Abstract

The chemical diversity of organic semiconductors coupled with the kinetic nature of film formation make it challenging to tune the structure of active-layer thin films in organic electronics across multiple length scales. We review techniques to tune aspects of film structure within a framework that accounts for the competition between the time available for structural development and the time required by the organic semiconductors to order, defined by a dimensionless time, τ, that describes the ratio of these two quantities. By considering these two competing time scales, we propose general guidelines to tune the film structure accordingly.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A significant advantage of organic semiconductors compared with their inorganic counterparts is their chemical tunability, as functionalization and derivatization of the conjugated core allows for modification of macroscopic properties. However, these ensemble-average physical and optoelectronic properties are not purely a function of chemistry—the structure that organic semiconductor thin films adopt across multiple length scales plays a critical role in influencing the resulting function of these materials. For example, in organic thin-film transistors in which lateral charge transport is important, the organic semiconductor’s grain size in active layers, preferred in- and out-of-plane molecular orientation, and crystal structure can all affect device performance.[1] Determining the extent to which each of these factors affects charge transport in devices is challenging because changing the crystallization conditions often impacts more than one parameter of film structure and the extent to which parameters affect performance is likely material-dependent. However, there are a handful of examples using select organic semiconductors where specific aspects of film structure were tuned in isolation, providing a quantification of the extent to which each can impact charge transport. Generalizing the observations across various material systems and devices, it appears that differences in the crystal structure[2–6] and the preferred in-plane[7,8] and out-of-plane molecular orientations[9–12] can each affect the field-effect mobilities of devices by roughly an order of magnitude. Likewise, for molecular semiconductors that crystallize as spherulites, decreasing their grain sizes over three orders of magnitude can affect the field-effect mobilities of thin-film transistors by to up to two orders of magnitude.[13,14] Thus, having appreciable control of the film microstructure across these various length scales is important for device optimization. In organic solar cells whose active layers comprise of more than one organic semiconductor constituent, the structure-property relation ships are further complicated by finite miscibility between and possible co-crystallization of the active-layer components.[15,16]

The structure that molecular and polymeric semiconductors adopt in thin films is difficult to predict and control across these multiple length scales for two reasons. First, interactions are weaker and less directional than the covalent bonds found in crystalline inorganic semiconductor counterparts; different crystal structures, or polymorphs, in single-component systems and morphological richness in multi-component systems typically not seen in inorganic semiconductors are thus accessible with molecular and polymeric semiconductors. From an energetic perspective, organic semiconductors thus have a more diverse energy landscape with many local minima. Second, the inability to predict structures in these thin films is further exacerbated by the fact that structural development typically occurs during film formation, and most deposition methods employed to form films of organic semiconductors take place rapidly, thereby restricting structural development and resulting in kinetically arrested film structures. While computational advancements have allowed for excellent modeling of the thermodynamic energy landscape, modeling kinetically driven processes remains a complicated challenge across a number of disciplines, requiring significantly more processing time and better resolution of the weak intermolecular forces at play.

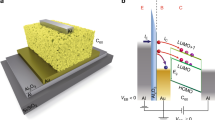

While we cannot predict a priori the resulting film structure for an organic semiconductor, the weak and less directional interactions present in organic semiconductor systems provide an opportunity to tune the film structure using empirically derived guidelines. For example, ordering across length scales (i.e., crystallinity, grain size, extent of phase separation) typically increases with the time that molecules are provided to rearrange, all else being equal.[14,17] Since the time scales for structural development and film formation are coupled, attaining more ordered films typically requires using deposition techniques that form films over longer time periods. Figure 1 illustrates this concept; the y-axis represents the time that is available for structural development prior to vitrification, and corresponding deposition techniques are listed to the right of the figure. Techniques that form films on short time scales (i.e., seconds to minutes), including variations of spin-coating, doctor-blading, and thermal evaporation, provide less time for structural ordering and typically result in less-ordered poly-crystalline films. Conversely, techniques that form films on longer time scales (i.e., hours to days), like physical vapor transport, provide more time for structural ordering and result in more-ordered films; in some cases these techniques are even used to grow high-quality single crystals. Thus, using different deposition techniques is one effective means of altering the kinetics of structural development, as many others have detailed.[18–21]

Ordering in organic semiconductor films typically increases with increasing time available for structural development (which is coupled to the time for film formation) and with decreasing time needed by the organic semiconductor to order. The ratio of these two time scales defines a dimensionless quantity, τ.In this review, we examine methods of altering τ to tune the structural development of organic semiconductor active layers for thin-film transistors and solar cells.

Finer control over structural development can also be attained without changing deposition techniques if either the time available for structural development (represented by the y-axis in Fig. 1) or the time required by the material to order (represented by the x-axis in Fig. 1) can be tuned. The ratio of time available for structural development to time required by the material to order can be represented by τ. The more readily a material crystallizes and orders (i.e., the smaller the denominator of τ) or the more time molecules have to rearrange prior to vitrification (i.e., the larger the numerator of τ), the more ordered the film will be with a given deposition technique. This concept is visualized in Fig. 1 with red and blue representing more and less order, respectively.

While the time scale for structural development is generally coupled to the time scale for film formation, it can be altered by modification of the deposition conditions. For example, using solvents with higher boiling points or spin-coating solutions at slower rates extends the time available for structural development, thereby increasing t. In this review, we examine ways to modify or decouple the time scales for film formation and structural development, i.e., tuning τ. Greater structural order within organic semiconductor active layers results in better intermo-lecular charge transport, and thus, efforts are typically aimed to make τ larger. However, depending on the molecular system and its use in devices, sometimes less ordered or higher energy states are desirable for optimal device performance. For example, a number of molecular semiconductors have been found to exhibit metastable polymorphs with better charge transport properties than their more energetically favored counterparts.[22,23] Opportunities to decrease t will increase the accessibility of these metastable polymorphs. On a larger length scale, the optimal crystalline grain size can vary depending on device application as well. While large crystal grains are desirable in thin-film transistors, TFTs, to reduce the number of charge-trapping grain boundaries that are present within the device channel, large-scale crystallization of organic-semiconductor constituents in the photoactive layers of organic solar cells is undesirable as it is often accompanied by macro-phase separation, which reduces donor-acceptor interfacial area at which excitons can dissociate.[24] Thus, strategies to both increase and decrease τ are needed to fine-tune the film structure depending on application needs.

Of the examples we have culled, the techniques used to tune τ and thereby structural ordering fall into two strategies. First, the denominator of τ represents the time needed by an organic semiconductor to order prior to solidification (i.e., the time needed for nucleation and growth to take place). This time scale is dictated primarily by the chemical properties of the organic semiconductor, which can include different functional groups or isomers in molecular materials and different molecular weights, regioregularities, or compositional heterogeneities along the lengths of polymer semiconductors. Molecules with strong π–π interactions more readily crystallize compared to those having bulky side groups and therefore can develop their structures within the short time scales of film formation compared to bulkier counterparts having weaker π–π interactions. Alternatively, the numerator of τ—the time available for structural development—can be altered by changing the processing solvent or deposition conditions of solution-processable organic semiconductors since the rate at which the solvent evaporates during film formation can dictate the time available for structural ordering. While typical efforts have focused on attaining greater order (i.e., accessing conditions to increase τ), unique opportunities to control ordering arise, as we will highlight, if the time for structural development is far shorter than the time needed by the organic semiconductor for structural ordering (i.e., conditions at which τ ≪ 1). Under such conditions, the organic semiconductor vitrifies before any substantial structural development can take place, and structural development can be subsequently induced in a more controlled manner via post-deposition treatments. This approach—though not universally applicable—allows us to move away from the time constraints imparted by film formation.

We will show in the following sections that employing strategies to alter τ results in remarkable tunability over the film structure across multiple length scales with direct effects on TFT and solar cell performance. We have chosen to organize our review by the parameters of the film structure that are affected when τ is tuned, focusing specifically on examples where tuning τ results either in changes in the crystal structure, in- or out-of-plane molecular orientation, crystalline grain size, or, for two-component active layers, the extent of phase separation and where these structural changes are further correlated with electrical performance of devices. We note that yet another method by which structural ordering can be increased during deposition is the concurrent application of an external field, such as shear[23] or centripetal forces.[22] Most commonly these techniques are used to increase the in-plane alignment of crystalline grains. We discuss these techniques only to the extent that they are employed in the examples of tuning τ that we highlight, and we refer the reader to other reviews for a more complete discussion of the use of external fields to induce ordering.[1,25]

Accessing different crystal structures

Given the weak and non-directional intermolecular bonds present in molecular systems, molecules can often crystallize in more than one crystal structure—a phenomenon termed polymorphism. Such subtle differences in molecular packing can impact the material’s physical properties, including absorptivity and solubility. In the specific example of molecular semiconductors for organic electronics, polymorphism is of particular relevance given the sensitivity of intermolecular charge transport on the details of molecular packing. Single crystals of different polymorphs may be grown from saturated solutions with different solvents[3,26] or from the vapor phase with physical vapor transport at different temperatures,[6,27] and typically, field-effect transistors constructed from single crystals of different polymorphs have yielded mobilities that differ by a factor between 2 and 10.[3,26] Although the crystallographic direction along which these measurements were made were not reported by the authors, the mobilities extracted from individual polymorphs in themselves must necessarily vary given that charge transport is anisotropic along different crystallographic directions and is most efficient along the π-stacking direction.[28,29] Assessing how different polymorphs influence mobilities in thin-film devices is yet more complicated given the polycrystalline nature of the active layers. Mobilities extracted from these devices thus inadvertently reflect the ensemble-average charge transport characteristics across grains having different in-plane orientations spanning the channel lengths. Additionally, controllably accessing different polymorphs in polycrystalline thin films may be more challenging than accessing them as single crystals, as the presence of the substrate has been shown to affect polymorph selection.[2,30–32] Despite these challenges, a handful of strategies have been developed to tune τ to access alternative polymorphs in thin films and evaluate their effects on device performance.

