Abstract

In formulation development, certain excipients, even though used in small quantities, can have a significant impact on the processability and performance of the dosage form. In this study, three common disintegrants, croscarmellose sodium (CCS), crospovidone (xPVP), and sodium starch glycolate (SSG) as well as the surfactant sodium lauryl sulfate (SLS) were evaluated for their impact on the processability and performance of a typical dry granulation formulation. Two model compounds, the mechanically brittle and chemically inert acetaminophen and the mechanically ductile carboxylic acid aspirin, were used for the evaluation. It was found that the disintegrants were generally identical in their impact on the processability and little difference was observed in the granulation and compression processes. The exception is that when xPVP was used in the formulation of the brittle acetaminophen, lower compression forces were needed to reach the same tablet hardness, suggesting a binding effect of xPVP for such systems. In general, CCS and xPVP tend to provide slightly better disintegration than SSG. However, in the case of aspirin, a strong hydrogen bonding interaction between the carboxylic acid group of aspirin and the carbonyl group of xPVP was observed, resulting in slower release of the drug after fast disintegration. SLS was found to have a significant impact on the processability due to its lubricating effect, resulting in higher compression forces needed to achieve the target tablet hardness. Due to the higher degree of compression, the disintegration and dissolution of both drugs became slower despite the wetting effect of SLS.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

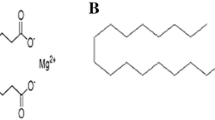

In formulation development, certain excipients, even though used in small quantities, can have a significant impact on the processability and performance of the dosage form. Among them, disintegrant and surfactant are the two types of excipients used to influence disintegration and dissolution, and could impact the bioavailability of drugs from tablets. Croscarmellose sodium, crospovidone, and sodium starch glycolate are the three most common super disintegrants used in formulations. Croscarmellose sodium (CCS) is a cross-linked polymer of carboxymethylcellulose sodium. It has a fibrous morphology and good hydrophilicity that facilitates water wicking (uptake by capillary action) capability, and its cross-linked chemical structure creates an insoluble hydrophilic, highly absorbent material which results in good swelling properties. It is reported that placebo tablets made with CCS has a fast onset of water uptake (1). Sedimentation volume and direct particle size measurement have shown significant swelling after exposure to water (1–3). Wicking and swelling are the two mechanisms that contribute to the disintegration functionality of CCS. Crospovidone (xPVP) is a water-insoluble synthetic cross-linked homopolymer of N-vinyl-2-pyrrolidinone. While swelling also contributes to the disintegration function of xPVP, the extent of swelling is much lower for xPVP compared to other super disintegrants (1,2). Crospovidone has a porous morphology that facilitates rapid hydration by capillary action, resulting in fast onset of water uptake in tablets (1,4); therefore, wicking is also a contributing mechanism for its disintegration function. The other mechanism that contributes to the disintegrating function of xPVP is strain recovery/deformation where upon contacting the disintegration media, it recovers its pre-compression shape and causes disintegration (4–6). Sodium starch glycolate (SSG) is the sodium salt of a cross-linked partly O-carboxymethylated potato starch, and it functions by its enormous swelling capability (1,3). While among the three super disintegrants, CCS is reported to have the best disintegration efficiency in many cases in the literature (1,2,7), they each have their own distinct advantages. Since xPVP is non-ionic, its performance is independent of pH of the media while the disintegration efficiency of CCS and SSG both decreases with decreasing pH due to the conversion to the acid form (1). Since SSG functions mainly by swelling, its disintegrating efficiency is less impaired by the presence of lubricants and compression pressure, which are factors that would impact the wicking mechanism of disintegration (2,8,9).

During formulation development, besides considerations of specific properties of the disintegrants mentioned above, chemical compatibility and potential interaction between the disintegrant and the API are critical in the selection of the disintegrant. It is also usually assumed that the low level of disintegrants in the formulation does not impact the processability of the tablet formulation; however, little study is done to test this hypothesis. In addition, many of the studies done previously in evaluating the performance of disintegrants uses a direct compression process, while in reality many tablets are made with a granulation process prior to compression and the disintegrants can be used both intra-granularly and extra-granularly. In such cases, it is important to understand the impact of the excipient selection on the granulation process, granule properties, and the subsequent tablet compaction process, and also the impact of the granulation step on the performance of the disintegrants.

