Abstract

Nowadays, macro- and microalgae are being increasingly used as promising raw materials for the food, cosmetic and pharmaceutical industries, thanks to their biodiversity and its variety on valuable bioactive compounds such as carbohydrates, polyunsaturated lipids, proteins and pigments, among others. Furthermore, more efficient and environmentally friendly processes for bioactives’ recovery are requested not only by the industry but also by the society. This chapter presents an overview on the use of downstream green processes, mainly based on compressed fluids extraction techniques, in order to recover bioactives from algae that can be lately used in several potential applications for the food, pharmaceutical and cosmetic industries, which is the pillar of algae-based biorefinery.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

The increasing knowledge regarding the positive impact of diet on human health has brought about a great interest for seeking new bioactive products of natural origin to be used as functional ingredients for the development of functional foods. The concept of functional food is defined as food that besides the basic nutritional and energetic value provides additional health benefits thanks to the one or more functional ingredients that contains (Merichel Plaza et al. 2009). This definition implies that a functional food must improve well-being or reduce the risk of illness (Diplock et al. 1999).

Micro- and macroalgae have been suggested as a potential natural source of new compounds with biological activity that could be used as functional ingredients, due to their antioxidant (Lv et al. 2015), anti-inflammatory (Caroprese et al. 2012), antidiabetic (Yu Ran et al. 2015), neuroprotective (Pangestuti and Kim 2011), anticancer (Souza et al. 2018), anti-allergic (Thanh-Sang et al. 2012) and antimicrobial activities (Rodriguez-Meizoso et al. 2010), among others.

The development and production of these functional ingredients have become of great interest for the food industry, although pharmaceutical and cosmetic industries are also aware of the important bioactive compounds that can be obtained from marine natural sources such as algae and microalgae, thus extending its interest and applicability. In this sense, many algae-derived secondary metabolites are known for their skin benefits, which include protection from UV radiations and prevention of ageing, rough texture, wrinkles, and skin flaccidity (Ariede et al. 2017), of upmost importance for new cosmetics’ development. On the other hand, some important secondary metabolites (such as meroterpenoids) have been isolated from marine organisms presenting interesting pharmacological properties, which show cytotoxic activity towards several human cell lines, anti-inflammatory, etc. (García et al. 2018).

At present, the world is not only worried about food and human health but also about the global environmental awareness that continues to be on the rise. This is true in many countries, but especially in Europe and the USA. Climate change, global warming and the realistic threat of a lack of resources in the future for the rapidly growing world population have contributed to push process greenness and sustainability (Herrero and Ibáñez 2018). Sustainability can be understood as a rational way of improving processes to maximize production while minimizing the environmental impact (Herrero and Ibáñez 2015). Considering this framework, the study of the use of solvents that are generally recognized as safe (GRAS) for its use in the food industry, such as water, CO2 or ethanol, combined with compressed fluids techniques are the most promising engineering approach that offers a fast, cost-effective and environmentally friendly extraction of bioactive compounds from algae. Application of high pressure and moderate-high temperature to the GRAS solvents modifies their properties, contributing to a better extraction process, improving the mass transfer rate and preserving the biological potential of the extracts. In this chapter, green extraction techniques, such as supercritical fluid extraction (SFE), gas expanded liquid (GXL) extraction, pressurized liquid extraction (PLE) and subcritical water extraction (SWE), are presented, and applications to algae bioactives extraction are discussed. Moreover, other important aspects related to upstream processes optimization and biorefinery of algae (achieved through downstream process integration for valorising, in a rational way, all the different algae fractions) are also described.

1.1 Marine Resources

Prokaryotic life originated in the oceans about 3.6 billion years ago while eukaryotic life originated between 0.6 and 1 billion years later (Ibáñez and Cifuentes 2013). The long evolution period of marine life compared to terrestrial has generated a huge diversity in terms of number of different species, genes, etc. Furthermore, marine organisms live in hostile environments of light, salinity, and temperature; thus, they must adapt to survive, producing a great variety of secondary (and biologically active) metabolites. This ability, coupled with the immense diversity of species, provides an almost inexhaustible source of natural bioactive compounds from marine resources. Nowadays, the most important source of information for these bioactive compounds is The Dictionary of Marine Natural Products (Blunt and Munro 2008), which lists over 30,000 purified compounds and tends to present a growing number of compounds every year.

Among the marine sources, algae are the most promising due to their easy cultivation and fast growth. Algae are photosynthetic aquatic organisms that possess simple reproductive structures. In general, these can be categorized as unicellular microscopic (microalgae) and multicellular macroscopic organisms (macroalgae). Although the number of different alga species has been estimated to be between one and ten million (Metting 1996), approximately only 40,000 species have been described (Suganya et al. 2016), which involves almost an unlimited field of research.

Macroalgae are classified into groups based on their pigmentation: Chlorophyceae (green algae), Phaeophyceae (brown algae) and Rhodophyceae (red algae) (Oncel 2017). Macroalgae have been extensively utilized as food (or food technological ingredients) for many years, and thus are farmed commercially in several countries (Baghel et al. 2015) (over 30 million tons in 2016) (FAO 2018).

On the other hand, microalgae cultivation is increasing quickly, mainly in large scale, both in outdoor and in indoor production. Microalgae could grow in autotrophic conditions, heterotrophic conditions with enough nutrients but no light availability and even in mixotrophic conditions and, hence, they are able to utilize both inorganic and organic compounds from the medium (Carvalho et al. 2014). Regarding pigment composition, microalgae are classified into nine divisions. Some of the largest groups include Phaeophyceae, Chlorophyceae, Pyrrophyceae (dinoflagellates), Bacillariophyceae (diatoms), Chrysophyceae (golden-brown) and Rhodophyceae (Oncel 2017).

One of the main applications of micro- and macroalgae biomass is biodiesel production (Mata et al. 2010) because of the high level of triglycerides they contain (Yen et al. 2013). Algae as a potential renewable resource is not only used for biofuels (Suganya et al. 2016) but also for food for aquaculture (Suganya et al. 2016), biofertilizer (Marris 2006), environmental applications such as CO2 mitigation (Bilanovic et al. 2009) or wastewater treatment (Hodaifa et al. 2008), and to obtain high added value foods (Ibáñez and Cifuentes 2013), cosmetics (Ariede et al. 2017) and pharmaceutical products (Thanh-Sang et al. 2012).

In the following section, algae will be presented as a source of different bioactive compounds of interest for the food, cosmetics, and pharmaceutical industries. A revision about the different types of bioactives that have been described in algae is presented, including compounds such as lipids, proteins and peptides, polysaccharides, carotenoids, phenolics, and alkaloids. Table 11.1 presents a summary of potential functional compounds found in different microalgae and macroalgae, together with their possible health effects.

2 Algae as Source of Bioactive or Valuable Compounds

2.1 Lipids

Algae can produce different kinds of lipids such as glycolipids, phospholipids (polar lipids), glycerolipids with neutral storage lipids, and free fatty acids. Lipid percentages vary within the type of algae, containing 7–16% dry weight for macroalgae and from 1.9% up to 40% for microalgae (Suganya et al. 2016).

Among the lipids, polyunsaturated fatty acids (PUFAs) are the most-studied compounds in algae. PUFA fraction in algae is often higher than in terrestrial vegetables (Kumari et al. 2010). In fact, several microalgae are able to synthesize ω-3 and ω-6 long chain PUFAs, which are essential natural antioxidants for body health, at levels as high as 10–70% of total fatty acids (Kumari et al. 2013), exceeding 20% of their total lipid content (Bellou et al. 2014). However, the amount of PUFAs and the number or position of double bonds on the carbon chain can vary according to the algal species and growing conditions (Villarruel-Lopez et al. 2017). In general, many microalgae have PUFAs such as EPA (eicosapentaenoic acid, ω-3 C20:5), DHA (docosahexaenoic acid, ω-3 C22:6) and ARA (arachidonic acid, ω-6 C20:4).

The specific interest in ω-3 essential PUFAs are their beneficial effects such as the reduction of the risks of heart disease (Chen et al. 2011), depression (Giles et al. 2013), inflammation (Yates et al. 2014), and cancer (Giros et al. 2009; Pottel et al. 2014).

