Abstract

Indonesia has a long history of sugar production and a significant potential to enhance both sugar and bioethanol production. This chapter examines the life cycle energy balance and GHG emissions of bioethanol production and the conditions for the development of sugarcane-based agro-industry in Indonesia to meet both sugar self-sufficiency and biofuel blending targets in domestic transport. The life cycle greenhouse gas (GHG) emissions in the production and use of ethanol are estimated at 29 gCO2eq per MJ of ethanol produced, equivalent to a 67% reduction in comparison to gasoline emissions. Net energy value (NEV) and net renewable energy value (NREV) are −7 MJ l−1 and 17.7 MJ l−1, while the energy yield ratio (ER) is 6.1. At present conditions, 450 million liters of bioethanol can be annually produced in the country using sugarcane molasses, a low-value coproduct. This gives a marginal contribution equivalent to 1% of the total gasoline consumption in 2015. However, using both molasses and cane juice, Indonesia can meet the blending targets set for 2020 (i.e., 4.45 BL ethanol) and 2025 (i.e., 11.48 BL ethanol). This translates into sugarcane feedstock obtained from 1.60 Mha and 2.76 Mha land, respectively. Improved resource efficiency can be achieved, exploring the bioelectricity production potential from sugarcane biomass, enhanced yields, and modernization of sugarcane mills. An orchestrated strategy for upgrading technologies and production methods along the whole chain of agro-industries in the sugar-ethanol segment is required for Indonesia to realize its biofuel potential.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Sugarcane industries

- Life cycle analysis

- Ethanol production

- Blending targets

- Fossil fuel substitution

- Bioelectricity

- Indonesia

1 Introduction

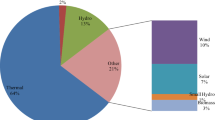

Indonesia’s energy system is largely fossil fuel-based (Ministry of Energy and Mineral Resources [MEMR] 2016). Indonesia became an importer of fossil oil after 2003 due to the declining domestic production and increasing oil consumption (BP Statistical Review of World Energy 2016). The country accounts for 35% of the total energy demand in Southeast Asia (International Energy Agency [IEA] 2017). The share of modern renewables is still limited. The contribution of biomass in the primary energy supply was 20% in 2015, but traditional biomass dominates in cooking and thermal services (MEMR 2016). Indonesia aims at reducing energy dependency and GHG emissions, as well as diversifying energy sources (Kumar et al. 2013; Mujiyanto and Tiess 2013).

Located in a tropical region, Indonesia is endowed with abundant biomass resources. There is significant consumption of traditional biomass in the residential sector, not least in the most remote areas. But there is understanding that modernization of biomass utilization can be a valuable strategy to meet increasing energy demand, create jobs, and reduce poverty (Yan and Lin 2009). In fact, the government of Indonesia sees bioenergy as an attractive option to promote socioeconomic development and improve energy security. Therefore, bioenergy is receiving increased attention in the country. A main preoccupation is to combine the local resource potential with competitive technological options to provide modern and reliable energy services and, at the same time, promote sustainable development. In addition, deforestation and land degradation are the main sources of GHG emissions in Indonesia and the primary cause for the loss of biodiversity and ecosystem services (Ramdani and Hino 2013; Susanti and Maryudi 2016; Uusitalo et al. 2014). Finding ways to reduce the degradation of forest resources and improve agriculture while also deploying bioenergy could have both environmental and social positive impacts.

The government has responded to energy security and climate challenges through legislation, targets and strategies for renewable energy, green growth, and natural resource management. A number of goals have been set, including an increase in renewable energy to 23% by 2025 (Bridle et al. 2018; Mujiyanto and Tiess 2013). Through its Nationally Determined Contribution (NDC), Indonesia has pledged to reduce emissions by 26% in relation to a business-as-usual scenario by 2020. Given that the transport sector poses particular energy security concerns, the government aims at raising biofuel use to 5% of the total national energy consumption by 2025 (Jupesta 2010; Hasan et al. 2012). These targets can be seen within the broader program of green growth, which aims at transforming energy and development pathways to achieve long-term sustainability.

