Abstract

The technique of weak magnetic stress internal detection is manifested in the weak magnetic field environment, including the geomagnetic field. The aim of weak magnetic stress internal detection technology is to detect the area of stress damage. Stress damage degree of ferromagnetic components is determined by detecting the weak magnetic signal on the surface of stress concentration area of ferromagnetic components. Weak magnetic stress internal detection technology of the pipeline can effectively detect the stress concentration region where the pipeline has not formed macroscopic defects, and advance the pipeline safety alarm time, which makes up for the weaknesses of the traditional magnetic flux leakage internal detection technology. In this chapter, the key technologies of the weak magnetic stress internal detection are stated. The detection mechanism, influencing factors, and engineering tests of weak magnetic stress detection technology are deeply analyzed. Furthermore, the future development direction of the weak magnetic stress internal detection technology is proposed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Stress concentration is an essential reason for sudden accidents in long oil and gas pipelines. In particular, a large number of stress concentration regions exist in the process of pipe manufacture and construction of new pipelines. Some stress concentration areas have reached the critical yield points, leading to the occurrence of sudden accidents after the pipeline is made available for production [1,2,3]. In order to prevent accidents, some traditional nondestructive testing techniques are often used, including magnetic powder, magnetic flux leakage, eddy current, and infiltration and so on. These technologies all have played an important role in defect monitoring, accident prevention, and other side effects of the pipeline. However, only macroscopic defects can be found. It is impossible to carry out effective evaluation of the stress concentration region of the unformed defect due to construction, welding, foundation settlement, internal media pressure, thermal expansion, and other factors, and thus sudden accidents caused by stress damage cannot be avoided [4, 5]. From the analysis of pipeline accidents in recent years, it is obvious that new pipeline accidents happen frequently, and no macroscopic defects are formed at this time [6,7,8]. Weak magnetic method can effectively judge the stress concentration area of ferromagnetic metal components and evaluate the service life of ferromagnetic components. It gets the advantages of light equipment, no special magnetization, fast and convenient detection, high sensitivity, etc. Thus, this technology has been widely valued by domestic and foreign scholars [9, 10].

Based on the weak magnetic stress detection technology, this chapter first analyzes the factors that affect the weak magnetic stress detection. At the same time, the application of weak magnetic stress detection technology in engineering is summarized and the future development of this technology is prospected.

2 Weak Magnetic Stress Internal Detection Technology of Pipeline

2.1 Weak Magnetic Stress Internal Detection Mechanism of Pipeline

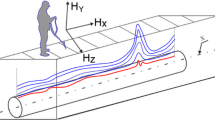

The weak magnetic detection method is to determine the stress damage region and the degree of stress damage of the workpiece by detecting a weak magnetic signal in the stress concentration region of the ferromagnetic metal components in the geomagnetic environment [11,12,13,14]. Under the combined action of the geomagnetic field and the applied load, the magnetic domain in stress concentration region will cause the magnetostriction. As a result, the magnetic domain lattice will be orientation and irreversible reorientation, and will form additional magnetic poles in the stress and deformation concentration region. This phenomenon macroscopic displays an abnormality of the magnetic field Hp around the component, that is the tangential magnetic signal component at the maximum stress concentration region appears an extremum Hp(x) = Hpmax and the normal magnetic signal component Hp(y) changes sign and has zero value in the abnormal region [15,16,17]. According to the ferromagnetic theory [18, 19], the stress causes change of the shape and distribution of the magnetic domain inside the ferromagnetic component and the self-magnetization increases in the form of a leakage magnetic field on the surface of the ferromagnetic component in the geomagnetic environment, especially the signal normal component Hp(y) crosses zero and the tangential component reaches a maximum at the defect and stress concentration region, as shown in Fig. 1.

2.2 Weak Magnetic Stress Internal Detection Technology of the Pipeline

The pipeline weak magnetic internal detection system applies the principle of weak magnetic detection and uses the media conveyed in the pipeline as the power to complete the nondestructive testing evaluation of the pipeline. The pipeline weak magnetic internal detection system mainly includes three parts: the pipeline weak magnetic internal detection device, the mileage calibration device, and the data analysis and processing system. The structure diagram of internal weak magnetic detection device of the pipeline is shown in Fig. 2.

