Abstract

As of today, about 70% of the transportation infrastructure has already built for the needs of customers, business and society, where Railways is the major infrastructure. Due to huge investment for renewal and overhaul, there is emergent need to maintain the infrastructure with high availability with minimum cost and risk, being, transportation is the backbone of the economy. These infrastructures normally lead to degradation due to operational loads, environmental factors and frequent interventions. Hence, planning and optimization of the maintenance actions with the constrained resources is implemented properly for the efficient operation. Due to the hierarchical nature of Railways, there is necessary for railway infrastructure managers to design a generic framework for the decision-making process when planning maintenance and interventions, which is an important functional block of asset management in railway infrastructures. This chapter proposes an integrated methodology to perform maintenance decision making using definitive “building blocks” namely Reliability, Availability, Maintainability and Safety (RAMS), Life Cycle Costing (LCC) and Risk assessment. It has to incorporates the “building blocks” at different planning levels in asset hierarchy; namely network, route, line and component and planning hierarchy; namely Strategic Asset Management Plan (SAMP), Route Asset Plan (RAP), Route Delivery Plan (RDP) and Implementation of Asset Maintenance Plan (IAMP) as proposed in IN2SMART which was renamed from ISO 55000 Asset Management Framework.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Of all the transportation systems, railways are one of the most prioritized infrastructures due to its increase in reliance of customers and cargo over a period. Due to frequent loading of trains, environmental conditions, changing environment, inefficient operation, material degradation, the systems and components in the Railway infrastructure deteriorate over a period. To maintain the demands of the society and improve the performance and utilization of trains, there is a necessity of maintenance actions and process that needs to be performed on corrective or preventive basis. If the infrastructure degrades in such a way that any maintenance action doesn’t make enough improvement, then infrastructure managers (IM) proposes to renewal or overhaul. In addition to these two main maintenance strategies, there are a combination of several maintenance strategies that are implemented to increase the availability and safety of the railway infrastructure. These collection of failures and maintenance actions that have effect on availability and safety constitute Reliability, Availability, Maintainability and Safety (RAMS). Each of these maintenance actions incur direct and indirect costs and the total cost shouldn’t be more the prescribed budget. Hence, there is necessary to conduct life cycle costing (or analysis) (LCC) of the railway infrastructure during various phases of life cycle such as design, manufacturing, installation, operation, maintenance and disposal [50]. Although some studies considered RAMS and LCC separately (see e.g. [62, 67, 71]), still there is a need for an integrated approach for RAMS and LCC for railway industry [44]. If the maintenance actions are performed beyond a certain number of failures or reaching threshold for degrading components, then these actions will have higher consequences that could lead to higher risk.

To calculate RAMS, LCC and risk parameters, IMs are required to store different kinds of databases for monitoring and measurement of several infrastructure elements. Due to the centralized or decentralized system of different IMs in the World, these databases are stored in different locations with different partners which are quite disparate in nature [20]. For some assets, RAMS calculation is a straightforward calculation based on frequency of failure and maintenance actions. But due to the advancements of technologies such as condition-based maintenance [69], predictive maintenance and Maintenance 4.0 [31], IMs are interested more in degradation behaviour of the critical assets. In that case, RAMS need to be calculated considering the degradation behaviour, prediction of future condition and estimating the remaining useful life with different threshold limits. Traditionally, there are few methods are used to estimate RAMS parameters in this context, such as Markov modelling [7, 9], Petri-net approach [56], Particle Filter [46] and Bayesian approaches [37]. Due to the existence of different database storages, there will be a lot of challenges to calculate RAMS parameters such as delay in processing of data, localization, contractual limitations, data cleaning etc. Hence, IMs need to adopt a comprehensive architecture to store or structure the existing data to improve the monitor RAMS performance of railways.

Railway infrastructure constitute of different systems (of systems), subsystems, components and items that exit in the hierarchical nature with dependability on its operational functions. There is a variation of degree of functional and degradation of the components that will have an influence on the quality and performance of the infrastructure. To maintain the quality of the infrastructure, there is a need for measurement (or opportunistic inspection) of these components at specific times [21]. The quality will be quantified by several indicators, or key performance indicators (KPIs) such as service reliability, availability, cost-effectiveness, infrastructure safety, etc. [13]. As an IM, he/she is more interested to maintain these indicators within the prescribed or allocated budget constraints as recorded in their capital expenditure (CAPEX) and operational expenditure (OPEX). They are also constrained with number of resources available at their expense, such as human and machines for measurement and maintenance. In addition, as a responsibility of infrastructure, IMs tends to maintain the infrastructure in such a way that could lead to a smaller number of accidents, disruptions, CO2 emissions according to government guidelines. Hence, there is a necessity for optimization of the maintenance activities in terms of cost effectiveness, RAMS and risk assessment. Although some studies and EU projects proposed RAMS, LCC and Risk assessment in different “building blocks” [30, 39, 42], there are only few studies that implement an integrated approach for all these building blocks for improving the performance of Railways.

To optimize RAMS, LCC and Risk, there is necessary to implement maintenance planning and scheduling of maintenance actions to obtain preferred KPIs [35, 65]. Traditionally, planning can be implemented at three main stages; strategic, tactical and operational planning. Intelligent Innovative Smart Maintenance of Assets by integRated Technologies (IN2SMART), an EU project, proposes four main maintenance planning schemas, mainly, strategic asset management plan (SAMP), route asset plan (RAP), route delivery plan (RDP) and implementation of asset maintenance plan (IAMP) based on ISO 55000 framework [27]. Maintenance planning and decision making also need to be performed based on context with detection and prediction of assets for estimation of RAMS [64, 63]. These planning schemas differ in time horizon and selection of asset in hierarchical structure of infrastructure [36]. There is still a lot that needs to be done in the context of planning hierarchy and asset hierarchy within the asset management framework on how to plan for the assets and how all assets interdependent on the planning and asset hierarchy. In addition, there is also a lot of scope on how RAMS will be defined at each planning schema. To implement maintenance planning, several combinations of strategies to be selected based on extraction of RAMS parameters and the best alternative strategies will be selected based on optimization algorithms. Within this context, this book chapter proposes an integrated RAMS, LCC and Risk assessment methodology for the maintenance planning of Railway infrastructure within the context of asset and planning hierarchy.