Since humans have difficulty in synthesizing fatty acids with more than 18 carbons, these fatty acids should be obtained from food (Hamed et al. 2015) and in general, algae have low ω-6:ω-3 ratio, as recommended by the WHO. Although fish and seafood are the major source of long-chain PUFAs, it is important to remark that algae have been suggested as a feed for aquaculture with the idea of obtaining the desired fatty acid profile in fish and seafood for consumers.

Other important microalgae-derived lipids are phytosterols, which have been used as additives in many food products such as spread, dairy products and salad dressing (Luo et al. 2015). Phytosterols have been reported to have many beneficial health effects in humans, including immunomodulatory (Caroprese et al. 2012), anti-inflammatory (Ciliberti et al. 2017), anti-hypercholesterolemic (Chen et al. 2014), antioxidant (Lv et al. 2015) and anticancer (Kazlowska et al. 2013).

2.2 Proteins and Peptides

Algae can become a potential protein source. The protein content recorded for green and red algae can reach 47% of the dry weight (Ibáñez and Cifuentes 2013) and ranged between 60% and 70% in microalgae such as Arthrospira platensis, Chlorella vulgaris of Isochrysis galbana (Matos et al. 2017). These have been used as a supplement in food, animal feed or aquaculture due to their optimal balance of essential amino acids.

Peptides from protein hydrolysis have been studied due to their bioactivities. Some peptides have potential benefits such as antioxidative (Hu et al. 2015), binding or inhibiting specific receptors (Samarakoon et al. 2014), growth factors, hormones, immunomodulators (de Jesus Raposo et al. 2013), antihypertensive, anticoagulant and antiproliferative (Samarakoon and Jeon 2012).

2.3 Polysaccharides

Macroalgae contain large amounts of polysaccharides, mainly cell wall structural polysaccharides such as alginates (brown algae) and carrageenans and agar (red algae) (Ibáñez and Cifuentes 2013); meanwhile, microalgae have a low content (approximately 10% of dry matter) of carbohydrates (Villarruel-Lopez et al. 2017). Nevertheless, macro- and microalgal polysaccharides have health-promoting properties such as anti-inflammatory, antitumour, anti-adhesive, antiviral, antibacterial, immunomodulatory and infection-prevention activities (Gallego et al. 2018). For example, beta glucans are considered immune stimulators while cellulose and starch can act as dietetic fibres, and sulphated polysaccharides have antioxidant and antitumoural activities (Villarruel-Lopez et al. 2017).

2.4 Phenolic Compounds

The main bioactivity associated with algal phenolic compounds is their antioxidant effect through scavenging of reactive oxygen species (ROS) or enhancement of intracellular antioxidant defences. For example, extracts from microalgae Euglena cantabrica exhibit high antioxidant activity due to their high concentration of phenolic acids, particularly gallic and protocatechuic acids (Jerez-Martel et al. 2017).

Phlorotannins are the major phenolic compounds in brown macroalgae and the most-studied group of phenolic compounds from algae because they constitute an extremely heterogeneous group of molecules, providing a wide range of potential biological activities in addition to antioxidant activity: antiproliferative (Montero et al. 2016), antibiotic (Tanniou et al. 2014), anti-allergic (Kim and Himaya 2011), antidiabetic and anti-inflammatory activities (Catarino et al. 2017).

Other phenolic group with interesting bioactive properties are flavonoids. For instance, it has been reported in microalgae that the synergistic effects of chlorogenic and caffeic acids with 13-cis-retinoic acid cannot only prevent lipid peroxidation, but also regress cancer (de Jesus Raposo and Miranda Bernardo de Morais 2015). The flavonoid content in macroalgae has been also studied (Yoshie-Stark et al. 2003).

2.5 Alkaloids

Alkaloids present special interest because of their pharmacological activities. Structurally, alkaloids isolated from marine algae mostly belong to the phenylethylamine and indole groups.

Some alkaloids detected in marine macroalgae and microalgae have been associated with relief from depression (phenylethylamine), increased heart rate and blood pressure (tyramine), diuretic effects and inhibition of gut movements (hordenine), treatment of cardiovascular and kidney disorders (dopamine), antitumour, antibacterial and antifungal activity (caulerpin) or antioxidant activities (fragilamide) (Güven et al. 2010).

2.6 Carotenoids

Carotenoids are lipophilic compounds that present significant interest as food colorants, feed supplements, nutraceuticals, and for cosmetic and pharmaceutical purposes. Their C40 structure is based on isoprene units which can contain oxygen, so they can be classified into two main groups: carotenes and xanthophylls (Gong and Bassi 2016). More than 600 different naturally occurring carotenoids are now known, not including cis and trans isomers.

Carotenoids from marine macro- and microalgae have been described as powerful antioxidants and their beneficial physiological functions, such as anticancer, anti-obesity, antidiabetic, anti-inflammatory, and cardioprotective activities have also been reported (Hoang Van and Eun 2017). For instance, some of the most-studied carotenoids extracted from algae with beneficial effects on health are fucoxanthin, β-carotene, lutein and zeaxanthin from macro- and microalgae; and astaxanthin, canthaxanthin, capsanthin, α-carotene, crocetin, β-cryptoxanthin, lycopene, neoxanthin and phytoene from microalgae (Christaki et al. 2013; Gallego et al. 2018).

3 How to Improve the Production of Bioactive Metabolites

As it was mentioned in the introduction, macro and microalgae have raised an enormous interest, thanks to their potential for being a good source of high added-value compounds that can be used in cosmetic, food and pharmaceutical industries. Furthermore, it is well established that secondary metabolites production can be strongly increased by many factors. Figure 11.1 offers an overview on different ways to increase the production of valuable components from algae: marine biotechnology (through genetic engineering, selection and improvement of strains, metabolic flux modelling, etc.) and optimization of processes including both upstream (strain selection and cultivation conditions) and downstream processes (biomass processing, extraction and purification methods). The main objective would be the integration of these factors in a biorefinery approach, which allows a high production of the bioactives of interest.

3.1 Marine Biotechnology

Marine or blue biotechnology can be defined as the application of genetic engineering to marine resources. Thus, by using genetic engineering, it is possible to modify genes and improve algae strains obtaining transgenic algae which are able to overexpress genes and overproduce valuable target compounds.

Marine biotechnology involves the study of the metabolic pathways which lead to the synthesis of bioactive compounds. It is important to consider all biochemical reactions, and their stoichiometry, which occur within the metabolic network. This knowledge will lead to modify or model the metabolomic flux, increasing (or decreasing) the production of selective bioactive metabolites (Ibáñez and Cifuentes 2013).

It is true that genetic manipulation in algae has been limited to a few species due to the complexity and large genome size. Microalgal genome sizes range from 12.6 Mbp for the Ostreococcus tauri and 168 Mbp for the Emiliania huxleyi to an estimated 10,000 Mbp for the Karenia brevis (Cadoret et al. 2012). These large genome sizes can be difficult to sequence and transform.

Furthermore, it is very difficult to obtain new microalgal strains since nuclear transformation has a low efficiency and transgenes expression is not stable (Leon and Fernandez 2007).

Recently, some researchers have proposed new methods to ensure stability and a higher expression of transgenes. For instance, Diaz-Santos et al. (2016) proposed an interesting approach to express transgenes in microalgae using co-transformation with two naked promoterless genes, which are randomly inserted into the nuclear genome. They reached a successful co-transformation of Chlamydomonas reinhardtii, concluding that this transformation system could be universally applicable to any microalgal species.

In conclusion, more intense research and the study of new genetic engineering techniques are necessary to better understand, both genetically and metabolically, the complex network involved in the synthesis of bioactive compounds of interest; this way, the full potential of macro and microalgae could be reached.

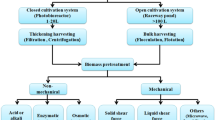

3.2 Optimization of Upstream and Downstream Processes

Upstream and downstream processes involve all stages from the selection of macro and microalgae strains and cultivation to extraction and/or purification of secondary metabolites.

3.2.1 Upstream Processes

Of course, depending on the bioactive compound of interest, a specific algae strain must be chosen since metabolite composition is extremely variable among species. Nowadays, there is a huge quantity of compounds obtained from different algae which can be found in many industries. For example, carotenoids such as β-carotene and astaxanthin are obtained from the green microalga Dunaliella salina and Haematococcus pluvialis, respectively. Another interesting example is the use of Isochrysis galbana, which is rich in ω-3, as an ingredient for functional biscuits (Gouveia et al. 2008).

