Abstract

Porous cordierite ceramics (PCCs) were prepared by using emulsion template method using pure oxide as raw materials. The cell microstructures were constructed by the first-principle calculation. The thermal stability of cordierite was verified by the lattice vibration calculation at high temperature, band gap, and DOS. The microstructures and the effects of solid content on mechanical properties were investigated. PCCs with solid content of 40% had the uniform pore structure, which can be used in special industries.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

With the continuous improvement control of porous materials, the application fields and application scope of porous ceramics are also expanding [1, 2]. At present, its applications have spread to many scientific fields, such as environmental protection, energy saving, chemical industry, petroleum, smelting, food, pharmaceuticals, biomedicine, and so on [3,4,5,6]. The scientific fields of smelting, food, pharmaceuticals, and biomedicine have attracted the attention of global materials science [3,4,5,6,7,8,9,10]. Among them, porous cordierite ceramics (PCCs) can be used under relatively severe working conditions due to their extremely low thermal expansion coefficient and excellent thermal shock resistance, and become a common catalyst carrier material and high temperature and high pressure filter [11,12,13,14,15,16]. Currently, it is mainly made by artificial synthesis in industry. Compared with naturally occurring cordierite , synthetic cordierite has superior performance. With the continuous efforts of scientists for many years, porous cordierite ceramics have been developed to a great extent, and have achieved great economic and social benefits, but there are still several aspects to be further studied and improved [17,18,19,20]. Thermomechanical properties , the relationship between porosity and strength, precise control methods for pore size and shape distribution of materials, and reduction of production costs.

In this experiment, PCCs were prepared by using emulsion template method using pure oxide as raw materials. The microstructures and thermal stability were determined by first-principles calculation. The effects of solid content on mechanical properties were investigated.

Experiments

Commercially available materials, magnesia (AR, Sinopharm Chemical Reagent Co., Ltd. Shanghai, China), alumina (AR (analytical reagent), Xuancheng Jingrui New Material Co., Ltd. Anhui Province, China), and silica (AR, Shenzhen Crystal Materials Chemical Co., Ltd. Guangdong Province, China), were blended together to obtain ceramic suspensions and were ball milled for 12 h with ZrO2 balls (10 mm), 2.0 wt% ammonium polyacrylate salt (Adamas Reagent Co., Ltd.), 0.5 wt% PVA (AR, Adamas Reagent Co., Ltd.) and different addition of mullite fibers (Beijing Chemical Works). Afterward, 2.0 wt% propyl gallate (C10H12O5) (AR, Adamas Reagent Co., Ltd.) was dissolved in ethanol (AR, Beijing Chemical Works) and added to suspended particles, until arriving an in situ modified state [21]. Then, octane (200 vol%, AR, Beijing Chemical Works) was added to the suspension, followed by the emulsification process under continuous stirring by an electric mixer (HR1613, Philips) at full speed for 5 min. Finally, all the emulsions were transferred to culture vessels (2 cm in height and 9 cm in diameter) and dried at room temperature. After oil and water evaporate, the dried samples were shaped. Finally, the samples were sintered at different temperatures for 2 h. The morphology was observed by scanning electron microscopy (SEM, S4800, Hitachi, Japan). The pore size distribution of the samples was evaluated by mercury intrusion porosimeter (PoreMasterGT60, Quantachrome).

