Abstract

Droplet size, polydispersity, physical and polymorphic stability of milk fat nanoemulsions produced by hot high-pressure homogenization and stabilized by whey protein isolate (WPI pH 4.0 or 7.0) or sodium caseinate (NaCas pH 7.0) were evaluated for 60 days of storage at 25 °C. Smaller droplets were observed for the NaCas pH 7.0 nanoemulsion, which also showed a lower polydispersity index, resulting in a stable emulsified system for 60 days. On the other hand, the nanoemulsion with bigger droplet size (WPI pH 4.0) showed reduced stability, probably due to the pH near the isoelectric point of the whey proteins. The nanostructured milk fat exhibited the same melting behavior as the bulk milk fat, with a balance between liquid and crystallized fat, and crystals in polymorphic form β′. This could be an advantage concerning the application of the system for delivery of bioactive compounds and improvement of the sensory properties of fat-based food. In summary, nanoemulsions stabilized by NaCas (pH 7.0) showed higher kinetic stability over the storage time, which from a technological application point of view is a very important factor in the food industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the food industry, nanoemulsions are one of the most interesting fields of application of nanotechnology, for their ability to encapsulate, protect, and release bioactive agents (Cerqueira et al. 2014). The droplet size (< 200 nm) is strongly responsible for the stability of nanoemulsions to gravitational separation, however, the stability does not depend exclusively on particle size, but also on the characteristics of the fat, the type of emulsifier, the manufacturing process, and the pH of the emulsified system (Walker et al. 2017).

The nature of the emulsifier at the oil–water interface plays a critical role in determining the overall functional attributes of the nanoemulsions (Jafari and McClements 2018). Synthetic emulsifiers are low molecular weight surfactants, which stand out for the high stability conferred to the nanosystems. They include polyglycerol esters, sorbitan esters, polysorbates, monoacylglycerols, and diacylglycerols (Silva et al. 2015). However, there is an increasing demand of consumers and the food industry for natural ingredients, which has led to studies regarding the use of proteins as an alternative to stabilize emulsions and liquid nanoemulsions. Whey protein concentrate (Chevallier et al. 2016), whey protein isolate (Teo et al. 2016), sodium caseinate (Furtado et al. 2017) and whey protein fractions, including β-lactoglobulin and lactoferrin (Furtado et al. 2017) have been evaluated as stabilizers of emulsions and nanoemulsions. Their effect as an emulsifier depends on a combination of factors such as concentration, viscosity of the continuous phase, flexibility and molecular size, surface hydrophobicity, net protein surface load, pH, ionic strength, manufacturirng processes, and storage temperature (Teo et al. 2016; Ruttarattanamongkol et al. 2015).

In the process of obtaining an oil-in-water (O/W) nanoemulsion, the lipid phase obtained from natural vegetable oils is usually liquid at any temperature. This characteristic derives from its chemical composition, which presents homogeneity of long-chain unsaturated fatty acids and a low melting point. When the crystallization of the lipid phase is desirable in a nanoemulsified system, it can be achieved by modifying the vegetable oils by hydrogenation, fractionation or interesterification (O’Brien 2009). Another alternative can be the use of a naturally plastic fat, as is the case of milk fat. The natural plasticity of milk fat is due to its heterogeneous composition, which presents more than 400 fatty acids, of which approximately 65% are saturated fatty acids. This composition results in an extensive melting range (− 40 to 40 °C) and the concomitant presence of liquid and solid fat in a proportion that varies according to the processing and storage temperatures (Lopez et al. 2001; Wright and Marangoni 2006). The physical state of the droplet interior depends on the nature of the oil phase used (such as its crystallization and melting behavior) and the thermal history of the system. The solidified lipid phase retards molecular diffusion processes, which are useful for inhibiting the chemical degradation or controlling the release of encapsulated compounds (Jafari and McClements 2018).

For the production of exclusive milk-based systems, milk fat and its fractions (olein and stearin) have been used as the lipid phase to obtain emulsions and nanoemulsions stabilized by sodium caseinate and/or whey proteins. These emulsions were obtained at the natural milk pH (~ 6.8) at temperatures ranging from 55 to 65 °C and different high-pressure homogenization conditions (30–600 bar with 1–10 homogenization cycles) (Relkin et al. 2008; Bugeat et al. 2011; Truong et al. 2014, 2015; Ruttarattanamongkol et al. 2015; Chevallier et al. 2016; Zychowski et al. 2016). The results suggested that, as also observed in lipid systems emulsified with vegetable oils, the higher homogenization pressure led to smaller droplet diameter and slower crystallization rate (Truong et al. 2014, 2015). Despite the number of studies on this subject, anhydrous milk fat unmodified, has not been investigated. Only Relkin et al. (2008) and Truong et al. (2015) evaluated emulsified systems at the nanometric scale with modified milk fat (olein and stearin) as the lipid phase and sodium caseinate as an emulsifier, but the physical stability of the nanoemulsions throughout the storage was not investigated.

