Abstract

The behaviors of several types of inclusions on the surface of liquid steel were examined using a confocal laser scanning microscope, CLSM . While alumina inclusions are likely to attract each other, agglomerate, and grow fast by the agglomeration, the other types of inclusions such as spinel and calcium aluminate rarely interact with each other. The analysis on the observation result of the CLSM indicates that the attraction force and the agglomeration play a significant role in the growth of alumina inclusions. Moreover, the behaviors of liquid calcium aluminate inclusions, which were intentionally injected, could be carefully observed. Their agglomeration took place only when they occasionally collide under the existence of external force, in spite of relatively low collision probability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Although nonmetallic inclusions in steel often impose harmful effect on the product quality, they usually float in molten steel and are possibly removed into top slag because of density difference. Obviously, the efficiency of floatation and removal of inclusions is dependent on the size of inclusions. It has been also known that the agglomeration by random collisions in molten steel is one of the most important mechanisms of physical growth of inclusions [1]. Therefore, it will be greatly necessary to understand about the mechanism of inclusion growth by agglomeration for proper inclusion control.

Since the observation technique using laser scanning confocal microscope was innovatively brought for a direct examination on the behavior of inclusions, [2] a few more notable researches of in situ observation about the behaviors of various type of inclusions have been subsequently made [3,4,5,6]. In spite of meaningful and intensive discussions in those works, however, more explanation is required in the unclear phenomena, such as different interactive tendencies of each type inclusion. In this research, the behaviors of various kinds of inclusions on the molten steel surface were examined using a laser scanning confocal microscope . In situ observation on the agglomeration behaviors of each inclusion was discussed.

Experimental

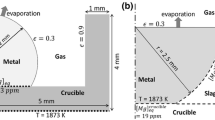

In situ observation was carried out using a laser scanning confocal microscope (1LM21H/SVE17SP, Lasertec), which consists of He–Ne laser source, a detector, video recording unit, and a high temperature image furnace. Figure 1 schematically shows the gold-coated image furnace, where sample can be heated by radiation from a halogen lamp in the bottom. The sample can be observed through an observation window equipped on the top of the furnace.

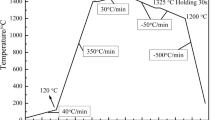

A steel sample, which was prepared in advance to fit in a small alumina crucible (ϕ 9 mm, h 4 mm), was placed on a platinum sample holder. During heating, temperature was controlled by PID temperature control program and R-type thermocouple placed under the platinum holder. Various atmospheric conditions in the furnace were chosen to allow the formation of various types of inclusions, such as Al2O3, MgO · Al2O3, and CaO–Al2O3. For the better observation of calcium aluminate liquid inclusions, synthetic inclusions with a typical composition (12CaO · 7Al2O3) were prepared by premelting and pulverizing into fine powder under 38 μm. The inclusion powders were inserted between two steel disks after thoroughly mixing with far larger amount of iron powders (~150 μm). After the observation, the inclusions on the surface of sample were identified using SEM (Leo 430, Leo Electron Microscopy) and EPMA (JXA-8800, JEOL) (Table 1).

Results and Discussion

As expected, different types of inclusions could be observed under the different atmospheres. Observed inclusions under each atmospheric condition are summarized in Table 2.

When Ar gas was used without any reducing gas addition, large number of inclusions with irregular shape, which was identified as solid alumina inclusions by SEM or EPMA analysis, could be observed on the surface of molten steel. The alumina inclusions showed very strong tendency to attract each other and agglomerated so easily that they could grow to be large cluster in very short time. This observation on the alumina inclusion agrees well with the previous researches [2].