Responding to concerns about the rapidly growing consumption of imported petroleum fuels, the government initiated a biofuel program in 2006 which included mandatory biofuel blending. Ambitious targets were set for biofuels: 30% biodiesel and 20% bioethanol by 2025 (Indonesia Regulation 12/2015) (Global Agriculture Information Network [GAIN] 2016, 2018). Unfortunately, due to the lack of biofuel production infrastructure, feedstock supply gaps, and stronger focus on palm oil and diesel, the bioethanol production in the country remains negligible (GAIN 2017a). Although agricultural crops and residues are currently utilized for liquid biofuel and bioelectricity generation in Indonesia, the adoption of biofuels has been slower than anticipated. Fuel ethanol for domestic blending effectively ended in 2010 due to economic and political reasons (GAIN 2015; Khatiwada and Silveira 2017).

This chapter addresses the conditions and potential for the development of first-generation sugarcane-based bioethanol industry in Indonesia. We consider feedstock and the industrial capacity for bioethanol production in the country in the context of present policies and transformations required to address increasing demand for transport fuels and climate change. Currently, only first-generation biofuels are produced at industrial scale in Indonesia, mostly palm oil-based biodiesel. Second-generation biofuels can be produced from a variety of biomass sources such as wood, residues, and waste, and the so-called third-generation biofuels can be derived from algae. These options shall be explored in the future as the country develops an integrated strategy for bioenergy. For the time being, Indonesia is still to capitalize on opportunities derived from efficiency improvements in the sugarcane agro-industry, which is the first step in building a robust solid biofuel industry. Therefore, the focus of this chapter is on this first step.

2 Land and Sugarcane for Sugar and Bioethanol Production

Indonesia has a long history as sugar producer and is one of the top 10 sugarcane producers in the world. The country was self-sufficient until 1985, as reported by the Indonesian Sugar Cane Statistics (Badan Pusat Statistik [BPS] 2013). Sugarcane crop plantations cover 445 thousand hectares mainly in Java (60.3%) and Sumatra (36.7%) (Ministry of Agriculture [MoA] 2018). Java’s sugarcane mills have contributed 63% of the Indonesian white sugar production in 2015/2016 (GAIN 2017b). Opportunities exist for expansion of sugarcane plantations in response to national policies and growing global markets for biofuels. However, the majority of the sugarcane cultivation is done by smallholders in Java (MoA 2018). Thus, any program for performance improvement needs to consider ways to build upon the existing structure, so as to empower and benefit multiple small producers.

Figure 13.1 shows the evolution of sugarcane yields (tonne ha−1) and sugarcane plantation areas (in Mha) in Indonesia between 1990 and 2016. Notably, yields have fluctuated significantly, while the total sugarcane area has not varied as much in the last few decades. Lack of modernization of sugarcane systems, including cultivation practices and industrial operations, along with increasing competition are the main reasons for decreased performance of sugarcane-based agro-industry (Khatiwada and Silveira 2017).

Sugarcane-planted areas and yields in Indonesia (1990–2016). (Source: Food and Agriculture Organization of the United Nations (FAOSTAT 2018))

Indonesia plans to achieve sugar self-sufficiency by 2020 and, at the same time, has defined mandatory bioethanol targets. Despite the national demand around 5.93 million tonnes sugar, only around two million tons are presently being produced nationally (GAIN 2017b). Approximately 40 mills (out of the total 63 mills) are over 100 years old. The sugar price is regulated in the country, which compromises the competitiveness of the sugar industry and hampers production expansion.

As mentioned previously, Indonesia has a bioethanol blending mandate for the transportation sector. Figure 13.2 shows the projections for gasoline and bioethanol for meeting the blending mandate until 2025. The main potential feedstocks for bioethanol in the country are sugarcane and cassava. However, sugarcane has the greatest potential considering factors such as (i) food crop with surplus production, (ii) plant productivity, (iii) potential biofuel yield, (iv) plant development readiness, (vi) government policies in place, and (vii) possibility to expand plantations in marginal land (Hambali et al. 2016).

