Abstract

This chapter presents the main control architectures and management schemes to accommodate an intelligent EV operation in the power system. The main issues related to EV electrical grid integration consider the capabilities of an EV to offer a number of grid services, while taking into account the EV battery constraints. Grid services by EVs are possible if a number of requirements involving the vehicle architecture and its communication capabilities are met. Given this background, each EV can play a key role in the grid and this is possible using different business models. Three business models by three major EV projects are discussed and compared.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

4.1 Introduction

A liquid-fueled vehicle can be designed with little respect for the fueling infrastructure. An electric vehicle (EV) has a more intimate connection with its fueling infrastructure and this requires a rethinking of today’s pervasive models. It will not be enough to just create an “electric gasoline pump.” We believe that designers must re-conceptualize the process of fueling and the ways that fueling and driving patterns fit together. Further, we must consider the comparative advantages and disadvantages of liquid fuels versus electricity and how those may affect fueling. Otherwise, like the old generals who strategize from their prior experience and “Fight the last war,” we may build an inconvenient, overly expensive fueling infrastructure that fails to take advantage of the radical differences in the characteristics of electricity as a fuel.

For example, the EV must respect fueling rate limits (in amperes or watts) that vary with location, but are inherently much slower than liquid fuels. On the other hand, EV fueling connections can provide valuable services, unlike liquid fuels that only consume energy. This example shows that the design of electrical fueling may be very different from that of liquid fuels. More broadly, the design must consider interactions between the vehicle and the user, the power capability (in watts), the total energy transferred (in watt-hours), the minimization of component costs, the lifetime, and the safety of refueling (see Fig. 4.1).

Factors characterizing a vehicle [1]

The vehicle characteristics, the grid-connection or electric vehicle supply equipment (EVSE), the building circuit, the local distribution system, and energy markets must operate well together.

Before considering business models and control, we analyze the fueling functions of an electric vehicle, and how they influence the design of the EV and its grid-connection infrastructure. Those, in turn, enable and limit the possible business models.

4.2 Vehicle Fueling Functions

A functional analysis must first consider the fueling functions of a vehicle. In this section, we consider fueling (or recharging) functions related to transportation; in the next section, we consider the fueling functions related to the electrical system.

Liquid-fuel vehicles lack an option for slow refuel, at a convenient location and at a lower cost (e.g., a plug adjacent to one’s home or apartment parking location, charging overnight at a cost equivalent to 0.25–0.50 €/l, or $1/gallon in the USA). On the other hand, the fast and en route fueling functions are better suited to liquid fuels. The fueling capacity of a petrol vehicle is 21.4 MW, or an effective refuel rate of 5.3 MW after considering the much lower efficiency of petrol [2]. The proposed IEC61851 vehicle connector standard permits up to 43.6 kW power level from standard three-phase AC connection at the 400 VAC, typical in Europe, whereas some off-board DC chargers allow 50 kW. In either of the electrical cases, the capacity rate is about 1/100 the rate of gasoline.

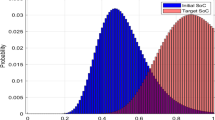

As a result of inherent differences in fueling rate, the function of “refueling en route” is inherently slower for electric vehicles. This is a natural limitation for some high-duty-cycle commercial vehicles. But most consumers rarely take trips longer than today’s advanced EV batteries. A sample for European driving patterns has shown an average daily distance of about 40 km. In a larger US sample of individually owned (private) light vehicles, the average daily driving was 52 km (32.6 mi) or 19,000 km per year. Excluding days of no driving, average daily driving was 72 km (44.7 mi). Trips over 240 km (150 mi) occur only 9 times per year for the average person [2]. An average size EV battery would provide 150–200 km range. Since the driving data suggest few trips per year longer than this, en-route electric refueling may be more cost-effective than a much larger battery. This can be accomplished, for example, by combining a meal stop with refueling at 43 kW recharge. A 45-min lunch break would accumulate 30 kWh, so if we calculate driving at 6 km/kWh, that lunch break adds 180 km of range.

