Abstract

Nanotechnology involves the study at microcospic scale and has the potential to be the key to a brand new world in the field of construction and building materials. Although replication of natural systems is one of the most promising areas of this technology, scientists are still trying to grasp their astonishing complexities. This chapter covers the nanoscale analysis of Portland cement hydration products and the use of nanoparticles to increase the strength and durability of cementitious composites. It also covers the development of self-cleaning materials and materials that reduce air pollutants through photocatalysis.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Portland cement hydration products

- Nanoparticles

- Photocatalysis

- Self-cleaning materials

- Bactericidal capacity

10.1 General

The speech of the physicist Richard P. Feynmam, entitled “There’s plenty of room at the bottom” (Feynman 1960), that took place in a meeting of the American Physical Society in 1959 at CalTech is considered to be the beginning of the nanotechnology era. This last term was nonetheless presented in 1974 by Professor Norio Taguchi, meaning the processing of materials, atom-by-atom or molecule-by-molecule (Taniguchi 1974). A more accurate definition of nanotechnology was presented in 1981 by Drexler (1981), such as the production with dimensions and precision between 0.1 and 100 nm. In medium terms nanotechnology involves the study at microcospic scale (1 nm = 1 × 10−9 m). As a comparison, one must realize that a human hair has 80,000 nm thickness and that the DNA double helix has 2 nm diameter. Between 1997 and 2003 the investment in nanotechnology increased at 40% reaching 35000 million euro (Andersen and Molin 2007). Some estimates predict that products and services related to nanotechnology could reach 1,000.000 million euro/year beyond 2015 (NSF 2001). The report RILEM TC 197-NCM, “Nanotechnology in construction materials” (Zhu et al. 2004), is the first document that synthesis in a clear manner the potential of nanotechnology in terms of the development of construction and building materials, namely:

-

The use of nanoparticles, carbon nanotubes and nanofibres to increase the strength and durability of cimentitious composites as well as for pollution reduction;

-

Production of cheap corrosion-free steel;

-

Production of thermal insulation materials with a performance 10 times higher than commercial current options;

-

Production of coats and thin films with self-cleansing ability and self-color change to minimize energy consumption;

-

Production of nanosensores and materiais with sensing ability and self-repairing ability.

One of the most promising areas in the field of nanotechnology and also mentioned in the RILEM TC 197-NCM report relates to the replication of natural systems. The continuous improvement of these systems carried out over millions of years led to the development of materials and “technologies” with exceptional performance and fully bio-degradable. For instance, the abalone shells are made with 0.2 mm thickness layers, and each one is made by a “mortar” 0.5 μm thickness of calcium carbonate crystals bound altogether with a protein. The final result is a composite material with a toughness that is 3000 times the toughness of the calcium carbonate crystals (Li et al. 2004; Meyers et al. 2009). Mussels and barnacles, can produce a natural glue as good as synthetic adhesives that allows them to maintain a high adhesion to submerged rocks (Hedlund et al. 2004; Khandeparker and Chandrashekhar 2007; Kamino 2010). The great advantage relates to the fact that synthetic adhesives are based on epoxy, melamine-urea-formaldehyde, phenol or organic solvents. These compounds are toxic and responsible for eczema and dermatitis, and even cancer. Another example of the high performance of natural systems comes from the spider silk which possesses a strength/mass ratio that exceeds the steel ratio (Porter and Vollrath 2007; Lee et al. 2009; Harrington et al. 2010). Even comparing the performance of carbon nanotubes, a high-technology product with spider silk, one realizes how natural systems are well-optimized. First discovered in Russia in 1952, carbon nanotubes were some years later re-discovered in Japan. These materials have a tensile strength 100 times over steel but as a downside side they are extremely costly (20 to 1000 euros/g) (Man 2006). Another biomimicry-related finding relates to the coral reef formation. Those natural systems use sea water to produce calcium, magnesium and carbonate to generate a carbonate crystal (aragonite). The coral reef formation is a very complex process, dependent on several factors, the main being photosynthesis (Barnes 1970; Holcomb 2010). Recently the enterprise Calera has announced the possibility of producing calcium carbonate using sea water and CO2 (Mitchell 2009; Geyer et al. 2009). Unfortunately the scientific information available so far is insufficient to take that for granted. However, the information concerning the technological process were not disclosed, only that the process is already being used in an experimental facility near the Moss Landing power plant (California), using carbon dioxide generated by the power plant to produce“cement”. One high-impact application of nanotechnology in the field of energy consumption relates to the development of nanomaterials with very high-insulation performance, such as aerogel (Fig. 10.1) previously mentioned in Chap. 3.

