Abstract

For the example of 09G2S steel Charpy samples, the impact strength and failure mechanism of low-alloy steel is considered in impact flexure at 213–293 K. The initial samples are compared with samples subjected to equal-channel angular pressing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

In the process of developing a technology, creating the corresponding material, and manufacturing the product, it is important to study the physicomechanical properties and other characteristics of the materials involved.

One approach to increasing the strength of metals is severe plastic deformation, by methods such as equal-channel angular pressing [1–6]. For structural steels, it is not only important to increase the strength but also to increase the low-temperature stability, especially for materials with ultrafine-grain structure. The influence of severe plastic deformation on the low-temperature stability of metals is complex. In many studies, the low-temperature stability declines on account of decrease in grain size, whereas in others it increases. Therefore, the influence of severe plastic deformation on the failure of metals requires further study.

The possibility of increasing the strength and low-temperature stability of 09G2S steel by creating submicrocrystalline structure was established in [7]. The increase in the energy required for the failure of 09G2S steel after equal-channel angular pressing with n = 8 passes at T = 823 K is associated with greater relief of the fracture and change in the failure micromechanism: from quasi-shear fracture to ductile pitting fracture. For 06MBF steel with submicrocrystalline structure, researchers noted increase in strength, decrease in impact strength, and increase in critical brittleness temperature in [8]. It has been established that the impact strength and work of crack nucleation on failure is less after the formation of submicrocrystalline structure.

The failure of steel samples in impact flexure was investigated in [9–11]. The formation of submicrocrystalline structure does not change the cold-brittleness threshold but narrows the range of ductile–brittle transition, as shown in [9, 10]: it was found that the failure of steel 10 with its initial structure is of ductile–brittle type (microshear and pitting microrelief); after equal-channel angular pressing, by contrast, failure is associated with the formation of ductile ridges and steps (after four passes) or extended sections characterized by little relief (after six passes). The narrowing of the range of ductile–brittle transition was established for unalloyed moderate-carbon steel with ultrafine-grain structure in [11]. However, the interval is shifted to lower temperatures. The suppression of ductile–brittle transition in steels with bcc structure was shown for the example of omnidirectional isothermal forging and intense hot rolling of 12GBA pipe steel in [12]. Combining methods of severe plastic deformation offer certain benefits, such as control of the steel’s impact strength [13].

In the present work, we study the failure of low-alloy structural steel with a structure formed by considerable deformation and impact flexure, at low temperatures.

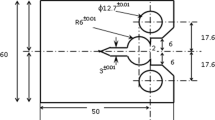

The metal is subjected to equal-channel angular pressing in equipment permitting simple shear at the intersection of two channels (separated by an angle of 120°). A PSU 125 ZIM hydraulic press producing a force of 1250 kN is used for equal-channel angular pressing. After heating and holding in a muffle furnace at 773 K, a 19.7 ± 100 mm cylindrical workpiece is placed in the equipment for equal-channel angular pressing; the equipment has already been heated to 773 K by means of a built-in furnace. To decrease the surface friction of the workpiece at the channel wall, we use Rosoil-Angelina lubricant, with additions of graphite flakes.

We investigate samples of low-alloy 09G2S steel before and after equal-channel angular pressing. Its chemical composition is as follows: 0.1% C, 0.85% Si, 1.41% Mn, 0.17% Cr, 0.18% Ni, and 0.35% Cu. The remainder is Fe. A Worldwide Analytical Systems (WAS, Germany) Foundry Master atomic-emission spectrometer is used for the chemical analysis.

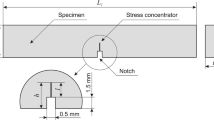

The 09G2S steel workpieces are subjected to 16 passes of equal-channel angular pressing by the BC route (90° rotation of the workpiece relative to its longitudinal axis before each successive pressing cycle) at 773 K. The strain is ε16 = 10.67. After equal-channel angular pressing, samples of Charpy type with V‑shaped cuts are prepared in accordance with State Standard GOST 9454–78. The impact-flexure tests are conducted by means of an Amsler RKP-450 (Zwick, Germany) pendulum hammer, at 293, 273, 253, 233, and 213 K.