4.3 Functions in Relation to Electrical Infrastructure

We now consider the reverse perspective: what are the functions that the vehicle and its electrical or fuel storage can serve to the fueling infrastructure? For liquid fuels, there is only one function: the purchase of liquid fuels provides the primary revenue stream to the petroleum extraction, transport, and refining industries. The real-time operation of liquid fueling uses a simple pump drawing fuel from an underground tank to a tank in the vehicle. This fueling process is fast and low-cost. Although the fueling equipment is expensive, it is deployed only in a few selected locations with high traffic, the duty cycle is high, and the payback on fueling infrastructure investment reasonable.

With electricity as a fuel, the potential functions that the vehicle can serve to the electrical system lead to a more rich analysis. A key to this analysis derives from the opportunity implied by the first bullet in Table 4.1 because electricity is ubiquitous in modern human settlements, it offers the opportunity for slow, low-cost fueling at a convenient location (e.g., while parked at home or another destination, not requiring investment in a specialized refueling location). The consequence of convenience and ubiquity is that the vehicle can be connected to the fueling system most of the time; in OECD countries, private cars are typically driven 1 hour per day, idle 23 hours a day. Different types of vehicles can be refueled using a common refueling infrastructure that can be depicted as follows:

Figure 4.2 depicts two forms of electrical recharge equipment. Each has a pedestal and an electric cable connecting to the vehicle. In (a), the pedestal transmits AC electricity from the power grid and a charger is in the vehicle. The charger converts grid AC electricity to DC matched to the voltage needed by the battery. In (b), the charger is in the pedestal, and the cable transmits DC electricity to the car for direct battery charging [3].

Thus, we come to the question of, what other functions can connected vehicles provide and what electrical infrastructures are required to make those functions possible. Table 4.2 gives a list of potential grid functions and markets. Some of these functions require features that not all EVs share. Some grid functions require data communication between the grid operator and the vehicle or EVSE, some require higher power flow (over 10 kW or minimally over 6 kW), and some require discharging of the vehicle battery to the grid. The latter functions are possible with more advanced hardware components that will be distinguished later.

The grid functions in Table 4.2 can be defined as follows:

-

Load and revenue: due to driving, the vehicle inherently needs to refuel, so unless the electricity is given away, it provides a revenue stream to the fuel supplier.

-

Scheduled charging: Times of higher system electrical load are roughly predictable; therefore, as simple a device as a timer, or a timer and air temperature sensor, can be used to set the charge minimal or low rate during times likely to be stressful to the grid. This is of value to the electric system. It is compensated to the customers only if there is a corresponding rate structure, such as off-peak electric rates.

-

Responsive charging and discharging: requires some form of signal from a grid operator or grid monitor to the vehicle or to an EVSE controlling the vehicle. Some of these services can be dispatched by a local monitor (e.g., of frequency or of power factor). Others require communications from distribution equipment, from the local distribution electric system operator, or from the regional transmission operator (e.g., spinning reserves or local substation overload). When vehicles can both charge and discharge at moderately high power (6 kW up), they can be managed as dispatchable storage resources, which have very high value to various types of grid operators.

-

Backup power: Energy stored in a car can be used to power the building to which the car is connected, if the local electrical system goes down. This of course requires the ability of the car to discharge the battery to the local grid, and also requires failsafe disconnection of the building from the grid, as well as other sensing and safety mechanisms. Providing backup (emergency) power, unlike responsive services, does not require communication to the grid operator, but generally will require more safety switches, and more communication to the building electrical system. This is sometimes referred to as “vehicle to home,” in contrast to “vehicle to grid,” suggesting that the power somehow stops flowing at the building boundary, or that it has a value at times other than power failures. We do not use the “vehicle to home” terminology because it obscures the very different technical problems and the serious safety problem of grid disconnection, thus we use the term “backup power”

Of the functions above, generally, “responsive” services can provide the greatest value. Backup power is of lower market value. Nevertheless, responsive services and backup power both can potentially produce revenue (or value to the customer in the case of backup power), whereas scheduled charging only reduces the already-low fuel cost of electric refueling. Electrical “load,” of course, is by definition a cost to the vehicle operator, it does not provide revenue to the vehicle.

A quantitative analysis of the relative values of these services has been provided elsewhere [12] and is beyond the scope of this article, but sufficient to say that the most valuable services, in the higher priced of today’s markets, can return a substantial fraction of the value of the vehicle. And even in more moderate markets, grid services can be more valuable than the fuel cost of electricity.

