Abstract

Humanity has been used microbial biomass for food production and now; for biofuels, drugs, and other useful compounds. Different microorganisms are employed in the production of biomass ranging from bacteria, yeast, fungi, and algae which are used to produce food, bioactive compounds, enzymes, hydrolysates, among others. Due to the accelerated population growth in the world and the need to meet its nutritional requirements, the search for alternatives that help to solve this social problem is one of the most pressing tasks.

Several studies have demonstrated the nutritional value of microbial biomass related to a high protein content, an excellent source of vitamins and minerals necessary for a quality diet. The production of unicellular biomass has been carried out through submerged and solid-state fermentations. For the production of biomass, the design of various culture media has been considered, where different sources of carbon, nitrogen, pH, and aeration level have been some of the evaluated variables that favor the yields of protein production. The use of various agro-industrial waste as carbon source in the biomass production could contribute in solving a problem of accumulation of waste causing soil contamination. This chapter describes the state of the art of unicellular biomass production, microorganisms used, types of fermentation, carbon sources used, agro-industrial residues used as substrate, characteristics of biomass produced and other related topics.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

11.1 Introduction

The use of biomass has been reported since ancient times. There are records of the use of yeast to produce food since 7000 BC. Currently the use of this material has different purposes, besides the production of food it can be used to produce biofuels as a good option to replace fossil fuels (which are one of the main causes of global warming), and other useful compounds and medicines as well (Zabed et al. 2019; Pérez-Torrado et al. 2015).

Biomass is a product derived from biological material such as plants, animals, and microorganisms, which is composed mainly of carbon, hydrogen, oxygen, and nitrogen (Balaman 2019; Houghton 2008). From another perspective, bioactivity is the process of catalysis to transform a raw material into a desired product, either a protein or some other useful compounds. Microorganisms are employed to produce a specific product or products from macromolecules from the culture medium (Lübbert 2017).

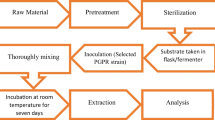

The biomass production by non-photosynthetic microorganisms is affected by several factors; the substrate used in the fermentative process, treatments to modify the availability of the substrate to the microorganism, the bioreactor utilized, operational conditions, and downstream processing for separation and purification (Moo-Young and Gregory 1986; Reihani and Khosravi-Darani 2018).

The microbial biomass has different uses in a wide range of applications, for example; in food industry can be used as a Single-Cell Protein (SCP), which is expected to become an auxiliary source of food in the near future. Henceforth; SCP can help to suffice the food demand related to the accelerated growth of the population. It is therefore necessary a twofold increase in the amount of food produced, since by 2050, it is estimated that the number of inhabitants on the planet will increase from 7 billion to 9 billion (Spalvins et al. 2018; Rasouli et al. 2018; Objetivo 2011). Another application is the extraction of various compounds, for example, lipids, carotenoids, oligosaccharides, free polyphenols, and folates which are added to foods to increase their nutritional value (Catchpole et al. 2010; Rai et al. 2018).

Moreover, biorefinery is one of the fields where the use of biomass has had a great boom, promoting the research in the development of analogous fuels, which are expected to replace fossil fuels, one of the main factors that related to the climate change on the planet. For example, different yeasts use carbon sources to modify the composition of fatty acids as well as the accumulation of triglycerides present in the cell (Faife-Pérez et al. 2012; Shields-Menard et al. 2018). Oleaginous yeasts can reach between 40% to 70% of lipids in their cellular structure, allowing be a good raw material for biodiesel conversion and its implementation as a fuel.

11.2 Fermentation

One of the main forms to produce biomass is through fermentation. Biotransformation via fermentation is the main biological procedure for biomass production. Under optimal conditions, microorganism can double the amount of biomass in a short period of time (Schulz and Oslage 1976). Fermentation is one of the oldest methods in food processing which helps for their conservation for longer time. From the biochemistry point of view; it is a metabolic process where energy is generated from organic compounds without the involvement of exogenous oxidizing agents (Bourdichon et al. 2012). Furthermore, the fermentation can be defined as a process where decontamination and detoxification phenomena, of hazardous compounds obtained from agro-industrial waste, are possible (Farinas 2015).

There are two types of fermentation, liquid/submerged or solid-state fermentation. Each one is described below.

11.2.1 Liquid or Submerged Fermentation

Submerged fermentation is a process which utilizes substrates containing free water; such as broths and molasses. The substrate is quickly consumed, so, it is necessary a constant replacement of the culture medium to provide new nutrients. In these fermentation methodologies, the fermentation products may or may not be released in the fermentation broth, it depends if they are extracellular or intracellular. (This type of fermentation is used mainly in microorganisms that need a high moisture content in the medium to be able to develop at an optimum level Subramaniyam and Vimala 2012).

11.2.2 Solid-State Fermentation

Solid-state fermentation unlike submerged state fermentation, is the process whereby a microorganism growing in a non-soluble material, serves as a physical support and as a nutrient source, in the absence of a large amount of free water (Couto and Sanromán 2006).

A very important aspect of solid-state fermentation is the choice of microorganism that will be used in this type of process. The microorganisms which are most suitable for this type of fermentation are fungi due they do not require the presence of free water in the substrate. The second group of microorganisms are some yeasts that, like filamentous fungi, do not require a large amount of water in the medium. Moreover, there are certain bacteria that can develop in a solid-state medium (Farinas 2015; Soccol et al. 2017).

In addition to energy sources, microorganisms require different nutrients to satisfy their energetic needs. Some microorganisms use compounds with simple structures, while others use very complex compounds. However, four types of compounds predominate in solid medium: lipids, carbohydrates, nucleic acids, and proteins (Kampen 2014).

To maximize the production of biomass, it is necessary to use different sources of carbon together with a balance with nitrogen sources, minor elements, trace elements, and vitamins (García-Garibay et al. 2014).

11.3 Carbon Sources

In order to survive the microorganisms, they require different nutrients to obtain energy and produce different organic compounds through fermentation. Carbon sources are considered a factor with great importance in the formulation of the culture medium. Usually at laboratory scale pure sugars are utilized as carbon sources to achieve a better performance (Yatmaz and Turhan 2018) and have a better bioprocess control.