Sodium lauryl sulfate (SLS) is the most commonly used surfactant for solid dosage forms. At higher levels over the solution critical micelle concentration (CMC), it can be used to enhance the solubility of poorly soluble drugs (10). At lower levels, it is used as a wetting agent to improve disintegration and hence dissolution by reducing surface tension of poorly soluble formulations and enhance wicking (11). However, the fatty acid structure and amphiphilic activity of SLS also makes it a lubricant (11–13). Since lubrication reduces inter-particle cohesion, a higher degree of compression (13) can be required to achieve the same hardness, in which case the reduced porosity could slow down disintegration. Due to the dual function of SLS, its impact on the disintegration and dissolution has been variously reported (14). It is therefore one of our objectives here to understand the trade-offs and worthiness of using low level of SLS in a formulation by evaluating its effect on both the processability (compaction) and the performance (dissolution) of the drug product.

In this study, the impact of different types of disintegrant as well as SLS on the processability and performance of tablets made by roller compaction was evaluated. Two model APIs were used in this study: acetaminophen (solubility 12.78 mg/mL) that is not expected to have any interaction with excipients and aspirin (solubility 3 mg/mL), which is a carboxylic acid that can potentially cause disproportionation (salt partially turning into free acid) of CCS and SSG, and have hydrogen bonding interaction with xPVP. The potential interactions with the excipients and the difference in the solubility of the two compounds will affect the interplay of API properties and disintegrant and surfactant functionality in a formulation.

MATERIALS AND METHODS

Material

The following ingredients were used as received from the suppliers: acetaminophen (G. Amphray Laboratories, Maharashtra, India), aspirin (Siddharth Carbochem Products Ltd., Jalgaon, India), microcrystalline cellulose (MCC, Avicel PH 102) (FMC BioPolymer, Cork, Ireland), anhydrous lactose (DT) (Kerry Bio-Science, Norwich, NY), croscarmellose sodium (Ac-d-Sol) (FMC BioPolymer, Newark, DE), crospovidone (Polyplasdone XL-10) (ISP Technologies, Calvert City, KY), sodium starch glycolate (Explotab Type A) (JRS Pharma, Pirna, Germany), sodium lauryl sulfate (NF, EP, BP, JP), (Spectrum Chemical Mfg. Corp., Gardena, CA), and magnesium stearate (Mallinckrodt Baker, Inc., St. Louis, MO).

Equipment

Equipment used in this study included roller compactor (Alexanderwerk WP 120, Remscheid, Germany), Quadro Comil (U5, Ontario, Canada), Conta blender (Sams Techno Mech Pvt. Ltd., Thane, India), tablet press (Korsch XL100, Berlin, Germany), envelope density tester (GeoPyc 1360, Norcross, GA), tablet hardness tester (Dr. Schleuniger, 8M, Aesch, Switzerland), tablet disintegration tester (LabIndia, DT1000, Pune, India), tablet friability tester (LabIndia, FT 1020, Pune, India), film coater (Gansons Autocoater, GAC 275/380, Thane, India), dissolution tester (LabIndia DS8000, Pune, India), and UV-visible spectrophotometer (Shimadzu, UV-1800, Japan).

Preparation of Dry Granules by Roller Compaction

The formulation contains 20% drug, 76% filler (combination of MCC and lactose at 1:1 ratio for all studies), 1.5% disintegrant and 0.5% magnesium stearate intragranularly (before granulation), and 1.5% disintegrant and 0.5% magnesium stearate extragranularly (after granulation). When sodium lauryl sulfate (SLS) was used, the filler composition was reduced to 74% and 2% SLS was incorporated intragranularly. The API, fillers, and intra-granular disintegrant were blended using a bin blender for 600 revolutions, followed by co-milling using a flat impeller and 0.6-mm round screen. The blend was then lubricated by adding intragranular magnesium stearate and blended in a bin blender for 125 revolutions. The lubricated pre-blend was then dry granulated using Alexanderwerk WP 120 roller compactor with 40-mm width smooth upper roll and knurled lower roll. Screen sizes for the upper and lower mill screens used were 3.15 and 1 mm, respectively. For all batches, granulator speed was kept at 80 rpm, and roll gap was fixed at 2.4 mm; the roll pressure was set at 55 bar with small deviations to maintain the constant roll gap.