4.3.1 Business Models

If society is to transition to electric transportation, someone has to buy the cars, the EVSEs, and the electricity. Someone has to maintain the cars and EVSEs. Someone has to put EVSEs in public places, on city streets, at stops along throughways, in locations which the owners of those public properties may not directly benefit from the charging. A countervailing factor to these costs, and as we are noting, one of the biggest differences between liquid fuel and electricity, is that EVs have considerable value to the electric system. However, capturing that value is complex and requires infrastructure with some critical features added beyond purely fueling functions. For all these reasons, it is appropriate to discuss business models.

4.3.1.1 Business models for electric vehicle sales

Tax incentives for EVs, as they exist today in many countries, are a valuable policy to reduce the initial high cost of vehicles and overcome resistance to a new product. A recent comprehensive analysis of the cost versus the consumer willingness to pay for EVs suggests that such tax credits are important at the initial phases of the market, when batteries are especially expensive [13]. Apart from the value of this policy to start the industry, the business models for the liquid-fueled vehicle and electric vehicle are the same: the operator buys the vehicle, uses it for transportation and pays for fuel and repairs. By contrast, for electric fueling, there are several new business models, as follows.

4.3.1.2 EVSE as Appliance

The simple business model is the vehicle owner purchases and maintains the EVSE and buys electricity. The automaker makes money selling the vehicle, the EVSE manufacturer is selling a piece of electrical equipment, the electrician has a service job installing EVSEs, and the electric utility sells electricity.

4.3.1.3 EV Charging as a Service

This model packages all EVSE management and cost into a single package service with a monthly fee. We’ll call this “charging services.” The customer buys an EV and signs up for the charging service. The service installs an EVSE in their home or regular parking location(s), submeters the electricity and possibly pays for it at a €/kWh rate, provides some form of “in-plan” public charging, and charges the vehicle owner fees, for example, either monthly or per distance driven. One variant is to have the vehicle owner use an id such as a card swipe, to gain access to the public chargers. This provides an incentive for drivers to sign up for the plan and in turn, provides a funding stream to purchase and maintain public charging spots, and of course to pay for the electricity use.

4.3.1.4 EV Battery and Charging as a Package Service

This is like the prior example, except that the EV charging service additionally owns the battery in the car. This works like the example above, with the service additionally purchasing the battery within the car. To repay the expensive battery would, of course, require substantially higher monthly fees. One interesting byproduct is that the vehicle owner has a lower possessive stake in the battery. For example, batteries can be swapped for service, upgraded or downgraded, or swapped en route simply to provide a way of very fast “charging.”

4.3.1.5 Paying the Owner for Providing Grid Services

Whereas the above are all taking payment from the vehicle owner, this fourth business model achieves revenue by aggregating cars to provide grid services, and can pay the vehicle owner for those services. For responsive services with two-way power flow, the value can be greater than the cost of purchasing fuel and maintaining the EVSE, so there could be a net positive payment to the vehicle owner. There are some additional requirements on the EV, and on the EVSE, in order to achieve this value.

4.4 Requirements of Electric Vehicles for Electric Grid Interaction

The opportunity to provide grid services using electric vehicles is possible if a set of hardware, software, and communication requirements are considered from the beginning in the value chain development for a vehicle.

The software aggregation of EVs can be achieved given that vehicles have an accessible hardware and software architecture which can externally be monitored and controlled during plug-in periods.

Monitoring and control functions should therefore include the following:

-

Monitoring of internal vehicle data, relevant to the aggregator

-

Control of refueling operations, charging and discharging

4.4.1 Monitoring of Internal Vehicle Data

EV coordination is fundamental for providing grid services using vehicles: this entails monitoring several internal vehicle data that can be acquired in real-time from the Vehicle Management System (VMS), and the Battery Management System (BMS). Accessing the vehicle info allows an aggregator defining the energy status of the vehicle, the charge stored in the battery, and potentially any other relevant parameters. The following internal vehicle data are required by an aggregator for the EV status identification.

-

Nominal battery energy, E n, stored once in the aggregator database

-

Battery State-of-Charge, SOC, real-time monitored

-

Instant power while providing grid services, real-time monitored (aggregated power)

The nominal energy of the battery is an invariant parameter which is expressed in kWh as follows:

where C n (Ah) is the nominal capacity of the battery pack [4], while V BATT (V) is the nominal voltage of the battery pack. The nominal energy is required by the VPP since it represents the absolute reference of energy of the vehicle.