Historically, different materials have been used as carbon sources in substitution of pure substrates to produce biomass. However, the use of these materials brings the disadvantage that there may be variation in the production yield (Stanbury et al. 2017). Despite this, the usage of different agroindustry residues, as carbon source, has been carried out giving added value to these residues (Reihani and Khosravi-Darani 2018) and to obtain microbial biomass.

The waste generated in agriculture after harvest and sequential processing creates a severe problem of pollution. However, it is known that these residues contain a high amount of hemicellulosic and/or lignocellulosic compounds, which can be used as carbon sources for different fermentation processes (Patel and Shukla 2017).

11.4 Agro-Industrial Waste Used as Carbon Source

Agro-industrial waste is the most abundant renewable resource and is produced in huge amounts every year, causing pollution, and represents an economic challenge for companies. It is estimated that about five billion tons of this type of waste are generated annually. So, it is necessary to use them efficiently for the development of new products and applications in order to reduce their impact on the environment (Bharathiraja et al. 2017; Motaung and Linganiso 2018). Agro-industrial residues are those that are not commercialized after the harvest process, among them are mainly sugar cane bagasse, corn residues (stems, leaves, husks, and cobs), wheat and rice straw, rice bran, nutshells, and others. However, they can have different uses, these residues are widely used as cattle feed and compost material and in recent years biorefinery and microbial biomass production are the main trends to consider (Popa 2018).

These residues are also used as fodder for livestock, fuel for stoves, and water heaters (Sarkar et al. 2012). To dispose of waste in an easy and inexpensive way, these are often incinerated outdoors. This practice ends up being more harmful due to air pollution and consequently soil erosion. On the other hand, waste may also be buried avoiding air pollution. The incorporation of such residues in the soil significantly increases its quality and health; however, it is usually an expensive way, because of the required effort and time (Singh and Singh 2012).

11.5 Composition of Agro-Industrial Waste

Agro-industrial waste consists mainly of carbohydrates, proteins, and fibers. Carbohydrates are the most abundant components in these residues and within this category are cellulose, starches, pectins, among others.

Lignocellulose, which is formed by cellulose, hemicellulose, and lignin, is one of the main components of agro-industrial waste. Different residues come to be composed of 20–30% lignocellulose, which can have a great potential for bioconversion and fermentation (Singh et al. 2015). The composition of lignocellulose can vary according to the species from which it is obtained, in addition to the age of the plant, the state of maturation, or growth conditions (Sharma et al. 2019).

11.5.1 Cellulose

It is one of the most abundant biopolymers on the planet; it is a fibrous substance insoluble in water which is found in the cell walls of plants, fungi, and algae as structural material (Kushwaha et al. 2016). Structurally it is formed by a chain of hundreds or even thousands of glucoses linked by a bond β 1-4 (Ummartyotin and Manuspiya 2015) (Fig. 11.1).

11.5.2 Hemicellulose

Hemicellulose is a group of compounds found in most plants which is a renewable resource that can be used for different purposes. Some studies of these compounds have been focused on the release of carbohydrate monomers through different ways, for example, by means of chemical or enzymatic hydrolysis during production of new biofuels as an alternative of fossil fuels (Ebringerova et al. 2005). These polysaccharides are structurally formed by hexoses (galactose, mannose, and glucose) and pentoses (arabinose and xyloses) linked by covalent bonds (Fig. 11.2). Hemicellulose is a hydrophilic polymer and its degree of polymerization (80–200) is small compared to the polymerization degree of cellulose (10,000). As a result of this, they show greater chemical and thermal stability, so they are more soluble in water and the hydrolysis process is simpler (Ummartyotin and Manuspiya 2015; Ajao et al. 2018).

11.5.3 Lignin

Lignin is one of the most abundant phenolic polymers in the world. It has a complex structure as it combines aliphatic chains as well as aromatic compounds. The three main compounds of lignin are p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol (Fig. 11.3). Lignin forms esters and ethers with hemicellulose for the formation of various compounds including lignocellulose (Bajpai 2017a; Chio et al. 2019).

11.6 Sources of Nitrogen

To grow properly, microorganisms have specific nutritional requirements such as nitrogen which is present in various molecules mainly as amino and amide groups. It is common to find nitrogen in microorganisms in its reduced form as primary, secondary, or tertiary amines groups, whereas the oxidized form of this element, such as nitro or nitrous groups, is very rare (Egli 2009).

The relationship between carbon and nitrogen content in nutrient source is an important factor that affects the microorganism growth. A deficiency in the nitrogen content can affect the microbial biomass production yield. There are different sources of organic and inorganic nitrogen which microorganisms can use in their development (Li et al. 2017).

Like the carbon sources behavior, nitrogen sources have the function of stabilizing the pH in the fermentation processes. Nitrogen sources applied in fermentation may be either inorganic or organic. In the first case, inorganic or mineral sources include ammonium salts, ammonia, nitrates, and within the organic can be used urea, yeast extract, corn liquor, or peptone. In addition, it is sometimes necessary to use different mineral sources for optimal biomass growth. In the case of ammonia, which is the nitrogen source most used by autotrophs, nitrogen is in its reduced form, which makes it easier to assimilate (Reihani and Khosravi-Darani 2018; Ohkouchi and Takano 2014).

From the different types of nitrogen source; ammonium salts are one of the preferred. They are the compounds in which inorganic nitrogen can be used for the amino acids formation, unless the same microorganism possesses enzymes or enzymatic complexes that can form ammonium ions from different sources of inorganic nitrogen (Atkins 2016).

11.7 Types of Biomass

11.7.1 Biomass from Microalgae

Microalgae are microorganisms which can convert solar energy into chemical energy through photosynthesis, have been used mainly to produce biofuels. Recently, it is highlighted their use to produce food and pharmaceuticals. It has been shown that algae have a large amount of mainly unsaturated lipids, proteins, and carbohydrates, which can be used in a wide variety of markets (Priyadarshani and Rath 2012; Vanthoor-koopmans et al. 2013; Ramanna et al. 2017). Due to the variety of species, culture conditions and post-cultivation, there is a great potential of biomass from algae for the production of food and biofuels (Walsh et al. 2018). Moreover only a few microalgae species have been included in the “generally regarded as safe” classification for food sources categorized by the US Food and Drug Administration, with examples including Haematococcus spp., Dunaliella spp., Chlorella spp., Arthrospira spp., and Schizochytrium spp. (Hashemian et al. 2019).