Some processing parameters should be considered to produce milk fat and protein nanoemulsions, including the homogenization temperature. Whereas vegetable oils can be processed at room temperature (~ 25 °C), milk fat can only be homogenized above 50 °C, to ensure that the product is in a liquid state. A higher initial temperature of the system, coupled with the increase in temperature due to homogenization, leads to heat treatment conditions that favor denaturation of whey proteins and a consequent change in conformation and ability to interact with the fat droplet.

Thus, knowledge about the physical properties of nanostructured milk fat stabilized by dairy proteins at different pH is necessary to evaluate the potential of application of these nanoemulsified lipid systems. In this context, the objective of this study was to evaluate the physical and polymorphic stability of anhydrous milk fat nanoemulsions stabilized by whey protein isolate at pH 4.0 or 7.0 (WPI pH 4.0 or WPI pH 7.0) and sodium caseinate at pH 7.0 (NaCas pH 7.0) as natural emulsifiers. Nanoemulsions were produced by hot high-pressure homogenization and the physical and polymorphic stability was evaluated for 60 days of storage at 25 °C. Studies on this subject can contribute to enhance the encapsulation technology, where nanostructured milk fat can be used as a carrier of bioactive lipophilic agents.

Materials and methods

Materials

The materials used for the production of the nanoemulsions were: whey protein isolate (WPI: 92.03 ± 0.18% protein, 0.05 ± 0.06% fat, and 3.41 ± 0.05% ash) and sodium caseinate (NaCas: 92.51 ± 1.87% protein, 0.78 ± 0.10% fat, and 3.78 ± 0.1% ash) kindly donated by Arla Foods (Videbæk, Denmark); anhydrous milk fat (AMF) provided by Fonterra Ltda. (Auckland, New Zealand) [AMF, 99.8 ± 0.1% fat; 0.2 ± 0.04% moisture, and composed mostly of myristic acid (14.15% C14:0), palmitic acid (34.81% C16:0), stearic acid (10.64% C18:0) and oleic acid (19.98% C18:1)]; and deionized water which was purified on a Milli-Q system supplied by Millipore Corporation (resistivity value of 18.2 MΩ cm at 25 °C). All reagents used in the study were of analytical grade.

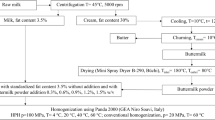

Preparation of protein solutions and emulsions

Protein solutions were prepared by dissolving 2% (w/w) of dairy protein (WPI or NaCas) in phosphate buffer (30 mM). The solutions were kept under magnetic stirring for 1 h at room temperature (25 °C). Then, the pH of the WPI solutions was adjusted to 4.0 or 7.0 with 1 M HCl or 1 M NaOH. The pH of the NaCas solution was adjusted to 7.0 with 1 M NaOH. Sodium azide (0.02%) was added as an antimicrobial agent and the solutions were stored at 5 ± 1 °C overnight to allow complete hydration of the proteins. Before the production of the pre-emulsion with 10% anhydrous milk fat (AMF), the protein solutions were characterized for turbidity in a BEL Photonics 2000 UV/Vis spectrophotometer (Piracicaba, SP—Brazil) with an optical density at 420 nm.

To prepare the pre-emulsion, the AMF and the protein solution were heated to 60 °C and mixed slowly. The mixtures were subjected to continuous stirring for 5 min at 15,000 rpm using a T18 Ultra Turrax (IKA, Königswinter, Germany). The pre-emulsions were subjected to hot high-pressure homogenization in a Panda 2K NS1001L double-stage homogenizer (Niro, Soave, Italy). Three homogenization cycles were performed using 80 MPa and 5 MPa pressure in the first and second stages, respectively. The nanoemulsions were stored at 25 °C until further characterization.

After 1 day of storage, the nanoemulsions were characterized for mean diameter, size distribution, and polydispersity index. The physical stability of the nanoemulsions was evaluated at time zero and after 1, 3, 7, 15, 30, and 60 days of storage at 25 °C. The mean diameter, the size distribution, and the polydispersity index were assessed throughout the storage period, and microstructure was evaluated after 7 and 60 days of storage. The nanoemulsions were freeze-dried and evaluated for melting behavior and polymorphism.