The SOC of the vehicle battery, as defined in [4, 5], is the measure of the charge left in the battery with respect to its nominal capacity. This can be expressed as follows:

where C (Ah) is the actual capacity contained in the battery at the time of measuring.

The third information needed to the aggregator is the power used by the EV during grid service operations. This could be achieved using either smart meters on a charging station or possibly BMS data.

In smart charging applications, the charging/discharging power should be measured in real-time and the information sent back to the aggregator which keeps track of the energy exchanged between the EV and the grid. The power levels used are constrained by the charging infrastructure available, i.e., electrical cables, transformer rating, circuit breakers, fuses, etc. In this context, EV coordination strategies are aiming to avoid, or at least postpone, any grid reinforcement [6].

The fast-charging scenario of EVs is not considered in the requirements definition for responsive power, as en route charging on demand is incompatible with EV coordination. Fast-charging entails the installation of ad hoc charging infrastructures as well as it requires a more complex refueling management which cannot be influenced by higher level coordination [3].

4.4.2 Capabilities of the EV, the EVSE, and the VPP

There is a natural break in functions and thus components between the EVSE and the EV. For business models involving providing grid services, there may also be another control and synchronization system, alternatively called the Virtual Power Plant (VPP), or the “aggregator,” that would synchronize power flow to, and possibly from, the EVs. The capabilities of each are discussed below.

4.4.3 EVSE Capabilities

The EVSE is the stationary side, fixed in place and connected to a particular building’s electrical system. The EV is the mobile side, it will be connected to many different points, and it has full knowledge of the vehicle characteristics and appropriate level of charge or discharge based on current conditions (e.g., battery temperature and wear characteristics). These characteristics alone dictate much of their division of functions and capabilities. These are the required EV capabilities:

-

Power connection from the building or grid

-

Standard connector to car

-

No activation of power to connector until EV connection is confirmed

-

Signal maximum current to EV using standard protocol

-

Overcurrent protection (may be provided by building breakers)

-

Ground-fault detection

-

Trip upon ground fault or over current

Optional Capabilities

-

Digital communications with car

-

Stored information for:

-

Grid location, circuit ampacity, and grid capabilities

-

Authorizations (e.g., for backfeeding or emergency power)

-

-

Metering of energy used in kWh

-

Authorization of car/customer/driver to be allowed to charge

-

Metering of kWhs

-

Allocation of billed amounts to proper entity

-

Transfer of billing or credit information to back office

-

Real-time communications link between car and grid dispatch

-

Fail-safe detection of building isolation (emergency power function)

Note that today’s standards require only limited communications between the EVSE and the EV: the EVSE tells the EV how much current it can draw and the EV confirms that the EVSE’s connector is in fact plugged into an EV. In the IEC standard, not the J1772 standard, the cable also signals how much current it can carry, by a simple passive resistor in the cable (under the US National Electrical Code, NEC 625, the J1772 cord must be permanently connected to the EVSE, so there is no need for a separate rating of the capacity of the cable).

The EVSE power capabilities are determined by standards. The primary two being IEC 62196-2, which applies worldwide, and SAE J1772, adopted by the USA and Japan. The SAE connector is the less capable, with a maximum of 19.2 kW and single-phase only. The IEC proposed standard provides for either single or three phase, and up to 44 kW. Each can be used at several power levels, as shown in Table 4.3.

4.4.4 EV Capabilities

On the EV, much more can be done due to two factors. First, the EV has intimate communications with the battery and power electronics systems. This allows monitoring of the many onboard systems. Second, due to the requirements of driving and charging, the EV controls current from the grid (and optionally to the grid) continuously. The power electronics components (and associated losses) are there already. By contrast, for each control function of the EVSE, it needs only to switch on or off. The EVSE is most economically and efficiently implemented as one or more switches, perhaps simple mechanical contractors (e.g., circuit breakers or latching relays). If power electronics were added on the EVSE side, they would introduce higher cost and complexity plus losses and heat.