For example, Giri et al.[23] found that the rate of shearing solutions of 6,13-bis(triisopropylsilylethynyl) pentacene, TIPS-pentacene [see Fig. 2(a)], during film formation dictates the in-plane alignment and grain size of crystals and, notably, the packing that the molecules adopt. By varying the shear rate between 0.4 to 8 mm/s, they could vary the solvent evaporation time, thereby providing some tunability over τ. Slower shearing rates led to longer solvent evaporation times (larger τ), resulting in films with greater in-plane ordering and larger crystalline grains having the known bulk crystal structure of TIPS-pentacene. Faster shearing rates led to shorter solvent evaporation times (smaller τ), resulting in films with smaller spherulites and with TIPS-pentacene adopting a new metastable crystal structure. Determining the metastable crystal structure from the thin-film x-ray diffraction, Giri et al.[23] found that it has a closer intermolecular π–π distance than the stable bulk crystal structure, which is expected to coincide with a lower barrier to intermolecular charge transport. While TFTs constructed from films with greater in-plane ordering and larger crystalline grains, which in the present case correspond to the slowest-sheared TIPS-pentacene films, would be expected to yield the highest field-effect mobilities, the highest field-effect mobilities [as high as 4.6 cm2/(Vs)] were actually observed in devices with films that were sheared at an intermediate speed of 2.8 mm/s, as shown in Fig. 2(b). This shearing speed yielded a film structure in which the gain in field-effect mobility due to the presence of the metastable crystal structure and the reduction in mobility due to the reduced in-plane ordering and grain size are balanced.[23]

(a) Chemical structure of TIPS-pentacene and illustration of the solution-shearing setup used by Giri et al. Reproduced from Ref. 23 with permission from Macmillan Publishers Ltd: Nature, copyright 2011. (b) Mobilities of thin-film transistors as a function of the shearing speed with which TIPS-pentacene films were formed. Optical micrographs show the reduction in in-plane ordering of crystals with increasing shearing speed. Scale bars represent 200 µm. Adapted from Ref. 23 with permission from Macmillan Publishers Ltd: Nature, copyright 2011. (c) Conceptual illustration of 1D self-confinement that gives rise to a metastable polymorph. Reproduced from Ref. 33 with permission from Macmillan Publishers Ltd: Nature Communications, copyright 2014.

In their follow-up work, Giri et al. utilized high-speed in situ microbeam grazing-incidence wide-angle x-ray scattering (uGIWAXS) coupled with high-speed in situ polarized optical microscopy, to observe the development of the metastable crystal structure. They found that the metastable crystal structure is more readily accessed due to confinement effects that arise from different crystallization rates at the organic semiconductor solution surface compared to in the bulk of the solution. At faster shearing rates (smaller τ), surface crystallization takes place more rapidly, effectively confining the fluid in the underlying layer—a phenomenon they term one-dimensional (1D) self-confinement.[33] Nanoscale confinement is a demonstrated method for altering crystal growth and accessing alternative polymorphs[34–37] because the increased surface area to volume ratio alters the balance of surface and volume free energies.[34] The 1D self-confinement approach reported by Giri et al. to access a metastable TIPS-pentacene crystal structure is akin to the use of nanoporous templates commonly utilized by the pharmaceutical industry during crystal growth to access alternative polymorphs stemming from confinement.[34–35] Indeed, the metastable crystal structure of TIPS-pentacene can also be accessed through lateral confinement during solution shearing.[38] Interestingly, Giri et al.[33] found that changing the solvent (while keeping evaporation conditions, shearing speed, and solution concentration constant) provides yet another tuning knob over polymorph selection, with solvents having larger molar volumes, such as decalin (256 Å3/mol), yielding the metastable polymorph more readily than solvents with smaller molar volumes, such as tetrahydrofuran (134 Å3/mol). These results point out that altering crystallization kinetics need not be the only pathway to alternative crystal structures; tuning solvent-molecule interactions, i.e., changing the time TIPS-pentacene needs to crystallize, can also influence t, thereby providing access to different crystal- and micro- structures in organic semiconductor thin films.

Thin films can be regarded as vertically confined systems, where interactions with the substrate can influence crystallization kinetics (i.e., tune τ) and therefore structural development, potentially allowing access to kinetically trapped metastable states unattainable in thicker films. Several thermally evaporated molecular semiconductors, including pentacene,[32,39–41]] thiotetracene,[42] and N,N’-dioctyl-3,4:9,10-perylene tetracarboxylic diimide, [43] have been shown to adopt different polymorphs below a material-specific critical film thickness typically 50 nm or thinner. A number of solution-deposited organic semiconductors, such as alkylated phthalocyanine[44] and terthiophene,[45,46] have likewise demonstrated thin-film phases. However, in solution-deposited thin films, decoupling the effects of film thickness from the rate of solvent evaporation in tuning polymorph selection is challenging since thinner films are obtained by faster spin-coating and therefore also at conditions which the solvent evaporates faster. For example, film thickness has been shown to drastically affect hole mobilities of TFTs fabricated from spun-cast thin films of 2,7-dioctyl [1]benzothieno[3,2-b][1]benzothiophene, C8-BTBT, the molecular semiconductor that has yielded TFTs with the highest reported field-effect mobilities to date.[22] The field-effect mobility of C8-BTBT-containing devices increases by approximately two orders-of-magnitude as the active layer thickness is decreased from 50 to 10 nm, as shown in Fig. 3(a).[42] Yuan et al. attributed these ultra-high mobilities in part to the presence of a metastable polymorph of C8-BTBT that they were able to kinetically trap in thin spun-cast films with thicknesses between 10 and 18 nm. However, whether this metastable polymorph is trapped due to rapid solvent-evaporation and 1D self-confinement, similar to what was observed with TIPS-pentacene, or due to substrate effects, remains unclear. Obtaining such thin films of ca. 10 nm thickness can be challenging with solution-processed small molecules since the dilute concentrations of solutions required to achieve such thicknesses typically do not render the formation of macroscopically continuous thin films. Yuan et al.[42] circumvented this challenge by blending C8-BTBT with polystyrene to increase the viscosity of the solution. During spin-coating, polystyrene preferentially segregated to the dielectric interface, as shown in Fig. 3(b), thereby providing the added benefit of passivating the dielectric surface.[42]

(a) Mobilities of C8-BTBT thin-film transistors as a function of thickness and with and without polystyrene (PS) added to the active layer. The inset shows the distribution of mobilities. (b) Cross-sectional transmission electron microscope image of a C8-BTBT:PS film showing C8-BTBT as the dark thin layer with 10–20 nm thickness. Scale bar represents 100 nm. Figures reprinted from Ref. 22 with permission from Macmillan Publishers Ltd: Nature Communications, copyright 2014.

In solution-deposited thin films, t can be tweaked by changing the solvent evaporation rate, providing access to metastable crystal structures. However, significantly tuning tremains challenging because there is a limit to which solvent evaporation rates can be modified. An alternative strategy to gain greater control over structural development is to completely decouple deposition from structural development and to subsequently induce crystallization with post-deposition processing, such as thermal and solvent-vapor annealing or through the use of external fields (i.e., electrical, magnetic, thermal).[1] In this manner, one can circumvent the inherent constraints of t. For example, solvent-vapor annealing can often induce plasticization of the film, allowing the molecules to reorganize after deposition. Whereas film formation takes places on the order of seconds or minutes, solvent-vapor annealing allows structural development to occur over minutes to hours independent of the time constraints of film formation.