Physical characteristics and stability of the nanoemulsions

Droplet size, size distribution, and polydispersity index

The droplet size was analyzed by light scattering using the Mastersizer 2000 equipment (Malvern Instruments, Malvern, UK). The solvent used to read the droplet size was the phosphate buffer (30 mM). The mean droplet size was characterized in terms of the D32 (mean surface diameter) according to Eq. 1, and the polydispersity index was obtained by Span calculation, according to Eq. 2.

where ni is the number of particles with diameter di; and d10, d50, and d90 represents 10, 50, and 90% of the cumulative volume of the droplets, respectively.

Turbiscan measurements

The kinetic stability was monitored using a Turbiscan ASG equipment (Formulaction, l’Union, France). Immediately after preparation, the nanoemulsions were placed in cylindrical glass tubes with a flat bottom (140 mm in height and 16 mm in diameter). The stability of the systems was analyzed using the backscattering profiles (BS), with scans at 880 nm in length at different heights (mm). The initial height of the sample (H = 0 mm) was considered the lower part of the measuring cell. The creaming index was detected by varying the particle concentration between the top and bottom of the tubes. When creaming takes place in a nanoemulsion, the ΔBS curves show a peak at heights between 0 and 20 mm. The variation of the peak width over time may be related to the migration kinetics of small particles (Huck-Iriart et al. 2013). In order to classify and compare the stability between the samples, the TSI (turbiscan stability index) was calculated (Eq. 3). This parameter considers the variations that occur in the system over time. The TSI was calculated according to backscattering changes that indicate the particles aggregation and dynamic migration by Turbisoft 2.0. This kinetics are based on the following computation, comparing every scan of a measurement to the previous one, on the selected height, and dividing the result by the total selected height in order to obtain a result which does not depend on the quantity of product in the measuring cell. The calculation used for this coefficient followed the method of Llinares et al. (2018) and Trujillo-Cayado et al. (2018), according to the following equation:

where scanref and scani are the initial backscattering and the backscattering value after a certain time, respectively. hj are the different heights of the measurements cell at which backscattering has been measured and, hence, TSI is the sum of all the scan differences at a given time.

Microstructure

The microstructure of the nanoemulsions was assessed by optical microscopy (Olympus BX 50 microscope—San Jose, CA, USA) coupled to a digital camera (Media Cybernetics, Bethesda, MD, USA). For that, 10 μL of the nanoemulsion was transferred onto glass slides and carefully covered with glass coverslips, using a 40× magnification.

Physical characteristics of bulk and nanostructured milk fat

Melting behavior

The melting behavior of the anhydrous milk fat (AMF) and the nanoemulsions was determined by Differential Scanning Calorimetry (DSC) (DSC Q2000—TA Instruments, New Castle, DE, USA) with calibration by indium, according to the AOCS method Cj—1-94 (AOCS 2009). Samples were weighed in aluminum pans (~ 10 mg). The melting curves were performed under the following conditions: For AMF, the temperature was maintained at − 80 °C for 30 min, followed by a heating rate of 5 °C per min to 80 °C. For the previously freeze-dried nanoemulsions, the temperature was maintained at 25 °C for 5 min, followed by a heating rate of 5 °C per min until 100 °C.

Polymorphism

The polymorphic form of both the anhydrous milk fat and the nanoemulsions was determined by the AOCS method Cj—2-95 (AOCS 2009). For AMF, the fat was melted and stabilized at 15 °C for seven days. For the nanoemulsions, the samples were freeze-dried and evaluated at 25 °C. The analyses were performed in a Philips PW 1710 diffractometer (PANalytical, Almelo, The Netherlands), using the Bragg–Brentano (θ:2θ) geometry with Cu Kα radiation source (λ = 1.54056 Å, 40 kV voltage, and 30 mA current). The measurements were obtained with step interval of 0.02°/2θ and counting time of 2 s, from 15° to 30° (2θ angular sweep). The polymorphic form was identified from the characteristic interplanar spacing of the crystals (short spacings).

Experimental design and statistical analysis

Three experiments were carried out. The effect of the type of nanoemulsion (WPI pH 7.0, WPI pH 4.0 and NaCas pH 7.0 nanoemulsion) on the turbidity, particle diameter, and polydispersity index was evaluated by analysis of variance (ANOVA) and Tukey’s test to compare the means at a significance level of 5%.