Compression of Granules into Tablets

Subsequent to roller compaction, the dry granules were blended with extragranular disintegrant in the bin blender for 75 revolutions and lubricated with extragranular magnesium stearate by blending for 100 revolutions. The lubricated final blends were then compressed into 500-mg tablets with a hardness target of 13 SCU using round, standard concave tooling of 11.28 mm diameter and Korsch XL100 instrumented hydraulic tablet press.

Disintegration Studies

Disintegration testing was performed using LabIndia DT-1000 equipment following USP disintegration protocol. Six tablet samples were tested in purified water at 37°C ± 2°C for each batch, and the maximum and minimum disintegration time was recorded.

Dissolution Studies

The USP dissolution methods for acetaminophen and aspirin tablets were used for this study. For acetaminophen tablets, 900 mL of pH 5.8 phosphate buffer was used in USP Apparatus II. For aspirin tablets, 500 mL of pH 4.5 acetate buffer was used in USP Apparatus I. In both cases, a rotation speed of 50 rpm was used, and the media temperature was controlled at 37.0 ± 0.5C. Samples were analyzed by UV-Vis spectrometer at 5, 10, 15, 20, and 30 min followed by recovery at 150 rpm at 45 min. The wavelength used for detection was 243 nm for acetaminophen and 265 nm for aspirin. Dissolution of each sample reported here was ran in six replicates.

FTIR Measurement of Interaction Between Aspirin and xPVP

The IR spectra were collected using a FTIR-ATR spectrometer (Nicolet Nexus 670, Thermo Fisher Scientific, Madison, WI, USA). Each spectrum was measured by accumulating 64 scans at 4 cm−1 spectral resolution over the range from 500 to 4000 cm−1 at ambient temperature. For preparation of the sample used for FTIR measurement, approximately 1:1 weight ratio of aspirin and xPVP was mixed by shaking in a scintillation vial. DI water of similar volume to the total powder was then added and mixed to form a slurry. The sample is then dried overnight at room temperature in a vacuum oven, followed by drying at 60°C in a vacuum oven for 1 day to ensure complete removal of water.

RESULTS AND DISCUSSION

As described previously, the same process parameters were used for roller compaction of all batches. The key process parameters during compression as well as ribbon, granule, and tablet properties for acetaminophen batches and aspirin batches are summarized in Table I. The listed values are average of three measurements for envelop density, two measurements for bulk and tap density, and one measurement for particle size distribution and friability. Tablet thickness and hardness values are average of 50–70 in-process measurements, and compression force and ejection force values are average of 5–7 in-process measurements. Numbers in the parentheses are standard deviations. Geometric mean diameter was calculated from the PSD data.

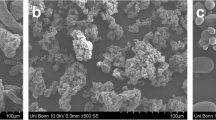

Impact of Types of Disintegrants, API Properties, and Presence of Surfactant on the Processability: Ribbon Property, Granule Powder Properties, and Compression Parameters

For both acetaminophen and aspirin, changing the super disintegrant in the formulation resulted in little difference in the granule properties as well as the downstream compression parameters and tablet properties. For acetaminophen batches, ribbon splitting was consistently observed across all three disintegrants, while intact ribbons were obtained for all aspirin batches. This could be a result of the different compaction properties between the two APIs since acetaminophen is brittle, while aspirin is a ductile material (15–19). In this case, API properties were more dominant in the roller compaction granulation process and resultant granule properties than disintegrant types. The only observable difference was that compression of acetaminophen tablets with crospovidone required lower compression force to achieve similar hardness than the other two disintegrants. To confirm the significance of the difference, an ANOVA statistical analysis was performed on all recorded compression forces for the three batches using JMP 10. The results of the comparison using Tukey-Kramer honestly significant difference (HSD) test are shown in Fig. 1. A highly significant difference (p < 0.0001) was found between the compression forces used for the batch made with xPVP and those used for the batches made with SSG and CCS. This suggests that xPVP may have a binding effect during compaction, especially for brittle compounds, where the ductile compaction properties of xPVP can be complementary. On the other hand, for a ductile API like aspirin that formed intact ribbons, the binding properties of crospovidone become less important during tablet compression, and therefore similar compression forces were used for all three batches (Table I). While a statistically significant difference in the compression forces was also observed for acetaminophen batches made with CCS and SSG, the difference was relatively small, and not as conclusive as for xPVP.

