Abstract

Grain processing (cereal and pulse) occupies a large and important portion in food production chain in India, and is one of the oldest and most important of all food technologies. Cereal grains and pulses are grown widely throughout the world and their dietary and economic importance is globally appreciated and recognized. In Indian economy, cereals and pulses occupy a prominent place and remain the most consumed staple food. For ten consecutive years from 2006 to 2016 a rising trend in the production of food grains has been registered. Grains like wheat, paddy, maize, barley and pulses touched an increased level of 25, 20, 12, 2 and 1 lac tons, respectively. The production of millets, however, declined to a recorded level of 66,900 tons from 2010 to 2019. Cereal grains grown all over the country face potential losses during processing, hence posing a serious threat to the countries food reserves. Moreover, food security has always been the overriding goal of agricultural policy in India. The rapid growth in production followed by losses in cereals demands the utilization of the novel processing technologies. The introduction of novel technologies has improved the processing and utilization of cereal grains in different countries. Emerging technologies viz. radio frequency, microwave, irradiation and high-pressure processing have found potential application for storage and processing of cereals. The present chapter envisages the present and future scenario of the novel processing technologies to be used to reduce the losses in cereals.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

The cereals sector occupies a very important place in the Indian economy and the value output among the production of all crops. Steady growth of food grains has been introduced due to the rise of high yielding rice and wheat varieties in late 1960s and early 1970s. India has been producing 20.6 Mt of rice during 1950–1951 and 89.48 Mt in 1999–2000. From 2000–2001 to 2009–2010 the production transformed with growth in area turning negative and in production and yield standing at 1.59% and 1.61%, respectively. Wheat also being the major crop of India, the country produced 6.5 Mt in 1950–1951, 76 Mt in 2000–2001. During 2000–2001 to 2009–2010 the growth in area in wheat has been 1.21% and in production and yield was 1.89% and 0.68% respectively. Similarly, production of coarse cereals has augmented from 15.4 to 32.0 Mt between 1950–1951 and 2000–2001. Because of little or no technological revolution in zone of total coarse cereals during 1980–1981 to 1989–1990 and 2000–2001 to 2009–2010 reproducing swing to other crops or fairly dry area continued to be unused. The production of wheat and pulses was estimated to be 81.47 million tons and 16.51 million tons, respectively in 2011. For the year 2012, the production of crops like rice, wheat, maize, pulses and millets was 1.58, 15.7, 9.5, 2.2, 0.96 and 1.07 Million tons, respectively. The production of the crops in the year 2013, 2014, 2015, 2016 and 2017 is given in Table 1.

Food security has always been an issue in India, despite the high amount of cereal grain production. It is found that 1.3 billion tons, roughly 1/3rd of the food is lost or wasted every year. The post-harvest losses comprise essentially on-farm losses and those in transportation and storage in different marketing channels. Storage losses annually is estimated to be 14 million ton of food grains worth $ 16,000 million per year (FAO). While in low income countries, losses primarily occur during the early and middle stages of the supply chain (FAO, 2011). Post-harvest losses have led to economic losses, Table 2 lists the individual estimation of economic post-harvest losses. Higher losses during post-harvest processing have lead scientists to develop new techniques for the safe storage of foods in an economical manner.

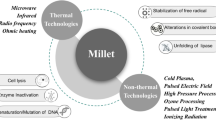

The accurate post-harvest practices and proper storage of crops can show a major role in extending shelf life and reducing spoilage. Important technologies (radio frequency, microwave, irradiation and high-pressure processing) have also been found to have potential application for storage and processing of cereals. Existing food processing techniques create a few limits which has led to the development of innovative technologies (Toepfl et al. 2006). These innovative techniques are environment friendly and reduce the water use. High hydrostatic pressure (HHP), pulsed electric fields (PEFs), ultrasound (US), and cold plasma (CP) are used to exemplify scalable and flexible food manufacturing techniques. Significant, science-based achievements have been made to better understand the basic principles underlying HHP and PEF processing (Hendrickx and Knorr 2002, Raso and Heinz 2006). Understanding the impact of such technologies on foods will enable to design suitable foods and to create process-structure-function relationships. The needs of consumer in terms of preference, acceptance and quality can be fulfilled by the use of non-thermal processes. The current review will emphasize on the present and future scenario of the emerging non-thermal processes and their potential application for storage and processing of cereals.