To evaluate the effect of storage time, the experimental design was defined as a 3 × 6 factorial completely randomized blocks design. The effect of the type of nanoemulsion (WPI pH 7.0, WPI pH 4.0 and NaCas pH 7.0), the storage time (1, 3, 7, 15, 30, and 60 days), as well as the interaction between these factors on the mean particle diameter, and polydispersity index were evaluated by analysis of variance (ANOVA) and Tukey’s test for comparison of means at a significance level of 5%. All data were analyzed using STATISTICA 7.0 software (StatSoft Inc, Tulsa, OK, USA).

Results and discussion

Physicochemical characteristics and stability of the nanoemulsions

The physicochemical properties of a nanoemulsion are largely determined by the particle properties, including composition, size, electric charge, aggregation state, physical state, and interfacial composition (Jafari and McClements 2018). Table 1 shows some of these properties for both the milk fat nanoemulsions stabilized with WPI at pH 7.0, and 4.0, and NaCas pH 7.0. The type of nanoemulsion significantly affected the mean diameter and the polydispersity index of the droplets. Significant differences were observed for turbidity of the protein solutions. When the whey proteins (WPI) were used to stabilize the nanoemulsions, the highest turbidity (1.650) was observed for the WPI pH 4.0-solution. At this pH, the proteins are close to the isoelectric point (pI ~ 4.9), which minimizes the electrostatic repulsion between the protein molecules and favors the protein aggregation, thus increasing turbidity. On the other hand, the lower turbidity observed at pH 7.0 suggests that the whey proteins are soluble at this pH (Combrinck et al. 2014).

All droplets presented a mean diameter less than 200 nm (Table 1), which characterizes them as nanoemulsions (Walker et al. 2017). The lowest mean diameter was observed for the NaCas pH 7.0-stabilized nanoemulsion, (117.1 ± 2.5 nm), followed by the WPI pH 7.0 (140.5 ± 8.9 nm) and WPI pH 4.0-stabilized nanoemulsion (173.3 ± 8.3 nm). The nanoemulsion stabilized by WPI pH 4.0 also showed significantly higher polydispersity index values. The polydispersity index is a measurement of the stability of the system, thus, lower polydispersity index values result in more stable systems. The difference in droplet size between treatments may be probably due to the thermal stability and conformation of the different nanosystems. The thermal treatment, pH and high pressure affect protein solubility and conformation (Walstra et al. 2006; Damodaran et al. 2007), which affect the interactions between the emulsifier and the fat droplet and, consequently, the thickness of the emulsifier layer at the oil–water interface (McClements 2015). Thus, they are possibly the main factors affecting particle size, since all nanoemulsions were subjected to the same processing conditions: the pre-emulsions preheated at 60 °C were subjected to three homogenization cycles (80 MPa), which resulted in an increase of approximately 20 °C in the inlet temperature and a consequent exposure of proteins to approximately 80 °C for 15 min. This heat treatment condition drastically affects the conformation and solubility profile of whey proteins, whereas caseins with open and flexible molecular structure do not undergo important heat-induced conformational changes (McClements 2015). In its native state, the whey protein isolate is soluble over a wide pH range (2–9), but its solubility is drastically changed after heating to 70 °C/1–10 min, with minimal solubility indexes at pH 4.5 (Damodaran et al. 2007). The denaturation of the globular proteins, by the application of heat, is due to the entropy increase of the water clathrate structure surrounding the hydrophobic portions of proteins with exposure of the hydrophobic regions of the β-lactoglobulin, which contains disulfide bonds between cystine residues (Cys66–Cys160 and Cys106–Cys119) and a free SH residue (Cys121). The exposure of the hydrophobic regions favors the interaction between the protein and the lipid phase, and the exposure of the free SH group favors protein interactions, leading to the formation of aggregates responsible for a reduction in solubility at pH 4.5 (Farrell et al. 2004; Rodrigues et al. 2015). These aggregates, when adsorbed around the droplet, can result in a more compact layer, promoting an increase in viscosity of the protein film and greater stability against coalescence (Kuhn and Cunha 2012).