Cultivation conditions are essential in algae biorefinery. The main factors are supply of carbon dioxide (commonly CO2), nutrient source (i.e. nitrogen and phosphorus) and source and origin of illumination (Vanthoor-Koopmans et al. 2013), and also it is important to take into account other factors such as temperature control, algae concentration, pH, cultivation systems such as ponds or photobioreactors. All these factors are vital for the proper growth of algae. For instance, it is well known that the microalgae Haematococcus pluvialis can grow as motile biflagellated green cells when it is subjected to favourable conditions, but under stress conditions (nutrient deficiency, high light intensity or salt stress), the cells lose their motility, their size increases and forms red cysts, allowing its survival for long and stressful periods (Hagen et al. 2002). Thus, in green cells, chlorophylls and carotenoids such as lutein and β-carotene can be found while in red cell phase, astaxanthin and its derivatives (esters, mainly) constitute up to 98% of the total carotenoid content (Boussiba et al. 1999). In terms of light, Aravantinou and Manariotis (Aravantinou and Manariotis 2016) observed a greater growth rate of Chlorococcum sp. under artificial light conditions instead of direct sunlight, proving the importance of light intensity and light source on biomass production.

The second main step in upstream processing is harvesting, which has to be optimized for each particular algae strain. In this sense, there are many ways to recover biomass but they are mostly focused in centrifugation and filtration.

Biomass processing is related to the proper disruption of the cell, since most of metabolites of interest are located inside the cell. It includes different techniques such as enzymatic treatments, microwave-assisted processes, pulsed electric fields or high-pressure homogenization. In this sense, Carullo et al. (2018) studied the effect of two different cell disruption techniques in the microalgae Chlorella vulgaris and demonstrated that it was possible to selectively recover small-sized cytoplasmic compounds using pulsed electric fields, and high molecular weight intracellular components using high-pressure homogenization.

3.2.2 Downstream Processes

Downstream processes involve the extraction and purification methods to isolate the valuable compounds of interest from algae. These procedures can be extremely expensive and can consume a huge quantity of organic solvents, so the optimization of these steps is vital for the global economic viability of the algae biorefinery. As an alternative to conventional processes (such as solid–liquid extraction or Soxhlet extraction), green processes have been proposed as a clean, sustainable and environmentally friendly approach. Table 11.2 shows a list of alternative processes that have been recently used to extract compounds from many sources, including macro and microalgae. These processes are microwave-assisted extraction (MAE), ultrasound-assisted extraction (UAE), enzyme-assisted extraction (EAE), supercritical fluid extraction (SFE), pressurized liquid extraction (PLE) in which subcritical water extraction (SWE) is included, and gas-expanded liquids (GXLs). Even though these techniques are based on different principles, all of them have in common the use of minimal amount of food-grade solvents and its intensification through the employment of microwaves, ultrasound, enzymes or high pressure/temperature (Mendiola et al. 2013) that allow improving the selectivity and the global efficiency of the extraction process.

3.2.2.1 Assisted Extraction Techniques

Microwave-assisted extraction is based on the use of microwave radiation that causes heat both inside the matrix and the solvent. In algae, this heat provokes an enormous pressure inside the cells and favours the rupture of the cell wall, thus exposing its constituents to the solvent. Furthermore, the heat helps the solvent to diffuse into the cells, thus improving the transfer of the bioactive compounds between the matrix and the solvent (Tatke and Jaiswal 2011). MAE has been widely used to extract bioactives from algae such as lipids, high-value pigments, proteins, vitamins, carbohydrates and others (Kapoore et al. 2018). Although different organic solvents can be employed, those selected for MAE applications should absorb microwave radiation and, therefore, usually polar and protic solvents are used. Some applications of MAE for the extraction of lipids, pigments and proteins from different algae species such as Chlorella sp., Nannochloropsis salina, Phaeodactylum tricornutum and Porphyridium purpureum have been developed using GRAS solvents (Gilbert-Lopez et al. 2017a; Juin et al. 2015; Martinez-Guerra et al. 2014; Patil et al. 2013).

For instance, Martinez-Guerra et al. (2014) studied the extraction of lipids from microalgae using MAE. In this case, algal lipids were extracted from dry Chlorella sp. using ethanol as solvent. In comparison to the conventional Bligh and Dyer (BD) method, they obtained an increase in lipid extraction yields (from 13.9% to 20.1%) with a higher fatty acids ethyl esters conversion of the algal lipids (from 78.1% up to 96.2%) under optimum conditions (algae biomass: ethanol molar ratio of 1:250–500 and 2.0–2.5% sodium hydroxide catalyst with reaction times around 6 min).

Another interesting approach was given by Gilbert-Lopez et al. (2017a). They used MAE to obtain high valuable extracts from Phaeodactylum tricornutum. Under optimum conditions (30 °C, 100% ethanol and 2 min of extraction), they obtained a higher extraction yield (14.51%) and recovered a good amount of lipids such as EPA and carotenoids such as fucoxanthin, even higher than those reported from brown algae.

Ultrasound-assisted extraction also relies on the disruption of cell walls, increasing the contact between solvent and matrix. In this case, the driving force that favours the extraction of the bioactives is the acoustic cavitation produced by the use of high-frequency sounds. Some algae such as Arthrospira platensis and Chlorella sp. have been used to extract valuable compounds using UAE, with an important increase in the extraction yield. As an example, Zhao et al. (2013) studied different treatments to extract carbohydrates from fresh Chlorella sp. UAE treatment showed the best results, reaching the maximum glucose yield (36.94 ± 2.46 g per 100 g dry cell weight) considering the following extraction conditions: ultrasonic power of 800 w, extraction time of 80 min, flow rate of 1.52 L/min and cell concentration of 0.3 g/L. Another interesting example was given by Hadiyanto and Suttrisnorhadi (2016), who efficiently extracted phycocyanin from Arthrospira platenis using UAE. Results showed a significant increase of the extraction yield using UAE (up to 15.7%) in comparison to conventional extraction (11.13 %) under UAE optimal conditions (52.5 °C, 42 min of extraction time and ultrasound frequency of 42 Hz).

One interesting aspect common to both techniques is that it is possible to extract bioactive compounds directly from wet biomass without using any solvent. For instance, Adam et al. (2012) performed a solvent-free ultrasound-assisted extraction from fresh Nannochloropsis oculata biomass in order to recover lipids. As the water of the wet alga was used as solvent, lipids were effectively separated into two distinct phases, simplifying the oil recovery. Furthermore, using scanning electron microscopy (SEM), they could observe that after UAE, external structure of cells surface had changed, in contrast to non-treated cells, which appear to be intact. This means that UAE directly from fresh microalgae cells could be an innovative and sustainable option to extract lipids from microalgae.

Passos et al. (2015) studied both pretreatment methods (MAE and UAE) directly from microalgal biomass, finding that all pretreated microalgal biomass had a higher content of all soluble organic macromolecules (proteins, carbohydrates and lipids) than non-pretreated biomass. However, these procedures can damage or degrade thermolabile compounds if extraction conditions are carried out under extremely high temperatures.

Another alternative extraction method relies on the use of enzymes, which are capable of degrading or disrupting cell walls and membranes, thus allowing a better release of bioactives (Munish et al. 2012). In vegetable matrices, pectinases, cellulases and hemicellulases are commonly used. Since algae have a similar cell wall, these enzymes have been also employed for degradation of their cell walls, as many authors have confirmed. For instance, Zuorro et al. (2016) used a multi-enzyme pretreatment based on cellulase and mannanase enzymes for the release of intracellular material, specifically lipids, from the marine microalga Nannochloropsis sp, reaching up to 90 % of lipid recovery under optimal conditions. Another interesting example was given by Huo et al. (2015). They applied a mixture of enzymes (cellulase, pectinase and hemicellulase) to extract oil from wet microalgae Scenedesmus sp. G4, obtaining up to 86.1% of lipids under optimal conditions and proving the great impact of enzymes on the integrity of microalgae cell. The main problem encountered by using this methodology is the low efficiency of the lysis process and the time required to complete the reaction (that can take from hours to days) (Grosso et al. 2015).

