Abstract

Nanoscience and nanotechnology primarily deal with the synthesis characterization exploration and exploitation of nanostructural materials. Polymer nanocomposite materials have lately received great attention in both academia and industry. Small additions of inorganic usually surface-treated nanoparticles have a very positive effect on the electrical properties of insulating polymers. Biopolymers are polymers produced by living organisms in other words they are polymeric biopolymers. Cyclodextrins are a group of naturally occurring cyclic oligosaccharides, with six, seven, or eight glucose subunits linked by α-(1, 4) glycosidic bonds in a torus shaped structure and are denominated as α-, β-, and γ-CD respectively. In the present study, zincoxide/biopolymer nanocompositie was successfully fabricated by a simple and cost effective method. The possible nanomaterial zincoxide was successfully synthesized by simple precipitation technique and then effectivcly impregenated through the β-cyclodextrin matrix. The morphology of the synthesized nanocompositie was investigated using scanning electron microscopy and transmission electron microscopy. The crystalline nature of the nanocomposite was studied using an X-ray diffractometer. XRD analysis revealed the spherical shape allignment of zincoxide with hexagonal wurtzite structure. UV-Vis, FTIR spectral analysis and AFM studies where also performed for the synthesized nano compositie.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nanotechnology deals with the science of production, manipulation and use of materials at subatomic level to produce novel products. It has tremendous applications in diagnostic devices, drug delivery, tissue engineering, environmental chemistry, water filtration etc. Nano-sized metal particles have great attention due to its unique optical, electrical and magnetic properties [1]. The two approaches followed for the synthesis of nanomaterials are (i) top down and (ii) bottom up approaches. Top down approach involves synthesis of nanomaterials from bulk, materials through size reduction using mechanical methods such as mechanical milling [2, 3]. Bottom up approach involves synthesis of nanomaterials from the self-assembly of their constituent atoms into larger, organized systems using chemical or vapour methods. Bottom up approaches have been widely used by the researchers due to advantages like reproducibility, relative case of scale up and high degree of control on morphology. zincoxide nanoparticles become one of the most important functional materials due to its unique optical, electronic properties such as near-UV emission, catalytic, optical transparency, electric conductivity, piezoelectricity etc. It has superior durability, greater selectivity and heat resistance than organic and inorganic materials [4].

Recently, zincoxide nanomaterials have been observed to have important application in improved photocatalytic degradation of dyes. Many researchers have reported their achievements in preparing zincoxide nanomaterials and its composites through different methods and their improved application in photocatalytic degradation of organic dyes have been extensively studied [5]. Different methods like simple precipitation method, hydrothermal method, aerosol, micro-emulsion, ultrasonic, sol–gel method, evaporation of solution and suspensions, evaporative decomposition of solution (EDS), solid state reaction, conventional ceramic fabrication, wet chemical synthesis, spray pyrolysis method [6,7,8,9,10,11] etc. have been adopted by researchers for the synthesis of nanosized ZnO. Among these synthetic routes, simple precipitation technique compared with other traditional methods provides a facile route for low cost and large-scale production, which does not need expensive raw materials and complicated equipments [7, 12]. The preparation of zincoxide nanostructures by the simple precipitation technique from zinc salt solutions, such as Zn(NO3)2, Zn(CH3COO)2· 2H2O, ZnSO4, with alkali solutions containing LiOH, NH4OH, NaOH, etc. have been investingated [7].

Cyclodextrins (CDs) are a group of naturally occurring cyclic oligosaccharides, with six, seven, or groups makes the upper and lower eight glucose subunits linked by α-(1, 4) glycosidic bonds in a torus shaped structure and are denominated as α-, β- and γ-CD respectively. These are biopolymers which contain primary and secondary hydroxyl groups at the 2, 3 and the 6 positions, respectively [13]. They form a rigid structure because of the formation of a belt of intermolecular hydrogen bonds between hydroxyl groups at the 2 and 3 positions of adjacent glucose units. The rotation of the primary hydroxyl groups is possible, thus reducing the effective diameter of the cavity on the primary side of the molecule thereby the upper and lower end of the molecule is rendered hydrophilic. The cavity of the cyclodextrins is rendered hydrophobic because of the presence of glycosidic oxygens and C–H units. Greater attention has recently been focused on cyclodextrin based polymers in a wide variety of applications because of their unique sorption properties. Recently, a number of insoluble cyclodextrin polymers have been widely used for various applications such as contaminants removal from wastewater, protein refolding, drug delivery etc. In the present work zincoxide/β-cyclodextrin nanocompositie was successfully synthesized by a facile route and characterized by XRD, SEM, TEM, FTIR, UV-VIS absorption spectra, AFM etc.

