specific gravity and increase the incidence of translucent end.

Water stress during tuber bulking usually affects total tuber yield more than quality. A large photosynthetic-active leaf surface area is necessary to maintain high tuber bulking rates for extended periods. Sustaining a large photosynthetic active leaf surface area over a full growing season requires continued development of new leaves to replace older, less efficient ones. Water stress hastens leaf senescence and interrupts new leaf formation, resulting in an unrecoverable loss of tuber bulking.

Potato yield and quality are susceptible to excess soil moisture as well. Excess soil moisture from frequent or intensive irrigation or rainfall during any growth stage leaches nitrate nitrogen below the plant root zone, potentially resulting in nitrogen-deficient plants, reduced fertilizer use efficiency, and an increased hazard to groundwater. Saturation of the soil profile for more than 8–12 h can cause root damage due to a lack of oxygen required for normal respiration. Excess moisture at planting promotes seed piece decay and delayed emergence due to decreased soil temperature. Potatoes that are over-irrigated during vegetative growth and tuber initiation have a greater potential for developing brown center and hollow heart and are generally more susceptible to early die problems. Excess soil moisture can also lead to tuber quality and storage problems.

Irrigation Management

Irrigated potato production occurs over a wide range of conditions. Arid regions may have sustained hot, dry periods where irrigation provides more than 90% of the water needed for crop production. Humid regions may have short dry periods where irrigation is needed to sustain optimal soil water levels for maximum yield and quality and provides less than 10% of the water needed for crop production. Regardless of the climatic circumstances, the purpose of irrigation management is to maximize potato yield and quality by maintaining soil water content within specified limits throughout the growing season through timely, controlled water application.

Soil Water-Holding Capacity

Soil serves as the reservoir for plant nutrient and water needs. Soil has a finite capacity to hold water against gravity, which is called the water-holding capacity. A graphical representation of how water is held in soil is shown in Fig. 13.2. A given volume of soil consists of solids composed of minerals and organic matter, as well as pores, which are occupied by air and water. When soil pores are filled with water, the soil is said to be saturated (Fig. 13.2a). Under conditions of free drainage, the force of gravity will drain water from the largest pores. This free-draining water is called gravitational water , which is only available to plants during the time it is percolating through the root zone. After 12–48 hours, drainage will decrease to a negligible rate. The water content, at this point, is commonly called field capacity or upper-drained limit (Fig. 13.2b).

Water is held in the soil as a film around soil particles by molecular attraction and by water surface tension forces producing what is commonly called capillary action . Hence, water held in soil pores is called capillary water (Fig. 13.2c), which is available for plant use. As plants remove water from the soil, it is extracted from progressively smaller pores until the remaining water exists as a thin film around soil particles held tightly by molecular attraction. The molecular attraction is strong and a large amount of energy is required to remove the remaining water from the soil, so much so that plants cannot obtain water and, consequently, wilt and die. Soil water content at this point is called the permanent wilting point and is graphically illustrated in Fig. 13.2d. The volume of water held in the soil between field capacity and the permanent wilting point is called available water. Available water can also be expressed as inches of water per inch or ft. of soil depth. It is then referred to as the water-holding capacity of the soil.

Each soil has a unique relationship between soil water content and soil water energy potential called the soil water release curve . This relationship, which is highly dependent on soil texture, is shown graphically in Fig. 13.3 for four soil textures. The rather flat curve of a typical loamy sand soil indicates a narrow range in moisture content between field capacity and the permanent wilting point, indicating low water-holding capacity. In contrast, the sloping curve of the silt loam soil has a much wider range in soil moisture content between the permanent wilting point and field capacity, indicating greater water-holding capacity.

Soil moisture content is often expressed as a percentage on either a weight (gravimetric) or volumetric basis. Care must be taken to make sure which moisture content basis is being employed or measured. Conversion between the two requires knowledge of the soil’s bulk density, since volumetric water content = gravimetric water content x bulk density (dry mass per unit volume). For example, if the gravimetric soil moisture of a silt loam soil with a bulk density of 1.37 g/cm3 is 23.4%, soil moisture content on a volumetric basis is then 32.1% (23.4 × 1.37 = 32.1). Soil moisture content measured on a volumetric basis is preferred for irrigation management computations because bulk density of the soil is not required. Soil moisture contents used in this publication are expressed on a volumetric basis. General soil moisture contents at critical points along with water-holding capacity for agricultural soils are given in Table 13.1. Inspection of available water listed in Table 13.1 reveals that soils having a significant portion of silt have the greatest water-holding capacity, offering the greatest flexibility in potato irrigation management.

