Abstract

Quantification of glucose is critical in healthcare applications. Herein, in order to take advantage of both catalytic activity of NiO for glucose oxidation and high conductivity of CNTs, NiO films with different thicknesses were deposited on the surface of stacked-cup carbon nano tube (SCCNT) using atomic layer deposition (ALD) technique. Using the NiO/SCCNT composites, we demonstrated the fabrication of an electrochemical sensor with high sensitivity of 1252.3 μA cm−2 mM−1 and an ultrafast response (<2 s) for glucose determination in alkaline solution (0.1 M KOH). Additionally, exploiting ALD technique provided us with an opportunity to deposit NiO on the SCCNT surface with different thicknesses, which in turn, enabled us to evaluate thoroughly the effect of different thicknesses of NiO on glucose measurement.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Glucose is a vital biochemical substance whose detection, quantitatively or qualitatively, is of great importance not only in clinical diagnostic tests but also in food, textile and other industries [1]. Diabetes, as a widespread metabolic disorder relevant to glucose, is being changed to a prevalent challenge for human healthcare due to change in lifestyle and environmental pollutants [2]. Evaluation of glucose can be useful as a diagnostic test for diabetes mellitus, which is a global health problem with devastating social and economic impact, as well as for cancer treatment. Therefore, many efforts have been directed to evaluate glucose using different kinds of organic and inorganic materials. Among inorganic substances, nanomaterials, such as Au, Ni, Pd, Pt, Cu, RuO2, Co3O4, WO3 and NiO as well as a vast variety of their compositions have been exploited in order to enhance the capabilities of sensors [3]. Herein, we took advantage of carbon nanotubes decorated nickel oxide, which had been prepared by a very precise method named atomic layer deposition (ALD). Using ALD technology gave us the opportunity to not only prepare a sensitive and selective sensor for glucose but also to investigate effects of thickness of nickel oxide layer on catalytic activity and performance of the proposed sensor for glucose determination.

2 Experimental

2.1 Preparation of NiO/SCCNT Composites

First, 120 mg of SCCNT were dispersed in 110 mL of HNO3 in a round bottom flask and refluxed at 105 °C in an oil bath for 6 h with continuous stirring. The mixture was filtrated and repeatedly washed with distilled water until the neutral point, around pH 7. Oxidized SCCNT were collected and kept in an oven at 80 °C for 16 h. Afterwards, samples for ALD were prepared by dispersing 1.5 mg of Oxidized SCCNT in 2 mL of absolute ethanol by ultrasonic agitation for half an hour. Dispersed SCCNT were drop casted on acetone cleaned aluminium foil (10 cm × 10 cm). Then, ALD was performed in a hot walled, closed chamber type GEMSTAR-6 system from ARRADIANCE, inc. using argon (Air Liquide 99.99% purity) as carrier and purging gas for metal precursor. The temperature of the Ni(Cp)2 container was maintained at 90 °C, while ozone (using pure oxygen in a BMT803 N ozone delivery system, ozone was delivered at a concentration of 100 to 250 g/Nm3) was introduced as generated. The temperatures of the metal precursor and oxidant manifolds and the reaction chamber were maintained at 120 °C, 115 °C and 200 °C, respectively. ALD cycles were performed by sequential pulsing Ni(Cp)2 and ozone for 2 s and 0.5 s, with an exposure/purging time as 30 s/20 s and 20 s/10 s, respectively. After ALD, samples were collected by meticulous scratching off the NiO ALD coated SCCNT from the aluminium foil. Prepared composites were denoted as S25, S50, S100, S200 and S400 where the numbers indicate the number of deposition cycle in ALD.

2.2 Electrode Preparation

In order to modify bare SPE, 1.0 mg of each SCCNT/NiO composites, i.e. S25, S50, S100, S200 and S400, were ultrasonically dispersed in closed polyethylene vials containing distilled water (1 mL). After obtaining homogeneous dispersion of all CNT/NiO composite, desirable amount of CNT/NiO dispersions were directly dropped cast onto the surface of carbon working electrode and left at room temperature to dry until further use.

3 Result and Discussion

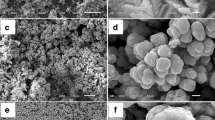

3.1 TEM

The detailed structure and morphology of the as synthesized NiO/SCCNT samples was analysed by transmission electron microscopy (TEM). Figure 1 shows TEM and high-resolution TEM (HRTEM) images for some samples, i.e. coated by 25, 50 and 100 layers of NiO. The diameter of the SCCNT as found by TEM images is around 75–110 nm. To differentiate between the samples, a thorough investigation was made by taking the TEM images of individual SCCNT/NiO composites. It can be clearly seen that, SCCNT are equally and conformably coated from the inner and the outer surfaces with NiO nanoparticles. The thickness of the NiO coating increases with the no. of ALD cycles, the average thickness calculated for samples coated with 25, 50, 100, 200 and 400 cycles is 0.9 nm, 1.8 nm, 4.1 nm, 6.8 nm and 13.9 nm, respectively. The layer thickness increase proportionately with the no. of ALD cycles and the growth per cycle (GPC) is calculated as 0.034 nm), proving the self-limiting growth behaviour of the ALD process.

