Abstract

Wine- or cider-making is highly associated with biotechnology owing to the traditional nature of must fermentation.. Nowadays, there have been considerable developments in wine- or cider-making techniques affecting all phases of wine or cider production, but more importantly, the fermentation process. It is well-known that the transformation of grape must by microbial activity results in the production of wine, and the fermentation of apples (or sometimes pears) in the production of cider. In this process, a variety of compounds affecting the organoleptic profile of wine or cider are synthesized. It is also common sense that in wine- or cider-making, the main objective is to achieve an adequate quality of the product. The technological progress and the improved quality of the wines or ciders have been associated with the control of technical parameters. Herein, cell immobilization offers numerous advantages, such as enhanced fermentation productivity, ability for cell recycling, application of continuous configurations, enhanced cell stability and viability, and improvement of quality (Margaritis and Merchant 1984; Stewart and Russel 1986; Kourkoutas et al. 2004a).

The objective of the present chapter is to analyze and assess data on the impact of immobilization technologies of viable microbial cells on the alcoholic and malolactic fermentation (MLF) of wine and cider. The immobilized biocatalysts are evaluated for their scale-up ability and their potential future impact in industrial application is highlighted and assessed. Handicaps associated with maintenance of cell viability and fermentation efficiency during preservation and storage, constraining the industrial use of immobilized cell systems are discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

12.1 Introduction

Wine- or cider-making is highly associated with biotechnology owing to the traditional nature of must fermentation.. Nowadays, there have been considerable developments in wine- or cider-making techniques affecting all phases of wine or cider production, but more importantly, the fermentation process. It is well-known that the transformation of grape must by microbial activity results in the production of wine, and the fermentation of apples (or sometimes pears) in the production of cider. In this process, a variety of compounds affecting the organoleptic profile of wine or cider are synthesized. It is also common sense that in wine- or cider-making, the main objective is to achieve an adequate quality of the product. The technological progress and the improved quality of the wines or ciders have been associated with the control of technical parameters. Herein, cell immobilization offers numerous advantages, such as enhanced fermentation productivity, ability for cell recycling, application of continuous configurations, enhanced cell stability and viability, and improvement of quality (Margaritis and Merchant 1984; Stewart and Russel 1986; Kourkoutas et al. 2004a).

The objective of the present chapter is to analyze and assess data on the impact of immobilization technologies of viable microbial cells on the alcoholic and malolactic fermentation (MLF) of wine and cider. The immobilized biocatalysts are evaluated for their scale-up ability and their potential future impact in industrial application is highlighted and assessed. Handicaps associated with maintenance of cell viability and fermentation efficiency during preservation and storage, constraining the industrial use of immobilized cell systems are discussed.

12.2 Cell Immobilization Methods

12.2.1 Prerequisites for Cell Immobilization

Various materials are available for cell immobilization. However, not all carriers are considered suitable for food production. The main prerequisites that should be fulfilled by cell immobilization supports include:

-

1.

A large surface of the immobilization support, with functional groups for cells to adhere to,

-

2.

Easy-handling and regeneration of the immobilization support,

-

3.

Cost-effectiveness of the support and immobilization process,

-

4.

Acceptance of immobilization support by the consumers and avoidance of negative effects on the final food product (e.g., off-flavor formations),

-

5.

Retention of immobilized cell viability,

-

6.

Avoidance of negative effects of cell immobilization on biological and metabolic activity of immobilized cells, and

-

7.

Food-grade purity of the immobilization support.

12.2.2 Effects of Cell Immobilization

Cell immobilization might cause desirable or undesirable alterations in the metabolism of cells (Melzoch et al. 1994; Norton and D’Amore 1994; Walsh and Malone 1995). It might affect cell growth and physiology (Melzoch et al. 1994; Jamai et al. 2001), metabolic activity (Navarro and Durand 1977; Buzas et al. 1989; Hilge-Rotmann and Rehm 1990; Jamai et al. 2001), stress tolerance (Nolan et al. 1994; Norton and D’Amore 1994; Lodato et al. 1999), cells survival and viability (Argiriou et al. 1996; Kourkoutas et al. 2003a) and flavor formation (Bakoyianis et al. 1993; Bardi et al. 1997). It has been difficult to predict the type and magnitude of these possible metabolic changes due to immobilization as a number of parameters are involved, such as mass transfer limitations by diffusion (Webb et al. 1986), changes in the cell morphology and oxygen uptake (Shirai et al. 1988), altered membrane permeability (Brodelius and Nilsson 1983), media components deficiency (Chen et al. 1990), surface pressure and osmotic pressure changes (Vijayalakshmi et al. 1979), contacts between cells in limited space (Shuler 1985), etc. For example, immobilization of Saccharomyces cerevisiae resulted in increased ethanol production and glucose consumption, higher ploidy and RNA content (Doran and Bailey 1986), lower internal pH value (Galazzo et al. 1987) and altered glucose catabolic pathways compared to free cells in suspensions, and in increased enzyme activity and therefore productivity (Galazzo and Bailey 1990).

12.2.3 Advantages of Immobilized Cell Systems

The advantageous effects of immobilization applications could be summarized in the following:

-

1.

Prolonged activity and stability of the immobilized cells, since the immobilization support may act as a protective agent against physicochemical changes (pH, temperature, heavy metals, solvents, etc.),

-

2.

Higher cell densities than usually achieved, resulting in higher productivities and increased substrate uptake and yield,

-

3.

Increased tolerance to high substrate concentration and final product inhibition,

-

4.

Reduced risk of microbial contamination attributed to high cell densities and enhanced fermentation activity,

-

5.

Ability for low-temperature fermentation and/or maturation for certain food products,

-

6.

Ability for regeneration and re-use,

-

7.

Versatility in the selection of bioreactors,

-

8.