Optimum Soil Moisture

Many field research studies have focused on determining optimum soil moisture for irrigated potato production. Most studies on the water stress-sensitive Russet Burbank variety indicate that available soil water (ASW) in the root zone (0–18 in) should be maintained above 65% to avoid yield and quality losses. In general, however, the average ASW of the root zone should be maintained between 70 and 85% during the active growth period for optimum results. In practice, ASW in the root zone will fluctuate above and below this range for short periods of time immediately before and after irrigation. This is particularly true with set-move sprinkler systems and furrow irrigation systems. Solid-set sprinkler, drip, center-pivot, and linear-move sprinkler systems allow for light, frequent irrigations and can be managed to minimize soil moisture fluctuations.

The optimal range for soil moisture at planting is about 70–80% ASW. This moisture level will provide ideal conditions for planting and early sprout development. Excessively wet soil conditions may slow soil warming and delay sprout development and emergence. Cool, wet soil conditions can increase seedpiece decay and physiological aging of seed, resulting in higher stem and tuber numbers. Excessively dry soils should be irrigated prior to planting to avoid potential seedpiece decay problems that sometime result from irrigating between planting and emergence.

During the latter part of the growing season plants begin to senesce, and crop water use rates markedly decrease. Consequently, care should be taken to adjust irrigation amounts to avoid developing excessively wet soil conditions. High soil moisture during this period can produce enlarged lenticels that provide openings for soft rot bacteria to enter the tubers. Pink rot and Pythium leak infections are also increased by excessive late-season soil moisture.

Available soil water should be allowed to decrease to about 60–65% at vine kill to provide optimal conditions for promoting tuber skin set and development of skin texture in russet potato varieties. Drier soil conditions at vine kill increase the chances of developing stem-end discoloration.

Pre-harvest irrigation should be timed to optimize soil conditions and tuber hydration levels at harvest. Tubers that have matured under relatively dry soil conditions (less than 60% ASW) will likely be dehydrated, which will increase their susceptibility to blackspot bruise. Under these conditions, fields should receive irrigation at least 1 week prior to harvest to completely rehydrate tubers. If ASW has been kept above 60% during tuber maturation, fields can be irrigated 2–3 days prior to harvest. Care should also be taken to avoid getting fields too wet at harvest because of increased potential for shatter bruise and increased soil separation and storage rot problems .

Evapotranspiration (ET)

Evapotranspiration represents the sum of water used by plants for transpiration and water loss due to evaporation from the soil surface. Evapotranspiration varies according to meteorological conditions, surface soil wetness, the stage of growth, and amount of crop cover. The meteorological parameters which affect ET are solar radiation, relative humidity, ambient air temperature, and wind speed. Since these can vary considerably from day to day, so will ET. Furthermore, seasonal ET will vary from year to year in response to yearly meteorological trends.

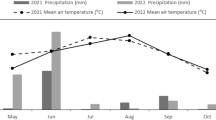

Daily potato ET throughout the 2015 growing season at three locations in the U.S. Pacific Northwest are shown in Fig. 13.4. Evapotranspiration is low at crop emergence and increases rapidly with crop development and increasing solar radiation and temperature into the summer months. Evapotranspiration decreases gradually as the crop begins to senesce until vine kill. Differences in the start, peak, and end of daily ET values, shown in Fig. 13.4, for the three locations are due to differences in planting and harvest dates and seasonal meteorological conditions. The dependence of ET on meteorological conditions is evident by the variation in daily ET throughout the growing season. Seasonal ET for the three locations over a 15-year period is also shown in Fig. 13.4. Seasonal ET is substantially lower at Klamath Falls, OR, compared to the other two locations. Seasonal ET at Aberdeen, ID, and Burbank, WA, are similar with Burbank, WA, being greater 6 of the 15 years. The magnitude of seasonal and daily variations in ET shown in Fig. 13.4 demonstrates that an irrigation scheduling method that accounts for these variations is necessary to maximize crop production. Published daily ET values, as shown in Fig. 13.4, provide a basis upon which to develop an irrigation management program. In-field soil moisture measurement is also required to account for site-specific differences in ET resulting from differences in the type of irrigation system used; soil water-holding capacity; topography; and local meteorological conditions, such as wind and precipitation .

