Abstract

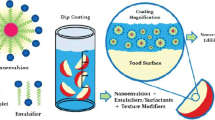

Nanoemulsions are the emulsions having droplet size below 100 nm developed by adopting pressure- or energy-based methods like homogenizers with a high-pressure valve or using microfluidizers. Within the droplets, the combination of functional food components is possible with the continuous or interfacial region. It provides the ability to encapsulate and release at a single delivering system. Such systems can carry numerous functional components, and the release of these components is controlled with a particular environmental trigger. In milk and milk-based products, various organoleptic characteristics like mouthfeel, taste, flavor, consistency, and rheological characteristics are considered as the quality determinants. The achievement of desired quality parameters in a product can be done by controlling the distribution and droplet size assisted by emulsification process. The stabilizing ability of emulsion in milk is possible without using any extraneous stabilizing agents due to inherent emulsifying capacity of milk proteins. The demand for nanoemulsions over conventional emulsions is increasing day by day, and research is emphasized on their particular applications and properties like functional beverages and foods, improved bioavailability of nutrients, and enhanced physical stability. The dairy-based products can be used as ingredients which are having different functions that supply physical stability as well as health and nutritional benefits. This chapter is focused on the nanoemulsion formation and their applications in dairy-based industries.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

The definition for emulsion by the International Union of Pure and Applied Chemistry (IUPAC) is: “In the case of emulsion, liquid crystals or liquid droplets are always dispersed in a liquid”. Emulsion are formed by mixing two or more immiscible phases or fluids where dispersed phase (in the form of droplets) is suspended in continuous phase (Fig. 4.1). Milk is an oil-in-water emulsion in which fat molecules are mostly situated in spherical globules. A blend of water and oil may result in a rough nonpermanent emulsion, which will isolate into two different systems upon standing because of the mixture of the scattered globules. The characteristics of the emulsion droplets depend upon various factors like pH, temperature, ionic strength, total soluble solids, and type of emulsifiers (mostly proteins, i.e., casein or whey protein) present at the interface. Emulsion can be classified as nanoparticles, microcapsules, and microreservoir as per the particle size. Emulsifying agents, and oil are the most essential components to make a stable emulsion. There are many oils that can be used for the nanoemulsion methods like coconut oil, evening primrose oil, castor oil, corn oil, linseed oil, olive oil, peanut oil, and mineral oils. An emulsifying agent ought to be nontoxic and good in taste, possess chemical stability, and have the capacity to decrease the surface tension beneath 10 dynes/cm. Around the scattered stage, these globules ought to be adsorbed quickly and should form a reasonable film on the emulsion mixture. Emulsifies are also called as emulgents which help to stabilize the emulsion by a raise in their kinetic stability. The emulsifying agents should be helpful for maintaining a sufficient viscosity and zeta potential in the system, which ensures optimum stability. Emulsifying agents frames particulate by developing monomolecular as well as multimolecular films around the scattered globules. Whey and casein proteins present in milk act as good emulsifying agents. The adsorption of these proteins takes place at the interface of air-water/oil-water avoiding the coalescence by maintaining the interfacial membranes. Due to the amphiphilic structure, proteins present in milk behave as surface-active components in emulsion, and they stabilize the emulsion droplets by combining steric stabilization and electrostatic mechanism (Corredig 2009).

Different nanomaterials prepared by (i) membrane emulsification and (ii) membrane mixing (adapted from Charcosset 2016)

There are two types of emulsion based on their dispersion phase.

Oil-in-Water Type of Emulsion (O/W)

The emulsion in which water acts as dispersion medium (continuous phase) and oil will be dispersed in it, for example, milk, where fat globules are the dispersed phase and water is the dispersion medium.

Water-in-Oil Type of Emulsion (W/O)

It is a type of emulsion in which oil is the dispersion phase and water is dispersed in it. These types of emulsion are also called as oil emulsion . The best examples for this type of emulsion are butter and cold cream.

