Abstract

In this study, the effect on energy parameters and total equivalent warming impact (TEWI) using R1234ze(E) as a substitute for R22 in an air-conditioning device was investigated. The R22 system was retrofitted with R1234ze(E) changing compressor oil. The experimental data was obtained for three different ambient temperatures (30, 35 and 40 °C). It was seen that the power consumption of R1234ze(E) was smaller than that of R22 about by 41%. Although the cooling capacity of R1234ze(E) was 50% lower, its coefficient of performance (COP) was reduced only by 5% compared to R22. Furthermore, refrigerant charging amount of R1234ze(E) was smaller by 16% than R22. The results indicated that TEWI value of R1234ze(E) was lower than that of R22 by 65% due to small GWP (global warming potential) value and proper COP of the alternative refrigerant tested in the study. Hence, it can be expressed that R1234ze(E) can be used in air-conditioners of small capacity as an alternative to R22.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

According to Regulation (EU) No 517/2014, the refrigerants with GWP > 750 will be prohibited to use in air-conditioning systems including 3 kg or less refrigerant after January 1, 2025 [1]. Currently, R410A having a GWP of 2088 is widely used in split type air-conditioners [2]. In recent years, R32 with GWP of 675 is becoming widespread in the market for split type air-conditioners of low capacity. Almost all synthetic refrigerants with low GWP have a characteristic of flammability. Thus, there is a limit for the amount of gas charge into the systems.

The phase-out process of R22 is still continuing in developing countries. At the same time, the available devices operating with R22 are currently utilized by changing their refrigerants with alternative ones. The global warming potential (GWP) value of almost all HFC gases that can be used as alternatives to R22 is close to that of R22. The studies related to the application of refrigerants with low GWP are currently conducted. One of the suitable synthetic refrigerants is HFO-based R1234ze(E).

Many previous investigations focused on using R1234yf or R1234ze(E) as a substitute for R134a usually in refrigeration systems [3,4,5,6,7]. Moreover, the cooling capacity of R1234yf was seen to be slightly smaller than that of R134a for varied compressor rotational speed in automotive air-conditioners [8, 9]. In order to be a guiding reference for experimental investigations, some theoretical studies were also conducted comparing the thermodynamic performance of these new generation refrigerants in different refrigeration systems [10,11,12]. Some review papers have been published considering R1234ze(E) and R1234yf [13, 14].

R134a was compared with R1234yf and R1234ze(E) refrigerants considering vending machines at different ambient temperatures [15]. They determined that COP of R1234ze(E) and R134a was almost the same, but that of R1234yf was smaller about by 5% in comparison with the other two refrigerants. In addition, the suction pressure of R1234ze(E) was smaller than that of R134a and R1234yf. The literature survey points out that the energetic performance of R22 is better than that of HFC-based refrigerants with zero ODP value used as alternatives to R22 [16,17,18,19,20].

Similarly, R22, R1234yf and R1234ze(E) were compared for air-conditioning systems in a [21]. COP values of R1234ze(E) were determined higher about by 5–9% compared to R1234yf. The cooling capacity of R1234ze(E) was found to be low, but power consumption was seen to be decreased as well depending on reduced compressor discharge temperature. It was pointed out that R1234ze(E) may be a suitable candidate refrigerant for air-conditioners. In the experimental investigation by Devecioğlu and Oruç [22], R1234ze(E) was used as a substitute for R134a in a refrigeration system and energy performance of the system was improved utilizing a plate-type heat exchanger in order to reduce the cooling capacity loss.

In this study, R22 split type air-conditioner of small capacity was retrofitted with R1234ze(E). The energy parameters of the system such as cooling capacity and COP of R1234ze(E) were compared with those of R22. TEWI analysis was also performed to analyze environmental impacts. Thus, some suggestions were remarked on the suitability of using R1234ze(E) as a substitute for R22 in available air-conditioning systems. Utilization of HFOs and especially R1234ze(E) in air-conditioning systems operating with R22 is not seen in the literature. In this respect, the present investigation is different from previous comparisons of R22 and HFC-based refrigerants.

2 Experimental Setup

A split type air-conditioner having a cooling capacity of 2.05 kW and originally constructed to work with R22 was used as an experimental setup to study energetic parameters. The detailed information on utilized experimental setup can be found in the previous study by Oruç et al. [20]. The experimental setup is schematically demonstrated in Fig. 1.