Irradiation Technology

Food convenience and approachability can be amplified by increasing food production, improvements in supply chain and inhibition of post-harvest losses as being the critical section for certifying future food security. About 20–30% of normal food is lost during harvesting due to insect infestation alone during storage.

Most of the agricultural crops are usually contaminated with insects, pests and pathogenic non-spore forming bacteria, which are responsible for majority of the health problems. According to the UNICEF, WHO and UNDP report of 2018, each year approximately 3.5 million people are killed by the infectious and parasitic diseases, most of which occur in the developing countries. During the past two decades several technologies have emerged in the food sector to enhance the shelf life and do the value addition to the food. Although, there exist several methods for controlling the post-harvest losses like spraying insecticides and fumigants (including ethylene dibromide, malathion, pyrethrins, phosgene) but, the residues of these chemicals has led to a substantial decline in their usage because of their toxicity effects to humans. The most promising alternative to these materials appears to be gamma-irradiation which can be given after packing the food and there are least chances of re-contamination (Christensen 1982; Kleinkopf et al. 2003).

History and Present Status

In India, the first irradiation pilot plant was set up in 1967 at Food Irradiation and Processing Laboratory (FIPLY), Trombay for the irradiation of wheat (to inhibit insect growth) and potatoes (to inhibit sprouting). During 1967–1973 several experimental trials were carried out for the irradiation of many fruits, vegetables, pulses and sea foods for the enhancement of shelf life and the data generated was reviewed jointly by Indian Council of Medical Research (ICMR), National Institute of Nutrition (NIN), Food Corporation of India (FCI), Joint FAO/WHO Expert Committee on Food Irradiation (Loaharanu and Ahmad 1991). During 1991, the standards for food irradiation were drafted and in 1994, first consent for the use of irradiation technology for spices, onion and potato was received from the Ministry of Health and Family Welfare under the Prevention of Food Adulteration Act (PFA) Rules then (now Food Safety and Standard Authority of India). The first functional irradiation plant was set up in Navi Mumbai and the plant is functional since 2000, with a capacity of 30 tons raw materials (spices and dry vegetables) per day. During 2003, another plant was built in Nasik Maharashtra with a capacity of 10 tons of raw materials (onions, cereals and cut flowers) per day (Kume and Todoriki 2013). During 2015, 2100 tons of spices and dehydrated vegetables such as coriander, turmeric and red pepper, and 108 tons of onion were irradiated. During 2016–17 more than 700 tons of mangoes were exported to the US after irradiation. A bilateral agreement with the USA for irradiated fresh fruits was established and the export of irradiated mango has increased (FSSAI 2016- http://www.fssai.gov.in/). Mangoes are irradiated only in USDA approved units, these are Krushak, Lasalgaon, and Maharashtra State Agricultural Marketing Board, Mumbai. Maharashtra-based Kay-Bee Exports became the first Indian company to export pomegranates to the North American market. By the end of 2017, India had 15 commercial irradiation plants. During, 2016, a bilateral agreement was signed between the Indian Agricultural Association, Hindustan Agro Cooperation Ltd. and United Innovation Corporation (a subsidiary of ROSATOM State Atomic Energy Corporation of Russia) for the development of 25 food irradiation centers (Ihsanullah and Rashid 2017).

Plasma Technology

Plasma is referred to as the fourth state of matter as continual addition of energy between the states of matter, gas molecules will become ionized and so carry a net positive charge. If enough molecules are ionized to effect the overall electrical characteristics of the gas the result is called a plasma. A plasma contains electrons, positive ions, neutral gas atoms or molecules, UV light and also excited gas atoms and molecules, which can convey a huge amount of internal energy. Plasma treatments are performed in an evacuated enclosure, or chamber. The air is pumped out and a gas is allowed to flow in at low pressure before energy in the form of electrical power is applied. Plasma is a source of green processing technology satisfying the requirements of food industry . The technology modifies food components to be used for different attributes with its overall quality criterions like nutritional and microbial. Plasma technique is one of the modern technologies applied worldwide for several applications (Garofulic et al. 2015; Misra et al. 2015).