Microemulsion (the definition given by IUPAC) is the “dispersion made of water, oil, and surfactant(s) which is isotropic and thermodynamically stable system with diameter varying approximately from 10 to 100 nm and usually 10 to 50 nm.” Nanoemulsion are overlapping microemulsions in size but possess better structural components and prolonged thermodynamic stability, or they are thermodynamically stable transparent dispersion of oil and water stabilized by an interfacial film of surfactant and co-surfactant molecules having droplet size of less than 100 nm. Microemulsions are thermodynamically steady, and these are the systems with equilibrium state, whereas nanoemulsion are not in equilibrium but are having a capacity of spontaneous phenomena to divide into the constituent phases, and they can remain stable for several years due to extreme kinetic stability. Nanoemulsion technique is possible to control morphology, surface area, geometry, homogeneity, rheological behavior, and other properties of particle without or with minimum usage of reducing agents or external stabilizing agents. It provides a better absorbability of oil-dissolvable supplements in cell-culture innovation. Other than the stabilization benefits, nanoemulsion might be utilized as substitutes for vesicles and liposomes (Fig. 4.1). These types of emulsion have more surface area and better kinetic stability against coalescence or creaming and can be considered as a good carrier for hydrophobic bioactive compounds. Emulsion in dairy products are less stable toward the variations in ionic strength, pH, and processing situations such as shearing, heating, or cooling. Nanoemulsion technology is offering a number of new advances to milk industry for the improvement of safety, quality, shelf life, and healthiness of products. The lipophilic components can be solubilized using nanoemulsion. The absorption of nanoemulsion will be very high due to their good surface area and minute droplet size. These emulsion can be made into different forms like foams, liquids, sprays, and creams. Nanoemulsion can be utilized for the bioavailability enhancement of valuable nutrients in dairy-related products. Nowadays, the attention has laid on the use of nanoemulsion in food-processing industries to deliver functional properties of ingredients in food matrix mainly in dairy industry.

4.2 Advantages of Nanoemulsion in Dairy Sector

-

(i)

The small-sized droplets account for a vast decline in the gravity compel, and the brownian movement might be adequate for reducing gravity. This implies no creaming or sedimentation happens during the storage period in the milk.

-

(ii)

The flocculation of drops can also be prevented with the help of these small-sized milk droplets which helps in stabilizing the total system.

-

(iii)

It provides an opportunity to improve the texture, mouthfeel richness, and taste of milk by altering the flow ability.

-

(iv)

The major ingredients of milk like proteins, fat, sugars, carbohydrates, vitamins, etc. can be coated using this technique which helps them to cope up with the harsh conditions of pH change in the stomach and also enhance the bioavailability of nutrients.

-

(v)

The encapsulation of the milk components and the process of droplet size reduction will help in increasing the shelf life.

-

(vi)

Such types of emulsion will have a very small size and thus a big surface area which help in the higher rate of penetration through the skin and are also helpful in transferring the necessary components to the body through the skin. Small size also assists in uniform and quick distribution throughout the body. Even their small droplet size can also help in increasing the rate of various processes like wetting, distributing, and penetrating power.

-

(vii)

Nanoemulsion are transparent fluids requiring a small amount of surfactants, whereas microemulsions need high amounts of surfactants.

-

(viii)

They also help in introducing certain good flavoring agents and thus enhance the overall acceptability of products.

-

(ix)

The liposomes and vesicles can be replaced by the use of these types of the emulsions because of higher stability for a longer period. These emulsion can also help in the formation of liquid crystalline films around the drops.

4.3 Methods of Nanoemulsion Formation

Nanoemulsion preparation requires advanced techniques like homogenization and high pressure along with sophisticated instruments. Milk fat due to the effect of buoyancy will float on the surface of milk, to form a layer of cream and produce the phenomenon such as layering, seriously affecting the quality of dairy products. Different methods used in nanoemulsion development are discussed in the following sections.

4.3.1 High-Energy Approaches

High-energy approaches rely on providing intensive energy to disrupt the oil globules and water into very fine droplets with the help of high-pressure homogenizers and microfluidizers. Energy inputs modulate the properties of the nanoemulsion and excellently prevent droplet disruption and coalescence.

4.3.1.1 High-Pressure Homogenizers

Homogenization facilitates the production of dairy products with improved texture, taste, flavor, and shelf life. High-pressure homogenization is the most commonly used method of producing fine emulsion in the food industry. Regular high-weight homogenizers work on weights apparently in the range of 50 and 100 MPa. A coarse emulsion is usually produced using a high-speed blender and is then fed directly into the input of the high-pressure valve homogenizer. The pump of the homogenizer draws coarse emulsion to a chamber on its backstroke and then forces it to pass through a narrow valve at the end of the chamber on its forward stroke. Emulsion experiences a mix of extreme aggravating forces such as cavitation, turbulance and shear which convert bigger droplets into smaller ones. A variety of valves have been designed for different types of applications. Most commercial homogenizers use spring-loaded valves so that the gap through which the emulsion passes can be varied. Decreasing the gap size increases the pressure drop across the valve, which causes a greater degree of droplet disruption and smaller droplets to be produced. On the other hand, narrowing the gap increases the energy input required to form an emulsion, thereby increasing manufacturing costs. The wide range of sorts of spouts will be accessible to upgrade the proficiency of droplet size reduction in homogenizer.