This chapter starts by introducing the basics of RAMS, LCC and Risk assessment building blocks in Sect. 2. Section 3 briefs about different maintenance planning levels incorporated in Railways in accordance with IN2SMART (EU) project. Next Sect. 4 describes different types of databases exist in Railways. Section 5 provides a summary of the existing methodologies of RAMS and LCC in other European Union (EU) projects based on RAMS, LCC and Risk Assessment and further highlighted the importance of selection of maintenance planning at asset level or planning level. Section 6 proposed a novel methodology for an integrated RAMS, LCC and Risk assessment for maintenance and intervention planning to optimize the performance.

2 Introduction to RAMS, LCC and Risk Assessment

RAMS, LCC and Risk assessment are often used as optimization targets in the strategic maintenance planning for entire networks or subnets. At this level, they are one of the key decision-criteria for investments and maintenance strategies.

While RAMS describe the technical performance of an asset (system, module, component), LCC deals with the economic performance and Risk assessment deals with the consequences of actions. There are strong relationships and dependencies between RAMS, LCC and Risk assessment.

2.1 Definition of RAMS

RAMS of a system can be characterised as a qualitative and quantitative indicator of the degree that the system, or the sub-systems and components comprising that system, can be relied upon to function as specified and to be both available and safe [6].

RAMS according to EN 50126 is an abbreviation describing a combination of Reliability (R), Availability (A), Maintainability (M) and Safety (S):

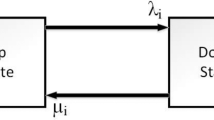

Reliability is defined as “the probability that an item can perform a required function under given conditions for a given time interval”.

Availability: “the availability of an object being in a condition in order to fulfil a required function under given terms and given period or during an alleged span of time provided that the required auxiliary materials/external tools are available”.

Maintainability: “the feasibility that a certain maintenance measure could be executed for a component under existing boundary conditions within a defined span of time, if the maintenance will be made under defined conditions and defined process and auxiliary materials will be used”.

Safety: “the non-existence of an unacceptable damage risk. With respect to safety the common safety method has to be taken into account”.

Typical key parameters and risk related analyses are summarized in Fig. 1.

2.2 Definition of LCC

The following explanations are based on the work done in INNOTRACK. A more detailed description can be found in the “Guideline for LCC and RAMS analysis” [26].

A life cycle cost analysis calculates the cost of a system, asset or component over its entire life span. The method is one of the most recommended for investment projects, assessment of different solutions over the whole life cycle and comparison of various strategies.

LCC phases are:

-

Concept and definition,

-

design and development,

-

production,

-

installation,

-

operation and maintenance and

-

disposal.

For a LCCA a system description and a cost structure are necessary shows the life cycle phases according EN 60300 and the related “headers” in the cost matrix shown in Fig. 2. Life cycle cost analysis (LCCA) is a layered method to assess all incurred costs within the technical life cycle of the system. In general, the main phases of a life cycle of the system are design and development, manufacturing, installation, operation and maintenance and disposal phases.

2.3 Definition of Risk Assessment

Risk is usually described by certain expected or unexpected events with subsequent consequences [54]. The outcome of the risk is either positive or negative that can be measured by its associate likelihood or occurrence of those events with respective consequences. Risk can be a quantitatively defined as product of frequency of events (occurrence) and respective consequences. Risk can be defined from different perspectives; financial, business, environmental, social, etc.

In Railways, the risk needs to be contained based on condition of the asset and respective type of maintenance action has to be taken. Hence, risk management aims to maintaining the control over uncertainty with reduced negative outcomes with proper treatment on the assets, for example maintenance actions. The three main steps in the risk management process are identification, analysis and evaluation of risks. For the informed decision making, one must consider the several possible events with their respective causes, consequences and probabilities of risk to take necessary action to reduce the overall risk of the asset [45] (see Fig. 3).

The first step in the risk management is the Risk identification that aims to generate a thorough list of risks based on events that will impact the condition of the assets. For each risk event, there is need to collect possible causes and sources that can potentially impact the performance of the system [54]. In the context of the conditional data, several failure events and its possible combination of precursors, drivers, failure modes and failure effects are identified.

The second step is the risk analysis that aims to develop either qualitative or quantitative approach to analyse the impact of the identified risks that might affect the performance of the asset [47]. This step involves the calculation of several risk events with their respective frequency (probability of occurrence) and its level of consequences on the system. In some cases, the probability of detection of specific failure modes are also considered.

The next step in the risk management framework is the risk evaluation. This step is used to calculate the level of significance of each type of risk. If the overall risk is evaluated against the risk criteria, then this process is called risk assessment. The risk criteria will be determined by the legal and regulatory authorities. This step also signifies in establishing the main criteria for decision making w.r.t to their treatment and prioritization of tasks [28].

Risk assessment and management is a crucial task for many parties and agents like asset owners, maintainer or operators [48]. Although the terms safety and risk sometimes seem to be interchangeably, they refer to two separate aspects of system conditions. However, the task of Safety Management and Risk Management are not independent. Where Safety refers to a current condition Risk refers to the likelihood of maltreatment occurring in the future. Risk could be expressed by the severity of harm multiplied with the probability of the occurrence of harm.

3 Maintenance Planning in Railways

The main goals of IM of railways is to make sure that the assets are operating at maximum availability with minimum amount of effort. The effort here, signifies about budget, human resources, possession time and machine resources. Due to the several actions taking place on the assets, such as operation, inspection and maintenance, there is a necessary to implement maintenance planning. The maintenance process is a complex decision-making process in the asset management framework that able to achieve the required goals of IM. In practice, not a single model cannot able to achieve the asset requirements. Instead, several models in conjuncture with each other are required to achieve the prescribed key performance indicators (KPI). In addition, the planning can be segregated into several planning levels that are well defined with time horizon, decision variables, constraints, asset level and restrictions that will be imposed based on objectives.

In general, these planning levels are defined as; strategic, tactical and operational planning. Mostly, the main parameter that distinguishes among these planning levels is time horizon. In addition, these time horizons also varies with each stakeholder, infrastructure manager and application that depends on objective. The definitions of these planning levels are as follows [36].

-

Strategic planning is defined at the decisions that mainly influence the maintenance management at the top-level with long-term horizon. The scope of the strategic planning mainly focuses at the systematic level and planning of long-term policies or methods that need to be implemented against KPIs. The planning process involves the selection of maintenance strategies for maintenance possession, allocation of the budget, improvement of the capacity and defining contractual agreements [2].

-

Tactical planning is defined at the network level that involves more concrete specifications of the maintenance activities to be performed with predefined specific objectives within short-term horizon [3]. A simple example of tactical planning is the planning of maintenance actions within traffic management system with specific possession times on the field.