Similar to plants, the chemical composition of algae is not a constant factor since it can be affected by various factors such as temperature, pH, salinity, lighting, CO2, growth phase and physiological state (Paula et al. 2013).

11.7.2 Biomass of Algae as a Food Supplement

Different microalgae and macroalgae stand out for their high protein content, which can be compared with the content of other foods such as milk, meat, eggs, and soy. In addition, protein production yield is much higher than traditional sources, so, seaweed and microalgae have a production at 2.5–7.5 ton/Ha/year and 4–15 ton/Ha/year, respectively, while other protein sources, such as soy and other known legumes, have a production at around of 1–2 ton/Ha/year (Bleakley et al. 2017).

Nowadays, technological developments and research focus on the use of algae as micro-ingredients, obtaining very specific benefits. Moreover, the growth of algae biomass production suggests that the use of algae as a micro-ingredient can become the basis of different products for livestock feed, as well as in aquaculture (Shields and Lupatsch 2012).

Although there are different data on the use of algae as an animal supplement, only the use of microalgae supplements had been studied. Different genera of microalgae, such as Chlorella and Scenedesmus sp., attracted the attention of the researchers, because they had a large amount of carotenoid compounds and crude protein (Table 11.1). It was observed that the animals gained weight by consuming algal biomass (Lum et al. 2013).

However, the use of Algae as biomass has some disadvantages, such as non-absorption by the human digestive system due to the cellulose content in the cell wall of the biomass. Secondly, they also concentrate heavy metals and phycotoxins which can be a health problem (Nasseri et al. 2011; Kay and Barton 1991). Finally the incorporation of microalgal biomass into food products has the challenge of sensory profiles to address to enable future food products to become mainstream in the wider marketplace (Birch and review 2019).

In the human diet, various algae are consumed, including Spirulina and Chlorella, which have been commercialized since the 1960s. Despite the nutritional characteristics of algae, the quality of this material is also measured by the content of compounds such as heavy metals, aromatic polycyclic hydrocarbons, toxins, pathogens, and pesticides that can become harmful when consumed (Muys et al. 2018). Despite the nutrients offered by algae as food, the organoleptic characteristics are not favorable, making it difficult for potential consumers to accept it. So, it is necessary to develop new products that are pleasing to the general public (Becker 2007).

11.7.3 Biomass of Algae as Fuel

As a raw material for fuel production, algae biomass shows as an advantage the impact to counteract the greenhouse effect on the planet: due to the high yields of biomass production, algae are able to absorb large amounts of CO2, which is one of the main causes of the problem of climate change (Ambat et al. 2019).

Microalgae can use the nutrients found in wastewater and carbon dioxide to achieve biomass growth which is rich in lipids that can be used in biodiesel production. There are several methods by which it is possible to obtain fuel from the lipids of microalgae; one of these is transesterification catalysis (acid/base) or another is enzymatic biocatalysis (He et al. 2018; Liu et al. 2016).

11.7.4 Microalgae Biomass Production

Regardless of the great versatility of algae as food and as a biofuel, the cost of production is very high, due to the complexity of their collection. It is estimated that in the biofuels production between 20% and 30% of cost corresponds to the collection process and algae biomass production (de Assis et al. 2019; Molina Grima et al. 2003).

In addition to this, the spread of algae for food additives could solve the problem of bioremediation of wastewater mainly in control of nitrogen and phosphorus levels. Therefore, they are looking for new ways to produce them more effectively and efficiently. It has been shown that algae are able to better assimilate the nutrients contained in waters of this type. Several studies have shown that microalgae can reduce between 82–92% nitrogen and 58–98% phosphorus, in addition to reducing the chemical oxygen demand (Ambat et al. 2019; Zhou et al. 2012; Marin-Batista et al. 2019).

In addition to the optimal parameters for the algae growth (temperature, inorganic nutrients, such as nitrogen, phosphorus, sulfur, and water), the production of the biomass may require control of conditions of two types: (1) the use of CO2, and (2) the use of light (Ramanna et al. 2017). It has been studied that the limitation of nitrogen, in addition to the combination with levels of other metals, leads to algae stress, which is reflected in the reduction of biomass production (Singh et al. 2016).

To separate different biomass fractions, it is necessary to degrade the cell wall of the algae. This wall protects the algae from biodegradation related to enzymatic attacks caused by different microorganisms. Different methods have been used to achieve the cell wall break, including physical and mechanical treatments which, despite being able to degrade the cell wall, often get to negative yields in energy terms: the loss of energy is greater than for biomass production. Kavitha et al. (2017) performed pretreatments using bacteria for the degradation of cell walls in microalgae, obtaining better yields compared to physical and mechanical pretreatments, which require higher energy consumption.

11.8 Fungal Biomass Production

Currently, fungi are used for the production of secondary metabolites, which have medicinal and industrial importance, since medicines and foods can be made with these metabolites (Nigam and Singh 2014). In addition, they are sources of different pigments such as carotenoids, melanin, among others (Dufossé 2018).

One of the uses of fungus is for the production of mycoprotein, which is a food product derived from the continuous fermentation of the fungus Fusarium venenatum, which has been noted for its high protein yield and a low amount of fats (Denny et al. 2008), being a very interesting nutritional source compared with other sources (Table 11.2).

The chemical analysis of mycoprotein demonstrates a wide variety of nutrients. This food is also combined with low-energy and high-fiber content. Mycoprotein has a low fat content which consists mainly of unsaturated fatty acids predominantly linoleic and linolenic acid. The fiber consists of a mixture of chitin and β-glucan that performs physiologically as dietary fiber and does not have an adverse effect on mineral status (Finnigan et al. 2017)

For the production of this type of food, it is possible to use different cellulosic materials (straw, sugarcane bagasse, corn cob, etc.) as a source of carbon in the fermentation (Moo-Young et al. 1993). However, to make use of these materials rich in cellulose, it is necessary to implement a pretreatment for this type of material to facilitate access of microorganisms to the available glucose.