3.2.2.2 Compressed Fluids’ Extraction Techniques

Compressed fluids’ extraction techniques such as SFE, PLE, SWE or GXL are the most innovative methods that have been recently used to obtain high-value compounds from many matrices, including macro and microalgae. The main advantage is that all of them can use green solvents such as CO2, water or ethanol. Furthermore, the possibility of changing the solvent physicochemical properties and solvating power by changes in pressure and/or temperature of the system provides a great selectivity and efficiency for obtaining a huge range of bioactives with different characteristics.

Despite several differences in the basic principles of SFE, GXL and PLE, they all have in common that they must operate under medium-to-high pressures; for this reason, it is possible to use the same equipment for the three extraction techniques. SFE is based on the use of solvents at temperatures and pressures above their critical points, while PLE operates using liquids at temperatures above their normal boiling points and pressures enough to keep the extracting fluid in the liquid state. GXLs extraction is an intermediate technique between PLE and SFE. GXLs are liquids whose volume has been increased when pressurized with a condensable gas (e.g., CO2). Under these conditions, at least two fluid phases or a single phase above the bubble point curve but below the critical composition exists (Herrero et al. 2013). Figure 11.2 shows a general scheme of the equipment that can be used for SFE, GXL and PLE. In the following sections, a more detailed explanation on the different configurations employed for each process is included.

3.2.2.2.1 Supercritical Fluid Extraction

Briefly, when a fluid is forced to a temperature and pressure above its critical point, it is considered to be a supercritical fluid, and it shares physicochemical characteristics from both liquid and gas states. Some of these properties are low viscosity, high diffusivity and tunable density, which can be easily modified depending on the temperature and pressure applied and, consequently, the solubility of the target compound in the fluid is also modified. Carbon dioxide (CO2) is the most-employed fluid in SFE, since it has moderate critical temperature and pressure (31.2 °C and 73.8 bar) and it can be recycled, so it can be considered as environmentally friendly. Moreover, a very interesting point is that CO2 will become a gas at atmospheric conditions, so once the extraction is finished, the CO2 from the extract is directly evaporated, and the extract is completely solvent-free.

As mentioned, Fig. 11.2 shows the scheme of a pilot plant that can be used for SFE, GXL extraction and PLE. In SFE configuration, the CO2 is initially cooled to 0–5 °C in order to be pumped as a liquid; the system includes the possibility of adding a co-solvent as modifier of the polarity of CO2. Once the mixture is achieved, the fluid is heated to the selected extraction temperature and pumped at the selected pressure into an extraction vessel (E1 and/or E2), kept at working temperature. Algae are placed inside the extraction cell in a basket. If several extraction vessels are used, it is possible to increase productivity since while one is used for extraction, the other can be simultaneously filled with the material. Once the extraction is finished, the pressure is reduced through a control valve (R1) and the extract precipitates and is recovered in the separator vessels (S1 and/or S2). A series of collection vessels at sequentially lower pressures may be employed to trap and fractionate the extract. Flow rate and extraction pressure are controlled by the pumping rate and by the setting of the control valve for a particular pumping rate, respectively. On a pilot and industrial scale, CO2 is recycled by condensing it, filtering it and sending it back to the reservoir for being pumped in the following extraction.

There are many reviews which summarize the potential of supercritical fluid extraction to obtain bioactives from different natural sources, including algae. For instance, SFE has been used to extract lipids from Nannochloropsis oculata, Tetraselmis suecica, Dunaliella salina and Crypthecodinium cohnii, among others; and carotenoids from Haematococcus pluvialis, Chlorococcum littorale, Chlorella vulgaris or Scenedesmus almeriensis, among others (Gallego et al. 2018).

As expected, extraction conditions are different depending not only on the compound of interest but also on the algae species. A clear example of this dependence was given by Bong and Loh (2013). In this study, they compared the fatty acid composition and tocopherol content of lipid extracts from Nannochloropsis oculata and Tetraselmis suecica using supercritical fluid extraction and optimum conditions were totally different in both algae (80 °C, 20.7 MPa and 40 °C, 62 MPa, respectively). The same approach occurred for carotenoids. Gilbert-Lopez et al. (2017b) reported that lutein was efficiently extracted from Scenedesmus obliquus using SFE at 50 °C, 36 MPa and 120 min as extraction time, whereas Macías-Sánchez et al. (2010) reported that the same carotenoid was optimally recovered from Scenedesmus almeriensis at 60 °C, 40 MPa and 300 min as extraction time.

One of the most important drawbacks of using supercritical CO2 (scCO2) as extracting solvent is its low polarity, so polar bioactive components cannot be extracted. In this case, an alternative is the use of a polar co-solvent or modifier in small percentages (i.e. ethanol from 1 to 15%) that allows increasing the polarity of the resulting supercritical solvent mixture, thus favouring the extraction of more polar compounds.

For instance, Solana et al. (2014) used a 5% of ethanol as co-solvent for the extraction of α-linolenic acid (αLnA) from Scenedesmus obliquus, Chlorella protothecoides and Nannochloropsis salina. The highest amount of αLnA was reached at 45 °C and 15 MPa after 30 min of extraction.

On the other hand, Ota et al. (2009) extracted β-carotene from Chlorococcum littorale comparing SFE with and without ethanol as co-solvent, reaching a high yield (up to 90%) with 10% of ethanol and optimum conditions of 60 °C, 30 MPa and 180 min of extraction time; a yield of 40% was obtained with pure CO2 as extracting solvent.

Selection of co-solvent is also important for the bioactivity of the obtained extract. For example, Saravana et al. (2017) compared sunflower oil, soybean oil, canola oil, ethanol, and water as co-solvents to support scCO2 extraction of carotenoids, mainly fucoxanthin, and phlorotannins from brown seaweed Saccharina japonica. A 2% sunflower oil as co-solvent showed higher carotenoid content and antioxidant activity than the control (scCO2 only).

Regarding microalgae extraction, in general, a drying step prior to scCO2 extraction is required because they are grown in liquid cultures. Reyes al. (2016) studied the direct extraction of carotenoids from Neochloris oleoabundans paste (containing around 70–80% water) mixing this paste with adsorbents as supporting media. Results showed that chitosan was the adsorbent with better adsorbent capacities for the recovery of carotenoids. These results are interesting to avoid the drying step, which is energy consuming and could be detrimental for the bioactivity of the extracted compounds.

3.2.2.2.2 Gas-Expanded Liquid Extraction

When increasing the amount of polar solvent mixed with CO2, a different type of solvent is achieved: the so-called “carbon dioxide expanded liquid (CXL)”. CXL is a particular case of gas-expanded liquid (GXL) in which carbon dioxide is used as expanding media; CXLs are considered to be half way from pressurized liquids to supercritical fluids (Herrero et al. 2017).

In general terms, GXLs have densities similar to that of organic solvents (without CO2 added), while their viscosities are between those of supercritical fluids and liquids. GXLs show a wide range of physicochemical properties compared to supercritical fluids, since more diverse properties can be obtained considering the wide variety of different green organic solvents that can be employed (Cunico and Turner 2017). Several physicochemical properties change by changing the pressure and/or temperature in CXL systems; among them are the following properties: density, compressibility, viscosity, mass transfer and dielectric properties. For more in-depth information about GXLs, readers are referred to Sánchez-Camargo et al. (2018).

As shown in Fig. 11.2, the equipment needed to work under CXL conditions is the same as the one required for carrying out SFE; the only difference is that under CXLs conditions, a higher amount of solvent is used and, commonly, lower pressures are employed. In general, the instrumentation consists of two pumps, one for carbon dioxide and another for the solvent, a system for heating the extraction cell(s) (medium–high pressure vessel(s)), valves for controlling the fluid flow path and pressure and a collection device. Operation starts by mixing the liquid solvent with CO2 at medium–high pressures (CO2 will expand and the volume of the fluid mixture will increase, depending on the pressure conditions); the fluid is then injected in the medium–high pressure vessel where the extraction takes place (at certain temperature conditions controlled by a heating system); after the extraction time, the outlet valve (R1) is open to control flow/pressure and the extract is continuously collected in a separator vessel (S1).