SLS has previously been reported to have a lubricating effect in formulations (11,13), which reduces the compactability of the final blends. A similar effect was observed here. For both acetaminophen and aspirin batches with SLS, significantly higher compression forces were needed to achieve tablets of similar hardness compared to those without SLS. Also, higher friability was observed for tablets that contain SLS. Interestingly, adding SLS in the formulation has prevented ribbon splitting for the brittle acetaminophen formulation, resulting in intact ribbons. This could also be a result of the lubricating effect of SLS during processing which reduces the sticking and friction between the ribbon and the rolls hence preventing ribbon splitting.

Impact of Types of Disintegrant on Tablet Performance: Disintegration and Dissolution

The range of disintegration times and the dissolution profiles for acetaminophen batches are summarized in Fig. 2a. Acetaminophen was chosen as one of the model compounds due to its relatively inert structure that is not expected to have an interaction with the disintegrants or SLS. It is also considered a highly soluble compound which dissolves quickly in the dissolution media in comparison to aspirin; therefore, the comparative study of the two compounds may also reveal the effect of API solubility on the response to change of excipients. As shown in Fig. 2a, the batch made with SSG appears to have a slightly longer disintegration time compared to the other two disintegrants. This difference is confirmed in the dissolution profiles where the batch made with SSG has less release at the 5-min time point, but quickly catches up at later time points. Despite the difference, all three batches achieve complete release of acetaminophen at 15 min.

The range of disintegration times and dissolution profiles for aspirin batches are summarized in Fig. 2b. As mentioned in the “INTRODUCTION” section, since CCS and SSG can potentially disproportionate and become less hydrophilic under acidic microenvironment, they are believed to be less effective for acidic compounds. However, this effect was not observed when comparing the effectiveness of the three disintegrants across acetaminophen and the carboxylic acid aspirin batches. (Aspirin tablet samples made with CCS were also placed on stressed stability condition, under which the disproportionation effect would become more pronounced. However, a slowing down in dissolution was not observed up to 3 weeks of stressing at 60°C and 1 month at 40°C and 75% RH.) Both CCS and SSG have slightly longer disintegration time than xPVP for acetaminophen, yet they have similar or slightly shorter disintegration time (CCS) compared to xPVP for aspirin. The rank order of the disintegration time was well correlated with the release at the 5-min time point for aspirin batches. Interestingly, following the quick disintegration, the release of the aspirin batch made with xPVP was slower through the rest of the dissolution test. Since other components in the formulation were the same, it appears that xPVP was inhibiting the release of aspirin into the dissolution media. Similarly in the study carried out by Zhao etc. on direct-compressed aspirin tablets made with CCS, SSG, and xPVP, the batch made with xPVP also appeared to have poor dissolution that does not improve significantly with the increase of the xPVP level (7).

The carbonyl group on polyvinylpyrrolidone (PVP) has been well reported in the literature to be a strong hydrogen bonding accepter. Since the carboxylic acid group on aspirin is a strong hydrogen bonding donor, if a strong hydrogen bonding interaction exists between aspirin and xPVP, then some aspirin molecules can be trapped in the porous and non-soluble matrix of xPVP, slowing down the overall release of aspirin. To verify this hypothesis, FTIR was used to probe the hydrogen bonding interaction between aspirin and xPVP. Figure 3a shows the spectrum overlay of pure aspirin, pure xPVP, and a mixture of both. The mixture was obtained by completely drying an aqueous suspension of both components to ensure intimate mixing. Details of the sample preparation can be found in the “MATERIALS AND METHODS” section. The peaks at 1650 and 1675 cm−1 are characteristic of carbonyl stretching of xPVP and aspirin, respectively. In the mixture, all major aspirin peaks were still prominent in the spectral range; the peak at 1675 cm−1 was broadened to the lower wavenumber side, suggesting contributions from the carbonyl group on xPVP. In addition, a new shoulder peak appears around 1625 cm−1 that was absent from both pure xPVP and pure aspirin. Since the majority of the peaks in the mixture are attributed to aspirin, for easier visualization and comparison, the aspirin spectrum was subtracted from the mixture and compared with pure xPVP spectrum in Fig. 3b. In the subtracted spectrum, one peak at 1650 cm−1 matches the carbonyl group of xPVP, and a second peak at 1625 cm−1 has a 25-cm−1 redshift, which is consistent with the formation of hydrogen bonding for a carbonyl group. Previously, it was reported in literature that polyvinylpyrrolidone (PVP), which has the same structural unit as xPVP, exhibited strong hydrogen bonding interaction with carboxylic acid groups (20,21).