10.2 Cementitious Composites with Enhanced Strength and Durability

10.2.1 Investigation of Portland Cement Hydration Products

Concrete is the most used construction material on Planet Earth and presents a higher permeability that allows water and other aggressive elements to enter, leading to carbonation and chloride ion attack, resulting in steel corrosion problems. Therefore, the nanoscale study of the hydration products (C–S–H, calcium hydroxide, ettringite, monosulfate, unhydrated particles and air voids), as a form to overcome durability issues, is a crucial step in the concrete eco-efficiency. Investigations in this field have already been carried out in recent years (Porro and Dolado 2005; Balaguru and Chong 2006). Mojumdar and Raki (2006) have already analyzed calcium silicate nanophase composites which will allow the future development of anti-corrosion and fire-retardant coatings. Until very recently electronic microscopy has allowed the understanding of the morphology, as well as the composition of hydration products. However, the use of nanotechnology currently allows the possibility of the knowledge of the elastic modulus by nanoindentation techniques (AFM). In nanoindentation a material with known characteristics is used to make a mark in another material with unknown properties and through the specific nature of this mark it is possible to infer the properties of the marked material. Recently Mondal (2008) used nanoindentation in cementitious phases and obtained the following elastic modulus: 35 MPa for the Ca(OH)2 phase; 26 and 16 MPa for high- and low-stiffness C–S–H and 10 MPa for the porous phase. Other authors (Constantinides et al. 2003; Dejong and Ulm 2007; Constantinides and Ulm 2007) have already confirmed the existence of different types of CSH, low density, high density and ultra-high density. More recently some authors (Pellenq et al. 2009) from MIT have used nanotechnology to develop a molecular model for the hydration products of Portland cement. These authors confirm that the molecular model is in excellent agreement with experimental values obtained by nanoindentation techniques.

10.2.2 Composites with Nanoparticles

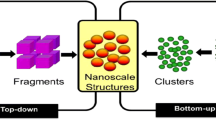

Nanoparticles have a high-surface area to volume ratio providing high-chemical reactivity. They act as nucleation centers, contributing to the development of the hydration of Portland cement. Most investigations use nanosilica while some already used nano-Fe2O3. The production of nanoparticles can be obtained either through a high-milling energy (Sobolev and Ferrada-Gutierrez 2005) or by chemical synthesis (Lee and Kriven 2005). Porro et al. (2005) mentioned that the use of nanosilica particles increases the compression strength of cement pastes. The same authors state that the phenomenon is not due to the pozzolanic reaction, because calcium hydroxide consumption was very low but, instead, due to the increase use of silica compounds that contributes to a denser microstructure. According to Lin et al. (2008), the use of nanosilica on sludge/fly ash mortars, compensates the negative effects associated to the sludge incorporation in terms of setting time and initial strength. Sobolev et al. (2008) reported that nanosilica addition led to an increase of strength by 15% to 20%. Other authors (Gaitero 2008; Gaitero et al. 2009) believe that nanosilica leads to an increase of C–S–H chain dimension and also to an increase of C–S–H stiffness. Chen and Lin (2009) used nanosilica particles to improve the performance of sludge/clay mixtures for tile production. The results show that nanoparticles improved the reduction of water absorption and led to an increase of abrasion and impact strength. Others (Vera-Agullo et al. 2009) also confirm that the use of nanoparticles (nanotubes, nanofibers, nanosilica or nanoclay) is responsible for a higher hydration degree of cementitious compounds, as long as a higher nanoparticle dispersion can be achieved. Nasibulin et al. (2009) reported an increase in strength by 2 to 40 times for electric conductivity, which means a high potential for sensing ability. Several authors confirm the suitability of mortars with Fe2O3 nanoparticles to act as sensing materials (Li et al. 2004; Qing et al. 2008; Lin et al. 2008). Chaipanich et al. (2010) mentioned that 1% of carbon nanofibres (by binder mass) can compensate the strength reduction associated with the replacement of 20% fly ash. Gdoutos--Konsta et al. (2010) also studied the effect of carbon nanofibres on cement pastes (0.08% by binder mass) observing an increase in the mechanical strength. Those authors used ultra-sounds to achieve a high-nanofibre dispersion stating that this is a crucial step in order to obtain a high performance of nanotubes in the cement matrixes. Nevertheless, the fact that carbon nanotubes are not cost-efficient prevents the increase of its use in commercial applications in a near future.

10.3 Photocatalytic Applications

The most known application of nanomaterials in the construction industry relates to the photocatalytic capacity of semiconductor materials. Several semiconductors materials, such as TiO2, ZnO, Fe2O3, WO3 and CdSe, possess photocatalytic capacity (Makowski and Wardas 2001). However, TiO2 is the most used of all because of its low toxicity and stability (Djebbar and Sehili, 1998). Titanium dioxide can crystallize as rutile, anatase and brookite, being the first form the most stable (thermodynamically speaking), it is also the most available form (it is the 9th most abundant element in the Earth crust), being currently used as additive in the painting industry.

The anatase and brookite forms are meta-stable and can be transformed into rutile by thermal treatment. Being a semiconductor with photocatalytic capacity, when TiO2 is submitted to UV rays (320–400 nm), in the presence of water molecules (Husken et al. 2009), it leads to the formation of hydroxyl radicals (OH) and superoxide ions (O2 −). Those highly-oxidative compounds react with dirt and inorganic substances promoting their disintegration. The photocatalysis of TiO2 is also responsible for the reduction of the contact angle between water droplets and a given surface, leading to super-hydrofobic or super-hydrophilic surfaces increasing their self-cleansing capacity. Water repellent surfaces are one of the features of natural systems as it happens in the leaves of the lotus plant, whose microstruture allows self-cleansing ability (Fig. 10.2). According to Fujishima et al. (2008), the potential of photocatalysis can be perceived by the high number of citations (almost 3700) of a related paper published on Nature in 1972, as well as by the number of papers concerning photocatalysis investigations that increased in an exponential pattern between 1997 and 2007. Another form to evaluate the potential of this technology is by knowing that the Japanese Corporation TOTO Ltd has already issued 1200 international patent requests in this field. So far 500 have been approved. The applications related to photacatalysis cover five different groups (Fig. 10.3).