Pipeline weak magnetic stress internal detection device mainly realizes the detection of the stress concentration region on the pipeline and ensures the stable running of the detector. The device mainly includes four parts: a driving unit, a measuring unit, a computer unit, and a power supply unit.

The mileage calibration device precisely locates of the stress concentration regions on the pipeline and the particular components of the pipeline. It is mainly composed of three parts: the external marking of the pipeline, the synchronous time calibration inside and outside the pipeline, and the odometer wheels record. All these three elements work together in order to record the mileage and other information.

Data analysis and processing system carry out the work of visual processing of the weak magnetic data detected by the weak magnetic sensor. At the same time, the final test results of stress concentration area of pipeline are generated. The weak magnetic sensor detects the data that are displayed on the computer after a series of processing. The data interpreter can visually observe the distribution of the stress concentration region. At the same time, the interface shows the mileage information. The location of stress concentration region is determined and marked by mileage information, providing a basis for the detection or evaluation of pipeline service life [20, 21].

3 Influencing Factors in the Internal Detection of Weak Magnetic Stress

The pipeline internal detection environment is complicated. During the detection process, there is a liftoff value between the weak magnetic stress detection probe and the pipe wall. The detection signal is influenced by external magnetic field strength, probe liftoff value, the value of the external load, and detection temperature. The external magnetic field strength and probe liftoff value has the most significant influence on the detection signal. Therefore, we focus on the analysis of the influence of the external magnetic field strength and the probe liftoff value on the weak magnetic signal in this chapter.

3.1 Influence of External Magnetic Field on Weak Magnetic Signal

In order to study the magnetic signal distribution in the stress concentration region, a magnetostatic model of the steel plate with stress concentration region is established. The size of steel plate is 470 mm × 50 mm × 14.7 mm, and the size of stress concentration region is 10 mm × 10 mm × 5 mm. According to the actual physical properties of X70 steel, the Poisson’s ratio of the material properties is set to 0.28, and the elastic modulus is 2 × 106 for simulation. The magnetostatic model diagram is shown in Fig. 3.

The scanning path is set in the direction of the tensile force of 1 mm liftoff above the steel plate research area, and the variation of magnetic memory signal B above this path under different external magnetic field strength is studied. The results of the study area in the geomagnetic field environment are shown in Fig. 4. The amplitude of the magnetic signal increases and the signal characteristics become more pronounced with the increase of the stress.

In order to research the influence of external magnetic field on the magnetic signal in the study area, the spatial magnetic field strength should be increased in the case of the same degree of stress concentration. The magnetic curve under the action of different external magnetic fields is shown in Fig. 5. In this figure, the stress concentration region is in the range of −5 mm to 5 mm on the abscissa.

It can be seen from Fig. 5, that the value of the magnetic signal on the surface of the stress concentration area increases as the external magnetic field strength increases. However, the difference between the magnetic signal in the stress concentration region and the nearby signal reduces; when the external magnetic field reaches the maximum, the signal in the stress concentration region is unrecognizable, and the magnetic memory signal feature is covered.

3.2 Influence of Liftoff on Weak Magnetic Signal

In order to study the variation law of magnetic signal under different liftoff values, the variation law of the magnetic signal in the range of the liftoff value of 0–15 mm is shown in Fig. 6 in the case of a certain degree of stress concentration. In the figure, X coordinates 180–220 mm is the stress concentration region. It can be seen from Fig. 6 that there is still a magnetic signal when the measuring point has a certain liftoff value from the surface, and when the liftoff value is small, the stress concentration region can be clearly distinguished. The magnetic induction intensity gradually decreases with the gradual increase of the liftoff value. When the liftoff value is less than 10 mm, it can be seen that curves calculated by the model have excellent repeatability and the stress concentration region can be identified. As the liftoff increases, the magnetic induction intensity of the steel plate surface decreases significantly, the identification level of the stress concentration zone decreases, and the magnetic signal is undetectable.