Some interesting applications of CXLs for the extraction of bioactive compounds from algae have been recently published. For instance, Golmakani et al. (2012) described one of the very first uses of GXL to algal biomass. In this case, two alternative extraction techniques (GXLs and pressurized ethyl lactate: ethanol) were applied to obtain high-value lipids from Arthrospira platensis. Results obtained after chemometric optimization allowed understanding the effects of the different factors involved in the studied processes and provide the optimum conditions to get the maximum γ-linolenic acid (γLnA) recovery and lipid yield. GXL (40 °C, 300 atm, 50% ethanol, 90 min extraction time) provided γLnA recovery of 24.7% and total yields of 6.7% (w/w), while PLE (180 °C, 20.7 MPa, ethanol: ethyl lactate 1:1 and 15 min extraction time) provided total yields up to 20.7% (w/w) and γLnA recoveries of 68.3%. In this case, GXL provided lower yields and recoveries than PLE, but gave higher selectivity and demonstrated its performance as intermediate between PLE and supercritical fluids for the extraction of medium-polar compounds.

Reyes et al. (2014) used a Box–Behnken experimental design to examine the effects of mild operating temperature (40–70 °C) and pressure (20–35 MPa), using ethanol in scCO2 (0–13% w/w) on the astaxanthin content, extraction yield, and antioxidant activity of Haematococcus pluvialis extract. Since astaxanthin is a carotenoid whose molecular weight and functional groups give low solubility in scCO2, two approaches can be followed to increase its extraction: the first one is to force the extraction by increasing the extraction time and pressure (above 50 MPa), while the other is to employ higher amount of ethanol to increase astaxanthin solubility in scCO2. In the work by Reyes et al. (2014), after demonstrating the important effect of ethanol content in supercritical CO2 (more significant than pressure and temperature), authors move to the GXL region using higher ethanol content (50–70%, w/w), mild temperature (30–60 °C) and low pressure (7 MPa). Comparing CXE (Carbon Dioxide Expanded Extraction) with scCO2 at optimum extraction conditions (20 MPa, 13% (w/w), 55 °C for scCO2 and 7 MPa, 50% (w/w) ethanol, 45 °C for CXE), CXE showed better results in terms of extraction yield, astaxanthin content and astaxanthin recovery than scCO2 extraction. In fact, these results were better than any previously published manuscript concerning astaxanthin extraction from H. pluvialis.

3.2.2.2.3 Pressurized Liquid Extraction

Pressurized liquid extraction (PLE) is based on the use of high temperature (below the critical point) and pressures enough to keep the solvent in liquid state. If water is used as extracting solvent, it is called subcritical water extraction (SWE) or pressurized hot water extraction (PHWE) and can be considered as the greenest alternative involving the use of pressurized liquids. Thanks to the high temperatures and pressures, the solvent possesses increased solubility and decreased viscosity, allowing a better mass transfer rates and penetration into the matrix while improving the efficiency of the extraction process.

When working under PLE conditions, instrumentation needed consists of the following: a solvent pump, an extraction vessel (E1), pressure valves, heating systems for controlling temperature and a collection vessel (S1). The solvent is introduced inside the extraction cell by the pump (pressures required range between 35 and 200 bar). Pressure is controlled inside the extraction cell by two on/off valves (or one on/off valve and the restrictor, R1) and the extraction cell is placed inside a heating system, which controls the applied temperature (usually, high-temperature area employed is above the boiling point of the solvent and below its critical point). A collection vessel is needed to recover the extract. It is important to mention that the solvents employed for the extraction should be oxygen-free in order to avoid oxidation of the bioactives as well as to prevent cavitation in the pump; degassing by ultrasounds and helium purge are two systems that can be employed for this purpose.

Depending on the matrix and on the target compound(s), a proper selection of the extracting solvent is needed. Thus, for the extraction of more polar lipids such as short-chain fatty acids and tocopherol or carbohydrates, water can be chosen, whereas less polar lipids such as PUFAs can be extracted using ethanol (Pieber et al. 2012; Rodriguez-Meizoso et al. 2010). In this sense, Otero et al. (2018) studied the selectivity of five solvents of different polarities (hexane, ethyl acetate, acetone, ethanol and ethanol:water 50:50) in the lipid composition of Fucus vesiculosus by PLE. Results showed that long-chain fatty acids including oleic acid, arachidonic acid and EPA are selectively extracted using ethyl acetate, producing extracts that at least double the fatty acids quantity in comparison to the other solvents. Nevertheless, the lowest ω-6/ω-3 ratio was achieved with ethanol: water 50:50 (the most polar solvent) with a value of 1.92, much lower than those recommended by FAO (ω-6/ω-3 = 10) (FAO 2010). It is well known that a low ω-6/ω-3 ratio exerts suppressive effects on cardiovascular diseases (Simopoulos 2002).

Several examples can be found in the literature about the use of PLE to extract carotenoids from many different algae species using different solvents such as ethanol, water, acetone and their mixtures. The diversity of solvents that have been employed can be explained by the wide range of polarities of bioactive carotenoids; for example, violaxanthin, neoxanthin and lutein could be effectively extracted from Chlorella vulgaris using acetone at 50 °C and 10 MPa (Plaza et al. 2012); fucoxanthin and zeaxanthin could be extracted from Himanthalia elongata using ethanol as solvent at 100 °C and 10.3 MPa (Plaza et al. 2010); and also from Phaeodactylum tricornutum using ethyl acetate at 100 °C and 10 MPa (Derwenskus et al. 2019); astaxanthin and derivatives could be efficiently extracted from Haematococcus pluvialis using pressurized ethanol at 50 °C and 10.3 MPa (Jaime et al. 2010).

3.3 Integrated Processes

The integration of processes dealing with the extraction of bioactive compounds from macro- and microalgae is a hot topic. Some interesting approaches have been employed in the literature; for instance, Hernandez et al. (2014) studied the effect of microwave pretreatment prior to scCO2 extraction in different microalgae. Interestingly, the authors reported that the microwave (MW) effect strongly depends on the microalgae tested; whereas in the microalga Scenedesmus almeriensis, a positive effect on the yield of lipids was shown, Nannochloropsis gaditana seemed to be negatively affected by the microwave-assisted pretreatment. The same approach was studied in Chlorella vulgaris, in which Dejoye et al. (2011) concluded that the integration of MAE and scCO2 extraction gives a high quality and yield of recovered lipids.

Among the most promising integration of processes are those involving the coupling of extraction and purification, considering that depending on the extraction conditions and the chemical characteristics of the target compound, sometimes, it would be difficult to obtain pure extracts. Supercritical antisolvent fractionation (SAF), supercritical antisolvent (SAS) or solution-enhanced dispersion (SEDS) by supercritical fluids are processes that could be coupled online to obtain dried encapsulated particles. In general terms, these techniques are based on contacting an organic solution with scCO2. During mixing, the rapid mutual diffusion at the interface of scCO2 and the liquid extract containing the compounds causes the precipitation of solutes, allowing to obtain completely solvent-free products. These processes can also be used to encapsulate or co-precipitate target compounds by super saturation of the polymer/solute, leading to sub-micrometric particles with controlled size. For example, Machado et al. (2016) coupled an enzymatic lysis assisted by ultrasounds, without biomass freezing, for the cell wall disruption of Haematococcus pluvialis, with the subsequent encapsulation of carotenoids in the copolymer poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV) using SEDS technique.

3.4 Biorefinery

The concept of biorefinery relies on the capability of improving the recovery of different products from a unique biomass. In other words, the main idea consists of the integration of multiple and sequential processes that allow the fractionation of a single biomass into different and isolated compounds of high added value (Subhadra and Grinson 2011).

Therefore, a great effort is being carried out in the development of biorefinery platforms to best exploit available resources. In this sense, a microalgae biorefinery platform was designed in our research group involving the integration of compressed fluids technologies such as SFE, GXLs and PLE in a holistic approach, in which the residue of each extraction is used as a raw material for the next step.

The compressed fluids’ biorefinery platform involves the extraction of target compounds of different polarities through the addition/removal of CO2 and therefore moving from SFE (with neat CO2) to conventional organic solvents (working under high pressure and temperature) and considering, as intermediate steps, the use of CO2 plus modifier and/or CXLs. In this approach, working under medium/high pressures, different physicochemical properties can be conveniently modified through the addition of compressed CO2 (such as polarity, viscosity and diffusivity) (Herrero et al. 2017).