Lotus effect (Benedix et al. 2000)

Major areas of activity in titanium dioxide photocatalysis (Benedix et al. 2000)

Considering the cost to clean graffiti paintings (in Los Angeles city this could amount to 100 million euro/year (Castano and Rodriguez 2003) )one can realize the huge potential of the photocatalytic capacity of nanomaterials.

10.3.1 Self-Cleaning Ability

Although self-cleaning properties of photocatalysts materials are known since the 60s (Fujishima and Honda 1972), only recently they start to be used in a wide-scale (Fujishima et al. 1999). Cassar and Pepe (1997) patented a concrete block with self-clening ability (Table 10.1).

The first application of self-cleaning concrete took place in the church “Dives in Misericordia” in Rome (Fig. 10.4). This building was designed by the Arqº Richard Meyer and officially opened in 2003. It is composed of 346 pre-stressed concrete blocks made with white cement and TiO2 (binder 380 kg/m3 and W/B = 0.38) (Cassar et al. 2003).

Visual observations carried out six years after its construction revealed only slight differences between the white color of the outside concrete surfaces and the inside block surfaces (Chen and Poon 2009b). Diamanti et al. (2008) studied mortars containing TiO2 having noticing reductions in the contact angle between water and solid surface of almost 80%. Ruot et al. (2009) mentioned that the photocatalytic activity is dependent on the matrix properties. Increasing the TiO2 content in cement pastes above 1% leads to a proportional increase in the photocatalytic activity, as for mortars a TiO2 content increase just lead to a very small increase in the photocatalytic activity (Fig. 10.5). Those authors suggest that most TiO2 particles in mortars are not reached by UV radiation.

Photocatalytic activity of cement-based materials versus the TiO2 content, within the first 7 h of illumination (Ruot et al. 2009)

The use of TiO2 thin films on tiles or glasses has significant potential in terms of self-cleaning ability. According to Fujishima et al. (2008) Japan buildings must be cleaned at least every five years to maintain a good appearance, while that covered with self-cleaning tiles should remain clean over a span of 20 years without any maintenance.

10.3.2 Air Pollution Reduction

The subject of air pollutants such as VOCs released from building materials have already been addressed in . Chap. 2. In the last years several investigations have been carried out in order to use photocatalysis to reduce air pollution. The reaction of photocatalytic oxidation of pollutants, generates water and carbon dioxide as by-products. Murata et al. (1997) patented a paving block for the reduction of air pollution (Table 10.2):

Zhao and Yang (2003) mentioned a high-photocatalytic capacity for indoor air pollution reduction when using P25 TiO2 (70% anatase + 30% rutile) with 300 nm diameter and a specific surface of 50 m2/g. Yu (2003) studied cementitious paving blocks for NO x reduction, noticing that the photocatalytic capacity is reduced by the presence of dust, grease or plastic gum, thus suggesting that these blocks should not be placed in pedestrian areas. Maier et al. (2005) reported a fast pollution reduction in indoor air by the use of gypsum plasters containing 10% TiO2 (Fig. 10.6). Those authors mentioned that although air pollution reduction is dependent on the UV intensity, nevertheless, visible light still allows acceptable degradation rates. Those plasters were used to cover some bedrooms in Sweden, being responsible for a reduction on VOC of about 1/3 (to 26 μg/m3).

Degradation of formaldehyde in plasters containing TiO2 (Maier et al. 2005)

Strini et al. (2005) mentioned that TiO2 thin films have a photocatalytic capacity which is 3 to 10 times higher than for TiO2 based cementitious composites. In 2006 the results of the PICADA (2006) project “Photo-catalytic innovative coverings applications for de-pollution assessment” aiming to the development of TiO2-based coatings for self-cleaning and air pollution reduction coatings were disclosed. This consortium gathered 8 partners (Italcementi, Millenium Chemicals, AUT, NCSRD, CNR ITC, CSTB, Dansk Beton Teknik and GMT) and was financed in 2.3 million euro by the EU (Gurol, 2006). Aside from the study of small specimens in laboratory the PICADA project also covered pilot tests at macro-scale (1:5) in order to reply the effect of a street by using (18 × 5.18 m2) “walls” and an artificial NO x pollution source (Fig. 10.7). The results showed a reduction in the NO x emissions between 40% to 80%. However, results published in a scientific journal mentioned NO x reductions between 36.7% to 42% (Maggos et al. 2008). The use of a three-dimensional numerical model (MIMO) based on the data generated in the pilot test allowed the insertion of win velocity and temperature in order to predict the reductions in air pollution by the photocatalytic activity of the facade coatings containing TiO2.

The canyon street pilot site (PICADA 2006)

In another macro-scale test carried out in the PICADA project, the ceiling of an underground car park (322 m2) was painted with TiO2-based paint. Then the park was sealed and polluted by the exhaust gas from a single car. The results showed a 20% reduction on NO x emissions, due to the photocatalytic capacity of the paint in the ceiling. Wang et al. (2007) confirmed that in the last few years a lot of investigations has been made about the reduction of indoor air pollution when using UV radiation but very few have analyzed the possibility of using photocatalysts active under visible light. Poon and Cheung (2007) mentioned that TiO2 cementitious composites with increased porosity show a high NO x emissions reduction. Those authors compared the performance of several TiO2 forms, concluding that although P25 is much more reactive it does not have a very high performance/cost ratio. Guerrini and Peccati (2007) mentioned a case of a street in Bergamo, Italy, paved with blocks (12,000 m2) of photocatalytic properties where high reductions of NO x emissions (45%) have been reported. In Antwerp a park with 10,000 m2 of semiconductors paving blocks also showed a reduction in NO x emissions (Beeldens 2007). In Tokyo cement mixtures containing TiO2 colloidal solutions were used to coated several road areas (Fig. 10.8). The results obtained in an area of 300 m2 show a 50 mg to 60 mg/day NO emissions degradation (Fujishima et al. 2008).