Microfluidizer technology more efficiently converts high fluid pressure into shear forces and helps the industries to meet the performance standards for high-pressure homogenization. During microfluidization, the product enters the system via an inlet reservoir and is delivered by a high-pressure intensifier pump into an interaction chamber at speeds of up to 400 m/s and pressures in the range 20–275 MPa. In the fixed-geometry interaction chamber, the liquid is divided into two or more microstreams, and these high-velocity streams undergo a sudden pressure drop on collision at a perpendicular angle, causing turbulence, cavitation, shear, and ultimately droplet disruption. Through this process, a uniform distribution of small particles is maintained. The product is subjected to instant cooling followed by collection in the output reservoir (Fig. 4.2).

4.3.1.2 Microfluidizer

It is a mixing technique , which is somewhat similar in the high-pressure homogenizer. A high-pressure displacement pump is used in the device to force the product through the interaction chamber composing of many small channels called microchannel. Prior to the homogenizer by microfluidizer, the aqueous phase and oil phase were combined together to yield a coarse emulsion, usually obtained by high-speed homogenizer. The coarse emulsion then passed through a microfluidizer to produce stable nanoemulsion (Koroleva and Yurtov 2012; McClements 2012).

4.3.1.3 Ultrasonication

The ultrasound waves when pass through a liquid medium, the interaction between the ultrasonic waves, liquid, and dissolved gas leads to a phenomenon known as acoustic cavitation. Ultrasonic emulsification offers several benefits over conventional emulsification methods used in dairy systems such as mechanical shaking, high- or ultrahigh-pressure homogenization and microfluidization in terms of improved energy efficiency, higher emulsion stability, lowered requirement of surfactants, and controllable size distributions. Ultrasonic cavitation will produce strong mechanical action, under an appropriate ultrasonic frequency, resulting in better emulsification. Ultrasonic homogenizers are especially reasonable for less-consistency liquids and less appropriate for high viscous frameworks. The utilization of ultrasound has numerous points of interest; for example, less power utilization , less utilization of surfactant, droplet size reduction, and more homogeneous nature of emulsion. Omega-3-rich nanoemulsions are arranged by utilizing an ultrasound gadget (Cavazos-Garduño et al. 2015). Strunz et al. (2008) examined that the utilization of the Brazil nut (wealthy in monounsaturated fatty acid and polyunsaturated fatty acid) can influence the plasma lipids, apolipoprotein, and other practical characteristics of antiatherogens with high-density lipoproteins, i.e., HDL. The lipid nanoemulsion was set up by delayed ultrasonic illumination in the fluid media and a two-step advanced ultracentrifugation of the unrefined emulsion (Table 4.1, Fig. 4.3).

4.3.2 Low-Energy Methods

Low-energy methods result in the spontaneous formation of fine droplets with controlled variation in developing conditions of incompatible oil/water/emulsifier systems. Some commonly used low-energy methods such as membrane emulsification, spontaneous-emulsification, phase inversion etc., along with their applications are summarized in Table 4.2.

4.3.2.1 Membrane Emulsification

This is a quite old method based on low-energy approach developed by Suzuki and others in 1981. The process can produce stable nanoemulsion by controlling the fine droplet size as well as distribution with lower energy input (104–106 J/m3) and without high mechanical stress (Ribeiro Filho et al. 2005). This approach is considered the best for nanoemulsion formation; however, droplet size is comparatively higher than other methods of nanoemulsion formation.

4.3.2.2 Spontaneous Emulsification

This method involves the mixing of appropriate amounts of oil , water, surfactant, and/or co-surfactant and is the simplest method. Mixing speed, ionic strength, and pH variations are done to form nanoemulsions spontaneously. Fine oil droplets can be formed when an oil/surfactant mixture is added to water. The sequence of addition is not critical because this kind of nanoemulsion is formed spontaneously. But, the system compositions (oil-to-emulsion ratio content, the surfactant-to-emulsion ratio) and preparation conditions (stirring speed) may influence emulsion properties (Kelmann et al. 2007; Saberi et al. 2013).

4.3.2.3 Phase Inversion Composition (PIC)

This method is based on progressive dilution with water or oil, and this composition is optimized at a particular temperature. This phase change is driven by Gibbs free energy of the emulsion resulting in spontaneous inversion of the surfactant’s curvature between positive and negative (Sonneville-Aubrun et al. 2009).

4.4 Emulsion Stability of Milk

Fine droplet size of nanoemulsion accounts for its stability against gravitational separation and then alteration in properties. The small droplet size of nanoemulsion confers stability against sedimentation (or creaming) because the Brownian motion and consequently the diffusion rate are higher than the sedimentation (or creaming) rate induced by the gravitational force. Ostwald ripening or molecular diffusion, which arises from emulsion polydispersity and the difference in solubility between small and large droplets, is the main mechanism for nanoemulsion destabilization. The nanoemulsion which are vitamin-rich and stabilized are used to fortify milk, which shows much better health benefits to humans by increasing the bioavailability of that nutrient. The necessary micronutrients like lipophilic vitamins are very important and necessary for human physiology and wellness, so there is a huge growth and demand in the field of food fortifying with vitamins. In emulsion, there should be a homogeneous distribution of the dispersion-phase medium. However, flocculation, coalescence, and sedimentation result in instability of emulsion (Fig. 4.4).