The film structure cannot be significantly altered once crystallization has occurred, and thus, post-deposition processing techniques are best applied to films that are nominally amorphous as-deposited.[1] To attain nominally amorphous films, solidification needs to take place prior to molecular ordering. In essence, we are accessing conditions where t is small and where molecules can be kinetically arrested in a glassy, disordered state. However, preventing crystallization from occurring during film formation is challenging with molecular semiconductors that were intentionally designed to π-stack strongly in the solid state. One method of doing so is to change the deposition conditions to rapidly vitrify the films before crystallization can take place. For example, rapid thermal evaporation of molecular semiconductors onto a cool substrate provides less opportunity for molecular rearrangement. Alternatively, to decrease the propensity of molecules to crystallize during film formation, bulky side groups, such as those in triethylsilyl anthradithiophene, TES ADT, can be introduced, which effectively increases the time necessary for structural ordering to take place, thereby decreasing τ. One can also introduce significant non-planarity to the molecular semiconductor of interest, such is the case with contorted hexabenzocoronene, cHBC,[9] and its derivatives[47] to increase the time required by the molecule to self-assemble, thereby decreasing τ and suppressing crystallization upon deposition. If crystallization upon deposition persists, a glass-inducing diluent can be used to vitrify the film upon deposition. When the appropriate additive is employed, it can retard, or even inhibit crystallization and induce vitrification of organic semiconductor thin films. Stingelin-Stutzmann et al.[48] demonstrated this technique, successfully depositing from solution a vitrified rubrene film. They found that the glass-inducing species must have sufficient physio-chemical compatibility with the molecular semiconductor of interest, so that the constituents are mutually miscible in solution and the additive is capable of frustrating subsequent crystallization. In the case of rubrene, chemically similar oligoacenes were used.[48] Left alone, such glassy films may age and crystallize at ambient conditions over extended timescales (i.e., days to years), or post-deposition processing can be applied to induce and complete crystallization on shorter time scales, ranging from seconds to days.

Post-deposition processing of these amorphous films has rendered access to morphological richness and structural complexities. Post-deposition solvent-vapor and thermal annealings, for example, have allowed us to controllably access three different polymorphs of cHBC in the same film.[5] Starting with a nominally amorphous cHBC film and applying only 30 min thermal and 4 h solvent-vapor annealing steps in opposite sequences, we can access films having the same polymorph yet different preferential out-of-plane molecular orientations or films having different polymorphs and the same preferential out-of-plane molecular orientations. In this way, we are able to decouple the relative impact of crystal structure and molecular orientation on charge transport in thin-film transistors. We found that, in the case ofcHBC, accessing the right crystal structure and the appropriate out-of-plane preferential orientation can each improve field-effect mobility by an order of magnitude.[5]

Tuning in- and out-of-plane orientations

In addition to crystal structure, how the crystals are oriented on the surface of a substrate also affects charge transport in devices. Ideally, molecular semiconductor crystals should be oriented so that the direction of π-stacking aligns with the direction of charge transport in the device. Thus, for thin-film transistors in which charge transport occurs laterally, molecules should ideally be aligned with their π-planes perpendicular to the substrate, yielding π-stacking parallel to the substrate. In addition to affecting mobility, preferential out-of-plane molecular orientation in thin films can also affect the films’ absorptivity and electronic structure.[49–51] For example, the energy of the highest occupied molecular orbital of poly(3-hexylthiophene), P3HT, films varies from −3.8 eV for films with P3HT having a face-on orientation to −4.0 eV for films with P3HT having an edge-on orientation; incorporating such differently oriented P3HT films into bilayer solar cells with PCBM causes the devices’ open circuit voltage, VOC, to vary nearly linearly from 0.25 to 0.45 V with the highest occupied molecular orbital, HOMO, energy level of the P3HT films.[52]

Surface interactions, which can occur at either the substrate or air interface, can dictate the orientation of molecular semiconductors in thin films. Modifying a substrate’s surface chemistry via self-assembled monolayer adsorption is one known strategy to tune the preferred molecular orientation without having to change-processing conditions.[53] Typically, highly conjugated molecules and polymers favor an edge-on orientation on chemically neutral substrates unless there are specific substrate-molecule interactions (generally with the molecule’s π-electrons) that make a face-on orientation favorable. For example, pentacene adopts a face-on orientation when deposited on clean gold surfaces due to the favorable interactions between gold and pentacene’s π-electrons and an edge-on orientation otherwise when such favorable interactions are reduced.[54]

In addition to providing tunability over the crystal structure, changing the solvent evaporation rate to alter τ also provides some tunability over the out-of-plane orientation of molecules. For example, rather than using high boiling point solvents such as chlorobenzene (Tb = 131 °C) that are typically used to disperse blends of fullerenes and P3HT for solar cell fabrication, Yang et al. investigated the effects of spin-coating and drop-casting P3HT from two lower boiling point solvents, chloroform (Tb = 61 °C), and methylene chloride (Tb = 40°C), in which P3HT is soluble and marginally soluble, respectively.[55] Drop-casting and spin-coating P3HT from chloroform resulted in polymer chains adopting predominantly edge-on and face-on orientations, respectively. Since the edge-on orientation of P3HT is thought to be thermodynamically preferred on a neutral surface such as that used in this case,[56–58] Yang et al.[55] attributed this change in orientation to kinetic trapping of the face-on orientation with the faster solvent evaporation that occurs with spin-coating as opposed to drop-casting. This observation is consistent with those of DeLongchamp et al.,[59] who found that the extent of P3HT’s edge-on orientation in films spun-cast from chloroform solutions correlated inversely with spin-coating speed. In the context of τ, a larger τ is accessed with drop-casting, resulting in the more thermodynamically favored edge-on orientation whereas with smaller τ, stemming from spin-coating, the kinetically trapped face-on orientation is accessed instead.

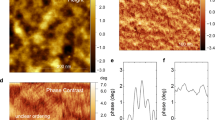

Interestingly, Yang et al. only observed changes in the polymer’ s preferred out-of-plane orientation with deposition technique when chloroform is the casting solvent for P3HT. As shown in the two-dimensional (2D) grazing-incidence x-ray diffraction, 2D-GIXD, images in Fig. 4, deposition from dicloromethane yielded films with P3HT preferentially oriented edge-on with both spin-coating and drop-casting. Yang et al.[55] attributed this observation to the fact that, unlike P3HT in chloroform, P3HT is not completely dissolved in dichloromethane. When P3HT in dichloromethane is heated and spin-coated atop a heated substrate, a broader range of orientations, including the face-on orientation, can be observed. Because P3HT crystallizes more rapidly from dichloromethane than from chloroform given its poorer solubility in dichloromethane, we are accessing a larger τ in crystallization from dichloromethane compared with from chloroform. With an effectively larger τ, P3HT spuncast from dichloromethane attains the more energetically favored edge-on orientation over a broader range of deposition conditions. These changes in P3HT’s orientation are expected to correlate with charge transport in devices, and indeed, Yang et al. found that TFTs fabricated with films that were spun-cast from dichloromethane or drop-cast from either solvent having preferentially edge-on orientated P3HT result in field-effect mobilities that are four times higher than those fabricated with spin-coated films from chloroform having face-on orientated P3HT.

2D-GIXD images of P3HT spun-cast (left) and drop-cast (right) from solution with chloroform (top) and dichloromethane (bottom), resulting in P3HT adopting either an edge-on or face-on orientation as noted. Adapted with permission from Ref. 55. Copyright 2007, AIP Publishing LLC.

Molecular parameters, such as molecular weight and regioregularity, can also affect the time scale required for structural development and thus must also be taken into consideration in attempts to kinetically arrest any preferential orientation in polymer semiconductor thin films.[56] For example, high molecular weight P3HT with low regioregularity (Mw = 175 kg/mol, RR = 81%) tends to adopt a face-on orientation upon spin-coating and edge-on orientation upon drop-casting fromchloroform, while lowmolecularweightP3HT withhigh regioregularity (Mw = 28 kg/mol, RR = 96%) always adopts an edge-on orientation irrespective of deposition technique.[56] As longer polymer chains and/or more defective chains with the introduction of regioirregularity require more time to rearrange, τ is smaller for high molecular weight and regioirregular P3HT. It is thus easier to kinetically arrest such a polymer in its face-on orientation. On the contrary, lower molecular weight and/or less defective counterparts can more easily undergo structural rearrangement under the same time constraints: τ is effectively larger for them and the time scales provided by spin-coating are typically long enough to access an edge-on orientation.

By accessing τ ≪ 1 and effectively decoupling film formation from structural development, the out-of-plane molecular orientation can be subsequently tuned through varying post-deposition processing conditions. Specifically, we found that by either solvent-vapor annealing amorphous cHBC films with hexanes vapor, thermally annealing them, or contacting them with a cross-linked poly(dimethylsiloxane) (PDMS) stamp, we can induce crystallization with increasing extents of out-of-plane ordering. cHBC films contacted with PDMS resulted in films with the greatest extent of out-of-plane ordering, and devices constructed from such films resulted in field-effect mobilities that were nearly a factor of 30 higher than those constructed with hexanes-vapor-annealed cHBC films, which crystallized more rapidly and adopted a greater distribution oforientations.[9]

Alternatively, rather than tuning the out-of-plane orientation of molecules, post-deposition processing can also be applied to tune the in-plane ordering of molecular semiconductors.[1] For example, TES ADT forms a nominally amorphous, kinetically trapped film upon spin-coating from toluene; subsequent exposure to dichloroethane vapor plasticizes the film and induces crystallization and spherulite formation.[60,61] Specifically, Lee et al. found that the spherulitic growth rate during solvent-vapor annealing can be decreased by up to a factor of 3 by modifying the surface energy of the underlying substrate via self-assembled monolayer adsorption, thereby increasing molecule-substrate interaction. By patterning a substrate with different surface energies and then using solvent-vapor annealing to induce crystallization of the TES ADT film, Lee et al. showed that the difference in crystallization speed on varying surfaces can be used to break the symmetric and radial growth of TES ADT and instead direct crystal growth along complex geometries, such as serpentine channels.[61]