-

Operational (or dynamic) planning is defined at the on-field which has more concrete description of maintenance optimization with maintenance activities, maintenance scheduling of man and human resources. This planning level focuses on day-to-day planning of the maintenance activities. Online information and processing of the existing maintenance schedules with new maintenance optimization of the schedules is crucial [55].

The following subsections provide Intelligent Asset Management framework introduced by D2.1 of IN2SMART [11] as shown in Fig. 4.

3.1 Strategic Asset Management Plan (SAMP)

Existing optimization articles are aimed at supporting:

-

Design choices, e.g. unballasted versus ballasted track, wood/concrete S&C. The main objective is to ensure that maintenance issues and constraints are considered during the design phase [17].

-

Significant maintenance policies and contracts, such as grinding and tamping [16]. These optimization studies are aimed at:

-

Testing and/or identifying different maintenance organisations in order to select the most efficient.

-

Supporting technical decision making, e.g. operational parameters, planning constraints and time tolerances.

-

-

Renewal policies regarding specific components, such as signalling components and track equipment.

These articles mainly focused on track assets and maintenance processes and only a few discussed about other technical domains. Some multi-objective analyses have also been performed in order to support Asset Management decision making, based on both performance and costs objective functions.

3.2 Tactical and Route Asset Management Plan (RAMP)

The tactical Asset Management mainly focuses on the following points.

-

Supporting investment decision making and, more precisely, the choice of the best renewal configuration (complete/partial/no track renewal). In this case, OPEX-CAPEX studies are used to analyse the profitability of the options considered.

-

Renewal projects, scheduling and planning. Projects are usually included into programs and/or CAPEX trajectories, which are decided and dimensioned at the strategic level. The main issue here is to support allocating budgets and resources over time and assets groups.

In summary, the main objective at this level relates to the prioritisation of asset renewal, subject to strategic decisions.

3.3 Implementation of the Asset Management Plan (IAMP)

The last level of optimization studies focuses on operational planning and resources management. Providing optimization methods for this specific scope is particularly challenging, as it is necessary to integrate realistic operating conditions while there is a huge increase in the number of factors to be integrated, as this level is closer to the specifics of each elementary component.

There are two main topics discussed in literature:

-

Maintenance planning and specific operation scheduling. Based on concept of condition-based maintenance operation

-

Resources scheduling such as track possessions, budget or maintenance teams. Optimising inspections agenda based on journey times between assets, supporting asset prioritisation based on risks of failure and other indicators.

3.4 Interactions Among Planning Levels

Figure 5 also provides a summary of the inputs that are repeated in the various levels, along with the possible models applied at each stage. From the Figure, the definition of RAMS parameters varies with the planning schema and they are interrelated from one planning level to another planning level.

However, not much has been specified regarding the feedback among different stages of planning levels, i.e. about the information going from the lower levels of planning to the higher levels of planning. These connections will be briefly presented in this section. The information coming from the Route Asset Plan stage to the Strategic Asset Management Plan stage can be summarised in these two points.

-

First, changes will be triggered in the overall strategy and policies. The aim will be to satisfy the needs at a lower level, for instance, at route level.

-

Hence, there will be an adaptation of restrictions such as budget depending on these needs.

The two stages in the Asset Management Plan also have a strong connection, as the planning becomes closer to the asset and the particularities of the different areas of the infrastructure.

-

The RDP must adapt the provisional plan to satisfy external factors and further demands.

-

Therefore, the amount of possessions might vary to adapt to these changes, which is a key issue in the tender phase.

Finally, there will be a strong feedback interaction from the Implementation of the Asset Management Plan to the Route Delivery Plan.

-

Unscheduled events would trigger changes in the execution scheme coming from the RDP, which would also affect the preparation of work and the operation of the network.

-

The adaptation to faults and unexpected events could also induce changes in the budget and resources required, which might encourage a change in the strategy to be followed from that point onwards.

4 Architecture of Failure and Cost Database

From the experiences gained from IN2SMART Research and Innovation (R&I) activities, a generic architecture of failure and cost database must be constructed. The following are the challenges faced to extract RAMS parameters from databases of each IMs are as follows:

-

There are different database source sources that will store the asset data depends on the type of data such as failure, maintenance, inspection, traffic, measurement, registry, weather database etc.

-

The information of a single asset needs to be extracted from all the above database sources that will need to be conducted for techniques such as pre-processing, data alignment, data cleaning and data mining

-

This data is often accessed and retrieved by not only personnel in their own organization but also from other multiple stakeholders

-

Data is stored in different formats and there is a need to standardize and harmonize the data to conduct RAMS and LCC analysis

-

There are some direct RAMS parameters from these database sources such as time to failure, time to carry out maintenance, number of failures, etc.

-

There is need for indirect way to extract RAMS parameters such as time to reach maintenance limit, availability, safety indicators, number of preventive maintenance actions etc.

-

Collection of cost database is a huge issue that needs to be sorted out by individual IMs. Though some IMs are organized the cost database, there is still a standard type of method is necessary to collect and store the data

-

The indicators of safety and risk are often qualitative or quantitative depends on the objectives of the use case.

A generic architecture of failure and cost database is developed from the lessons learned from R&I activities is shown in Fig. 6. The description of the architecture is as follows.

Each of IMs are several basic databases sources as listed in blue boxes such as Failure data, maintenance data, measurement data, condition data, inspection data and traffic data. There are two types of parameters as discussed above; direct and indirect parameters. These databases incur respective costs as shown in green boxes. Respectively, these databases incur respective costs such as cost of failures, cost of maintenance, cost of measurement, cost of inspection and cost of traffic delays. These extractions of costs are divided into two types; direct and indirect costs. The indirect costs are mainly due to unexpected costs in addition to the above costs such as overhead costs, procurement costs and consequence costs. These costs may vary depending on organization to organization and country to country. In addition, Asset register and weather database are generic database sources that does not incur costs. This vast amount of database requires data standardization and harmonization to get better benefits from the integrated RAMS, LCC and Risk methodology.

4.1 Guidelines for Future Data Standardization

There is a need for harmonization of the data for the railway to accomplish the main objective of UIC, International Union of Railways acting upon the SSO (Standards Setting Organisation) with leaflets [66]. It comprises of several railways that aims to achieve common rules for ensuring data for design, construction, operation, safety, security and maintenance of the railway system. Several deliverables consist of the activities that will facilitate uniform data standardization.

In that aspect, to provide attractive modes of transport for customer, there is necessary to make a technical harmonization and compatibility in terms of [58]:

-

Compatibility among infrastructure, rolling stock and different stakeholders

-

Compatibility among traction units

-

Compatibility among different units of railways; traffic management systems, traffic signalling, operation and maintenance and management.