Emulsion stability pathways : This process starts with (a) the uniform distribution of drops of oil in water, (b) flocculation, (c) coalescence, and (d) creaming/sedimentation. (e) The final step occurs with the separation of the two states, i.e., the entire division of components into two phases. The above-figured arrows represent all the potential pathways and also show the positions where the reversible reactions can be possible by means of simple redistribution

The flocculation is a process in which formation of network/clump takes place by the accumulation of small drops (droplets). Basically, this formation of network takes place because of the production of uneven forces of repulsion and attraction, which results in the attraction of droplets for accumulation. There may be other factors accounting for the accumulation, but electrostatic force is the major one. Sometimes the electrostatic repulsive forces can also help in the maintenance of stability of emulsion by the process of repulsion of droplets from each other which helps in fine uniform dispersion of drops all over the surface. The next step is coalescence in which two or more small drops merge with each other for the formation of one fine large drop. This process of formation of big-sized particle can occur only by the association of small droplets and can be triggered during creaming and flocculation. Various methods are there for the prevention of coalescence by using proteins and emulsifier . The process of coalescence can be prevented by providing the surface with strong charge which can avoid the association of drops. The mechanism of creaming is caused by the density variation among continuous and dispersed phase which results in the development of buoyancy force. The reduced size of droplets will help in the prevention of creaming. All the abovementioned preventive measures help in the prevention or slowing down of the rate of creaming and hence the extension of shelf life in dairy and dairy-related products.

4.5 Nanoemulsion in Food Industry

In the present aggressive market, new technical innovation is fundamental to keep the administration in food industry as consumer demand is changing rapidly. The future has a place for new items and innovative procedures with the objective of upgrading the execution of processes and enhancing the security and nature of food items by dragging out their time span of usability and freshness. Nanotechnology can possibly change dairy and food sectors which show a bright future in this field. The uses of nanotechnology in dairy and food businesses involve packaging with the help of nanocomposite bottles, nanolaminates, and containers having silver nanoparticles. Nanoparticulate delivery systems involving nanocapsules and nanodispersions have been used as a suitable form to improve the digestibility of food, bioavailability of active components, pharmacological activities of certain compounds, while nanosensors are involved in food safety and biosecurity. Nanoparticles might be utilized for impacting the surface characteristics, nutritious change and also to recognize pathogens in food materials. Food bundling which includes eatables and nano wrapper can broaden timeframe of their realistic usability. “Keen” bundling containing nanosensors which are hostile to the activators of microorganism, counteract gas and humidity and discharge nano against microorganisms can be useful for expanding the time span of food usability.

4.5.1 Food Packaging (Nano Outside)

Nowadays, food business operators and consumers are demanding significantly more from packaging regarding ensuring the performance, freshness, and well-being of foods. Food packaging is the area in which utilization of nanotechnology will be more in future (Bhushan 2017). It has been announced that around 400–500 nanopacking items are being utilized in food business in which nanotechnology is utilized as a part of the production of 25% of all food packing in the coming decade. The main function of nanopacking is to extend the shelf life of food products by enhancing the barrier nature of food packets by reducing moisture and gas exchange and also the exposure to ultraviolet light .

4.5.2 Food “Fortification” Through Nanotechnology

Nanotechnological organizations are attempting to strengthen the handling of dairy and food items using nanoencapsulated supplements, their appearance, and taste which are modified by nanocreated hues, the glucose and fat content expelled/disabled with the help of nano-adjustment, and enhanced mouth feel. The fortification of food can be utilized to build dietary demands, for instance. The consideration of “medicinally gainful” nanocontainers will empower chocolate-based chips or hot chips. Nanotech would likewise empower particular food items like dessert and chocolate to decrease the measure of glucose and fat that a body could ingest. This process can be achieved by utilizing nanosized substances to keep the body from processing/retaining these segments of sustenance. Along these lines, the nano business can display the low-quality food as a well-being food .

4.5.3 Nanotechnology in Association with Dairy Processing

According to the consultancy of Helmut Kaiser (2009), “nanofoods” are contributing an expanding development in the improvement of nanoproducts related to dairy and food sector and also for the application of patent. It is possible to connect nanotechnology for the creation of materials like nanoscale food components, contaminant detection, and for making nano gadgets for sub-atomic and cell science from how the development of food is possible to how it gets bundled. The nanotechnology used for sustenance and dairy sectors are secured by two important means, viz., substances which are added in food (nano-inside) and dairy bundling/ packaging (nano-outside). Nanocoating is applicable to dairy products like cheese, and the process of nanotechnology has played an important role in the improvement of nanoscale-palatable film having a width of 5 nm which is undetectable to our normal eye. Nanocoating can also act as a barrier against gas, moisture, and lipids. Other applications of nanocoating are the carriers of antioxidants, antimicrobials, colors, nutrients, and flavors which are the important functional agents and improvement of storage life and textural properties of manufactured foods even in open conditions. By 2003, over 90% of nanopackaging was based on nanocomposites, in which nanomaterials were used to improve the barrier properties of plastic wrapping for foods and dairy products. Nanopackaging can also be designed to release antimicrobials, antioxidants, enzymes, flavors, and neutraceuticals to extend the shelf life (Cha and Chinnan 2004).