Tuning grain size

Slowing the solvent evaporation rate during organic semiconductor deposition generally provides the molecules with more time to rearrange and typically leads to larger crystalline grains. At the extreme of slow evaporation from saturated solutions, single crystals of organic semiconductors are accessible. In the formation of polycrystalline organic semiconductor thin films, a drawn out solvent evaporation period can result in larger crystalline grains. Using in situ GIXD with sub-second time resolution, Wei Chou et al. recently observed the structural development of spin-coated TIPS-pentacene. They probed spin-coating speeds between 1000 and 2000 rpm and found the solvent evaporation rate and drying time to depend strongly on the rotation speed, which in turn dictates microstructural development in these organic semiconductor thin films. Specifically, they found that crystallization takes place in two distinct stages: rapid crystallization that appears to be independent of the spin-coating speed and a slower crystallization process dictated by the evaporation of residual solvent that strongly depends on the spin-coating speed, as summarized in Fig. 5(a).[14] The resulting morphologies of the films appear to be strongly correlated with the time of residual solvent removal; extending the time for solvent removal effectively increases the time available for structural development and thereby increases τ. Spin-coating TIPS-pentacene solutions at 2000 rpm as opposed to 1000 rpm results in a smaller τ; these films have smaller spherulitic domains [see optical micrographs in Fig. 5(a)] and crystallite correlation lengths (12.5 versus 16.3 nm).[14] Not surprisingly, given the changes in film morphology, field-effect mobilities of TFTs fabricated from TIPS-pentacene demonstrate an inverse dependence with spin-coating speeds; the field effect mobility increased by two orders-of-magnitude from 5 × 10−4 to 2 × 10−2 cm2/(Vs) as the spin-coating speed decreased from 2000 to 1000 rpm and the crystalline grain size is increased concomitantly.[14] Using an even slower spinning speed of 300 rpm, a maximum field-effect mobility of 0. 7 cm2/(Vs) was obtained.[14]

(a) Scheme summarizing the duration of different structural development processes occurring during spin-coating of TIPS-pentacene from toluene. Optical micrographs of the resulting morphologies for spin-coating at 1000 and 2000 rpm are shown; scale bar represents 50 µm. Adapted from Ref. 14 with permission from The Royal Society of Chemistry, copyright 2015. (b) Mobilities linearly correlate with the duration of crystallization, controlled by the spin-coating speed. Reproduced from Ref. 14 with permission from The Royal Society of Chemistry, copyright 2015.

Already a common practice in the polymer community, the use of nucleating agents to tune nucleation density and crystallization kinetics in molecular and polymeric semiconductor thin films is becoming increasingly popular. Nucleating agents act as impurities, increasing the rate of nucleation and often hastening the crystallization process. For example, TES ADT forms a nominally amorphous film upon spin-coating from solution that can be subsequently solvent-vapor annealed to induced crystallization.[60] By adding up to 2.00 mol% of a fluorinated derivative of TES ADT to the solutions prior to spin-coating, Lee et al. found that films with the nucleating agent crystallized within 7 s as opposed to 175 s for films having nominally the same footprint but without any nucleating agents.[62] This dramatic increase in nucleation density resulted in a three orders-of-magnitude decrease in the spherulite size and an order-of-magnitude decrease in the field-effect mobility in TFTs constructed from these films.[13] Following up on this work, Lee et al. found that different derivatives seeded TES ADT crystal growth with different efficiency that depends on the nucleating agents’ propensity to crystallize, their solubility in the solvent of choice, and their chemical similarity to TES ADT.[62] Nucleating agents with greater propensity to aggregate, lower solubility, and less chemical similarity to TES ADT effectively increased nucleation density, resulting in the formation of smaller spherulites.

Smaller grains necessitate a larger number of charge-trapping grain boundaries over a given footprint of organic semiconductor thin films. For this reason, smaller grains within transistor channels are generally associated with lower mobilities. However, smaller grains can be beneficial in bulk-heterojunction solar cells. If the acceptor and donor domains in the active layer are larger than the exciton diffusion length characteristic of the materials pair, excitons may relax prior to dissociation at a donor-acceptor interface, thereby reducing power-conversion efficiency.[24,63,64] To ensure that the domain sizes are commensurate with the characteristic exciton diffusion length, Treat et al. used commercially available and electrically insulating molecules, 1,3:2,4-bis(3,4-dimethylbenzylidene)sorbitol (DMDBS) and tris-tert-butyl-1,3,5-benzenetrisamide (BTA) that are demonstrated nucleating agents for isotactic polypropylene, i-PP,[65] to manipulate the structural development of poly(3-dodecylthiophene), P3DDT; P3HT; [6,6]-phenyl-C61-butyric acid methyl ester, PC61BM; and TIPS-pentacene in solution and in the solid state.[66] As with i-PP, the introduction of the nucleating agents reduces the grain sizes of the organic semiconductors without affecting the overall crystallinity or crystal structure.[66] Critical for organic semiconductors, Treat et al.[66] also found that the addition of these nucleating agents does not adversely affect the charge transport characteristics of thin films. Lindqvist et al. demonstrated the utility of this approach specifically for solar cells having fullerene derivatives as the electron acceptor, whose bulk-heterojunction active layers are known to undergo large-scale crystallization and phase separation with prolonged heating.[24,63,64] Using several types of nucleating agents, they induced the formation of nanocrystalline PC61BM domains upon spin-coating, which dramatically improved the thermal stability.[63] For example, solar cells containing poly[2,3-bis-(3-octyloxyphenyl)quinoxaline-5,8-diyl-alt-thiophene-2,5-diyl] and PC61BM in which PC61BM crystallization was pre-seeded with C60 can be annealed at 130 °C for 1 h without resulting in significant grain coarsening in the bulk-heterojunction and accordingly degradation in device performance, whereas comparable devices in the absence of the nucleating agent were shorted within 30 min of thermal annealing, likely because the growth of macroscopic PC61BM crystals bridges the two electrodes in these devices.[63]

Tuning degree of phase separation

In active layers consisting of two (or more) components, as is the case for organic bulk-heterojunction solar cells, phase separation of the constituent materials significantly influences the performance of devices. Multiple phases can exist, including amorphous phases of the pure components, an amorphous phase consisting of both the components, crystalline phases of the pure components, and a co-crystalline phase of both the components.[67] Though our understanding of the structure within the precise active layers consisting of these various phases is not yet crisp, some general structure-function relationships have developed. An active layer with the components intimately mixed is undesirable because free electrons and holes will likely recombine. However, an active layer having domains larger than the exciton diffusion length, which is typically estimated to be 5–50 nm for most organic semiconductors,[68–70] is also undesirable as then excitons relax before they have an opportunity to dissociate into free carriers at the donor-acceptor interface.

When depositing solutions to form films, well-dissolved components have less aggregates in solution that can act as nuclei to crystallization compared with less soluble components, and they thus require more time to order upon deposition. However, the short time scales afforded by solution-based deposition techniques, such as spin-casting or doctor-blading, typically provide little time for structural rearrangement. Thus, in such cases of film formation from solution, typically t is small, and, as a result, the films formed are kinetically trapped and lack significant phase separation of the constituents. However, the extent of phase separation can be increased with post-deposition-processing treatments. For example, morphological studies of as-cast P3HT: PC61BM active layers show that the components are well-mixed and that the films lack significant phase separation.[71] Upon thermal annealing of the active layer (typically for ca. 10 min at ca. 110 °C),[72] the extent of phase separation increases and distinguishable phase-pure polymer and fullerene domains form that are tens-of-nanometers in size.[73] This moderate increase in the extent of phase separation (as well as P3HT’s increased crystallinity) results in significant increases in the power-conversion efficiency of thermally annealed devices compared with those untreated.[71] Further annealing the active layer results in coarsening of the donor and acceptor domains beyond the optimal size for exciton dissociation and charge transport; a decrease in power-conversion efficiency follows as a consequence.[24]

Another recent trend in organic electronics has been the use of solvent additives—typically electrically inactive small molecules with high boiling points—to extend the time available for structural rearrangement of active layers and fine-tune the chemical compatibility of components to effectively increase τ.[74–77] Additives, such as 1,8-diiodooctane, DIO; 1,8-octanedithiol, ODT; diphenyl ether, DPE; and chloronaphthalene, CN, have been used in both molecular and polymer solar cells to alter the active-layer morphologies and increase power-conversion efficiencies. For example, the incorporation of DIO in the active layer of solar cells based on 7,7′-(4,4-bis(2-ethylhexyl)-4H-silolo[3,2-b:4,5-b’]dithiophene-2,6-diyl)bis(6-fluoro-4-(5′-hexyl-[2,2′-bithiophen]-5-yl)benzo[c][1,2,5]thiadiazole), p-DTS(FBTTh2)2, and [6,6]-phenyl-C71-butyric acid methyl, PC71BM, resulted in devices with power-conversion efficiencies as high as 7% (compared with 1.8% for additive-free solar cells).[78] Through time-resolved in situ GIXD studies during spin-coating, Perez et al.[79] showed that structural rearrangement in p-DTS(FBTTh2)2 and PC71BM films persists up to 90 s in the presence of DIO compared with being completed after 0.18 s in the absence of DIO. By effectively increasing τ with the addition of DIO, the constituents are able to rearrange and reach a higher degree of crystallinity; with DIO, the p-DTS (FBTTh2)2:PC71BM films sample an intermediate, metastable crystal structure before transforming to the final crystal structure, which is also different from than that accessed in films without DIO.[79]

For other comparable molecular bulk-heterojunction systems, approximating the donor’ s and acceptor’ s solubilities in potential additives from their Hansen solubility parameters has been proposed as an effective means ofselecting appropriate additives for a specific donor-acceptor pairing.[80] Specifically, Graham et al. examined blends of a thiophene- and isoindigo-containing oligomer [iI(TT2)] and PC61BM. Introducing additives that are poor solvents for both components, such as PDMS and triethylene glycol (TEG), produces favorable morphologies with smaller domain sizes and simultaneously increased hole mobilities (speculated to be due to the domains being more phase-pure), resulting in improved solar cell efficiencies. On the other hand, using high boiling point additives in which il(TT2) and PC61BM have improved solubility, such as N-methyl-2-pyrrolidone (NMP), DIO and CN, increases τ, thereby increasing the extent of phase separation by providing more time for the domains to coarsen, resulting in unfavorable morphologies with large domains that resulted in decreased device performance.