Using TiO2 photocatalytic material on roadway for pollution reduction (Fujishima et al. 2008)

Auvinen and Wirtanen (2008) studied the reduction of VOCs in indoor air when using paints with TiO2 applied in several substrates (glass, gypsum and polymer) noticing that the substrate does not influences the photocatalytic reaction. Those authors mentioned that organic additives must not be used for this paints because they will be damaged by the radical hydroxyls. Also that the photocatalytic reactions generates not only water and CO2 but also other pollutants that are harmful for human health. Other authors (Demeestere et al. 2008) confirm the reductions of NO x emissions between 23% and 63% when using TiO2-based tiles. They also reported that the accumulation of reaction products generated in the oxidation process reduces the photocatalytic activity. For the production of TiO2-based cementitious composites some authors (Husken et al. 2009) recommend the use of TiO2 as a solution with the mixing water because it allows for a better dispersion than if it is mixed with the cement. Also that a semiconductor with a high-specific surface gives better results than the use of a superior volume of low-specific surface semiconductor. These authors used a specific surface TiO2 (between 0.7 m2/g to 1.5 m2/g) which is much lower than the P25 form. Chen and Poon (2009b) found out that when using grounded glass for partial sand replacement the photocatalytic capacity, increases as much as 3 times for lighter glass (Fig. 10.9). Those authors suggest that glass particles can allow light to enter more deeply in the mortar leading to a higher oxidation rate.

Comparison of NO removal by samples of different glass colors based on 7-day curing age testing. (Chen and Poon 2009a)

Kolarik et al. (2010) confirmed that the photocatalytic reaction is a good way to reduce VOCs in indoor air. Ramirez et al. (2010) mentioned that the substrate porosity influences the photocatalytic reaction when TiO2 thin films are being used and that a high-porosity surface leads to a high photocatalytic reaction. Ballari et al. (2010) presented a model that can predict NO x emissions reduction using concrete with TiO2 particles. Hassan et al. (2010) used 41 MPa concrete blocks covered with 1 cm TiO2-based mortar layer in order to evaluate nanoparticles removal by abrasion tests and thus reducing the photocatalytic capacity in NO x emissions reduction. Those authors mentioned that even after 20,000 abrasion cycles the NO x emissions degradation and reduction remained stable.

10.3.3 Bactericidal Capacity

One of the most important applications of materials with photocatalytical properties concerns the destruction of fungi and bacteria. Indoor fungi and bacteria proliferation are one of the main causes responsible for construction materials degradation and also for health problems (Zyska 2001; Santucci et al. 2007; Wiszniewska et al. 2009; Bolashikov and Melikov 2009) because fungi are responsible for mycotoxins growth (Reboux et al. 2010). Saito et al. (1992) studied the addition of TiO2 powder with an average size of 21 nm (30% rutile and 70% anatase) to a bacterial colony. The results showed that 60 to 120 min were sufficient to destroy all the bacteria. Those authors state that using bigger TiO2 particles reduces the bactericidal capacity and that the best results are obtained for a TiO2 concentration between 0.01 to 10 mg/ml. Huang et al. (2000) also confirmed that using lower dimension TiO2 particles leads to a faster bacterial destruction. Those authors noticed that bacterial destruction begins after 20 min of UV radiation exposition, being that after 60 min all the bacteria have been destroyed. They also reported that after the destruction has been initiated the fact that UV radiation is stopped does not reduce the bactericidal effect (Fig. 10.10).

The effect of TiO2 photocatalytic reaction on cell viability. (Huang et al. 2000)

Some authors (Kuhn et al. 2003) believe that the bactericidal capacity associated with TiO2 photocatalysis is dependent on the use of UV-A radiation with a wavelength between 320 and 400 nm, being that UV-C type is only effective if the light is applied in a direct manner, thus preventing the treatment of less illuminated areas. Seven et al. (2004) found that zinc-based photocatalysis is as bactericidal as effective as TiO2. Cho et al. (2004) confirmed that hydroxyl radicals are mainly responsible for the bactericidal capacity of semiconductors photocatalysts. Those authors mentioned that hydroxyl radicals have a destruction capacity of E.coli bacteria which is 1000 to 10000 times more effective than the chemical disinfection products. Vohra et al. (2006) used silver-doped TiO2 noticing a 100% bacteria destruction just after 2 min, this compares in a most favorable manner with current TiO2 which took 2 h to achieve the same destruction level. The bactericidal capacity is reduced over time because of the accumulation of dead bacteria and viruses (Bolashikov and Melikov 2009). Other authors (Chen et al. 2009) used wood specimens coated with a TiO2 thin film (1.5 mg/cm2) noticing that the photocatalytic reaction prevented fungi growth. Calabria et al. (2010) analyzed the application of TiO2 thin films (20 to 50 nm thickness) by the sol–gel process in adobe blocks as a way to increase their water absorption and the bactericidal capacity. Those authors mentioned that TiO2 thin films could be more cost-effective than current commercial paints. One of the main disadvantages of the bactericidal effect associated with photocatalysis relates to the need of UV radiation with a wavelength between 200 to 400 nm, however, recent findings show some possibilities in the development of composite materials with photocatalytic properties even when exposed to visible light (Dunnill et al. 2009; Chen et al. 2010). The use of titanium and trioxide tungsten-based films showed high-photocatalytic capacity under visible light above 400 nm (Song et al. 2006; Saepurahman and Chong 2010). Herrmann et al. (2007) mentioned several questions that should be addressed in a near future:

-

Use of semiconductors which are not TiO2 based;

-

Photocatalysis activation using visible light;

-

Development of semiconductors with improved bactericidal capacity.

10.4 Conclusions

Nanotechnology has the potential to be the key to a brand new world in the field of construction and building materials. Although the replication of natural systems is one of the most promising areas of this technology, scientists are still trying to grasp their astonishing complexities. Recent years showed an intensive use of the potential of some photocatalytic nanomaterials, by the development of products with self-cleaning ability, products capable of reducing air pollution and with bactericidal capacity. The results of these investigations show that the titanium dioxide is the most widely used semiconductor in the photocatalytic reaction due to its low toxicity and stability. They also show that the efficiency of the photocatalytic reaction is dependent on the type of TiO2, being that a mixture of rutile (30%) and anatase (70%) seems to be the most reactive. The use of TiO2 with a high-specific surface area also shows a higher reactivity. As to the use of TiO2 dispersed in cement matrix it is less effective than as thin films.

References

Andersen M, Molin M (2007) NanoByg- a survey of nanoinnovation in Danish construction. ISBN 978-87-550-3589-8, Rise National Laboratory, Technical University of Denmark

Auvinen J, Wirtanen L (2008) The influence of photocatalytic interior paints on indoor air quality. Atmosp Environ 42:4101–4112. doi:10.1016/j.atmosenv.2008.01.031

Balaguru P, Chong K (2006) Nanotechnology and concrete: Research opportunities. ACI FALL 2006 Convention, Nanotechnology of Concrete: Recent Developments and Future Perspectives, Code 76031.ACI

Ballari M, Hunger M, Husken G, Brouwers H (2010) NO x photocatalytic degradation employing concrete pavement containing titanium dioxide. Appl Catal B: Environ 95:245–254. doi:10.1016/j.apcatb.2010.01.002

Barnes D (1970) Coral skeletons: An explanation of their growth and structure. Science 170:1305–1308. doi:10.1126/science.170.3964.1305

Beeldens A (2007) Air purification by road materials: results of the test project. In: Baglione P, Cassar I (ed) RILEM Int. Symp. on photocatalysis environment and construction materials, 187–194, Italy

Benedix R, Dehn F, Quaas J, Orgass M (2000) Application of titanium dioxide photocatalysis to create self-cleaning building materials. Lacer 5:158–168

Bolashikov Z, Melikov A (2009) Methods for air cleaning and protection of building occupants from airborne pathogens. Build Environ 44:1378–1385. doi:10.1016/j.buildenv.2008.09.001

Calabria J, Vasconcelos W, Daniel D, Chater R, Mcphail D, Boccaccini A (2010) Synthesis of sol-gel titania bactericidal coatings on adobe brick. Constr Build Mater 24:384–389. doi:10.1016/j.conbuildmat.2009.08.020

Cassar I, Pepe C (1997) Paving tile comprising an hydraulic binder and photocatalytic particles. EP-patent 1600430A1, Italcementi, Italy

Cassar L, Pepe C, Tognon G, Guerrini G, Amadelli R (2003) White cement for architectural concrete possessing photocatalytic properties. 11th International Congress on the Chemestry of Cement, Durban

Castano V, Rodriguez R (2003) A nanotechnology approach to high performance anti-graffiti coatings. Presentation at the Nanotechnology in Crime Prevention Conference, London

Chaipanich A, Nochaya T, Wongkeo W, Torkittikul P (2010) Compressive strength and microstructure of carbon nanotubes-fly ash cement composites. Mater Science Eng A527:1063–1076. doi:10.1016/j.msea.2009.09.039

Chen L, Lin D (2009) Applications of sewage sludge ash and nano-SiO2 to manufacture tile as construction material. Const Build Mater 23:3312–3320. doi:10.1016/j.conbuildmat.2009.06.049

Chen J, Poon C (2009a) Photocatalytic construction and building materials: from fundamentals to applications. Build Environ 44: 1899–1906. doi:10.1016/j.buildenv.2009.01.002

Chen J, Poon C (2009b) Photocatalytic activity of titanium dioxide modified concrete materials—Influence of utilizing recycled glass cullets as aggregates. J Environ Manag 90: 3436–3442. doi:10.1016/j.jenvman.2009.05.029

Chen F, Yang X, Wu Q (2009) Antifungal capability of TiO2 coated film on moist wood. Build Environ 44:1088–1093. doi:10.1016/j.buildenv.2008.07.018

Chen F, Yang X, Mak H, Chan D (2010) Photocatalytic oxidation for antimicrobial control in built environment: A brief literature overview. Build Environ 45:1747–1754. doi:10.1016/j.buildenv.2010.01.024