4.6 Application of Nanoemulsion in Dairy Products

Consumer focus has changed from energy-providing foods to functional foods associated with required health benefits. This may include fortification with bioactive compounds for nutritional enrichment and antioxidant incorporation to enhance the shelf life, stability, etc.

4.6.1 Ice cream

Ice cream is a mix of a compound colloid food that includes the globules of fat, crystals of ice, air bubbles, and a serum phase which is unfrozen. Generally, the size of the ice crystals and air bubbles range from 20 to 50 μm. In general, the fat globules make a coat around the air bubbles, and the protein or the emulsifier forms a coat around fat globules. Different equipment and techniques are involved in the development of nanoemulsion in ice cream. Curcumin is the polyphenoilc component of turmeric with various health benefits like antioxidant, anti-inflammatory, antitumorigenic, anticoagulant, antibacterial, anticarcinogenic, etc. However, its wide usage as functional ingredient is limited due to poor water solubility, bioaccessibility, absorption in GI tract, and being quite prone to degradative changes at an alkaline pH, high temperature, and in presence of light (Aditya et al. 2014). This problem can be resolved by the development of nanoemulsion and incorporation in food system acting as carrier. Ice cream is one such product which is liked by almost all the age groups and in all seasons; so, it can be the best vehicle for the encapsulated curcumin (Fig. 4.5).

4.6.2 Yogurt

Yogurt is a type of milk product prepared by the process of fermentation with bacterial addition and also the incorporation of sweeteners and flavors. Yogurt is commonly utilized in daily diets due to the wide range of health benefits. The bacteria used to make yogurt are known as yogurt cultures. Fermentation of lactose by these bacteria produces lactic acid, which acts on milk protein to give yogurt its texture and characteristic tart flavor. To produce yogurt, milk is first heated, usually to about 85 °C (185 °F), to denature the milk proteins so that they do not form curds. After heating, the milk is allowed to cool to about 45 °C (113 °F). The bacterial culture is mixed in, and the temperature of 45 °C is maintained for 4–12 hours to allow fermentation to occur. Fish oil can be used as supplements to different food items, but because of less solubility in water, it is challenging to add fish oil into fortified and functional foods which may result in poor bioavailability. For a higher bioavailability and better protection against the quality declination, nanoemulsion technique is considered as the most advanced and effectual encapsulation method in which lipids are added to the liquid phase which will enhance the dispersion in the food systems. The water solubility of lipophilic bioactive compounds and oils can be increased with the help of nanoemulsion technology. High-energy methods like sonication and high-pressure homogenization are normally used for the preparation of fish oil nanoemulsion. Nanoemulsion is helpful in protecting the antioxidant potential of γ-oryzanol and aids in the health benefits of yogurt. Yogurt fortified with fish oil/γ-oryzanol nanoemulsion can be prepared by the incorporation of 13 g fish oil or γ-oryzanol nanoemulsion in 100 g sample of yogurt and refrigeration at 4 °C for 21 days in a glass jar which is tightly closed. There will be a gradual decrease in the peroxide value, syneresis, and acidity along with a higher retention of docosahexaenoic acid and eicosapentaenoic acid during the incorporation of γ-oryzanol and fish oil-enriched nanoemulsion in yogurt. The viscosity of yogurt fortified with γ-oryzanol/fish oil nanoemulsion will be lower. Incorporation of nanoemulsion will not alter the crystallization and melting nature of yogurt which are fortified.

4.6.3 Quality Preservation

The main reason for the spoilage in milk is due to the action of microorganisms and can be determined by sensory, sanitary, technological, and nutritional parameters. Addition of Thymus capitatus essential oil or their nanoemulsion into a variety of spoiled milk will retard the bacterial growth, thereby improving the microbiological as well as physicochemial qualities, and also their incorporation in semiskimmed ultrahigh-temperature milk will enhance the fermentative and oxidative stability. Degradation of protein by enzymes is responsible for the age gelation of ultrahigh-temperature milk and poor stability of stored milk which is pasteurized. As compared to nanoemulsion, free essential oils are more effective against protein degradation. The quality preservation and shelf-life extension of milk can be easily achieved by nanoencapsulated or bulk T. capitatus essential oil .