Different substrates can be used for biomass production of these organisms. Oshoma et al. (Marin-Batista et al. 2019) demonstrated that banana peel is a good substrate for the production of Aspergillus niger biomass obtaining better yields than with other substrates, like orange peel among others (Oshoma and Eguakun-Owie 2018). Alemu (Singh et al. 2016) indicates that the best process for a better yield of biomass of filamentous fungus is the solid-state fermentation (Alemu 2013) using agro-industrial wastes (Table 11.3).

Ugalde (Kavitha et al. 2017) lists certain filamentous fungi which can be used in the production of biomass and thus generate foodstuffs where the genera stand out: Aspergillus, Fusarium, Rhizopus, Trichoderma, Cephalosporium, Mucor, Monilia, Penicillium, Spicaria, Paecilomyces, and Cunninghamella (Ugalde and Castrillo 2002) (Table 11.3).

The presence of mycotoxins in certain fungal species especially Aspergillus parasiticus and Aspergillus flavus is a major hindrance in their use. These toxins are known to produce many allergic reactions, diseases, and liver cancer in humans as well in animals. Hence, it is required to eliminate contamination (Anupama 2000).

Although fungi usually grow more slowly than yeasts, the yields in biomass production are usually similar. However, as shown in Table 11.3, they can grow in different agro-industrial residues under very similar temperature conditions.

11.9 Yeast Biomass

Yeasts are considered fungi; they reproduce by fission or by budding. It has been documented that yeasts can cause some deterioration in food and beverages. It is also possible to apply yeasts in fermentative processes for food generation. It has been applied in agriculture, production of biofuels, medicines, chemical industry, and even environmental protection (Jach and Serefko 2018; Fleet 2011). They are divided into two families: Ascomycota and Basidiomycota.

Yeasts can be used for the treatment of different residues generated in various industries; an example of this is the treatment of vinasse to produce unicellular protein (Table 11.3). Different studies have shown that it is possible to use this waste from the wine industry as a substrate for yeast fermentation, to reduce the pollution. Dos Reis et al. in 2018 reported that Candida parapsilosis was grown in medium with 5 g/L of peptone and 70% v/v of vinasse (Dos Reis et al. 2018).

It have been shown that yeasts have a resistance to different factors such as acid and alkaline pH, antibiotics, different sterilizing agents, and they can grow on different carbon sources ranging from carbohydrates (glucose, sucrose, and maltose), biopolymers (starch, cellulose, hemicellulose, and pectin), alcohols, hydrocarbons, fatty acids, and organic acids (Yang and Zheng 2014).

One of the uses of yeast biomass is the obtention of different oligosaccharides due to the presence of β-glucan in the yeast cell wall. The β-glucan is composed of glucoses linked by β-1-6 and β-1 bonds, which gives to the cell wall some stability and rigidity. This structure is similar to that of cellulose because, like this one, it is also has a crystalline region and an amorphous region (Bychkov et al. 2010).

11.9.1 Yeast Biomass as Food

Yeasts are applied to produce different functional foods and are considered a fundamental part in obtaining of nutraceuticals. Yeasts have different applications in the functional food industry, since they can be used as probiotics. Several studies show that the cell wall of yeasts has a large amount of nutrients such as proteins and B vitamins. Extracts obtained from these microorganisms are a source of metabolites that have bioactive compounds (carotenoids, folates, and γ-aminobutyric acid). Also yeast are producers of enzymes and that the products of their viability can be metabolites with high nutraceutical value (Rai et al. 2018).

One of the applications of yeast biomass is the production of unicellular protein, which can be employed as a substitute for other protein sources such as soy and fish protein used for animal feed. However, traditional production of this type of feed requires pure strains of certain types of yeasts and crop optimization processes (Yang and Zheng 2014). Due to the growing interest in production of unicellular protein from raw material, i.e., from agro-industrial waste, it has become a less expensive process (Kieliszek et al. 2017).

Nigam (Nigam 2000) demonstrated that for yeast growth in sugar cane bagasse, the pretreatment of support by hydrolysis is necessary for a greater availability of glucose to obtain higher biomass yield. In addition, the presence of a high amount of amino acids such as lysine, arginine, and isoleucine is reported in the yeast biomass (Nigam 2000).

A wide variety of yeasts has been used in the production of unicellular protein (Table 11.4). The composition of biomass in nutritional terms is variable and rich (Table 11.5). So, the production of unicellular protein from yeast is a viable alternative for obtaining nutritionally rich foods.

11.9.2 Biofuels Obtained by Yeast Fermentation

Many yeasts are known for their enzymatic complexes capable of producing ethanol (Adelabu et al. 2019) In the production of this biofuel, it is preferable to use yeasts instead of bacteria, due to the tolerance that they have against to different inhibitory factors, such as, ethanol, and other organic acids.

For the production of biodiesel, from oleaginous biomass, using yeasts; three main steps are required: (1) The culture of the microorganism, (2) The breaking of the cell wall, and (3) The extraction of the lipids of the microorganism for their subsequent transesterification (Yellapu et al. 2016).

11.10 Biomass of Bacteria

The biomass of certain bacteria, such as photosynthetic bacteria, is not only rich in proteins, but also in other compounds such as, carotenoids, biological cofactors, vitamins, among others (Shipman et al. 1975).

11.10.1 Biomass of Bacteria as Food

One of the main uses given to the biomass of these organisms is mainly for aquaculture. Due to its high demand, the implementation of new protocols to enhance the biomass production has been required to satisfy the consumer demand (Kiessling and Askbrandt 1993). Different methods are used to produce unicellular protein from photosynthetic bacteria. One of them is the use of bovine animal waste. This type of bacteria is found mainly in wells, dykes, or other types of water sources. Also, this type of bacteria is used in the biogas industry due to the high biogas production. Some residues generated are a good source of nutrients, various studies reported that in addition to proteins, a large amount of carotenoids and vitamins should be obtained as valuable subproduct (Vrati 1984).

To produce biomass, it is possible to use heterotrophic bacteria which can convert phosphorus and nitrogen from waste obtained from fish farming. This type of bacteria requires a C:N ratio between 12:15 for optimum biomass production (Jach and Serefko 2018). Few hydrogen oxidizing bacteria can obtain good yields in the production of unicellular protein. The production of these bacteria is carried out via autotrophic biochemical route, in environments with CO2. Dou Junei in 2018 demonstrated that this type of bacteria has good yields at a temperature of 30 °C, with pH 7 and using NH4HCO3 as a source of nitrogen (Fleet 2011).