The sample fractures are analyzed by means of Hitachi TM3030 scanning electron microscope (Japan), in secondary electrons.

The equal-channel angular pressing of 09G2S steel in two passes by the BC route at 673 K decreases the impact strength KCV at 213 K from 2.67 to 1.52 MJ m–2, as shown in [14]. Most of the fracture surface corresponds to brittle shear failure. At the same time, if forging for three cycles (with initial and final forging temperatures of 1173 and 1023 K, respectively) is combined with equal-channel angular pressing in four passes in the same conditions, the impact strength is increased to 2.93 MJ m–2. More than of 80% of the fracture surface corresponds to brittle failure with mixed relief, including a combination of intragrain shear and ductile pitting.

After 16 passes of equal-channel angular pressing by the BC route at 773 K, low-alloy 09G2S steel acquires ultrafine-grain structure. The impact strength KCV for 09G2S steel is shown in Fig. 1 and in Table 1. In Fig. 2, as an example, some stress diagrams are shown for impact samples. As a result of equal-channel angular pressing, the impact strength is significantly decreased. For example, at normal temperature, the impact strength of the steel is reduced by a factor of 1.73 after equal-channel angular pressing (from 2.6 to 1.5 MJ m–2). With decrease in test temperature, the difference in the KCV values for the two states increases—by a factor of almost 6.7 at 213 K (2.34 MJ m–2 in the initial state and 0.35 MJ m–2 after equal-channel angular pressing). The upper threshold of cold brittleness is about 225 K for the initial steel but around 250 K after strengthening.

At different test temperatures, the following sections are seen in fractures of impact samples for the initial steel and the strengthened steel: failure source, the central zone, and the shear zone. In each zone, the fracture differs in its degree of development (fracture geometry, type, and scale).

For Charpy samples in the initial state, the fracture surfaces are matte, with distinct relief. For a 09G2S steel sample with a cut in the initial state at T = 233–293 K, we note considerable tension over the sample thickness at the cut tip and lip, as a result of the formation and development of shear (Fig. 3a). Such fracture indicates ductile crack nucleation and considerable impact work in its nucleation. That is confirmed by the loading diagram in Fig. 2a.

For failure at 293, 273, 253, and 233 K, the macrorelief of the samples is of the same type. The crack motion at the surface inclined at about 30°–45° to the line of the cut. Much of the work of failure is consumed in forming the lip of the cut, where brittle failure occurs.

At 213 K, we note ductile–brittle failure for the sample in the initial state, with about 50% brittle failure. We observe skew fracture with 45° inclination of the fracture plane. The tension of the sample in the ductile fracture region is also considerable (Fig. 3b). The impact strength at 213 K is 2.34 MJ m–2. That is approximately 20% less than at higher temperatures. The brittle fracture zone has a metallic sheen and accounts for half of the sample’s fracture surface. Among the excluded regions are the zone at the cut tip, which corresponds to nucleation; and the zone of ductile-crack development, which includes subcritical crack growth and the shear zone (the lip of the cut and the prefracture zone), as we see in Fig. 3b. In Fig. 2b, which corresponds to failure of the sample with the initial structure, we see that the resistance to crack nucleation and propagation at 213 K is less than at 293 K (Fig. 2a).

For the 09G2S steel sample after equal-channel angular pressing, the fracture surface at 213 K shows traces of ductile and brittle failure. The skew fracture runs at ~10° to the sample cross section. The lip of the cut amounts to no more than 5% of the fracture surface. The same pattern is observed for the samples at 233 K and some samples at 253 K. After equal-channel angular pressing, the crack in the 09G2S steel sample at 213 K is inclined at around 30° to the line of the cut. With decrease in test temperature, the impact strength declines approximately fourfold: from 1.5 MJ m–2 at 293 K to 0.35 MJ m–2 at 213 K. The resistance to crack nucleation and propagation at 213 K is considerably less than at 293 K.