Ability for continuous operation bioreactor systems, and

-

9.

Reduction of maturation times in certain circumstances.

12.3 Alcoholic Fermentation by Immobilized Cells

Cell immobilization in alcoholic fermentation is a rapidly expanding research area because of its attractive technical and economic advantages compared to the conventional free cell system (Sakurai et al. 2000; Sree et al. 2000; Shindo et al. 2001; Lu et al. 2002). However, for industrial wine and cider production it is important to identify a suitable support for cell immobilization that meets the prerequisites named above and results in overall improvement of the sensory characteristics of the final product. Another criterion that is sought after in an immobilized system is the suitability for use in low temperature fermentations, since low temperature fermentation leads to an improved quality product.

12.3.1 Alcoholic Fermentation of Wine Using Immobilized Cells

Immobilization supports have been grouped into four categories (Kourkoutas et al. 2004a):

-

1.

Inorganic supports,

-

2.

Organic supports,

-

3.

Membrane systems,

-

4.

Natural supports and cell aggregates.

12.3.1.1 Inorganic Supports

Kissiris (a cheap, porous volcanic mineral found in Greece, similar to granite, containing 70% SiO2, 13% Al2O3, and other inorganic oxides) was successfully used as immobilization support of S. cerevisiae for wine production in both batch (Kana et al. 1989) and continuous bioreactor systems (Bakoyianis et al. 1992; Bakoyianis et al. 1993). Kissiris-supported biocatalyst showed increased ethanol productivity and biocatalytic stability for about 2.5 years during successive preservations at 0°C (Argiriou et al. 1996). Similar studies involved γ-alumina in the form of porous cylindrical pellets as immobilization support for wine making (Kana et al. 1989; Loukatos et al. 2000).

Although inorganic supports offered many advantages such as abundance, enhanced fermentation productivity and cost effectiveness, they were considered inappropriate for wine-making because they are characterized as unsuitable materials for human nutrition. Nevertheless, they seem to have a potential in production of alcohol (Bakoyianis and Koutinas 1996; Koutinas et al. 1997) or distillates (Loukatos et al. 2003), as mineral residues do not distill.

12.3.1.2 Organic Supports

Organic immobilization supports mainly include those composed of polysaccharides or other polymers. The most popular polysaccharides proposed in wine fermentation are alginates (Suzzi et al. 1996; Silva et al. 2002). Calcium alginate was used for immobilizing Candida stellata alone or in combination with S. cerevisiae to enhance glycerol formation in wine (Ciani and Ferraro 1996). The same immobilized biocatalyst along with an inoculum of S. cerevisiae was used at pilot scale and under non-sterile conditions, in order to control wild microflora (Ferraro et al. 2000). Most efforts have focused on application of alginates for the secondary fermentation of sparkling wines (Fumi et al. 1988; Busova et al. 1994; Colagrande et al. 1994). In fact, application of immobilized cell technology in the production of sparkling wines is the only case to have been commercially available, imitating the traditional Champagne method.

However, gel-like supports discourage scale-up and industrial applications, since they are mechanically unstable in high-capacity bioreactors. In addition, it is difficult to attain consumer acceptance, in case they are not of food-grade purity (e.g., polyvinyl alcohol).

12.3.1.3 Membrane Systems

References concerning the use of membrane systems in wine and cider production are scarce in literature. In a previous study, a single-vessel membrane bioreactor was found unsuitable for continuous dry wine production, as high levels of unfermented sugars were reported (Takaya et al. 2002). However, a double-vessel continuous membrane configuration resulted in sugar content < 4 g/L, which was considered satisfactory for dry wine-making. Additionally, wine productivity in the latter was 28 times higher compared to batch systems.

12.3.1.4 Natural Supports and Cell Aggregates

Food-grade natural immobilization supports, such as delignified cellulosic materials (Bardi and Koutinas 1994), gluten pellets (Bardi et al. 1996), and brewer’s spent grains (Mallouchos et al. 2007), were successfully used for ambient and low-temperature wine-making, resulting in improved profiles of volatile by-products (Bardi et al. 1997; Mallouchos et al. 2002; Mallouchos et al. 2003). The commercial potential of immobilized yeast on gluten pellets and delignified cellulosic material was evaluated by the production of freeze-dried biocatalysts without using a protecting medium during freezing and freeze-drying (Iconomopoulou et al. 2002; Iconomopoulou et al. 2003). The freeze-dried immobilized biocatalysts retained high viability and showed long operational stability during low-temperature wine-making. The possibility of storage of freeze-dried immobilized biocatalysts for long time intervals without any loss of cell viability and fermentation activity is of crucial importance for industrial application.

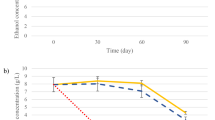

The use of fruit pieces in developing an immobilized biocatalyst that would meet all the required prerequisites was an obvious alternative. Fruit pieces are of food-grade purity, cheap, abundant and could be easily accepted by consumers. Apple (Kourkoutas et al. 2001), quince (Kourkoutas et al. 2003b) and pear pieces (Mallios et al. 2004) were proposed as immobilization supports due to ease in the immobilization technique and to the distinctive aromatic potential and improved sensory characteristics of the produced wines. The immobilized yeasts resulted in rapid fermentations, as wine production was effective in 12 h at 30°C and in 4 days at 10°C (Kourkoutas et al. 2003b). Apple-supported biocatalyst was able to reactivate and ferment after successively increased periods of storage (up to 120 days) at 30°C (Kourkoutas et al. 2003a). The ability of storage at ambient temperature for such long time periods is considered very attractive for the industrialization of the process.

Apple pieces were also used as support for immobilizing Kluyveromyces marxianus IMB3 for high-temperature wine-making at 45°C (Kourkoutas et al. 2004b). The fermented grape must contain 3–4% alcohol and special types of semi-sweet wines were produced by the addition of potable alcohol.