Use of bacterial biomass is limited due to high cost. Harvesting is difficult due to small size of bacteria and hence the cells must be flocculated in order to ease a higher solid slurry obtention, prior centrifugation. Bacterial cells also have a high concentration of nucleic acids (Anupama 2000).

11.11 Conclusion

The production of microbial biomass has been an alternative that has helped humanity to meet various needs, including food and fuel production. While there is a large amount of biomass that can be used to meet the demands of these two sectors, it is necessary to develop new bioprocesses or to optimize some existing ones to increase the yields of the products of interest. In addition, the development of new technologies will allow us to contribute to the solution of pollution problems caused by large amount of agro-industrial waste, which are not used. Currently, our working group (Bioprocesses & Bioproducts Group) has carried out research based on the use of agro-industrial waste to obtain compounds of commercial interest, including the production of single-cell protein hoping to contribute to meeting food needs.

References

Adelabu BA, Kareem SO, Oluwafemi F, Abideen Adeogun I (2019) Bioconversion of corn straw to ethanol by cellulolytic yeasts immobilized in Mucuna urens matrix. J King Saud Univ Sci 31(1):136–141. https://doi.org/10.1016/j.jksus.2017.07.005

Adoki A (2008) Factors affecting yeast growth and protein yield production from orange, plantain and banana wastes processing residues using Candida sp. Afr J Biotechnol 7(3):290–295. https://doi.org/10.5897/AJB07.247

Ahmed S, Ahmad F, Hashmi AS (2010) Production of microbial biomass protein by sequential culture fermentation of Arachniotus sp., and Candida utilis. Pakistan J Bot 42(2):1225–1234. https://doi.org/10.1007/s13213-011-0357-8

Ajao O, Marinova M, Savadogo O, Paris J (2018) Hemicellulose based integrated forest biorefineries: implementation strategies. Ind Crop Prod 126:250–260. https://doi.org/10.1016/j.indcrop.2018.10.025

Alemu T (2013) Process of optimization and characterization of protein enrichment of orange wastes through solid state fermentation by Aspergillus niger isolate no. 5. J Biol Sci 13(5):341–348. https://doi.org/10.3923/jbs.2013.341.348

Ambat I, Tang WZ, Sillanpää M (2019) Statistical analysis of sustainable production of algal biomass from wastewater treatment process. Biomass Bioenergy 120(Dec 2018):471–478. https://doi.org/10.1016/j.biombioe.2018.10.016

Anupama RP (2000) Value-added food: single cell protein. Biotechnol Adv 18(6):459–479. https://doi.org/10.1016/S0734-9750(00)00045-8

Anvari M, Khayati G (2011) Submerged yeast fermentation of cheese whey for protein production and nutritional profile analysis. Adv J Food Sci Technol 3(2):122–126

Atkins CA (2016) Nitrogen metabolism. Encycl Food Grains 2:123–128. https://doi.org/10.1016/b978-0-12-394437-5.00104-2

Azam S, Khan Z, Ahmad B, Khan I, Ali J (2014) Production of single cell protein from orange peels using Aspergillus niger and Saccharomyces cerevisiae Pakistan Council of Scientific and Industrial Research Laboratories Complex. Glob J Biotechnol Biochem 9(1):14–18. https://doi.org/10.5829/idosi.gjbb.2014.9.1.82314

Bajpai P (2017a) Carbon fibre from Lignin 77. Springer, Singapore. https://doi.org/10.1007/978-981-10-4229-4

Bajpai P (2017b) Single cell protein production from lignocellulosic biomass. Springer, Singapore. https://doi.org/10.1007/978-981-10-5873-8

Balaman ŞY (2019) Introduction to biomass—resources, production, harvesting, collection, and storage. In: Decision-making for biomass-based production chains. Elsevier, San Diego, pp 1–23. https://doi.org/10.1016/B978-0-12-814278-3.00001-7

Becker EW (2007) Micro-algae as a source of protein. Biotechnol Adv 25:207–210. https://doi.org/10.1016/j.biotechadv.2006.11.002

Bharathiraja S, Suriya J, Krishnan M, Manivasagan P, Kim S-K (2017) Production of enzymes from agricultural wastes and their potential industrial applications. Adv Food Nutr Res 80:125–148. https://doi.org/10.1016/bs.afnr.2016.11.003

Birch CS, Bonwick GA (2019) Invited review ensuring the future of functional foods. Int J Food Sci Technol 54:1467–1485. https://doi.org/10.1111/ijfs.14060

Bleakley S, Hayes M, Bleakley S, Hayes M (2017) Algal proteins: extraction, application, and challenges concerning production. Foods 6(5):33. https://doi.org/10.3390/foods6050033

Bourdichon F, Casaregola S, Farrokh C et al (2012) Food fermentations: microorganisms with technological beneficial use. Int J Food Microbiol 154(3):87–97. https://doi.org/10.1016/j.ijfoodmicro.2011.12.030

Bychkov AL, Korolev KG, Lomovsky OI (2010) Obtaining mannanoligosaccharide preparations by means of the mechanoenzymatic hydrolysis of yeast biomass. Appl Biochem Biotechnol 162(7):2008–2014. https://doi.org/10.1007/s12010-010-8976-2

Catchpole O, Ryan J, Zhu Y et al (2010) The journal of supercritical fluids extraction of lipids from fermentation biomass using near-critical dimethylether. J Supercrit Fluids 53(1–3):34–41. https://doi.org/10.1016/j.supflu.2010.02.014

Chio C, Sain M, Qin W (2019) Lignin utilization: a review of lignin depolymerization from various aspects. Renew Sust Energ Rev 107:232–249. https://doi.org/10.1016/j.rser.2019.03.008

Choi MH, Park YH (1999) Growth of Pichia guilliermondii A9, an osmotolerant yeast, in waste brine generated from kimchi production. Bioresour Technol 70(3):231–236. https://doi.org/10.1016/S0960-8524(99)00049-8

