Summary

While most natural cheeses are consumed directly as table cheese, which can be eaten directly or with crackers or bread, they are also used extensively as ingredients in culinary dishes. Nevertheless, cheeses are in many cases manufactured specifically for use as an ingredient rather than as table cheese. The manufacture of ingredient cheeses involves protocols which impart specific functionalities, such as controlled textural/rheological properties (e.g., sliceability, shreddability or crumbliness) and cooking properties (e.g., Mozzarella with customized flow and stringiness suited to specific pizza brands). Ingredient cheeses are used in an array of culinary dishes, formulated food products and ready-prepared meals. The types and level of functional attributes required from ingredient cheeses depend on the application in which they are used. The functionalities of the unheated and heated cheese are key quality determinants of ingredient cheese. These are strongly influenced by micro- and macrostructure. At a microstructural level, rennet-curd cheese is a matrix comprised of a calcium phosphate para-casein network, which imbibes the cheese serum (moisture and dissolved solids) and encases the fat phase. The network may be viewed as a polymer network, in which the casein polymers are cross-linked mainly by calcium and calcium phosphate. The degree of polymer cross-linking and the relative proportion of fat in the network control the response of the unheated cheese matrix to stresses and strains encountered during the size-reduction processes involved in shredding, grating or eating, and the response of the heated cheese during baking and grilling. At the macrostructural level, cheese is an assembly of fused curd particles (microstructures), with the extent of fusion depending on both the microstructure of the curd particles and the processes to which the curd particles are subjected such as salting, moulding, texturizing and pressing. Hence, a key approach in designing ingredient cheeses with target functionalities is the control of cheesemaking operations that affect the microstructure and macrostructure.

Cheese functionality is dynamic, changing with storage time owing to ongoing biochemical changes including proteolysis and lipolysis which affect flavour and rheology. Hence, there is a time window within which functionality is optimal, depending on the application.

Significant volumes of natural cheese are converted to processed cheese products which are used extensively as ingredient cheese products. Processing enables the functional characteristics of the natural cheese to be modified, extended and/or stabilized to varying degrees.

In contrast to ingredient cheeses, cheese ingredients are products derived from cheese by subjecting it to secondary processing treatments; examples include cheese powders and enzyme-modified cheeses (EMCs). Cheese ingredients are used primarily as flavorings in an extensive array of snack and formulated food products.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

18.1 Introduction and Definitions

There are at least 1000 different natural cheese varieties (IDF 1981). These are generally consumed as table cheese, which may be arbitrarily defined as cheese eaten on its own or as an accompaniment to bread or crackers during a meal. Many of these cheeses have long been used as ingredients in the preparation of culinary dishes in the home and hostelries, notable examples including toasted sandwiches, quiche, omelettes, pasta, pizza and lasagne (Fig. 18.1). In these applications, cheese imparts functionalities that contribute to the preparation and sensory properties of the food in which they are included. Pertinent functionalities of unheated cheese include crumbliness, sliceability, spreadability, shreddability or gratability, while those of the heated cheese include overall appearance, flavour, extent of flow, stringiness, fluidity, and oiling-off. The type and level of functionality required depends on the application (Tables 18.1 and 18.2).

The volume of cheese being consumed as an ingredient has increased greatly since the 1970s owing to rapid growth of the food service and prepared consumer food sectors. This trend has given rise to the commercial use of the terms, ingredient cheese and cheese ingredients . Ingredient cheese, as distinct from table cheese, may be defined arbitrarily as cheese manufactured with targeted functionalities designed to optimise its quality as an ingredient in specific applications, e.g., pizza. The production of ingredient cheese generally involves alteration of the manufacturing protocol so as to impart specific functionalities as specified in business-to-business relationships, and which typically include controlled cooking properties, e.g., low- or non-melt cream cheese or Cheddar cheese; customized degrees of flow, oiling-off and stringiness in pizza-style Mozzarella.

In contrast to ingredient cheeses, cheese ingredients are products derived from cheese by subjecting it to secondary processing treatments; examples include cheese powders and enzyme-modified cheeses (EMCs) (Fig. 18.1). The treatments applied during secondary processing may be minimal (e.g., grating and drying in the case of dried Parmesan) or more extensive (e.g., shredding, heating and structural transformation as in the manufacture of EMCs or cheese powders). Cheese ingredients are used primarily as flavourings in an extensive array of snack and formulated food products.

Processed cheese products, which involve significant secondary processing of natural cheese together with other ingredients (cf. Chap. 17), are used extensively as ingredient cheese products, because their functionalities are readily customized and stabilized by varying formulation, processing conditions and cooling conditions. Nevertheless, they are widely consumed as table products (e.g., spreads) in many parts of the world. Similarly, analogue cheese products (cf. Chap. 17) are widely used as substitute/imitation ingredient cheeses.

Ingredient cheese products are delivered in different formats to the consumer through two main sectors, namely:

-

the retail sector, as an ingredient in prepared consumer foods such as frozen pizza, cheese-filled tortellini or ravioli, dried pasta dishes, cheesecake and savoury scones;

-

the food service sector, as an ingredient in various dishes (e.g., lasagne, pizza, omelette, cheese panini, sandwiches);

Ingredient cheese is also used in the industrial sector in the manufacture of various assembled food products (e.g., frozen pizza, frozen cheese burgers, quiche), co-extruded foods (e.g., cheese-filled meat balls and sausages), formulated foods (e.g., gratins, prepared meals, dried soups) and cheese ingredients (e.g., cheese powders, dried cheese).

The current Chapter focuses on natural cheese and cheese-based products as an ingredient, drawing on relevant properties such as flavour, texture and cooking attributes as discussed in Chaps. 13 and 14.

18.2 Overview of Functional Requirements of Cheese as an Ingredient

As an ingredient suited to specific food applications, cheese must possess one of more functionalities, some of which are listed in Tables 18.1 and 18.2. The functional properties of raw cheese are determined largely by its taste/aroma and rheological characteristics, which are discussed in Chaps. 13 and 14, respectively.

18.2.1 Organoleptic Characteristics

The organoleptic characteristics of cheese are perceived by the senses and include taste (sweet, salty, sour, bitter, umami), smell (aroma), sight (e.g., colour; smoothness; extent of free oil; surface dryness, glossiness or matt), and touch (e.g., mouthfeel, softness, tenderness, chewiness, stickiness, juiciness, moistness, ‘fattyness’ and mouth-coating) (Delahunty and Drake 2004). These are important in both unheated (e.g., sandwiches, salads) and heated (e.g., sandwiches, salads, spaghetti Bolognese, lasagna, pasta dishes) cheese applications. Flavour, which represents taste and aroma, may be considered as a sine qua non , with objectionable flavours generally resulting in rejection of the food (cheese) despite other organoleptic attributes (e.g., mouthfeel and tenderness), usage attributes (e.g., shreddability, sliceability) and cooking behaviour (e.g., colour, degree of melting and flow, stringiness) being satisfactory. The importance of cheese flavour is highlighted by the use of mature cheese and cheese products (processed cheese products, cheese powders and cheese sauces) containing added highly intense cheese flavour preparations (e.g., enzyme-modified cheeses, enzyme-hydrolyzed dairy ingredients) in many cheese ingredient applications, such as ready-prepared meals, snacks, soups and sauces. The increasing importance of cheese flavour is also highlighted by the increasing use of cheeses, such as mature Cheddar and Colby, which have poor stretchability compared to Mozzarella, in pizza cheese toppings. Cheese flavour is discussed extensively in Chap. 13, and will not be discussed further.

18.2.2 Size-Reduction Properties of Unheated Cheese

The primary stage of preparation of any food containing cheese requires that the cheese be reduced in size so as to facilitate:

-

deposition onto surfaces (e.g., shredded Mozzarella cheese onto pizza base),

-

layering/spreading onto a surface

-

mixing/blending with other ingredients (e.g., shredded cheese with water and optional ingredients in the preparation of processed cheese products, cheese powders, cheese sauces, fresh cheese desserts)

Size reduction is achieved by cutting into relatively large pieces, crumbling, slicing, shredding, dicing, grating and/or shearing.