With respect to the mean droplet diameter, it is worth mentioning the effect of the molecular size of the natural emulsifier on the thickness of the emulsifier layer at the oil–water interface, once the size of the molecule differs both by the type of protein and pH in the evaluated systems. In milk, caseins are much larger (20–400 nm) than whey proteins (3–6 nm), but to obtain sodium caseinate, casein is precipitated with acid and dissolved in alkali followed by drying of casein solution by atomization (Walstra et al. 2006). Thus, there are considerable differences between sodium caseinate and casein micelles. Functionally, the sodium caseinate is more soluble and hydrodynamically it is smaller (10-100 nm) than the casein micelles (20–400 nm) (Pan et al. 2013; Thomar and Nicolai 2015). β-lactoglobulin is a small molecule with 162 amino acid residues, which is aggregated in a octomeric form at pH 3.5–5.5 and in a dimeric form at pH 5.5–7.5 (Fox et al. 2015).

Figure 1 shows a schematic representation of the milk fat nanoemulsions stabilized by WPI at pH 7.0, WPI at pH 4.0, and NaCas at pH 7.0. Whereas all systems were subjected to the same processing conditions, the larger particles observed in the WPI pH 4.0-stabilized nanoemulsions (173.3 ± 8.3 nm) were probably due to the lower solubility which favors the formation of aggregates, besides the structure of β-lactoglobulin, which is in the form of octomers at this pH. Then, intermediate particles were observed in the WPI pH 7.0-stabilized nanoemulsions (140.5 ± 8.9 nm), in which β-lactoglobulin is in the form of dimers, whereas the smaller particles were obtained after milk fat stabilization by NaCas pH 7.0. In general, due to a high proportion of hydrophobic residues and open and flexible molecular structure of the casein molecules, these adsorb more easily at the interface when compared to whey proteins (Damodaran et al. 2007; Thomar and Nicolai 2015). The higher solubility, the better emulsifying ability and the smaller NaCas size when compared to caseins, may favor this interaction, resulting in a layer around the particles strongly adsorbed to the milk fat and with a less dense hydrophilic layer, thus characterizing a smaller particle.

The nanoemulsion stability during storage at 25 °C was evaluated by the mean diameter, polydispersity index, stability by Turbiscan, and the microstructure of the particles for 60 days. The type of emulsion significantly affected the mean particle diameter, which was not affected by the storage time or by the interaction between these two factors (Supplementary Material). On the other hand, all factors significantly affected the polydispersity index. Figure 2a shows that both the nanoemulsions stabilized with WPI pH 7.0 and NaCas pH 7.0 presented a similar size distribution, which remained practically constant during the 60 days of storage at 25 °C. This behavior suggests a higher nanoemulsion stability when compared to the WPI pH 4.0-stabilized emulsion, which presented a larger size distribution, indicating lower stability. The nanoemulsion microstructure (Fig. 2b) shows evenly distributed milk fat droplets, with no visual particle aggregation or protein flocculation, suggesting that the protein content used was enough to stabilize the system (Dickinson 2010). At low pH, the droplets were visually larger, corroborating the previously discussed results regarding the particle diameter and size distribution. The larger particle sizes are due to the low emulsifying ability of aggregated proteins at pH 4.6, and therefore, larger globules, or it could be that the droplets have begun to aggregate.

a Curves of the particle size distribution of nanoemulsions made with milk fat stabilized by dairy proteins during the storage at 25 °C; b optical microscopy of nanoemulsions after 7 and 60 days of storage at 25 °C. ×40 magnification. Scale bar: 50 µm. WPI Whey protein isolate, NaCas sodium caseinate

Figure 3 shows the changes in the backscattering profile (ΔBS) of the nanoemulsions as a function of the height of the Turbiscan tube, after different periods of storage. The nanoemulsion produced with WPI pH 4.0 was shown to be less stable, probably due to the higher migration rate, since the particles were larger, more polydisperse, and with reduced electrical charges, favoring the droplet aggregation and destabilization by the creaming mechanism. When compared to the fresh nanoemulsion (day zero), it suggests that destabilization increased with the storage time, i.e., there is a decrease in backscattering in the lower part of the tube and a concomitant increase in the upper zone, due to the formation of a cream layer. In addition, the lower density of the lipid droplets relative to the dispersant liquid may have favored a gravitational separation (McClements 2015). A destabilization by creaming was also observed by Zychowski et al. (2016), in milk fat emulsions stabilized by whey proteins at natural milk pH after storage at 25 °C.