Couto SR, Sanromán MÁ (2006) Application of solid-state fermentation to food industry—a review. J Food Eng 76(3):291–302. https://doi.org/10.1016/j.jfoodeng.2005.05.022

de Assis LR, Calijuri ML, Assemany PP, Berg EC, Febroni LV, Bartolomeu TA (2019) Evaluation of the performance of different materials to support the attached growth of algal biomass. Algal Res 39:101440. https://doi.org/10.1016/j.algal.2019.101440

Denny A, Aisbitt B, Lunn J (2008) Mycoprotein and health. Nutr Bull 33(4):298–310. https://doi.org/10.1111/j.1467-3010.2008.00730.x

Dharumadurai D, Subramaniyan L, Subhasish S, Nooruddin T, Annamalai P (2011) Production of single cell protein from pineapple waste using yeast. Innov Rom Food Biotechnol 8:26–32

Dos Reis KC, Coimbra JM, Duarte WF, Schwan RF, Silva CF (2018) Biological treatment of vinasse with yeast and simultaneous production of single-cell protein for feed supplementation. Int J Environ Sci Technol 16(2):1–12. https://doi.org/10.1007/s13762-018-1709-8

Dufossé L (2018) Red colourants from filamentous fungi: are they ready for the food industry? J Food Compos Anal 69(April 2017):156–161. https://doi.org/10.1016/j.jfca.2017.11.002

Ebringerova A, Hromadkova Z, Heinze T, Ebringerová A, Hromádková Z, Heinze T (2005) Hemicellulose. Adv Polym Sci 186:1–67. https://doi.org/10.1007/b136816

Egli T (2009) Nutrition, microbial. In: Encyclopedia of microbiology. Elsevier, Amsterdam, pp 308–324. https://doi.org/10.1016/B978-012373944-5.00083-3

Faife-Pérez E, Otero-Rambla MA, Alvarez-Delgado A (2012) Producción de Biodiesel a Partir de Microorganismos Oleaginosos. Parte l: Levaduras y bacterias. ICIDCA Sobre los Deriv la Caña Azúcar 46:26–35

FAO (2011) Objetivo: acabar con las pérdidas y desperdicios de alimentos en la cadena de producción. http://www.fao.org/in-action/seeking-end-to-loss-and-waste-of-food-along-production-chain/es/. Accessed 9 May 2019

Farinas CS (2015) Developments in solid-state fermentation for the production of biomass-degrading enzymes for the bioenergy sector. Renew Sust Energ Rev 52:179–188. https://doi.org/10.1016/j.rser.2015.07.092

Fatemeh S, Reihani S, Khosravi-Darani K (2018) Mycoprotein production from date waste using Fusarium venenatum in a submerged culture. Applied Food Biotechnology 5(4):243–252

Finnigan T, Needham L, Abbott C (2017) Mycoprotein. In: Sustainable protein sources. Elsevier, Amsterdam, pp 305–325. https://doi.org/10.1016/B978-0-12-802778-3.00019-6

Fleet GH (2011) Yeast spoilage of foods and beverages. In: The yeasts. Elsevier, Amsterdam, pp 53–63. https://doi.org/10.1016/B978-0-444-52149-1.00005-7

García-Garibay M, Gómez-Ruiz L, Cruz-Guerrero AE, Bárzana E (2014) SINGLE CELL PROTEIN | yeasts and bacteria. In: Encyclopedia of food microbiology. Elsevier, Cambridge, pp 431–438. https://doi.org/10.1016/B978-0-12-384730-0.00310-4

Hashemian M, Ahmadzadeh H, Hosseini M, Lyon S, Pourianfar HR (2019) Production of microalgae-derived high-protein biomass to enhance food for animal feedstock and human consumption. In: Advanced bioprocessing for alternative fuels, biobased chemicals, and bioproducts. Elsevier, Duxford, pp 393–405. https://doi.org/10.1016/B978-0-12-817941-3.00020-6

He Y, Wu T, Wang X, Chen B, Chen F (2018) Cost-effective biodiesel production from wet microalgal biomass by a novel two-step enzymatic process. Bioresour Technol 268:583–591. https://doi.org/10.1016/j.biortech.2018.08.038

Houghton RA (2008) Biomass. In: Encyclopedia of ecology. Elsevier, Amsterdam, pp 253–257. https://doi.org/10.1016/B978-0-444-63768-0.00462-5

Jach ME, Serefko A (2018) Nutritional yeast biomass: characterization and application. In: Diet, microbiome and health. Elsevier, Amsterdam, pp 237–270. https://doi.org/10.1016/B978-0-12-811440-7.00009-0

Kampen WH (2014) Nutritional requirements in fermentation processes. In: Fermentation and biochemical engineering handbook. Elsevier, Amsterdam, pp 37–57. https://doi.org/10.1016/B978-1-4557-2553-3.00004-0

Kavitha S, Subbulakshmi P, Rajesh Banu J, Gobi M, Tae Yeom I (2017) Enhancement of biogas production from microalgal biomass through cellulolytic bacterial pretreatment. Bioresour Technol 233:34–43. https://doi.org/10.1016/j.biortech.2017.02.081

Kay RA, Barton LL (1991) Microalgae as food and supplement. Crit Rev Food Sci Nutr 30(6):555–573. https://doi.org/10.1080/10408399109527556

Kieliszek M, Kot AM, Bzducha-Wróbel A, BŁażejak S, Gientka I, Kurcz A (2017) Biotechnological use of Candida yeasts in the food industry: a review. Fungal Biol Rev 31(4):185–198. https://doi.org/10.1016/j.fbr.2017.06.001

Kiessling A, Askbrandt S (1993) Nutritive value of two bacterial strains of single-cell protein for rainbow trout (Oncorhynchus mykiss). Aquaculture 109(2):119–130. https://doi.org/10.1016/0044-8486(93)90209-H

Kushwaha S, Singh R, Suhas CM, Carrott PJM, Gupta VK (2016) Cellulose: a review as natural, modified and activated carbon adsorbent. Bioresour Technol 216:1066–1076. https://doi.org/10.1016/j.biortech.2016.05.106

Li Z, Wang D, Shi YC (2017) Effects of nitrogen source on ethanol production in very high gravity fermentation of corn starch. J Taiwan Inst Chem Eng 70:229–235. https://doi.org/10.1016/j.jtice.2016.10.055