Irrigation Method

Potato can be grown under many types of irrigation systems; however, some are better suited than others for consistently obtaining high-quality tubers. The water sensitive nature of potato, combined with its shallow root zone, favors irrigation systems that are capable of light, frequent, and uniform water applications. Using these criteria as a basis for ranking the suitability of common irrigation methods, the order of preference from highest to lowest would be: drip, solid-set portable sprinkler, linear-move, center-pivot, side-roll sprinkler, hand-move sprinkler, and furrow. In practice, economics are often the overriding factor in irrigation system selection along with compatibility with soil type, crop rotation, and cultural practices. Buried permanent drip is expensive, incompatible with traditional deep tillage and heavy field traffic associated with traditional potato harvest, and is not suitable for maintaining high moisture levels in the upper level of coarse-textured soils. However, in response to decreasing irrigation water supply in many areas, this technology is being revisited. Advances in GPS location and equipment guidance technology now allow deep tillage and harvest without danger of drip tape damage. With proper tape installation and management, permanent drip tape can have a design life of at least 15 years, which makes its yearly cost more competitive with other irrigation systems. Optimum tape depth depends on soil texture and crops to be grown in the rotation. For example, Neibling and Brooks (1995) evaluated yield and quality of Russet Burbank under solid set and 4 depths of drip tape placement (3, 8, 12, and 16 in) on a sandy loam soil and found that maximum yield and quality occurred with 3-in depth, followed by 12-, 8-, and 16-in depths. Tape was installed above and below seed piece location and in-line vertically with it in each hill. Yield response was due, in part, to the location and shape of wetting zones as shown in Fig. 13.5. Yield and quality were highest for the 3-in placement due to more water in the active root zone. Yield and quality were lower for 12- and 16-in depths, because most of the water was applied below the active root zone due to limited capillarity water movement in the soil. Low yield and quality at the 8-in depth was due to excessive water near the seed piece and limited root development. In a more extensive study in India, Patel and Rajput (2007) studied tape depths of 0, 5, 10, 15, and 20 cm (0, 2, 4, 6, and 8 in) also in a sandy loam soil. Optimum yield was obtained at the 4-in depth in 2 of the 3 years studied and at the 6-in depth in the third year.

Alternative drip tape placement (Shock et al. 2005) evaluated multiple potato row/tape configurations on a single 72-in bed. Treatments were two rows 36-in apart with tapes directly above each, two rows 36-in apart with a drip tape offset about 7 in to the inside of each potato row, and four rows 16-in apart with one drip tape centered between each pair of rows with plants staggered in each of the paired rows. Soil texture was silt loam, and the variety was Umatilla Russet. Plant population levels were low (18,150 plants/acre) or high (24,200 plants/acre). Total yield, marketable yield, and yield of U.S. #1 was variable, with treatment in 2003 and 2004. In general, the higher plant population with four staggered rows per bed had the highest water use efficiency and the most desirable tuber size.

Temporary surface drip irrigation systems using thin-wall drip tape , flexible lay flat hose for main lines, and a portable water filtration system and pump are used on small fields. The drip tape is used a single year then recycled, with the remaining system components relocated to another site for subsequent seasons. Solid-set portable sprinkler systems are also expensive. Center-pivots are highly susceptible to excessive runoff under the outer towers unless conservation tillage practices are utilized. Side-roll and hand-move sprinklers are prone to wind skips under the windy conditions common to many arid regions. Furrow irrigation is susceptible to poor water application uniformity and excessive deep percolation and leaching. Sprinkler is the most common method of potato irrigation the U.S. Pacific Northwest, with center-pivot, side-roll, solid-set, and hand-move sprinkler being widely utilized.

Irrigation Scheduling

Effective irrigation scheduling requires regular quantitative monitoring of soil moisture and knowledge of soil water-holding capacity, crop water use, and crop rooting depth. Excess irrigation usually results from applying too much water at a given irrigation rather than from irrigating too frequently. This is particularly true for side-roll and hand-move sprinkler systems , where soil water-holding capacity and crop rooting depth are overestimated, resulting in set times that are too long and furrow irrigation in which irrigation depth is difficult to control. These assumptions lead to plant water stress when soil moisture falls below desired limits 2–3 days before irrigation and subsequent irrigation applications exceed soil water storage capacity. This characteristic problem can generally be attributed to inadequately designed systems, irrigation system equipment limitations, or improper irrigation management.

Quantitative irrigation scheduling involves maintaining a daily soil water balance that accurately accounts for water input from irrigation and rainfall and water depletion due to crop water use and leaching. Where soil salinity is not of concern, the goal is to minimize leaching during the growing season to conserve soil nutrients for maximum nutrient use efficiency by limiting irrigation depth to the amount of soil water storage available (soil water depletion). Leaching is commonly assumed to be zero when computing the soil water balance but can be substantial if the irrigation has poor application uniformity or rainfall occurs immediately following irrigation. Local daily ET estimates are assumed to represent daily soil water depletion by the crop but can differ from actual crop water use due to field-specific climatic differences from the weather station conditions used to estimate ET. Although calculation of water application based on nozzle size, spacing, and pressure usually provides a good estimate of water applied, application may be reduced by excessively hot, windy days or system maintenance issues. This technique, combined with quantitative measurements of soil moisture to adjust the computed soil water balance to actual field conditions, provides a method for determining the timing of irrigations. Computing a daily soil water balance implicitly determines the desired irrigation application depth as well. Seasonal water application is obtained by summing irrigation depths over the growing season.