Figure 11.3 shows a scheme of the compressed fluids’ platform mentioned above. In this kind of biorefinery platform, the residue of one extraction is the matrix to be treated in the next step; taking into account that all the steps are done in the same equipment, different extraction processes (carried out at medium-high pressure) were sequentially used to extract valuable compounds from algae biomass. Biorefinery started using a dry biomass sample and applying an SFE (CO2 as solvent) as first step to obtain non-polar bioactives, including carotenoids and lipids; the residue of SFE was subsequently treated with a CXL (and/or PLE with ethanol) to obtain the polar lipids, carotenoids and chlorophylls; and finally, by means of SWE, sugars and proteins were obtained. By this approach, the sample is treated with increasing polarity solvents to provide different extracts enriched in valuable compounds. This was the approach followed by Gilbert-Lopez et al. (2015) in which different compounds were obtained from Isochrysis galbana. Thus, the extraction process was partially selective according to the polarity of the solvent/mixture of solvents used. First extracts using scCO2 were rich in triacylglycerides, while extracts obtained using CXL were rich in fucoxanthin, the main carotenoid in Isochrysis galbana. The latest extracts obtained were enriched in proteins and carbohydrates.

Similar results were obtained using Scenedesmus obliquus as dry biomass. In this case, not fucoxanthin but lutein and β-carotene were extracted in the GXL step (Gilbert-Lopez et al. 2017b).

It is worth mentioning that the same biorefinery approach can be used to extract compounds starting from high polarity to low polarity, by just inverting the order of the processes involved (PLE with water, PLE with ethanol, CXL and SFE with neat CO2). The viability of this approach has been recently demonstrated considering wet microalgae as starting material (Ibáñez et al. 2017).

It is also important to emphasize that through the integration of green chemistry into biorefineries and the use of low environmental impact technologies such as those based on the use of compressed fluids, future sustainable production chains of biofuels and high-value chemicals from biomass can be established, thus improving the economic viability of the whole biorefinery.

4 Conclusions

In this chapter, we presented an overview of the bioactive compounds that can be obtained from macro and microalgae with potential use in the food, cosmetic and pharmaceutical industries. Although not exhaustive, the information has been selected considering some of the most important compounds that can be synthesized by algae and can provide benefits for human health. Some of them are major components such as proteins, lipids and carbohydrates and other minor components (secondary metabolites) generated to protect algal cells against stress conditions. Emphasis has been put on the different possibilities for promoting the enrichment in high-value metabolites, ranging from marine biotechnology to processes (both upstream and downstream) that can be optimized to obtain highly enriched fractions in different components. But the main focus of the chapter has been the description of new technologies to extract valuable compounds from algae, among them are some extraction processes assisted by microwaves, ultrasounds or enzymes and processes based on the use of compressed fluids (SFE, GXL, PLE and SWE). In the framework of this book, these processes have in common that they are greener, more efficient, avoid the use of toxic organic solvents and can be sustainable. Several recent applications of these technologies to the extraction of valuable compounds from algae are described in the text, demonstrating the usefulness and the advantages of such processes compared to conventional ones. Finally, a biorefinery platform based on compressed fluids technology is presented as an example of the possibilities offered by these technologies to completely valorize algae biomass. This platform is intended to be placed in a whole process involving the optimization of the different necessary steps: efficient production of biomass using CO2 formed by combustion of fossil fuels in thermoelectric power plants, extraction of valuable bioactives using environmentally friendly processes and processing of the oily fraction to produce biofuels; exhausted material can be also used for other purposes (such as fabrication of furniture.). This way, it will be possible to move towards a more sustainable world, in which circular economy will take the lead and sustainable development challenges will start to be met.

References

Adam F, Abert-Vian M, Peltier G et al (2012) “Solvent-free” ultrasound-assisted extraction of lipids from fresh microalgae cells: a green, clean and scalable process. Bioresour Technol 114:457–465

Aravantinou AF, Manariotis ID (2016) Effect of operating conditions on Chlorococcum sp. growth and lipid production. J Environ Chem Eng 4(1):1217–1223

Ariede MB, Candido TM, Morocho Jacome AL et al (2017) Cosmetic attributes of algae – a review. Algal Res 25:483–487

Baghel RS, Trivedi N, Gupta V et al (2015) Biorefining of marine macroalgal biomass for production of biofuel and commodity chemicals. Green Chem 17(4):2436–2443

Bellou S, Baeshen MN, Elazzazy AM et al (2014) Microalgal lipids biochemistry and biotechnological perspectives. Biotechnol Adv 32(8):1476–1493

Bilanovic D, Andargatchew A, Kroeger T et al (2009) Freshwater and marine microalgae sequestering of CO2 at different C and N concentrations – response surface methodology analysis. Energy Convers Manage 50(2):262–267

Blunt JW, Munro MHG (2008) Dictionary of marine natural products, 1st edn. Champmann & Hall/CRC, Boca Raton

Bong SC, Loh SP (2013) A study of fatty acid composition and tocopherol content of lipid extracted from marine microalgae, Nannochloropsis oculata and Tetraselmis suecica, using solvent extraction and supercritical fluid extraction. Int Food Res J 20(2):721–729

Boussiba S, Bing W, Yuan JP et al (1999) Changes in pigments profile in the green alga Haeamtococcus pluvialis exposed to environmental stresses. Biotechnol Lett 21(7):601–604

Cadoret JP, Garnier M, Saint-Jean B (2012) Microalgae, functional genomics and biotechnology. In: Piganeau G (ed) Genomic insights into the biology of algae, vol 64. Academic, Cambridge, pp 285–341

Caroprese M, Albenzio M, Ciliberti MG et al (2012) A mixture of phytosterols from Dunaliella tertiolecta affects proliferation of peripheral blood mononuclear cells and cytokine production in sheep. Vet Immunol Immunopathol 150(1–2):27–35

Carullo D, Abera BD, Casazza AA et al (2018) Effect of pulsed electric fields and high pressure homogenization on the aqueous extraction of intracellular compounds from the microalgae Chlorella vulgaris. Algal Res 31:60–69

Carvalho JCM, Matsudo MC, Bezerra RP et al (2014) Microalgae bioreactors. In: Bajpai R, Prokop A, Zappi M (eds) Algal biorefineries, cultivation of cells and products, vol 1. Springer, Dordrecht, pp 83–126

Catarino MD, Silva AMS, Cardoso SM (2017) Fucaceae: a source of bioactive phlorotannins. Int J Mol Sci 18(6):1327

Chen J, Shearer GC, Chen Q et al (2011) Omega-3 fatty acids prevent pressure overload-induced cardiac fibrosis through activation of cyclic GMP/protein kinase G signaling in cardiac fibroblasts. Circulation 123(6):584–593

Chen J, Jiao R, Jiang Y et al (2014) Algal sterols are as effective as beta-sitosterol in reducing plasma cholesterol concentration. J Agric Food Chem 62(3):675–681

Christaki E, Bonos E, Giannenas I et al (2013) Functional properties of carotenoids originating from algae. J Sci Food Agric 93(1):5–11

Ciliberti MG, Francavilla M, Intini S et al (2017) Phytosterols from Dunaliella tertiolecta reduce cell proliferation in sheep fed flaxseed during post partum. Mar Drugs 15(7):216

Cunico LP, Turner C (2017) Supercritical fluids and gas-expanded liquids. In: Pena-Pereira F, Tobiszewski M (eds) The application of green solvents in separation processes. Elsevier, Atlanta, pp 155–214

de Jesus Raposo MF, Miranda Bernardo de Morais AM (2015) Microalgae for the prevention of cardiovascular disease and stroke. Life Sci 125:32–41

de Jesus Raposo MF, Santos Costa de Morais RM, Miranda Bernardo de Morais AM (2013) Health applications of bioactive compounds from marine microalgae. Life Sci 93(15):479–486

Dejoye C, Vian MA, Lumia G et al (2011) Combined extraction processes of lipid from Chlorella vulgaris microalgae: microwave prior to supercritical carbon dioxide extraction. Int J Mol Sci 12(12):9332–9341

Derwenskus F, Metz F, Gille A et al (2019) Pressurized extraction of unsaturated fatty acids and carotenoids from wet Chlorella vulgaris and Phaeodactylum tricornutum biomass using subcritical liquids. GCB Bioenergy 11(1):335–344

Diaz-Santos E, Vila M, Vigara J et al (2016) A new approach to express transgenes in microalgae and its use to increase the flocculation ability of Chlamydomonas reinhardtii. J Appl Phycol 28(3):1611–1621