4.4.5 Interaction Among EV, EVSE, and Aggregator

There are many possible ways that the EV, the EVSE, and an aggregator or VPP can interact. In this section, we review three approaches taken from actual projects. They are characterized by three parameters:

-

Market integration and EV utilization concept

-

Architecture

-

Technology and standards

By “market integration” is meant the way that the EV, directly or indirectly, is connected to the power market to generate savings and possibly revenue for the EV owner. The number and composition of market stakeholders involved depend heavily on the business models and market environments in consideration. By “utilization concept” is meant which functionalities the EV will support, consisting of the following three concepts:

-

EV as load

-

Smart Charging, determined by time of day (and/or grid conditions)

-

Two-way power flow and real-time control

(None of the integration projects reviewed here uses just dumb charging, that is, just load, although most commercial electric cars do, and no commercial electric cars have the capabilities needed for code-compliant emergency power).

4.5 Example of EV Integration Projects

The market integration and utilization concept chosen shape the architecture of a project. By “architecture” is meant the stakeholders and mechanisms used to influence the EV’s behavior and interface it with power system and market. Architecture may be centrally controlled (totally controlled by the aggregator), distributed control (the EV is autonomous), or a mixture [7].

The technology descriptions of the projects cover two topics. First, the components in both soft- and hardware that has been developed to support the computation and logic necessary for managing smart or bidirectional charging are described. Second, the communication protocols used for transferring data between the entities are listed.

Related to technologies are the standards used by the projects. The standards can be subdivided into equipment and communication standards and are also mentioned in the project descriptions.

This section will introduce two European and one American EV integration project. They have been chosen since they represent some of the biggest and most innovative research projects within the field.

Apart from the above, they all share certain traits when it comes to the integration approach followed. They are all “economic” integrations where money is earned through market participation. They also share a focus on existing markets and implement an either centralized or partly centralized architecture. Such similarities could be seen as a prerequisite for arriving at common solutions applicable for all such projects. There are, however, still many differences in the implementations, which illustrates the challenges to standardization.

The main elements in the architecture are the EV, the EV User, the Electric Vehicle Supply Equipment (EVSE), and the more generic Aggregator role, which would represent the “interface” between a group of EVs and the power system or energy market.

As will be shown by the following, the projects differ in by which means the above entities should communicate, what information should flow between them, and, in the end, which entity will control the behavior of the EV.

4.5.1 The Edison Project

EDISON [8, 9] is short for “Electric vehicles in a Distributed and Integrated market using Sustainable energy and Open Networks” and is a research project partly funded through the Danish Transmission System Operator (TSO)—Energinet.dk.

The goal is to develop optimal solutions for EV integration, including network issues, market solutions, and optimal interaction between different energy technologies (Fig. 4.3). The technical platforms developed by EDISON should be globally applicable and it has been tested on the Danish island of Bornholm.

The EDISON consortium consists of the Danish utilities DONG Energy and Østkraft, the Danish Technical University (DTU), as well as IBM, Siemens, Eurisco, and the Danish Energy Association. The 3-year project will conclude in 2012 but might be followed by an EDISON 2 project. The project Web page can be found at http://www.edison-net.dk.

4.5.1.1 Market Integration and EV Utilization Concept

While several market integration concepts are within the research scope of EDISON, the initial focus is on the current Nordic NordPool market. Within NordPool, the EVs can be connected to the day-ahead or intraday market. Alternatively, the EVs can participate in the TSO ancillary service markets an provide different types of reserves. The first project phase will put its emphasis on the first and indirectly connect the EVs with the day-ahead spot market by controlling the charging in correspondence with hourly energy prices. This follows the smart charging utilization concept.

4.5.1.2 Architecture

The setup shown in Fig. 4.3 represents the implementation done in EDISON. The setup uses a centralized architecture where an aggregator, called the “fleet operator” in EDISON, directly controls the charging patterns of the EV to facilitate smart charging. The conceptual role of a fleet operator could be maintained by any commercial party willing to adhere to the requirements of the Nordic power market. An EV in EDISON is seen as relatively simple with little local intelligence. The argument is that most OEM EVs initially will lack the capabilities for local optimization. The EV needs only to implement an interface that would allow the fleet operator to extract status information, such as state of charge, and possible constrains set by the OEM. In EDISON, the charging spot would play the role of a “proxy” in that it would extract EV information and enforce smart charging on behalf of the fleet operator. The user will in EDISON communicate her or his charging preferences directly to the aggregator.