Cho M, Chung H, Choi W, Yoon J (2004) Linear correlation between inactivation of E.coli and OH radical concentration in TiO2 photocatalytic disinfection. Water Res 38: 1069–1077. doi:10.1016/j.buildenv.2010.01.024

Constantinides G, Ulm F (2007) The nanogranular nature of C–S–H. J Mech Phys Sol 55:64–90. doi:10.1016/j.jmps.2006.06.003

Constantinides G, Ulm F, Vliet K (2003) On the use of nanoindentation for cementitious materials. Mater Struct 36:191–196. doi:10.1016/j.buildenv.2010.01.024

Dejong M, Ulm F (2007) The nanogranular behavior of C–S–H at elevated temperatures (up to 700°C). Cem Concr Res 37:1–12. doi:10.1016/j.cemconres.2006.09.006

Demeestere K, Dewulf J, De Witte B, Beeldens A, Van Langenhove H (2008) Heterogeneous photocatalytic removal of toluene from air on building materials enriched with TiO2. Build Environ 43:406–414. doi:10.1016/j.buildenv.2007.01.016

Diamanti M, Ormellese M, Pedeferri M (2008) Characterization of photocatalytic and superhydrophilic properties of mortars containing titanium dioxide. Cem Concr Res 38:1343–1353. doi:10.1016/j.cemconres.2008.07.003

Djebbar K, Sehili T (1998) Kinetics of Heterogeneous photocatalytic decomposition of 2, 4-Dichlorophenoxyacetic acid over TiO2 and ZnO in aqueous solution. Pest Sci 54:269–276. doi:10.1016/j.jcis.2005.08.007

Drexler K (1981) Molecular engineering: An approach to the development of general capabilities for molecular manipulation. Proc. Natl. Acad. Sci USA 78:5275–5278

Dunnill C, Ziken Z, Pratten J, Wilson M, Morgan D, Parkin I (2009) Enhanced photocatalytic activity under visible light in N-doped TiO2 thin film produced by APCVD preparations using t-butylamine as a nitrogen source and their potential for antibacterial films. J Photochem Photobiol A: Chem 207:244–253. doi:10.1016/j.jphotochem.2009.07.024

Feynman R (1960) There’s plenty of room at the bottom (reprint from the speech given at the annual meeting of the West Coast section of the American Physical Society). Eng Sci 23:22–36

Fujishima A, Honda K (1972) Electrochemical photolysis of water at a semiconductor electrode. Nat 238:37–38. doi:10.1038/238037a0

Fujishima A, Hashimoto K, Watanabe T (1999) Photocatalysis. Fundamentals and its Applications, BCK Inc, Japan

Fujishima A, Zhang X, Tryk D (2008) TiO2 photocatalys and related surface phenomena. Surface Sci Reports 63:515–582. doi:10.1016/j.surfrep.2008.10.001

Gaitero J (2008) Multi-scale study of the fibre matrix interface and calcium leaching in high performance concrete. PhD Thesis, Centre for Nanomaterials Applications in Construction of Labein-Tecnalia, Spain

Gaitero J, Zhu W, Campillo I (2009) Multi-scale study of calcium leaching in cement pastes with silica nanoparticles. Nanotechnology in Construction 3, Springer, Berlin, Heidelberg

Gdoutos-Konsta M, Metaxa Z, Shah S (2010) Highly dispersed carbon nanotube reinforced cement based materials. Cem Concr Res 40:1052–1059. doi:10.1016/j.cemconres.2010.02.015

Geyer R, Del Maestro C, Rohloff A (2009) Greenhouse gas footprint analysis of the Calera process. University of California, California

Guerrini G, Peccati E (2007) Photocatalytic cementitious roads for depollution. In: Baglione P, Cassar I (ed) RILEM Int. Symp. on photocatalysis environment and construction materials, 179–186, Italy

Gurol M (2006) Photo-catalytic construction materials and reduction in air pollutants. Sacramento State Center for California Studies, The California State University. http://www.csus.edu/calst/government_affairs/reports/PHOTO-CATALYTIC.pdf. Accessed 3 July 2011.

Harrington M, Masic A, Holten-Andersen N (2010) Iron-clad fibers: A metal-based biological strategy for hard flexible coatings. Sci 216–220. doi: 10.1126/science.1181044

Hassan M, Dylla H, Mohammad L, Rupnow T (2010) Evaluation of the durability of titanium dioxide photocatalyst coating for concrete pavement. Const Build Mater 24:1456–1461. doi:10.1016/j.conbuildmat.2010.01.009

Hedlund J, Berglin M, Sellborn A, Andersson M, Delage L, Elwing H (2004) Marine adhesives as candidates for new biomaterial. Transactions—7th World Biomaterials Congress

Herrmann J, Duchamp C, Karkmaz M, Hoai B, Lachheb H, Puzenat E, Guillard C (2007) Environmental green chemistry as defined by photocatalysis. J Hazard Mater 146:624–629. doi:10.1016/j.jhazmat.2007.04.095

Holcomb M (2010) Coral calcification: insights from inorganic experiments and coral responses to environmental variables. PhD Thesis, Massachusetts Institute of Technology MIT, Cambridge

Huang Z, Maness P, Blakem D, Wolfrum E, Smolinski S, Jacoby W (2000) Bactericidal mode of titanium dioxide photocatalysis. J Photochem Photobiol A:Chem 130:163–170. doi:10.1016/S1010-6030(99)00205-1