4.6.4 Cheese

Dairy protein emulsion can act as delivery systems in the fortification of cheese with the help of D3 vitamin. In the presence of sunlight or after the uptake of supplements and fortified food, essential vitamins like D vitamins will be synthesized in the body. By delivering vitamin D3 in the oil-in-water emulsion phase, retention of curd can be increased due to the more interaction between the curd and emulsifier. The retention of curd can be improved even more by mixing the emulsion with milk proteins, because of the increased interaction between casein protein of curd and dairy proteins. If vitamin D is used in less amounts for the fortification of cheese and because of the increased vitamin/whey protein ratio, there will be a huge loss of vitamin present in whey. By adding D3 vitamin as an emulsion and dairy proteins as emulsifying agents, the retention of vitamin in cheese curd can be increased. Nonfat dry milk, whey protein concentrate, and caseinates are the different varieties of protein powder that can be incorporated for the formulation of emulsion which will not alter the D3 vitamin retention of curd. In an oil carrier, it is better to use milk protein emulsifying agents rather than nanoemulsified D3 vitamin .

4.6.5 Milk

The fortification of food with necessary micronutrients like vitamin A, D and E have health benefits to humans and improve the quality of life by resisting diseases like osteomalacia, suppressed immune system, osteoporosis, cancer, cardiovascular disease, vision loss etc. The solubility and bioavailability of vitamins can be increased by encapsulating these vitamins using nanoemulsion based on lipids. Oil-in-water-type emulsion are very effective type of emulsion for the encapsulation and stabilization of lipophilic vitamins and thereby increase their bioavailability. Hence, the intake of milk which enriched with vitamin D3 and calcium is very effective in its bioavailability and helps in the reduction of risk factors like aging, bone mass loss, and bone fractures. Gruenwald (2009) stated that skimmed milk is a poor source of vitamins and is fortified with vitamin D3 which helps to increase calcium absorption in human beings. Basically, vitamin D is a lipid-soluble neutraceutical which helps in the intestinal absorption of calcium, balance of phosphorus, and promotion of bone formation. Because of the water-insoluble nature, vitamin D is not found in food and beverages like low-fat milk and milk products which are the main sources of phosphorus and calcium. Higher efficiency, solubility, and stability can be easily achieved by lipid nanoparticles by acting as a carrier.

4.6.6 Effects of Processing

This portion covers the general effects that occur when emulsifiers related to milk are subjected to common processing conditions of food at the production stage of emulsified foods. In addition to the general processes like shear and heat, processing using high pressure is also noticed. This portion will focus on proteins because they are the major emulsifying agents present in milk. Hydrophobicity, size, solubility, flexibility, and charge are the major physicochemical characteristics that explain the capacity of a protein to stabilize and form emulsion. Any type of process that can influence these parameters can also have impact on the properties of emulsion. Also, there will be a complex intermediate relation between several such attributes. For example, to minimize a direct interaction with fluid solvent, the hydrophobic remains of proteins commonly hide in their own core for maintaining solubility. The exposure of these residues will enhance the surface activity of protein, but through hydrophobic interactions, they will also increase their susceptibility to aggregation. Thus, there will be a reduction in their solubility, and as a result, their diffusing ability and stability toward the interface will gradually fall. The common scheme which explains the processing energy inputs like shear, heat, or high pressure and their effect on solubility, structure of protein, and also functional properties is given in Fig. 4.6.

Processing energy effect on the structure of protein and its functionality, a general scheme. (a) Quaternary structure of protein. (b) Releasing of several surface-active monomers of protein. (c) Unfolding of tertiary structure due to further processing results in surface activity and optimal hydrophobicity. (d) Occurrence of hydrophobic aggregation due to overprocessing. (e) Disruption of the primary structure, which results in the reduction of functionality

Protein ingredient which are produced commercially are normally subjected to treatments like shear and heat, and as a result they form aggregates when rehydrated in the preparation for use. A low surface activity and slower adsorbtion ability are the properties of protein aggregates which may result in a lower effectiveness in the stabilization of emulsion. Thermal processing may cause variations in hydration mainly for higher hydrophobic residuals which decrease the hydrogen bonding, vary the steric parameters and volume, and finally degrade the general structure. A lower temperature can make an impact on the weaker bonds which disrupt the quaternary structure (i.e., separation of oligomers) trailed by the breakdown of the tertiary structure. The emulsification and foaming ability of skimmed milk powder (SMP) will be highly reduced due to thermal treatments. Parris et al. (1991) observed that thermal treatment on SMP stimulates the connection between casein micelles and whey proteins, resulting in higher hydrophilic aggregates having minimal solubility but with an enhanced emulsifying and foaming action. Dairy proteins can stabilize emulsion, and they are commonly oil-in-water emulsion, and water is the main constituent in such systems (Wilde 2009). Milk proteins like caseins are highly sensitive to the strength of ions mainly the range of calcium. So hardness of water has a tremendous effect on the emulsion stability which is stabilized by the action of caseins. Higher level of calcium may cause flocculation of emulsion which are stabilized by casein (Schokker et al. 2000; Dickinson 2003).