The specifications of measuring instruments utilized in experiments are presented in Table 1. The thermodynamic properties of investigated refrigerants are determined through REFPROP software [23].

2.1 Tested Refrigerants

HFOs are unsaturated organic compounds and consisted of hydrogen, fluorine and carbon. They are synthetic refrigerants including carbon–carbon double bond. R1234ze(E) is suitable for middle temperature applications of air- and water cooled chillers, refrigerators and heat pump systems [14]. Chemical formulation is in the form of 1,3,3,3-tetrafluoropropene (Trans, CHF=CHCF3). R1234ze(E) used in the study is an HFO-based refrigerant with a GWP of 6. Both investigated refrigerants are pure substances. Therefore, their temperature glide values are zero. Retrofitting of the system was achieved by changing the compressor oil such that mineral oil (MO) and polyol ester oil (POE) types were used for the cases of R22 and R1234ze(E), respectively. In the experimental study, 800 g of R22 was charged into the system, while this amount was 670 g for investigating the case of R1234ze(E). The refrigerant of R22 is neither flammable nor toxic. R1234ze(E) is also non-toxic, but is classified by ASHRAE as slightly flammable so that high amounts of this refrigerant should not be charged into indoor systems. Some thermodynamic and physical properties of the tested refrigerants are given in Table 2 [23,24,25].

qlatent is latent heat of evaporation, ρ is density and k is thermal conductivity coefficient. Subscripts of liq, vap, bo, cr refer to liquid, vapor, boiling and critic, respectively.

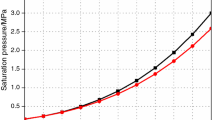

It is seen in Fig. 2 that the vapor pressure of R1234ze(E) is considerably lower than that of R22. Generally, the system can be safely operated at lower pressures. Liquid density of R1234ze(E) is smaller compared to R22. Hence, the required amount of refrigerant charging into the system will be decreased in the case of using R1234ze(E).

2.2 Evaluation of Experimental Data

The cooling capacity, Qe, of the system is calculated as

where \(\dot{m}\) is the mass flow rate, while ho,e and hi,e are the enthalpy values at outlet and inlet of evaporator, respectively. Then, the coefficient of performance (COP) of the system can be determined as

where Wcomp is power consumption of the compressor. When the temperature of the air flowing over condenser was reached a specified value, then the system was attained steady-state regime.

Total equivalent warming impact (TEWI) is a parameter indicating the global warming impact of refrigeration and air-conditioning systems [26]. TEWI develops from the direct contribution of used refrigerant to greenhouse gas and indirect contribution of CO2 emission because of energy consumption of the system during its working period. TEWI is expressed as the emission of kg CO2. TEWI can be calculated as follows [27]

where m is the amount of refrigerant charged into the system in kg and αr is the recovery efficiency. The refrigerant leakage into the atmosphere directly contributes to greenhouse gas formation. Annual refrigerant leakage, L, is defined as percentage of total refrigerant amount. N is the operation period of system in years. For computing indirect contribution, annual power consumption of system, Eannual, is found in kWh/year. The system has been assumed to operate different periods for each month. β is the indirect emission factor in kgCO2/kWh which represents amount of CO2 emission for generating 1 kWh energy, and it changes depending on the method of electric energy generation [26]. The numerical values of mentioned parameters in Eq. (3) are given in Table 3. Some parameters are obtained from experimental data, and the other ones are taken by assumptions for TEWI calculations. The mass of refrigerant charged into air-conditioner, m, and Eannual are obtained from experimental study.

Only the case of cooling mode was considered for air-conditioner in the investigation. The cooling is needed from May to September in most regions of Turkey. The assumed average operating hours for each month are presented in Table 4. For the daily working period, air-conditioner worked on an on-off basis and full consumption of energy was assumed to take place only half of 8–12 h period.

3 Results and Discussions

The distribution of cooling capacity, Qe, with ambient temperature, Ta, is given in Fig. 3 for tested refrigerants. Generally, Qe is reduced as a result of increasing Ta. It can be noted that Qe of R22 is higher about by 95% compared to R1234ze(E). Hence, this alternative refrigerant may not compensate the amount of Qe computed for peak loads. Therefore, the basic components should be selected larger for the air-conditioner which will be operated using R1234ze(E) to deliver the same amount Qe in R22 case.