Hence, the behaviour of unheated cheese during size-reduction operations is a critical function. Depending on the application, the cheese may be required to exhibit particular size-reduction attributes (e.g., ability to be portioned, sliced, shredded, diced, grated or crumbled) that facilitate its use in the primary stages of preparation of various dishes, e.g., the ability of Parmesan to grate for lasagna; Feta to crumble easily into salads; Gouda to slice cleanly or to bend when in sliced form, Cream cheese or mature Camembert to spread on crackers. The size-reduction behaviour of cheeses is determined mainly by its rheology, which determines its response (fracture, deformation, flow, adhesiveness, springiness) to stresses and strains (e.g., cutting, shear, compression) applied during the size-reduction operations per se. The rheology of cheese (Chap. 14) is a function of:

-

composition (e.g., levels of moisture, fat and protein), microstructure, which represents the spatial distribution of its compositional components and the level of intra- and intermolecular attractions between the components,

-

macrostructure which represents the arrangement of, and attractions between, the different macro-components (e.g., curd particles, gas pockets, veins and/or rind) and determines the presence of heterogeneities such as curd granule junctions , cracks and fissures,

-

the physico-chemical state of its components (e.g., ratio of solid-to-liquid fat as affected by temperature, degree of aggregation, hydration and hydrolysis of the protein).

In addition to size-reduction attributes, unheated cheese is generally required to contribute to the organoleptic characteristics, including colour, appearance, flavour, aroma and texture of the food in which it is included. Appearance criteria of the cheese used may include attributes such as the smoothness of slices, smoothness and dimensions of shreds, the extent of sticking and balling of shreds, the size and uniformity of crumbled cheese pieces, the level of curd fines, the sharpness and uniformity of appearance of cut edges and corners of portions, the degree of bending, drying or cracking of exposed slice sections (e.g., in sandwiches, baguettes), the opacity or translucence .

18.2.3 Cooking Properties

In most applications as an ingredient, the behaviour of cheese on heating and cooking is critical. The heated cheese, following grilling or baking, may be required to melt, flow, stretch, brown, blister, oil-off and/or stretch to varying degrees. It may also be expected to be chewy (as in pizza pie ) and contribute to certain mouth-coating characteristics (as in sauces and pasta dishes). In many dishes, e.g., sauces, the cheese is required to have the ability to interact with other food components such as water, carbohydrates, proteins and fats during food preparation. In food service, the cooked cheese may be expected to remain smooth and moist, without congealing, developing a ‘skin’ or becoming ‘stodgy’ over time or during cooling (during service and consumption) (Guinee et al. 2015).

18.3 Basis of Functional Properties in Cheese

As discussed above, many of the functional properties required in unheated cheese as an ingredient are based to a large extent on its structure and rheology. These determine its deformation and fracture behaviour when subjected to stresses and strains, as applied during size reduction. The rheological behaviour of the cheese during usage is ultimately determined by competition between internal forces responsible for the integrity of the matrix structure and external forces responsible for fracture and demolition. Hence, understanding the basis of functionality and how to tailor it requires us to ask the following question: what is the structure of the cheese matrix and what are the principal forces that are responsible for its integrity? This in turn necessitates an examination of cheese matrix, especially the casein network, in relation to its formation and the forces that bind the casein macromolecules within that network .

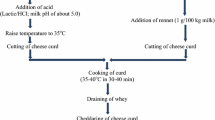

18.3.1 Formation of Rennet-Curd Cheeses

The manufacture of rennet-curd cheeses involves the formation of a gel in response to the enzymatic cleavage and removal, by the coagulant, of the stabilising surface layer of the casein micelles (κ-casein glycomacropeptide) (cf. Chaps. 4 and 7). This results in the surfaces of the resultant para-casein micelles interacting and forming a continuous gel network, which occludes the fat globules and moisture. During the cheesemaking process, the gel is subjected to several processes which interactively result in its dehydration: cutting, stirring, cooking, acidification, drainage of whey, moulding, salting and pressing. The moisture content decreases from ~88 % in the gel prior to cutting to 35–50 % in the curd after pressing, depending on the variety. The moisture content may decrease further during ripening depending on the presence/absence of packaging, the type of packaging, and the relative humidity of the environment. Simultaneously, the casein is concentrated from ~2.5 % (w/w) in the milk to 16–20 % in semi-soft chesses such as Feta, Camembert, and to 25–32 % in hard cheeses like Cheddar, Emmental and Parmesan. The moisture-to-protein ratio (g water/g protein) decreases from ~4 in the native casein micelles in milk to ~3.6, 2.4, 1.52, 1.4, 1.2 and 1.0 in Feta, Camembert, Cheddar, half-fat Cheddar and Parmesan, respectively. Consequently, the dehydration process results in removal of essentially all the bulk phase serum (moisture + dissolved solutes including lactose, soluble salts and non-protein nitrogen) and part of the serum entrapped within the native casein micelles, as whey. The moisture remaining in the cheese curd following pressing corresponds to moisture that has not been removed from the para-casein micelles during the cheesemaking process.

18.3.2 Structure of Rennet-Curd Cheeses

The structure of rennet-curd cheeses may be considered at two levels, namely the microstructure and the macrostructure. Microstructure represents spatial distribution of the compositional components (casein, minerals, fat, moisture and dissolved solutes such as lactose, lactic acid, soluble salts and peptides) at the micro-scale level (e.g., >25× magnification) and the level of intra- and intermolecular attractions between the components. In the case of cheese, the microstructure represents the structure within individual curd particles; while it is usually observed directly using various forms of microscopy (e.g., transmission- and scanning electron microscopy, confocal laser scanning microscopy) other methods such rheometry, x-ray crystallography, fluorescence spectroscopy and differential scanning calorimetry may be used as indirect measures of the properties of the structure. The macrostructure represents the overall structure, as observed visually by the unaided eye or at very low levels of magnification (<10× magnification) with the aid of light microscopy. Macrostructure in the case of cheese may be considered as representing the gross aspects of structure within the moulded cheese, such as curd granule junctions , eyes and slits/cracks.

The microstructure of rennet-curd cheese may be defined as a highly concentrated matrix (Fig. 18.2), consisting of:

Structural resolution of cheese showing its macrostructure and microstructure. The macrostructure consists of an assembly of curd particles or curd pieces (chips) fused through interaction of surfaces; the degree fusion at curd particle/curd chip junctions (J) depends on potential of microstructure to flow (deform under pressure and moulding) and conditions of moulding and pressing. The microstructure within curd particles or curd chips consists of a calcium phosphate para-casein network (P) which imbibes the serum phase (moisture and dissolved salts) within its pores and encases the fat (F) which occurs as globules in varying degrees of coalescence

-

a calcium phosphate para-casein network of extensively dehydrated, fused para-casein micelles

-

a fat phase (in the form of globules, coalesced globules and/or pools) that is entrapped by the casein network

-

a solvent phase consisting water and dissolved solutes (e.g., lactose, lactic acid, soluble salts, water-soluble peptides, enzymes), corresponding to residual serum retained by the para-casein micelles.

The fusion of casein within the network is mediated by various interactions, including:

-

calcium bridges formed by divalent calcium ions which bind to dissociated acidic amino acid residues (glutamate and aspartate) on different molecules, and to colloidal calcium phosphate (attached to serine phosphate groups), and

-

hydrophobic interactions between uncharged amino acid residues

Overall, the structure may be envisaged as a polymer network, comprised of chains of fused para-casein micelles, interconnected by numerous calcium and hydrophobic cross-links to form a single macroscopic entity. The volume fraction of the network and degree of fusion (aggregation) of the para-casein particles forming the network increase as the levels of fat and moisture are reduced. Conversely, the volume fraction of the network decreases as the levels of the latter components, which may be considered as diluents, increase. This is clearly seen on comparing the structures of Cheddar cheese of varying fat content (Fig. 18.3). Hence, controlling the concentration and degree of fusion of para-casein through manipulation of the different manufacturing steps and their sequence, is critical in defining the properties of the final cheese, including rheological properties (e.g., ratio of viscous to elastic characteristics), physical properties (e.g., deformability, firmness, chewiness, ability to be slice, shred and grate) and opacity/translucence.