Additives, particularly DIO and ODT, have also been studied extensively for the polymer-fullerene pairs consisting of poly[2,6-(4,4-bis(2-ehtylhexyl)-4H-cyclopenta[2,1-b;3,4-b’]-dithiophene)-alt-4,7-(2,1,3-benzothiadiazole)], PCPDTBT, and either PC61BM[81] or PC71BM.[82–84] The incorporation of additives in the active layer has been shown to alter the phase separation characteristics between PCPDTBT and fullerene, as well as the crystallinity, crystal structure, grain size, and out-of-plane orientation of PCPDTBT.[84] These structural changes caused power-conversion efficiencies of devices comprising bulk-heterojunctions of PCPDTBT:PC71BM to increase from 3.4 to 5.1% with the addition of DIO[82] and from 2.8 to 5.5% with the addition of ODT.[85] The structural changes have been attributed to the increased solubility of the fullerenes and concomitantly decreased solubility of PCPDTBT in the additives, thereby enhancing PCPDTBT nucleation.[81,83] From time-resolved GIXD studies, Rogers et al.[83] found that ODT induces nucleation of polymeric crystallites within 2 min of deposition and significantly increases the time for structural development to 40 min, as shown in Fig. 6. In the context of our discussion of tuning τ, that PCPDTBT more readily nucleates in the presence of an additive decreases the denominator of τ and that a high boiling point additive increases the time available for structural reorganization increases the numerator of τ. Both of these changes effectively increase τ and allow for more substantial structural ordering to take place across multiple length scales before solidification takes place. However, the presence of metastable polymorphs reinforces the idea that these morphologies are still far from equilibrium. Recent in situ GIXD studies of P3HT and PC61BM with ODT and CN have found that the presence of these additives impact P3HT in a similar fashion; the additives reduce the solubility of P3HT, causing rapid nucleation, and concurrently decreasing the time needed for structural development.[86] Thus, these two mechanisms result in an effectively larger τ and correspondingly, films with greater crystallinity, crystallite sizes, and out-of-plane ordering.[86]

Wide-angle x-ray scattering plots of PCPDTBT:PC70BM blends cast from CB containing (a–c) 3% or (d) 0% ODT at the specified time points after spin-coating. Reprinted with permission from Ref. 83. Copyright 2012 American Chemical Society.

In addition to the kinetics of film formation and crystallization, the chemical compatibility of the components also dictates phase separation characteristics in bulk-heterojunction active layers. Increasing the time available for structural development (i.e., larger τ) reduces the influence of kinetics and increases the influence of intermolecular interactions in the development of films’ microstructure and morphology. In general, donor and acceptor components may have different solubilities in a processing solvent, which can influence the relative compatibilities of the three components in the blend[87] and thus provide an additional tuning knob to change the morphology. The chemical compatibilities and interactions to be considered in a three-component solution are those of the solvent-donor, solventacceptor, and donor-acceptor. According to the Flory–Huggins theory, the miscibility between two components or a component and its solvent correlates inversely with square of the differences in their solubility parameters; the adjustment of the interaction parameters allows the morphology of the film be further tuned with solvent selection. For example, Pavlopoulou et al.[88] explored the effect of choice of processing solvent on miscibility and resulting film structure of P3HT and poly[[N,N’-bis(2-octyldodecyl)-napthalene-1,4, 5,8-bis(dicarboximide)-2,6-diyl]-alt-5,5′-(2,2′-bithiophene)], P(NDI2OD-T2), active layers. Three high boiling point solvents—xylene, chlorobenzene, and dichlorobenzene—in which P3HT and P(NDI2OD-T2) have different solubilities were explored. P3HT and P(NDI2OD-T2) have appreciable solubilities in both chlorobenzene and dichlorobenzene, but P(NDI2OD-T2)’s solubility in xylene is poor.[88] Interestingly, solar cells fabricated with active layers spun-cast from xylene yielded the highest power-conversion efficiencies, which Pavlopoulou et al.[88] attributed to a favorable intermixed network of nanocrystalline domains of the two polymers. They speculate that this morphology arises from unfavorable P(NDI2OD-T2)–xylene interactions in solution, which enhances P(NDI2OD-T2)’saffinity for P3HT.[88]

Solar cells constructed from ternary blends have become ofinterest as they provide a means of tuning a solar cell’ s open-circuit voltage with active layer composition.[89–94] With three components in the active layer, the number of potential intermolecular interactions increases, but similar mixing principles still apply. Thompson and co-workers[89–94] have demonstrated the compatibility of polymer or fullerene pairs to play a crucial role in tuning the VOC of ternary blend solar cells otherwise thought to be pinned to that of the highest lying HOMO of the polymer donors. For example, poly(3-hexylthiophene-thiophene-diketopyrrolopyrrole), P3HTT-DPP-10%, and poly[3-hexylthiophene-co-3-(2-ethylhexyl)thiophene], P3HT75-co-EHT25, or poly(3-hexylthiophene-thiophene-thienopyrroledione), P3HTT–TPD-10%, or fullerene pairs, PC61BM and indene–C60 bisadduct, ICBA, with similar surface energies, or in other words small interaction parameter, χ, are necessary to generate ternary-blend solar cells with VOCs that are tunable with blend composition.[95,96] In contrast, P3HTT–DPP-10% and poly[N-9′-heptadecanyl-2,7-carbazole-alt-5,5-(4′,7′-di-2-thienyl-2′,1′,3′-benzothiadiazole)], PCDTBT, exhibit a large X, so there is little mixing between the two polymer donors. Because of the lack of physical interactions between the polymer donor constituents, the VOC of these ternary blend solar cells with a fullerene derivative is pinned and determined by the higher of the two HOMO levels of the constituents. Indeed, in the numerous other materials combinations that exhibit pinned VOC when incorporated as solar cells, isolated and phase-pure domains of the constituents—sometimes even large fibrils—have been observed.[97,98]

Conclusions and forward perspective

The mobilities and power-conversion efficiencies of organic semiconductor-based TFTs and solar cells, respectively, have drastically improved in the last few years, due in large part to the design of novel materials and greater exploration of their processing–structure–function relationships. Because structural development has to take place on a second to minute time scale that is limited by the constraints of film formation, predicting, and controlling the kinetically driven development of film structure is challenging. However, empirical guidelines can be gleaned from the multitude of processing-structure studies performed, and furthermore, a semi-quantitative framework for these guidelines can begin to take shape when we consider the time that is available for structural development to take place and the time needed by the material to order. Changes in the structure with processing across multiple length scales begin to show similar trends when the ratio, τ, of these two time scales is considered. By effectively increasing the time available for structural development through increasing τ, films adopt structures that are closer to the thermodynamically favored state, which may include accessing the bulk lowest-energy polymorph, a preferentially edge-on out-of-plane orientation on neutral surfaces, large crystal grains, and also greater extents of phase separation in multicomponent thin films. By effectively decreasing the time available for structural development through decreasing τ, films adopt a more disordered structure, which on the one extreme include the formation of an amorphous glass, but can also include the formation of polycrystalline films with small crystalline grains, metastable polymorphs, and mixing of constituents. Depending on the specific materials system and the device applications, film structures that are more or less kinetically trapped may be desired and τ may need to be decreased or increased, accordingly.

τ can be tuned by changing either the time available for structural development or the time needed by the material to order. While the time that is available for structural development is typically coupled to the time of film formation, it can be altered by changing the solvent evaporation rate or through the use of additives, as we have reviewed. The denominator of τ—the time required for the organic semiconductor to order— can also be altered by modifying the organic semiconductor or its compatibility with the solvent and other constituent components of the active layer. When the time available for structural development is very short and the time required by the organic semiconductor for ordering is very long, resulting in τ ≪ 1, then the film is kinetically trapped in a disordered state; crystallization can be subsequently induced via post-deposition processing techniques, which results in an effective decoupling of the time scales for film formation and structural development and greater control over the resulting film structure.