Plasma, a quasi-neutral gas, comprises a number of active elements, like radicals, ions, electrons, metastable excited species, and vacuum ultraviolet radiation that have enough energy to breakdown covalent bonds and start new reactions to form volatile compounds (Şen et al. 2012). Plasma technology is safe for its usage as the active components (phytocomponents) vanish instantly once it is turned off (Misra et al. 2011). Nutritional, functional, and sensory properties are retained by plasma technology, hence, confirming its quality standards. Plasma as a non-thermal process is majorly used for the cereals based industry, which covers more than 50% of consumption (Poutanen et al. 2014). In addition to the decontamination, this technology promises several requirements for cereal industry like maintaining the nutrition content of food. This process is used for the processing of brown rice to maintain its nutritional content, the process basically modifies the cooking quality which makes it more suitable for consumption (Mir et al. 2017).

It has been sated in different studies that plasma pretreatment of seeds encourage their germination and reduce bacterial and fungal growth. It was observed that in case of plasma 13.56 MHz and 300 MHz −300 GHz or below that viz. 50–100 Hz region of electromagnetic fields can reduce the growth of pathogens. A patent by Menashi (1968) stated the sterilizing effect of plasma, after which a lot published about the sterilizing effect of plasma technology (Lerouge et al. 2001; Moisan et al. 2001; Boudam et al. 2006; Violleau et al. 2008). These articles focused on the corn seeds treated with oxygen plasma technique, it was reported that the rate of germination of corn seed increased. Studies on the effect of plasma technology was also reported for legumes wherein it was reported that the sowing quality and production increased (Filatova et al. 2011). Brown rice (long grain) was modified using plasma technology by Chen et al. (2014). Low pressure plasma technique was used by Denis et al. (2015) for the decontamination of wheat grains. Thirumdas et al. (2016) stated that the hydrophilicity of brown rice increased after treating it with radio frequency low pressure plasma technology. Effect of corona discharge plasma was studied on sprouting of rape seeds by Puligundla et al. (2017).

High Pressure Processing (HPP)

Development of new high quality foods require non-conventional method for food processing like high pressure (HP). The range of pressure varies from some tens of MPa in homogenizers or supercritical fluid extractors to several hundreds of MPa in ultra-HP homogenizers or HP pasteurization units. Several other exciting applications of HPP, viz., food structure engineering is available, in addition to the inactivation of microorganisms (Diels and Michiels 2006, Knorr et al. 2008, Sharma and Yadav 2008). Other applications include improvement of the functional properties such as emulsifying, texture, dough-forming and whipping properties of foods and food ingredients (Hoover et al. 1989). It has been studied recently that HPP may reduce the anti-nutritional factors in grains while preserving food quality and constituents, in addition to serve as a promising non-thermal technology applied to food products.

It has been reported that allergenic proteins (7S globulins) of rice grains gets solubilized in other treatments, while no changes occur at modest pressure in treated grains in terms of superficial variation in character color. Tofu subjected to HHP has shown increasing protein digestibility when treated with HPP in addition to reduce the load of microorganisms.

Rice grains immersed in water exhibited solubilization and consequent release of rice allergenic proteins was studied by Kato et al. (2000). It was studied that 0.2–0.5 mg per gram of rice was released with maximum amounts obtained in the pressure range of 300–400 MPa. According to Kato et al. (2000) pressure treatment induces some modifications in the rice grains such as loss of the endosperm, a tightly packed structure within the bulk of starch granules and consequently, breaking it down to single starch granules.

Development of off flavors was prevented by treating with high pressure without affecting the nutritional content and limits the conditions of storage needed to extend shelf life of food products. The off flavors depend on the action of lipoxygenase (Baker and Mustakas 1972). Thermal inactivation of enzymes at atmospheric pressure occurs in the temperature range 60–70 °C.

In contrast, pressure–temperature inactivation occurs in the pressure range 50–650 MPa at temperatures between 10 and 64 °C. Multicycling is the multiple application of pressure alone or in combination with temperature for the same total treatment time but with various numbers of cycles. Ludikhuyze et al. (1998) reported the multicycling application of pressure to inactivate lipoxygenase. These authors found that in the pressure range of 350–525 MPa and thermal treatment at 10–40 °C, the use of multicycles exerted an additional inactivation effect on lipoxygenase, compared to single cycle treatments.