Additionally, fruit-based biocatalysts were found suitable for continuous wine-making (Kourkoutas et al. 2002a, b; Mallios et al. 2004), as the immobilized biocatalyst showed high operational stability up to 95 days (Kourkoutas et al. 2002a).

Taking into account that grape skins are the principal undesired solid wastes of the wine-making process and raisins are directly related to the main raw material of wine, their use as immobilization supports was an interesting approach (Mallouchos et al. 2002; Tsakiris et al. 2004a, b). They were both found suitable for low-temperature fermentation and a positive influence on wine aroma was evident. The main advantage, however, is that the grape skins and the extracted residues of raisins from wineries and potable producing plants, which are difficult to dispose of, could be alternatively beneficially exploited.

Natural immobilization of single microorganisms, such as flocculating yeasts and cell aggregates forming pellets or solid microspheres, offer practical potentiality as the metabolic state of the immobilized cells may remain unaltered, since artificial immobilization techniques may induce cell damage. This is the simplest and the least expensive immobilization method. However, interactions among cells are not easily controlled and cell aggregates are very sensitive to conditions usually dominating in fermentors. In Saccharomyces cereivisiae, a number of proteins called flocculins (Caro et al. 1997) are responsible for cell–cell adhesion and formation of aggregates.

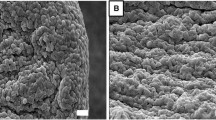

A novel technique of co-immobilization a filamentous fungus and a flor yeast avoiding chemical crosslinkers or external supports was recently reported (Peinado et al. 2005; Peinado et al. 2006). The technique was based on reproducing conditions adequate for a forced symbiosis of Penicillium and Saccharomyces cereivisiae. As a result, formation of hollow biocapsules with walls composed of mycelium and trapped yeast cells was obtained after killing of Penicillium by the ethanol produced. The mycelium walls enclosed an inner space partially occupied by yeast cells. The yeast biocapsules were successfully used in must fermentation producing wine with increased acetaldehyde and isobutanol, but reduced ethyl acetate and acetoin contents compared to free cells fermentation.

12.4 Cell Immobilization and Malolactic Fermentation

MLF is a difficult and time-consuming process that does not always proceed favorably under the natural conditions of wine. Traditional MLF is used worldwide to produce high-quality wines, although delay or failure is not an unusual outcome. During MLF l-malic acid is converted to l-lactic acid and carbon dioxide by malolactic bacteria, principally of the genera Oenococcus, Pediococcus and Lactobacillus. Lactic acid is “less acidic” than malic acid, as it is a mono-acid compared to the two-acid malic acid. Consequently, total acidity is decreased during MLF (deacidification).

MLF usually results in microbial stability (Lonvaud-Funel 1995) and in improvement of the organoleptic properties. Besides deacidification, it induces a dramatic change in the organoleptic quality of wines, since the characteristic taste of malic acid disappears. MLF is usually encouraged by wine-producers in cold climates where ripe grapes contain a high malic acid content resulting in too acidic wines, in instances where it is required enhanced microbial stability (i.e., prior bottling), and in situations where the flavorful by-products (such as diacetyl) are essential in order to provide the recognizable sensory notes desired in certain wine types. MLF is crucial for wines originating from Burgundy (especially for Chardonnay variety), as well as for heavy red wines, as such originating from Bordeaux. However, MLF is not always advantageous, as in wines with very low total acidity; it may cause a further reduction affecting both flavor and biological stability (Lonvaud-Funel 1995; Versari et al. 1999). Hence, it should be discouraged and may even be considered destructive in grapes from warm regions having small amounts of malic acid, in wines of poor microbial stability, and in wines where by-products of MLF may provide an unpleasant character.

During recent years several attempts have been proposed to induce biological deacidification of wines by involving the use of immobilized cells on various matrices. The use of immobilized lactic acid bacteria (LAB) for controlling MLF is desirable, as it offers the following advantages:

-

1.

As spontaneous MLF is time consuming and growth of malolactic bacteria microflora depends on physicochemical properties and composition of wine (e.g., fatty acids, ethanol and SO2 may inhibit growth of malolactic bacteria), cell immobilization techniques aim to increase tolerance of malolactic bacteria.

-

2.

The use of immobilized malolactic bacteria results in higher cell densities and hence, acceleration of the process.

-

3.

The use of selected cultures results in development of characteristic organoleptic properties (Maicas et al. 1999).

-

4.

The immobilized cultures allow reuse of cells and favor application of continuous process (Lonvaud-Funel 1995; Kosseva et al. 1998; Maicas et al. 2001).

The first efforts involved immobilization of Lactobacillus casei cells in polyacrylamide gels (Diviès and Siess 1976; Totsuka and Hara 1981; Rossi and Clementi 1984). Nevertheless, the proposed technology was practically restricted to laboratory use, since industrial application of the immobilized biocatalysts was never attempted due to safety regulations. The use of alginates (Spettoli et al. 1982; Naouri et al. 1991) hardly offered an alternative, because they proved mechanically unstable in long term industrial applications (e.g., when exposed to high pressures).