Diplock AT, Agget PJ, Ashwell M et al (1999) Scientific concepts of functional foods in Europe consensus document. Br J Nutr 81(4):S1–S27

FAO (2010) Fats and fatty acids in human nutrition. Report of an expert consulation. FAO Food Nutr Pap 91:1–166

FAO (2018) The state of world fisheries and aquaculture [Online]. http://www.fao.org/state-of-fisheries-aquaculture/en/. Accessed 17 Sept 2018

Gallego R, Montero L, Cifuentes A et al (2018) Green extraction of bioactive compounds from microalgae. J Anal Test 2(2):109–123

García PA, Hernández AP, San Feliciano A et al (2018) Bioactive prenyl- and terpenyl-quinones/hydroquinones of marine origin. Mar Drugs 16(9):292

Gilbert-Lopez B, Mendiola JA, Fontecha J et al (2015) Downstream processing of Isochrysis galbana: a step towards microalgal biorefinery. Green Chem 17(9):4599–4609

Gilbert-Lopez B, Barranco A, Herrero M et al (2017a) Development of new green processes for the recovery of bioactives from Phaeodactylum tricornutum. Food Res Int 99:1056–1065

Gilbert-Lopez B, Mendiola JA, van den Broek LAM et al (2017b) Green compressed fluid technologies for downstream processing of Scenedesmus obliquus in a biorefinery approach. Algal Res 24:111–121

Giles GE, Mahoney CR, Kanarek RB (2013) Omega-3 fatty acids influence mood in healthy and depressed individuals. Nutr Rev 71(11):727–741

Giros A, Grzybowski M, Sohn VR et al (2009) Regulation of colorectal cancer cell apoptosis by the n-3 polyunsaturated fatty acids docosahexaenoic and eicosapentaenoic. Cancer Prev Res 2(8):732–742

Golmakani MT, Mendiola JA, Rezaei K et al (2012) Expanded ethanol with CO2 and pressurized ethyl lactate to obtain fractions enriched in gamma-linolenic acid from Arthrospira platensis (Spirulina). J Supercrit Fluids 62:109–115

Gong M, Bassi A (2016) Carotenoids from microalgae: a review of recent developments. Biotechnol Adv 34(8):1396–1412

Gouveia L, Coutinho C, Mendonca E et al (2008) Functional biscuits with PUFA-omega 3 from Isochrysis galbana. J Sci Food Agric 88(5):891–896

Grosso C, Valentao P, Ferreres F et al (2015) Alternative and efficient extraction methods for marine-derived compounds. Mar Drugs 13(5):3182–3230

Güven KC, Percot A, Sezik E (2010) Alkaloids in marine algae. Mar Drugs 8(2):269–284

Hadiyanto H, Suttrisnorhadi (2016) Response surface optimization of ultrasound assisted extraction (UAE) of phycocyanin from microalgae Spirulina platensis. Emir J Food Agric 28(4):227–234

Hagen C, Siegmund S, Braune W (2002) Ultrastructural and chemical changes in the cell wall of Haematococcus pluvialis (Volvocales, Chlorophyta) during aplanospore formation. Eur J Phycol 37(2):217–226

Hamed I, Ozogul F, Ozogul Y et al (2015) Marine bioactive compounds and their health benefits: a review. Comp Rev Food Sci F 14(4):446–465

Hernandez D, Solana M, Riano B et al (2014) Biofuels from microalgae: lipid extraction and methane production from the residual biomass in a biorefinery approach. Bioresour Technol 170:370–378

Herrero M, Ibáñez E (2015) Green processes and sustainability: an overview on the extraction of high added-value products from seaweeds and microalgae. J Supercrit Fluids 96:211–216

Herrero M, Ibáñez E (2018) Green extraction processes, biorefineries and sustainability: recovery of high added-value products from natural sources. J Supercrit Fluids 134:252–259

Herrero M, Castro-Puyana M, Mendiola JA et al (2013) Compressed fluids for the extraction of bioactive compounds. TrAC-Trends Anal Chem 43:67–83

Herrero M, Mendiola JA, Ibáñez E (2017) Gas expanded liquids and switchable solvents. Curr Opin Green Sustain Chem 5:24–30

Hoang Van C, Eun J-B (2017) Marine carotenoids: bioactivities and potential benefits to human health. Crit Rev Food Sci Nutr 57(12):2600–2610

Hodaifa G, Martinez ME, Sanchez S (2008) Use of industrial wastewater from olive-oil extraction for biomass production of Scenedesmus obliquus. Bioresour Technol 99(5):1111–1117

Hu X, Yang XQ, Li LH et al (2015) Antioxidant properties of microalgae protein hydrolysates prepared by neutral protease digestion. Appl Mech Mater 707:149–153

Huo S, Wang Z, Cui F et al (2015) Enzyme-assisted extraction of oil from wet microalgae Scenedesmus sp G4. Energies 8(8):8165–8174

Ibáñez E, Cifuentes A (2013) Benefits of using algae as natural sources of functional ingredients. J Sci Food Agric 93(4):703–709

Ibáñez E, Gilbert-López B, Mendiola JA et al (2017) Integrated green extraction processes for downstream processing of microalgae wet biomass (GREENμWETBIO). Spain patent application

Jaime L, Rodriguez-Meizoso I, Cifuentes A et al (2010) Pressurized liquids as an alternative process to antioxidant carotenoids’ extraction from Haematococcus pluvialis microalgae. Lwt-Food Sci Technol 43(1):105–112

Jerez-Martel I, Garcia-Poza S, Rodriguez-Martel G et al (2017) Phenolic profile and antioxidant activity of crude extracts from microalgae and cyanobacteria strains. J Food Qual 4:1–8

Juin C, Cherouvrier J-R, Thiery V et al (2015) Microwave-assisted extraction of phycobiliproteins from Porphyridium purpureum. Appl Biochem Biotechnol 175(1):1–15

Kapoore RV, Butler TO, Pandhal J et al (2018) Microwave-assisted extraction for microalgae: from biofuels to biorefinery. Biology 7(1):18

Kazlowska K, Lin H-TV, Chang S-H et al (2013) In vitro and in vivo anticancer effects of sterol fraction from red algae Porphyra dentata. Evid-Based Compl Alt 493869

Kim SK, Himaya SWA (2011) Medicinal effects of phlorotannins from marine brown algae. In: Kim SK (ed) Advances in food and nutrition research, Marine medicinal foods: implications and applications, macro and microalgae, vol 64. Elsevier Academic, Atlanta, pp 97–109

Kumari P, Kumar M, Gupta V et al (2010) Tropical marine macroalgae as potential sources of nutritionally important PUFAs. Food Chem 120(3):749–757

Kumari P, Bijo AJ, Mantri VA et al (2013) Fatty acid profiling of tropical marine macroalgae: an analysis from chemotaxonomic and nutritional perspectives. Phytochemistry 86:44–56

Leon R, Fernandez E (2007) Nuclear transformation of eukaryotic microalgae – historical overview, achievements and problems. Adv Exp Med Biol 616:1–11

Luo X, Su P, Zhang W (2015) Advances in microalgae-derived phytosterols for functional food and pharmaceutical applications. Mar Drugs 13(7):4231–4254

Lv J, Yang X, Ma H et al (2015) The oxidative stability of microalgae oil (Schizochytrium aggregatum) and its antioxidant activity after simulated gastrointestinal digestion: relationship with constituents. Eur J Lipid Sci Technol 117(12):1928–1939

Machado FRS Jr, Trevisol TC, Boschetto DL et al (2016) Technological process for cell disruption, extraction and encapsulation of astaxanthin from Haematococcus pluvialis. J Biotechnol 218:108–114

Macías-Sánchez MD, Fernandez-Sevilla JM, Acien-Fernandez FG et al (2010) Supercritical fluid extraction of carotenoids from Scenedesmus almeriensis. Food Chem 123(3):928–935

Marris E (2006) Black is the new green. Nature 442:624

Martinez-Guerra E, Gude VG, Mondala A et al (2014) Extractive-transesterification of algal lipids under microwave irradiation with hexane as solvent. Bioresour Technol 156:240–247

Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sustain Energy Rev 14(1):217–232

Matos J, Cardoso C, Bandarra NM et al (2017) Microalgae as healthy ingredients for functional food: a review. Food Funct 8(8):2672–2685