On the other hand, in more reducing conditions, polygonal or globular small inclusions were observed with far smaller chances compared to the case of alumina inclusions. Under Ar + 1 vol%H2 and Ar + 2 vol%H2 conditions, MgO · Al2O3 and solid calcium aluminate (probably CaO · 2Al2O3) inclusions could be detected, respectively. Commonly in both types of inclusions, no sign of attractive interaction (nor repulsive) was found, and thus physical growth by agglomeration seems to be insignificant. In the experiments intentionally introducing synthetic inclusions, large number of CaO–Al2O3-based liquid inclusions could be successfully observed. Similar to MgO · Al2O3 and calcium aluminate inclusions, the liquid inclusions did not show any attractive interaction and tend to maintain the inter-particle distance as shown in Fig. 2. However, it is also evident that the liquid inclusions could be coalesced with ease when they happen to collide by random movement on the surface of molten steel.

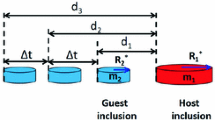

Different behaviors of the various inclusions could be confirmed by the change in the inter-particle distance as shown in Fig. 3. Contrary to other inclusions, which have no interactions on the molten steel surface, strong attraction between alumina inclusions was found to be effective even though the inclusion pair was initially departed from each other more than 100 μm. Based on the acceleration and the sizes of the inclusions, moreover, the force acting on the inclusion pairs could be in the range of 10−18 to 10−14 N.

To properly reveal the origin of the attractive force of various inclusions, the universal gravitation and the capillary forces were evaluated for several pairs of inclusions observed under the microscope. As indicated in Fig. 4, the gravitation force turned out to be very small compared to the attractive force between the inclusions, whereas the capillary force at the equilibrium position of molten steel surface between a pair of inclusions parallelly immersed plate is supposed to be larger than 10−2 N. For more practical estimation of the capillary force, very careful analysis on the depression depth of the molten steel surface may be required. Also, relatively small difference in the capillary force among each type of inclusions may imply that the capillary force is not mainly responsible for different attractive phenomena, contrary to the previous researches [2, 3]. Since the exceptional attractive behavior of the alumina inclusions is not clear yet, however, more elaborate study should be carried out regarding the interaction of the alumina inclusions.

Summary

For better insight into the physical growth of inclusions in molten steel, the behaviors of various types of inclusions on steel surface were observed by direct in situ observation using an LSCM. Various kinds of inclusions could be observed under different atmospheric conditions. While alumina inclusions show extraordinarily attractive behavior, other inclusions such as spinel and calcium aluminate did not show any interaction, keeping their inter-particle distance. Each tendency of various inclusions was discussed with the attractive forces and possible sources of the force.

References

Zhang L, Thomas BG, Wang X, Cai K (2002) Evaluation and control of steel cleanliness—Review. Paper presented at the 85th Steelmaking Conference, Nashville, Tennessee, 10–13 March, 2002

Yin H, Shibata H, Emi T, Suzuki M (1997) “In-situ” observation of collision, agglomeration and cluster formation of alumina inclusion particles on steel melts. ISIJ Int 37:936–945

Yin H, Shibata H, Emi T, Suzuki M (1997) Characteristics of agglomeration of various inclusion particles on molten steel surface. ISIJ Int 37:946–955

Shibata H, Yin H, Yoshinaga S, Emi T, Suzuki M (1998) In-situ observation of engulfment and pushing of nonmetallic inclusions in steel melt by advancing melt/solid interface. ISIJ Int 38:149–156

Misra P, Chevrier V, Sridhar S, Cramb AW (2000) In situ observations of inclusions at the (Mn, Si)-killed steel/CaO-Al2O3 interface. Metall Mater Trans B 31B:1135–1139

Colletti B, Vantilt S, Blanpain B, Sridhar S (2003) Observation of calcium aluminate inclusions at interfaces between Ca-treated, Al-killed steels and slags. Metall Mater Trans B 34B:533–538

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Kang, Y., Scheller, P.R., Sichen, D., Morita, K. (2019). In Situ Observation on the Interactions of Nonmetallic Inclusions on the Surface of Liquid Steel. In: Nakano, J., et al. Advanced Real Time Imaging II. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-06143-2_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-06143-2_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-06142-5

Online ISBN: 978-3-030-06143-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)