κ-Carrageenan, a naturally occurring polysaccharide isolated from sea wood, was used as support for immobilizing several LAB species, including Lactobacillus and O. oeni (formerly Leuconostoc oenos) cells (McCord and Ryu 1985; Crapisi et al. 1987a, b). Lactobacillus sp. cells were immobilized in 2% κ-carrageenan gel and subsequently used in a continuous-flow bioreactor to promote and control MLF. The immobilized cells showed enhanced operational stability in malic acid metabolism with the addition of 5% purified bentonite to the matrix and conversion rates up to 53.9% were reported (Crapisi et al. 1987a). The half-life of the bioreactor was extended to 46 days, while the minimum retention time for MLF accomplishment was decreased to about 2 h. Kosseva et al. (1998) reported an approximate 30% degradation of malic acid using immobilized L. casei cells on calcium pectate gels and chitopearls with an operational stability up to 6 months. The degradation of malic acid obtained using the immobilized cells was twice as high as compared to that obtained with the free cells. In another study, the possibility of using immobilised O. oeni cells on positively charged cellulose sponge [diethyl (DE) or diethylaminoethyl (DEAE) cellulose] for MLF of wine was investigated in a semi-continuous bioreactor (Maicas et al. 2001). The first 24 h, malic acid was almost completely metabolized, while in subsequent fermentations a drastic reduction of malolactic activity was evident. Recently, Lactobacillus casei ATCC 393 cells immobilized on delignified cellulosic material (DCM) were used for MLF of wine (Agouridis et al. 2005). As the repeated MLF batches proceeded, the activity of the immobilized biocatalyst was reduced from 80 to 2%. Acetic acid content was slightly reduced or remained stable and concentrations of the higher alcohols 1-propanol, isobutyl alcohol and amyl alcohol were decreased by 84, 23 and 11%, respectively, resulting in improved quality.

12.5 Cell Immobilization in Cider-Making

Cider-making is a complex process requiring two successive fermentations: (a) the alcoholic fermentation, and (b) the MLF. During cider production, the reduction of beverage acidity by bacteria inducing MLF is generally recognized as an important phase for flavor development. Therefore, attempts have been focused on simultaneous alcoholic and MLF.

A sponge-like material was proposed to immobilize both S. cerevisiae and L. plantarum for carrying out fermentation and partial maturation of cider (Scott and O’Reilly 1996). The sponge’s open porous network promoted extensive and rapid surface attachment of the microorganisms. Fermentations carried out with immobilized yeast and sequential addition of LAB enhanced fermentation rate and had a positive effect on flavor development. In another study, a bi-reactor composed of an alcoholic fixed immobilized Saccharomyces bayanus bed bioreactor coupled to a second fixed immobilized Leuconostoc oenos bed bioreactor was used for dry as well as sweet ciders by controlling dilution rate of the influent (Simon et al. 1996). Malic acid metabolism and acetaldehyde content in cider produced by Saccharomyces cerevisiae and immobilised L. oenos was temperature dependent, while concentrations of ethyl acetate and methanol were influenced by the type of L. oenos inoculation (Cabranes et al. 1998). Co-immobilization of Saccharomyces bayanus and L. oenos in Ca-alginate matrix was proposed for simultaneous alcoholic and MLF of apple juice in a continuous packed bed bioreactor (Nedovic et al. 2000). The continuous process resulted in faster fermentation compared to the traditional batch process, whereas a reduction of higher alcohols and an increase in diacetyl, attributed to the altered metabolism of immobilized cells was evident. Production of soft or dry cider was possible by controlling the feeding flow rates. Cells of Oenococcus oeni immobilized in alginate beads resulted in reduced ethyl acetate and acetic acid content when used as starter culture to conduct MLF of cider compared to the free cells system (Herrero et al. 2001).

The situation of conducting alcoholic and MLFs simultaneously by the same microorganism has been sought after by wine scientists. The first attempts involved transferring DNA encoding the malolactic enzyme from Lactobacillus delbrueckii to Saccharomyces serevisiae (Williams et al. 1984). Later on, a S. cerevisiae strain was generated containing the metabolic machinery for malate degradation, which was able to grow at pH values < 2.9 (Volschenk et al. 1997). However, the use of a novel yeast replacing all malolactic procedures is doubtful, but in no case efforts aiming at the accomplishment of such a splendid achievement should be distracted. Although there are some arguments concerning concurrent conduction of the two fermentations, it is not uncommon, especially among wine manufacturers in California (Kunkee 1997), who usually inoculate wine must with both malolactic bacteria and yeast.

12.6 Bioreactors in Wine and Cider-Making

Although there have been tremendous research activities, the main drawbacks constraining industrial application of immobilized bacteria for MLF apparently are: (a) inactivity of malolactic enzyme at wine pH (Colagrande et al. 1994), (b) instability of the required cofactor NAD which is particularly unstable in wine (Colagrande et al. 1994; Diviès et al. 1994), and (c) inhibition of LAB and MLF due to the high ethanol content (Rossi and Clementi 1984; Crapisi et al. 1987a). Nevertheless, they have already been widely studied at pilot plant production sizes. A summary of the main immobilization systems proposed for alcoholic and MLF of wine and cider is presented in Table 12.1. Although the high number of proposed immobilization supports and the advantages associated with the use of immobilized cells, industrial application is still limited. There are only a few attempts aimed at the application of immobilized cell technologies in wine and cider-making on a large scale (Colagrande et al. 1994; Diviès et al. 1994). Most of these efforts concern production of sparkling wine, and secondary MLF of wine. A wide range of fermentors varying shape and technical design are nowadays available to provide preferred flow/mixing and external mass transfer characteristics during processing. However, in the majority of wine and cider-making studies, packed bed configuration has been used, operating in batch, and in fewer cases, continuous mode on lab-to-pilot scale. The reason is a simple design, consisting of a column which is packed with the immobilized biocatalyst. However, for possible industrial applications, the use of mechanically unstable materials, such as hydrogels, should be limited to lower bed heights. Furthermore, packed-bed bioreactors are linked to several engineering problems associated with mass transfer limitations, accumulation of evolved gas (which can be in high concentrations mortal to living cells and reduces the useful volume), formation of preferential paths or channeling (causing concentration and temperature gradients), excessive pressure drop, as well as short circuiting and clogging.