Analysis of the fractures of low-alloy 09G2S steel samples (Fig. 4) permits the following conclusions.

For 09G2S steel in the initial state (before equal-channel angular pressing) in impact flexure at normal temperature (KCV = 2.6 MJ m–2), we observe pitted microstructure. As the pits grow larger, traces of slip of the material are seen on their internal surfaces in the form of undulations (steps). Such failure is also observed at 233–273 K.

In the case of fracture at 213 K (KCV = 2.34 MJ m–2), around 50% of the fracture area corresponds to brittle failure, with microrelief in the form of brittle-shear facets with a grooved pattern, which are typical of intragrain shear (Fig. 4a). In the middle of the frame, we see the transfer of the grooves from the atomic plane of one crystal to the adjacent crystal, where the atomic plane has a different orientation. The mean size of the shear facets is 10–20 μm, corresponding to the size of ferrite grains.

We know that equal-channel angular pressing decreases the grain size and greatly increases the strength. Pitted microstructure is also typical in the fracture of 09G2S steel after equal-channel angular pressing (BC route, n = 16, T = 773 K) at 293 K (KCV = 1.5 MJ m–2).

At 213 K (KCV = 0.35 MJ m–2), the microrelief of the sample reveals three basic sections in the zone of crack development, corresponding to the stages in its motion (Fig. 3d). The transition from one to the next occurs through a plane. This pattern may indicate stratification of the material. At the boundary, the crack velocity changes. The first stage of the crack is the longest, accounting for practically half of the sample cross section. We note an undulating fanlike pattern of steps and grooves whose direction matches that of the crack. At the bottom of the grooves, we see extended micropits (0.5–5 μm). In each section, the grooves converge at the point of mixed failure, where both brittle-shear facets and ductile micropitting are present (Fig. 4b).The size of these micropits is 25 μm or less. We also observe microcracks (length 5–20 μm) formed by the coalescence of micropores. As we see in Fig. 2d, the sample is characterized by low resistance to crack nucleation and propagation. Similar macro- and microrelief is present in the fractures of samples subjected to equal-channel angular pressing in tests at 233 K and in some samples in tests at 253 K.

Thus, for 09G2S steel in the initial state, ductile failure at 233–293 K is replaced by ductile–brittle failure at 213 K. After equal-channel angular pressing, ductile failure at 273–293 K is replaced by mixed fracture at 213–233 K (and in some cases at 253 K).

CONCLUSIONS

We have seen that equal-channel angular pressing (BC route, n = 16, T = 773 K) reduces the grain size of the initial steel and decreases its impact strength. In particular, note the following.

(1) The impact strength of low-alloy 09G2S steel is decreased by a factor of 1.73 on equal-channel angular pressing. The threshold of cold brittleness is shifted from around 225 to 250 K (by about 25 K).

(2) In impact flexure of Charpy samples of 09G2S steel, we observe brittle failure, with pitted microrelief in the fractures, at 233–293 K. After equal-channel angular pressing of the samples, the same results are obtained in tests at 273–293 K and in some cases at 253 K. At 213 K, ductile–brittle failure is observed for samples in the initial state.

(3) After equal-channel angular pressing (BC route, n = 16, T = 773 K), 09G2S steel undergoes mixed fracture on impact flexure at 213–233 K and in some cases at 253 K. The resistance to crack propagation is low.

REFERENCES

Segal, V.M., Development of material treatment by severe shear deformation, Russ. Metall. (Engl. Transl.), 2004, vol. 2004, no. 1, pp. 2–9.

Valiev, R.Z. and Aleksandrov, I.V., Ob”emnye nanostrukturnye metallicheskie materialy: poluchenie, struktura i svoistva (Bulky Nanostructured Metal Materials: Production, Structure, and Properties), Moscow: Akademkniga, 2007.