Hence, it is necessary to follow standardized rules based on technical harmonization of the data to ensure safe and reliable transport. The harmonization must be followed not only within a single organization but also among several organizations.

With the above background, it will be beneficial for carrying out RAMS analysis with the implementation of standard practices, compatibility and harmonization of the data. The business objectives can be achieved including the individual goals of the units into consideration to apply RAMS, LCC and Risk assessment with obtained uniformed data [68].

The accuracy of the implementation of integrated methodology depends on the quality of the collected data. In addition, there is also a lot of need for pre-processing of the data and this might influence the prediction accuracy of the methodology. In order to reduce these impacts, the standardization of failure, maintenance and conditional databases is required to perform an efficient analysis [59]. The advantage of the data harmonization is that more simpler models can be performed with better accuracy being harmonization will reduce the uncertainty issues in the database. Complex models can have significant impact on the maintenance planning but the development of these models will induce additional cost and time for IMs to implement in the demonstrators [59, 66].

In addition to asset failures, there are secondary failures induces into the system that also needs to be collected such as [59, 66]:

-

Failures induced by software

-

Failures induced due to human factors

-

Failures induced due to uncontrollable factors such as environmental

-

Failures induced due to common cause failures

-

Data corrupted due to security issues.

The existing reliability and maintenance data often do not consider the data from the above factors and assume this data is a random failure that could reflect the uncertainty of the data there by predictions. Hence, there is a necessary to incorporate standardized data encapsulation and harmonization methods to acquire data and store in an organized way. This will further helpful in improving the Architecture of failure and cost database.

Several factors that will influence RAMS as shown in Fig. 7, which are common and can be considered on various industrial applications. Precisely, not every lack of information poses a serious issue to perform RAMS analysis and care should be taken to prioritize those parameters according to the specific objectives of the business, i.e., planning level, asset level and organization level [4]. Markeset and Kumar [43] defined some of the factors influencing the management of RAMS data.

5 Methodology for RAMS and LCC

The main objective of this section is to provide an integrated methodology for RAMS and LCC for the maintenance planning.

5.1 Railway Asset Hierarchy

The hierarchical representation of railway infrastructure is shown in Fig. 5. Railway system comprises of complex system that are interconnected, interrelated and integrated together to perform the goals of the organization. Each block either system/subsystem/component/item has specific RAMS parameters or indicators. If RAMS analysis is performed from top-down approach, the output of RAMS analysis conducted at system level are considered as RAMS indicators at the subsystem level. Similarly, if RAMS analysis is performed from bottom-up approach, the RAMS analysis conducted at component level has indicators from subsystem level. The interesting aspect in this hierarchical nature of railway infrastructure is that the railway system is so complex such that predefined RAMS parameters/indicators cannot be extracted until there is a clear definition of objectives, planning level and requirements is known. Traditionally, railway IMs adopt hierarchical planning process according to the network; strategic, tactical, operational and/or short-term planning [22, 38]. It is also important to note that these RAMS parameters also change depends on the chosen asset. There exists a complex relation to even RAMS parameters among different hierarchical levels of the railway infrastructure [65].

The other way of looking into asset hierarchy will be based on whole railway network perspective that is shown in Fig. 8. Using a conventional top-down approach, the whole railway network can be broken down into operational routes where operation routes represents different areas of network. Each route further decomposes into several lines conventionally these lines are named between two important stations. Furthermore, these lines are further divided into track segments. Conventionally, each track segment is of 200 m or type of asset. As mentioned above, the RAMS targets/indicators are performed at network level and these parameters further expanded to the bottom levels.

Hierarchical representation of railway infrastructure [25]

Based on a hierarchical representation of the railway network, a framework for modelling railway infrastructure is presented by Rama and Andrews [56]. This framework is applicable for conducting RAMS analysis at various levels from individual item to large multi-asset networks. The hierarchical models are used as building blocks for infrastructure models with varying degrees of complexity. The data and information gathered on asset degradation, infrastructure utilisation levels, and intervention strategies are used to determine RAMS parameters.

Figure 9 shows the modified conceptual structure of the model [19]. Several degradation models/maintenance models/LCC models are developed using existing failure records, maintenance records or any other measurements data with associated costs databases. These modelling will be performed at the abstract level with comprehensive network and system details to obtain a system state model. The system state models can be any systems whether electrical system or track system. The system performance will be predicted based on KPIs defined in the asset management strategy [35].

Macchi et al. [41] implemented family-based approach (clusters which has common features) and emphasized that there must be a relation between RAMS parameters and the train service. The two-step methodology (building families of similar items and building a railway model) incorporates the reliability targets that can be homogenous by infrastructure managers, as seen in Fig. 10. Using system RAMS analysis, the second step defines failure consequences on service levels expected from the train’s circulation.

5.2 Asset Hierarchy Versus Planning Hierarchy

One of the main requirements for asset management perspective is to develop a generic methodology for RAMS, LCC and Risk assessment. However, the definition of the RAMS and cost parameters differs w.r.t asset hierarchy or planning hierarchy. For instance, the maintenance planning hierarchy is associated with asset hierarchy as shown in the Fig. 11. There is always a connection with maintenance optimization between railway assets and planning levels as shown in Fig. 12. The most presumptuous approximation for defining RAMS parameters are

-

Setting RAMS targets for network at SAMP planning level

-

Implementing RAMS optimization at RAP planning level

-

Conducting optimization of resources at RDP and IAMP planning level.

However, this will not always be right in most cases. Because the main issues that, hinder to this reasoning are:

-

often that the selection of asset and planning level depends on the business objectives which are sometimes at crossways

-

the asset management framework developed in the railway organization is not always makes important to the technical details at the IAMP level

-

the definition of asset varies with organization to organization because of their priority/criticality of the assets

-

segregation of defining planning levels from different divisions within the railway organization

-

due to involvement of multiple stakeholders and it is difficult to access resources and assets

-

understanding of RAMS parameters at different levels. Each asset level defines RAMS parameters differently and often they won’t interact together. For instance, at the SAMP level, most of the IMs are interested in availability of the asset but much focus on reliability. At the RAP/RDP level, it is a combination of different RAMS parameters. At the IAMP level, it is mostly about supportability and logistics of the resources.

Due to the above issues, it will not be practical per perceive that the RAMS & LCC methodology can be too strict to the definition of asset hierarchy and planning hierarchy. Hence, care should be considered in defining the assets and planning levels to understand and extract relevant RAMS parameters.