Recommendations

Food safety is a crucial issue in food industry , making decontamination an essential step in many food processing industries. It is gaining importance due to more restrictive food laws and higher quality expectations. Cereal grains are naturally contaminated by a variety of microorganisms which find their ways from air and dust, water and soil, and also from animal feces. The emerging technologies like plasma technology, high pressure process technology and gamma irradiation seem to be the promising techniques of future as well as to meet the ever growing consumer demands for safe food, food security and enhanced food shelf life so as to feed the huge population and to approach the distant markets while maintaining high quality of the food. At present more than 500,000 metric tons of food is getting processed annually worldwide. Considering the bans being imposed on using chemical fumigants in foods, these technologies are expected to gain wide popularity to reduce the post-harvest losses, increase shelf life of products and inhibit the enzymatic and microbial growth in foods. Moreover, these days focus is being given on developing mobile irradiation facilities, which can be taken to the site and used as soon as the food is harvested or produced. As on today food irradiation has now been approved by the various international regulatory bodies such as CODEX, IAEA, FAO and WHO and the regulatory authorities of over 60 countries globally for radiation processing of foods. These novel techniques lead to environmental friendly and sustainable food manufacturing processes with least energy requirements to provide shelf life extension and safety.

References

Baker EC, Mustakas GC (1972) Heat inactivation of trypsin inhibitor, lipoxygenase and urease in soybean: Effect of acid and base additive. J Am Oil Chem Soc 50:137–141

Boudam MK, Moisan M, Saoudi B, Popovici C, Gherardi N, Massines F (2006) Bacterial spore inactivation by atmospheric-pressure plasmas in the presence or absence of UV photons as obtained with the same gas mixture. J Phys D Appl Phys 39:3494–3507

Christensen CM (1982) Storage of cereal grains and their products. American Association of Cereal Chemists, St. Paul, MN

Denis B, Tina S, Christian R, Nadina MF, Gantenbein-Demarchi C, von Rohr PR (2015) Inactivation of microorganisms on granular materials: Reduction of Bacillus amyloliquefaciens endospores on wheat grains in a low pressure plasma circulating fluidized bed reactor. J Food Eng 159:48–56

Diels AM, Michiels CW (2006) High-pressure homogenization as a non-thermal technique for the inactivation of microorganisms. Crit Rev Microbiol 32(4):201–216

FAO (2011) Global food losses and food waste: extent, causes and prevention, by Gustavsson J, Cederberg C, Sonesson U, van Otterdijk R and Meybeck A, Rome. www.fao.org/docrep/014/mb060e/mb060e00.pdf

FAO (2019). http://www.fao.org/faostat/en/#data/QC

Filatova V, Azharonok M, Kadyrov V, Beljavsky A, Gvozdov A, Shik AA (2011) The effect of plasma treatment of seeds of some grain and legumes on their sowing quality and productivity. Rom J Phys 56:139–143

FSSAI (2016) Food safety and standards authority of India. http://www.fssai.gov.in/

Garofulic IE, Jambrak AR, Milosevic S, Dragovic-UV, Zoric Z, Herceg Z (2015) The effect of gas phase plasma treatment on the anthocyanin and phenolic acid content of sour cherry Marasca (Prunuscerasus var. Marasca) juice. LWT Food Sci Technol 62:894–900

Hendrickx ME, Knorr D (2002) Ultra high pressure treatment of foods. In: Hendrickx ME, Knorr D (eds) Ultra high pressure treatment of foods. Kluwer Academic

Hoover DG, Metrick C, Pepinean AM, Forkas DF, Knorr D (1989) Biological effects of high hydrostatic pressure on food microorganisms. Food Technol 3:99–107

Chen H H, Su Yi Lin, Nai WK (2014) Application of atmospheric plasma technology to long-grain brown rice modification. International conference on food and nutrition technology IPCBEE. vol. 72 © (2014) Singapore; IACSIT Press. https://doi.org/10.7763/IPCBEE.2014.V72.11

Ihsanullah I, Rashid A (2017) Current activities in food irradiation as a sanitary and phytosanitary treatment in the Asia and the Pacific Region and a comparison with advanced countries. Food Control 72:345–359

Kato T, Katayama E, Matsubara S, Omi Y, Matsuda T (2000) Release of allergic proteins from rice grains induced by high hydrostatic pressure. J Agric Food Chem 48:3124–3126

Kleinkopf GE, Oberg NA, Olsen NL (2003) Sprout inhibition in storage: current status, new chemistries and natural compounds. Am J Potato Res 80(5):317

Knorr D, Engel KH, Vogel R, Kochte CB, Eisenbrand G (2008) Statement on the treatment of food using a pulsed electric field. Mol Nutr Food Res 52:1539–1542. https://doi.org/10.1002/mnfr.200800391.