3.2 Electrochemical Behavior of Glucose at CNT/NiO Modified Electrode

The effect of the different thickness of deposited NiO onto CNT toward monitoring of glucose was explored by preparing different modified electrode using S25, S50, S100, S200 and S400. Here, we put our attentions on two important figure of merits i.e. sensitivity and linear dynamic range (LDR) for glucose measurement using these modified electrodes. For achieving this, calibration curves for measurement of glucose with different modified electrodes were obtained using cyclic voltammetry and sensitivity (slope of calibration curve) and LDR were extracted from them. As can be seen in Fig. 2, sensitivity of glucose determination increases with increasing the thickness of NiO up to S100, however, for higher thickness, i.e. S200 and S400, sensitivity decreases to some extent. This behavior can be explained as follows: for S25 sensor, the response to glucose is lowest due to the lack of sufficient active species for glucose oxidation. Increasing the NiO thickness endows higher sensitivity, and finally, for S100 the response reaches the highest value because available active sites for glucose oxidation reached the maximum. For higher thickness, e.g., S200 and S400, the available active sites in the proximity of surface cannot increase further, therefore, sensitivity curve reaches a plateau. On this basis, modified electrode with S100 composite was chosen for further sensing measurements.

The performances of S100 electrode in amperometric mode were assessed by successive addition of glucose aliquots to stirring solution of 0.1 M KOH. Best results regarding sensitivity and linearity were obtained when applied potential was held at 0.65 V. Accordingly, 0.65 V was selected for subsequent amperometric analyses.

Figure 3 exhibits that amperometric measurements of glucose result in the well-defined steady-state shape responses using the proposed sensor.

An attractive aspect of this sensor is ultra-fast response time toward glucose oxidation. The sensor respond almost immediately after addition of glucose and reaches 95% of steady-state current in less than 2 s. The obtained calibration curve from amperometric data is shown in the inset of Fig. 3. A good linearity is obtained for this modified electrode over a large range (from micro to millimolar) of glucose concentration. The calibration curve is linear over the concentration range of 2 µM to 2.2 mM with sensitivity of 1310.75 µA cm−2 mM−1 and determination coefficient (R2) of 0.9979. Form calibration tests, limit of detection was calculated to be 0.10 µM considering signal-to-noise ratio of 3. These figures of merit compare favorably with literature data, as demonstrated in Table 1.

4 Conclusion

Herein, we took advantage of carbon nanotubes decorated with nanometer nickel oxide layer, which had been prepared by a very precise ALD method. Using ALD gave us this opportunity to not only prepare a sensitive and selective sensor for glucose but also to investigate effects of thickness of nickel oxide layer on catalytic activity and performance of the proposed sensor for glucose determination. These results will be very critical due to the basic knowledge that can be extracted from them in order to design more efficient sensors for glucose.

References

Galant, A.L., Kaufman, R.C., Wilson, J.D.: Glucose: detection and analysis. Food Chem. 188, 149–160 (2015)

Ocvirk, G., Buck, H., DuVall, S.H.: Electrochemical glucose biosensors for diabetes care. Bioanal. Rev. 6 (2017)

Dhara, K., Mahapatra, D.R.: Electrochemical nonenzymatic sensing of glucose using advanced nanomaterials. Microchim. Acta 185 (2018)

Zeng, G., Li, W., Ci, S., Jia, J., Wen, Z.: Highly dispersed NiO nanoparticles decorating graphene nanosheets for non-enzymatic glucose sensor and biofuel cell. Sci. Rep. 6 (2016)

Jung, D.-U.-J., Ahmad, R., Hahn, Y.-B.: Nonenzymatic flexible field-effect transistor based glucose sensor fabricated using NiO quantum dots modified ZnO nanorods. J. Colloid Interface Sci. 512, 21–28 (2018)

Nie, H., Yao, Z., Zhou, X., Yang, Z., Huang, S.: Nonenzymatic electrochemical detection of glucose using well-distributed nickel nanoparticles on straight multi-walled carbon nanotubes. Biosens. Bioelectron. 30, 28–34 (2011)

Yang, H., Gao, G., Teng, F., Liu, W., Chen, S., Ge, Z.: Nickel hydroxide nanoflowers for a nonenzymatic electrochemical glucose sensor. J. Electrochem. Soc. 161, B216–B219 (2014)

Fan, Y., Yang, Z., Cao, X., Liu, P., Chen, S., Cao, Z.: Hierarchical macro-mesoporous Ni(OH)2 for nonenzymatic electrochemical sensing of glucose. J. Electrochem. Soc. 161, B201–B206 (2014)

Ghanbari, K., Babaei, Z.: Fabrication and characterization of non-enzymatic glucose sensor based on ternary NiO/CuO/polyaniline nanocomposite. Anal. Biochem. 498, 37–46 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Movlaee, K., Raza, H., Pinna, N., Leonardi, S.G., Neri, G. (2019). Ultrasensitive Non-enzymatic Electrochemical Glucose Sensor Based on NiO/CNT Composite. In: Andò, B., et al. Sensors. CNS 2018. Lecture Notes in Electrical Engineering, vol 539. Springer, Cham. https://doi.org/10.1007/978-3-030-04324-7_18

Download citation

DOI: https://doi.org/10.1007/978-3-030-04324-7_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-04323-0

Online ISBN: 978-3-030-04324-7

eBook Packages: EngineeringEngineering (R0)