4.5.1.3 Technologies and Standards

Between EV and EVSE, EDISON utilizes the IEC 61851 standard, which describes the charging of EVs using different AC or DC power voltages over a conductor using on- or off-board equipment. Apart from specifications for equipment interoperability and safety, the standard also defines simple EV–EVSE communication via a control pilot wire using a pulse width modulated (PWM) signal with a variable voltage level. This allows the EV to communicate its state to the EVSE. IEC 61851 is used in EDISON since it helps satisfy safety requirements and will improve interoperability.

The IEC 62196-2 Type 2 Mennekes plugs are used on the conductor connecting EV and EVSE.

Apart from the control pilot wire, EDISON will use Power Line Carrier (PLC) communication to support the exchange of information. Although not part of IEC 61851, this technology is a valid candidate for future standardization.

An EDISON I/O board is installed at the EV and the EVSE and includes a PLC adapter.

To connect the EVSE with the aggregator, the IEC 61850 standard is used. IEC 61850 was originally aimed at substation automation, but has been expanded to cover the monitoring and control of distributed energy resources. The standard includes a reusable data model that can be used to monitor and control both the EVSE and the EV.

The EVSE implements an IEC 61850 compliant server which uses HTTP/HTTPS-based RESTful Web services, instead of the MMS protocol usually associated with IEC 61850. The REST interface is combined with the SIP application level protocol to better facilitate scalability. The Transport Level Security (TLS) is used to provide data confidentiality.

After the aggregator has extracted information through the REST interface of the IEC server, it will use a software platform called the EDISON Virtual Power Plant (EVPP) that, through prediction and optimization, will compute a suitable charging strategy. The strategy is described using an IEC 61850-7-420 Energy and/or Ancillary Services Schedule (DSCH) which is sent to the EVSE IEC server. The schedule consists of a set of power set points and timestamps which will be followed by the EVSE during the charging of the EV.

An iPhone App and a Web page have been developed for the user to define charging requirements.

4.5.2 Vehicle-to-Grid Technology, University of Delaware

Vehicle-to-Grid (V2G) technology [10–12] is researched and developed at the University of Delaware (UD). The research focuses on the potential of V2G technology for improving the utilization of the EVs as active resources in the grid and market. The research conducted by UD V2G spans a broad set of disciplines such as soft- and hardware development, grid impact and driving pattern analysis, and aggregated fleet optimization. In addition to the technical aspects, UD V2G also covers policies, standards, and legislation and user adoption. For testing and demonstrating, UD V2G uses a fleet of V2G-enabled vehicles.

UD V2G is a research program rather than a project and will continuously work at research, development, and commercialization of V2G. Recently, the group has replaced the term “V2G” with “Grid Integrated Vehicle” to emphasize the importance of grid integration, regardless of which direction power is flowing.

AC Propulsion, a manufacturer of battery and propulsion systems, is an active partner in the project. The research is supported by the US Department of Energy (DOE) as well as several American utility companies. More information is available at http://www.udel.edu/V2G.

4.5.2.1 Market Integration and EV Utilization Concept

The UD V2G market integration concept has been tested by participating in the regulation services market where the vehicle responds to regulation power requests sent from PJM Interconnection, a Transmission System Operator (TSO). The bidirectional charging will allow the EVs to react to TSO requests for both up- and down regulation, and the EV user will be economically compensated for such services [13]. Regulating services has been implemented by UD V2G since it represents one of the most profitable markets to participate in. UD V2G publications have noted that their control mechanisms are also designed for other TSO markets such as spinning reserves and for distribution system services such as peak load reduction, valley filling, reactive power, and transformer upgrade deferral, but UD V2G cars are not actually participating in these markets yet.

4.5.2.2 Architecture

The UD V2G architecture depicted in Fig. 4.4 can be classified as partly distributed since the EV implements an intelligent agent that will use a negotiation-like communication toward the aggregator. The EV will control the charging process and be responsible for predicting and satisfying the energy requirements of the EV user.

Adding local intelligence and control in the EV can supply a better separation of concerns where a third party, like the aggregator, would not have full control over charging and free access to utilization data. This secures the EV against external mismanagement (e.g., driver’s need for driving range has priority) and simplifies the optimization in the aggregator.