In a recent study, a modification of packed-bed fermentor, a multi-stage fixed-bed tower (MFBT) bioreactor has been proposed for batch and continuous wine-making (Sipsas et al. 2009). It consists of a vertical cylindrical tank with five packed sections containing freeze-dried immobilized cells on gluten pellets. The MFBT bioreactor resulted in higher alcohol productivity compared to fermentations carried out in a packed-bed bioreactor and showed high operational stability. A relatively small (5,000–10,000 L) MFBT bioreactor (Fig. 12.1) (Loukatos et al. 2000; Koutinas et al. 1997) is proposed for the industrialization of immobilized cells in wine-making, as handling of the support at this scale could be performed without any problems, while cell immobilization could be carried out in the bioreactor. Application of the MFBT bioreactor at industrial scale eliminates insufficient mass transfer and enables support division, especially when mechanically unstable supports are used in order to minimize high pressures, which may result in support destruction and reduction of fermentation activity. Experiments concerning long term storage of the immobilized biocatalysts (Kourkoutas et al. 2003a) are very promising, since the preparation of new biocatalyst, emptying and filling of the bioreactor could be avoided when industrial production is halted. Taking into consideration the above discussion of technical problems, the scale-up of the proposed technology seems feasible.

Future research efforts should be directed towards application of other types of reactors (such as fluidized or gas-lift) already approved in beer production. A recent study was focused on the use of a membrane bioreactor for MLF of ethanol containing media (Lovitt et al. 2006).

12.7 Conclusions

Microbial cell immobilization can improve the efficiency of fermentation of alcoholic and MLF and the quality of the fermentation products. The selection of the suitable carrier and bioreactor system is a challenge and many issues should be taken into account, such as product quality, safety and stability, processing, investment and operating costs, as well as matters of legality (food grade purity, the use of cross linking agents, etc.). It is obvious that in alcoholic fermentation process a high number of technologies (cell adsorption, entrapment, and flocculation) and immobilization materials (both organic and inorganic) may have a positive impact on cell metabolism. The ability of storage for long time periods of freeze-dried immobilized biocatalysts produced by food-grade natural materials is considered very attractive for the industrialization of the process. Packed-bed reactors are still the first choice in the industrial sector, mainly due to the simplicity of the design and in combination with natural supports (such as fruit-based or cellulosic materials) seem to have potential in scale-up. The use of mechanically unstable materials, such as hydrogels, depends on innovations on the design of packed-bed columns (e.g., multiple sections are usually applied for biocatalysts division). Therefore, problems related to high pressures and insufficient mass transfers are minimized. Investment cost and difficulties in scale up are still the main issues constraining application of other bioreactor types in the fermentation processes.

In wine and cider production, the development of a fine taste is an undisputable goal and thus control of MLF is an important step. Immobilization in either gels or cellulosic materials aims to increase tolerance of malolactic bacteria and to accelerate the process. In cider-making, attempts have been focused on simultaneous alcoholic and MLF by co-immobilization of two different species or by the same microorganism, usually after genetic modification. Production of soft or dry cider is possible by controlling the feeding flow rates.

The main drawback inhibiting industrial use of immobilized biocatalysts for fermentation processes is related to maintenance of cell viability during production and storage, especially when production is halted, as wine and cider products are season dependent. Further application will depend on research results upon preservation of immobilized cells, as well as development of processes that can be readily scaled-up. Thus, research should be oriented towards the evolvement of reliable preservation and storage techniques that could be easily adopted by the industrial sector.

References

Agouridis N, Bekatorou A, Nigam P, Kanellaki M (2005) Malolactic fermentation in wine with Lactobacillus casei cells immobilized on delignified cellulosic material. J Agric Food Chem 53(7):2546–2551

Argiriou T, Kanellaki M, Voliotis S, Koutinas AA (1996) Kissiris-supported yeast cells: high biocatalytic stability and productivity improvement by successive preservations at 0°C. J Agric Food Chem 44:4028–4031

Bakoyianis V, Koutinas AA (1996) A catalytic multistage fixed-bed tower bioreactor in an industrial-scale pilot plant for alcohol production. Biotechnol Bioeng 49:197–203

Bakoyianis V, Kanellaki M, Kaliafas A, Koutinas AA (1992) Low temperature wine making by immobilized cells on mineral kissiris. J Agric Food Chem 40:1293–1296

Bakoyianis V, Kana K, Kalliafas A, Koutinas AA (1993) Low-temperature continuous wine making by kissiris-supported biocatalyst: Volatile byproducts. J Agric Food Chem 41:465–468

Bakoyianis V, Koutinas AA, Agelopoulos K, Kanellaki M (1997) Comparative study of kissiris, γ-alumina, and calcium alginate as supports of cells for batch and continuous wine-making at low temperatures. J Agric Food Chem 45:4884–4888

Bardi EP, Koutinas AA (1994) Immobilization of yeast on delignified cellulosic material for room temperature and low-temperature wine making. J Agric Food Chem 42:221–226

Bardi EP, Bakoyianis V, Koutinas AA, Kanellaki M (1996) Room temperature and low temperature wine making using yeast immobilized on gluten pellets. Process Biochem 31:425–430

Bardi E, Koutinas AA, Psarianos C, Kanellaki M (1997) Volatile by-products formed in low-temperature wine-making using immobilized yeast cells. Process Biochem 32:579–584

Brodelius P, Nilsson K (1983) Permealization of immobilized plant cells, resulting in release of intracellularly stored products with preserved cell viability. Eur J Appl Microbiol Biotechnol 17:275–280

Busova K, Magyar I, Janky F (1994) Effect of immobilized yeasts on the quality of bottle-fermented sparkling wine. Acta Alimentaria 23:9–23

Buzas Z, Dallmann K, Szajani B (1989) Influence of pH on the growth and ethanol production of free and immobilized Saccharomyces cerevisiae cells. Biotechnol Bioeng 34:882–884