Thus, our FTIR result supports the hypothesis that strong hydrogen bonds are forming between aspirin and xPVP. The porous morphology of xPVP increases its surface area for interaction and the probability to trap aspirin in its insoluble matrix. Based on the difference in the amount of aspirin released to the media at the 10- and 15-min time points, there was roughly 15% less release for tablet made with xPVP compared to those made with CCS and SSG. Since the formulation contains 20% aspirin, the unreleased aspirin was roughly 3% of the formulation, similar to the level of xPVP in the formulation. Since every vinylpyrrolidone monomer has one hydrogen bonding accepter site and every aspirin molecule has one hydrogen bonding donor site, the calculation suggests that roughly 60% of the xPVP can be hydrogen bonded with aspirin, resulting in slower release of aspirin into the dissolution media.

This result suggests that contrary to the common belief that the disproportionation of CCS and SSG under acidic environment can make them less effective for acidic compounds may not be a good assumption for selection of disintegrants. This is because other carboxylic acid compounds could also be prone to hydrogen bonding formation with xPVP, resulting in slower dissolution, even though rapid initial disintegration may be achieved. Since the hydrogen bonding donor groups (amine and hydroxyl) on acetaminophen were not as strong as carboxylic acid, a strong hydrogen bonding interaction with xPVP is not expected. This explains our observations for the dissolution of acetaminophen formulations with xPVP. It is worth mentioning that in the physiological fluids, the difference in pH and ionic strength could potentially have an impact on the strength of the interaction between xPVP and hydrogen bonding donor API (22–24) and, consequently, the release profile. In practice, if such hydrogen bonding is expected, performing dissolution in biorelevant media (FaSSIF and FeSSIF) is recommended to elucidate potential in vivo effect.

Impact of the Presence of Surfactant on Tablet Performance: Disintegration and Dissolution

The disintegration time and release profiles of acetaminophen and aspirin tablets made with and without SLS in the formulation are summarized in Fig. 4a, b. In both cases, CCS was used as the disintegrant. For both acetaminophen and aspirin, the disintegration time increased with the addition of SLS. The slower disintegration was also consistent with the lower release at the earlier dissolution time points up to 10 min for both compounds, although to a greater extent for the case of acetaminophen. Due to the lubricating effect of SLS, it is seen in Table I that for both acetaminophen and aspirin tablets, to achieve the same tablet hardness, a higher compression force was needed when SLS was added in the formulation, resulting in thinner tablets. A reduced tablet thickness due to the higher compression force could cause lower porosity which reduces the wicking mechanism of tablet disintegration. This causes the overall poorer disintegration and dissolution of the SLS containing formulations.

SLS is a commonly used surfactant for oral solid dosage forms to enhance the wettability and dissolution of a compound. However, as discussed above, the lubricating effect of SLS can adversely affect the disintegration when tablets have to be compressed to a higher solid fraction to achieve the desired hardness. For poorly water-soluble compounds, it was reported that the level of SLS in the formulation and the processing parameters need to be balanced and fine-tuned to achieve improved dissolution profile (11). For a typical processing condition and target tablet properties used for this study, the addition of SLS does not provide benefit to the disintegration and dissolution for the highly soluble and fast dissolving acetaminophen, as evidenced by Fig. 4a. For a less soluble compound that has slower dissolution such as aspirin, despite a slower disintegration with the addition of SLS, a faster release could be obtained at later dissolution time point. As shown in Fig. 4b, while the dissolution of aspirin with SLS is slower at the 5- and 10-min time points due to the slower disintegration, it eventually picked up and exceeded the formulation without SLS. The likely explanation is that SLS dissolved into the media and start to perform as a surfactant by decreasing the contact angle of aspirin, increasing its hydrophilicity and promoting faster dissolution.