Gasoline and bioethanol projection as per transport energy demand and blend mandates. (Source: Khatiwada and Silveira 2017). (Note: The projection is based on the historic trend and energy equivalent using linear regression analysis (interpolation and extrapolation). The primary Y-axis represents gasoline projection (with and without bioethanol blend) and ethanol requirement for mandatory blend, while the secondary Y-axis gives total energy consumption in the transport sector in Indonesia)

Sugarcane-based production systems comprise the production of sugar and coproducts, i.e., molasses and bagasse (Khatiwada and Silveira 2009). The sugarcane stalk is crushed in sugarcane mills, leaving the bagasse as residue. Sugar juice passes through multiple crystallization phases during which crystal white sugar is produced. When no more sugar can be recovered, there is still a residual syrup, molasses, a low-value coproduct that can be used for the production of fuel ethanol. Sugarcane juice can be diverted for the production of bioethanol, particularly when there is surplus sugarcane feedstock left after the sugar production. Bagasse is combusted in boilers to provide the energy (i.e., steam and electricity) requirements of the plant. The anhydrous ethanol used as the gasoline blend is obtained in the sugarcane biorefinery, following the process of fermentation, distillation, and dehydration of molasses or juice (in the case of surplus sugar). Sugarcane biomass (excess bagasse and residues) can be used for generating bioelectricity in efficient cogeneration plants (Khatiwada et al. 2012, 2016; Khatiwada and Silveira 2017).

Indonesia produced 27.2 million tonnes (Mtonnes) of sugarcane on 0.47 million hectares (Mha) of land in 2016 (FAOSTAT 2018). Thus, less than 1% of the total agricultural land was used for sugarcane. Currently, sugarcane juice is mainly used to produce sugar for domestic consumption, while molasses are readily available for bioethanol production. Khatiwada and Silveira (2017) made projections to verify whether the sugarcane feedstock can meet the national demand for both sugar and bioethanol. The projections considered the fact that Indonesia aims at becoming self-sufficient in sugar production; thus, the focus was on molasses-based bioethanol as a first step. When sugar demand is met, surplus cane juice is diverted for bioethanol production. The projections rely on land availability for sugarcane plantations estimated by Winrock International (i.e., 5 Mha) (Khatiwada and Silveira 2017; Winrock International 2009).

Table 13.1 shows the projections for sugar, sugarcane, and molasses production until 2025, indicating the amount of land required for meeting self-sufficiency in sugar and the molasses derived from the process. Doubling the planted area from 2015 is necessary to achieve sugar self-sufficiency in 2020.

Table 13.2 shows the projections for gasoline demand and the amount of bioethanol needed to meet the blending targets set by the Indonesian government.

In spite of the government’s plans, sugar production has dropped lately due to El Nino in 2015/2016 (GAIN 2017b). Climate change may also pose threats to sugarcane in Indonesia due to increasing average temperature, a key factor in the sugarcane ripening process (de Almeida Silva and Caputo 2012). Higher average temperature is likely to affect the sugar content negatively. There is, therefore, need to consider adaptation methods for addressing the impacts of changing temperatures.

3 Scenarios for Meeting Sugar Self-Sufficiency and Ethanol Blending Mandates

The blending mandates for ethanol aim at a 10% target by 2020 and 20% by 2025. However, there is currently no road map defining how the bioethanol blending targets will be achieved in the transport sector. Bioethanol producers have installed molasses-based plants with a capacity for 339 million liters in 2010. Surprisingly, both production and use of ethanol have come to a halt since then, due to lack of economic competitiveness in the sugarcane agro-industrial sector, decreasing yields, and volatile international prices for petroleum.

Khatiwada and Silveira (2017) developed scenarios to investigate conditions for sugarcane-based bioethanol production in Indonesia and for meeting bioethanol blending targets and sugar self-sufficiency. The parameters considered in four different scenarios are summarized in Table 13.3. The scenarios consider (a) land use with low-medium-high cane yields, (b) meeting sugar self-sufficiency by 2020, (c) meeting bioethanol mandates, and (d) use of available land for sugarcane production. The study shows that if surplus sugarcane juice and sugarcane by-products (e.g., molasses and bagasse) are used for energy production, there is no need for bioethanol and food production to outcompete each other.