Cabranes C, Moreno J, Mangas JJ (1998) Cider production with immobilized Leuconostoc oenos. J Inst Brew 104:127–130

Caro LH, Tettelin H, Vossen JH, Ram AF, Van den Ende H, Klis FM (1997) In silicio identification of glycosyl-phosphatidylinositol-anchored plasma-membrane and cell wall proteins of Saccharomyces cerevisae. Yeast 13:1477–1489

Chen C, Dale MC, Okos MR (1990) Minimal nutritional requirements for immobilized yeast. Biotechnol Bioeng 36:993–1001

Ciani M, Ferraro L (1996) Enhanced glycerol content in wines made with immobilized Candida stellata cells. Appl Environ Microbiol 62:128–132

Colagrande O, Silva A, Fumi MD (1994) Recent applications of biotechnology in wine production. Biotechnol Prog 10:2–18

Crapisi A, Nuti MP, Zamorani A, Spettoli P (1987a) Improved stability of immobilized Lactobacillus sp. cells for the control of malolactic fermentation in wine. Am J Enol Vitic 38:310–312

Crapisi A, Spettoli P, Nuti MP, Zamorani A (1987b) Comparative traits of Lactobacillus brevis, Lactobacillus fructivorans and Leuconostoc oenos immobilized cells for the control of malolactic fermentation in wine. J Appl Bacteriol 63:513–521

Diviès C, Siess MH (1976) Étude du catabolisme de l’acide L-malique para Lactobacillus casei emprisonée dans un gel de polyacrylamide. Ann Microbiol (Paris) 127:525–539

Diviès C, Cachon R, Cavin J-F, Prévost H (1994) Theme 4: Immobilized cell technology in wine production. Crit Rev Biotechnol 14:135–153

Doran PM, Bailey JE (1986) Effects of immobilization on growth, fermentation properties, and macromolecular composition of Saccharomyces cerevisae attached to gelatin. Biotechnol Bioeng 28:73–87

Ferraro L, Fatichenti F, Ciani M (2000) Pilot scale vinification process using immobilized Candida stellata cells and Saccharomyces cerevisiae. Process Biochem 35:1125–1129

Fumi MD, Trioli G, Colagrande O (1987) Immobilization of Saccharomyces cerevisiae in calcium alginate for sparkling wine processes. Biotechnol Lett 9:339–342

Fumi MD, Trioli G, Colombi MG, Colagrande O (1988) Immobilization of Saccharomyces cerevisiae in calcium alginate gel and its application to bottle-fermented sparkling wine production. Am J Enol Vitic 39:267–272

Galazzo J, Bailey JE (1990) Growing Saccharomyces cerevisae in calcium alginate beads induces cell alteration, which accelerate glucose conversion to ethanol. Biotechnol Bioeng 36:417–426

Galazzo JL, Shanks JV, Bailey JE (1987) Comparision of suspended and immobilized yeast metabolism using 31P Nuclear Magnetic Resonance spectroscopy. Biotechnol Tech 1:1–6

Herrero M, Laca A, Garcia LA, Díaz M (2001) Controlled malolactic fermentation in cider using Oenococcus oeni immobilized in alginate beads and comparison with free cell fermentation. Enzyme Microb Technol 28:35–41

Hilge-Rotmann B, Rehm HJ (1990) Comparison of fermentation properties and specific enzyme activities of free and calcium-alginate-entrapped Saccharomyces cerevisiae. Appl Microbiol Biotechnol 33:54–58

Iconomopoulou M, Psarianos K, Kanellaki M, Koutinas AA (2002) Low temperature and ambient temperature wine making using freeze-dried immobilized cells on gluten pellets. Process Biochem 37:707–717

Iconomopoulou M, Kanellaki M, Soupioni M, Koutinas AA (2003) Effect of freeze-dried cells on delignified cellulosic material in low-temperature wine making. Appl Biochem Biotechnol 104:23–36

Iconomou L, Kanellaki M, Voliotis S, Agelopoulos K, Koutinas AA (1996) Continuous wine making by delignified cellulosic materials supported biocatalyst. An attractive process for industrial applications. Appl Biochem Biotechnol 60:303–313

Jamai L, Sendide K, Ettayebi K, Errachidi F, Hamdouni-Alami O, Tahri-Jouti MA, McDermott T, Ettayebi M (2001) Physiological difference during ethanol fermentation between calcium alginate-immobilized Candida tropicalis and Saccharomyces cerevisiae. FEMS Microbiol Lett 204:375–379

Kana K, Kanellaki M, Papadimitriou A, Psarianos C, Koutinas AA (1989) Immobilization of Saccharomyces cerevisiae on γ-alumina pellets and its ethanol production in glucose and raisin extract fermentation. J Ferment Bioeng 68:213–215

Kosseva MR, Kennedy JF (2004) Encapsulated lactic acid bacteria for control of malolactic fermentation in wine. Artif Cells Blood Substit Immobil Biotechnol 32:55–65

Kosseva M, Beschkov V, Kennedy JF, Lloyd LL (1998) Malolactic fermentation in Chardonnay wine by immobilized Lactobacillus casei cells. Process Biochem 33:793–797

Kourkoutas Y, Komaitis M, Koutinas AA, Kanellaki M (2001) Wine production using yeast immobilized on apple pieces at low and room temperatures. J Agric Food Chem 49:1417–1425

Kourkoutas Y, Koutinas AA, Kanellaki M, Banat IM, Marchant R (2002a) Continuous wine fermentation using a psychrophilic yeast immobilized on apple cuts at different temperatures. Food Microbiol 19:127–134

Kourkoutas Y, Douma M, Koutinas AA, Kanellaki M, Banat IM, Marchant R (2002b) Room and low temperature continuous wine making using yeast immobilized on quince pieces. Process Biochem 39:143–148