Scanning electron micrographs of full (33 % fat, a) and low (3.0 %, b) fat Cheddar cheeses. The arrows correspond to the para-casein matrix and the arrowheads to the areas occupied by fat and free serum prior to their removal during sample preparation; bacteria (most likely starter lactococci) are visible in (a), being concentrated mainly at the fat-para-casein interface. Bar: 2 μm; 7000×. Modified from Fenelon et al. (1999)

The macrostructure of cheese may be defined as an assembly of curd particles (in the case of brine-salted cheeses) or curd chips or pieces (in the case of dry-salted cheeses such as Cheddar and Stilton) that are pressed and fused together into a whole (moulded cheese) (Fig. 18.2). The knitting of individual curd particles or chips/pieces into a macrostructure is influenced by many factors which may be summarized as follows (Fig. 18.4):

Factors that affect the macrostructure of cheese: curd particle propertieswhich determine the potential of curd particles to pack, flow and knit together, and the interaction of curd particlesas affected by the processes to which curd particles are exposed. The effects of the various factors are interactive

-

the microstructural-related properties of the particles or chips, which determine their potential to deform and flow into, and fuse with, other curd particles when subjected to moulding and pressing; critical factors include the degree of para-casein hydration (g water/g protein), level of calcium bound to the para-casein, protein-to-fat ratio of the matrix, and the salt content and pH of the moisture (solvent) phase which influence para-casein hydration.

-

the curd particle surface properties such as composition (protein-to-fat ratio, salt content, moisture content); it is noteworthy that the surface layer of curd particles tend to have lower levels of moisture and fat than the interior, to a degree influenced by temperature of curd particle/whey mixture during scalding (cooking), temperature and duration of scalding and pH at whey separation.

-

the size distribution of curd particles or pieces, which affects the packing arrangement, i.e., the neatness of fit, into a continuum.

-

pressing conditions including temperature and pressure which affect factors such as the strength of hydrophobic interactions, the extent of protein solubilisation and fat crystallisation and the ability of curd particles to flow and knit into a seamless whole, without notable inter-particle microstructural discontinuities and junctions.

-

the presence of interstitial air or air between curd particles.

-

storage conditions (temperature, time) which affect the extent of age-related changes in pH, equilibrium between soluble and para-casein bound calcium, proteolysis and fat coalescence, and hence, the ability of curd particles to merge and lose their identity .

18.3.3 Structure-Function Relationships of Rennet-Curd Cheese

18.3.3.1 Unheated Cheese

As the concentration of para-casein (network) increases, its volume fraction increases and its structure becomes less particulate and more of a single continuum (rather than assembly of individual sub-structures). Simultaneously, the mobility of the system becomes increasingly restricted as the lubricating contribution of moisture diminishes, where mobility may be defined as the potential of contiguous planes of the cheese matrix to move or undergo displacement, when cheeses are subjected to a stress or strain. However, for a given casein concentration, the level of calcium, which may be envisaged as the binding ‘glue’ between the caseins, is a critical factor affecting the potential of the casein network to undergo displacement. Consequently, cheeses generally become more elastic, firm and chewy as the levels of protein (casein) and calcium increase. Simultaneously, the cheese becomes less opaque (less white) and more translucent as the volume fraction of the casein network increases, owing to the increasing degree of structural continuity and the reduction in the extent of structural interfaces (e.g., moisture/network interface) where light scattering occurs. However, the degree of opacity increases as the fat content increases, owing to the increase of light scattering interfaces between the fat globules/pools and the casein and the moisture phase .

18.3.3.2 Heated Cheese

Heating cheese to a temperature encountered during baking or grilling (90–98 °C), results in two major microstructural changes:

-

contraction and shrinkage of the para-casein network (owing to a temperature-induced increase in the extent of hydrophobic interactions between the casein molecules) and the simultaneous expulsion of moisture;

-

liquefaction and coalescence of fat globules, resulting in the formation of free fat which is readily observed as an oily layer at the surface of the melting cheese mass.

Consequently, the melting cheese mass becomes more fluid, as both the oil and moisture act as lubricants between adjoining layers of the cheese matrix. These heat-induced changes in microstructure form the basis of what are generally known as melt properties (Table 18.2), including softening of the melting cheese, flow and spread of the melting cheese mass under its own weight during grilling or baking, stretchability and stringiness of the molten cheese mass when extended, oil exudation and the formation of a free oil layer on surface of molten cheese mass .

18.3.4 Comparison of the Structure-Function Relationships in Different Rennet-Curd Cheese Varieties

18.3.4.1 Microstructural Effects

The effect of changes in microstructure, due to differences in the levels of protein and calcium, are readily apparent on comparing different cheese varieties. Hard cheeses (e.g., Cheddar, Mozzarella, Gouda) with high levels of casein and calcium are elastic, hard, chewy and moderately opaque in colour, have good shreddability and sliceability, and exhibit moderate and melt/flow on cooking. A very high casein level, as in low-fat hard Cheddar cheese (~1.3 % fat, 40 % protein, 52 % moisture), results in very low moisture-to-protein ratios (e.g., ~1.3 g/g). These cheeses tend to be very hard, rubbery, chewy and translucent. On cooking, they are prone to drying-out, which may result in blistering, ‘puffing’ and hardening of the surface and a low degree of flow; the melted cheese generally is not very fluid, is tough and chewy.

The adverse effects of a high concentration of protein on the properties of low-fat cheese may be attenuated by modifications of the cheesemaking process to reduce the levels of protein and calcium (hence calcium-to-casein ratio) and by increasing the levels of moisture and proteolysis during maturation. The latter has the effect of hydrolysing or ‘chopping’ the para-casein molecules, thereby making the insoluble para-casein network less rigid and more soluble. In contrast to the above, cheeses with a high moisture content and low levels of casein and calcium, such as mature Camembert and Blue-type cheeses, are relatively soft, adhesive, spreadable, easily mixed with other ingredients, and flow extensively on heating .

18.3.4.2 Macrostructural Effects

The effects of macrostructure on cheese functionality are probably most evident when comparing brine-salted and dry-salted hard cheeses. Brine-salted cheeses such as Gouda, Mozzarella and Emmental usually display excellent sliceability and shreddability, owing to the high degree of curd particle knitting into a seamless whole moulded cheese. The slices, which are usually retailed or used in food service as slice-on-slice (without the need of separating foils), are flexible, bendable and peel easily without breaking. In contrast, slices of dry-salted cheese such as Cheddar are generally more brittle and can break easily along curd chip junctions (Fig. 18.2, centre plate; see also Figs. 14.2 and 14.3, Chap. 14) which may be considered as ‘fault lines’, especially when chip-to-chip surface knitting is poor, for one or more reasons including a relatively high degree of dehydration of the para-casein network due to a salting-out effect at the high salt-in-moisture concentrations in the surface layer of the chip surfaces during dry salting (cf., Chap. 9), high concentrations of calcium and phosphate, low contents of moisture and fat or a low temperature during pressing. Nevertheless, the adverse effects of ‘discontinuous’ macrostructure of dry-salted cheeses on their sliceability and shreddability may be ameliorated by altering the microstructure and rheology of the curd chips which make them more amenable to flowing and knitting together (e.g., alteration of pH, calcium level, ratio of soluble-to-insoluble calcium) and modifying the conditions of salting. Another example, where the effect of macrostructure on functionality is evident is in Parmesan cheese. The manufacture of Parmigiano Reggiano is characterised by the use of partly skimmed milk (~2.5 % fat), cutting the gel into small curd particles, cooking (scalding) of curd to a high temperature (54–58 °C), whey drainage at pH > 6.0, moulding into large wheels and a long salting time (~14 days) in high concentration brines (e.g., ~26 % NaCl) (Davis 1976; Kosikowski and Mistry 1997; Gobbetti 2004). These conditions are conducive to:

-

a very high degree of protein aggregation during manufacture, as promoted by temperature-induced hydrophobic interactions and the deposition of soluble calcium and phosphate as insoluble calcium phosphate;

-

small, highly dehydrated curd particles that pack closely but do not kit very well when moulded and pressed;

-

a curd with a relatively high protein-to-fat ratio and low-moisture content at salting.

The resultant cheese has a low-moisture content (<33 %, w/w), a very low moisture-to-protein ratio (~0.9, compared to ~1.7 in Gouda), a relatively high calcium-to-casein ratio and protein-to-fat ratio (~1.2–1.4, compared to 0.73–0.8 in Cheddar, and 0.9–1.0 in Emmental). Consequently, the cheese is very dry with a hard texture that fractures easily along its curd granule junctions (on application of a stress or strain) to yield to a ‘mealy’, granular/grainy texture on mastication as the poorly knitted curd particles (granules) come apart and are perceived as grains. Hence while the cheese is very hard, it is brittle and unsuited to slicing and shredding but ideally suited to grating for use as a sprinkling for dishes such as spaghetti Bolognese.