The kinetically trapped nature of most active layers’ film structures raises questions about batch-to-batch reproducibility, large-area uniformity, and the long-term stability of these films. Given that industrial manufacturing techniques, such as roll-to-roll printing, require a short time for film formation, thereby increasing the likelihood of a highly kinetically trapped film structure, understanding the stability of these film structures, and developing ways to arrest the desired structures, are particularly important. However, while the kinetically driven nature of the structural development of organic semiconductor thin films certainly poses many challenges, it also provides many opportunities for modifying the film structure and potentially accessing kinetically trapped states beneficial for device performance. Understanding the structural development that takes place during film formation, which can be gleaned from an increasing number of in situ structural studies, will help provide an understanding of how we can expect to tune τ, thereby providing more rational and potentially quantitative guidelines for film processing. Recent advances in synchrotron-based wide-angle and small-angle x-ray diffraction techniques with in situ thermal annealing,[5,99] solution shearing,[100] blade coating,[86] spm-coatmg,[79,101,102] pπnting,[103,104] and solvent-vapor annealing[105,106] have particularly helped elucidate the evolution of film structure during deposition and processing. The knowledge gleaned from tuning kinetic competitions in organic semiconductor thin-film structure development may be also of relevance to novel organic-inorganic materials, where the situation is yet more complicated. In the case of organometal halides that adopt the perovskite crystal structure, in addition to rapid structural development that is commonly observed with spin-coating, rapid chemical reactions occur as well. Since the morphology of perovskite thin films can evolve at room temperature, lessons learned in accessing and stabilizing kinetically trapped structures may help further increase efficiency and stability in solar cells comprising these materials as well.

References

A.M. Hiszpanski and Y.-L. Loo: Directing the film structure of organic semiconductors via post-deposition processing for transistor and solar cell applications. Energy Environ. Sci. 7, 592 (2014).

R. Pfattner, M. Mas-Torrent, I. Bilotti, A. Brillante, S. Milita, F. Liscio, F. Biscarini, T. Marszalek, J. Ulanski, A. Nosal, M. Gazicki-Lipman, M. Leufgen, G. Schmidt, L.W. Molenkamp, V. Laukhin, J. Veciana, and C. Rovira: High-performance single crystal organic field-effect transistors based on two Dithiophene-tetrathiafulvalene (DT-TTF) polymorphs. Adv. Mater. 22, 4198 (2010).

H. Jiang, X. Yang, Z. Cui, Y. Liu, H. Li, W. Hu, Y. Liu, and D. Zhu: Phase dependence of single crystalline transistors of tetrathiafulvalene. Appl. Phys. Lett. 91, 123505 (2007).

T. Matsukawa, M. Yoshimura, K. Sasai, M. Uchiyama, M. Yamagishi, Y. Tominari, Y. Takahashi, J. Takeya, Y. Kitaoka, Y. Mori, and T. Sasaki: Growth of thin rubrene single crystals from 1-propanol solvent. J. Cryst. Growth 312, 310 (2010).

A.M. Hiszpanski, R.M. Baur, B. Kim, N.J. Tremblay, C. Nuckolls, A.R. Woll, and Y.-L. Loo: Tuning polymorphism and orientation in organic semiconductor thin films via post-deposition processing. J. Am. Chem. Soc. 136, 15749 (2014).

L.A. Stevens, K.P. Goetz, A. Fonari, Y. Shu, R.M. Williamson, J.-L. Bredas, V. Coropceanu, O.D. Jurchescu, and G.E. Collis: Temperature-mediated polymorphism in molecular crystals: the impact on crystal packing and charge transport. Chem. Mater. 27, 112 (2015).

J. Park, C.-M. Keum, J.-H. Kim, S.-D. Lee, M. Payne, M. Petty, J.E. Anthony, and J.-H. Bae: Photo-assisted molecular engineering in solution-processed organic thin-film transistors with a blended semiconductor for high mobility anisotropy. Appl. Phys. Lett. 102, 013306 (2013).

F.S.U. Fischer, K. Tremel, M. Sommer, E.J.C. Crossland, and S. Ludwigs: Directed crystallization of poly(3-hexylthiophene) in micrometre channels under confinement and in electric fields. Nanoscale 4, 2138 (2012).

A.M. Hiszpanski, S.S. Lee, H. Wang, A.R. Woll, C. Nuckolls, and Y.-L. Loo: Post-deposition processing methods to induce preferential orientation in contorted hexabenzocoronene thin films. ACS Nano 7, 294 (2013).

Y. Hosokawa, M. Misaki, S. Yamamoto, M. Torii, K. Ishida, and Y. Ueda: Molecular orientation and anisotropic carrier mobility in poorly soluble polythiophene thin films. Appl. Phys. Lett. 100, 203305 (2012).

L. Biniek, N. Leclerc, T. Heiser, R. Bechara, and M. Brinkmann: large scale alignment and charge transport anisotropy of pBTTT films oriented by high temperature rubbing. Macromolecules 46, 4014 (2013).

K. Tremel, F.S.U. Fischer, N. Kayunkid, R. Di Pietro, R. Tkachov, A. Kiriy, D. Neher, S. Ludwigs, and M. Brinkmann: Charge transport anisotropy in highly oriented thin films of the acceptor polymer P(NDI2OD-T2). Adv. Energy Mater. 4, 1301659 (2014).

S.S. Lee, C.S. Kim, E.D. Gomez, B. Purushothaman, M.F. Toney, C. Wang, A. Hexemer, J.E. Anthony, and Y.-L. Loo: Controlling nucleation and crystallization in solution-processed organic semiconductors for thin-film transistors. Adv. Mater. 21, 3605 (2009).

K. Wei Chou, H. Ullah Khan, M.R. Niazi, B. Yan, R. Li, M.M. Payne, J.E. Anthony, D.-M. Smilgies, and A. Amassian: Late stage crystallization and healing during spin-coating enhance carrier transport in small-molecule organic semiconductors. J. Mater. Chem. C 2, 5681 (2014).

S. Mukherjee, C.M. Proctor, J.R. Tumbleston, G.C. Bazan, T.-Q. Nguyen, and H. Ade: Importance of domain purity and molecular packing in efficient solution-processed small-molecule solar cells. Adv. Mater. 27, 1105 (2015).

L. Zhang, F. Liu, Y. Diao, H.S. Marsh, N.S. Colella, A. Jayaraman, T.P. Russell, S.C.B. Mannsfeld, and A.L. Briseno: The good host: formation of discrete one-dimensional fullerene “channels” in well-ordered Poly(2,5-bis(3-alkylthiophen-2-yl)thieno[3,2-b]thiophene) oligomers. J. Am. Chem. Soc. 136, 18120 (2014).

S.K. Park, T.N. Jackson, J.E. Anthony, and D.A. Mourey: High mobility solution processed 6,13-bis(triisopropyl-silylethynyl) pentacene organic thin film transistors. Appl. Phys. Lett. 91, 063514 (2007).

A.A. Virkar, S. Mannsfeld, Z. Bao, and N. Stingelin: Organic semiconductor growth and morphology considerations for organic thin-film transistors. Adv. Mater. 22, 3857 (2010).

M.M. Ling and Z. Bao: Thin film deposition, patterning, and printing in organic thin film transistors. Chem. Mater. 16, 4824 (2004).

S.R. Forrest: The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 428, 911 (2004).

B.P. Rand and H. Richter: Organic Solar Cells: Fundamentals, Devices, and Upscaling, 1st ed. (CRC Press, Taylor & Francis Group, Boca Raton, FL, 2014).

Y. Yuan, G. Giri, A.L. Ayzner, A.P. Zoombelt, S.C.B. Mannsfeld, J. Chen, D. Nordlund, M.F. Toney, J. Huang, and Z. Bao: Ultra-high mobility transparent organic thin film transistors grown by an off-centre spin-coating method. Nat. Commun. 5, 3005 (2014).

G. Giri, E. Verploegen, S.C.B. Mannsfeld, S. Atahan-Evrenk, D.H. Kim, S.Y. Lee, H.A. Becerril, A. Aspuru-Guzik, M.F. Toney, and Z. Bao: Tuning charge transport in solution-sheared organic semiconductors using lattice strain. Nature 480, 504 (2011).

J.B. Kim, K. Allen, S.J. Oh, S. Lee, M.F. Toney, Y.S. Kim, C.R. Kagan, C. Nuckolls, and Y.-L. Loo: Small-molecule thiophene-C60 dyads as compatibilizers in inverted polymer solar cells. Chem. Mater. 22, 5762 (2010).

Y. Diao, L. Shaw, Z. Bao, and S.C.B. Mannsfeld: Morphology control strategies for solution-processed organic semiconductor thin films. Energy Environ. Sci. 7, 2145 (2014).

T. He, M. Stolte, C. Burschka, N.H. Hansen, T. Musiol, D. Kälblein, J. Pflaum, X. Tao, J. Brill, and F. Würthner: Single-crystal field-effect transistors of new Cl2-NDI polymorph processed by sublimation in air. Nat. Commun. 6, 5954 (2015).

J.A. Schneider, H. Black, H.-P. Lin, and D.F. Perepichka: Polymorphism in new thienothiophene-thiazolothiazole organic semiconductors. Chem Phys Chem 16, 1102 (2015).