Kume T, Todoriki S (2013) Food irradiation in Asia, the European Union and the United States: a status update. Radioisotopes 62:291–299

Lerouge S, Wertheimer MR, Yahia L (2001) Plasma sterilization: a review of parameters, mechanisms, and limitations. Plasmas Polym 6(3):175–188

Loaharanu P, Ahmad M (1991) Advantages and disadvantages of the use of irradiation for food preservation. J Agric Environ Ethics 4:14–30

Ludikhuyze L, Indrawati VBI, Weemaes C, Hendrickx M (1998) Effect of combined pressure and temperature on soybean lipoxygenase. 2. Modelling inactivation kinetics under static and dynamic conditions. J Agric Food Chem 46:4081–4086

Menashi W (1968) US Patent 3 383 163: Treatment of Surfaces

Mir AS, Manzoor AS, Sowriappan John Don Bosco (2017) Variations in brown rice quality among cultivars. In: Manickavasagan A, et al. (eds) Brown Rice. Springer International Publishing AG 2017 25. https://doi.org/10.1007/978-3-319-59011-0_2

Misra NN, Tiwari BK, Raghavarao KSMS, Cullen PJ (2011) Nonthermal plasma inactivation of food-borne pathogens. Food Eng Rev 3:159–170

Misra NN, Kaur S, Tiwari BK, Kaur A, Singh N, Cullen PJ (2015) Atmospheric pressure cold plasma (ACP) treatment of wheat flour. Food Hydrocoll 44:115–121

Moisan M, Barbeau J, Moreau S, Pelletier J, Tabrizian M, Yahia LH (2001) Low-temperature sterilization using gas plasmas: a review of the experiments and an analysis of the inactivation mechanisms. Int J Pharm 226:1–21

Puligundla P, Kim JW, Mok C (2017) Effect of corona discharge plasma jet treatment on decontamination and sprouting of rapeseed (Brassica napus L.) seeds. Food Control 71:376–382

Poutanen K, Sozer N, Della VG (2014) How can technology help to deliver more of grain in cereal foods for a healthy diet. J Cereal Sci 59:327–336

Raso J, Heinz V (2006) Pulsed electric field technology for the food industry. Fundamentals and applications. Springer

Şen Y, Bagcı U, Guleç HA, Mutlu M (2012) Modification of food contacting surfaces by plasma polymerization technique: reducing the biofouling of microorganisms on stainless steel surface. Food Bioprocess Technol 5:166–175

Sharma A, Yadav BS (2008) Resistant starch: physiological roles and food applications. Food Rev Int 24:193–234

Toepfl S (2006) Pulsed Electric Fields (PEF) for Permeabilization of cell membranes in food- and bioprocessing - applications, process and equipment design and cost analysis. PhD thesis, Fakultat III

Thirumdas R, Saragapani C, Ajinkya MT, Deshmukh RR, Annapure US (2016) Influence of low pressure cold plasma on cooking and textural properties of brown rice. Innov Food Sci Emerg Technol 37:53–60

Violleau F, Hadjeba K, Albet J, Cazalis R, Surel O (2008) Effect of oxidative treatment on corn seed germination kinetics. Ozone Sci Eng 30(6):418–422

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Bashir, K., Jan, K., Joshi, S., Jan, S., Azad, Z.R.A.A. (2019). Emerging Technologies in Cereal Processing: Present Status and Future Potential. In: Malik, A., Erginkaya, Z., Erten, H. (eds) Health and Safety Aspects of Food Processing Technologies. Springer, Cham. https://doi.org/10.1007/978-3-030-24903-8_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-24903-8_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-24902-1

Online ISBN: 978-3-030-24903-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)