Abstract

Trigeneration, or combined cooling, heat and power (CCHP), is the process by which electricity, heating and cooling are simultaneously generated from the combustion of a fuel. Trigeneration systems for serving the electricity, thermal and cooling loads in residential districts are a possible solution to enhance energy efficiency, reduce fossil fuel consumption and increase the use of renewable energy sources in the residential sector. Technical, economical and financial issues have to be taken into account when planning a trigeneration system or when expanding an existing generation system. In this chapter a two-step decision support procedure is presented for analysing alternative system configurations. The first step is based on a mixed integer linear programming model that allows to describe the system components in great detail and computes the annual optimal dispatch of the distributed generation system with a hourly discretization, taking into account load profiles, fuel costs and technical constraints. The optimal dispatch is then used for the economic evaluation of the investment, taking into account prices of commodities, taxation, incentives and financial aspects. The procedure allows to compare alternative plant configurations and can be used as a simulation tool, for assessing the system sensitivity to variations of model parameters (e.g. incentives and ratio debt/equity).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Trigeneration systems for serving the electricity, thermal and cooling loads in residential districts are a possible solution to enhance energy efficiency and to reduce fossil fuel consumption. They may include different kinds of generators (e.g. cogeneration units, boilers, electric heat pumps, gas absorption heat pumps, absorption chillers ), as well as hot storages and ice storages. In particular, combined heat and power (CHP) plants, or cogeneration units, allow to recover the combustion heat generated during the production of electricity, obtaining a saving of primal energy, a decrease in production costs of the total energy required and a reduction of CO 2 emissions. The systems are connected to the national electric grid, in order to purchase and sell electricity when needed. Trigeneration systems also represent a chance to increase the use of renewable energy sources in the residential sector: indeed cogeneration units can benefit from the Green Certificate for the produced electricity, if biofuels are used instead of fossil fuel; they are moreover supported with the energy efficiency certificate (White Certificate), if they are qualified as high-efficiency systems.

In this chapter a decision support procedure is introduced for the configuration of distributed generation systems in residential districts, where various types of energy demands (electrical load, thermal loads at various temperatures, cooling load) have to be served. In the configuration process alternative solutions have to be compared, both from a technical and an economical point of view, taking into account the energy consumption profiles that vary along the day and along the year, due to the weather conditions. The decision support procedure consists of two steps, see [1] and [5]. In the first step, by solving the mixed integer linear programming model introduced in Sect. 11.2, the annual optimal dispatch of the distributed generation system is determined with an hourly discretization, taking into account technical constraints, load profiles and fuel costs. The optimal dispatch is then used for the economic evaluation of the investment, taking into account prices of commodities, taxation and financial aspects. Starting from EBITDA (Earnings Before Interest, Taxes, Depreciation and Amortization) and from investment and financial parameters, the net present value (NPV ) of the investment, the payback time (PBT) and the internal rate of return (IRR) (see [6]) are computed. The decision support procedure allows to compare alternative plant configurations; it can also be used as a simulation tool, for assessing the system sensitivity to variations of parameter values. The decision support system is available as a web application (called GDPint) and can be freely accessed at www.rds-web.it. An interface allows the user to define the characteristics of the system components, the load profiles and the prices of the commodities.

A similar application is the “Distributed Energy Resources Customer Adoption Model” (DER-CAM) (see [10]), an economic and environmental model of customer-distributed energy resources adoption. The objective of this model is to minimize the cost of operating on-site generation and combined heat and power systems, either for individual customer sites or a micro-grid. To this aim DER-CAM addresses the following issues:

-

1.

What is the lowest cost combination of distributed generation technologies that a specific customer can install?

-

2.

What is the level of installed capacity of these technologies that minimizes cost?

-

3.

How should the installed capacity be operated so as to minimize the total customer energy bill?

It is assumed that the customer wishes to install distributed generation so as to minimize the cost of the energy consumed on site. Consequently, it is possible to determine the technologies and the capacity the customer is likely to install and to predict when the customer will be self-generating electricity and/or transacting with the power grid and, likewise, when he will be purchasing fuel or using recovered heat. DER-CAM does not allow the user to describe the actual components of the system to be evaluated, as it requires the user to choose the system elements from a given database. GDPint instead allows the user either to select the components from a database or to define the characteristics of the actual elements in the system: for example, for cogeneration units the actual minimum uptime and downtime can be taken into account and efficiency can be defined as a function of load and air temperature. Also the economic evaluation is more detailed in GDPint and allows taking into account how the investment is financed (e.g. the debt/equity ratio and incentives).

In software DCogEN [2, 3, 4] the evaluation of cogeneration districts is based on a much simpler system optimization model, as only one single period is considered at a time; as a consequence, however, intertemporal constraints for modelling the energy levels of electric storages and the minimum uptime and downtime constraints of cogeneration units cannot be included in the system optimization model.

The chapter is organized as follows. In Sect. 11.2 the mixed integer linear programming model is introduced for determining the hourly dispatch of a distributed generation system that minimizes the total generation cost over the time horizon. In Sect. 11.3 the heuristic procedure is described for approximating the optimal solution of large dimensional instances. In Sect. 11.4 a case study is discussed in which decisions on investment in a trigeneration system for a residential district are supported by an extensive analysis, both from a technical and a financial point of view, of five different configurations; in Sect. 11.5 references to investment problems analysed by GDPint are given and future work is outlined.

2 The Model for the Optimal Hourly Dispatchof a Trigeneration System

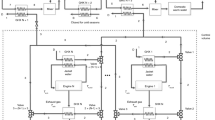

In this section we introduce the mixed integer linear programming model for determining the annual optimal dispatch, with an hourly discretization, of all the resources in a trigeneration system. The economic optimization of the power dispatch takes into account the technical constraints of the system components, the time profiles of the loads and the prices of fuel and electricity. The trigeneration system may include different kind of generators (cogeneration units, boilers, electric heat pumps, gas absorption heat pumps, absorption chillers, etc.) for serving different kinds of loads (electrical load, thermal loads at various temperatures, cooling load). A set of binary parameters describes the system topology, i.e. the power flows from generators to storages and loads. The thermal loads may be served by different generators, such as boilers, electric heat pumps, gas absorption heat pumps, cogeneration units and hot storages. The cooling load may be served by absorption chillers, reversible electric heat pumps, reversible gas absorption heat pumps and ice storages. The electrical load, which includes the electricity used by heat pumps and absorption chillers, may be generated by cogeneration units and/or purchased on the market, the system being connected to the national grid. Excess electricity production can be sold on the market.