18.3.5 Formation of Acid-Curd Cheeses and Their Basic Microstructure

The manufacture of acid-curd cheese products such as Cream cheese, Quark and Labne(h) involves acid-induced gelation of milk, in response to the reduction of pH to the isoeletric point of the caseins (cf., Chap. 16). This results in the surface of the casein micelles becoming more hydrophobic and interacting to form a continuous gel network that encloses the fat globules and moisture. The gel is then dehydrated and concentrated to the desired dry matter of the final fresh cheese using various operations such as breaking/stirring the gel, heating, filtration of the broken curd through cheese cloth, ultrafiltration, and/or centrifugation (cf., Chap. 16). Fresh acid-curd cheeses generally have a high moisture content (~60–80 %) and low levels of protein (5–14 %) and calcium (<~0.18 %); the fat content varies from ~0.5 % in Quark to ~35 % in double Cream cheese and ~50 % in Mascarpone. The moisture-to-protein ratio is quite high compared to rennet-curd chesses, e.g., ~5.5 in double Cream cheese, 6.3 in Quark to ~8.5 in Labne(h).

While the structure of acid-curd cheeses is generically similar to that of rennet-curd cheese, in that it is essentially a polymer network of casein, it differs in the following respects:

-

the polymer network is comprised of casein instead calcium phosphate para-casein;

-

the degree of calcium bridging contributing to casein interconnectivity and casein network formation is significantly lower. Owing to the low pH (~4.5–4.8), all the colloidal calcium phosphate has been solubilised during gel formation and removed in the cheese whey during subsequent concentration. Only calcium attached directly to acidic amino acid residues (aspartate and glutamate) remains with the casein, and this decreases as the pH is reduced. Despite the overall low level, the quantity of calcium is, nevertheless, a critical determinant of texture (chewy or mushy) in the case of Cottage cheese, which may be described as a ‘mainly acid-coagulated cheese’ even though a small quantity of rennet is used in manufacture (Farkye 2004a).

-

the volume fraction of the casein network is much lower and the degree of fusion between the casein particles (acidified casein micelles) making up the network is generally much lower because of the lower casein concentration and higher moisture content.

18.3.6 Structure-Function Relationships of Acid-Curd Cheese

Owing to the low volume fraction of the casein network and high moisture content, acid-curd cheeses generally have a soft, smooth consistency and mouthfeel. However, because of their high moisture-to-protein ratio, acid-curd cheeses tend to be susceptible to uncontrolled post-manufacture casein aggregation and dehydration via mobility and re-arrangement of their casein network caused by external stresses on the product (for example during transport/distribution and retailing) or internal stresses induced by changes in temperature during storage. In extreme cases, this can lead to protein precipitation and extensive wheying-off. This tendency is more pronounced when the moisture content of the product is high, as this facilitates the sedimentation of protein aggregates.

Protein aggregation is the basis of major sensory defects including excessive wheying-off and the development of a sandy/grainy texture during storage, especially where the concentrated milk gel is heated and hot-filled post fermentation (e.g., as in Cream cheese) and where the product is required to have a long shelf-life (e.g., up to 6 month for hot-packed Cream cheese and some fresh cheese preparations). Avoidance of such defects requires optimisation of the degree of casein aggregation at the different stages of manufacture through the control of appropriate features such as milk composition (e.g., casein-to-whey protein ratio), heat treatment of the milk and level of whey protein denaturation, optimisation of product pH, treatment of gel post whey separation (temperature, homogenisation, cooling) and the use of a suitable stabiliser . Where permitted, suitable stabilisers, such as guar gum and locus bean gum, can increase the viscosity of the aqueous phase and, thereby, minimise casein aggregation by limiting mobility and re-arrangement of the gel structure. The options available depend on the product, which determines the steps involved in manufacture (including the heat load and degree of shear applied to the concentrated acidified milk gel ), the sequence of steps, product composition and shelf-life .

18.4 Evaluation of the Rheological-Related Functional Properties of Cheese

18.4.1 Unheated Cheese

18.4.1.1 Sensory Tests

Several tests are available to assess the sensory properties of unheated cheese in a controlled environment (Delahunty and Drake 2004). These include:

-

discrimination tests (e.g., triangle, paired comparison and ranking tests) to evaluate differences between samples in terms of overall quality or some specific attribute by trained panelists;

-

descriptive sensory analysis to discern differences between samples based on quantitative scoring of a number of different attributes (e.g., harness, chewiness) according an agreed definition of attributes by a trained panel;

-

Consumer acceptability testing by panelists who are untrained but who regularly eat cheese.

These tests are generally expensive to undertake because of the requirement for a dedicated sensory laboratory, training of a panel, or recruitment and payment of consumer panels. Consequently, they are not used routinely in a factory environment for the measurement of functional properties of cheese.

In practice, the functional properties (e.g., shreddability, gratability, sliceability) are assessed by trained laboratory staff using empirical, in-house, sensory grading methods . Methods may include:

-

visual assessment of shred (e.g., cleanliness of cut surface, length, balling, fines) or slices (smoothness, cleanliness, surface irregularities, gloss and drying-out or curling on standing) for appearance;

-

manual pulling of slices to gauge elasticity, break force, cleanliness of break;

-

squeezing of shredded cheese in the fist and observing the recovery, or lack of it, when released.

Nevertheless, instrumental tests may be also used to measure the functionality of the cheese. Such tests may be indirect such as large strain deformation (e.g., compression of a cheese sample, e.g., cube) testing on a texture analyzer, or direct (e.g., measuring shreddability by passing the shredded cheese through a vibrating stack of discs of varying aperture) .

18.4.1.2 Large Strain Compression Tests

The rheological behaviour of cheese when subjected to large strain deformation (e.g., compression to >30–40 % of the original sample dimensions) and the magnitude of the outputs (e.g., fracture stress, σf; fracture strain, εf; firmness, σmax; gumminess, adhesiveness) may be indicative of how a cheese may shred, slice, grate or spread (cf. Table 18.1 and Chap. 14, O’Callaghan and Guinee 2004). Consequently, it is used commercially for this purpose, especially as a tool to monitor changes in fracture properties if a cheese recipe is being redesigned .

Cheeses with low fractures stress (σf) and firmness (σmax) are generally soft and adhesive and are not used in shredded/diced cheese applications, such as pizza pie, because of their tendency to ball and clump and to adhere to surfaces. Such cheeses include those with high moisture, a high degree of primary proteolysis, a low calcium-to-casein ratio, a low protein-to-fat ratio and include products such as mature Camembert, Chaumes, Havarti, Blue-type cheeses or Esrom. However, the adhesiveness and ability of these cheeses to flow under shear (i.e., spread) makes them ideal for blending with other materials such as butter, milk or flour in the preparation of fondues and sauces (Tables 18.1 and 18.2). Conversely, cheeses with a very high fracture stress and firmness and low facture strain (εf) tend to be hard and brittle and undergo elastic fracture on compression, i.e. fractures into distinct pieces with little tendency to adhere to one another (Chap. 14 and O’Callaghan and Guinee 2004). Such cheese, which include varieties such as Parmesan and Romano, generally display excellent gratability, e.g., when crushed between rollers, and are suitable for sprinkling onto dishes such as spaghetti Bolognese . However, these properties render the latter cheeses unsuitable in food applications that require sliced or shredded cheese, e.g., pizza, sandwiches or cheeseburgers. On the other hand, varieties with moderate to low firmness and low fracture strain, such as Feta or medium-mature Blue-type cheeses, tend to be relatively soft and short (crumble under low displacement). These are particularly suited for easy inclusion into mixed salads because of their crumbliness, their breaking into irregularly shaped, curd-like particles that are visually appealing to the consumer as they convey an image of ‘real’ cheese. Cheeses such as Emmental-type, Gouda and Maasdammer are ideal for slicing very thinly and are, therefore, particularly suited to applications such as continental breakfast cheese and filled cheese slices. This is because of their high degree of elasticity, springiness (high recovery from deformation following removal of deforming force) and “long” body (high fracture strain). Similarly, the springiness of low-moisture Mozzarella cheese (LMMC) endows it with good shreddability (low tendency to fracture or form curd fines) and non-stick properties that facilitate uniform distribution on the surface of pizza pies (Tables 18.1 and 18.2).