Liu F, Tian Y, Ding Y, Li Z (2016) Bioresource technology the use of fermentation liquid of wastewater primary sedimentation sludge as supplemental carbon source for denitrification based on enhanced anaerobic fermentation. Bioresour Technol 219:6–13. https://doi.org/10.1016/j.biortech.2016.07.030

Lübbert A (2017) Measurement and characterization of microbial biomass. In: Current developments in biotechnology and bioengineering. Elsevier, Amsterdam, pp 705–724. https://doi.org/10.1016/B978-0-444-63663-8.00024-0

Lum KK, Kim J, Lei XG (2013) Dual potential of microalgae as a sustainable biofuel feedstock and animal feed. J Anim Sci Biotechnol 4(1):1–7. https://doi.org/10.1186/2049-1891-4-53

Marin-Batista JD, Villamil JA, Rodriguez JJ, Mohedano AF, de la Rubia MA (2019) Valorization of microalgal biomass by hydrothermal carbonization and anaerobic digestion. Bioresour Technol 274:395–402. https://doi.org/10.1016/j.biortech.2018.11.103

Martínez EJ, Rosas JG, Sotres A et al (2018) Codigestion of sludge and citrus peel wastes: evaluating the effect of biochar addition on microbial communities. Biochem Eng J 137:314–325. https://doi.org/10.1016/j.bej.2018.06.010

Molina Grima E, Acién Fernández FG, Robles Medina A, Chisti Y (2003) Recovery of microalgal biomass and metabolies process options and economics. Biotechnol Adv 20:491–515

Moo-Young M, Gregory KF (1986) Microbial biomass proteins. Elsevier, London, pp 19–26

Moo-Young M, Chisti Y, Vlach D (1993) Fermentation of cellulosic materials to mycoprotein foods. Biotechnol Adv 11(3):469–479. https://doi.org/10.1016/0734-9750(93)90015-F

Motaung TE, Linganiso LZ (2018) Critical review on Agrowaste cellulose applications for biopolymers. Int J Plast Technol 22:185–216. https://doi.org/10.1007/s12588-018-9219-6

Muys M, Sui Y, Schwaiger B et al (2018) Bioresource technology high variability in nutritional value and safety of commercially available Chlorella and Spirulina biomass indicates the need for smart production strategies. Bioresour Technol 275:247–257. https://doi.org/10.1016/j.biortech.2018.12.059

Nasseri AT, Rasoul-Amini S, Morrowvat MH, Ghasemi Y (2011) Single cell: protein production and process. Am J Food Technol 6:103–116

Nigam JN (2000) Cultivation of Candida langeronii in sugar cane bagasse hemicellulosic hydrolyzate for the production of single cell protein. World J Microbiol Biotechnol 16(4):367–372. https://doi.org/10.1023/A:1008922806215

Nigam PS, Singh A (2014) Single cell protein | Mycelial fungi. In: Encyclopedia of food microbiology. Elsevier, Amsterdam, pp 415–424. https://doi.org/10.1016/B978-0-12-384730-0.00311-6

Ohkouchi N, Takano Y (2014) Organic nitrogen: sources, fates, and chemistry. In: Treatise on geochemistry. Elsevier, Amsterdam, pp 251–289. https://doi.org/10.1016/B978-0-08-095975-7.01015-9

Oshoma C, Eguakun-Owie SO (2018) Conversion of food waste to single cell protein using Aspergillus niger. J Appl Sci Environ Manag 22(3):350–355. https://doi.org/10.4314/jasem.v22i3.10

Patel S, Shukla S (2017) Fermentation of food wastes for generation of nutraceuticals and supplements. In: Fermented foods in health and disease prevention. Elsevier, Amsterdam, pp 707–734. https://doi.org/10.1016/B978-0-12-802309-9.00030-3

Paula A, Gouveia L, Bandarra NM, Franco JM, Raymundo A (2013) Comparison of microalgal biomass pro fi les as novel functional ingredient for food products. Algal Res 2(2):164–173. https://doi.org/10.1016/j.algal.2013.01.004

Pérez-Torrado R, Gamero E, Gómez-Pastor R, Garre E, Aranda A, Matallana E (2015) Yeast biomass, an optimised product with myriad applications in the food industry. Trends Food Sci Technol 46(2):167–175. https://doi.org/10.1016/j.tifs.2015.10.008

Popa VI (2018) Biomass for fuels and biomaterials. In: Biomass as renewable raw material to obtain bioproducts of high-tech value. Elsevier, Amsterdam, pp 1–37. https://doi.org/10.1016/B978-0-444-63774-1.00001-6

Priyadarshani I, Rath B (2012) Commercial and industrial applications of micro algae - a review. J Algal Biomass Utln 3(4):89–100. https://doi.org/10.1016/j.(73)

Rai AK, Pandey A, Sahoo D (June 2018) Biotechnological potential of yeasts in functional food industry. Trends Food Sci Technol 2019(83):129–137. https://doi.org/10.1016/j.tifs.2018.11.016

Rajendran S, Kapilan R, Vasantharuba S (2018) Single cell protein production from papaw and banana fruit juices using baker’s yeast. J Agric Environ Sci 18(4):168–172. https://doi.org/10.5829/idosi.aejaes.2018.168.172

Ramanna L, Rawat I, Bux F (2017) Light enhancement strategies improve microalgal biomass productivity. Renew Sust Energ Rev 80:765–773. https://doi.org/10.1016/j.rser.2017.05.202

Rasouli Z, Valverde-Pérez B, D’Este M, De Francisci D, Angelidaki I (2018) Nutrient recovery from industrial wastewater as single cell protein by a co-culture of green microalgae and methanotrophs. Biochem Eng J 134:129–135. https://doi.org/10.1016/j.bej.2018.03.010

Reihani SFS, Khosravi-Darani K (2018) Influencing factors on single cell protein production by submerged fermentation: a review. Electron J Biotechnol 37:34–40. https://doi.org/10.1016/j.ejbt.2018.11.005

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37(1):19–27. https://doi.org/10.1016/j.renene.2011.06.045

Schulz E, Oslage HJ (1976) Composition and nutritive value of single-cell protein (SCP). Anim Feed Sci Technol 1(1):9–24. https://doi.org/10.1016/0377-8401(76)90003-1