The TSI was chosen to assess the physical stability of the emulsions studied. This parameter has the advantage that quantify the overall emulsion destabilization as a function of storage time (Fig. 4). The higher the TSI value, the lower the system stability. The highest values of TSI were observed for WPI pH 4.0 stabilized nanoemulsion, which indicates the occurrence of droplet aggregation and hence a start of creaming after seven days storage at 25 °C. On the other hand, the nanoemulsions stabilized with WPI and NaCas at pH 7.0 presented non-linear TSI values over time, with slight instability during the first 15 days of storage, remaining stable thereafter, suggesting a slower migration and a lower aggregation in the nanoemulsions. Minor particles, such as those observed in the nanoemulsions stabilized by WPI and NaCas at pH 7.0, are more stable against aggregation due to the lower attractive forces acting between the droplets (Silva et al. 2012; McClements 2015).

Physical characteristics of bulk and nanostructured milk fat

Figure 5 shows the melting behavior of bulk and nanostructured milk fat. The extensive melting range (− 16.64 ± 0.31 °C to 45.99 ± 1.78 °C) observed for milk fat (Fig. 5a) is due to its complex chemical composition. In general, the milk fat melt peak can be divided into three temperature ranges, where the low and medium melting crystals are initially melted, followed by the high melting point crystals. In this melting temperature range, the milk fat is always present as a mixture of liquid and crystallized fat, and the ratio depends on the temperature. Nanostructured milk fat had the same melting behavior as bulk milk fat (Fig. 5b, c). The melting range of the nanostructured fat (27.1–49.9 °C) is represented mainly by di- or trisaturated triacylglycerols that remained solid at 25 °C, which was the storage temperature of the nanoemulsions. At this temperature, the fat droplets were in equilibrium between liquid and crystallized fat. However, the results suggest the presence of fat crystals was not sufficient to promote a partial coalescence destabilization, which is typical of emulsions containing solid fat (Ruttarattanamongkol et al. 2015). The same behavior was observed by Bugeat et al. (2011), with very similar melting profiles and two main endothermic peaks, one corresponding to the bulk milk fat and the other one corresponding to the emulsion stabilized by sodium caseinate at pH 6.7.

Melting behavior (a, b) of anhydrous milk fat; and c nanoemulsions made with milk fat stabilized by dairy proteins at different pH values. XRD patterns (d) of anhydrous milk fat; and e nanoemulsions made with milk fat stabilized by milk proteins at different pH values. WPI Whey protein isolate, NaCas sodium caseinate

Similarly, to the findings of the melting behavior, Fig. 5d, e shows that the bulk and nanostructured milk fat presented short spacings, characteristic of crystallization in the polymorphic form β′. The maintenance of polymorphic form β′ in nanostructured milk fat may be due to the high concentration of palmitic acid (~ 35%) and asymmetric triacylglycerols, such as POO (P = palmitic acid, O = oleic acid), PLO (P = palmitic acid, L = linoleic acid, O = oleic acid), SPO (S = stearic acid, P = palmitic acid, O = oleic acid) and PPS (P = palmitic acid, S = stearic acid) present in milk, which are determinant for promoting the stability of the polymorphic form in oils and fats, and crystallize preferentially in the polymorphic form β′ (Timms 1984; Viriato et al. 2018). Knowledge of the polymorphic form of fat crystals in nanostructured systems is important, once they may impact the physical and sensory properties of food emulsions (O’Brien 2009). The type of crystal affects the sensory quality of the products, crystallized fats in polymorphic form β′ present smaller diameter crystals, improving the ability to produce softer lipid bases and better sensory quality. For example, in ice cream, spreads and biscuit fillings, it is desirable to use lipid bases having small crystals so that they are not perceptible in the mouth during consumption (Lopez et al. 2002; Ribeiro et al. 2009; Rønholt et al. 2013).

Conclusion

Nanoemulsions consisting exclusively of dairy ingredients showed high stability for 60 days of storage at 25 °C. The milk fat nanoemulsified with NaCas pH 7.0 resulted in the most stable system, followed by the nanoemulsion stabilized with WPI pH 7.0. Although the milk fat nanoemulsified with WPI pH 4 showed some instability, no protein flocculation was observed in any of the systems studied, suggesting that the protein content used in the study (2%) was adequate for coating the fat droplets in systems with 10% anhydrous milk fat. At 25 °C, the nanostructured milk fat was partially solid, with crystals in the β′-form, with liquid domains, suggesting its potential as a carrier of lipophilic compounds. The crystallization in the β′-form observed in this study is desirable for food applications and especially for dairy products since they provide crystals with a smaller diameter, softer fats, and better sensory quality. Nanoemulsified systems requiring pH close to that of milk (pH 6.8) can use whey and caseinate proteins as a natural emulsifying agent. For fermented dairy systems, new studies may be carried out in order to obtain more stable systems, using, for example, protein combinations of different isoelectric points.