A detailed model of each system component is considered. Each absorption chiller is characterized by capacity, electric coefficient of performance and thermal coefficient of performance. Each boiler is characterized by maximum heating rate and fuel consumption function. Each electric heat pump is characterized by heating capacity, cooling capacity (if reversible), energy efficiency ratio and coefficient of performance, both dependent on the air temperature. Each gas absorption heat pump is characterized by heating capacity, cooling capacity (if reversible), electric coefficient of performance and fuel consumption rate. Each cogeneration unit is characterized by its minimum and maximum electrical power outputs, minimum uptime and downtime, heat recovery function and fuel consumption function. For all generators operation and maintenance cost per output unit are given. Hot storages and ice storages are characterized by maximum stored energy, energy rate from source to load and loss coefficients. The hourly dispatch is computed so as to minimize the total costs minus the revenues from the sale of electricity to the grid.

The notation of the proposed model is provided below for quick reference.

2.1 Sets

- H :

-

Set of temperature levels of thermal loads, indexed by h

- R :

-

Set of absorption chillers, indexed by r

- B :

-

Set of boilers, indexed by b

- P :

-

Set of electric heat pumps, indexed by p

- G :

-

Set of gas absorption heat pumps, indexed by g

- M :

-

Set of cogeneration units, indexed by m

- K :

-

Set of ice storages, indexed by k

- J :

-

Set of hot storages, indexed by j

- T :

-

Set of hours, indexed by t

2.2 Parameters

-

For absorption chiller r ∈ R:

- \(C_{r}^{O}\) :

-

Operation and maintenance cost per unit of thermal output

- \(\overline{\dot{Q}}_{r}^{C}\) :

-

Capacity

- \(U_{r}^{E}\) :

-

Electric coefficient of performance

- \(U_{r,h}^{H}\) :

-

Thermal coefficient of performance

- α r, h :

-

Binary parameter set to 1 if absorption chiller r can use h-temperature thermal power

-

For boiler b ∈ B:

- \(C_{b}^{O}\) :

-

Operation and maintenance cost per unit of thermal output

- \(C_{b}^{F}\) :

-

Fuel specific cost

- \(\overline{\dot{Q}}_{b}^{H}\) :

-

Maximum heating rate

- F b :

-

Fuel consumption per unit of thermal output

- α b, h :

-

Binary parameter set to 1 if boiler b generates h-temperature thermal power

-

For electric heat pump p ∈ P:

- \(C_{p}^{O}\) :

-

Operation and maintenance cost per unit of thermal output

- \(\overline{\dot{Q}}_{p}^{H}\) :

-

Heating capacity

- \(\overline{\dot{Q}}_{p}^{C}\) :

-

Cooling capacity (if electric heat pump is reversible)

- EER p, t :

-

Energy efficiency ratio (depends on the air temperature in hour t)

- COP p, t :

-

Coefficient of performance (depends on the air temperature in hour t)

- ρ p :

-

Binary parameter set to 1 if electric heat pump p can generate cold

- α p, h :

-

Binary parameter set to 1 if electric heat pump p generates h-temperature thermal power

-

For gas absorption heat pump g ∈ G:

- \(C_{g}^{O}\) :

-

Operating and maintenance cost per unit of thermal output

- \(C_{g}^{F}\) :

-

Fuel-specific cost

- \(F_{g}^{C}\) :

-

Fuel consumption per unit of cooling output

- \(F_{g}^{H}\) :

-

Fuel consumption per unit of thermal output

- \(U_{g}^{E}\) :

-

Electric coefficient of performance

- \(\overline{\dot{Q}}_{g}^{H}\) :

-

Heating capacity

- \(\overline{\dot{Q}}_{g}^{C}\) :

-

Cooling capacity (if gas absorption heat pump is reversible)

- ρ g :

-

Binary parameter set to 1 if gas absorption heat pump g can generate cold

- α g, h :

-

Binary parameter set to 1 if gas absorption heat pump g generates h-temperature thermal power

-

For cogeneration unit m ∈ M:

- \(C_{m}^{O}\) :

-

Operation and maintenance cost per unit of power output

- \(C_{m}^{F}\) :

-

Fuel-specific cost

- \(\underline{W}_{m}\) :

-

Minimum power

- \(\overline{W}_{m}\) :

-

Maximum power

- \(t_{m}^{U}\) :

-

Minimum uptime

- \(t_{m}^{D}\) :

-

Minimum downtime

- \(q_{m}^{(1)}\) :

-

Slope of the heat recovery function

- \(q_{m}^{(0)}\) :

-

Intercept of the heat recovery function

- \(F_{m}^{(1)}\) :

-

Slope of the fuel consumption function

- \(F_{m,t}^{(0)}\) :

-

Intercept of the fuel consumption function

- α m, h :

-

Binary parameter set to 1 if cogeneration unit m generates h-temperature thermal power

-

For ice storage k ∈ K:

- \(\overline{Q}_{k}^{C}\) :

-

Maximum stored energy

- \(Q_{k,0}^{C}\) :

-

Energy stored at the beginning of the first hour

- \(\overline{\dot{Q}}_{i}^{C,in}\) :

-

Energy rate from source

- \(\overline{\dot{Q}}_{k}^{C,out}\) :

-

Energy rate to load

- \(l_{k}^{C,in}\) :

-

Input loss coefficient (\(0 \leq l_{k}^{C,in} \leq 1\))

- \(l_{k}^{C,out}\) :

-

Output loss coefficient (\(l_{k}^{C,out} \geq 1\))

- \(l_{k}^{C}\) :

-

Tank loss coefficient (\(0 \leq l_{k}^{C} \leq 1\))

-

For hot storage j ∈ J:

- \(\overline{Q}_{j}^{H}\) :

-

Maximum stored energy

- \(Q_{j,0}^{H}\) :

-

Energy stored at the beginning of the first hour

- \(\overline{\dot{Q}}_{j}^{H,in}\) :

-

Maximum thermal input

- \(\overline{\dot{Q}}_{j}^{H,out}\) :

-

Maximum thermal output

- \(l_{j}^{H,in}\) :