J.Y. Lee, S. Roth, and Y.W. Park: Anisotropic field effect mobility in single crystal pentacene. Appl. Phys. Lett. 88, 252106 (2006).

V.C. Sundar, J. Zaumseil, V. Podzorov, E. Menard, R.L. Willett, T. Someya, M.E. Gershenson, and J.A. Rogers: Elastomeric transistor stamps: reversible probing of charge transport in organic crystals. Science 303, 1644 (2004).

C.C. Mattheus, A.B. Dros, J. Baas, G.T. Oostergetel, A. Meetsma, J.L. de Boer, and T.T.M. Palstra: Identification of polymorphs of pentacene. Synth. Met. 138, 475 (2003).

G. Schweicher, N. Paquay, C. Amato, R. Resel, M. Koini, S. Talvy, V. Lemaur, J. Cornil, Y. Geerts, and G. Gbabode: Toward single crystal thin films of terthiophene by directional crystallization using a thermal gradient. Cryst. Growth Des. 11, 3663 (2011).

S. Schiefer, M. Huth, A. Dobrinevski, and B. Nickel: Determination of the crystal structure of substrate-induced pentacene polymorphs in fiber structured thin films. J. Am. Chem. Soc. 129, 10316 (2007).

G. Giri, R. Li, D.-M. Smilgies, E.Q. Li, Y. Diao, K.M. Lenn, M. Chiu, D.W. Lin, R. Allen, J. Reinspach, S.C.B. Mannsfeld, S.T. Thoroddsen, P. Clancy, Z. Bao, and A. Amassian: One-dimensional self-confinement promotes polymorph selection in large-area organic semiconductor thin films. Nat. Commun. 5, 3573 (2014).

B.D. Hamilton, J.-M. Ha, M.A. Hillmyer, and M.D. Ward: Manipulating crystal growth and polymorphism by confinement in nanoscale crystallization chambers. Acc. Chem. Res. 45, 414 (2011).

M. Beiner, G.T. Rengarajan, S. Pankaj, D. Enke, and M. Steinhart: Manipulating the crystalline state of pharmaceuticals by nanoconfinement. Nano Lett. 7, 1381 (2007).

Y. Diao, K.M. Lenn, W.Y. Lee, M.A. Blood-Forsythe, J. Xu, Y.S. Mao, Y. Kim, J.A. Reinspach, S. Park, A. Aspuru-Guzik, G. Xue, P. Clancy, Z.N. Bao, and S.C.B. Mannsfeld: Understanding polymorphism in organic semiconductor thin films through nanoconfinement. J. Am. Chem. Soc. 136, 17046 (2014).

Y. Diao, K.E. Whaley, M.E. Helgeson, M.A. Woldeyes, P.S. Doyle, A.S. Myerson, T.A. Hatton, and B.L. Trout: Gel-induced selective crystallization of polymorphs. J. Am. Chem. Soc. 134, 673 (2012).

G. Giri, S. Park, M. Vosgueritchian, M.M. Shulaker, and Z. Bao: High-mobility, aligned crystalline domains of TIPS-pentacene with metastable polymorphs through lateral confinement of crystal growth. Adv. Mater. 26, 487 (2014).

I.P.M. Bouchoms, W.A. Schoonveld, J. Vrijmoeth, and T.M. Klapwijk: Morphology identification of the thin film phases of vacuum evaporated pentacene on SIO2 substrates. Synth. Met. 104, 175 (1999).

S.E. Fritz, S.M. Martin, C.D. Frisbie, M.D. Ward, and M.F. Toney: Structural characterization of a pentacene monolayer on an amorphous SiO2 substrate with grazing incidence x-ray diffraction. J. Am. Chem. Soc. 126, 4084 (2004).

S.C.B. Mannsfeld, A. Virkar, C. Reese, M.F. Toney, and Z. Bao: Precise structure of pentacene monolayers on amorphous silicon oxide and relation to charge transport. Adv. Mater. 21, 2294 (2009).

Q. Yuan, S.C.B. Mannsfeld, M.L. Tang, M.F. Toney, J. Luening, and Z. Bao: Thin film structure of tetraceno 2,3-b thiophene characterized by grazing incidence x-ray scattering and near-edge x-ray absorption fine structure analysis. J. Am. Chem. Soc. 130, 3502 (2008).

T.N. Krauss, E. Barrena, X.N. Zhang, D.G. de Oteyza, J. Major, V. Dehm, F. Wuerthner, L.P. Cavalcanti, and H. Dosch: Three-dimensional molecular packing of thin organic films of PTCDI-C-8 determined by surface x-ray diffraction. Langmuir 24, 12742 (2008).

G. Gbabode, N. Dumont, F. Quist, G. Schweicher, A. Moser, P. Viville, R. Lazzaroni, and Y.H. Geerts: Substrate-induced crystal plastic phase of a discotic liquid crystal. Adv. Mater. 24, 658 (2012).

O. Werzer, N. Boucher, J.P. de Silva, G. Gbabode, Y.H. Geerts, O. Konovalov, A. Moser, J. Novak, R. Resel, and M. Sferrazza: Interface induced crystal structures of dioctyl-terthiophene thin films. Langmuir 28, 8530 (2012).

C. Lercher, R. Resel, J.-Y. Balandier, C. Niebel, Y.H. Geerts, M. Sferrazza, and G. Gbabode: Effects of temperature on the polymorphism of α,ω-dioctylterthiophene in thin films. J. Cryst. Growth 386, 128 (2014).

A.M. Hiszpanski, J.D. Saathoff, L. Shaw, H. Wang, L. Kraya, F. Lüttich, M.A. Brady, M.L. Chabinyc, A. Kahn, P. Clancy, and Y.-L. Loo: Halogenation of a nonplanar molecular semiconductor to tune energy levels and bandgaps for electron transport. Chem. Mater. 27, 1892 (2015).

N. Stingelin-Stutzmann, E. Smits, H. Wondergem, C. Tanase, P. Blom, P. Smith, and D. de Leeuw: Organic thin-film electronics from vitreous solution-processed rubrene hypereutectics. Nat. Mater. 4, 601 (2005).

W. Chen, D.C. Qi, Y.L. Huang, H. Huang, Y.Z. Wang, S. Chen, X.Y. Gao, and A.T.S. Wee: Molecular orientation dependent energy level alignment at organic−organic heterojunction interfaces. J. Phys. Chem. C 113, 12832 (2009).

G. Heimel, I. Salzmann, S. Duhm, J.P. Rabe, and N. Koch: Intrinsic surface dipoles control the energy levels of conjugated polymers. Adv. Funct. Mater. 19, 3874 (2009).

L.-H. Li, O.Y. Kontsevoi, and A.J. Freeman: Orientation-dependent electronic structures and optical properties of the P3HT:PCBM interface: a first-principles GW-BSE study. J. Phys. Chem. C 118, 10263 (2014).

B. Kitchen, O. Awartani, R.J. Kline, T. McAfee, H. Ade, and B.T. O’Connor: Tuning open-circuit voltage in organic solar cells with molecular orientation. ACS Appl. Mater. Interfaces 7, 13208 (2015).

D.H. Kim, Y.D. Park, Y. Jang, H. Yang, Y.H. Kim, J.I. Han, D.G. Moon, S. Park, T. Chang, C. Chang, M. Joo, C.Y. Ryu, and K. Cho: Enhancement of field-effect mobility due to surface-mediated molecular ordering in regioregular polythiophene thin film transistors. Adv. Func. Mater. 15, 77 (2005).

K.S. Lee, T.J. Smith, K.C. Dickey, J.E. Yoo, K.J. Stevenson, and Y.L. Loo: High-resolution characterization of pentacene/polyaniline interfaces in thin-film transistors. Adv. Func. Mater. 16, 2409 (2006).

H. Yang, S.W. LeFevre, C.Y. Ryu, and Z. Bao: Solubility-driven thin film structures of regioregular poly(3-hexyl thiophene) using volatile solvents. Appl. Phys. Lett. 90, 172116 (2007).

H. Sirringhaus, P.J. Brown, R.H. Friend, M.M. Nielsen, K. Bechgaard, B.M.W. Langeveld-Voss, A.J.H. Spiering, R.A.J. Janssen, E.W. Meijer, P. Herwig, and D.M. de Leeuw: Two-dimensional charge transport in self-organized, high-mobility conjugated polymers. Nature 401, 685 (1999).

Z. Bao, A. Dodabalapur, and A.J. Lovinger: Soluble and processable regioregular poly(3-hexylthiophene) for thin film field-effect transistor applications with high mobility. Appl. Phys. Lett. 69, 4108 (1996).

J.F. Chang, B.Q. Sun, D.W. Breiby, M.M. Nielsen, T.I. Solling, M. Giles, I. McCulloch, and H. Sirringhaus: Enhanced mobility of poly(3-hexylthiophene) transistors by spin-coating from high-boiling-point solvents. Chem. Mater. 16, 4772 (2004).

D.M. DeLongchamp, B.M. Vogel, Y. Jung, M.C. Gurau, C.A. Richter, O.A. Kirillov, J. Obrzut, D.A. Fischer, S. Sambasivan, L.J. Richter, and E.K. Lin: Variations in semiconducting polymer microstructure and hole mobility with spin-coating speed. Chem. Mater. 17, 5610 (2005).