Computational Steps in Quantitative Irrigation Scheduling

-

Estimate field capacity and permanent wilting point based on predominate soil texture in the field using Table 13.1 as a guide.

-

Estimate current crop rooting depth based on site conditions and stage of growth. Rooting depth is often assumed to increase linearly between emergence and full crop height or row closure. The maximum effective rooting depth of potato will be in the range of 18–24 in for soils without a restrictive layer. The effective rooting depth prior to crop emergence can be assumed to be 8 in for practical purposes. As an example, if the stage of growth is 50% of maximum height or row closure and the maximum effective rooting depth is assumed to be 18 in, the effective rooting depth a can be estimated as 8 in plus 50/100 × (18–8) in = 8 + 5 in or 13 in.

-

Maintain a daily soil moisture balance based on estimated values of daily ET starting at crop emergence. An initial soil moisture storage value must be assumed to start the soil water balance based on previous end-of-year irrigation history and winter precipitation or obtained by measuring soil moisture at emergence. A numerical example of quantitative irrigation scheduling is shown in Table 13.2 for two 10-day periods; one at crop emergence and one after 100% effective cover. The assumptions and calculations used to obtain the values in Table 13.2 are:

-

Loamy sand soil with 1.8 in per ft water-holding capacity (WHC)

-

Terminal rooting depth of 20 in 40 days after emergence

-

Rooting depth = 8 (in) + (20–8) (in) ∗ X/40 up to 40 days after emergence where X represents the day of concern in the range of 0 to 40. Rooting depth = 20 in more than 40 days after emergence.

-

Initial available water at 0–12 in is 70% and 12–24 in is 100%

-

Total available water (TAW) = WHC (in/ft) ∗ Root depth (in)/12

-

Initial beginning available water (in) = TAW ∗ 70%/100

-

Ending available water (in) = Beginning available (in) + Irrigation + Precipitation – ET

-

Beginning available water (in):

-

Prior to reaching final rooting depth = Previous day ending available water (in) + [Previous day TAW – Current day TAW] ∗ Initial ASW (%)/100

-

After reaching final rooting depth = Previous day ending available water (in).

-

-

-

For furrow or irrigation systems with set-move sprinklers, irrigate when ASW decreases to 65–70% by applying the amount required to increase the soil moisture content to field capacity (soil water deficit). For irrigation systems designed for light, frequent irrigations, irrigate when soil water deficit is greater than the nominal application depth while maintaining ASW in the desired range.

-

Periodically monitor soil moisture or soil water potential and adjust the daily soil moisture balance, if necessary, to match actual field conditions .

Web-Based Quantitative Irrigation Scheduling

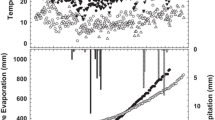

A web-based method of irrigation scheduling that uses the water-balance approach, discussed above, with user-defined crop and soil conditions and daily data from a user-selected AgriMet weather station, was developed by Dr. Troy Peters at Washington State University (http://weather.wsu.edu/is/). Short videos that lead the user through the account and field setup processes can be found at: http://www.uidaho.edu/extension/drought/. It delivers information to any web-connected device (smartphone, tablet, laptop, etc.) in a convenient, easy-to-understand format. It has been evaluated for multiple crops, including potatoes in WA and ID. Multiple output screens are available. Two of the most useful are shown in Fig. 13.6 for a potato field at the University of Idaho Research and Extension Center .

(left) WSU Irrigation scheduler mobile output showing estimated soil water in the root zone (blue line), irrigation, and rainfall. Yellow line represents field capacity; red is MAD = 0.35. To minimize crop stress, estimated soil water should be maintained between the yellow and blue lines. (right) Estimated deep percolation. Large increases in early August due to large rainfall events

Field Soil Water Measurement

Several methods are available to quantitatively measure soil moisture, only some are suitable for potato because of the critical threshold levels of available moisture and the limited root zone depth. Many of the methods are labor intensive and require training, experience, and expensive equipment. This requirement has led to the development of crop consulting firms specializing in irrigation management, which often provide crop nutrient and pest management services as well. A detailed discussion of soil moisture measurement methods is provided in the publication “Soil Water Monitoring and Measurement,” PNW 475, University of Idaho, College of Agriculture.

Tensiometers , which measure soil water potential and soil water content indirectly, have been used to successfully monitor soil water in potato fields. Good contact between the soil and tensiometer tip is essential for proper operation. Tensiometers are often installed in the potato hill at two depths, such as 8 and 16 in below soil level. Typically, the upper tensiometer is used to track ASW within the bulk of the root zone, while the lower is used to determine whether soil water at the bottom of the root zone is increasing or decreasing over time.