-

Input loss coefficient (\(0 \leq l_{j}^{H,in} \leq 1\))

- \(l_{j}^{H,out}\) :

-

Output loss coefficient (\(l_{j}^{H,out} \geq 1\))

- \(l_{j}^{H}\) :

-

Tank loss coefficient (\(0 \leq l_{j}^{H} \leq 1\))

- \(\alpha _{j,h}^{in}\) :

-

Binary parameter set to 1 if the input of hot storage j is h-temperature thermal power

- \(\alpha _{j,h}^{out}\) :

-

Binary parameter set to 1 if the output of hot storage j is h-temperature thermal power

-

Loads, outputs of non-dispatchable power plants and electricity prices in hour t ∈ T:

- \(L_{t}^{E}\) :

-

Electrical load

- \(L_{t}^{C}\) :

-

Cooling load

- \(L_{h,t}^{H}\) :

-

h-temperature thermal load

- \(L_{t}^{P}\) :

-

Photovoltaic production

- \(L_{t}^{S}\) :

-

Solar thermal production

- \(\alpha _{h}^{S}\) :

-

Binary parameter set to 1 if the solar thermal plant generates h-temperature thermal power

- μ t :

-

Purchase price of electricity

- λ t :

-

Sale price of electricity

-

Data related to the electricity market:

- \({\overline{W}}^{A}\) :

-

Maximum power that can be purchased from the grid

- \({\overline{W}}^{V }\) :

-

Maximum power that can be sold to the grid

Finally, let \(\hat{T}\) denote the subset of hours in which the electricity purchase price μ t is less than the electricity sale price λ t : for these hours constraints are introduced in the model so as to avoid arbitrage.

2.3 Decision Variables

The following symbols denote the decision variables pertaining to hour t ∈ T:

-

For absorption chiller r ∈ R:

- \(\dot{Q}_{r,t}^{C}\) :

-

Cooling power production of absorption chiller r

-

For boiler b ∈ B:

- \(\dot{Q}_{b,h,t}^{H}\) :

-

h-temperature thermal power production of boiler b

-

For electric heat pump p ∈ P:

- \(\dot{Q}_{p,t}^{C}\) :

-

Cooling power production of electric heat pump p

- \(\dot{Q}_{p,h,t}^{H}\) :

-

h-temperature thermal power production of electric heat pump p

-

For gas absorption heat pump g ∈ G:

- \(\dot{Q}_{g,t}^{C}\) :

-

Cooling power production of gas absorption heat pump g

- \(\dot{Q}_{g,h,t}^{H}\) :

-

h-temperature thermal power production of gas absorption heat pump g

-

For cogeneration unit m ∈ M:

- \(\dot{Q}_{m,h,t}^{H}\) :

-

h-temperature thermal power production of cogeneration unit m

- W m, t :

-

Power output of cogeneration unit m

- γ m, t :

-

Status of cogeneration unit m (on, if γ m, t = 1; off, if γ m, t = 0)

-

For ice storage k ∈ K:

- \(Q_{k,t}^{C}\) :

-

Energy stored in ice storage k at the end of the hour

- \(\dot{Q}_{k,t}^{C,in}\) :

-

Energy rate from source of ice storage k

- \(\dot{Q}_{k,t}^{C,out}\) :

-

Energy rate to load of ice storage k

-

For hot storage j ∈ J:

- \(Q_{j,t}^{H}\) :

-

Energy stored in hot storage j at the end of the hour

- \(\dot{Q}_{j,h,t}^{H,in}\) :

-

h-temperature power output of hot storage j

- \(\dot{Q}_{j,h,t}^{H,out}\) :

-

h-temperature power input of hot storage j

-

Variables related to exchanges on the electricity market in hour t ∈ T:

2.4 The Mixed Integer Linear Programming Model

The optimal scheduling of the trigeneration plant is determined by solving the mixed integer linear programming model

subject to the following constraints:

-

For t ∈ T

$$\displaystyle\begin{array}{rcl} \sum _{m\in M}W_{m,t} + L_{t}^{P} + W_{ t}^{A}& =& L_{ t}^{E} +\sum _{ r\in R}U_{r}^{E}\dot{Q}_{ r,t}^{C} +\sum _{ p\in P}\left ( \frac{\dot{Q}_{p,t}^{C}} {EER_{p,t}} + \frac{\sum _{h\in H}\dot{Q}_{g,h,t}^{H}} {COP_{p,t}} \right ) + \\ & & +\sum _{g\in G}\left [U_{g}^{E}\left (\dot{Q}_{ g,t}^{C} +\sum _{ h\in H}\dot{Q}_{p,h,t}^{H}\right )\right ] + W_{ t}^{V } {}\end{array}$$(11.2) -

For \(t \in \hat{ T}\)

$$\displaystyle{ \theta _{t} \in \left \{0,1\right \} }$$(11.3)$$\displaystyle{ 0\: \leq W_{t}^{A}\: \leq \:{\overline{W}}^{A}(1 -\theta _{ t}) }$$(11.4)$$\displaystyle{ 0\: \leq W_{t}^{V }\: \leq \:{\overline{W}}^{V }\theta _{ t} }$$(11.5) -

For t ∈ T

$$\displaystyle{ \sum _{r\in R}\dot{Q}_{r,t}^{C} +\sum _{ p\in P}\rho _{p}\dot{Q}_{p,t}^{C} +\sum _{ g\in G}\rho _{g}\dot{Q}_{g,t}^{C} +\sum _{ i\in I}\dot{Q}_{i,t}^{C,out} \geq L_{ t}^{C} +\sum _{ i\in I}\dot{Q}_{i,t}^{C,in} }$$(11.6) -

For h ∈ H and t ∈ T

$$\displaystyle\begin{array}{rcl} & & \alpha _{h}^{S}L_{ t}^{S} +\sum _{ b\in B}\alpha _{b,h}\dot{Q}_{b,h,t}^{H} +\sum _{ p\in P}\alpha _{p,h}\dot{Q}_{p,h,t}^{H} +\sum _{ g\in G}\alpha _{g,h}\dot{Q}_{g,h,t}^{H} +\sum _{ m\in M}\alpha _{m,h}\dot{Q}_{m,h,t}^{H} + \\ & & +\sum _{j\in J}\alpha _{j,h}^{out}\dot{Q}_{ j,h,t}^{H,out} \geq L_{ h,t}^{H} +\sum _{ r\in R}\alpha _{r,h}U_{r,h}^{H}\dot{Q}_{ r,t}^{C} +\sum _{ j\in J}\alpha _{j,h}^{in}\dot{Q}_{ j,h,t}^{H,in} {}\end{array}$$(11.7) -