5.3 Methodologies from Previous Projects

This subsection briefly describes the aims and objectives of past and present, EU framework projects and the relevant assessment methodologies used within their respective projects. The main importance of this section is to provide an extended list of efforts to put the concept of RAMS, LCC and sometimes Risk on previous projects and their applications in Railway sector.

5.3.1 INNOTRACK

The main objective of INNOTRACK [15] was to reduce maintenance and infrastructure costs by 30%, by the application and implementation of existing innovative infrastructure for optimising maintenance and inspection [26]. Each parameter in RAMS incurs respective costs and technical specifications reflects economic specifications. It was highlighted that main driver for RAMS analysis is to conduct LCC analysis and cost/benefit analysis for optimising the maintenance. The project also provided several guidelines to conduct RAMS approach and include LCC analysis by using various methods such as present value, sensitivity analysis and Monte Carlo probabilistic approaches.

5.3.2 D-Rail

The main objective of D-Rail was to identify the root causes of freight traffic derailments [10]. The project identified the relation among reliability, availability and supportability parameters and maintainability for several scenarios for setting up RAMS targets as. Each of these scenarios incur several costs that was attributed to it such as preventive maintenance (PM) cost, corrective maintenance (CM) cost, logistics costs, ownership costs, energy costs, etc.

5.3.3 SUSTRAIL

In SUSTRAIL, the dependability parameters were considered to perform RAMS and LCC analysis for a wagon [57]. Within the dependability of the systems, the availability was a combination of reliability, maintainability and maintenance support. Each of these indicators were extracted from parameters like failures, repairs, preventative maintenance and logistical support respectively. In this project, the costs were clearly segregated based on specific parameters. For example, the logistical support was part of the investment cost; preventative maintenance and material cost for preventive maintenance cost; failure and repairs for corrective maintenance cost and other indirect costs for consequences cost.

This methodology will be further revisited in the next subsections because it has laid a significant contribution that relates to the asset hierarchy and planning hierarchy. In a way, the top down approach highlighted can be replicated to the methodology. Means that the methodology developed can be naively perceived as

-

availability can be considered at the network level on SAMP planning

-

reliability, maintainability and maintenance support at the route on RAP planning

-

failure, repairs and other maintenance actions at the line on RDP planning

-

and corrective and consequences at the track segment on IAMP planning.

5.3.4 Automain

Automain provided a relation in planning hierarchy where the objectives come from the network to the implementation of the work [1]. RAMS (Reliability, Availability, Maintainability and Safety) and LCC (Life Cycle Cost) methodology were acknowledged as the two main methods for supporting the optimization process. It was highlighted that the Key Performance Indicators (KPIs) and categories of performance killers/drivers for RAMS and LCC need to be identified, developed and transformed. These KPIs and audits were part of the reviewing mechanisms to ensure the railway system operates w.r.t required performance.

5.3.5 MAINLINE

The main aim of MAINLINE project was to develop methods and tools that contribute to cost efficient and effective improvement of European railway infrastructure based on whole life cycle [40]. The Life Cycle Assessment Tool LCAT that was being developed in MAINLINE covers main assets such as bridges, tunnels, track, cuttings and retaining walls. The LCAT discourses on the asset condition and respective planning of future interventions by considering

-

(a)

maintenance and replacement strategies of the assets,

-

(b)

lifecycle performance of the assets and

-

(c)

conditional indicators from measurements.

The LCA results (related to CO2 and waste) was given as an input to LCC analysis with the financial objectives.

5.3.6 ON-TIME

The main aim of the ON-TIME project is ‘to improve railway customer satisfaction through increased capacity and decreased delays for passengers and freight’ (ON-TIME). Infrastructure planning, timetabling and operations, a general high-level measure of ‘Quality of Service’ (QoS) was incorporated in this project. The top factors show the key performance indicators (KPI) for QoS and the associated quantitative key measures and the bottom factors shows the static and dynamic factors that influence the QoS.

From the experiences from the previous project, it was clearly understood there is strong relation among RAMS, LCC and Risk parameters of the assets defined at asset hierarchy. The projects Innotrack and Sustrail highlighted the mainly on maintenance decisions based on RAMS and LCC. However, the generic methodology is not developed for implementing the maintenance planning at different planning levels. It is further discussed within R&I activities such that a generic methodology cannot be implemented for all planning levels at a once as it will too complex to perceive RAMS parameters at individual level and relation among them. The similar projects and standards for reliability and maintainability parameters with LCC can be found in [5].

6 Maintenance Decisions Based on RAMS, LCC and Risk

The previous section discusses on RAMS & LCC methodology in several existing projects. In order to improve the availability of the railway system with reduced overall cost and risk, there is a need to implement maintenance optimization process at several planning levels. The maintenance decisions can make use of building blocks of RAMS & LCC analysis including additional building block of risk analysis. The modified maintenance decisions can be made starting with business requirements as shown in Fig. 13 [50]. Business requirements define RAMS targets to achieve the goal of overall aim and vision of the railway organization. For optimizing the existing resources, there is necessary to include several strategies that can facilitate the better maintenance decision making. This further helps to define their maintenance budgets and contracts in short term and long term. RAMS, LCC and Risk methodology will facilitate these maintenance decisions. A single maintenance strategy consists of different decision variables or combination of several maintenance actions based on specific objectives and requirements. The above requirements can be defined in several maintenance strategies as M1, M2 and M3. From the previous projects, it is clearly highlighted LCC calculations plays a major role in defining the maintenance decision making. Hence, each maintenance incurs LCC costs as LCC1, LCC2 and LCC3. By including risk factors into the decision-making process, these strategies have individual risks as R1, R2 and R3. Now, a specific maintenance strategy(strategies) are to be selected based on higher performance with lower LCC cost and lower Risk.

Cost-effectiveness analysis produces quantitative results to assist the decision support system with risk analysis. Table 1 shows the calculation of cost-effectiveness from the LCC values of different maintenance strategies. When taking an optimized decision on maintenance strategy, it is necessary to measure the cost-effectiveness of different maintenance strategies. The best maintenance strategy can be selected which highest cost-effectiveness.

Figure 14 illustrates the modified relationship among maintenance management, asset performance and asset maintenance [39]. The asset management of the railway system consists of an integrated RAMS, LCC and Risk management that derives the asset performance. This performance depends on the optimized combination of maintenance strategies consists of asset maintenance. Asset maintenance management affects activities varying from minimal maintenance actions to the higher maintenance and also ranges from short-term to long-term.