4.7 Challenges and Future Trends

Traditionally , milk was widely regarded as a cheap source of functional ingredient, especially with the arrival of price-efficacious extraction and production technologies. The usage of dairy ingredient like caseins, milk fat globules, and whey are gradually increasing in foods due to their beneficial health-supporting features. The present report related to the future trends of food is of more concern regarding the capacity of food to provide a better quality to life and increased health conditions. Phospholipids, proteins, and peptides also have an effect on the health of human beings via the availability of essential type of amino acids, bioactivity, and signaling of homeostatic processes like enhancement in nervous and membrane function, satiety, etc. The proof for ensuring the health-promoting effects of dairy ingredient like peptides derived from casein, whey proteins (Frestedt et al. 2008), and milk phospholipids (Noh and Koo 2004; Dewettinck et al. 2008) shows that their inclusion in foods results in an increased health. Foods which can be emulsified are better dietary fat sources. As compared to conventional emulsifiers, whey proteins can impact on the emulsion rheology, mainly due to charge interactions and their interfacial rheology. Thus, dairy-based products can be used as ingredient which are having different functions that supply physical stability as well as health and nutritional benefits.

References

Aditya NP, Macedo AS, Doktorovova S, Souto EB, Kim S, Chang PS, Ko S (2014) Development and evaluation of lipid nanocarriers for quercetin delivery: a comparative study of solid lipid nanoparticles (SLN), nanostructured lipid carriers (NLC), and lipid nanoemulsions (LNE). LWT Food Sci Technol 59(1):115–121

Bhushan B (ed) (2017) Springer handbook of nanotechnology. Springer, Berlin/Heidelberg

Cavazos-Garduño A, Flores AO, Serrano-Niño JC, Martínez-Sanchez CE, Beristain CI, García HS (2015) Preparation of betulinic acid nanoemulsions stabilized by ω-3 enriched phosphatidylcholine. Ultrason Sonochem 24:204–213

Cha DS, Chinnan MS (2004) Biopolymer-based antimicrobial packaging: a review. Crit Rev Food Sci Nutr 44(4):223–237

Charcosset C (2016) Preparation of nanomaterials for food applications using membrane emulsification and membrane mixing. In: Nanotechnology in the Agri-Food Industry, Emulsions by Grumezescu AM, Academic Press, Vol. 3, pp 37-69. https://doi.org/10.1016/B978-0-12-804306-6.00002-7

Corredig M (2009) Molecular understanding of the interaction of dairy proteins with other food biopolymers. In: Dairy-derived ingredients. Woodhead Publishing, Cambridge, pp 371–393

Dewettinck K, Rombaut R, Thienpont N, Le TT, Messens K, Van Camp J (2008) Nutritional and technological aspects of milk fat globule membrane material. Int Dairy J 18(5):436–457

Dickinson E (2003) Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocoll 17(1):25–39

Donsì F, Annunziata M, Sessa M, Ferrari G (2011) Nanoencapsulation of essential oils to enhance their antimicrobial activity in foods. LWT Food Sci Technol 44(9):1908–1914

Frestedt JL, Zenk JL, Kuskowski MA, Ward LS, Bastian ED (2008) A whey-protein supplement increases fat loss and spares lean muscle in obese subjects: a randomized human clinical study. Nutr Metab 5:8

Ghosh V, Mukherjee A, Chandrasekaran N (2013) Ultrasonic emulsification of food-grade nanoemulsion formulation and evaluation of its bactericidal activity. Ultrason Sonochem 20(1):338–344

Gruenwald J (2009) Novel botanical ingredients for beverages. Clin Dermatol 27(2):210–216

Helmut Kaiser Consultancy (2009) Study: nanobased products inventory 2009 and commercialization. http://www.hkc22.com/nanobasedproducts.html. Accessed 15 June 2018.