For r ∈ R and t ∈ T

$$\displaystyle{ 0\: \leq \:\dot{ Q}_{r,t}^{C}\: \leq \:\overline{\dot{Q}}_{ r}^{C} }$$(11.8) -

For b ∈ B and t ∈ T

$$\displaystyle{ 0\: \leq \:\sum _{h\in H}\dot{Q}_{b,h,t}^{H}\: \leq \:\overline{\dot{Q}}_{ b}^{H} }$$(11.9) -

For p ∈ P and t ∈ T

$$\displaystyle{ 0\: \leq \dot{ Q}_{p,t}^{C}\: \leq \:\overline{\dot{Q}}_{ p}^{C} }$$(11.10)$$\displaystyle{ 0\: \leq \sum _{h\in H}\dot{Q}_{p,h,t}^{H}\: \leq \:\overline{\dot{Q}}_{ p}^{H} }$$(11.11)$$\displaystyle{ \frac{\dot{Q}_{p,t}^{C}} {\:\:\overline{\dot{Q}}_{p}^{C}\:\:} + \frac{\sum _{h\in H}\dot{Q}_{p,h,t}^{H}} {\:\:\overline{\dot{Q}}_{p}^{H}\:\:} \: \leq \: 1 }$$(11.12) -

For g ∈ G and t ∈ T

$$\displaystyle{ 0\: \leq \dot{ Q}_{g,t}^{C}\: \leq \:\overline{\dot{Q}}_{ g}^{C} }$$(11.13)$$\displaystyle{ 0\: \leq \sum _{h\in H}\dot{Q}_{g,h,t}^{H}\: \leq \:\overline{\dot{Q}}_{ g}^{H} }$$(11.14)$$\displaystyle{ \frac{\dot{Q}_{g,t}^{C}} {\:\:\overline{\dot{Q}}_{g}^{C}\:\:} + \frac{\sum _{h\in H}\dot{Q}_{g,h,t}^{H}} {\:\:\overline{\dot{Q}}_{g}^{H}\:\:} \: \leq \: 1 }$$(11.15) -

For m ∈ M and t ∈ T

$$\displaystyle{ \gamma _{m,t} \in \left \{0,1\right \} }$$(11.16)$$\displaystyle{ \sum _{\tau =t+1}^{\min (t+t_{m}^{U}-1,\left \vert T\right \vert ) }\gamma _{m,\tau } \geq \min \left (t_{m}^{U} - 1,\left \vert T\right \vert - t\right )\left (\gamma _{ m,t} -\gamma _{m,t-1}\right ) }$$(11.17)$$\displaystyle{ \sum _{\tau =t+1}^{\min (t+t_{m}^{D}-1,\left \vert T\right \vert ) }\left (1 -\gamma _{m,\tau }\right ) \geq \min \left (t_{m}^{D} - 1,\left \vert T\right \vert - t\right )\left (\gamma _{ m,t-1} -\gamma _{m,t}\right ) }$$(11.18)$$\displaystyle{ \underline{W}_{m}\gamma _{m,t}\: \leq \: W_{m,t}\: \leq \:\overline{W}_{m}\gamma _{m,t} }$$(11.19)$$\displaystyle{ 0\: \leq \:\sum _{h\in H}\dot{Q}_{m,h,t}^{H}\: \leq \: q_{ m}^{(0)}\gamma _{ m,t} + q_{m}^{(1)}W_{ m,t} }$$(11.20) -

For k ∈ K and t ∈ T

$$\displaystyle{ Q_{k,t}^{C} = \left (1 - l_{ k}^{C}\right )Q_{ k,t-1}^{C} +\ l_{ k}^{C,in}\dot{Q}_{ k,t}^{C,in} -\ l_{ k}^{C,out}\dot{Q}_{ k,t}^{C,out} }$$(11.21)$$\displaystyle{ 0\: \leq \: Q_{k,t}^{C}\: \leq \:\overline{Q}_{ k}^{C} }$$(11.22)$$\displaystyle{ 0\: \leq \:\dot{ Q}_{k,t}^{C,in}\: \leq \:\overline{\dot{Q}}_{ k}^{C,in} }$$(11.23)$$\displaystyle{ 0\: \leq \:\dot{ Q}_{k,t}^{C,out}\: \leq \:\overline{\dot{Q}}_{ k}^{C,out} }$$(11.24) -

For j ∈ J and t ∈ T

$$\displaystyle{ Q_{j,t}^{H} = \left (1 - l_{ j}^{H}\right )Q_{ j,t-1}^{H}+\ l_{ j}^{H,in}\sum _{ h\in H}\alpha _{j,h}^{in}\dot{Q}_{ j,h,t}^{H,in}-\ l_{ j}^{H,out}\sum _{ h\in H}\alpha _{j,h}^{out}\dot{Q}_{ j,h,t}^{H,out} }$$(11.25)$$\displaystyle{ 0\: \leq \: Q_{j,t}^{H}\: \leq \:\overline{Q}_{ j}^{H} }$$(11.26)$$\displaystyle{ 0\: \leq \:\sum _{h\in H}\alpha _{j,h}^{in}\dot{Q}_{ j,h,t}^{H,in}\: \leq \:\overline{\dot{Q}}_{ j}^{H,in} }$$(11.27)$$\displaystyle{ 0\: \leq \:\sum _{h\in H}\alpha _{j,h}^{out}\dot{Q}_{ j,h,t}^{H,out}\: \leq \:\overline{\dot{Q}}_{ j}^{H,out} }$$(11.28)

The objective function (11.1), to be minimized, represents the total cost, in a typical year, for satisfying the electrical, cooling and thermal loads, minus the revenues from the sold electricity. The net costs related to hour t consist of seven terms: the first term represents the operation and maintenance costs of the absorption chillers; the second term expresses the fuel cost and the operation and maintenance costs of the boilers; the third term represents the operation and maintenance costs for generating cooling and thermal power by electric heat pumps; the fourth term represents the fuel costs and the operation and maintenance costs of the gas absorption heat pumps; the fifth term expresses the fuel costs and the operation and maintenance costs of the cogeneration units; the sixth term represents the cost for purchasing electricity from the market; and the seventh term represents the revenues from electricity sold into the market. In the fifth term the fuel-specific cost \(C_{m}^{F}\) of cogeneration unit m is multiplied by the fuel consumption in hour t, given by the affine function \(F_{m}^{MI}\) of power output W m, t

where the intercept \(F_{m,t}^{(0)} > 0\) depends on the air temperature in hour t.