6.1 Integrated RAMS, LCC and Risk Assessment

The following conclusions are drawn from experience from previous EU projects:

-

Most of the developed methodologies consistently dictates that there is a cohesive relationship between RAMS parameters and cost parameters

-

The methodologies were not applied to the maintenance planning

-

Only few methodologies directly/indirectly identify risk as a defining parameter, but it was explicitly mentioned in their methodologies

-

In addition, specific maintenance scenarios were not discussed though optimization is pointed out

-

The bridge between RAMS and LCC and the hierarchical nature of railway assets and different maintenance planning levels were not clearly defined in the methodologies

-

It was identified that LCC is an important building block for implementation of maintenance planning

-

It is discussed such that these building blocks are more important for the strategic and tactical planning levels. But at the implementation level, these parameters can be considered indirectly because in day-to-day or week-to-week operations, mainly supportability and reducing risk are the highest priority

-

It is also discussed that RAMS acts as leading indicators for strategic level and as lagging indicators for tactical planning

-

The definition of RAMS and LCC parameters itself changes on asset and planning hierarchy.

Hence, to fill the gaps, there is a need to develop an integrated RAMS, LCC and Risk Assessment methodology is developed involving individual building blocks.

6.2 Generic Framework

This section provides a bridge between the developed generic framework and the building blocks. As part of IAMS asset management and decision support system, a generic framework is developed from maintenance and intervention planning in [24], which is shown in Fig. 15. The main building blocks in this framework are:

-

Architecture of failure database, i.e., data required to define RAMS

-

Architecture of cost database

-

Modelling structure to extract RAMS KPIs

-

RAMS, Costs and Risk Analysis blocks

-

Optimization of the parameters to obtain optimum maintenance and intervention plan.

Each of the building blocks are connected to develop an integrated RAMS, LCC and Risk methodology.

6.3 Proposed Methodology

From the experience from the previous projects and IN2SMART R&I activities, there are some major gaps on facilitating the RAMS and LCC methodology for maintenance planning. Therefore, the main novel contributions of this Deliverable are highlighted in the following points;

-

1.

Development of a generalized architecture of failure and cost database with further requirement of data harmonization from additional sources

-

2.

Development of an integrated RAMS, LCC and Risk assessment methodology

-

3.

Implementation of the developed methodology for maintenance planning

-

4.

Emphasised the importance of maintenance planning between asset hierarchy and planning hierarchy.

Based on the discussions with partners and infrastructure managers in specific, Fig. 16 illustrates the generic integrated RAMS, LCC and Risk assessment methodology for maintenance planning. There are eight building blocks to implement the maintenance planning and those building blocks are explained below.

Business/technical requirements of railway infrastructure: For every railway organization, to operate different assets as per the operational requirements, there is necessary to define the RAMS targets. These targets are defined from both RAMS specifications and RAMS constraints as per the existing asset infrastructure. These specifications will include required asset availability, maintenance capabilities and safety regulations down to asset level [33]. The constraints will include budgetary requirements, available resources and limitations of the risk. RAMS targets often reflect the Key Performance Indicators (KPIs) of the organization [52].

Architecture of RAMS and LCC database: Each IM has its own architecture for failure and cost database. The main objective is to collect failures, inspections, interventions, measurements and associated costs from different databases of their own IM. The International Union of Railways (UIC) also developed universal infrastructure data exchange format called RailTopo Model and RailML [8].

Extraction of RAMS parameters: There are specific parameters that exactly reflects the RAMS parameters. These parameters include time to failure, time to repair, number of accidents etc. Sometimes, there is a need to extract RAMS parameters from the conditional database. Furthermore, using specific thresholds on condition assessment, several RAMS parameters can be extracted. For instance, time to reach alert, time to reach maintenance, time to reach normal failure and time to reach acute failure [34, 42].

Estimation of RAMS parameters: After extraction of parameters, respective RAMS parameters are estimated depends on the RAMS targets defined in step 1. These parameters can be segregated into reliability, maintainability, availability and safety. Sometimes, there can be more terms associated with RAMS such as supportability, detectability and reparability [32]. The definition of these parameters will change according to the selection of planning schema at asset level or planning level [36].

RAMS analysis for different maintenance strategies: Several strategies (or alternatives or scenarios) needs to define based on decision variables for maintenance planning. The selection of number of strategies can be lower or higher depends on the availability of data, expected accuracy of optimization, level of constraints, number of decision variables and its levels [50]. It is better to include strategies that covers a wide spectrum of planning. To optimize the number of strategies, several tools can be implemented for example design of experiments to select optimum runs [53]. RAMS parameters are to be extracted either from deterministic or probabilistic approach for each specific maintenance strategy [14].

LCC analysis for different maintenance strategies: Each maintenance strategy needs to be assessed by implementing LCC analysis [72]. Sometimes, depends on the availability of cost database, there is necessary to implement either total LCC analysis or cost-benefit analysis [61]. Each maintenance action incurs specific costs and these individual costs needs to be summed during their entire lifecycle [12].

Risk Analysis and management for different maintenance strategies: Each maintenance alternative need to be assessed by implementing appropriate Risk Analysis or risk assessment or risk management based on specific targets defined in Step1 [18, 51]. There can be qualitative or quantitative methods. There are several risk analysis methods available in literature such as Failure Mode Effect Analysis (FMEA), Fault Tree Analysis (FTA), Monte Carlo Methods, etc. to analyse the risk associated with each specific strategy [45].

Optimization of maintenance plans: The optimization of outputs extracted from RAMS analysis, LCC analysis and Risk analysis will be carried out against constraints and objective function of maintenance plan. To be general, a specific or set of maintenance alternatives to be selected based on maximum RAMS, minimum cost and minimum risk. Further, these alternatives can be further assessed individually to consider the other direct or indirect parameters such as availability of resources, long term goals of organization, business risk, and short- or long-term strategies. Several algorithms can be used to conduct optimization of maintenance plans such as cost optimization [60], linear programming [29], multi-criteria optimization [23], stochastic programming, online optimization [70], etc. and others mentioned in [4].

As several times discussed, it is difficult to conceptualize a generic RAMS and LCC methodology for different planning levels. Hence, the combined idea of the infrastructure managers is to define these parameters at each asset hierarchy level and emphasize to be laid on interaction between these levels. It is also necessary to convert these parameters from bottom-up approach or top-down approach. This will be further useful in defining the asset management framework of each Infrastructure Manager. The integrated methodology can be further illustrated in the simplest manner as shown in Fig. 17. As discussed in [57], it is categorized based on activities, resources and timescales as:

Different planning hierarchy associated with RAMS parameters (modification from [57])

-

SAMP route or network level can consists of availability as a basis for defining maintenance strategies.