However, scenarios (Sc-1 and Sc-2) showed that it would not be possible to meet the stipulated bioethanol blending targets using only molasses, even if plantations are expanded for meeting the domestic sugar demand by 2020. Scenario 3 (Sc-3) examined under what conditions bioethanol mandates can be achieved by 2015, 2020, and 2025. For this, it is necessary to expand sugarcane plantations and also use cane juice for bioethanol production. In order to meet the bioethanol blending target of 10% by 2020, 1.6 Mha sugarcane fields are required; 1.07 Mha is sufficient to produce the sugarcane required for sugar production. This allows diverting the surplus sugar juice for bioethanol production. We need a total land area of 2.76 Mha for meeting both the domestic sugar demand and the bioethanol mandate of 20% blend by 2025. The total ethanol required for 20% blend in the transport sector in Indonesia is 11.48 billion liters (BL). We assume the estimation of available land proposed by Winrock International (Winrock International 2009) (i.e., 5 Mha) which is based on a digitalized geographical information system and excludes peat land, forest, and sensitive areas for sugarcane field expansion.

Figure 13.3 shows the land requirements, molasses-bioethanol production potential, and projected bioethanol demand to meet the national bioethanol targets during the period between 2015 and 2025 in Indonesia. Sugarcane plantation areas of 1.60 Mha and 2.76 Mha are required for meeting the dual objectives of sugar self-sufficiency and bioethanol mandates by 2020 and 2025, respectively. Juice ethanol is required to meet the blending targets set for 2020 (i.e., 4.45 BL ethanol) and 2025 (i.e., 11.48 BL ethanol). Moreover, as shown in Fig. 13.4, it is possible to go beyond present bioethanol targets even if we remain limited to the first-generation bioethanol production. Thus, 34% of the bioethanol blend mandate by 2020 and 63% by 2025 could be achieved when available land is used for sugarcane cultivation, and sugar juice is diverted for fuel ethanol production after meeting the domestic sugar demand in Indonesia.

Total land required (million hectares, Mha) for meeting sugar self-sufficiency and molasses ethanol production potential in billion liters (BL). (Source: Khatiwada and Silveira 2017). (Note: Ethanol required volume (BL) to meet the mandate is in primary Y-axis; total land (Mha) and ethanol produced (BL) are presented in the secondary Y-axis)

Percentage of gasoline substitution in the transport sector in Indonesia when sugarcane is produced from available land (without compromising sugar demand). (Source: Khatiwada and Silveira 2017). (Note: Primary Y-axis shows bioethanol potential, gasoline demand, and % of gasoline substitution; secondary Y-axis represents the corresponding sugarcane field)

4 Potential Energy and Climate Gains from Sugarcane Bioethanol Production and Fuel Substitution

How much energy is required to produce bioethanol, and what climate benefits can be accrued from substituting gasoline with bioethanol? Certainly, this depends on many factors, including the type and origin of the feedstock used and technology applied in the bioethanol production, among other factors. In case of bioethanol from sugarcane in Indonesia, a first step would be to use molasses for bioethanol production and then move forward to use also cane juice and later introduce second-generation technologies. Here, we will scrutinize the benefits from bioethanol produced from molasses in the context of Indonesia.

It is crucial to estimate the energy required during the life cycle of sugarcane molasses conversion to ethanol to make sure that there are resource gains along the production and use chain. In addition, it is important to understand the effects of the sugarcane-based agro-industry on climate change (i.e., in terms of greenhouse gas emissions). Therefore, a cradle-to-grave life cycle analysis of the sugarcane-molasses to biofuel pathway was carried out. The resource consumption and climate change impacts measured in terms of energy utilization (including fossil and biomass) and GHG emissions go from feedstock cultivation to bioethanol production and use, and include also transport, processing, and conversion features. The material and energy inputs in the form of fertilizers, chemicals, electricity, and corresponding environmental impacts are also considered. Thus, to estimate the life cycle emissions and energy consumption along the whole production chain, energy, material, and emission flows were included in the analysis in the form of energy consumption during the fuel production and energy and GHG emissions during the production and use of the fuel.

Table 13.4 provides the resource or energy consumption for the production of sugarcane molasses bioethanol. The total energy consumption is 28.18 MJ (fossil: 3.49 MJ and renewable: 24.69 MJ) per liter of ethanol produced. In the total energy consumption, cane milling (38%) and ethanol production (55%) consume most of the energy. In terms of fossil fuel consumption, the amount of nonrenewable energy required for the production of nitrogen fertilizers (cane cultivation) and coal use in cane milling and ethanol production is high compared to other activities.