Constraint (11.2) imposes the electric balance in every hour t. The total electricity supply is given by the production of cogeneration units and the output of photovoltaic plants. The electricity demand consists of four terms: the first term is the electrical load; the second term represents the electricity required by the absorption chillers for generating cooling power; the third and fourth terms express the electricity required by the electric heat pumps and by the gas absorption heat pumps. This constraint determines the amount \(W_{t}^{A}\) of electricity to be purchased from the market, if production is not sufficient to satisfy the hourly demand, or the amount W t V of electricity to be sold into the market, if production exceeds the hourly demand. Constraints (11.3), (11.4) and (11.5) state that in every hour \(t \in \hat{ T}\), in which the purchase price μ t is smaller than the sale price λ t , electricity cannot be simultaneously purchased and sold (“no-arbitrage” constraints).

Constraint (11.6) guarantees that the cooling load is served in hour t, i.e. the cooling power generated by absorption chillers, electric heat pumps and gas absorption heat pumps, plus the output of ice storages, is required not to be less than the sum of the cooling load and of the input of ice storages.

Constraint (11.7) requires the h-temperature thermal load to be served in hour t. The binary parameters \(\alpha _{h}^{S}\), \(\alpha _{r,h}\), α b, h , α p, h , α g, h , α m, h , \(\alpha _{j,h}^{out}\) and \(\alpha _{j,h}^{in}\) identify the devices (absorption chillers, boilers, electric heat pumps, gas absorption heat pumps, cogeneration units, solar thermal plants and hot storages, respectively) used for serving the h-temperature thermal load. The total production plus the output of hot storages cannot be less than the sum of the load, of the thermal power used by the absorption chillers and of the input of hot storages.

Constraint (11.8) imposes that the cooling power generated by absorption chiller r in hour t is nonnegative and bounded above by its capacity. Analogous restriction is expressed by constraints (11.10) and (11.13) for electric heat pump p and gas absorption heat pump g, respectively.

Constraint (11.9) states that the total thermal power generated by boiler b in hour t is nonnegative and bounded above by its capacity. Constraints (11.11) and (11.14) express analogous restrictions for electric heat pump p and gas absorption heat pump g, respectively.

Constraint (11.12) guarantees that electric heat pump p cannot simultaneously generate both cooling and thermal powers. Analogous restriction is expressed by constraint (11.15) for the gas absorption heat pump g.

The status of cogeneration unit m is represented by the binary variable γ m, t defined in constraint (11.16). Constraint (11.17) imposes that if cogeneration unit m is started up in hour t, it must be on either for the minimum uptime, if \(t + t_{m}^{U} - 1 < \left \vert T\right \vert \), or until the last hour \(\left \vert T\right \vert \), otherwise. Analogously, constraint (11.18) imposes that if cogeneration unit m is shut down in hour t, it must be off either for the minimum downtime, if \(t + t_{m}^{D} - 1 < \left \vert T\right \vert \), or until the last hour \(\left \vert T\right \vert \), otherwise. Constraint (11.19) states that in hour t the power production is between the minimum and the maximum power output, if its status is on, otherwise is 0. The associated thermal output is guaranteed by constraint (11.20) to be nonnegative and bounded above by the maximum thermal output, if its status is on, otherwise is 0. The maximum thermal output in hour t is given by the heat recovery function of cogeneration unit m, which is the affine function \(Q_{m}^{MI}\) of power output W m, t

with \(q_{m}^{(0)} > 0\).

The energy stored in ice storage k at the end of hour t, which is required by constraint (11.22) to be nonnegative and bounded above by the maximum storable energy, must satisfy the balance constraint (11.21). Constraints (11.23) and (11.24) impose that the input energy rate and the output energy rate of ice storage k in every hour t are nonnegative and bounded above by their maximum values, respectively. Analogously, the energy stored in hot storage j at the end of hour t, which is required by constraint (11.26) to be nonnegative and bounded above by the maximum storable energy, must satisfy the balance constraint (11.25). Constraints (11.27) and (11.28) guarantee that the thermal input and the thermal output of the hot storage j in every hour t are nonnegative and bounded above by their maximum values, respectively.

3 A Heuristic Procedure for Large Instances

The solution of the mixed integer linear programming model for the optimal annual dispatch requires to consider the set T of cardinality \(\left \vert T\right \vert = 8760\), because of the hourly discretization. The computational effort may therefore become a substantial issue, as the cardinality of the sets H, R, B, P, G, M, K, J and \(\hat{T}\) increases. In this section a heuristic procedure is introduced for approximating the optimal solution. The procedure consists of the three steps, A, B and C, described below.

In step A the following mixed integer linear programming model is solved:

subject to

-

For m ∈ M and t ∈ T

$$\displaystyle{ 0\: \leq \: W_{m,t}\: \leq \:\overline{W}_{m} }$$(11.32)$$\displaystyle{ 0\: \leq \:\sum _{h\in H}\dot{Q}_{m,h,t}^{H}\: \leq \:\left (q_{ m}^{(1)} + \frac{q_{m}^{(0)}} {\overline{W}_{m}} \right )W_{m,t} }$$(11.33)

The mixed integer linear programming model (11.31), (11.32), (11.33), (11.2) to (11.15) and (11.21) to (11.28) is based on the following assumptions:

-

1.

The fuel consumption of cogeneration unit m ∈ M is proportional to the power produced; therefore, in the fifth term of (11.31) the linear fuel consumption function

$$\displaystyle{ \left (F_{m}^{(1)} + \frac{F_{m,t}^{(0)}} {\overline{W}_{m}} \right )W_{m,t} }$$(11.34)is used.

-

2.