Mendiola JA, Castro-Puyana M, Herrero M et al (2013) Green foodomics. In: Cifuentes A (ed) Foodomics: advanced mass spectrometry in modern food science and nutrition. Wiley, Hoboken, pp 471–505

Metting FB (1996) Biodiversity and application of microalgae. J Ind Microbiol Biotechnol 17(5–6):477–489

Montero L, Sanchez-Camargo AP, Garcia-Canas V et al (2016) Anti-proliferative activity and chemical characterization by comprehensive two-dimensional liquid chromatography coupled to mass spectrometry of phlorotannins from the brown macroalga Sargassum muticum collected on North-Atlantic coasts. J Chrom A 1428:115–125

Munish P, Deepika S, Barrow CJ (2012) Enzyme-assisted extraction of bioactives from plants. Trends Biotechnol 30(1):37–44

Oncel SS (2017) Microalgae, taking over the role in the hydrogen future. In: Pires JCM (ed) Recent advances in renewable energy, Microalgae as a source of bioenergy: products, processes and economics, vol 1. Bentham Science, Sharjah, pp 98–149

Ota M, Watanabe H, Kato Y et al (2009) Carotenoid production from Chlorococcum littorale in photoautotrophic cultures with downstream supercritical fluid processing. J Sep Sci 32(13):2327–2335

Otero P, Quintana SE, Reglero G et al (2018) Pressurized liquid extraction (PLE) as an innovative green technology for the effective enrichment of Galician algae extracts with high quality fatty acids and antimicrobial and antioxidant properties. Mar Drugs 16(5):156

Pangestuti R, Kim S-K (2011) Neuroprotective effects of marine algae. Mar Drugs 9(5):803–818

Passos F, Carretero J, Ferrer I (2015) Comparing pretreatment methods for improving microalgae anaerobic digestion: thermal, hydrothermal, microwave and ultrasound. Chem Eng J 279:667–672

Patil PD, Reddy H, Muppaneni T et al (2013) In situ ethyl ester production from wet algal biomass under microwave-mediated supercritical ethanol conditions. Bioresour Technol 139:308–315

Pieber S, Schober S, Mittelbach M (2012) Pressurized fluid extraction of polyunsaturated fatty acids from the microalga Nannochloropsis oculata. Biomass Bioenerg 47:474–482

Plaza M, Herrero M, Cifuentes A et al (2009) Innovative natural functional ingredients from microalgae. J Agric Food Chem 57(16):7159–7170

Plaza M, Santoyo S, Jaime L et al (2010) Screening for bioactive compounds from algae. J Pharm Biomed Anal 51(2):450–455

Plaza M, Santoyo S, Jaime L et al (2012) Comprehensive characterization of the functional activities of pressurized liquid and ultrasound-assisted extracts from Chlorella vulgaris. Lwt-Food Sci Technol 46(1):245–253

Pottel L, Lycke M, Boterberg T et al (2014) Omega-3 fatty acids: physiology, biological sources and potential applications in supportive cancer care. Phytochem Rev 13(1):223–244

Reyes FA, Mendiola JA, Ibáñez E et al (2014) Astaxanthin extraction from Haematococcus pluvialis using CO2-expanded ethanol. J Supercrit Fluids 92:75–83

Reyes FA, Mendiola JA, Suarez-Alvarez S et al (2016) Adsorbent-assisted supercritical CO2 extraction of carotenoids from Neochloris oleoabundans paste. J Supercrit Fluids 112:7–13

Rodriguez-Meizoso I, Jaime L, Santoyo S et al (2010) Subcritical water extraction and characterization of bioactive compounds from Haematococcus pluvialis microalga. J Pharm Biomed Anal 51(2):456–463

Samarakoon K, Jeon Y-J (2012) Bio-functionalities of proteins derived from marine algae – a review. Food Res Int 48(2):948–960

Samarakoon KW, Ko J-Y, Lee J-H et al (2014) Apoptotic anticancer activity of a novel fatty alcohol ester isolated from cultured marine diatom, Phaeodactylum tricornutum. J Funct Food 6:231–240

Sánchez-Camargo AdP, Mendiola JA, Ibáñez E (2018) Gas expanded-liquids. In: Hunt AJ, Attard TM (eds) Supercritical and other high-pressure solvent systems: for extraction, reaction and material processing, green chemistry Series No. 57. The Royal Society of Chemistry, London, pp 512–531

Saravana PS, Getachew AT, Yeon-Jin C et al (2017) Influence of co-solvents on fucoxanthin and phlorotannin recovery from brown seaweed using supercritical CO2. J Supercrit Fluids 120(Part 2):295–303

Sathasivam R, Ki JS (2018) A review of the biological activities of microalgal carotenoids and their potential use in healthcare and cosmetic industries. Mar Drugs 16(1):26

Simopoulos AP (2002) The importance of the ratio of omega-6/omega-3 essential fatty acids. Biomed Pharmacother 56(8):365–379

Solana M, Rizza CS, Bertucco A (2014) Exploiting microalgae as a source of essential fatty acids by supercritical fluid extraction of lipids: comparison between Scenedesmus obliquus, Chlorella protothecoides and Nannochloropsis salina. J Supercrit Fluids 92:311–318

Souza RB, Frota AF, Silva J et al (2018) In vitro activities of kappa-carrageenan isolated from red marine alga Hypnea musciformis: antimicrobial, anticancer and neuroprotective potential. Int J Biol Macromol 112:1248–1256

Subhadra B, Grinson G (2011) Algal biorefinery-based industry: an approach to address fuel and food insecurity for a carbon-smart world. J Sci Food Agric 91(1):2–13

Suganya T, Varman M, Masjuki HH et al (2016) Macroalgae and microalgae as a potential source for commercial applications along with biofuels production: a biorefinery approach. Renew Sustain Energy Rev 55:909–941

Tanniou A, Vandanjon L, Incera M et al (2014) Assessment of the spatial variability of phenolic contents and associated bioactivities in the invasive alga Sargassum muticum sampled along its European range from Norway to Portugal. J Appl Phycol 26(2):1215–1230

Tatke P, Jaiswal Y (2011) An overview of microwave assisted extraction and its applications in herbal drug research. Res J Med Pla 5(1):21–31

Thanh-Sang V, Dai-Hung N, Kim S-K (2012) Marine algae as a potential pharmaceutical source for anti-allergic therapeutics. Process Biochem 47(3):386–394

Vanthoor-Koopmans M, Wijffels RH, Barbosa MJ et al (2013) Biorefinery of microalgae for food and fuel. Bioresour Technol 135:142–149

Villarruel-Lopez A, Ascencio F, Nuno K (2017) Microalgae, a potential natural functional food source – a review. Polish J Food Nutr Sci 67(4):251–263

Yates CM, Calder PC, Rainger GE (2014) Pharmacology and therapeutics of omega-3 polyunsaturated fatty acids in chronic inflammatory disease. Pharmacol Ther 141(3):272–282

Yen H-W, Hu IC, Chen C-Y et al (2013) Microalgae-based biorefinery – from biofuels to natural products. Bioresour Technol 135:166–174

Yoshie-Stark Y, Hsieh Y-P, Suzuki T (2003) Distribution of flavonoids and related compounds from seaweeds in Japan. J Tokyo Univ Fish 89:1–6

Yu Ran H, Yousof Ali M, Mi-Hee W et al (2015) Anti-diabetic and anti-inflammatory potential of the edible brown alga Hizikia fusiformis. J Food Biochem 39(4):417–428

Zhao G, Chen X, Wang L et al (2013) Ultrasound assisted extraction of carbohydrates from microalgae as feedstock for yeast fermentation. Bioresour Technol 128:337–344

Zuorro A, Maffei G, Lavecchia R (2016) Optimization of enzyme-assisted lipid extraction from Nannochloropsis microalgae. J Taiwan Inst Chem E 67:106–114

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Bueno, M., Gallego, R., Mendiola, J.A., Ibáñez, E. (2019). Downstream Green Processes for Recovery of Bioactives from Algae. In: Hallmann, A., Rampelotto, P. (eds) Grand Challenges in Algae Biotechnology. Grand Challenges in Biology and Biotechnology. Springer, Cham. https://doi.org/10.1007/978-3-030-25233-5_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-25233-5_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-25232-8

Online ISBN: 978-3-030-25233-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)