18.4.1.3 Empirical Instrumental Tests

In addition to large strain deformation analysis, empirical tests are sometimes used. The suitability of cheese for shredding may be assessed directly by determining the tendency of the shredded cheese to aggregate or clump when vibrated under controlled conditions similar to those used on commercial pizza production lines. Cheese, after storing at 4 °C for ≥12 h, is cut into cubes of fixed dimensions (e.g., 2.5 cm) and a fixed weight (W1) of shredded cheese is placed immediately on the top sieve of a stack of sieves ranging in aperture from 9.5 to 1 mm (Guinee et al. 2000a). The stack is vibrated at fixed amplitude for a given time, resulting in the cheese shreds passing through the stack to a degree dependent on their susceptibility to stick/clump or fracture. The cheese on each sieve is then weighed (W) and an aggregation index (AGI) is calculated:

where SA is the sieve aperture. A higher AGI value corresponds to a higher susceptibility to aggregation and clumping. Similar approaches are also used commercially, e.g., hand vibrating cheese in a colander and determining the quantity retained after a fixed time .

18.4.2 Heated Cheese

18.4.2.1 Sensory Tests

Similar to unheated cheese, the cooked cheese is routinely assessed using in-house, sensory tests. Typically, a defined weight of shredded cheese sample is distributed uniformly on a surface (e.g., heat-resistant glass plate, tin foil of given dimensions or pizza base) and placed in an oven under defined conditions (type of oven, temperature and heating time). The cheese is withdrawn and inspected visually for attributes such as uniformity, shred identity, degree of shred coalescence, degree of spread or flow, level of oiling-off, surface appearance (colour, moistness, oiliness, puffing, glossiness, scorched/black spots, blister coverage). The cheese may be assessed orally for parameters such as succulence, oiliness, dryness, moistness, mouth-coating, chewiness. Additionally, it may be checked for stringiness by inserting a fork and noting the appearance and length of the sheet or strings formed, and how readily they break. Depending on the application, several attributes are scored and noted .

18.4.2.2 Instrumental Tests: Empirical

18.4.2.2.1 Flowability

The degree of flowability on heating is frequently assessed by placing a sample of cheese (e.g., disc, cylinder) of fixed dimensions (e.g., disc, 45 mm diameter, 4.0 mm high) on a surface (e.g., heat-resistant glass plate, glass petri dish, glass cylinder with bung) and putting it in a controlled temperature environment (e.g., oven, water bath) under defined conditions of temperature and time. The sample is then withdrawn, allowed to cool and the change in a particular sample dimension (e.g., height of vertical cylinder, length of horizontal cylinder, diameter of disc) is measured. The flowability is the change in dimension, expressed as a percentage of the dimension in the unheated sample. Various tests have been described in the literature to measure flowability, also frequently known as the meltability, e.g. Arnott test, Schreiber test, Price-Olson test (Park et al. 1984).

18.4.2.2.2 Melt Time

Shredded cheese is distributed uniformly on a polished surface (e.g., tin foil, steel), marked out in rectangular grids (e.g., 9 × 9 cm), typically at a rate of 1.73 kg cheese/m2 and placed in an electric fan oven (e.g., at 280 °C) for a time that is sufficient for melting (e.g., ~3 min for Mozzarella) (Guinee et al. 2000a). The sample is then allowed to cool to room temperature and inspected for the coalescence of shreds into a homogeneous molten mass or the presence of individual shreds. The sample is then scored (e.g. on a scale of 1–5). A low score (e.g., 1) is assigned to samples showing individual shreds, especially where the shreds are hard, dried-out and scorched (brown); a high score (e.g., 5) is awarded when no traces of shred identity are evident and where the cheese mass is uniform and molten; and an intermediate scores assigned where some traces of shred identity remain and where the individual shreds are swollen and moist. In applications where a very flowable and fluid cheese is required (e.g., pasta dishes), a high score is desirable, whereas a low score is more suitable for controlled melt applications (e.g., for cheese slices in burgers).

A variation of the above test involves measurement of the time required for all the shreds to disappear completely to form a uniform molten mass, as assessed by viewing the melting samples through the glass door of an interior-lit oven. Obviously, this is suitable only for cheeses that melt within a reasonable time (e.g., 180–240 s at 280 °C at a cheese loading of 1.73 kg cheese/m2 .

18.4.2.2.3 Stretchability

Stretchability relates to the ability of the cooked cheese to form strings when extended, the dimensions of the strings (e.g., length, thickness), and/or the energy or work required to extend a given distance. The most basic method of assessment involves lifting the cooked cheese (on a pizza base or other surface) with a fork and sensorially gauging/scoring the string profile (thickness, number), length, smoothness and sheen (Fig. 18.5a).

Measurement of stretchability of molten cheese using different methods: (a) manual extension, (b) horizontal extension at a fixed velocity of 0.066 m/s along a twin rail (Guinee and O’Callaghan 1997; Guinee et al. 1999) and (c) vertical uniaxial extension to a distance of 0.38 m at a velocity of 1 cm/s on a TAHDi Texture Profile analyzer (Stable Micro Systems, Godalming, UK) with simultaneous measurement of force

More quantitative methods typically involve uniformly distributing a defined weight of shredded cheese on a surface, melting and instrumentally extending the molten cheese mass uniaxially under defined conditions of speed and measuring various aspects of the stretched cheese, including the distance at strand/string breakage, force required to extend a fixed distance and/or dynamic image analysis of forming strings (Apostolopoulos 1994; Pagliarini and Beatrice 1994; Guinee and O’Callaghan 1997). In the latter study, a defined weight of shredded cheese was loaded onto a pizza base (or other surface), pre-cut in halves and baked under defined conditions. The baked pizza is then loaded onto the cell of a stretching unit, comprising fixed and mobile elements. One half of the baked pizza is clamped to the fixed element, while the other half sits astride the mobile element. The mobile element is drawn at a fixed speed along a rail system stretching the molten cheese mass into strings or sheets until complete failure of the extended strings/sheets (Fig. 18.5b). Coupled with an overhead mounted mobile camera, both the dimensions of the strings and the length at breakage are measured (Guinee and O’Callaghan 1997).

A more recent development involves dynamic measurement of the force required to extend the molten cheese a fixed distance using a cheese extensibility rig on a texture analyzer, e.g., from Stable Microsystems (Fig. 18.5c). Shredded cheese is placed in a microwaveable plastic container (box) fitted with a comb (fork) that sits snugly inside it and has an adapter for rapid attachment to the load cell of the texture analyzer (Fig. 18.6). The cheese is loaded on top of the comb and the container/comb assembly is placed in a microwave oven under defined conditions and heated to 90–98 °C. The assembly is then withdrawn from the oven, the comb is attached to the cross-head of the texture analyzer and the molten cheese is extended a fixed distance (e.g., 38 cm) at a constant velocity (1 cm/s). The work required for extension is determined from the area of the resultant force/distance curve (Fig. 18.6).

Force (a, blue line) and cumulative work/energy (b, red line) required to extend 180-day-old Cheddar cheese at a velocity of 1 cm/s on a TAHDi Texture Profile analyzer (cf. Fig. 18.5c). McCarthy and Guinee (unpublished results)

18.4.2.2.4 Oiling-Off

Moderate release of free oil from cheese during heating is desirable in most cooking applications. Free oil forms a protective ‘apolar’ layer on the surface of the melting cheese mass, reducing the extent of dehydration and minimizing the risk of associated defects, i.e., crusting, puffing and extensive blistering. Conversely, excessive release of free oil is undesirable, being unaesthetic and creating the impression of excessive fat content. Several approaches have been used to estimate free oil release, some more empirical than others.

An early method involved placing a cheese disc of specified dimensions on a circular filter paper, heating under defined conditions of time and temperature and cooling. Free oil released on heating was absorbed by the filter paper forming a ring, the diameter of which was indicative of the extent of oiling-off. More recent methods involve placing a defined weight of shredded cheese in glass centrifuge tubes/containers, heating in a boiling water bath, adding distilled water and centrifuging to recover the free oil. The addition of a water:methanol mix to the supernatant followed by recentrifugation allows the formation of defined fat layer and enables accurate quantitative determination (Kindstedt and Rippe 1990; Kindstedt and Fox 1991).

18.5 Effects of Different Factors on the Functionality of Unheated Cheese

18.5.1 Rheological-Based Functional Characteristics

The functionality of unheated cheese is to a large extent determined by its flavour and rheological properties (e.g., fracture stress, fracture strain, firmness/hardness), which are discussed in detail in Chaps. 13 and 14. The key factors influencing the rheological characteristics are:

-

composition (moisture, fat, protein, calcium) (cf. Chap. 14)

-

pH (cf. Chap. 14)

-

degree of proteolysis (cf. Chap. 14)

-

cheese variety and structure (Sect. 18.3).