The neutron probe is likely the most precise and reliable tool for soil water measurement, since it determines volumetric soil water content directly. However, licensing, training, and associated operational costs limit its use to consulting firms and large farms.

Time domain reflectometery (TDR) offers many features that make it well suited to soil water measurement in potato. However, initial equipment costs can be quite high. Other traditional instruments, such as resistance blocks, are also available and can be effectively used for water management.

Recently, many new devices have become commercially available for monitoring soil water content. Typically, they consist of two components, soil water sensors and a data logger that may also contain a cell phone or other data transmitter. Most sensors are designed to measure the bulk electrical properties of the soil; such as capacitance or dielectric constant. These bulk electrical properties are highly dependent upon soil water content. Thus, with calibration, devices designed to measure bulk electrical properties provide an effective means of determining soil water content. Soil salinity and bulk density can affect response of these devices, leading to erroneous or erratic soil water content readings. In general, any of the devices can become an effective tool for irrigation management. However, it takes experimentation and field experience to develop confidence in using a given device.

Many of the new soil water monitoring systems relate to delivery of soil water content data to a website that can be accessed from any web-connected device, and most have smartphone apps. Some data logger/cell transmitters are designed to use several different soil water sensors. These units allow convenient, remote access to soil water data and can be a very effective water management tool. Field installation does require some time but is still reasonable for most producers. In general, several systems will perform adequately if properly installed in appropriate soils. Other important considerations for equipment selection include the type of data desired, equipment cost and longevity, yearly cost of cell phone or other data transmission plan, and ease of use.

Benefits of these systems include nearly real-time information collected at intervals ranging from 30 min on some equipment, to user-selected intervals on others. Easy access to trends in water content with time, provides additional insight into soil water dynamics, and with experience, can be used to forecast potential water deficits at some soil depths unless the irrigation operation is modified. An example of one output is shown in Fig. 13.7 for the same field at the UI Kimberly Research and Extension Center used in Fig. 13.6. In this figure, sensors are installed at four different depths, with a shallow one for early season, then the top three for remaining season scheduling, and the deepest sensor for detection of over-irrigation. In this case, the field was well-irrigated until the first of August, with 8- and 12-in sensors indicating water content in the appropriate range rising after irrigation to about field capacity and dropping to about 65% available soil moisture before irrigation .

Data logger output accessed from website. Irrigation (blue lines) applied by 10-h solid set. Watermark readings in kPa (or centibars). Threshold for irrigation is 65 kPa for this silt loam soil. Note minimal fluctuation in 18- and 24-in sensors until large August rains, showing deep percolation at that time. Note lack of soil water response on days indicated by purple. These days were hot with strong winds

Soil Water-Holding Capacities for Irrigation Scheduling

For quantitative irrigation scheduling a soil water release curve is needed to relate soil water potential to volumetric soil moisture. The generalized soil water release curves shown in Figs. 13.8, 13.9, 13.10, and 13.11 can be used to relate soil water potential, volumetric soil moisture, ASW, and water depletion. These curves represent the primary soil-water relationships upon which an effective irrigation management program is developed. They allow the use of soil moisture or water potential measurements to calculate the net irrigation application amount needed to fill the soil water reservoir to field capacity. For example, if tensiometers show an average soil water potential of –40 kPa (centibars) in a sandy loam soil (Fig. 13.8), then available soil moisture is 62% and it’s time to irrigate with a net application of 0.36 in/ft of crop root zone depth. Soil water monitoring alone can be used for irrigation scheduling if performed on a real-time basis and used to directly control an irrigation system capable of immediate response. In practice though, most field scale irrigation systems are not capable of immediate response. Thus, a soil-water balance is computed daily using estimated daily ET and forecasted daily ET to anticipate when the next irrigation should occur and the amount of water to apply. This computed soil-water balance is reconciled to actual field conditions through use of the soil water release curve, quantitative soil moisture measurements, and visual observations of the crop.

The ranges of soil water potential and volumetric soil water content corresponding to 65% available soil moisture for different soils is shown in Table 13.3. These values are obtained from the generalized soil water release curves shown in Figs. 13.8, 13.9, 13.10, and 13.11. These values are not absolute, but serve as a general guide for effective irrigation management.

Irrigation System Operational Parameters for Irrigation Scheduling

The primary irrigation system information needed for irrigation scheduling is net irrigation application amount, or rate of water application. For center-pivot and linear-move irrigation systems , the net application amount is dependent upon system capacity, wet run time between irrigations, and system application efficiency. For side-roll, hand-move, and solid-set sprinkler systems, the net application rate depends upon operating pressure, nozzle size, sprinkler spacing, and system application efficiency. System application efficiency is a measure of how much of the water exiting the irrigation system is stored in the crop root zone. As with all irrigation systems, some water is lost due to wind drift and evaporation under sprinkler irrigation and to deep percolation resulting from non-uniform water application. While wind drift and evaporation reduce the amount of water reaching the root zone, they also reduce the amount of water that would have been removed from the root zone in their absence. Thus, they do not represent a total loss, just less efficient irrigation. Typical irrigation system application efficiencies for Idaho are given in Table 13.4.