The purpose of the EVSE in the UD V2G architecture, aside from facilitating the power supply and Internet connection, is to supply information on possible grid-related charging constraints. The user can through a Web interface formulate her or his driving requirements. The collected trip information is then feed to the vehicle.

4.5.2.3 Technologies and Standards

In the UD V2G project setup, an electric vehicle contains a Vehicle Smart Link (VSL) implemented on an automotive-grade Linux computer. The VSL will communicate with the VMS and BMS of the EV to get battery information and to control charging. The Society of Automotive Engineers (SAE) J1772 standard is used for the equipment connecting EV and EVSE. J1772 defines the electrical and physical characteristics of conductive charging for EVs including requirements to inlets and connectors. An IEC 62196-2 version has also been developed. Either in-band communication over the pilot line or PLC communication is used for sending data via the charging cord.

Knowledge of grid and EVSE constraints are captured by a configuration file residing in the EVSE and will be sent to the VSL upon plug-in. This and direct wired communications ensure that the vehicle knows its electric power system node location, and the constraints, billing, and allowed services at that point. The EVSE is a repository of information (in the configuration file) rather than a computing agent with active control over V2G.

The VSL will communicate the battery status and trip predictions to the aggregator to signal the capacity of each EV. The aggregator uses the UD V2G “Coalition server” software to calculate the capacity of the EV (including grid constraints, battery state of charge, and scheduled or anticipated driver needs) and dispatch the TSO regulation requests accordingly. The result is a stream of power requests from the aggregator to the vehicle that states the number of watts with which the EV should charge or discharge.

Both the VSL and the aggregator use software agents based on the Java Agent Development Framework (JADE). The agents communicate via the Agent Communication Language (ACL) as defined by Foundation for Intelligent Physical Agents (FIPA). The concepts of coalition formation and multi-agent systems are applicable to the project in the sense that multiple entities (EVs) will group and cooperate to achieve some common goal, in this case revenue through TSO services. The UD V2G architecture, however, differs from the above concepts in that a coordinating entity, namely, the aggregator, will be present. The use of agents also fits nicely with the fully distributed architecture.

4.5.3 E-Mobility Berlin Pilot Project

The German E-Mobility Berlin project was initiated by Daimler AG (Mercedes-Benz) and the utility RWE [14]. Among the participants are also battery, EVSE, and other automobile OEMs. The project introduces a fleet of 100 EVs supplied by Daimler and 500 EVSEs that are delivered and powered by RWE in the streets of Berlin for a large field test. The project is aimed at developing and testing standardized solutions for electric vehicles.

Daimler is heavily involved in EV standardization in Europe and supports the vision of roaming. The project was launched in 2008 and will continually expand the field tests with new vehicles and technologies. More information is available at http://www.rwemobility.com.

4.5.3.1 Market Integration and EV Utilization Concept

The aggregator in the e-mobility project is initially seen as the utility company, e.g., RWE, who could sell energy to EV users and reward them for flexibility. By letting the user specify an “end of charge” time, the utilization concept of smart charging is supported. E-mobility does not directly address bidirectional charging and the use of the EV for ancillary services. The protocols and use cases of the project, however, are designed to be open for additional unspecified utilization concepts.

4.5.3.2 Architecture

The e-mobility project puts a lot of emphasis on the EV–EVSE interaction in its architecture. As illustrated in Fig. 4.5, the EV acts as a client toward a server implemented at the EVSE. The tariffs and charging options of the utility company will be represented by the EVSE, which will serve as a proxy.

Despite the presence of an aggregating entity, the setup is only partly centralized since the EV will implement a lot of decision logic by knowing the needs and requirements of the end-user and use them in a negotiation-like communication with the EVSE.

4.5.3.3 Technologies and Standards

Each car is equipped with a Smart Charge communication unit that can communicate with the EVSE by using the e-mobility Smart Charge Protocol (SCP) over PLC. The SCP defines a series of application level messages that are sent back and forth in the following sequence. After a plug-in has been detected, “identification” messages will be used to configure the connection session and to establish identification, billing, and contract details (for roaming). The EV will then request a list of EVSE-provided services in a “service discovery” message. Services include the charging and payment options available at the specific EVSE. The EV will then send its energy demand and intended charging behavior in a “power discovery” message. The EVSE will compare the charging behavior with knowledge on local grid and equipment capabilities and send back price listings. When charging and billing have been settled, a series of messages initiates the power connection and monitors the charging process. SPC messages are encoded according to the Smart Message Language (SML), which is a mark-up language similar to XML that has been used for smart meter communication. Transport Layer Security (TLS) is used to supply data confidentiality through encryption. The DoIP protocol is used for EV diagnostics.