The dependence of power consumption of compressor, Wcomp, on Ta is demonstrated in Fig. 4. Wcomp increases at higher Ta values for both refrigerants. Evidently, Wcomp of R1234ze(E) is seen to be lower than that of R22 about by 50%. This result occurs due to reduced pressure values at the suction and discharge of the compressor.

Figure 5 indicates COP distribution for the refrigerants. It is clear that COP is reduced as Ta increases for both refrigerants. Moreover, the highest COP can be obtained in R22 which has grater COP about by 5% in comparison with R1234ze(E).

The values of TEWI, which indicates direct contribution of refrigerant emission to the atmosphere and indirect contribution of CO2 (originated due to required energy of an air-conditioner during its operation life) on global warming impact, are shown in Table 5. Obviously, while the direct contribution of R1234ze(E) is 4, that of R22 is 1448 CO2-eq. Similarly, the indirect contribution of R1234ze(E) is smaller about by 40% compared to R22. As a result, TEWI of R1234ze(E) is computed to be lower nearly by 65% than TEWI of R22.

4 Conclusion

The general finding from the present experimental study can be summarized as follows:

-

R1234ze(E) can be suitably used in air-conditioners with small capacity; however, some basic components of the system such as evaporator and condenser should be larger in this case.

-

Reduced amount of Wcomp for R1234ze(E) is a significant result. Since COP of R1234ze(E) is lower only by 5% COP of R22, the tested alternative refrigerant is suggested to be utilized in air-conditioners.

-

Considering flammability risk, refrigerant should not be preferred for larger systems requiring a higher amount of refrigerant charge. Fortunately, the required mass is reduced when R1234ze(E) is utilized.

-

Since evaporation pressure and compressor discharge pressures of R1234ze(E) were determined to be lower, it can be safely used in the air-conditioners designed to operate with R22.

-

Compared to R22, TEWI of R1234ze(E) was calculated to be lower about by 65%, and therefore, the alternative refrigerant has a substantial reduced impact on global warming. Hence, R1234ze(E) may be utilized in air-conditioners for the long term.

References

Regulation (EU) No 517/2014 of the European Parliament and the Council of 16 April 2014 on fluorinated greenhouse gases and repealing Regulation (EC) No 842/2006. Official Journal of the European Union. http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014R0517&from=EN. Accessed 19 Dec 2017

Devecioğlu AG (2017) Seasonal performance assessment of refrigerants with low GWP as substitutes for R410A in heat pump air conditioning devices. Appl Therm Eng 125:401–411

Fukuda S, Kondou C, Takata N, Koyama S (2014) Low GWP refrigerants R1234ze(E) and R1234ze(Z) for high temperature heat pumps. Int J Refrig 40:161–173

Navarro-Esbri J, Mendoza-Miranda JM, Mota-Babiloni A, Barragan-Cervera A, Belman-Flores JM (2013) Experimental analysis of R1234yf as a drop-in replacement for R134a in a vapor compression system. Int J Refrig 36:870–880

Navarro-Esbri J, Moles F, Barragan-Cervera A (2013) Experimental analysis of the internal heat exchanger influence on a vapour compression system performance working with R1234yf as a drop-in replacement for R134a. Appl Therm Eng 59:153–161

Mota-Babiloni A, Navarro-Esbri J, Barragan-Cervera A, Moles F, Peris B (2014) Drop-in energy performance evaluation of R1234yf and R1234ze(E) in a vapor compression system as R134a replacements. Appl Therm Eng 71:259–265

Jankovic Z, Atienza JS, Suarez JAM (2015) Thermodynamic and heat transfer analyses for R1234yf and R1234ze(E) as drop-in replacements for R134a in a small power refrigerating system. Appl Therm Eng 80:42–54

Zilio C, Brown JS, Schiochet G, Cavallini A (2011) The refrigerant R1234yf in air conditioning systems. Energy 36:6110–6120

Cho H, Lee H, Park C (2013) Performance characteristics of an automobile air conditioning system with internal heat exchanger using refrigerant R1234yf. Appl Therm Eng 61:563–569

Navarro-Esbri J, Moles F, Peris B, Barragan-Cervera A, Mendoza-Miranda JM, Mota-Babiloni A, Belman JM (2014) Shell-and-tube evaporator model performance with different two-phase flow heat transfer correlations. Experimental analysis using R134a and R1234yf. Appl Therm Eng 62:80–89