18.5.2 Cheese Shreddability

Good shreddability is characterized by free flow of the shredded cheese and a low tendency of the cheese shreds to stick together to form balls or clumps. It is essential to minimize ‘irreversible’ sticking and clumping in situations where the shredded cheese may be, in effect, compressed temporally, for example when holding in storage bins prior to being fed to cheese depositor/applicator units (e.g., pizza production lines) or when retail or catering packs of shredded cheese are stacked during distribution. While some clumping may occur in the latter situations, it is important that clumps are easily broken up by vibration/fluidization or, simply, by shaking (retail packs). Poor shreddability leads to clumping of the cheese shreds, which leads to blocking of cheese dispensing units on pizza pie production lines, poor distribution of cheese on pizza pies and matting of shredded cheese when placed in retail packs.

18.5.2.1 Shreddability of Retail Cheeses

The shreddability of a range of commercial cheeses, as measured using the aggregation index (AGI) , indicate that variety has a marked influence (Fig. 18.7). Such a trend is expected owing to inter-varietal differences in elasticity as affected by moisture content, casein content, degree of proteolysis, pH, calcium-to-casein ratio and protein-to-fat ratio. Hence, cheese such as Emmental and Gruyere with relatively low moisture, high protein, low proteolysis and a high calcium-to-casein ratio tend to have a better shreddability (lower AGI) than cheeses such as Tetilla and Fontina which have relatively high moisture, high degree of proteolysis, low calcium and low protein-to-fat ratio.

Susceptibility of shredded cheese to clumping (as measured by aggregation index) in different cheese types: Gruyère (A), Emmental (B), Appenzeller (C), substitute Pizza cheese (D), Kackaval (E), low-moisture Mozzarella (F), Cheddar (G), Tetilla (H), Fontina (I). From Guinee et al. (unpublished results)

18.5.2.2 Changes in Shreddability of Mozzarella During Storage

Studies on the shreddability of Mozzarella show that it changes during storage at a low temperature (4–8 °C) and that there is a time window where it is optimal (Kindstedt 1995). Young (1–5 days old) Mozzarella cheese tends to have poor shred, as reflected by the tendency of the cheese shreds to ball/or clump, especially when the shredded cheese is under pressure, as occurs in practice where shredded cheese is stored temporally in bins (e.g., up to 100 kg) prior to use in pizza pie manufacture. Thereafter, shreddability improves, being optimal after ~3weeks storage at 4 °C, but deteriorates progressively on further storage and the cheese becomes soft and sticky. These changes are associated with corresponding changes in moisture distribution and water-binding capacity of the cheese . In fresh curd, free moisture retained in the cheese after plasticization has not yet been absorbed. On ageing, free water is absorbed as the water-binging capacity of the para-casein increases due to calcium solubilisation and proteolysis. However, on prolonged ripening excessive proteolysis leads to excessive solubilization of the para-casein, a loss of matrix elasticity and an increase in stickiness .

18.5.2.3 Other Factors That Affect Shreddability

Apart from composition, other factors which are conducive to clumping of shredded cheese include:

-

longer shred length and shred diameter which increase the chance of shred entanglement,

-

free fat content

Most rennet-curd cheeses contain non-globular fat or free fat, formed as a result of disruption of the native milk fat globule membrane due to shear forces applied during cheesemaking operations, e.g., cutting, stirring, pressing, casein network shrinkage and concentration. The presence of free fat is confirmed by microscopy which shows the presence of non-spherical clumps (e.g., in cheese such as Cheddar) or pools (e.g., in Mozzarella) of fat (see Fig. 18.3). The effect of non-globular fat on shreddability depends on the ratio of solid-to-liquid fat, which decreases as the temperature is raised. At temperatures where milk fat is largely in the liquid state (60 % of total fat at 20 °C), free fat exudes to the surface of the cheese shreds where it acts as an adhesive for other shreds. This defect is compounded by temperature fluctuations during storage, e.g., cooling after holding at ambient temperature (~ 20 °C) leads to solidification of exuded fat which makes the breaking-up of clumps of cheese shreds more difficult as the solid fat forms a rigid bridge between neighbouring shreds. Hence, in practice, cheese is usually maintained at low temperature prior to, and after, shredding , e.g., at <2 °C before use in pizza manufacture and <8 °C in retail outlets.

18.6 Effects of Different Factors on the Functionality of Heated Cheese

The behaviour of cheese on cooking is important in most applications, e.g., grilled cheese sandwiches, pizza pie, cheeseburgers, pasta dishes and sauces. The functionalities or attributes required depend on the cooking application (Table 18.2). Hence, heated cheese for pizza pie is generally required to exhibit high stringiness, moderate chewiness, flow and oiling-off and mild to medium flavour (much of the flavour being supplied by the tomato sauce and toppings other than cheese). Conversely, such attributes are undesirable in pasta dishes which require a high melt and flow, soft mouthfeel and medium to strong flavor. The functionality of heated cheese, frequently referred to as cooking properties, is influenced by many factors.

18.6.1 Effect of Cheese Type

A comparison of the cooking properties of different cheeses indicates inter- and intra-varietal differences in melt time, flowability, stretchability and apparent viscosity (Table 18.3). The inter-varietal differences in functional properties reflect differences in conditions of manufacture (e.g., pH at whey drainage, texturisation), composition (e.g., pH, calcium-to-casein ratio, protein content, moisture-to-protein ratio, protein-to-fat ratio), degree of maturity (e.g., pH 4.6-soluble N) (Table 18.4). These, in turn, influence the volume fraction of the para-casein network, its structure, water-binding capacity and rheological response when subjected to heating (cf. Sects. 18.3.1–18.3.4).

The pasta filata cheeses were differentiated from all other varieties by their superior stretchability, relatively high apparent viscosity, moderate flowability and melt time. These attributes make them ideally suited for pizza pie, i.e., sufficiently rapid melt and desirable levels of stringiness, chewiness and flow. Some pasta filata cheeses , e.g., Provolone dolce and string cheese have a very high viscosity, which undoubtedly is associated with over-chewiness on pizza pie. While the functional requirements of the pizza market varies according to brand, Mozzarella cheese with the following characteristics is generally acceptable: melt time, <120 s; flowability, ≈40–55 %; stretchability, >75 cm; apparent viscosity, ≈800–400 Pa.s; AGI ≈ 3.5–4.5 (Table 18.3, Figs. 18.7 and 18.8). While the degree of browning required on pizza pie appears to depend very strongly on the pizzeria, generally a low degree is desirable.

The superior stringiness of pasta filata cheeses, compared to other cheese varieties, may be attributed primarily to plasticization of the curd during the kneading/stretching process. In this process, the milled curd (pH ~5.2) is heated to ~57–60 °C and kneaded, in hot water or dilute brine (e.g., 4 % NaCl) at ~78–82 °C. The combined effect of high temperature, low pH and kneading are conducive to the formation of para-casein fibres of high tensile strength. These fibres are orientated linearly and separated by pools of fat (columns) with the same orientation (McMahon and Oberg 2011). Confocal laser scanning micrographs of the curd before and after texturization clearly demonstrate the formation and linearization of protein fibres (Fig. 18.9). Conversely, stringiness, which is typical for LMMC and other pasta filata cheeses, such as Kashkaval and Provolone, is an undesirable attribute for applications such as sauces, pasta dishes, gratins, fondues or toasted sandwiches. Cheeses such as mature Cheddar, Emmental, Raclette and Gouda are much more satisfactory because of their excellent flowability and flavour and the absence of stringiness on baking or grilling .

Confocal laser scanning micrographs showing protein (a, b) and fat (c, d) as light grey areas against a dark background in unheated Mozzarella cheeses after storage for 1 (a, b) or 20 (c, d) days at 4 °C. The 1-day-old sample shows extensive linearization of para-casein into fibres (a) and of fat into pools (b). The 20-day-old sample shows that the para-casein fibres have swollen and expanded as a consequence of hydration (c), forcing the occluded fat into smaller pools. Bar = 25 μm. Modified from Guinee et al. (2000b)

In some applications, melt (softening of the melted cheese mass) is essential but very limited, or no, flow is required so as to preserve the shape and identity of the cheese. Commercially, the absence of heat-induced flow is frequently referred to as flow resistance and cheeses designed with flow resistance as ‘controlled flow’ cheeses . Examples of applications where flow resistance is required include fried Paneer, fried Halloumi, grilled or fried burgers containing cheese insets, deep-fried breaded cheese sticks and some baked cheese applications. In such applications, most mature natural cheeses are unsuitable owing to excessive flow and oiling-off and disintegration of the cheese during cooking. In the case of cheese insets in deep-fried burgers, such attributes would result in the cheese permeating the interstices of the coarse meat emulsion and losing its shape and visual effect in the cooked product. Nevertheless, flow resistance may be engineered into rennet-curd natural cheeses by a number of processes

-

high heat treatment of the milk;

-

addition of whey proteins to the milk followed by high heat treatment;

-

homogenization of the cheese milk, e.g., at a pressure ≥15 MPa.