The cogenerator heat recovery is proportional to the power produced; therefore, in constraint (11.33) the upper bound to thermal output is expressed by the linear heat recovery function

$$\displaystyle{ \left (q_{m}^{(1)} + \frac{q_{m}^{(0)}} {\overline{W}_{m}} \right )W_{m,t}. }$$(11.35) -

3.

The minimum power output of cogeneration unit m ∈ M is zero, as expressed by constraint (11.32).

-

4.

The cogeneration units are not subject to minimum up time and minimum downtime constraints; therefore, constraints (11.17) and (11.18) are neglected.

The four hypotheses above imply that the binary variables γ m, t are no longer needed, which allow definition (11.16) to be neglected. Let \(W_{m,t}^{{\ast}}\) denote the optimal power production of cogeneration unit m in hour t determined by the approximated model.

In step B the binary parameter \(\gamma _{m,t}^{{\ast}}\), for m ∈ M and t ∈ T, is first assigned the value \(\gamma _{m,t}^{{\ast}} = 1\), if \(W_{m,t}^{{\ast}}\geq \underline{ W}_{m}\), or \(\gamma _{m,t}^{{\ast}} = 0\), otherwise. The values of parameters \(\gamma _{m,t}^{{\ast}}\) are then suitably redefined, if necessary, in order to satisfy minimum up time and minimum downtime constraints.

In step C the objective function (11.1) is minimized subject to constraints (11.2) to (11.15) and (11.21) to (11.28), where variables γ m, t , for m ∈ M and t ∈ T, are assigned the values \(\gamma _{m,t}^{{\ast}}\) computed in step B.

4 The Economic Evaluation of the Trigeneration System

After the simulation of one year of optimized operation of the trigeneration district, the procedure computes the EBITDA (Earnings Before Interest, Taxes, Depreciation and Amortization) that depends on the optimal values of the decision variables \(W_{t}^{A}\), \(W_{t}^{V }\), γ m, t , W m, t , \(\dot{Q}_{b,h,t}^{H}\), \(\dot{Q}_{g,t}^{C}\) and \(\dot{Q}_{g,h,t}^{H}\) resulting from the optimization model

The first term of EBITDA in (11.36) is the value of total energy load:

-

The electrical load is evaluated at the electricity purchase price.

-

The value of the cooling load is the cost of the electricity needed to satisfy it by an electric heat pump of coefficient of performance COP rif.

-

The value of the total thermal load is the cost of the fuel needed to satisfy it by a boiler of efficiency EER rif.

The reference values COP rif and EER rif are chosen by the user. If the expansion of an existing plant is under evaluation, the parameters COP rif and EER rif may be assigned the values characterizing the corresponding components in the existing plant: this allows the expanded plant to be compared, in terms of reduction of generation costs, with respect to the existing one. The second term of EBITDA in (11.36) represents the net revenues from selling electricity to the grid. The third and fourth terms represent the fixed and variable costs of cogeneration units and boilers, respectively. The fifth and sixth terms represent fixed and variable costs of gas absorption heat pumps. The last four terms are the fixed costs of absorption chillers, electric heat pumps, ice storages and hot storages, respectively.

Cooling and thermal loads, \(L_{t}^{C}\) and \(L_{h,t}^{H}\), as well as the intercept \(F_{m,t}^{(0)}\) of the fuel consumption function of cogeneration unit m, depend on the air temperature in hour t, which is not known with certainty when investment decisions have to be taken. Further uncertainties are related to fuel prices and market electricity prices. For these uncertainties to be taken into account explicitly, a stochastic programming model should be solved, with uncertainties of the above-mentioned model parameters represented by a scenario tree. In real instances, however, the solution of the stochastic optimization problem corresponding to the problem under study requires a computational time not compatible with an on-line use of the decision support procedure. Planned future work will be concerned with computing lower and upper bounds of the optimal objective function value of the stochastic model: this will be done by solving a set of stochastic subproblems, each one with a very small number of scenarios (e.g. two or three), and by evaluating, at different levels of information, how the deterministic solution performs in the stochastic framework, following [7] and [8], respectively. In the current version of the decision support procedure the user can introduce information related to the variability of weather conditions, which influences load and efficiency, by assigning up to three sets of yearly data for air temperatures (in order to represent three possible situations: warm, cold and average) with the associated probability of occurrence. Analogously, the user can introduce information related to the variability of prices by assigning up to three sets of yearly data and the associated probability of occurrence. An average EBITDA is computed if variability of input parameters is taken into account. Also, in order to better describe the expansion of a trigeneration system, the evolution in time of the system configuration may be taken into account and the optimal annual dispatch is determined for each configuration of the system, e.g. a transitional configuration in the first year, in which a reduced energy load is served, and a final configuration. For each configuration the corresponding average EBITDA is computed.

The methodology used to assess the profitability of the trigeneration system is based on the analysis of annual cash flows, in accordance with the instructions contained in [6].

5 Case Studies

In [11] the decision support system has been used for assessing the profitability of a new investment in a CHP system fed by biofuel and for comparing it with a natural gas boiler. In such a comparison several aspects have been taken into account, like incentives, volatility of biofuel prices, higher investment costs of CHP plants and a low load factor (i.e. concentration in few hours) of the thermal load in the residential district. The optimal dispatch of the system has therefore to be determined considering the irregular profiles of space heating and domestic hot water demands, the technical features of different generators (boilers and CHPs), like minimum power output, flexibility constraints and efficiency, and the variability of commodity prices (for electric energy) every hour. The use of a biofuel in distributed power plant, with capacity not greater than 1 MW, allows to apply for either the all-inclusive feed-in tariff or the Green Certificates (see [9]). The sensitivity of the investment profitability has been analysed under different hypotheses of biofuel price. The evaluation has been performed using both community and extra-community bio-oils, which have different prices and benefit from different incentive mechanisms.

In this chapter we consider a residential district of typical dimensions in Northern Italy, consisting of 359 flats of small size (50 m 2 on average), with a total surface of 18 000 m 2 and volume 52 000 m 3, to be served by a trigeneration system for providing space heating, cooling and domestic hot water (DHW). The annual energy loads and their peaks are shown in Table 11.1. The total thermal load consists of two parts: demand of district heating and demand of domestic hot water.