References

AOCS (2009) Official methods and recommended practices of the American Oil Chemists’ Society. American Oil Society, Champaign

Bugeat S, Briard-bion V, Pérez J, Pradel P, Martin B, Lesieur S, Bourgaux C, Ollivon M, Lopez C (2011) Enrichment in unsaturated fatty acids and emulsion droplet size affect the crystallization behaviour of milk triacylglycerols upon storage at 4 °C. Food Res Int 44:1314–1330

Cerqueira M, Pinheiro A, Silva H, Ramos P, Azevedo M, Flores-López M, Rivera M, Bourbon A, Ramos Ó, Vicente A (2014) Design of bio-nanosystems for oral delivery of functional compounds. Food Eng Rev 6:1–19

Chevallier M, Riaublanc A, Lopez C, Hamon P, Rousseau F, Croguennec T (2016) Aggregated whey proteins and trace of caseins synergistically improve the heat stability of whey protein-rich emulsions. Food Hydrocoll 61:487–495

Combrinck J, Otto A, Du Plessis J (2014) Whey protein/polysaccharide-stabilized emulsions: effect of polymer type and pH on release and topical delivery of salicylic acid. AAPS PharmSciTech 15:588–600

Damodaran S, Parkin KL, Fennema OR (2007) Fennema’s food chemistry, 4th edn. CRC Press, Boca Raton

Dickinson E (2010) Flocculation of protein-stabilized oil-in-water emulsions. Colloids Surf B 81:130–140

Farrell HM Jr, Jimenez-Flores R, Bleck GT, Brown EM, Butler JE, Creamer LK, Hicks CL, Hollar CM, Ng-Kwai-Hang KF, Swaisgood HE (2004) Nomenclature of the proteins of cows’ milk—sixth revision. J Dairy Sci 87:1641–1674

Fox PF, Uniacke-Lowe T, McSweeney PLH, O’Mahony JA (2015) Milk proteins. In: Dairy chemistry and biochemistry. Springer, Cham, pp 145–239 https://doi.org/10.1007/978-3-319-14892-2_4

Furtado GF, Mantovani RA, Consoli L, Hubinger MD, Cunha RL (2017) Structural and emulsifying properties of sodium caseinate and lactoferrin influenced by ultrasound process. Food Hydrocoll 63:178–188

Huck-Iriart C, Ruiz-Henestrosa VMP, Candal RJ, Herrera ML (2013) Effect of aqueous phase composition on stability of sodium caseinate/sunflower oil emulsions. Food Bioprocess Technol 6:2406–2418

Jafari SM, McClements DJ (2018) Nanoemulsions: formulation, applications, and characterization. Academic Press, Cambridge

Kuhn KR, Cunha RL (2012) Flaxseed oil—whey protein isolate emulsions: effect of high pressure homogenization. J Food Eng 111:449–457

Llinares R, Ramírez P, Carmona J, Carrillo F, Munñoz J (2018) Formulation and optimization of emulsions based on bitter fennel essential oil and EO/BO block copolymer surfactant. Colloids Surf A 536:142–147

Lopez C, Lavigne F, Lesieur P, Bourgaux C, Ollivon M (2001) Thermal and structural behavior of milk fat. 1. Unstable species of anhydrous milk fat. J Dairy Sci 84:756–766

Lopez C, Bourgaux C, Lesieur P, Ollivon M (2002) Crystalline structures formed in cream and anhydrous milk fat at 4 °C. Lait 82:317–335

McClements DJ (2015) Food emulsions: principles, practices, and techniques, 3rd edn. CRC Press, Taylor & Francis Group, Cambridge, p 690

O’Brien RD (2009) Fats and oils: formulating and processing for applications, 3rd edn. CRC Press, Boca Raton, p 744

Pan K, Zhong Q, Baek SJ (2013) Enhanced dispersibility and bioactivity of Curcumin by encapsulation in casein nanocapsules. J Agric Food Chem 61:6036–6043

Relkin P, Yung JM, Kalnin D, Ollivon M (2008) Structural behaviour of lipid droplets in protein-stabilized nano-emulsions and stability of α-tocopherol. Food Biophys 3:163–168

Ribeiro APB, Basso RC, Grimaldi R, Gioielli LA, Gonçalves LAG (2009) Instrumental methods for the evaluation of interesterified fats. Food Anal Methods 2:282–302