-

RAP/RDP or line level can consist of failures, repairs and preventive maintenance actions as defining maintenance strategies.

-

IAMP or route, line or component level can consist of corrective actions and consequential costs as basis for maintenance strategies.

7 Conclusion

Railway infrastructure is a complex system which has different systems and components in hierarchical nature. In order to manage its performance with high availability and track performance, it is necessary to implement maintenance planning for short, medium- and long-term horizons. In order to implement it, this chapter proposed an integrated RAMS, LCC and Risk assessment methodology for supporting maintenance planning decision process. To increase the performance of Railways, there is still a lot of work to be done in formalizing the combinations of data formalization and standardization, planning hierarchy, asset hierarchy, estimation of RAMS parameters, complexities in degradation behaviour and uncertainties, etc. Due to advancements in technologies from other infrastructure, there will be a scope of improvement on above aforementioned areas to make the Railways sustainable due to competition from other transport infrastructure, degrading infrastructure, budget restrictions and increase in demands from the society.

References

AUTOMAIN (2013) D4.2 Optimised maintenance activities like, grinding, tamping and other maintenance processes. https://automain.uic.org/IMG/pdf/wp4_11-09-09-2013-f-d4_2-optimised_maintenance_activities_like_grinding_tamping_and_other_maintenance_processes.pdf

Al-Turki U (2011) A framework for strategic planning in maintenance. J Qual Maint Eng 17(2):150–162

Baldi MM, Heinicke F, Simroth A, Tadei R (2016) New heuristics for the stochastic tactical railway maintenance problem. Omega 63:94–102

Blischke WR, Murthy DP (2011) Reliability: modeling, prediction, and optimization. Wiley

CAPACITY4RAIL (2014) D5.2.1 Compendium and evaluation of RAMS, LCC and migration tools, and methods and sources of data. http://www.capacity4rail.eu/IMG/pdf/d5.2.1_-_compendium_and_evaluation_of_rams_lcc_and_migration_tools_and_methods_and_sources_of_data.pdf

CENELEC E (1999) 50126: railway applications—the specification and demonstration of Reliability. Availability, Maintainability and Safety (RAMS)

COMMISSION IE (2006) IEC 61165: application of Markov techniques

Ciszewski T, Nowakowski W, Chrzan M (2017) RailTopoModel and RailML–data exchange standards in railway sector. Arch Transp Syst Telemat 10

Consilvio A, Di Febbraro A, Sacco N (2016) Stochastic scheduling approach for predictive risk-based railway maintenance. In: 2016 IEEE international conference on intelligent rail transportation (ICIRT) 2016. IEEE, pp 197–203

D-RAIL (2014) D7.2 RAMS analysis and recommendation. http://d-rail-project.eu/IMG/pdf/DR-D7_2-F2-RAMS_analysis_and_recommendation-20140926.pdf

Dambra C, Papa F, Mazzino N, Crovetto C (2017) IN2SMART D2.1 system requirements and functional, form fit and interfaces specifications. EU

D’Ariano A, Meng L, Centulio G, Corman F (2017) Integrated stochastic optimization approaches for tactical scheduling of trains and railway infrastructure maintenance. Comput Ind Eng

EN 15341 (2007) Maintenance key performance indicators. European Committee for Standardization (CEN), Brussels, Belgium

Ebeling CE (2004) An introduction to reliability and maintainability engineering. Tata McGraw-Hill Education

Ekberg A, Paulsson B (2010) INNOTRACK: concluding technical report. International Union of Railways (UIC)

Famurewa SM, Asplund M, Galar D, Kumar U (2013) Implementation of performance based maintenance contracting in railway industries. Int J Syst Assur Eng Manag 4(3):231–240

Famurewa SM, Xin T, Rantatalo M, Kumar U (2015) Optimisation of maintenance track possession time: a tamping case study. Proc Inst Mech Eng Part F J Rail Rapid Transit 229(1):12–22

Fecarotti C, Andrews J (2016) Producing effective maintenance strategies to control railway risk

Fourie CJ, Zhuwaki NT (2017) A modelling framework for railway infrastructure reliability analysis. S Afr J Ind Eng 28(4):150–160

Galar D, Thaduri A, Catelani M, Ciani L (2015) Context awareness for maintenance decision making: A diagnosis and prognosis approach. Meas J Int Meas Confed 67:137–150

Garambaki A, Thaduri A, Seneviratne A, Kumar U (2016) Opportunistic inspection planning for railway emaintenance. IFAC-PapersOnLine 49(28):197–202

Gent T (2001) Tactical tools for integrated rail service planning. In: Proceeding of the world congress on railway research 2001

van Horenbeek A, Pintelon L, Muchiri P (2010) Maintenance optimization models and criteria. Int J Syst Assur Eng Manag 1(3):189–200

IN2SMART D9.2 (2019) Generic framework for decision support system in maintenance and interventions planning [Homepage of IN2SMART], [Online]

INFRALERT (2017) D3.2 Application of physical, data-driven and symbolic models from component to system level. http://infralert.eu/wp-content/multiverso-files/4_56128ae071b45/INFRALERT-D3.2.pdf. Accessed 15 Sept 2019

INNOTRACK (2006) INNOTRACK Guideline for LCC and RAMS Analysis. http://www.charmec.chalmers.se/innotrack/deliverables/sp6/sp6.html. Accessed 16 Feb 2019

ISO 55000 (2014) Asset management

ISO I (2009) IEC 31010: 2009. Risk management-risk assessment techniques

Jayakumar A, Asgarpoor S (2006) Maintenance optimization of equipment by linear programming. Probab Eng Inf Sci 20(1):183–193

Jiménez-Redondo N, Calle-Cordón A, Kandler U, Simroth A, Morales FJ, Reyes A, Odelius J, Thaduri A, Morgado J, Duarte E (2017) Improving linear transport infrastructure efficiency by automated learning and optimised predictive maintenance techniques (INFRALERT). In: IOP conference series: materials science and engineering 2017. IOP Publishing, pp 012105

Kans M, Galar D, Thaduri A (2016) Maintenance 4.0 in railway transportation industry. In: Proceedings of the 10th world congress on engineering asset management (WCEAM 2015) 2016. Springer, Cham, pp 317–331

Karim R, Jagare V, Lindberg L, Kumar U (2015) Robust and Reliable Transport System (RTS)—a strategic agenda for resource pooling, collaboration, innovation and research. https://www.ltu.se/cms_fs/1.129828!/file/RTS_2015_webb.pdf. Accessed 10 Feb 2019