2 Materials and Methods

Zincnitrate, ammoniumcarbonate, β-cyclodextrin and ethanol were purchased from Merck, India Pvt.Ltd. Deionised water was used throughout the reaction process. All the reagents used in this study were of analytical grade. The synthetic procedures for the zincoxide particles by direct precipitation method is described below. The Zn(NO3)2 solutions (1.5 mol/L) was slowly dropped into the (NH4)2CO3 solution a (2.25 mol/L) with vigorous stirring. And then, the precipitate derived from the above reaction was collected by filtration and rinsed three times with high-purity water followed by ethanol. Subsequently the washed precipitate was dried at 80 °C to form the precursor zincoxide. Finally, the precursors was calcined at a temperature of 550 °C for 2 h in the muffle furance [14] to obtain the nanosized zincoxide particles. The precursor zincoxide nanoparticles is mixed with 50 ml of a solution containning biopolymer β-cyclodextrin under proper proportions and stirred uniformly for about 8 h. The resulting mixture is poured in an autoclave coated with teflon lining maintained at 160 °C for 12 h, filtered washed with ethanol and water and dried at 60 °C for 2 h. The synthesized nanocimposite was characterised by XRD, SEM, TEM, FTIR, UV-VIS absorption spectra, AFM etc.

3 Results and Discussion

3.1 XRD

X-ray diffraction paterrn is used to confirm the purity, phase, average particle size and over all synthesized nanocomposites. From Fig. 1, the peaks at 2θ = 31°, 34°, 36°, 47°, 56°, 62°, 67° and 69° of zincoxide/β-cyclodextrin nanocomposites are corresponding to (100), (002), (101), (102), (110), (103), (112) and (201) in the JCPDS data card 89-0510. Hexagonal structure of zincoxide was confirmed by the (1 0 1) crystalline peak and the average crystal size of synthesized zincoxide nanoparticle is found to be 39 nm.

The presence of β-cyclodextrin as well as zincoxide characteristic reflections indicated the maintenance of the β-cyclodextrin and ZnO nanoparticles in crystallographic organization of the nanocomposite. The presence of high and narrow shaped peaks highlight that zincoxide nanoparticles possess high crystallinity and low surface defects [15] and were of ultrapure phase.

3.2 SEM

Figure 2 depicts the uniform distribution of granular zincoxide into the polymer matrix. It is observed that zincoxide nanoparticles are almost spherical in shape and are effectively impregnated through the biopolymer matrix & hence it appears as agglomerated macromolecules.

3.3 TEM

Figure 3 shows the TEM image of the prepared zincoxide/β-cyclodextrin nanocomposite. The size of the particle observed is in the range of 40 nm which is in good agreement with Debye–Scherer formula using XRD. After composite formation, zincoxide nanoparticles were found to be entrapped in the bio polymer matrix.

3.4 FTIR

Fourier transform infrared spectroscopy (FTIR) data of the zincoxide/β-cyclodextrin nanocomposite is represented in the Fig. 4. The absorption band characteristic of Cyclodextrin was observed at 3448 cm−1 corresponding to OH group and the peaks near 1637 cm−1 1543 cm−1 and 1460 cm−1 are assigned to symmetric and asymmetric stretching vibration of COO− groups [16]. The band around 1100 cm−1 (C-O-C) stretching were attributed to saccharide structure [17]. The absorption band around 2922 cm−1 may be due to the C-H stretching of the CH2 group. The peak around 450 cm−1 is the characteristic absorption of Zn-O bond.

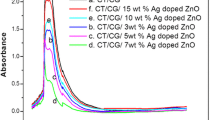

3.5 UV-Vis

The UV-vis absorption spectra of the synthesised nanocomposite is shown in Fig. 5. A broad absorption peak was observed around 360–380 nm which is characteristic band for the pure ZnO [18]. A red shift in the absorption edge may be due to the changes in the morphologies, particle size and surface microstructures [19] which may be due to the presence of the biopolymer β-CD. It is known that the ZnO nanoparticles with absorption at higher wavelength in the UV-visible spectrum have higher particles size [18]. The band gap energy can be determined by substituting the value of the absorption peak at a given wavelength in the following equation [20].

where h = 4.14 × 10−15 eVs, c = 2.99 × 108 m/s, λg = wavelength and Eg is the band gap energy.

The band gap energy is caluculated according to Eq. (1) and it is shown in the Fig. 6. From the figure the Eg value is caluculated to be around 3.02 eV. Figure 6 shows the band gap energy of the ZnO/β-cyclodextrin nanocomposite.

3.6 AFM

Surface topology of the synthesized zincoxide nanoparticles was studied by Atomic Force microscope (AFM) analysis as shown in Fig. 7(a and b). The results showed a uniform surface and indicated that the particles have uniform dimensions.

4 Conclusion

The zincoxide/β-cyclodextrin nanocomposite was prepared by a facile process. The XRD pattern of the synthesized nanocomposite shows that the particle size was 39 nm. From SEM analysis, it is found that the particles are almost spherical in shape in which the zincoxide nanoparticles were effectively impregnated through the biopolymer matrix. The band gap energy of the ZnO/β-cyclodextrin nanocomposite is caluculated to be around 3.02 eV. TEM results confirm that the zincoxide nanoparticles (with a mean diameter of 40 nm) were encapsulated by the biopolymer. The FTIR spectra confirms the functional groups of β-cyclodextrin and zinxoxide. The AFM results showed a uniform surface and indicated that the particles have uniform dimensions.