Results and Discussion

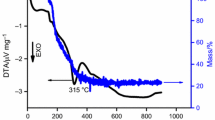

The energy band theory is a major theoretical basis for studying microscopic motion. It is based on the viewpoint of quantum mechanics, so that individual electrons in a solid are no longer bound to individual atoms, but move throughout the whole solid. Although the single electron theory is an approximation theory, its actual development proves that it has become the basis for accurately summarizing the laws of electron motion in some important fields. The band theory divides crystals into metals, semiconductors, and insulators according to electrical properties. It not only explains the conductive properties of the crystal but also explains the optical, magnetic. and thermal properties of the crystal. The energy band structure calculated by the first principle can explain the difference between metal, semiconductor, and insulator. When the band gap is 0 eV or very small, the solid is a metal material, and electrons can easily obtain energy at room temperature and transition to rewinding to conduct electricity. When the band gap is greater than 9 eV, it is an insulating material, and it is difficult for electrons to transition to the conduction band, and thus it is impossible to conduct electricity. The semiconductor material has a band gap of 1–3 eV between the conductor and the insulator. As shown in Fig. 1, the cordierite microstructure was closely combined by SiO2, Al2O3 tetrahedron and MgO octahedron, and the gap of the band gap was 4.6875 eV. The band length was a transition, so cordierite had a stable structure. As shown in Fig. 2, it can be seen from the state density analysis that the DOS state had the X-axis symmetry characteristic and belong to the semiconductor or insulator, which further verified the thermal stability of cordierite . It can be seen from Fig. 3 that the microstructure of cordierite was calculated at high temperature, and its microstructure did not change at room temperature and high temperature of 1300 °C, so cordierite had excellent high-temperature resistance.

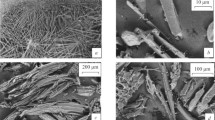

The effect of different solid contents on the morphology of PCCs is shown in Fig. 4. When the solid content was 20%, the particles and particles cannot be bridged together because of fewer solid particles. When the oil phase was removed, the spherical structure collapsed to form an irregular macroporous structure . With the increase of solid content , the pore structure tended to be uniform. When the solid content was 40%, the porous structure with uniform pore size distribution was formed, and PCCs were formed by high temperature sintering. As shown in Fig. 5, the pore wall became thinner after high temperature sintering. Cordierite , as rod-like particles, was arranged on the pore wall after high temperature sintering to form porous structure . The strength of PCCs is mainly determined by the properties of the products. The second impurity phase will not appear by pure oxide as raw materials. Cordierite as the main crystal phase can improve its thermal stability and the mechanical strength.

Conclusions

In this experiment, PCCs were prepared by using an emulsion template method using pure oxide as raw materials. The first-principle calculation was used to construct the cell microstructures to verify its excellent properties. Its stability was verified by band gap. DOS verified its non-conductivity. The thermal stability was verified by the lattice vibration calculation at high temperature. The microstructures and the effects of solid content on mechanical properties were investigated. PCCs with solid content of 40% had the uniform pore structure, which can be used in special industries.

References

Wang S, Ma X-Y, Wang Y-L, Cui S-P, Nie Z-R, Li Q-Y, Wei Q (2019) Preparation and desalination performance of porous planar cordierite membranes using industrial solid waste as main silica source. Ceram Int 45:5932–5940

Hu Y, Xiao Z, Wang HP, Ye C, Wu YQ, Xu SQ (2019) Fabrication and characterization of porous CaSiO3 ceramics. Ceram Int 45:3710–3714

Deng X, Wu Y, Wei T, Ran S, Huang L, Zhang H, Li F, Han L, Ge S, Zhang S (2018) Preparation of elongated mullite self-reinforced porous ceramics. Ceram Int 44:7500–7508

Gao HT, Liu XH, Chen JQ, Qi JL, Wang YB, Ai ZR (2018) Preparation of glass-ceramics with low density and high strength using blast furnace slag, glass fiber and water glass. Ceram Int 44:6044–6053

Qiu L, Zou H, Tang D, Wen D, Feng Y, Zhang X (2018) Inhomogeneity in pore size appreciably lowering thermal conductivity for porous thermal insulators. Appl Therm Eng 130:1004–1011

Sandoval ML, Talou MH, Tomba Martinez AG, Camerucci MA, Gregorová E, Pabst W (2018) Porous cordierite-based ceramics processed by starch consolidation casting–microstructure and high-temperature mechanical behavior. Ceram Int 44:3893–3903