Husken G, Hunger M, Brouwers H (2009) Experimental study of photocatalytic concrete products for air purification. Build Environ 44:2463–2474. doi:10.1016/j.buildenv.2009.04.010

Kamino K (2010) Molecular design of barnacle cement in comparison with those of mussel and tubeworm. J Adhesion 86:96–110

Khandeparker L, Chandrashekhar A (2007) Underwater adhesion: The barnacle way. Int J Adhesion Adhesives 27:165–172. doi:10.1016/j.ijadhadh.2006.03.004

Kolarik B, Wargocki P, Skorek-Osikowska A, Wisthaler A (2010) The effect of a photocatalytic air purifier on indoor air quality quantified using different measuring methods. Buil Environ 45:1434–1440. doi:10.1016/j.buildenv.2009.12.006

Kuhn K, Chaberny I, Massholder K, Stickler M, Benz V, Sootag H, Erdinger L (2003) Disinfection of surfaces by photocatalytic oxidation with titanium dioxide and UVA light. Chemosphere 53:71–77. doi:10.1016/S0045-6535(03)00362-X

Lee S, Kriven W (2005) Synthesis and hydration study of Portland cement components prepared by organic steric entrapment method. Mater Struct 38:87–92. doi:10.1007/BF02480579

Lee S, Pippel E, Gosele U, Dresbach C, Qin Y, Chandran C, Brauniger T, Hause G, Knez M (2009) Greatly increased toughness of infiltrated spider silk. Sci 324:488–492. doi:10.1126/science.1168162

Li H, Xiao H, Ou J (2004) A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem Concr Res 34: 435–438. doi:10.1016/j.cemconres.2003.08.025

Lin D, Lin K, Chang W, Luo H, Cai M (2008) Improvements of nano-SiO2 on sludge/fly ash mortar. Waste Manag 28:1081–1087. doi:10.1016/j.wasman.2007.03.023

Maggos T, Plassais A, Bartzis J, Vasilakos C, Moussiopoulos N, Bonafous L (2008) Photocatalytic degradation of NO X in a pilot street configuration using TiO2-mortar panels. Environ Monitor Assess 136:35–44. doi:10.1007/s10661-007-9722-2

Maier W, Nilsson C, Holzer M, Lind J, Rosebom K (2005) Photocatalytic plaster for indoor air purification. 1st National Congress of Construction Mortars, APFAC, Lisbon

Makowski A, Wardas W (2001) Photocatalytic degradation of toxins secreted to water by cyanobacteria and unicellular algae and photocatalytic degradation of the cells of selected microorganisms. Current Topics in Biophysics 25: 19–25. www.nanoes.com.hk/…/Water/Photocatalytic_degration-of-toxins.pdf

Man S (2006) Nanotechnology and construction. Nanoforum report, Institute of Nanotechnology

Meyers M, Lim C, Nizam B, Tan E, Seki Y, Mckittrick J (2009) The role of organic intertile layer in abalone nacre. Mater Sci Eng C29:2398–2410. doi:10.1016/j.msec.2009.07.005

Mitchell S. (2009) Capturing carbon. Concrete Construction. World of Concrete 54:104

Mojumdar S, Raki L (2006) Synthesis, thermal and structural characterization of nanocomposites for potential applications in construction. J Therm Anal Calorimetry 86: 651–657. 10.1007/s10973-006-7720-1

Mondal P (2008) Nanomechanical properties of cementitious materials. PhD Thesis in Civil and Environment Engineering. Northwestern University, Illinois

Murata Y, Tawara H, Obata H, Murata K (1997) NO x -cleaning paving block. European patent 0 786 283 A1. Mitsubhisi Materials Corporation, Japan

Nasibulin A, Shandakov S, Nasibulina L, Cwirzen A, Mudimela P, Habermehl-Cwirzen K, Grishin D, Gavrilov Y, Malm J, Tapper U, Tian Y, Penttala V, Karppinen M, Kauppinen E (2009) A novel cement-based hybrid material. New J Physics 11, nº 023013. 10.1088/1367-2630/11/2/023013

NSF (2001) Societal implications of nanoscience and nanotecnology, USA

Pellenq R, Kushima A, Shahsavar R, Vliet K, Buehler M, Yip S, Ulm F (2009) A realistic molecular model of cement hydrates. In: Bazant Z (ed), Northwestern University, PNAS

PICADA (2006) Photocatalytic innovative coverings applications for depollution assessment. innovative facade with de-soiling and de-polluting properties. EC GRD1-2001-00669

Poon C, Cheung E (2007) NO removal efficiency of photocatalytic paving blocks prepared with recycled materials. Constr Build Materials 21:1746–1753. doi:10.1016/j.conbuildmat.2006.05.018

Porro A, Dolado J (2005) Overview of concrete modeling. Proc International conference on applications of nanotechnology in concrete design, pp 35–45

Porro A, Dolado J, Campillo I, Erkizia E, De Miguel Y, De Ybarra Y, Ayuela A (2005) Effects of nanosilica additions on cement pastes. Proc International conference on applications of nanotechnology in concrete design, pp 87–96

Porter D, Vollrath F (2007) Nanoscale toughness of spider silk. Nanotoday 2, 3

Qing Y, Zenan Z, Deyu K, Rongshen C (2008) Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr Build Mat 21:539–545. doi:10.1016/j.conbuildmat.2005.09.001