The value of ER is highly sensitive to changes in cane yield. Improvements in agricultural practices will improve cane yield, thus leading to higher energy ratio (ER). This is definitely one issue that deserves attention. An efficient cogeneration system with the use of high pressure/temperature boilers and turbines/generators can improve the energy output. In this way, not only the internal energy demand is met in the sugarcane mills but surplus bioelectricity can be produced. The efficient cogeneration plant can produce 100–150 kWh of surplus electricity per tonne of cane processed using sugarcane biomass (bagasse and trash) (Khatiwada et al. 2012).

Considering the environmental impact or GHG emissions from sugarcane farming/cultivation and cane transport, 53.2 kg of carbon dioxide equivalent (kgCO2eq) per tonne cane (tc) or 4158 kgCO2eq is produced per hectare (ha) of sugarcane area. If we consider the resource consumption or energy inputs, 24.1 GJ (of which 22.5 GJ are nonrenewable and 1.6 GJ are renewable) are consumed per hectare (ha) during the sugarcane cultivation and harvesting phases.

The environmental impact of converting sugarcane molasses to bioethanol was analyzed based on the emissions during the complete life cycle chain. The cane cultivation leads to 49 kgCO2eq per tonne cane (tc) harvested, N2O emissions being the major contributor. This is followed by cane trash burning and decomposition. The transport of cane and filter cake emits 4.9 kgCO2eq tc−1. Life cycle emissions from sugarcane bioethanol production are estimated at 29.1 gCO2eq MJ−1 of bioethanol, leading to a 67% emission reduction compared to gasoline. The cane cultivation phase contributes most to the total emissions (Fig. 13.5). The major contribution within the cultivation phase is the production and application of nitrogen fertilizers.

Net greenhouse gas emissions of ethanol production in Indonesia. (Source: Khatiwada et al. 2016)

Besides sugar and bioethanol production in sugarcane mills, there is significant potential to produce bioelectricity when sugarcane biomass (bagasse and trash/residues) is efficiently used in combined heat and power plants. With efficient cogeneration, 100–150 kWh tonne−1 surplus power can be generated after meeting the internal energy requirements in sugarcane mills (Khatiwada et al. 2012). The Indonesian power sector is dominated by coal and natural gas (MEMR 2016). Thus, the use of sugarcane biomass (bagasse and trash) from sugar ethanol production can contribute to improving the total energy and cost balance of the industry, while also generating renewable electricity to the grid.

Table 13.5 shows the bioelectricity potential considering sugar self-sufficiency and bioethanol mandates. Our estimations show that, at present conditions, if efficient CHP plants are used, 563MW (i.e., 4.94 TWh) can be produced and connected to the grid in Indonesia. Surplus bioelectricity would amount to 12.8 TWh (i.e., 1461 MW) if the sugarcane biomass (i.e., bagasse and trash) obtained after meeting the sugar self-sufficiency in Indonesia in 2020 is used for electricity generation.

Similarly, sugarcane bioenergy can produce 8.54 TWh, 19.22 TWh, and 33.16 TWh as sugarcane bagasse and residues are used after meeting the bioethanol blending targets in 2015, 2020, and 2025, respectively. Total electricity sales were 187.5 TWh in 2013 in Indonesia. Under present conditions, the share of bioelectricity in the national electricity mix would be around 3%. Sugarcane biomass can produce around 6.5% of bioelectricity when sugar self-sufficiency is met in 2020, considering the projected electricity consumption for the same year.

Bioelectricity is carbon-neutral when sustainability requirements are met, and it can replace carbon-intensive coal electricity in Indonesia. In fact, bioelectricity has become a complementary option to hydropower in other sugarcane-producing countries such as Brazil and Nepal (Khatiwada et al. 2012). However, there are presently no studies on the regulatory frameworks and institutional arrangements required for promoting bioelectricity in Indonesia. There is an urgent need to explore the bioelectricity potential as part of concerted actions to promote biofuels and renewable energy at large as well as part of strategies to improve energy access and achieve the SDGs (Sustainable Development Goals) (International Renewable Energy Agency [IRENA] – International Energy Agency [IEA] 2017)

5 Conditions for Developing the Sugar-Bioethanol Potential in Indonesia

Indonesia is largely dependent on fossil fuels, including oil, coal, and natural gas, and is on a nonsustainable track when it comes to its energy matrix. Despite large renewable sources, only a small portion of the energy demand in the country is met with renewables. It is, therefore, imperative to change the current patterns of energy consumption to put the country on a sustainable track. Increased ability to deploy modern bioenergy can potentially contribute to positive impacts such as improved energy security, welfare, and capacity to meet greenhouse gas (GHG) mitigation commitments.