K.C. Dickey, J.E. Anthony, and Y.L. Loo: Improving organic thin-film transistor performance through solvent-vapor annealing of solution-processable triethylsilylethynyl anthradithiophene. Adv. Mater. 18, 1721 (2006).

S.S. Lee, S.B. Tang, D.-M. Smilgies, A.R. Woll, M.A. Loth, J.M. Mativetsky, J.E. Anthony, and Y.-L. Loo: Guiding crystallization around bends and sharp corners. Adv. Mater. 24, 2692 (2012).

S.S. Lee, S. Muralidharan, A.R. Woll, M.A. Loth, Z. Li, J.E. Anthony, M. Haataja, and Y.-L. Loo: Understanding heterogeneous nucleation in binary, solution-processed, organic semiconductor thin films. Chem. Mater. 24, 2920 (2012).

C. Lindqvist, J. Bergqvist, C.-C. Feng, S. Gustafsson, O. Bäcke, N.D. Treat, C. Bounioux, P. Henriksson, R. Kroon, E. Wang, A. Sanz-Velasco, P.M. Kristiansen, N. Stingelin, E. Olsson, O. Inganäs, M.R. Andersson, and C. Müller: Fullerene nucleating agents: a route towards thermally stable photovoltaic blends. Adv. Energy Mater. 4, 1301437 (2014).

T. Agostinelli, S. Lilliu, J.G. Labram, M. Campoy-Quiles, M. Hampton, E. Pires, J. Rawle, O. Bikondoa, D.D.C. Bradley, T.D. Anthopoulos, J. Nelson, and J.E. Macdonald: Real-time investigation of crystallization and phase-segregation dynamics in P3HT:PCBM solar cells during thermal annealing. Adv. Funct. Mater. 21, 1701 (2011).

K. Sreenivas, H.V. Pol, and G. Kumaraswamy: The influence of DMDBS on the morphology and mechanical properties of polypropylene cast films. Polym. Eng. Sci. 51, 2013 (2011).

N.D. Treat, J.A. Nekuda Malik, O. Reid, L. Yu, C.G. Shuttle, G. Rumbles, C.J. Hawker, M.L. Chabinyc, P. Smith, and N. Stingelin: Microstructure formation in molecular and polymer semiconductors assisted by nucleation agents. Nat. Mater. 12, 628 (2013).

B.A. Collins, J.R. Tumbleston, and H. Ade: Miscibility, crystallinity, and phase development in P3HT/PCBM solar cells: toward an enlightened understanding of device morphology and stability. J. Phys. Chem. Lett. 2, 3135 (2011).

O.V. Mikhnenko, H. Azimi, M. Scharber, M. Morana, P.W.M. Blom, and M.A. Loi: Exciton diffusion length in narrow bandgap polymers. Energy Environ. Sci. 5, 6960 (2012).

P.E. Shaw, A. Ruseckas, and I.D.W. Samuel: Exciton diffusion measurements in poly(3-hexylthiophene). Adv. Mater. 20, 3516 (2008).

T.M. Clarke and J.R. Durrant: Charge photogeneration in organic solar cells. Chem. Rev. 110, 6736 (2010).

M.T. Dang, L. Hirsch, G. Wantz, and J.D. Wuest: Controlling the morphology and performance of bulk heterojunctions in solar cells lessons learned from the benchmark poly(3-hexylthiophene):[6,6]-Phenyl-C61-butyric acid methyl ester system. Chem. Rev. 113, 3734 (2013).

G. Li, V. Shrotriya, J. Huang, Y. Yao, T. Moriarty, K. Emery, and Y. Yang: High-efficiency solution processable polymer photovoltaic cells by self-organization of polymer blends. Nat. Mater. 4, 864 (2005).

S. van Bavel, S. Veenstra, and J. Loos: On the importance of morphology control in polymer solar cells. Macromol. Rapid Commun. 31, 1835 (2010).

U. Vongsaysy, B. Pavageau, G. Wantz, D.M. Bassani, L. Servant, and H. Aziz: Guiding the selection of processing additives for increasing the efficiency of bulk heterojunction polymeric solar cells. Adv. Energy Mater. 4, 1300752 (2014).

Y.-W. Su, C.-M. Liu, J.-M. Jiang, C.-S. Tsao, H.-C. Cha, U.S. Jeng, H.-L. Chen, and K.-H. Wei: structural evolution of crystalline conjugated polymer/fullerene domains from solution to the solid state in the presence and absence of an additive. J. Phys. Chem. C 119, 3408 (2015).

F. Etzold, I.A. Howard, N. Forler, D.M. Cho, M. Meister, H. Mangold, J. Shu, M.R. Hansen, K. Müllen, and F. Laquai: The effect of solvent additives on morphology and excited-state dynamics in PCPDTBT:PCBM photovoltaic blends. J. Am. Chem. Soc. 134, 10569 (2012).

H.-C. Liao, C.-C. Ho, C.-Y. Chang, M.-H. Jao, S.B. Darling, and W.-F. Su: Additives for morphology control in high-efficiency organic solar cells. Mater. Today 16, 326 (2013).

T.S. van der Poll, J.A. Love, T.-Q. Nguyen, and G.C. Bazan: Non-basic high-performance molecules for solution-processed organic solar cells. Adv. Mater. 24, 3646 (2012).

L.A. Perez, K.W. Chou, J.A. Love, T.S. van der Poll, D.-M. Smilgies, T.-Q. Nguyen, E.J. Kramer, A. Amassian, and G.C. Bazan: Solvent additive effects on small molecule crystallization in bulk heterojunction solar cells probed during spin casting. Adv. Mater. 25, 6380 (2013).

K.R. Graham, P.M. Wieruszewski, R. Stalder, M.J. Hartel, J. Mei, F. So, and J.R. Reynolds: Improved performance of molecular bulk-heterojunction photovoltaic cells through predictable selection of solvent additives. Adv. Funct. Mater. 22, 4801 (2012).

Y. Gu, C. Wang, and T.P. Russell: Multi-length-scale morphologies in PCPDTBT/PCBM bulk-heterojunction solar cells. Adv. Energy Mater. 2, 683 (2012).

J.K. Lee, W.L. Ma, C.J. Brabec, J. Yuen, J.S. Moon, J.Y. Kim, K. Lee, G.C. Bazan, and A.J. Heeger: Processing additives for improved efficiency from bulk heterojunction solar cells. J. Am. Chem. Soc. 130, 3619 (2008).

J.T. Rogers, K. Schmidt, M.F. Toney, G.C. Bazan, and E.J. Kramer: Time-resolved structural evolution of additive-processed bulk heterojunction solar cells. J. Am. Chem. Soc. 134, 2884 (2012).

J.T. Rogers, K. Schmidt, M.F. Toney, E.J. Kramer, and G.C. Bazan: Structural order in bulk heterojunction films prepared with solvent additives. Adv. Mater. 23, 2284 (2011).

J. Peet, J.Y. Kim, N.E. Coates, W.L. Ma, D. Moses, A.J. Heeger, and G.C. Bazan: Efficiency enhancement in low-bandgap polymer solar cells by processing with alkane dithiols. Nat. Mater. 6, 497 (2007).

L.J. Richter, D.M. DeLongchamp, F.A. Bokel, S. Engmann, K.W. Chou, A. Amassian, E. Schaible, and A. Hexemer: In situ morphology studies of the mechanism for solution additive effects on the formation of bulk heterojunction films. Adv. Energy Mater. 5, 1400975 (2015).

N.D. Treat, A. Varotto, C.J. Takacs, N. Batara, M. Al-Hashimi, M.J. Heeney, A.J. Heeger, F. Wudl, C.J. Hawker, and M.L. Chabinyc: Polymer-fullerene miscibility: a metric for screening new materials for high-performance organic solar cells. J. Am. Chem. Soc. 134, 15869 (2012).

E. Pavlopoulou, C.S. Kim, S.S. Lee, Z. Chen, A. Facchetti, M.F. Toney, and Y.-L. Loo: Tuning the morphology of all-polymer OPVs through altering polymer-solvent interactions. Chem. Mater. 26, 5020 (2014).

P.P. Khlyabich, A.E. Rudenko, B. Burkhart, and B.C. Thompson: Contrasting performance of donor-acceptor copolymer pairs in ternary blend solar cells and two-acceptor copolymers in binary blend solar cells. ACS Appl. Mater. Interfaces 7, 2322 (2015).

R.A. Street, P.P. Khlyabich, A.E. Rudenko, and B.C. Thompson: Electronic states in dilute ternary blend organic bulk heterojunction solar cells. J. Phys. Chem. C 118, 26569 (2014).

P.P. Khlyabich, A.E. Rudenko, R.A. Street, and B.C. Thompson: Influence of polymer compatibility on the open-circuit voltage in ternary blend bulk heterojunction solar cells. ACS Appl. Mater. Interfaces 6, 9913 (2014).

R.A. Street, D. Davies, P.P. Khlyabich, B. Burkhart, and B.C. Thompson: Origin of the tunable open-circuit voltage in ternary blend bulk heterojunction organic solar cells. J. Am. Chem. Soc. 135, 986 (2013).