Similarly, high heat treatment of the cheese milk (e.g., ≥85 °C for 5 min) at a low pH in the manufacture of acid-heated coagulated varieties (Farkye 2004b) gives cheeses such as Paneer and Quesco Blanco, which are flow resistant. In the case of Cream cheeses, high heat treatment of milk and/or the curd (e.g., >85 °C for 5–15 min) and high pressure homogenization of the milk and/or curd result in flow-resistant products. In the latter products, high heat treatment of milk results in a high level of whey protein denaturation (e.g., ~60 % of total whey proteins) and their complexation with casein. On subsequent baking or grilling of the cheese, the included whey proteins appear to undergo gelation and thereby impede the flow of the heated cheese mass.

Controlled-flow processed cheese products (PCPs) can be easily designed through control of formulation (e.g., inclusion of whey protein at a level ≥ 2 %, addition of a high level of sodium ortho- or polyphosphates, use of natural cheese with a high content of intact casein and a high calcium-to-casein ratio) and processing conditions (e.g., increasing processing shear and time) (Guinee 2009, 2011; Chap. 17). Such approaches provide a convenient means of converting natural cheeses into PCPs with varying degrees of flow resistance. A major problem with natural rennet-curd cheese varieties is that the functionality of the heated and unheated cheese tends to be unstable, changing as protein hydrolysis and hydration continue to increase during maturation. There is a time window in which the physico-chemical (e.g., casein hydrolysis and hydration) and functional attributes are optimal for specific applications; prolonging ripening outside this window alters the magnitude of the different attributes (e.g., stretchability, flow, viscosity) and results in deterioration of the overall functional acceptability of the cheese.

18.6.2 Effect of Protein Concentration and Proteolysis

It is difficult to determine the direct effects of altering the concentration of any one compositional component, including protein, on the functionality of melted cheese since the levels of the different components tend to vary simultaneously, e.g., fat reduction is accompanied by increases in the levels of protein and moisture and decreases in the levels of moisture-in-non-fat substances and fat-in-dry matter. Nevertheless, results on the functionality of reduced-fat cheese provide insights on the effects of protein. Increasing the protein content of cheese (e.g., from 26 % to 40 % in Cheddar-type cheese while reducing fat from ~32 % to 5 %) generally results in significant increases in apparent viscosity and melt time and reductions in flowability and stretchability of the heated cheese (Fig. 18.10). Based on analysis of cheese microstructure and structure-function relationships (Sects. 18.3.2–18.3.3), these changes are due to:

Effect of fat and protein content on age-related changes in the flowability (a) and stretchability (b) of full-fat (filled circle, filled triangle; 26 % protein, 31 % fat) and reduced-fat (open circle, open triangle; 39 % protein, 7 % fat) Cheddar cheese, baked at 280 °C for 4 min. Modified from Guinee et al. (2000b)

-

increases in the concentration and volume fraction of the para-casein network (Fig. 18.9) (cf. Sects. 18.4.2–18.4.4)

-

reduction in the moisture-to-protein ratio (from ~1.5 to 1.2)

-

reduction in fat content

-

reduction in the lubricating effects of moisture and fat.

For a given protein content, increasing the level of protein hydrolysis results in higher flowability, lower apparent viscosity and a reduction in stretchability. This is readily apparent when observing the changes in the latter attributes over the course of maturation in any cheese. The effect of proteolysis and maturation may be envisaged as a reduction in the concentration of intact para-casein molecules constituting the protein network (cf., Sects. 18.4.2–18.4.4). Proteolysis during maturation results in hydrolysis and solubilization of the para-casein, as indicated by the increases in the level of pH 4.6-soluble protein which does not contribute to the structure and integrity of the para-casein network.

18.6.3 Effect of Ripening Time

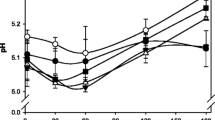

Studies on the cooking properties of various cheeses (Cheddar, Mozzarella and Swiss) have shown that functionality is dynamic, with the various functional attributes undergoing age-related changes to a degree depending on the composition and cheese variety(Figs. 18.8, 18.9, and 18.10).

Low-moisture Mozzarella cheese (LMMC) is the most intensively studied, because of its very large production (~1.7 million tonnes in 2013) and it being the principal cheese used in pizza pie. The functionality of LMMC improves markedly during the first 2 weeks of storage at 4 °C, as reflected by decreases in melt time and apparent viscosity and increases in flowability and stretchability; this status is maintained until ~40–50 days (Fig. 18.11). The improved functionality is due to increases in protein hydrolysis, ratio of soluble to casein-bound calcium and para-casein hydration (Fig. 18.12) (Kindstedt and Guo 1997; Guinee et al. 2000b; McMahon and Oberg 2011). The vapour pressure of water bound by the para-casein is lower than that of free water and thus has a lower propensity to evaporate during baking. The exudation of free oil from the shredded cheese during baking also limits dehydration; the free oil forms an apolar surface layer, which impedes the escape of water vapour. The changes in protein hydration appear to be the result of a number of factors, including :

Typical changes in functional attributes of low-moisture Mozzarella cheese during storage at 4 °C: melt time, flowability and stretchability after heating at 280 °C and apparent viscosity at 70 °C. From Guinee et al. (1997)

Typical changes of low-moisture Mozzarella cheese during storage at 4 °C: primary proteolysis, as measured by pH 4.6-soluble nitrogen, and para-casein hydration. Modified from Guinee et al. (2002)

-

a small increase in pH (from ~5.15 to ~5.35–5.40 at 5 days), as a result of solubilisation of calcium phosphate to replenish calcium removed from the aqueous phase of the curd during plasticization in hot water.

-

an increase in primary proteolysis of para-casein by residual rennet and/or plasmin, and the ensuing solubilisation of some of the para-casein

On prolonged storage, up to 75 days, the unbaked cheese generally becomes too soft and sticky while the baked cheese becomes excessively flowable and ‘soupy’ and lacks the desired chewiness, which is reflected by the relatively low apparent viscosity. These changes in functionality are attributed to excessive proteolysis. However, stretchability remains relatively constant even when the product is stored for up to 4 months at 4 °C, suggesting that the level of primary proteolysis in the cheese at this time (i.e., pH 4.6-soluble N ~ 12 % total N) is insufficient to significantly impair stretchability. Indeed, experiments show that young Cheddar cheese (i.e., 15–35 days; with a pH 4.6-soluble N level of <12 % total N) has good stretchability, similar to that of LMMC. In contrast, Cheddar with a pH 4.6-soluble N level >15 % of total N has inferior stretchability compared to LMMC (Guinee 2003).

Maillard browning on pizza pie results from heat-induced reactions between the carbonyl group of reducing sugars (lactose and galactose) and the amino groups of peptides and amino acids. The degree of browning is related to the sugar-fermenting and proteolytic characteristics of the starter culture used (Kindstedt 1993; McMahon and Oberg 2011). Most strains of Streptococcus thermophilus and Lacobacillus delbrueckii ssp. bulgaricus, which are commonly used in the manufacture of LMMC, are unable to metabolize galactose. Hence, cheese made solely with these cultures is susceptible to browning. Attempts to control the level of browning in pizza cheese include control of residual sugars and/or proteolysis products via:

-

adjusting the ratio of Lb. helveticus to Sc. thermophilus in the starter culture,

-

the use of galactose-positive strains of Lb. delbrueckii ssp. bulgaricus,

-

the use of proteinase-negative starter strains to limit the formation of free amino groups,

-

the use of curd washing to remove lactose from the cheese curd.

The propensity of LMMC to brown on baking changes markedly during ripening. Fresh cheese curd (<2–5 days) shows a high propensity to browning; this decreases markedly during the first few weeks of ripening due to the metabolism of lactose and/or galactose by galactose-fermenting starters but increases progressively thereafter owing to the accumulation of small peptides and amino acids.