The e-mobility project has contributed significantly to the standardization of the IEC 62196-2 Type 2 compatible Mennekes plug. The EVSE equipment supports conductive charging in accordance to IEC 61851.

References

Marra F, Træholt C, Larsen E, Wu Q (2010) Average behavior of battery-electric vehicles for distributed energy studies. In: IEEE innovative smart grid technology conference, Manchester

Pearre NS, Kempton W, Guensler RL, Elango VV (2011) Electric vehicles: how much range is required for a day’s driving? Transport Res C 19(6):1171–1184. doi:10.1016/j.trc.2010.12.010

Marra F, Sacchetti D, Træholt C, Larsen E (2011) Electric vehicle requirements for operation in smart grids. In: IEEE proceedings of innovative smart grid technology (ISGT 2011), Manchester

Marra F, Pedersen AB, Sacchetti D, Andersen PB, Traeholt C, Larsen E (2012) Implementation of an electric vehicle test bed controlled by a virtual power plant for contributing to regulating power reserves. In: Proceedings of IEEE Power and Energy Society (PES) General Meeting, San Diego, CA

Dogger JD, Roossien B, Nieuwenhout F (2011) Characterization of Li-ion batteries for intelligent management of distributed grid- connected storage. IEEE Trans Energy Conversion 26(1):256–263

Clement-Nyns K, Haesen E, Driesen J (2010) The impact of charging plug-in hybrid electric vehicles on a residential distribution grid. IEEE Trans Power Syst 25(1):371–380

You S, Træhold C, Poulsen B (2009) A market-based virtual power plant. In: Proceedings of the international conference on clean electrical power (ICCEP), IEEE, June 2009

Binding C, Gantenbein D, Jansen B, Sundstroem O, Andersen PB, Marra F, Poulsen B, Traeholt C (2010) Electric vehicle fleet integration in the Danish EDISON project—a virtual power plant on the Island of Bornholm. In: Proceedings of IEEE power & energy society general meeting 2010, Minneapolis, MN, USA, 25–29 July 2010. Also available as IBM RZ 3761

Østergaard J, Foosnæs A, Xu Z, Mondorf TA, Andersen CA, Holthusen S, Holm T, Bendtsen MF, Behnke K (2009) Electric vehicles in power systems with 50% wind power penetration: the Danish case and the EDISON programme. In: Paper presented at European conference on electricity & mobility, Würzburg, Germany

Kempton W, Tomic J (2005) Vehicle-to-grid power implementation: from stabilizing the grid to supporting large-scale renewable energy. J Power Sources 144(1):280–294

Kamboj S, Pearre N, Kempton W, Decker K, Trnka K, Kern C (2010) Exploring the formation of electric vehicle coalitions for vehicle-to-grid power regulation. In: Proceedings of 2010 AAMAS workshop on agent technologies for energy systems

Kempton W, Tomic J (2005) Vehicle-to-grid power fundamentals: calculating capacity and net revenue. J Power Sources 144(1):268–279

Hidrue MK, Parsons GR, Kempton W, Gardner MP (2011) Willingness to pay for electric vehicles and their attributes. J Resour Energy Environ Econ 33:686–705. doi:10.1016/j.reseneeco.2011.02.002

Caleno F (2010) E-Mobility Project in Italy. In: Paper presented at EV charging infrastructures & grid integration 2010, London

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media New York

About this chapter

Cite this chapter

Kempton, W., Marra, F., Andersen, P.B., Garcia-Valle, R. (2013). Business Models and Control and Management Architectures for EV Electrical Grid Integration. In: Garcia-Valle, R., Peças Lopes, J. (eds) Electric Vehicle Integration into Modern Power Networks. Power Electronics and Power Systems. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-0134-6_4

Download citation

DOI: https://doi.org/10.1007/978-1-4614-0134-6_4

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-0133-9

Online ISBN: 978-1-4614-0134-6

eBook Packages: EnergyEnergy (R0)