4 Engineering Application of the Weak Magnetic Stress Internal Detection Technology

In 2017, the Φ1219 weak magnetic stress internal detection equipment was developed in Shenyang University of Technology and carried out the internal testing service for the third line of the West-East Lianmuqin–Liaodun–Yandun–Hongliu–Guazhou Station in China. According to the amplitude gradient change of the weak magnetic signal, the stress concentration region level is judged. The data belongs to the normal range and detection is completed.

After the pipeline weak magnetic stress detector is operated in the pipeline, an image of the weak magnetic signal can be obtained according to the detected amplitude of the weak magnetic signal. Magnetic memory is an internal detection signal. The signal image of the pipeline is shown in Fig. 7.

Weak magnetic stress internal detection signal of the pipeline. (a) Weak magnetic signal near the girth weld. (b) Characteristics of stress concentration signal caused by indentation at the end of the steel pipe. (c) Signal characteristics of the elbow. (d) Obvious stress concentration region

Weak magnetic stress internal detecting device is composed of a plurality of magnetic sensors as shown in Fig. 2. As shown in Fig. 7, in the detection of multichannel probes, magnetic sensor is used to detect data in each line. The signals shown in the figure have different characteristics of weak magnetic signals, which are generated by different typical characteristics of pipelines. The technique of weak magnetic inner detection is very sensitive to stress concentration region. There is a significant difference in weak magnetic signal between stress concentration region and nonstress concentration region. This makes it possible to clearly distinguish between the girth weld, the spiral weld seam, the elbow, and the like.

5 Future Prospects

At present, the weak magnetic stress internal detection technology of the pipeline has made great achievements in engineering application, however, further research is still needed in theory and engineering applications, mainly in the following three points:

-

1.

Study on the formation mechanism of weak magnetic stress signals. It is difficult to establish the magnetomechanics coupling relationship with the traditional theory. The mechanism of weak magnetic signal generation in stress concentration region is not unified, and the mechanism research of weak magnetic stress detection technology is still a severe problem.

-

2.

Method for judging the stress level of weak magnetic signals. The pipe forms stress concentrations under various loading conditions. When the stress concentration is at different stages, the material microstructure changes and the corresponding weak magnetic stress detection signal characteristics are different. According to this, we can effectively identify and process the weak magnetic signals at different stages and divide the stress level in different stages based on the characteristic parameters of weak magnetic signals that are the key scientific problem of component life evaluation.

-

3.

Automatic recognition method of weak magnetic signals. At present, the identification of the internal detection data in the weak magnetic stress of long oil and gas pipelines relies on artificial recognition, which has the disadvantages of low efficiency and a large error. Realizing automatic recognition of massive data in pipeline weak magnetic stress will significantly improve data interpretation efficiency and reduce human error.

The engineering application effect of weak magnetic stress detection technology is good. At the same time, it has a broad development and application space in the field of pipeline detection. The key to the development and application of this technology is to study its basic theory.

References

Liu, B., He, L. Y., Huo, X. L., et al. (2017). Study on the MMM signal characteristics in magnetic field based on Kp perturbation algorithm. Chinese Journal of Scientific Instrument, 38(1), 151–158.

Liu, B., He, L. Y., Zhang, H., et al. (2017). The axial crack testing model for long distance oil-gas pipeline based on magnetic flux leakage internal inspection method. Measurement, 103, 275–282.

Gorkunov, E. S. (2015). Different remanence states and their resistance to external effects. Discussing the so-called magnetic memory method. Insight-Non-Destructive Testing and Condition Monitoring, 57(12), 709–717.

Liu, B., Cao, Y., & Wang, G. Q. (2016). Study on characteristics of magnetic memory signal of phase transition point based on the LAPW algorithm. Chinese Journal of Scientific Instrument, 37(8), 1825–1832.

Xu, K., Qiu, X., & Tian, X. (2017). Investigation of metal magnetic memory signals of welding cracks. Journal of Nondestructive Evaluation, 36(2), 20.