Opportunities exist to develop a sustainable sugar-bioethanol industry based on sugarcane in Indonesia. Although the country has been a producer of sugar and bioethanol, and has put in place policies to promote biofuels in transport and renewable energy at large, there is still much to be done to set the sugar-bioethanol industry on track toward a modern and efficient industry. Reasons for the slow transformation of the industry can be found in various bottlenecks and policy incoherence and lack of interplay between local practices and national agendas for energy, climate, and development.

Most sugarcane mills operating in Indonesia are old, and 65% of them have been operating for more than 100 years. Old cultivation practices and industrial operations, along with increasing competition, are the main reasons for reduced performance of the sugarcane agro-industries in the past years. It is important to explore development toward a bio-based economy, with integrated resource utilization for harnesing the full potential of bioresources in Indonesia. Meanwhile, opportunities are being lost to pursue sugar self-sufficiency and bioethanol production for meeting the country’s mandatory blending targets.

Modernization of sugarcane systems are much needed for the country to capitalize on the opportunities in this sector. The production of bioethanol from bagasse is a “low-hanging fruit.” But to fully explore the modernization potential, strategies and incentives need to be put in place at various stages of the production and use chain. Improvements in agricultural management practices as well as supply-chain logistics are necessary for improving energy efficiency and sugarcane yields. The productivity gains accrued from the modernization of agricultural and production systems will benefit both food and fuel production, whereas bioelectricity generated from the sugar-ethanol industries can help to diversify energy sources and improve the competitiveness of the sector . Renewable bioelectricity from sugarcane biomass provides an attractive way to reduce fossil fuel energy dependency and reduce emissions, while also promoting the sustainable development.

Clearly, the area planted will have to be expanded as population and the demand for sugar increases. The amount of molasses increases together with sugar production, thus offering an opportunity to also expand the production of bioethanol. However, the use of juice will be needed if the blending targets are to be met with national bioethanol production for 2020 (i.e., 4.45 BL ethanol) and 2025 (i.e., 11.48 BL ethanol). This translates into sugarcane feedstock obtained from 1.60 Mha and 2.76 Mha land, respectively. It is possible to go beyond the present bioethanol targets even if we remain limited to the first-generation bioethanol production. Measures of 34% of bioethanol blend mandate by 2020 and 63% by 2025 could be achieved when available land is used for sugarcane cultivation, and sugar juice is diverted for fuel ethanol production after meeting the domestic sugar demand in Indonesia. Sustainable bioenergy production from degraded land can reduce the potential conflict with other food crops.

Today, the availability of sugarcane molasses as a bioethanol feedstock is closely tied to the demand for crystalline sugar in the household and commercial sectors. While molasses offer a first step to boost bioethanol production, achieving the blending targets ultimately requires higher agricultural productivity and/or wider availability of agricultural residues to facilitate the coproduction of biofuels and electricity.

The difficulty in achieving the blending targets for fuel ethanol arises from a number of factors, including policy uncertainty, opportunity costs for production and use of molasses, and structural problems in the sugar and bioethanol sectors . The bioethanol price remains higher than gasoline, despite the price regulation for bioethanol. Thus, bioethanol cannot compete with gasoline. In fact, the stakeholders indicate that the market price is at a deadlock. As a result, producers of bioethanol are more prone to selling their product to smaller industries for purposes other than fuel (e.g., cosmetic and pharmaceutical industries). This market is limited and does not offer enough incentive for production expansion.

In the mid-term, bioenergy deployment may focus on the conversion of biomass into marketable bioproducts and energy. This can be done using biorefineries for multiple products and services (e.g., liquid biofuels, biogas, bioelectricity, feed) with current available commercial technologies. Meanwhile, a more complex system using different feedstocks and conversion technologies can be explored and integrated over time. In the long-term, Indonesia should consider the incorporation of second-generation bioenergy to improve resource efficiency and reduce emissions, as well as delink the expansion of bioenergy production from the expansion of energy crops.