Kourkoutas Y, Kanellaki M, Koutinas AA, Banat IM, Marchant R (2003a) Storage of immobilized yeast cells for use in wine-making at ambient temperature. J Agric Food Chem 51:654–658

Kourkoutas Y, Komaitis M, Koutinas AA, Kaliafas A, Kanellaki M, Marchant R, Banat IM (2003b) Wine production using yeast immobilized on quince biocatalyst at temperatures between 30 and 0°C. Food Chem 82:353–360

Kourkoutas Y, Bekatorou A, Banat IM, Marchant R, Koutinas AA (2004a) Immobilization technologies and support materials suitable in alcohol beverages production: a review. Food Microbiol 21:377–397

Kourkoutas Y, McErlean C, Kanellaki M, Hack CJ, Marchant R, Banat IM, Koutinas AA (2004b) High-temperature wine making using the thermotolerant yeast strain Kluyveromyces cerevisiae IMB3. Appl Biochem Biotechnol 112:25–35

Koutinas AA, Bakoyianis V, Argiriou T, Kanellaki M, Voliotis S (1997) A qualitative outline to industrialize alcohol production by catalytic multistage fixed bed tower (MFBT) bioreactor. Appl Biochem Biotechnol 66:121–131

Kunkee RE (1997) A heady concoction of alcoholic and malolactic fermentations. Nat Biotechnol 15:224–225

Lodato P, Segovia De Huergo M, Buera MP (1999) Viability and thermal stability of a strain of Saccharomyces cerevisiae freeze-dried in different sugar and polymer matrices. Appl Microbiol Biotechnol 52:215–220

Lonvaud-Funel A (1995) Microbiology of the malolactic fermentation: molecular aspects. FEMS Microbiol Lett 126:209–214

Loukatos P, Kiaris M, Ligas I, Bourgos G, Kanellaki M, Komaitis M, Koutinas AA (2000) Continuous wine making by γ-alumina-supported biocatalyst. Quality of the wine and distillates. Appl Biochem Biotechnol 89:1–13

Loukatos P, Kanellaki M, Komaitis M, Athanasiadis I, Koutinas AA (2003) A new technological approach for distillate production using immobilized cells. J Biosci Bioeng 95:35–39

Lovitt R, Jung I, Jones M (2006) The performance of a membrane bioreactor for the malolactic fermentation of media containing ethanol. Desalination 199:435–437

Lu ZX, Lu FX, Bie XM, Fujimura T (2002) Immobilization of yeast cells with polymeric carrier cross-linked using radiation techniques. J Agric Food Chem 50:2798–2801

Maicas S, Gil J-V, Pardo I, Ferrer S (1999) Improvement of volatile composition of wines by controlled addition of malolactic bacteria. Food Res Intern 32:491–496

Maicas S, Pardo I, Ferrer S (2001) The potential of positively charged cellulose sponge for malolactic fermentation of wine, using Oenococcus oeni. Enzyme Microb Technol 28:415–419

Mallios P, Kourkoutas Y, Iconomopoulou M, Koutinas AA, Psarianos C, Marchant R, Banat IM (2004) Low temperature wine-making using yeast immobilized on pear pieces. J Sci Food Agric 84:1615–1623

Mallouchos A, Reppa P, Aggelis G, Koutinas AA, Kanellaki M, Komaitis M (2002) Grape skins as a natural support for yeast immobilization. Biotechnol Lett 24:1331–1335

Mallouchos A, Komaitis M, Koutinas AA, Kanellaki M (2003) Wine fermentation by immobilized and free cells at different temperatures. Effect of immobilization and temperature on volatile by-products. Food Chem 80:109–113

Mallouchos A, Loukatos P, Bekatorou A, Koutinas A, Komaitis M (2007) Ambient and low temperature wine-making by immobilized cells on brewer’s spent grains: Effect on volatile composition. Food Chem 104(3):918–927

Margaritis A, Merchant FJA (1984) Advances in ethanol production using immobilized cell systems. Crit Rev Biotechnol 2:339–393

Martynenko NN, Gracheva IM, Sarishvili NG, Zubov AL, El’Registan GI, Lozinsky VI (2004) Immobilization of champagne yeasts by inclusion into cryogels of polyvinyl alcohol: Means of preventing cell release from the carrier matrix. Appl Biochem Microbiol 40:158–164

McCord JD, Ryu DDY (1985) Development of malolactic fermentation process using immobilized whole cells and enzymes. Am J Enol Vitic 36:214–218

Melzoch K, Rychtera M, Habova V (1994) Effect of immobilization upon the properties and behavior of Saccharomyces cerevisiae cells. J Biotechnol 32:59–65

Naouri P, Bernet N, Chagnaud P, Arnaud A, Galzy P (1991) Bioconversion of L-malic acid into L-lactic acid using a high compacting multiphase reactor (HCMR). J Chem Technol Biotechnol 51:81–95

Navarro JM, Durand G (1977) Modification of yeast metabolism by immobilization onto porous glass. Eur J Appl Microbiol 4:243–254

Nedovic VA, Durieux A, Van Nederveide L, Rosseels P, Vandegans J, Plaisant AM, Simon J-P (2000) Continuous cider fermentation with co-immobilized yeast and Leuconostoc oenos cells. Enzyme Microb Technol 26:834–839

Nolan AM, Barron N, Brady D, McAree T, McHale L, McHale AP (1994) Ethanol production at 45°C by an alginate-immobilized thermotolerant strain of Kluyveromyces marxianus following growth on glucose-containing media. Biotechnol Lett 16:849–852

Norton S, D’Amore T (1994) Physiological effects of yeast cell immobilization applications for brewing. Enzyme Microb Technol 16:365–375

Peinado RA, Moreno JJ, Maestre O, Mauricio JC (2005) Use of a novel immobilization yeast system for winemaking. Biotechnol Lett 27:1421–1424