Irrigation efficiency values need to be applied with caution when used for irrigation scheduling purposes. This is because they result in a self-fulfilling outcome; a low efficiency used in irrigation scheduling calculations results in low irrigation efficiency in the field from applying excess water. The best approach is to initially use an efficiency value at the upper range of those shown in Table 13.4 or higher. As the season progresses, if soil water monitoring consistently shows less water in the soil than predicted by the soil-water balance, the assumed irrigation efficiency value can be revised downward. This further highlights the necessity of routine, consistent soil water monitoring for irrigation management.

The first step in calculating net irrigation application (desired irrigation amount) is to determine gross water application. Gross water application depth per rotation for center-pivot irrigation systems as a function of system capacity and rotation time can be obtained from the relationships presented in Fig. 13.12. System capacity in gpm/acre needed to use the curves in Fig. 13.12 can be obtained from the sprinkler application package specifications or approximated by dividing total system flow rate by the acreage irrigated. Net application depth for an 80% application efficiency can be obtained directly from right-side axis of Fig. 13.12. Net application depth for any application efficiency can be calculated as:

Example:

Gross water application rate for set-move and solid-set sprinkler systems as a function of sprinkler flow rate and spacing can be obtained from the relationships presented in Fig. 13.13. Sprinkler flow rate can be estimated from Fig. 13.14 for brass straight-bore nozzles as a function of nozzle size and pressure. Net application rate for 70% application efficiency can be obtained directly from right-side axis of Fig. 13.13. Net application rate for any application efficiency can be calculated as:

Example:

Irrigation System Management

Center-Pivot Management

Center-pivot systems are sometimes designed with insufficient capacity to meet peak period daily water use. Instead, water banking is used to supply a small fraction of daily ET over the duration of the peak period. This allows for reduced system capacity that translates to reduced pump size, lower electrical demand charges, and reduced water application rates. Water banking is allowed because center-pivot systems are capable of providing light, frequent irrigations. Water banking applies to linear-move systems as well, but to a reduced extent by accounting for dry run time during repositioning. Water banking can potentially be applied to any irrigation system capable of light, frequent irrigations, such as drip and solid-set sprinkler. The degree to which water banking can be utilized is directly proportional to soil water-holding capacity and crop rooting depth. Potato grown on coarse-textured soils having water-holding capacities less than 1 in per ft. do not allow for water banking and must have a net system capacity equal to peak daily ET. For example, if peak ET is 0.34 in/day, then the net system capacity must be 6.4 gpm/acre [0.34 in/day × 18.86 (gpm/acre)/(in/day)] or a gross system capacity of 7.5 gpm/acre [6.4 (gpm/acre)/(85/100)] if application efficiency is 85%.

Center-pivot systems that utilize water banking must be managed to ensure that the soil-water reservoir is full at the beginning of the peak water use period. This requires planning and field soil moisture monitoring to the full depth of the crop root zone. Failure to do so will likely result in crop water stress near the end of the peak use period, the extent of which depends on soil and climatic conditions. The timing of the peak use period varies season to season, as does the duration of peak water use. Figure 13.15 depicts available soil moisture throughout the irrigation season for the condition where a center-pivot system is managed such that soil water is replenished to field capacity (100% ASW) early in the season (Fig. 13.15a) compared to one where soil water is replenished to only 90% ASW, either intentionally or inadvertently (Fig. 13.15b). Under both scenarios, the characteristic gradual drawdown of ASW occurs during the peak use period. However, in the second case, minimum ASW values fall below recommended limits, resulting in periodic plant water stress. When this occurs, there is no corrective course of action, as system capacity is fixed. The ultimate tuber yield and quality depends upon the season’s climatic conditions, as they determine daily ET.

The natural tendency is to speed up a center-pivot system when crop water stress develops. Increasing the speed of a center-pivot produces lighter applications and more frequent wetting of the soil and plant canopy, increasing the total amount of water lost to evaporation, and thereby decreasing the amount of water stored in the soil. Thus, system speed should remain the same or be reduced when crop water stress appears to effectively increase irrigation efficiency and stores a larger percentage of applied water in the crop root zone. However, if runoff occurs when the speed is reduced, it is better to run the pivot at the higher speed to reduce application depth.