The system configurations to be compared, which are defined in Table 11.2, are subsets of the following set of components:

-

Turbec T100 gas microturbine, with rated electrical power 105 kW and rated thermal power 167 kW

-

Condensing boiler, with rated thermal power 978 kW

-

Condensing boiler, with rated thermal power 300 kW

-

Condensing boiler, with rated thermal power 600 kW

-

4000 L tank, with thermal power 250 kW (input/output) and capacity 200 kWh, for hot storage

-

Array of 15 non-reversible gas absorption heat pumps GAHP-A-LT, each of 41.7 kW rated thermal power, with total thermal power 625.5 kW

-

Array of 15 reversible gas absorption heat pumps GAHP-AR-LT, with total thermal power 562.5 kW and total cooling power 253.5 kW

-

Array of reversible electric heat pumps, with total thermal power 550 kW and total cooling power 400 kW

-

Ammonia-water absorption chiller, with cooling power 88.6 kW

-

5370 L ice storage, with cooling power 250 kW and capacity 500 kWh

In Case 1 the thermal load for space heating and domestic hot water is satisfied by the reversible electric heat pumps, which also supply the cooling load, and by two condensing boilers (boilers 1 and 2, with total power 1278 kW). The hot water for the DHW demand is stored in the tank. Electricity is purchased on the market. The optimization model determines which source of heat will serve the thermal load in each hour, taking into account the hourly electricity price, the air temperature and the load levels. Table 11.3 shows that in the optimal solution about 25% of the thermal load is supplied by the electric heat pumps, which are more convenient than boilers when the electricity price is low and the thermodynamic cycle that depends on the air temperature is efficient. In this solution the total cost for providing space heating and DHW is less than the total cost of producing the required thermal power by a small boiler located in each flat (Fig. 11.1).

In Case 2 the cogeneration unit is added to the system considered in Case 1. The cooling load is served by the reversible electric heat pumps. Electricity may be either purchased on the market or produced by the cogeneration unit. Reversible electric heat pumps, condensing boilers and the cogeneration unit satisfy the thermal load for space heating and domestic hot water. In the optimal solution the reversible electric heat pumps supply the thermal load in hours in which the electricity price is low and the thermodynamic cycle that depends on the air temperature is efficient. The electricity load, as well as the electricity used by the electric heat pumps, is supplied by the market when the price is low, otherwise by the cogeneration unit: this happens in many hours during the summer, as well as in hours with high electricity prices—in these cases the cogeneration unit satisfies a portion of the electrical load and the thermal power output is either used for serving the DHW demand or stored in the tank for use in subsequent hours, if it exceeds the thermal load. In some hours it is convenient to generate electrical power by the cogeneration unit, even if the recovered thermal power is wasted: this corresponds to the thermal surplus reported in Table 11.3, which is about 0.75% of the total cogenerated heat. In the optimal solution the cogeneration unit works for 4, 751 equivalent hours per year, yielding an expected life of 14 years for the microturbine, the total number of working hours being 66, 000 h (Fig. 11.2).

In Case 3 the array of non-reversible gas absorption heat pumps is added to the system considered in Case 1. Table 11.3 shows that the thermal load is mainly satisfied by gas absorption heat pumps, as they use less natural gas than boilers: this is due to the fact that gas absorption heat pumps have a much higher Gas Utilization Efficiency than boilers (up to 150%), because a part of the thermal energy is taken from the air. The electric heat pumps are used almost exclusively for the cooling load (see Table 11.4) (Fig. 11.3).

In Case 4 both the cogeneration unit and the array of non-reversible gas absorption heat pumps are added to the system considered in Case 1. The model suggests that the reversible electric heat pumps satisfy the thermal load in hours when the electricity price is low and the air temperature allows an efficient thermodynamic cycle. The electricity load, as well as the electricity used by the electric heat pumps, is supplied by the market when the price is low, otherwise by the cogeneration unit, which produces the required electricity, while the recovered heat is used for satisfying the thermal load. As shown in Table 11.3 most of the thermal power demand is satisfied by gas absorption heat pumps, which use less natural gas than boilers; a small amount is supplied by the most convenient source among heat pumps and boilers (depending on hourly electricity price, air temperature and load levels) and the remaining part by the cogeneration unit. Table 11.5 shows that most of the electricity is provided by the cogeneration unit. High volumes of purchased and sold electricity are due to the hourly market prices that in some hours make it convenient to either sell or purchase electricity. In the optimal solution the cogeneration unit works only for 3, 465 hours per year, yielding an expected life of about 20 years for the microturbine. This system configuration requires the highest investment among the six considered, but yields the highest EBITDA (see Table 11.7) (Fig. 11.4).

In Case 5 the trigeneration system consists of the cogeneration unit, two condensing boilers (boilers 1 and 3, with total power 1578 kW), the hot water tank for supplying DHW demand and the absorption chiller coupled with the ice storage, as absorption chillers (unlike electrical heat pumps) can produce very low temperatures (e.g. −33∘C). In the absence of electric heat pumps, boiler 3, with 600 kW maximum heating rate, is used instead of boiler 2, with 300 kW maximum heating rate, in order to guarantee satisfying the peak demand of thermal power. This configuration is useful when it is preferred to reduce the amount of electricity purchased from the market (see Table 11.5). In the optimal solution the cogeneration unit works for 6 055 equivalent hours per year, yielding an expected life of 11 years for the microturbine (Fig. 11.5).

In Case 6 the configuration differs from the one in Case 3 as the array of reversible electric heat pumps is no longer included in the system and the cooling load is served by the array of reversible gas absorption heat pumps, coupled with the ice storage. In this configuration reversible gas absorption heat pumps serve both the thermal and the cooling loads, obtaining a decrease of the electrical load and requiring much lower investment cost with respect to Case 3. On the other hand, the cooling power production by reversible gas absorption heat pumps is less convenient than by reversible electric heat pumps (see the annual consumption of natural gas and electricity in Table 11.6); therefore, a lower EBITDA than in Case 3 is obtained, as shown in Table 11.7.

In Tables 11.3, 11.4 and 11.5 the results obtained by the optimal dispatch model in the six configurations are reported in aggregated form. The total energy supplied by every generator and the total energy of every usage in the year is reported for every case. A generator is not included in the trigeneration system if the sign “−” appears in the corresponding column (Fig. 11.6).