The bioenergy potential has been clearly recognized in Indonesia. Still, efforts need to be intensified in terms of policy adjustments, incentives, and coordinated actions around a strategy to guarantee a sustainable transition from traditional practices to modern and sustainable solutions. A holistic approach is required to improve competitiveness on both the agricultural and industrial sides, leading to enhanced energy service provision and improved self-sufficiency. The synergies between agricultural and industrial sectors are key to success in face of competing uses for land and water, the need for improved resource efficiency, and efforts to guarantee both food and fuel supply. The global climate benefits provide further incentive for Indonesia to explore its bioenergy potential. Linking bioenergy markets and ecosystem services to provide energy services, improve energy security, and promote sustainable livelihoods should be pursued as mutually reinforcing objectives to promote the sustainable development goals (SDGs) in Indonesia.

6 Conclusions

Sugar production for self-sufficiency and ethanol for meeting mandatory blending targets can be met from sugarcane feedstock using sustainable lands in Indonesia. Additional land areas of 1.60 Mha and 2.76 Mha are required for meeting the dual objectives by 2020 and 2025, respectively. Besides, there is an enormous potential to produce bioelectricity derived from sugarcane residues (trash and bagasse). The life cycle GHG emissions in the production and use of sugarcane-molasses bioethanol is 29 gCO2eq per MJ which is 67% less in comparison to gasoline emissions. The energy yield ratio is 6.1, that is, fossil energy consumption is quite low in comparison to final energy content of bioethanol. Finally, in order to harness the potential of sugarcane biofuels in Indonesia, integrated and holistic implementation plans are required, including modernization of sugarcane mills, investments for biorefineries, and adjustment in policy frameworks to guarantee a transition toward sustainble solutions.

References

Badan Pusat Statistik (2013) Badan Pusat Statistik BPS (Statistics – Indonesia). Indonesia Sugar Cane Statistics (Statistik Tebu Indonesia)

BP Statistical Review of World Energy (2016) Statistical review of world energy. http://www.bp.com/statisticalreview. Accessed 20 Nov 2018

Bridle R, Gass P, Halimajaya A, Lontoh L, McCulloch N, Petrofsky E, Sanchez L (2018) Missing the 23 per cent target: roadblocks to the development of renewable energy in Indonesia, Global Subsidies Initiative report. International Institute for Sustainable Development, Winnipeg

de Almeida Silva M, Caputo MM (2012) Ripening and the use of ripeners for better sugarcane management. In: Marin FR, Crop management – cases and tools for higher yield and sustainability. ISBN 978-953-51-0068-3 INTECH Open Access Publisher. https://www.alice.cnptia.embrapa.br/alice/bitstream/doc/924284/1/CropManagementCasesandToolsforHigherYieldandSustainability.pdf. Accessed 20 Dec 2018

Food and Agriculture Organization of the United Nations (2018) Food and agriculture data. http://www.fao.org/statistics/en/. Accessed 10 Nov 2018

Global Agriculture Information Network (2015) Indonesia biofuels annual 2015. Foreign Agricultural Service, United States Department of Agriculture.

Global Agriculture Information Network (2016) Indonesia biofuels annual 2016. Foreign Agricultural Service, United States Department of Agriculture.

Global Agriculture Information Network (2017a) Indonesia biofuels annual 2017. Foreign Agricultural Service, United States Department of Agriculture.

Global Agriculture Information Network (2017b) Indonesia sugar annual 2017. Foreign Agricultural Service, United States Department of Agriculture.

Global Agriculture Information Network (2018) Indonesia biofuels annual 2018. United States Department of Agriculture.

Hambali E, Nashirotun Nisya F, Thahar A, Nuryanti A, Wijaya H (2016) Potential of biomass as bioenergy feedstock in Indonesia. J Jpn Inst Energy 95(8):629–638

Hasan MH, Mahlia TMI, Nur H (2012) A review on energy scenario and sustainable energy in Indonesia. Renew Sustain Energy Rev 16:2316–2328. https://doi.org/10.1016/J.RSER.2011.12.007

International Energy Agency (2017) Southeast Asia energy outlook. World energy outlook special report. https://www.iea.org/publications/freepublications/publication/WEO2017SpecialReport_SoutheastAsiaEnergyOutlook.pdf. Accessed 10 Dec 2018.