References

Yong, N.L., et al.: Synthesis and characterization of silver oxide nanoparticles by a novel method. Int. J. Sci. Eng. Res. 4, 155–158 (2013)

Manikandan, S., Karthikeyan, N., Silambarasan, M., Rajan, K.S.: Sub-micron dispersions of sand in water prepared by stirred bead milling and ultrasonication: a potential coolant. Appl. Therm. Eng. 44, 1–10 (2012)

Silambarasan, M., Manikandan, S., Rajan, K.S.: Viscosity and thermal conductivity of dispersions of sub-micron TiO2 particles in water prepared by stirred bead milling and ultrasonication. Int. J. Heat Mass Transf. 55, 7991–8003 (2012)

Chitra, K., Annadurai, G.: Antimicrobial activity of wet chemically engineered spherical shaped ZnO nanoparticles on food borne pathogen. Int. Food Res. J. 20(1), 59–64 (2013). [6]. R. Mohamed, I. Mkhalid, E. Baeissa, M. Al-Rayyani

Goh, H.S.: ZnO nanoflake arrays prepared via anodization and their performance in the photodegradation of methyl orange. Turk. J. Chem. 1(35), 375–391 (2011)

Kanade, K.G.: Effect of solvents on the synthesis of nano-size zinc oxide and its properties. Mater. Res. Bull. 41, 590–600 (2006)

Darezereshki, E., et al.: A novel thermal decomposition method for the synthesis of ZnO nanoparticles from low concentration ZnSO4 solutions. Appl Clay Sci. 54, 107–111 (2011)

Kołodziejczak-Radzimska, A., Jesionowski, T.: Zinc oxide-from synthesis to application: a review. Materials 7, 2833–2881 (2014)

Nagaraju, G.: Surfactant free hydrothermally derived ZnO nanowires, nanorods, microrods and their characterization. Mater. Sci. Semicond. Process. 13, 21–28 (2010)

Zareie, M.: A simple method for preparation of micro-sized ZnO flakes. Mater. Lett. 91, 255–257 (2013)

Kale, R.B.: Morphological evolution of hydrothermally derived ZnO nano and microstructures. Opt.-Int. J. Light Electron. Opt. 127, 4621–4624 (2016)

Chen, C.: Synthesis and characterization of nano-sized ZnO powders by direct precipitation method. Chem. Eng. J. 144, 509–513 (2008)

Zhao, D., Zhao, L., Zhu, C.S., Huang, W.Q., Hu, J.L.: Water insoluble ß-cyclodextrin polymer crosslinked by citric acid synthesis and adsorption properties toward phenol and methylene blue. J. Inclus. Phenom. Macrocycl. Chem. 63, 195–201 (2009)

Chen*, C., Liu, P., Lu, C.: Synthesis and characterisation of nano-size ZnO powders by direct precipitation method, July 2008

Lupan, O., Emelchenko, G.A., Ursaki, V.V., Chai, G., Redkin, A.N., Gruzintsev, A.N., Tiginyanu, I.M., Chow, L., Ono, L.K., Roldan Cuenya, B., Heinrich, H., Yakimov, E.E.: Synthesis and characterization of ZnO nanowires for nanosensor applications. Mater. Res. Bull. 45, 1026–1032 (2010)

Dang, D.K., Sundaram, C., Ngo, Y.L.T., Chung, J.S., Kim, E.J., Hur, S.H.: One pot solid-state synthesis of highly fluorescent N and S co-doped carbon dots and its use as fluorescent probe for Ag+ detection in aqueous solution. Sens. Actuators B 255, 3284–3291 (2018)

Zhang, C.L., Liu, J.C., Yang, W.B., Chen, D.L., Jiao, Z.G.: Experimental and molecular docking investigations on the inclusion mechanism of the complex of phloridzin and hydroxypropyl β – cyclodextrin. Food Chem. 215, 124–128 (2017)

Chieng, B.W., Loo, Y.Y.: Synthesis of ZnO nanoparticles by modified polyol method. Mater. Lett. 73, 78–82 (2012)

Zak, A.K., Abrishami, M.E., Majid, W.H.A., Yousef, R., Hosseini, S.M.: Effect of annealing temperature on some structural and optical properties of ZnO nanoparticles prepared by a modified sol-gel combustion method. Ceram. Int. 37, 393–398 (2011)

Sharma, D., Sharma, S., Kaith, B.S., Rajput, J., Kaur, M.: Synthesis of ZnO nanoparticles using surfactant free in-air and microwave method. Appl. Surf. Sci. 257, 9661–9672 (2011)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Rajalakshmi, T.U., Alagumuthu, G. (2019). A Facile Route for the Fabrication of Nanocompositie by Effective Impregnation Through the Biopolymer Matrix and Its Characterisation. In: Rajan, M., Anand, K., Chuturgoon, A. (eds) Proceedings of the International Conference on Nanomedicine (ICON-2019). ICON 2019. Springer Proceedings in Materials. Springer, Cham. https://doi.org/10.1007/978-3-030-25135-2_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-25135-2_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-25134-5

Online ISBN: 978-3-030-25135-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)