Complex Multi-Component Interaction During Disintegration

To illustrate the complex multi-component interaction during disintegration, a local wetting and swelling study was designed with the result shown in Fig. 5. The study was done after the tablets made with and without SLS using CCS as the disintegrant were coated with Opadry®, and similar behavior is expected for uncoated core tablets. One drop of deionized water was placed onto the surface of each tablet, and photos were taken with an optical microscope. Figure 5a shows a comparison of acetaminophen tablets made with and without SLS, and Fig. 5b shows the same comparison for aspirin tablets also using CCS as the disintegrant. For acetaminophen tablet made without SLS, local swelling of the tablet core happened immediately and extensively after contacting with water droplet, and the swelling force was strong enough to break the coating. For the acetaminophen tablet made with SLS, while the swelling still happened, the process became slower and the swelling was to a much lesser degree (Fig. 5a). Since acetaminophen is highly soluble, the lubricating effect of SLS during tablet compression could dominate over the wetting effect in this case, resulting in overall slower wetting and wicking action. Therefore, the swelling of the formulation developed much more slowly and the swelling force was more laterally dissipated under the coating.

For aspirin tablets, very different local wetting and swelling behavior was observed. As shown in Fig. 5b, very limited swelling was observed for tablets both made with and without SLS despite the very different disintegration time reported earlier. The reduced rate of water uptake and swelling could be a result of local disproportionation of CCS with water as a result of the acidity of aspirin reducing the hydrophilicity of CCS. It is worth mentioning that although the acetaminophen and aspirin tablets made without SLS had very different local swelling behavior that suggests much better disintegrant functionality for acetaminophen tablets, similar disintegration time was observed for these tablets. This further illustrates the complex nature of the disintegration process, in which both the material properties and the external agitation and fluid dynamics can play a role. While the local swelling itself did not correlate with the disintegration time, since it caused breakage of the film as shown in Fig. 5a, it is likely to have a direct impact on the burst release at the earliest time point of dissolution (5 min) prior to full disintegration. The burst release was observed for the acetaminophen tablet without SLS as shown in Fig. 4a, and not for other tablets where the local swelling behavior was absent.

CONCLUSION

Three common super disintegrants CCS, xPVP, and SSG and the surfactant SLS were studied to evaluate their impact on processability and product performance using a typical roller compaction formulation. After roller compaction, similar ribbon and granule properties were achieved across the batches made with different disintegrants, suggesting interchangeability of the three disintegrants in terms of processability. For the brittle API, acetaminophen, a lower compression force was required to compress the batch made with xPVP, suggesting that xPVP may have some binding properties in such a case. For aspirin, slower release up to 30 min was observed for the tablets made with xPVP despite of the fast disintegration. FTIR data showed strong hydrogen bonding interaction between xPVP and aspirin, which could cause aspirin to be trapped in the porous insoluble xPVP matrix, resulting in the slower release.

The addition of SLS in the platform formulation resulted in decreased compactability of the granules due to the lubrication properties of SLS, which also eliminated ribbon splitting during roller compaction. With the addition of SLS, longer disintegration time was observed for both acetaminophen and aspirin tablets, which is likely due to the higher compression solid fraction required to achieve the same tablet hardness when SLS was added, causing a reduction of porosity and the wicking action of CCS. For the less soluble aspirin tablets, compared to tablets made without SLS, the release of tablets made with SLS picked up at 15 min despite of the slower initial disintegration. This suggests a competition between the lubrication effect in the solid state at earlier time points and the surfactant effect speeding up disintegration at later time points. Visual observation of the local wetting and swelling behavior was correlated with burst release at the earliest time point of dissolution and also suggests that SLS can suppress the functionality of CCS by reducing the swelling force and extent.

References

Zhao N, Augsburger LL. The influence of swelling capacity of superdisintegrants in different pH media on the dissolution of hydrochlorothiazide from directly compressed tablets. AAPS PharmSciTech. 2005;6(1):E120–E6.

Rojas J, Guisao S, Ruge V. Functional assessment of four types of disintegrants and their effect on the spironolactone release properties. AAPS PharmSciTech. 2012;13(4):1054–62.

Thibert R, Hancock BC. Direct visualization of superdisintegrant hydration using environmental scanning electron microscopy. J Pharm Sci. 1996;85(11):1255–8.

Desai PM, Liew CV, Heng PWS. Review of disintegrants and the disintegration phenomena. J Pharm Sci. 2016;105(9):2545–55.

Quodbach J, Moussavi A, Tammer R, Frahm J, Kleinebudde P. Tablet disintegration studied by high-resolution real-time magnetic resonance imaging. J Pharm Sci. 2014;103(1):249–55.