International Renewable Energy Agency – International Energy Agency (2017) Bioenergy for sustainable development. https://www.irena.org/eventdocs/Bioenergy%20Side%20Event%20-%20Brief%20on%20BIOENERGY%20AND%20SUSTAINABLE%20DEVELOPMENT%2020170105.pdf. Accessed 20 Dec 2018

Jupesta J (2010) Impact of the introduction of biofuel in the transportation sector in Indonesia. Sustainability 2:1831–1848. https://doi.org/10.3390/su2061831

Khatiwada D, Silveira S (2009) Net energy balance of molasses based ethanol: the case of Nepal. Renew Sustain Energy Rev 13:2515–2524. https://doi.org/10.1016/J.RSER.2009.06.028

Khatiwada D, Silveira S (2017) Scenarios for bioethanol production in Indonesia: how can we meet mandatory blending targets? Energy 119:351–361. https://doi.org/10.1016/J.ENERGY.2016.12.073

Khatiwada D, Seabra J, Silveira S, Walter A (2012) Power generation from sugarcane biomass – a complementary option to hydroelectricity in Nepal and Brazil. Energy 48:241–254. https://doi.org/10.1016/J.ENERGY.2012.03.015

Khatiwada D, Venkata BK, Silveira S, Johnson FX (2016) Energy and GHG balances of ethanol production from cane molasses in Indonesia. Appl Energy 164:756–768. https://doi.org/10.1016/J.APENERGY.2015.11.032

Kumar S, Shrestha P, Abdul Salam P (2013) A review of biofuel policies in the major biofuel producing countries of ASEAN: production, targets, policy drivers and impacts. Renew Sustain Energy Rev 26:822–836. https://doi.org/10.1016/J.RSER.2013.06.007

Ministry of Agriculture (2018) Directorate general of estate crops, Statistik Perkebunan Indonesia Komoditas Tebu 2015–2017 (Sugarcane). http://ditjenbun.pertanian.go.id/tinymcpuk/gambar/file/statistik/2017/Tebu-2015-2017.pdf. Accessed 20 Dec 2018

Ministry of Energy and Mineral Resources (2016) Handbook of energy and economic, Statistics of Indonesia. https://www.esdm.go.id/assets/media/content/content-handbook-of-energy-economic-statistics-of-indonesia-2016-lvekpnc.pdf. Accessed 20 Dec 2018

Mujiyanto S, Tiess G (2013) Secure energy supply in 2025: Indonesia’s need for an energy policy strategy. Energy Policy 61:31–41. https://doi.org/10.1016/J.ENPOL.2013.05.119

Ramdani F, Hino M (2013) Land use changes and GHG emissions from tropical forest conversion by oil palm plantations in Riau province, Indonesia. PLoS One 8:e70323. https://doi.org/10.1371/journal.pone.0070323

Susanti A, Maryudi A (2016) Development narratives, notions of forest crisis, and boom of oil palm plantations in Indonesia. For Policy Econ 73:130–139. https://doi.org/10.1016/J.FORPOL.2016.09.009

Uusitalo V, Väisänen S, Havukainen J et al (2014) Carbon footprint of renewable diesel from palm oil, jatropha oil and rapeseed oil. Renew Energy 69:103–113. https://doi.org/10.1016/J.RENENE.2014.03.020

Winrock International (2009) Implications of biofuel sustainability standards for Indonesia. Winrock International, Arlington

Yan J, Lin T (2009) Biofuels in Asia. Appl Energy 86:S1–S10. https://doi.org/10.1016/j.apenergy.2009.07.004

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Silveira, S., Khatiwada, D. (2019). Sugarcane Biofuel Production in Indonesia. In: Khan, M., Khan, I. (eds) Sugarcane Biofuels. Springer, Cham. https://doi.org/10.1007/978-3-030-18597-8_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-18597-8_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-18596-1

Online ISBN: 978-3-030-18597-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)