Based on [6], the analysis of annual cash flows is performed in order to assess the profitability of the different configurations of the trigeneration district. An industrial life of 20 years is considered, assuming that the worn parts of the cogeneration plant are replaced in Cases 2 and 5. In Table 11.7 the equity C 0, assumed to cover 50% of the total investment, the EBITDA of the reference year, the net present value (NPV ), the internal rate of return (IRR), the payback time (PBT) and the average debt service coverage ratio (DSCR) are reported for each configuration and in Fig. 11.7 the actualized cash flows in the time horizon are shown for the six configurations.

In configuration 1 the use of more efficient boilers and electric heat pumps than those installed in the reference system yields a reduction of generation costs that allows the investment to be paid in about 2 years, as shown in Fig. 11.7 by the intersection of the blue line with the abscissa line. In configuration 2 the addition of the cogeneration unit requires higher investment costs; on the other hand generation costs are further reduced, which yields a payback time of 2.5 years. In this case, moreover, a much lower electrical load is satisfied by the national grid. In configuration 3 the investment cost is higher than in Case 2, as gas absorption heat pumps are more costly than the cogeneration unit. Gas absorption heat pumps allow large reductions in consumption of natural gas and electricity (see Table 11.6). In this case the largest net present value is also achieved. Furthermore this solution also allows satisfying national and European regulations that require a prescribed fraction of production from renewable energy sources in satisfying thermal loads. Configuration 4 combines the advantages of configurations 2 and 3, as it allows achieving the largest energetic and economical savings, with an investment of 800 per flat. Configuration 5 has the highest payback time; however, it can be of interest when the proposed configuration is an expansion of an existing system, in which some components are already available (for instance the cogeneration unit) and new elements need to be added, in order to increase the energy load served. In this case the reduced investment cost would result in the light-blue line in Fig. 11.7 to be translated above and therefore in a shorter payback time. In configuration 6 a good level of profitability is achieved, while limiting the electrical consumption. If there are limitation on the maximum electric power to be purchase from the grid, this is the appropriate solution. In the absence of such limitation, configurations 3 or 4 appear to be the best. Configuration 4 requires a higher investment, but it allows to satisfy the energy loads with a lower fuel consumption and is therefore preferable if fuel prices increase.

6 Conclusions

In this chapter we have presented the procedure GDPint for the evaluation of investments in new trigeneration systems or in the expansion of an existing distributed generation system, taking into account both technical and financial aspects. The optimal dispatch model allows describing the system components in great detail and the economic evaluation allows the users to compare several financial structures. A case study is discussed in which six alternative configurations are compared. The software tool, which can be freely accessed at www.rds-web.it, has been extensively used by different kinds of stakeholders (power producers, banks, investors, etc.) as well as power plant engineers and regulation authority, providing a very useful feedback regarding the details to be taken into account in the procedure, as well as the information to be provided to the user for evaluating the investment decisions. Maintenance work is required to keep the tool up to date, with particular reference to the legislation on incentives and taxation. Further work is planned towards a more sophisticated representation of uncertainty, although limited by the quite large dimension of the problem to be solved.

References

Armanasco F, Brignoli V, Marzoli M, Perego O, Scagliotti M, Campanari S, Colombo L, Silva P (2006) Analisi tecnico-economica e sperimentazione di sistemi cotrigenerativi. Deliverable RdS - W.P. 1.1 06007178, RSE (www.rse-web.it)

Campanari S, Colombo L, Silva P (2007) Performance assessment of cogeneration systems for industrial district applications. In: Proceedings of the American Society of Mechanical Engineers (ASME) Turbo Expo 2007, Montreal. ASME Paper no. GT2007-27659, doi:10.1115/GT2007-27659

Campanari S, Manzolini G, Silva P (2008) A multi-step optimization approach to distributed cogeneration systems with heat storage. In: Proceedings of the American Society of Mechanical Engineers Turbo Expo 2008, Berlin. ASME Paper no. GT2008-51227, doi:10.1115/GT2008-51227

Campanari S, Manzolini G, Silva P (2009) Comparison of detailed and simplified optimization approaches for the performance simulation of gas-turbine cogeneration plants. In: Proceedings of the American Society of Mechanical Engineers Turbo Expo 2009, Orlando. ASME Paper no. GT2009-60114, doi:10.1115/GT2009-60114

Chemelli C, Gelmini A, Marciandi M (2008) Gendisplan: applicativo software per la definizione fuori linea dell’ottimo tecnico-economico nell’impiego di risorse energetiche afferenti ad una microrete. Deliverable RdS 08005854, RSE (www.rse-web.it)

EPRI. Technical assessment guide. Technical Report TR-102276-V1R7, Electric Power Research Institute, 1993

Maggioni F, Allevi E, Bertocchi M (2012) Measures of information in multistage stochastic programming. In: Stochastic programming for implementation and advanced applications (STOPROG-2012)

Maggioni F, Wallace SW (2012) Analyzing the quality of the expected value solution in stochastic programming. Ann Oper Res 200(1):37–54

MSE. Decreto legge sull’incentivazione della produzione di energia elettrica da fonti rinnovabili, http://www.sviluppoeconomico.gov.it/pdf-upload/decreto181208.pdf. Ministero dello Sviluppo Economico, 2009.

Stadler M, Cardoso G, Bozchalui M, Sharma R, Marnay C, Siddiqui A, Groissböck M (2012) Microgrid modeling using the stochastic distributed energy resources customer adoption model der-cam. Conference presentation lbnl-5937e, Lawrence Berkeley National Laboratory

Vespucci MT, Zigrino S, Bazzocchi F, Gelmini A (2011) A software tool for the optimal planning and the economic evaluation of residential cogeneration districts. In: Delimar M (ed) Proceeding of the 8th International Conference on the European Energy Market (EEM 2011), Zagreb, 2011

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media New York

About this chapter

Cite this chapter

Vespucci, M.T., Zigrino, S., Bazzocchi, F., Gelmini, A. (2013). Optimal Planning and Economic Evaluation of Trigeneration Districts. In: Kovacevic, R., Pflug, G., Vespucci, M. (eds) Handbook of Risk Management in Energy Production and Trading. International Series in Operations Research & Management Science, vol 199. Springer, Boston, MA. https://doi.org/10.1007/978-1-4614-9035-7_11

Download citation

DOI: https://doi.org/10.1007/978-1-4614-9035-7_11

Published:

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4614-9034-0

Online ISBN: 978-1-4614-9035-7

eBook Packages: Business and EconomicsBusiness and Management (R0)