Jia, J. U., Feng, X. U. E., & Hong, L. I. (2015). Microstructure and magnetic property variation with addition of rare earth element Dy in Co-Ni-Al ferromagnetic shape memory alloy. Journal of Iron and Steel Research, International, 22(9), 858–863.

Liu, B., Cao, Y., Wang, D., He, L. Y., & Yang, L. J. (2017). Quantitative analysis of the magnetic memory yielding signal characteristics based on the LMTO algorithm. Chinese Journal of Scientific Instrument, 38(6), 1412–1420.

Yang, L. J., Guo, T. Z., Gao, S. X., & Liu, B. (2017). Feature analysis on magnetic flux leakage detection signals for special parts of oil and gas pipelines. Journal of Shenyang University of Technology, 39(01), 43–47.

Lo, C. C. H., Paulsen, J. A., & Jiles, D. C. (2004). Quantitative evaluation of stress distribution in magnetic materials by Barkhausen effect and magnetic hysteresis measurements. IEEE Transactions on Magnetics, 40(4), 2173–2175.

Atherton, D. L., & Szpunar, J. A. (1986). Effect of stress on magnetization and magnetostrication steel. IEEE Transactions on Magnetics, 22(5), 514–516.

Li, P., Ma, R., Chen, X., et al. (2017). First-principles prediction and Monte Carlo study of half-metallic ferromagnetism of the C-doped honeycomb CdS monolayer. Japanese Journal of Applied Physics, 56(4), 041201.

Kim, D. Y., Kim, D. H., Moon, J., et al. (2015). Determination of magnetic domain-wall types using Dzyaloshinskii–Moriya-interaction-induced domain patterns. Applied Physics Letters, 106(26), 190.

Nomura, K., & MacDonald, A. H. (2016). Quantum Hall ferromagnetism in graphene. Physical Review Letters, 96(25), 256602.

Liu, Z., Xue, F. Q., Yang, G. G., et al. (2013). Experimental measurement method of sensitivity matrix for electromagnetic tomography. Chinese Journal of Scientific Instrument, 34(9), 1982–1988.

Ren, J. L., Sun, J. L., Zhou, P., et al. (2013). Engineering application prospect and research on magnetic memory in two-dimensional testing. China Academic Journal Electronic Publishing House, 49(22), 8–15.

Sun, X., & Liu, B. (2014). Weak magnetic detection for stolen oil hole on long-distance transportation pipeline. Journal of Shenyang University of Technology, 36(04), 436–440.

Wang, X., Wang, D. S., Wu, R., et al. (2016). Validity of the force theorem for magneto-crystalline anisotropy. Journal of Magnetism & Magnetic Materials, 159(3), 337–341.

Wang, D. S., Wu, R., & Freeman, A. J. (2015). Magnetocrystalline anisotropy of interfaces: First-principles theory for Co-Cu interface and interpretation by an effective ligand interaction model. Journal of Magnetism & Magnetic Materials, 129(2–3), 237–258.

Hillebrands, B., & Ounadjela, K. (2015). Spin dynamics in confined magnetic structures. Applied Physics Letters, 72(18), 159–724.

Yang, L. J., Shen, W., Gao, S. Z., & Liu, B. (2018). Low frequency electromagnetic tracking and positioning technology for pipeline internal detector. Journal of Shenyang University of Technology, 40(01), 48–53.

Yang, L. J., Ma, F. M., & Gao, S. W. (2016). Research of on-line inspecting pipeline magnetic flux leakage system. Chinese Journal of Scientific Instrument, 37(8), 1763–1780.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Liu, B., Yu, X.R., He, L.Y., Yang, L.J., Que, Y.B. (2019). Weak Magnetic Stress Internal Detection Technology of Long Gas and Oil Pipelines. In: Quinto, E., Ida, N., Jiang, M., Louis, A. (eds) The Proceedings of the International Conference on Sensing and Imaging, 2018. ICSI 2018. Lecture Notes in Electrical Engineering, vol 606. Springer, Cham. https://doi.org/10.1007/978-3-030-30825-4_18

Download citation

DOI: https://doi.org/10.1007/978-3-030-30825-4_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-30824-7

Online ISBN: 978-3-030-30825-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)