Sharma HK, Xu C, Qin W (2019) Biological pretreatment of lignocellulosic biomass for biofuels and bioproducts: an overview. Waste Biomass Valor 10(2):235–251. https://doi.org/10.1007/s12649-017-0059-y

Shields RJ, Lupatsch I (2012) Algae for aquaculture and animal feeds. In: Microalgal biotechnology: integration and econom. Walter de Gruyter, Boston, pp 23–37

Shields-Menard SA, Amirsadeghi M, French WT, Boopathy R (2018) A review on microbial lipids as a potential biofuel. Bioresour Technol 259:451–460. https://doi.org/10.1016/j.biortech.2018.03.080

Shipman RH, Kao IC, Fan LT (1975) Single-cell protein production by photosynthetic bacteria cultivation in agricultural by-products. Biotechnol Bioeng 17(11):1561–1570. https://doi.org/10.1002/bit.260171102

Shojaosadati SA, Khalilzadeh R, Sanaei HR (1998) Optimizing of SCP production from sugar beet stillage using isolated yeast. Iran J Chem Chem Eng 17(2):73–80

Singh S, Singh B, Mishra BK, Pandey AK, Nain L (2012) Microbes in agrowaste management for sustainable agriculture. In: Microorganisms in sustainable agriculture and biotechnology. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-2214-9

Singh P, Guldhe A, Kumari S, Rawat I, Bux F (2016) Combined metals and EDTA control: an integrated and scalable lipid enhancement strategy to alleviate biomass constraints in microalgae under nitrogen limited conditions. Energy Convers Manag 114:100–109. https://doi.org/10.1016/j.enconman.2016.02.012

Singh V, Sahu PK, Singh DP, Prabha R, Renu S (2019) Agrowaste bioconversion and microbial fortification have prospects for soil health, crop productivity, and eco-enterprising. Int J Recycl Org Waste Agric Lal 2015:1–16. https://doi.org/10.1007/s40093-019-0243-0

Soccol CR, Scopel E, Alberto L et al (2017) Recent developments and innovations in solid state fermentation. Biotechnol Res Innov 1(1):52–71. https://doi.org/10.1016/j.biori.2017.01.002

Spalvins K, Zihare L, Blumberga D (2018) Single cell protein production from waste biomass: comparison of various industrial by-products. Energy Procedia 147:409–418. https://doi.org/10.1016/j.egypro.2018.07.111

Stanbury PF, Whitaker A, Hall SJ (2017) Media for industrial fermentations. In: Principles of fermentation technology. Elsevier, Amsterdam, pp 213–272. https://doi.org/10.1016/B978-0-08-099953-1.00004-1

Subramaniyam R, Vimala R (2012) Solid state and submerged fermentation for the production of bioactive substances: a comparativity study. Int J Sci Nat 3(3):480–486. www.scienceandnature.org

Suntornsuk W (2000) Yeast cultivation in lettuce brine. World J Microbiol Biotechnol 16:815–818. http://sci-hub.se/https://doi.org/10.1023/A:1008926700452. Accessed May 7, 2019

Ugalde UO, Castrillo JI (2002) Single cell proteins from fungi and yeasts. Appl Mycol Biotechnol 2:123–149. https://doi.org/10.1016/S1874-5334(02)80008-9

Ummartyotin S, Manuspiya H (2015) A critical review on cellulose: from fundamental to an approach on sensor technology. Renew Sust Energ Rev 41:402–412. https://doi.org/10.1016/j.rser.2014.08.050

Vanthoor-koopmans M, Wijffels RH, Barbosa MJ, Eppink MHM (2013) Bioresource technology biorefinery of microalgae for food and fuel. Bioresour Technol 135:142–149. https://doi.org/10.1016/j.biortech.2012.10.135

Vrati S (1984) Single cell protein production by photosynthetic bacteria grown on the clarified effluents of biogas plant. Appl Microbiol Biotechnol 19(3):199–202. https://doi.org/10.1007/BF00256454

Walsh MJ, Gerber L, Doren V, Shete N, Prakash A, Salim U (2018) Financial tradeoffs of energy and food uses of algal biomass under stochastic conditions. Appl Energy 210:591–603. https://doi.org/10.1016/j.apenergy.2017.08.060

Yang M, Zheng S (2014) Pollutant removal-oriented yeast biomass production from high-organic-strength industrial wastewater: a review. Biomass Bioenergy 64:356–362. https://doi.org/10.1016/j.biombioe.2014.03.020

Yatmaz E, Turhan I (2018) Carob as a carbon source for fermentation technology. Biocatal Agric Biotechnol 16:200–208. https://doi.org/10.1016/j.bcab.2018.08.006

Yellapu SK, Bezawada J, Kaur R, Kuttiraja M, Tyagi RD (2016) Detergent assisted lipid extraction from wet yeast biomass for biodiesel: a response surface methodology approach. Bioresour Technol 218:667–673. https://doi.org/10.1016/j.biortech.2016.07.011

Zabed HM, Akter S, Yun J et al (2019) Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew Sust Energ Rev 105:105–128. https://doi.org/10.1016/j.rser.2019.01.048

Zaki M, Said SD (2018) Trichoderma Reesei single cell protein production from rice straw pulp in solid state fermentation. IOP Conf Ser Mater Sci Eng 345(1):012043. https://doi.org/10.1088/1757-899X/345/1/012043

Zhou W, Li Y, Min M et al (2012) Growing wastewater-born microalga Auxenochlorella protothecoides UMN280 on concentrated municipal wastewater for simultaneous nutrient removal and energy feedstock production. Appl Energy 98:433–440. https://doi.org/10.1016/j.apenergy.2012.04.005

Acknowledgments

The authors like to gratefully acknowledge Mexican Council of Science and Technology (CONACYT) for the financial support of scholarship of HALG.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Luna-García, H.A. et al. (2020). Production of Unicellular Biomass as a Food Ingredient from Agro-Industrial Waste. In: Zakaria, Z., Boopathy, R., Dib, J. (eds) Valorisation of Agro-industrial Residues – Volume I: Biological Approaches. Applied Environmental Science and Engineering for a Sustainable Future. Springer, Cham. https://doi.org/10.1007/978-3-030-39137-9_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-39137-9_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-39136-2

Online ISBN: 978-3-030-39137-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)