Llopis R, Sánchez D, Sanz-Kock C, Cabello R, Torrella E (2015) Energy and environmental comparison of two-stage solutions for commercial refrigeration at low temperature: fluids and systems. Appl Energy 138:133–142

Zheng N, Zhao L (2015) The feasibility of using vapor expander to recover the expansion work in two-stage heat pumps with a large temperature lift. Int J Refrig 56:15–27

Wang CC (2014) System performance of R-1234yf refrigerant in air-conditioning and heat pump system e an overview of current status. Appl Therm Eng 73:1412–1420

Mota-Babiloni A, Navarro-Esbri J, Moles F, Barragan-Cervera A, Peris B, Verdu G (2016) A review of refrigerant R1234ze(E) recent investigations. Appl Therm Eng 95:211–222

Sethi A, Vera Becerra E, Yana Motta S (2016) Low GWP R134a replacements for small refrigeration (plug-in) applications. Int J Refrig 66:64–72

Torella E, Cabello R, Sanchez D, Larumbe JA, Llopis R (2010) On-site study of HCFC-22 substitution for HFC non-azeotropic blends (R417A, R422D) on a water chiller of a centralized HVAC system. Energy Build 42:1561–1566

Llopis R, Torrella E, Cabello R, Sanchez D (2012) HCFC-22 replacement with drop-in and retrofit HFC refrigerants in a two-stage refrigeration plant for low temperature. Int J Refrig 35:810–816

Yang Z, Wu X (2013) Retrofits and options for the alternatives to HCFC-22. Energy 59:1–21

Aprea C, Maiorino A, Mastrullo R (2014) Exergy analysis of a cooling system: experimental investigation on the consequences of the retrofit of R22 with R422D. Int J Low-Carbon Technol 9:71–79

Oruç V, Devecioğlu AG, Berk U, Vural İ (2016) Experimental comparison of the energy parameters of HFCs used as alternatives to HCFC-22 in split type air conditioners. Int J Refrig 63:125–132

Oruç V, Devecioğlu AG (2018) Retrofitting an air-conditioning device to utilize R1234yf and R1234ze(E) refrigerants as alternatives to R22. J Brazilian Soc Mech Sci Eng 40(226):1–9

Devecioğlu AG, Oruç V (2018) Improvement on the energy performance of a refrigeration system adapting a plate-type heat exchanger and low-GWP refrigerants as alternatives to R134a. Energy 155:105–116

Lemmon EW, Huber ML, McLinden MO (2013) NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1, National Institute of Standards and Technology, Standard Reference Data Program, Gaithersburg

DuPont (2015) Thermodynamic properties of DuPontTM Freon® 22 (R22) Refrigerant. Technical Information. https://www.chemours.com/Refrigerants/en_US/assets/downloads/k05736_Freon22_thermo_prop.pdf. Accessed 27 Nov 2015

Honeywell (2014) Solstice® ze Refrigerant (HFO-1234ze), http://www.honeywell-refrigerants.com/europe/wp-content/uploads/2014/10/Solstice-ze-brochure-Fourth-Generation-LR-140925.pdf. Accessed 25 Jan 2015

Devecioğlu AG, Oruç V (2017) The influence of plate-type heat exchanger on energy efficiency and environmental effects of the air-conditioners using R453A as a substitute for R22. Appl Therm Eng 112:1364–1372

Belman-Flores JM, Rodríguez-Muñoz AP, Gutiérrez Pérez-Reguera C, Mota-Babiloni A (2017) Experimental study of R1234yf as a drop-in replacement for R134a in a domestic refrigerator. Int J Refrig 81:1–11

Acknowledgements

The authors are indebted to Dicle University Scientific Research Projects Coordination Unit for the research project no. MÜHENDİSLİK 15-004.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Devecioğlu, A.G., Oruç, V. (2020). Retrofitting of R-22 Air-Conditioning System with R1234ze(E). In: Dincer, I., Colpan, C., Ezan, M. (eds) Environmentally-Benign Energy Solutions. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-030-20637-6_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-20637-6_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-20636-9

Online ISBN: 978-3-030-20637-6

eBook Packages: EnergyEnergy (R0)