18.6.4 Cheese Composition

For rennet-curd cheeses , the following factors tend to give melted cheese with high flowability, higher fluidity (as measured by phase angle or loss tangent), and lower apparent viscosity:

-

higher moisture content,

-

lower calcium content,

-

lower pH in the range 5.2 to 6.0,

-

lower protein-to-fat ratio,

-

lower calcium-to-casein ratio

-

higher moisture-to-protein ratio

The effects of these parameters are largely due to reductions in the concentration and volume fraction of the para-casein network or degree of the calcium-induced cross-linking of the para-casein molecules in the network, associated with the lower calcium concentration, or the reduction in the ratio of colloidal (casein-bound) calcium to soluble calcium as the pH is reduced (cf., Sects. 18.3.2–18.3.3). Reducing the fat content of some cheeses, such as low-fat or reduced-fat variants of different varieties (e.g., Cheddar), causes significant impairment of the functional properties (e.g., reduced flow, reduced stretchability, very high viscosity, low fluidity; Fig. 18.10) despite the increase in moisture content. This effect is due the higher volume fraction of the casein network, but also the lower moisture-to-casein ratio which is indicative of a greater degree of fusion of the para-casein polymers constituting the network above .

18.6.5 Effect of Homogenization

Homogenization of milk is an integral part of the manufacturing process for soft, high-fat, acid-curd cheeses such as Cream cheese and Neufchatel, as it prevents creaming (flocculation and floatation of fat globules) during the relatively long gelation time (e.g., >4 h), and contributes to the formation of a homogeneous, thick, creamy texture in the end-product. The resulting textural characteristics ensue from the participation of the homogenized fat particles in the formation of a composite acid gel, which has a greater number of protein-protein interactions and is stiffer and more uniform than the corresponding gel from unhomogenized milk. Homogenization of cheese milk causes shearing of the native protein-phospholipid membrane of the fat globules and its replacement by a protein layer consisting of casein micelles, sub-micelles and whey proteins; this layer around the newly-formed fat globules is frequently denoted the recombined fat globule (RFG) membrane . The RFG membrane causes the fat globules to behave as fat-filled protein (FFP) particles , which can become an integral part of the gel network during acid- and rennet-induced gelation of milk.

In contrast, homogenization of milk or cream is rarely practiced in the manufacture of rennet-curd cheeses because it leads to defects in the resultant cheeses:

-

Poorer ability of the curd particles to knit and mat during manufacture;

-

Increased tendency of moulded curds to break/crack easily, making curd handling more difficult (in the case of Cheddar cheese , the curd tends to shatter during milling, and because of its larger surface area-to-volume ratio absorbs more of the added salt);

-

Increased moisture content (e.g., 1–2 % at a total homogenization pressure of ~20 MPa);

-

Altered curd rheology and texture, with the cheese being more easily fractured (lower facture strain), less elastic, ‘shorter’ and ‘bitty’;

-

Impaired cooking properties of the melted cheese, as reflected by its lack of surface sheen, markedly lower degrees of flow/spread and stringiness, and increased tendency to dry out/burn.

A comparison of flow and fluidity of full-fat cheeses made from control (unhomogenized) or homogenized milks clearly demonstrates the effect of homogenization (Fig. 18.13). While the effects of homogenization are undesirable in most cheese applications requiring moderate-high flow, fluidity and oiling-off, they, nevertheless, are advantageous in applications where a high degree of flow resistance is required (cf. Sect. 18.6.1). The effect of homogenization probably resides mainly in its formation of a recombined fat globule membrane, which stabilizes the fat globules to heat and thereby prevents free oil formation during cooking (baking/grilling). The lack of free oil, which may be considered as a lubricant facilitating relative displacement of the adjoining layers of the cheese matrix during melting, predisposes the cheese to dehydration, crusting, burning, and an inability to flow or form into a fluid, succulent, molten mass.

Effect of fat content and homogenization on the functional properties of Cheddar-type cheeses: flowability and stretchability during ripening at 8 °C, and the loss tangent of the 5-day-old cheeses as a function of temperature on heating from 20 to 90 °C. The cheeses were: full-fat Cheddar from unhomogenized milk (control, 30 % fat; filled circle ), full-fat Cheddar from milk homogenised at first and second stage pressures of 25 and 5 MPa, respectively (30 % fat, open circle), and low-fat Cheddar from unhomgenized milk (1.4 % fat, filled triangle ). Modified from Guinee et al. (2000c)

18.6.6 Cheesemaking Conditions

The functionality of cheeses can be s changed significantly by altering cheesemaking conditions. Several parameters can be varied:

-

Milk standardization, including the level of casein (e.g., which can be altered by ultrafiltration of the milk) and protein-to-fat ratio;

-

Milk pre-treatments, including pasteurization temperature and time, and homogenization pressures, which affect whey protein content and stability of the fat to heat-induced coalescence and destabilization;

-

Type of starter culture, which influences the extent and type of proteolysis, sugar metabolism and propensity to browning;

-

pH at different stages of manufacture including at set (rennet addition), whey drainage, curd salting and plasticization, owing to its effects on the calcium-to-casein ratio and moisture-to-protein ratio;

-

Gel cutting, stirring and cooking conditions (including gel firmness during cutting, rate of heating, stirring speeds, holding time prior to whey drainage), which influence pH and moisture content;

-

Heating, temperature of the curd during cooking and stretching (plasticization) of pasta filata cheeses , which influences residual rennet activity and, ultimately, the level of rennet-induced proteolysis in the cheese;

-

Curd pH at plasticization of pasta filata cheeses, which influences the level of casein-bound calcium and the water -binding capacity of the casein;

-

Salting method of pasta filata cheeses.

Alterations in the above parameters exert their effect on functionality by virtue of their impact of key compositional parameters (e.g., moisture, moisture-to-protein ratio, calcium-to-casein ratio), microstructure (e.g., volume fraction of the casein network, extent of calcium phosphate mediated of cross-linking and aggregation of casein), and macrostructure (e.g., degree to which curd particles flow and knit together into a cohesive structural whole).

Other factors that influence the composition and functionality of cheese include the stage of lactation and diet of the cows, and plant design.

18.7 Dried Cheese Products

Dehydrated cheese products are industrially-produced cheese-based ingredients which were developed for the US Army during World War II as a means of preserving cheese solids under conditions to which natural cheese would not normally be subjected, e.g., a temperature >21 °C for long periods. Since then, they have become ingredients of major economic importance owing to their widespread use as flavouring agents and/or nutritional supplements in a wide range of foods. These include bakery products, biscuits, dehydrated salad dressings, sauces, snack coatings, soups, pasta dishes, savoury baby meals, cheese dips, au gratin potatoes and ready-prepared dinners. They are also included in processed and analogue cheese products as flavouring agents or as a functional ingredient in powdered instant cheese preparations, which can be reconstituted by the consumer for the preparation of instant functional cheeses, e.g., pizza-type cheese, for domestic use. Advantages over natural cheese as an ingredient in the above applications include:

-

convenience of use in fabricated foods. Cheese powders can be applied easily to the surface of snack foods (e.g., popcorn, potato crisps, nachos) or incorporated into food formulations, e.g., by dry mixing with other ingredients such as skim milk powder (e.g., for dried soup, sauce or cake mixes) or by blending into wet formulations. In contrast, natural cheeses require size reduction prior to their use in these applications.

-

their longer shelf-life, because of their lower water activity (aw) than natural cheese. The aw of natural cheeses ranges from ~0.99 for Quark to 0.917 for Parmesan (see Chap. 9); for processed cheese products, it ranges from ~0.93 to 0.97 and from ~0.2–0.3 for various dairy powders. Owing to their relatively high stability, cheese powders may be stored for a long period without alteration or deterioration of quality. In contrast, the changes which occur in natural cheese during storage may influence its usage/functionality, e.g., the ease with which it can be size-reduced or its interaction with other ingredients, and its flavour profile and intensity. Hence, cheese powders are more amenable than natural cheese to inventory management and the formation of end-products (e.g., sauces, soups) with more consistent quality in large-scale manufacturing operations.

-

the greater diversity of flavours that can be provided by cheese powders, made possible by the use of different types of cheese, EMCs and other ingredients in their preparation.

Dehydrated cheese products may be classified into four categories, depending on the ingredients used:

-

1.

Dried grated cheeses , e.g., Parmesan and Romano

-

2.