Seemingly minor changes in application efficiency can result in a significant difference in center-pivot system performance. A 3–8% difference in application efficiency will occur between nighttime and daytime irrigation, resulting in differences in soil water storage. As a result, center-pivot speed should be adjusted such that rotation time is not a multiple of 24 h. Otherwise, areas of the field consistently watered during the daytime will have 3–8% less water stored in the soil for crop use. This small difference accumulated over time can result in water stressed areas within the field.

Conservation tillage practices, such as basin or reservoir tillage, are usually required to improve infiltration uniformity with potato under center-pivot irrigation. The hilling of potato plants causes water to concentrate in the furrow between hills under high application rates, which can result in deep percolation with water bypassing the crop root zone and/or runoff with even slight slopes. Runoff water collects in low areas causing excessive infiltration, while upslope areas have reduced infiltration and become water stressed, creating spatially differing irrigation requirements. The cumulative field scale effect is reduced yield and quality, reduced water and nutrient efficiency, and localized leaching of chemicals from the root zone. Planting potato in wide beds to minimize concentration of water in furrows has been shown to increase tuber yield and quality and reduce seasonal irrigation requirements 5–15% (King et al. 2011).

In recent years all center-pivot manufacturers and other sources have introduced equipment that can control irrigation depth on a spatial basis in a field (variable rate irrigation). Water depth can be controlled either on a pie-shaped basis by automatically adjusting system travel speed (one-dimensional control), or in irregular-shaped management zones (two-dimensional zone control), the size of which depends upon the number of individual control sections along the irrigation system lateral. In the latter case, water application depth is controlled by pulsing sprinklers on/off in a control zone using an appropriate duty cycle (timing). The additional equipment for two-dimensional control adds substantial cost to the irrigation system in terms of equipment and added maintenance. Theoretically, the sensitivity of potato to water stress suggests that tuber yield and quality can be improved and/or variability reduced field wide if water can be applied as needed everywhere in the field. Spatial differences in ASW and, hence, optimum irrigation depth, may be present initially or develop throughout the irrigation season due to spatial differences in ET and water infiltration. Spatial differences in water infiltration develop due to runoff and subsequent runon under irrigation and/or rainfall. These spatial differences in optimum irrigation depth are dynamic throughout the irrigation season making routine spatial analysis necessary to develop a dynamic prescription map to control the variable-rate irrigation system. Routine development of a prescription map is paramount to realizing improved tuber yield and quality from variable-rate irrigation systems .

Set-Move Sprinkler Management

Side-roll and solid-set sprinkler systems are normally designed to deplete soil water storage between irrigations during the peak use period. Thus, soils with greater soil water storage allow for longer irrigation intervals, resulting in reduced equipment and capital costs.

The preceding operating principal is contrary to the need to minimize soil-water fluctuations for optimum tuber yield and quality. The most typical irrigation management problems occurring with set-move sprinkler systems are irrigation intervals that are too long and excessive water applications during an irrigation set. This may be a result of overestimating soil water-holding capacity and crop rooting depth, or an insufficient number of sprinkler laterals requiring too many days to traverse the field. The maximum irrigation interval can be calculated as:

Maximum irrigation intervals based on a peak ET of 0.33 in/day for different soil types and root zone depths are shown in Table 13.5. Irrigation intervals exceeding 5 days during peak ET periods will likely result in ASW levels below 65%, which can adversely affect tuber yield and quality. However, in practice, irrigation intervals exceeding 5 days are not uncommon.

Field studies were conducted at Aberdeen, ID, in 1997 to evaluate the effect of irrigation frequency on potato yield and quality. Irrigation intervals of 4, 5, 6, and 7 days during tuber development were used in the study. The irrigation system was solid-set sprinkler. The soil type was a Declo silt loam with a water-holding capacity of approximately 2.2 in/ft. Water application amounts were determined based on replacement of estimated ET. Total yield, U.S. No. 1 yield, and yield of tubers >10 oz are shown in Table 13.6.

An irrigation interval of 6 days resulted in the highest total yield, while the yield of U.S. No. 1 grade tubers decreased as the irrigation interval increased beyond 5 days. Yield of tubers over 10 oz. also decreased as the irrigation interval increased beyond 4 days. The results of this study show that there is an optimum irrigation interval for maximizing total yield and quality based on the water-holding capacity of the effective root zone and the rate of crop water use. This optimum interval is strongly dependent on soil texture and will be shorter for coarse-textured soils than heavier-textured soils. The percentage of large tubers is also strongly influenced by irrigation interval. Thus, irrigation management can be a useful tool in achieving tuber size goals .