Moreton R. Disintegrants in tableting. Pharmaceutical dosage forms—tablets. Boca Raton: CRC Press; 2008. p. 217–249.

Zhao N, Augsburger LL. Functionality comparison of 3 classes of superdisintegrants in promoting aspirin tablet disintegration and dissolution. AAPS PharmSciTech. 2005;6(4):E634–E640.

Cid E, Jaminet F. Influence of adjuvants on the speed of dissolution and stability of acetylsalicylic acid in tablets. I. Effects of some disintegrating agents. J Pharm Belg. 1971;26(1):38–48.

Gebre-Mariam T, Winnemoller M, Schmidt PC. An evaluation of the disintegration efficiency of a sodium starch glycolate prepared from enset starch in compressed tablets. Eur J Pharm Biopharm. 1996;42(2):124–32.

Ruddy SB, Matuszewska BK, Grim YA, Ostovic D, Storey DE. Design and characterization of a surfactant-enriched tablet formulation for oral delivery of a poorly water-soluble immunosuppressive agent. Int J Pharm. 1999;182(2):173–86.

Aljaberi A, Chatterji A, Dong Z, Shah NH, Malick W, Singhal D, et al. Understanding and optimizing the dual excipient functionality of sodium lauryl sulfate in tablet formulation of poorly water soluble drug: wetting and lubrication. Pharm dev Technol. 2013;18(2):490–503.

Wang J, Wen H, Desai D. Lubrication in tablet formulations. Eur J Pharm Biopharm. 2010;75(1):1–15.

Pandey P, Bindra DS, Gour S, Trinh J, Buckley D, Badawy S. Excipient—process interactions and their impact on tablet compaction and film coating. J Pharm Sci. 2014;103(11):3666–74.

Lowenthal W. Disintegration of tablets. J Pharm Sci. 1972;61(11):1695–711.

Cantor SL, Kothari S, Koo OMY. Evaluation of the physical and mechanical properties of high drug load formulations: wet granulation vs. novel foam granulation. Powder Technol. 2009;195(1):15–24.

Pedersen S, Kristensen HG. Change in crystal density of acetylsalicylic acid during compaction. STP Pharma Sci. 1994;4(3):201–6.

Obiorah BA, Shotton E. The effect of waxes, hydrolysed gelatin and moisture on the compression characteristics of paracetamol and phenacetin. J Pharm Pharmacol. 1976;28(8):629–32.

Patel NK, Poola NR, Babar A, Plakogiannis FM. Fluidized-bed agglomeration of acetaminophen; direct compression of tablets and physiologic availability. Drug dev Ind Pharm. 1989;15(8):1175–98.

Imbert C, Tchoreloff P, Leclerc B, Couarraze G. Indices of tableting performance and application of percolation theory to powder compaction. Eur J Pharm Biopharm. 1997;44(3):273–82.

Yuan X, Xiang TX, Anderson BD, Munson EJ. Hydrogen bonding interactions in amorphous indomethacin and its amorphous solid dispersions with poly(vinylpyrrolidone) and poly(vinylpyrrolidone-co-vinyl acetate) studied using 13C solid-state NMR. Mol Pharm. 2015;12(12):4518–28.

Li J, Zhao J, Tao L, Wang J, Waknis V, Pan D, et al. The effect of polymeric excipients on the physical properties and performance of amorphous dispersions: part I, free volume and glass transition. Pharm Res. 2015;32(2):500–15.

Wood JLJ. pH-controlled hydrogen-bonding. Biochem J. 143(3):775–7.

Yang S, Zhang Y, Zhang X, Xu J. The influence of pH on a hydrogen-bonded assembly film. Soft Matter. 2007;3(4):463–9.

Deshmukh YS, Graf R, Hansen MR, Rastogi S. Dissolution and crystallization of polyamides in superheated water and concentrated ionic solutions. Macromolecules. 2013;46(17):7086–96.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest editors: Otilia M. Koo, Panayiotis P. Constantinides, Lavinia M. Lewis, and Joseph Reo

Rights and permissions

About this article

Cite this article

Zhao, J., Koo, O., Pan, D. et al. The Impact of Disintegrant Type, Surfactant, and API Properties on the Processability and Performance of Roller Compacted Formulations of Acetaminophen and Aspirin. AAPS J 19, 1387–1395 (2017). https://doi.org/10.1208/s12248-017-0104-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12248-017-0104-6