Kelmann RG, Kuminek G, Teixeira HF, Koester LS (2007) Carbamazepine parenteral nanoemulsions prepared by spontaneous emulsification process. Int J Pharm 342(1–2):231–239

Koroleva MY, Yurtov EV (2012) Nanoemulsions: the properties, methods of preparation and promising applications. Russ Chem Rev 81(1):21–43

Kuo F, Subramanian B, Kotyla T, Wilson TA, Yoganathan S, Nicolosi RJ (2008) Nanoemulsions of an anti-oxidant synergy formulation containing gamma tocopherol have enhanced bioavailability and anti-inflammatory properties. Int J Pharm 363(1–2):206–213

Laouini A, Fessi H, Charcosset C (2012) Membrane emulsification: a promising alternative for vitamin E encapsulation within nano-emulsion. J Membr Sci 423:85–96

Li PH, Chiang BH (2012) Process optimization and stability of D-limonene-in-water nanoemulsions prepared by ultrasonic emulsification using response surface methodology. Ultrason Sonochem 19(1):192–197

Liedtke S, Wissing S, Müller RH, Mäder K (2000) Influence of high pressure homogenisation equipment on nanodispersions characteristics. Int J Pharm 196(2):183–185

McClements DJ (2012) Nanoemulsions versus microemulsions: terminology, differences, and similarities. Soft Matter 8(6):1719–1729

Noh SK, Koo SI (2004) Milk sphingomyelin is more effective than egg sphingomyelin in inhibiting intestinal absorption of cholesterol and fat in rats. J Nutr 134(10):2611–2616

Oh DH, Balakrishnan P, Oh YK, Kim DD, Yong CS, Choi HG (2011) Effect of process parameters on nanoemulsion droplet size and distribution in SPG membrane emulsification. Int J Pharm 404(1–2):191–197

Parris N, Purcell JM, Ptashkin SM (1991) Thermal denaturation of whey proteins in skim milk. J Agric Food Chem 39(12):2167–2170

Preetz C, Hauser A, Hause G, Kramer A, Mäder K (2010) Application of atomic force microscopy and ultrasonic resonator technology on nanoscale: distinction of nanoemulsions from nanocapsules. Eur J Pharm Sci 39(1–3):141–151

Qian C, McClements DJ (2011) Formation of nanoemulsions stabilized by model food-grade emulsifiers using high-pressure homogenization: factors affecting particle size. Food Hydrocoll 25(5):1000–1008

Ribeiro Filho HM, Delagarde R, Peyraud JL (2005) Herbage intake and milk yield of dairy cows grazing perennial ryegrass swards or white clover/perennial ryegrass swards at low-and medium-herbage allowances. Anim Feed Sci Technol 119(1–2):13–27

Saberi AH, Fang Y, McClements DJ (2013) Fabrication of vitamin E-enriched nanoemulsions by spontaneous emulsification: effect of propylene glycol and ethanol on formation, stability, and properties. Food Res Int 54(1):812–820

Schokker EP, Singh H, Creamer LK (2000) Heat-induced aggregation of β-lactoglobulin A and B with α-lactalbumin. Int Dairy J 10(12):843–853

Solè I, Pey CM, Maestro A, González C, Porras M, Solans C, Gutiérrez JM (2010) Nano-emulsions prepared by the phase inversion composition method: Preparation variables and scale up. J Colloid Interface Sci 344(2):417–423

Sonneville-Aubrun O, Babayan D, Bordeaux D, Lindner P, Rata G, Cabane B (2009) Phase transition pathways for the production of 100 nm oil-in-water emulsions. Phys Chem Chem Phys 11(1):101–110

Strunz CC, Oliveira TV, Vinagre JC, Lima A, Cozzolino S, Maranhão RC (2008) Brazil nut ingestion increased plasma selenium but had minimal effects on lipids, apolipoproteins, and high-density lipoprotein function in human subjects. Nutr Res 28(3):151–155

Subramanian B, Kuo F, Ada E, Kotyla T, Wilson T, Yoganathan S, Nicolosi R (2008) Enhancement of anti-inflammatory property of aspirin in mice by a nano-emulsion preparation. Int Immunopharmacol 8(11):1533–1539

Tang SY, Shridharan P, Sivakumar M (2013) Impact of process parameters in the generation of novel aspirin nanoemulsions–comparative studies between ultrasound cavitation and microfluidizer. Ultrason Sonochem 20(1):485–497

Wilde PJ (2009) Emulsions and nanoemulsions using dairy ingredients. In: Dairy-derived ingredients by Corredig, M, Woodhead Publishing,Cambridge, UK, pp 539–564.

Yilmaz E, Borchert HH (2005) Design of a phytosphingosine-containing, positively-charged nanoemulsion as a colloidal carrier system for dermal application of ceramides. Eur J Pharm Biopharm 60(1):91–98

Yuan Y, Gao Y, Zhao J, Mao L (2008) Characterization and stability evaluation of β-carotene nanoemulsions prepared by high pressure homogenization under various emulsifying conditions. Food Res Int 41(1):61–68

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Panghal, A. et al. (2019). Nanoemulsions: A Promising Tool for Dairy Sector. In: Prasad, R., Kumar, V., Kumar, M., Choudhary, D. (eds) Nanobiotechnology in Bioformulations. Nanotechnology in the Life Sciences. Springer, Cham. https://doi.org/10.1007/978-3-030-17061-5_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-17061-5_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-17060-8

Online ISBN: 978-3-030-17061-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)