Li, L. and Virta, J., Ultrahigh strength steel wires processed by severe plastic deformation for ultrafine grained microstructure, Mater. Sci. Technol., 2011, vol. 27, no. 5, pp. 845–862.

Maier, G.G., Astafurova, E.G., Maier, H.J., et al., Annealing behavior of ultrafine grained structure in low-carbon steel produced by equal channel angular pressing, Mater. Sci. Eng., A, 2013, vol. 581, no. 1, pp. 104–107.

Donic, T., Martikán, M., and Hadzima, B., New unique ECAP system with ultrasound and backpressure, IOP Conf. Ser.: Mater. Sci. Eng., 2014, vol. 63, no. 1, art. ID 012047. http://iopscience.iop.org/article/10.1088/1757-899X/63/1/012047/pdf. Accessed April 17, 2016.

Ivanov, A.M., Lukin, E.S., and Petrova, N.D., Regularities of deformation and fracture of steels subjected to equal channel angular pressing and thermal processing, Mater. Sci. Forum, 2008, vols. 584–586, pp. 643–648.

Yakovleva, S.P., Makharova, S.N., and Borisova, M.Z., Structure, properties, and fracture of a low-alloy steel in the submicrocrystalline state, Russ. Metall. (Engl. Transl.), 2006, vol. 2006, no. 4, pp. 337–343.

Botvina, L.R., Tyutin, M.R., Levin, V.P., et al., Specific static, shock, and fatigue destruction of 06MBF steel with submicrocrystalline structure, Zavod. Lab.,Diagn. Mater., 2008, vol. 74, no. 1, pp. 43–49.

Klevtsov, G.V., Valiev, R.Z., Raab, G.I., et al., Mechanism of impact fracture of steel 10 with submicrocrystalline structure in the range of ductile-brittle transition, Deform. Razrushenie Mater., 2011, no. 8, pp. 9–13.

Valiev, R.Z., Klevtsov, G.V., Klevtsova, N.A., et al., The effect of modes of equal-channel angular pressing and subsequent heating on the strength and mechanism of failure of steel 10, Deform. Razrushenie Mater., 2013, no. 1, pp. 21–25.

Klevtsov, G.V., Valiev, R.Z., Klevtsova, N.A., et al., The strength and fracture mechanism of unalloyed medium-carbon steel with ultrafine-grained structure under single loads, Phys. Met. Metallogr., 2018, vol. 119, no. 10, pp. 1004–1012.

Panin, V.E., Derevyagina, L.S., Lemeshev, N.M., et al., On the nature of low-temperature brittleness of BCC steels, Phys. Mesomech., 2014, vol. 17, no. 2, pp. 89–96.

Ivanov, A.M. and Lukin, E.S., An effective method for control of hit viscosity of steels, Izv. Samar. Nauchn. Tsentra, Ross. Akad. Nauk, 2012, vol. 14, no. 4 (5), pp. 1239–1242.

Petrova, N.D., Ivanov, A.M., and Syromyatnikova, A.S., Effect of thermoplastic processing mode on mechanical properties and destruction mechanism of low-alloyed steel at low temperature testing, Fundam. Issled., 2015, no. 2-1, pp. 30–35.

ACKNOWLEDGEMENTS

The impact tests were conducted on equipment in the Collective Use Center at Yakutsk Scientific Center, Siberian Branch, Russian Academy of Sciences.

We thank N.D. Kovalenko for producing the images of the fracture surfaces.

Funding

This work was supported by the Siberian Branch of the Russian Academy of Sciences, project III.28.1.1, program III.28.1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Ivanov, A.M. Low-Temperature Fracture of Low-Alloy Steel after Severe Plastic Deformation. Russ. Engin. Res. 40, 33–37 (2020). https://doi.org/10.3103/S1068798X20010098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X20010098