Peinado RA, Moreno JJ, Villalba JM, González-Reyes JA, Ortega JM, Mauricio JC (2006) Yeast biocapsules: A new immobilization method and their applications. Enzyme Microb Technol 40:79–84

Rossi J, Clementi F (1984) L-malic acid catabolism by polyacrylamide gel entrapped Leuconostoc oenos. Am J Enol Vitic 36:100–102

Sakurai A, Nishida Y, Saito H, Sakakibara M (2000) Ethanol production by repeated batch culture using yeast cells immobilized within porous cellulose carriers. J Biosci Bioeng 90:526–529

Scott JA, O’Reilly AM (1996) Co-immobilization of selected yeast and bacteria for controlled flavour development in an alcoholic cider beverage. Process Biochem 31:111–117

Shindo S, Takata S, Taguchi H, Yoshimura N (2001) Development of a novel carrier using natural zeolite and continuous ethanol fermentation with immobilized Saccharomyces cerevisiae in a bioreactor. Biotechnol Lett 23:2001–2004

Shirai Y, Hashimoto K, Yamaji H, Kawahara H (1988) Oxygen uptake rate of immobilized growing hybridoma cells. Appl Microbiol Biotechnol 29:113–118

Shuler ML (1985) Immobilized whole cell bioreactors: potential tools for directing cellular metabolism. World Biotechnol Rep 2:231–239

Silva S, Ramon-Portugal P, Silva P, Texeira MF, Strehaiano P (2002) Use of encapsulated yeast for the treatment of stuck and sluggish fermentations. J Intern des Sci de la vigne et du vin 36:161–168

Simon JP, Durieux A, Pinnel V, Garré V, Vandegans J, Rosseels P, Godan N, Plaisant AM, Defroyennes J-P, Foroni G (1996) Organoleptic profiles of different ciders after continuous fermentation (encapsulated living cells) versus batch fermentation (free cells). In: Wijffels RH, Buitelaar RH, Bucke C, Tramper J (eds) Immobilized cells: Basics and applications. Elsevier BV, Amsterdam, pp 615–621

Sipsas V, Kolokythas G, Kourkoutas Y, Plessas S, Nedovic VA, Kanellaki M (2009) Comparative study of batch and continuous multi-stage fixed-bed tower (MFBT) bioreactor during wine-making using freeze-dried immobized cells. J Food Eng 90:495–503

Spettoli P, Bottacin A, Nuti MP, Zamorani A (1982) Immobilization of Leuconostoc oenos ML 34 in calcium alginate gels and its application to wine technology. Am J Enol Vitic 33:1–5

Sree NK, Sridhar M, Suresh K, Banat IM, Rao IV (2000) High alcohol production by repeated batch fermentation using an immobilized osmotolerant Saccharomyces cerevisiae. J Ind Microbiol Biotechnol 24:222–226

Stewart GG, Russel I (1986) One hundred years of yeast research and development in the brewing industry. J Inst Brew 92:537–558

Suzzi G, Romano P, Vannini I, Turbanti L, Domizio P (1996) Cell-recycle batch fermentation using immobilized cells of flocculent Saccharomyces cerevisiae wine strains. World J Microbiol Biotechnol 12:25–27

Takaya M, Matsumoto N, Yanase H (2002) Characterization of membrane bioreactor for dry wine production. J Biosci Bioeng 93:240–244

Totsuka A, Hara S (1981) Decomposition of malic acid in red wine by immobilized microbial cells. Hako Kogaku Zasshi 59:231–237

Tsakiris A, Bekatorou A, Psarianos C, Koutinas AA, Marchant R, Banat IM (2004a) Immobilization of yeast on dried raisin berries for use in dry white wine-makin. Food Chem 87:11–15

Tsakiris A, Sipsas V, Bekatorou A, Mallouchos A, Koutinas AA (2004b) Red wine making by immobilized cells and influence on volatile composition. J Agric Food Chem 53:1357–1363

Versari A, Parpinello GP, Cattaneo M (1999) Leuconostoc oenos and malolactic fermentation in wine: a review. J Ind Microbiol Biotechnol 23:447–455

Vijayalakshmi M, Marcipar A, Segard E, Broun GB (1979) Matrix bound transition metal for continuous fermentation tower packing. Ann NY Acad Sci 326:249–254

Volschenk H, Viljoen M, Grobler J, Petzold B, Bauer F, Subden RE, Young RA, Lonvaud A, Denayrolles M, Van Vuuren HJJ (1997) Engineering pathways for malate degradation in Saccharomyces cerevisiae. Nat Biotechnol 15:253–257

Walsh PK, Malone DM (1995) Cell growth in immobilization matrices. Biotechnol Adv 13:13–43

Webb C, Fukuda H, Alkinson B (1986) The production of cellulose in a spouted bed fermentor using cells immobilized in biomass support particles. Biotechnol Bioeng 28:41–50

Williams SA, Hodges RA, Strike TL, Snow R, Kunkee RE (1984) Cloning the gene for malolactic fermentation of wine from Lactobacillus delbrueckii in Escherichia coli and yeasts. Appl Environ Microbiol 47:288–293

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2010 Springer Science+Business Media, LLC

About this chapter

Cite this chapter

Kourkoutas, Y., Manojlović, V., Nedović, V.A. (2010). Immobilization of Microbial Cells for Alcoholic and Malolactic Fermentation of Wine and Cider. In: Zuidam, N., Nedovic, V. (eds) Encapsulation Technologies for Active Food Ingredients and Food Processing. Springer, New York, NY. https://doi.org/10.1007/978-1-4419-1008-0_12

Download citation

DOI: https://doi.org/10.1007/978-1-4419-1008-0_12

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4419-1007-3

Online ISBN: 978-1-4419-1008-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)