Kumar S, Espling U, Kumar U (2008) Holistic procedure for rail maintenance in Sweden. Proc Inst Mech Eng Part F J Rail Rapid Transit 222(4):331–344

Kumar U, Ahmadi A, Verma AK, Varde P (2015) Current trends in reliability, availability, maintainability and safety: an industry perspective. Springer, Berlin

Kumar U, Galar D, Parida A, Stenström C, Berges L (2013) Maintenance performance metrics: a state-of-the-art review. J Qual Maint Eng 19(3):233–277

Lidén T (2015) Railway infrastructure maintenance-a survey of planning problems and conducted research. Transp Res Procedia 10:574–583

Lin J, Asplund M, Parida A (2013) Bayesian parametric analysis for reliability study of locomotive wheels. In: 2013 proceedings annual reliability and maintainability symposium (RAMS) 2013. IEEE, pp 1–6

Lusby RM, Larsen J, Ehrgott M, Ryan D (2011) Railway track allocation: models and methods. OR Spectrum 33(4):843–883

Lyngby N, Hokstad P, Vatn J (2008) RAMS management of railway tracks. Handbook of performability engineering. Springer, Berlin, pp 1123–1145

MAINLINE (2013) Deliverable 5.4: Proposed methodology for a Life Cycle Assessment Tool (LCAT). http://www.mainline-project.eu/IMG/pdf/ml-d5.4-f-proposed_lcat_methodology.pdf

Macchi M, Garetti M, Centrone D, Fumagalli L, Pavirani GP (2012) Maintenance management of railway infrastructures based on reliability analysis. Reliab Eng Syst Saf 104:71–83

Mahboob Q, Zio E (2018) Handbook of RAMS in railway systems: theory and practice. CRC Press

Markeset T, Kumar U (2003) Design and development of product support and maintenance concepts for industrial systems. J Qual Maint Eng 9(4):376–392

Martorell S, Villanueva JF, Carlos S, Nebot Y, Sánchez A, Pitarch JL, Serradell V (2005) RAMS C informed decision-making with application to multi-objective optimization of technical specifications and maintenance using genetic algorithms. Reliab Eng Syst Saf 87(1):65–75

Meyer T, Reniers G (2016) Engineering risk management. Walter de Gruyter GmbH & Co KG

Mishra M, Odelius J, Thaduri A, Nissen A, Rantatalo M (2017) Particle filter-based prognostic approach for railway track geometry. Mech Syst Signal Process 96:226–238

Modarres M (2016) Risk analysis in engineering: techniques, tools, and trends. CRC Press

Mokkapati C, Tse T, Rao A (2009) A practical risk assessment methodology for safety-critical train control systems

ON-TIME, D1.2—A framework for developing an objective function for evaluating work package solutions (Cost function). http://kajt.org/onewebmedia/ONT-WP01-D-NRI-030-02%20-%20D1.2%20-%20A%20framework%20for%20developing%20an%20objective%20function%20for%20evaluating%20work%20package%20solutions%20.pdf

Patra AP (2009) Maintenance decision support models for railway infrastructure using RAMS & LCC analyses

Podofillini L, Zio E, Vatn J (2006) Risk-informed optimisation of railway tracks inspection and maintenance procedures. Reliab Eng Syst Saf 91(1):20–35

Praticò FG, Giunta M (2017) Proposal of a key performance indicator for railway track based on LCC and RAMS analyses. J Constr Eng Manag 144(2):04017104

Prescott D, Andrews J (2013) Modelling maintenance in railway infrastructure management. In: 2013 proceedings annual reliability and maintainability symposium (RAMS) 2013. IEEE, pp 1–6

Purdy G (2010) ISO 31000: 2009—setting a new standard for risk management. Risk Anal: Int J 30(6):881–886

Quiroga LM, Schnieder E (2010) A heuristic approach to railway track maintenance scheduling. WIT Trans Built Environ 114:687–699

Rama D, Andrews JD (2015) A holistic approach to railway infrastructure asset management. Int J Perform Eng 11(2):107–120

SUSTRAIL (2015) D5.1 RAMS and LCC analysis. http://www.sustrail.eu/IMG/pdf/sustrail_d5_1_13042015.pdf

Simões GMP (2008) RAMS analysis of railway track infrastructure

Smith DJ (2005) Reliability, maintainability and risk: practical methods for engineers; 1993

Soleimanmeigouni I, Ahmadi A, Letot C, Nissen A, Kumar U (2016) Cost-based optimization of track geometry inspection. In: World congress of railway research: 29/05/2016–02/06/2016

Stenström C, Norrbin P, Parida A, Kumar U (2016) Preventive and corrective maintenance–cost comparison and cost–benefit analysis. Struct Infrastruct Eng 12(5):603–617

Swier J (2004) Exposing the real infrastructure cost drivers. Railw Gaz Int 160(1)

Thaduri A, Kumar U, Verma AK (2014) Computational intelligence framework for context-aware decision making. Int J Syst Assur Eng Manag 5(1):1–12

Thaduri A, Galar D, Kumar U (2015) Railway assets: a potential domain for big data analytics, 2015. Elsevier, pp 457–467

Tzanakakis K (2013) Maintenance planning using LCC KAI RAMS. In: The railway track and its long term behaviour. Springer, Berlin, pp 293–296

UIC SSO (2019) UIC—International union of railways—Standards Setting Organisation. https://uic.org/spip.php?page=leaflets-irs-table. Accessed 16 Feb 2019

Vatn J (2002) A life cycle cost model for prioritisation of track maintenance and renewal. Innov Cost Eff Railw Track 2:20–25

Villemeur A (1992) Reliability, availability, maintainability and safety assessment, assessment, hardware, software and human factors. Wiley

Wenzel R (2011) Condition-based maintenance: tools to prevent equipment failures

Wu Q, Cole C, McSweeney T (2016) Applications of particle swarm optimization in the railway domain. Int J Rail Transp 4(3):167–190

Zoeteman A (2006) Asset maintenance management: state of the art in the European railways. Int J Crit Infrastruct 2(2–3):171–186

Zoeteman A (2001) Life cycle cost analysis for managing rail infrastructure. Eur J Transp Infrastruct Res 1(4)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Thaduri, A., Kumar, U. (2020). Integrated RAMS, LCC and Risk Assessment for Maintenance Planning for Railways. In: Karanki, D., Vinod, G., Ajit, S. (eds) Advances in RAMS Engineering. Springer Series in Reliability Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-36518-9_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-36518-9_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36517-2

Online ISBN: 978-3-030-36518-9

eBook Packages: EngineeringEngineering (R0)