Rodrigues RM, Martins AJ, Ramos OL, Malcata FX, Teixeira JA, Vicente AA, Pereira RN (2015) Influence of moderate electric fields on gelation of whey protein isolate. Food Hydrocoll 43:329–339

Rønholt S, Mortensen K, Knudsen JC (2013) The effective factors on the structure of butter and other milk fat-based products. Compr Rev Food Sci Food Saf 12:468–482

Ruttarattanamongkol K, Afizah MN, Rizvi SSH (2015) Stability and rheological properties of corn oil and butter oil emulsions stabilized with texturized whey proteins by supercritical fluid extrusion. J Food Eng 166:139–147

Silva H, Cerqueira M, Vicente A (2012) Nanoemulsions for food applications: development and characterization. Food Bioprocess Technol 5:854–867

Silva EK, Gomes MTS, Hubinger MD, Cunha RL, Meireles MAA (2015) Ultrasound-assisted formation of annatto seed oil emulsions stabilized by biopolymers. Food Hydrocoll 47:1–13

Teo A, Goh KKT, Wen J, Oey I, Ko S, Kwak HS, Lee SJ (2016) Physicochemical properties of whey protein, lactoferrin and Tween 20 stabilised nanoemulsions: effect of temperature, pH and salt. Food Chem 197:297–306

Thomar P, Nicolai T (2015) Dissociation of native casein micelles induced by sodium caseinate. Food Hydrocoll 49:224–231

Timms RE (1984) Phase behaviour of fats and their mixtures. Prog Lipid Res 23:1–38

Trujillo-Cayado LA, Alfaro MC, Muñoz J (2018) Effects of ethoxylated fatty acid alkanolamide concentration and processing on d-limonene emulsions. Colloids Surf A 536:198–203

Truong T, Bansal N, Sharma R, Palmer M, Bhandari B (2014) Effects of emulsion droplet sizes on the crystallization of milk fat. Food Chem 145:725–735

Truong T, Morgan GP, Bansal N, Palmer M, Bhandari B (2015) Crystal structures and morphologies of fractionated milk fat in nanoemulsions. Food Chem 171:157–167

Viriato RLS, Queirós MS, da Gama MAS, Ribeiro APB, Gigante ML (2018) Milk fat as a structuring agent of plastic lipid bases. Food Res Int 111:120–129

Walker RM, Gumus CE, Decker EA, McClements DJ (2017) Improvements in the formation and stability of fish oil-in-water nanoemulsions using carrier oils: MCT, thyme oil, and lemon oil. J Food Eng 211:60–68

Walstra P, Wouters JTM, Geurts TJ (2006) Dairy science and technology, 2nd edn. CRC Press, Taylor & Francis Group, Boca Raton

Wright AJ, Marangoni AG (2006) Crystallization and rheological properties of milk fat. In: Fox PF, McSweeney PLH (eds) Advanced dairy chemistry. Lipids, vol 2, 3rd edn. Springer, New York, pp 245–281

Zychowski LM, Logan A, Augustin MA, Kelly AL, Zabara A, O’Mahony JA, Conn CE, Auty MAE (2016) Effect of phytosterols on the crystallization behavior of oil-in-water milk fat emulsions. J Agric Food Chem 64:6546–6655

Acknowledgements

The authors thank Arla Foods for the donation of whey protein isolate and sodium caseinate, and Fonterra Ltda for the donation of anhydrous milk fat. We also acknowledge the National Council for Scientific and Technological Development (CNPq) for Granting the Ph.D. scholarship (140529/2015-2) and the Unicamp Student Support Service (SAE) for granting the scientific initiation scholarship. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES) Finance Code 001.

Author information

Authors and Affiliations

Contributions

MSQ and RLSV worked on the design of the experiment, performed the nanoemulsions in high pressure homogenizer, performed the characterization analyzes of the nanoemulsions, interpreted and discussed the results and wrote the manuscript. DAV performed the nanoemulsions in high pressure homogenizer and assisted the performed of the characterization analyzes of the nanoemulsions. APBR was responsible for equipments, supervised the analysis, and revised the manuscript. MLG coordinated the design of the experiment, supervised the entire study, interpreted and discussed the results, and revised the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

de Souza Queirós, M., Viriato, R.L.S., Vega, D.A. et al. Milk fat nanoemulsions stabilized by dairy proteins. J Food Sci Technol 57, 3295–3304 (2020). https://doi.org/10.1007/s13197-020-04362-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04362-0