Li Y, Li J, Feng W, Wang X, Nian H (2017) Design and preparation of the phase change materials paraffin/porous Al2O3@graphite foams with enhanced heat storage capacity and thermal conductivity. ACS Sustain Chem Eng 5:7594–7603

Naga SM, Sayed M, Elmaghraby HF, Khalil MS, El-Sayed MA (2017) Fabrication and properties of cordierite/anorthite composites. Ceram Int 43:6024–6028

Shin DS, Kim HG, Ahn HS, Jeong HY, Kim Y-J, Odkhuu D, Tsogbadrakh N, Lee H-B-R, Kim BH (2017) Distribution of oxygen functional groups of graphene oxide obtained from low-temperature atomic layer deposition of titanium oxide. RSC Adv 7:13979–13984

Li J, Ma Y, Wang X, Liu L, Wang C (2017) Highly permeable macroporous cordierite ceramics with controlled microstructure produced by particle-stabilized emulsions with a reactive thermal treatment. J Eur Ceram Soc 37:3203–3211

Pia G, Casnedi L, Sanna U (2016) Porosity and pore size distribution influence on thermal conductivity of yttria-stabilized zirconia: experimental findings and model predictions. Ceram Int 42:5802–5809

Tokizono T, Tsuru Y, Atsumi T, Hosokawa N, Ohnuma T (2016) Theoretical approaches for studying anisotropic negative thermal expansion: a case of cordierite. J Ceram Soc Jpn 124:744–749

Wang F, Yin JW, Yao DX, Xia YF, Zuo KH, Xu JQ, Zeng YP (2016) Fabrication of porous SiC ceramics through a modified gelcasting and solid state sintering. Mater Sci Eng A Struct Mater Prop Microstruct Process 654:292–297

Wang X, Li J-H, Xie Y-M, Zhang H-Y (2016) Three-dimensional fully interconnected highly porous hydroxyapatite scaffolds derived from particle-stabilized emulsions. Ceram Int 42:5455–5460

Zhang RB, Qu Q, Han BY, Wang BL (2016) A novel silica aerogel/porous Y2SiO5 ceramics with low thermal conductivity and enhanced mechanical properties prepared by freeze casting and impregnation. Mater Lett 175:219–222

Baitalik S, Kayal N (2017) Processing and properties of cordierite-silica bonded porous SiC ceramics. Ceram Int 43:14683–14692

Liu T, Tang Y, Li Z, Wu T, Lu A (2016) Red mud and fly ash incorporation for lightweight foamed ceramics using lead-zinc mine tailings as foaming agent. Mater Lett 183:362–364

Lu J, Cong X, Lu Z (2016) Influence of magnesia on sinter-crystallization, phase composition and flexural strength of sintered glass-ceramics from waste materials. Mater Chem Phys 174:143–149

Lu Z, Lu J, Li X, Shao G (2016) Effect of MgO addition on sinterability, crystallization kinetics, and flexural strength of glass–ceramics from waste materials. Ceram Int 42:3452–3459

Ma N, Du LJ, Liu WT, Zhang XY, Huo WL, Qu YN, Gan K, Wang YL, Yang JL (2016) Preparation of porous Si3N4 ceramics with unidirectionally aligned channels. Ceram Int 42:9145–9151

Gonzenbach ARSUT, Tervoort E, Gauckler LJ (2006) Ultrastable particle-stabilized foams. Angew Chem 118:3606–3610

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. U1607113 and U1803116), Program of Qinghai Science and Technology Department (Grant No. 2017-HZ-8058).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Luan, X., Huang, K., Zhao, S., Li, J. (2020). Porous Cordierite Prepared by Emulsion Template Method Based on the First-Principles Calculation. In: Li, B., et al. Advances in Powder and Ceramic Materials Science. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36552-3_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-36552-3_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36551-6

Online ISBN: 978-3-030-36552-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)