Ramirez A, Demeestere K, De Belie N, Mantyla T, Levanen E (2010) Titanium dioxide coated cementitious materials for air purifying purposes: Preparation, characterization and toluene removal potential. Build Environ 45:832–838. doi:10.1016/j.buildenv.2009.09.003

Reboux G, Bellanger A, Roussel S, Grenouillet F, Millon L (2010) Moulds in dwellings: Health risks and involved species. Rev Mal Respir 27:169–179

Ruot B, Plassais A, Olive F, Guillot L, Bonafous L (2009) TiO2-containing cement pastes and mortars: Measurements of the photocatalytic efficiency using rhodamine B-based colourimetric test. Sol Energy 83:1794–1801. doi:10.1016/j.solener.2009.05.017

Saepurahman M, Chong F (2010) Preparation and characterization of tungsten-loaded titanium dioxide photocatalyst for enhanced dye degradation. J Hazard Mater 176:451–458. doi:10.1016/j.jhazmat.2009.11.050

Saito T, Iwase J, Horic J, Morioka T (1992) Mode of photocatalytic bactericidal action of powdered semiconductor TiO2 on mutans streptococci. J Photochem Photobiol B: Biol 14:369–379. doi:10.1016/1011-1344(92)85115-B

Santucci R, Meunier O, Ott M, Herrmann F, Freyd A, De Blay F (2007) Fungic contamination of residence: 10 years assessment of analyses. Rev Franc d’Allergol Immun Clin 47:402–408

Seven O, Dindar B, Aydemir S, Metin D, Ozinel M, Icli S (2004) Solar photocatalytical disinfection of a group of bacteria and fungi aqueous suspensions with TiO2, ZnO and Sahara desert dust. J Photochem Phototobiol A: Chem 165:103–107. doi:10.1016/j.jphotochem.2004.03.005

Sobolev K, Ferrada-Gutierrez M (2005) How nanotechnology can change the concrete world: part 2. Am Ceram Soc Bull 84: 16–19. www.cognoscibletechnologies.com/…/How-Nanotechnology-Can-Change-the-concrete-world-I.pdf

Sobolev K, Flores I, Hermosillo R, Torres-Martinez L (2008) Nanomaterials and nanotechnology for high-performance cement composites. American Concrete Institute, ACI Special Publication 254: 93–120. https://pantherfile.uwm.edu/sobolev/www/…/7-Sobolev-ACI-F.pdf

Song H, Jiang H, Liu X, Meng G (2006) Efficient degradation of organic pollutant with Wox modified nano TiO2 under visible radiation. J Photochemical Phototobiol A: Chem 181:421–428. doi:10.1016/j.jphotochem.2006.01.001

Strini A, Cassese S, Schiavi L (2005) Measurement of benzene, toluene, ethylbenzene and o-xylene gas phase photodegradation by titanium dioxide dispersed in cementitious materials using a mixed flow reactor. Appl Catal B: Environ 61:90–97. doi:10.1016/j.apcatb.2005.04.009

Taniguchi N (1974) On the basic concept of ‘Nano-Technology’. Proc. Intl Conf Prod Eng Tokyo, Part II, Japan Society of Precision Engineering 2:18–23

Vera-Agullo J, Chozas-Ligero V, Portillo-Rico D, Garcia-Casas M, Gutierrez-Martinez A, Mieres-Royo J, Gravalos-Moreno J (2009) Mortar and concrete reinforced with nanomaterials. Nanotechnology in Construction 3, Springer, Berlin Heidelberg

Vohra A, Goswami D, Deshpande D, Block S (2006) Enhanced photocatalytic disinfection of indoor air. Appl Catal B: Environ 65:57–65. doi:10.1016/j.apcatb.2005.10.025

Wang S, Ang H, Tade M (2007) Volatile organic compounds in indoor environment and photocatalytic oxidation: State of the art. Environ Int 42:1843–1850. doi:10.1016/j.envint.2007.02.011

Wiszniewska M, Walusiak-Skorupa J, Gutarowska B, Krakowiak A, Pałczyński C (2009) Is the risk of allergic hypersensitivity to fungi increased by indoor exposure to moulds? Int J Occup Med Environ Health 22:343–354

Yu J (2003) Deactivation and regeneration of environmentally exposed titanium dioxide based products. Testing report, Nº E183413, Chinese University of Hong Kong

Zhao J, Yang X (2003) Photocatalytic oxidation for indoor air purification: a literature review. Build Enviro 38:645–654. doi:10.1016/S0360-1323(02)00212-3

Zhu W, Bartos P, Porro A (2004) Application of nanotechnology in construction. Summary of a state-of-the-art report. RILEM TC 197-NCM. Materials Struct 37:649–658. 10.1007/BF02483294

Zyska B (2001) Fungi in indoor air in European Countries. Mikologia Lekarska 8:127–140

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2011 Springer-Verlag London Limited

About this chapter

Cite this chapter

Torgal, F.P., Jalali, S. (2011). Nanotechnology Achievements. In: Eco-efficient Construction and Building Materials. Springer, London. https://doi.org/10.1007/978-0-85729-892-8_10

Download citation

DOI: https://doi.org/10.1007/978-0-85729-892-8_10

Published:

Publisher Name: Springer, London

Print ISBN: 978-0-85729-891-1

Online ISBN: 978-0-85729-892-8

eBook Packages: EngineeringEngineering (R0)