Furrow Irrigation

Furrow irrigation of potato does not produce the tuber quality obtainable with other forms of irrigation, even with best achievable management practices. Water is required to traverse the field by overland flow in the furrow. The time required for the water to advance to the end of the furrow leads to greater water application at the inflow end compared to the outflow end, resulting from the difference in infiltration opportunity time. Furthermore, infiltration is a highly variable phenomena, with applications to individual plants ranging from half to twice the field average (Trout et al. 1994). Thus, furrow irrigation cannot achieve the degree of uniform water application needed to produce consistently high-quality tubers on a commercial field scale basis.

A common furrow irrigation practice for potato is to irrigate alternate furrows on successive irrigations to overcome some of the difficulty in applying small irrigation applications. Consequently, only about 15% of the soil surface is wetted, and water is expected to move upward laterally to wet the whole root zone. In the absence of a clay soil or dense soil layers, gravity causes water to move faster downward than laterally. Thus, attempts to completely wet the root zone to the top of the hill usually fail and result in excessive deep percolation losses. The lateral water distribution problem results in significant variation in soil water contents in the hill. Consequently, potato roots near the furrow experience widely varying soil water contents, while the upper portion of the hill remains dry.

A consequence of non-uniform water distribution between and along furrows is wide variation in nitrogen availability due to both dry soil regions and leaching losses. This tends to further reduce tuber quality under furrow irrigation and reduces nutrient use efficiency.

These limitations have caused many producers to abandon furrow irrigation in favor of sprinkler irrigation. A common approach is to utilize a completely portable sprinkler irrigation system to irrigate potato, moving the system around the farm according to the crop rotation, and use furrow irrigation for the other row crops. The advantages of higher gross income and reduced risk with sprinkler irrigation are usually enough to justify the use of sprinklers for potato production. The ability to inject fertilizers and pesticides through sprinkler systems provides another significant advantage over furrow irrigation .

Irrigation Uniformity

Perfectly uniform water application is not physically or economically feasible on a field scale. Thus, some degree of variability in water application exists for all irrigation systems. The degree of water application uniformity is influenced by irrigation system type, design, and operating conditions. Regular maintenance of all irrigation systems is necessary to achieve the highest degree of uniformity throughout the life of the system. Irrigation uniformity is economically important because variations in water application, caused by worn or malfunctioning equipment, accumulate over the growing season. Portions of the field with large deviations from optimum water application rates will suffer serious losses in tuber yield and/or quality.

Summary

The primary goal of potato irrigation management is to minimize soil moisture fluctuations and maintain available soil water within the optimum range of 70–85%. Irrigation systems best suited to this task are those that are capable of light, uniform, and frequent water applications. An effective irrigation management program must include regular quantitative monitoring of soil water availability and scheduling irrigations according to crop water use, soil water-holding capacity, and crop rooting depth. Potato is more sensitive to water stress than most other crops, have relatively shallow root systems, and are commonly grown on coarse-textured soils. These conditions dictate utilization of a quantitative irrigation scheduling method for consistent, optimum economic potato production.

References

Jensen ME, Burman RD, Allen RG (1990) Evapotranspiration and irrigation water requirements. ASCE manuals and reports on engineering practice no. 70. American Society of Civil Engineers, New York, NY

King BA, Tarkalson DD, Bjorneberg DL, Taberna JP (2011) Planting system effect on yield response of russet Norkotah to irrigation and nitrogen under high intensity sprinkler irrigation. Am J Potato Res 88:121–134

Neibling WH, Brooks RH (1995) Potato production using subsurface drip irrigation: water and nitrogen management. In: Proceedings 5th international microirrigation congress, American Society of Agricultural Engineers, Orlando, FL, April 1995, pp 656–663

Patel N, Rajput TBS (2007) Effect of drip tape placement depth and irrigation level on yield of potato. Agric Water Manage 88:209–225

Shock CC, Eldridge EP, Pereira AB (2005) Planting configuration and plant population effects on drip-irrigated Umatilla russet potato yield and grade. Oregon State University Agricultural Experiment Station, special report 1062, pp 156–165

Stark JC (1996) Information management systems for on-farm potato research. Potato research and extension proposals for cooperative action. University of Idaho, College of Agriculture, pp 88–95

Sterling R, Neibling WH (1994) Final report of the water conservation task force. Idaho Department of Water Resources, Boise

Trout TJ, Kincaid DC, Westermann DT (1994) Comparison of Russet Burbank yield and quality under furrow and sprinkler irrigation. Am Potato J 71:15–28

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 This is a U.S. government work and not under copyright protection in the U.S.; foreign copyright protection may apply 2020

About this chapter

Cite this chapter

King, B.A., Stark, J.C., Neibling, H. (2020). Potato Irrigation Management. In: Stark, J., Thornton, M., Nolte, P. (eds) Potato Production Systems. Springer, Cham. https://doi.org/10.1007/978-3-030-39157-7_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-39157-7_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39156-0

Online ISBN: 978-3-030-39157-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)