Abstract

Purpose

Superdisintegrants are typically used at low concentrations in tablets. As a result, the spatial distribution of disintegrant particles within the tablet may be inhomogeneous, resulting in varied disintegration times. This study aimed to investigate the effect of disintegrant spatial distribution on tablet disintegratability.

Methods

Tablets with various degrees of disintegrant spatial distribution were engineered using a novel experimental design. The effects of relative spatial distribution of disintegrant particles on tablet tensile strength, liquid penetration rate and disintegration time were investigated.

Results

It was observed that increased clustering of disintegrant particles generally promoted faster tablet disintegration due to more localized swelling and strain recovery of sodium starch glycolate and crospovidone, respectively. However, for tablets with insoluble fillers and sodium starch glycolate, a high degree of disintegrant clustering prolonged disintegration due to the formation of gel plugs which impeded liquid penetration into the tablet and caused the tablet to break up into floccules instead. Tablets made with insoluble fillers were also found to be more sensitive to changes in disintegrant spatial distribution compared to those containing soluble fillers.

Conclusion

Overall, the effects of disintegrant spatial distribution were dependent on the type of disintegrant and filler used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The oral tablet is the most common and preferred dosage form for delivering medications to patients (Moreton 2008; Turkoglu et al. 2009). Upon ingestion and wetting, the tablet breaks up into multiple subunits or fragments by disintegrant action (Moreton 2008; Alderborn 2013). The conventional disintegrants are plant-derived polymeric materials, such as starches and microcrystalline cellulose (MCC). Subsequently, more efficient disintegrants, known as superdisintegrants, were introduced. Examples include sodium starch glycolate (SSG) and crospovidone (XPVP) that were produced by chemically modifying starch and povidone, respectively (Quodbach et al. 2016).

Various mechanisms of disintegrant action have been proposed for different disintegrants (Desai et al. 2014). The more commonly discussed mechanisms are swelling, strain recovery and wicking. Swelling refers to the omnidirectional volumetric expansion of disintegrant particles in an aqueous medium and this is the most observable disintegration mechanism (Faroongsarng et al. 1994; Quodbach et al. 2014). When the disintegrant particles swell beyond the diameter of tablet pores, often by the cumulative force of disintegrant clusters, the swelling force pushes the tablet matrix apart (Patel et al. 1966). Starch and its derivatives act mainly through this mechanism (Moreton 2008), particularly for SSG which has been shown to be capable of very strong moisture absorption and large volumetric increase (Young et al. 2005; Augsburger et al. 2007). However, some swelling excipients could gelatinize after volume expansion and this could delay tablet disintegration. Strain recovery is the reversible viscoelastic process of deformation (Patel et al. 2007). Compacted disintegrant particles are constrained in a high-energy metastable shape (Lendlein et al. 2002) which, when wetted, release the stored energy, allowing the disintegrant particles to partially regain their original shape (Moreton 2008). The expansion due to strain recovery is unidirectional and in the opposite direction of the compaction force exerted (Quodbach et al. 2014), causing the tablet to break up. Strain recovery is the main mechanism of action reported for XPVP (Desai et al. 2012). Wicking refers to the process of liquid uptake into the tablet via capillary action (Kissa 1996; Moreton 2008). Besides penetrating through tablet pores, liquid can also traverse through a continuous network formed by hydrophilic particles (Shotton et al. 1972). Besides disintegrants, other hydrophilic components present in the tablet also confer hydrophilicity to the tablet matrix and promote liquid entry. Wicking causes weakening of the tablet structure by disrupting inter-particle bonds (Curlin 1955; Patel et al. 1966). However, wicking alone may not result in tablet disintegration (Patel et al. 1966) but could provide water for other disintegrant mechanisms such as swelling and strain recovery (Nogami et al. 1967; Khan et al. 1975). It must be noted that the swelling of disintegrants might also result in the closure of tablet pores and hinder the process of wicking (Soundaranathan et al. 2023). In most cases, the limiting factor affecting disintegrant performance is either liquid uptake or volumetric expansion, and many recent studies have attempted to identify the performance-controlling mechanism for various tablet formulations and assess the impact on tablet disintegration (Maclean et al. 2021; Markl et al. 2021; So et al. 2021).

Segregation issues may arise when powder mixtures are transferred or agitated as particles in a mixture often differ in their size, shape, density and/or surface properties (Twitchell 2013). Many investigators focused on the spatial distribution of drugs, but few investigate the effect of excipients, particularly the spatial distribution of disintegrants on tablet disintegration. Using imaging techniques such as near infrared and micro-focus X-ray, investigators demonstrated that low concentrations of drugs could exist as clusters in tablets (Lewis et al. 2001; Rigby et al. 2004). As superdisintegrants are also typically incorporated in tablets at low concentrations, non-homogeneous spatial distribution of the superdisintegrant particles may arise. A recent study found that non-homogeneous distribution of the disintegrant, due to insufficient mixing, can result in poor tablet disintegration and delay dissolution (Kondo et al. 2023). Spontaneous segregation of components within the die after filling and prior to compaction is possible due to differences in physical attributes of components and the agitative forces contributed by punch movement. This could result in inter- or intra-batch variations in the spatial distribution of disintegrant particles in tablets, potentially affecting tablet disintegration. It is hence of interest to determine whether and how various degree of disintegrant spatial distribution would influence tablet disintegration time, especially for formulations where the concentration of disintegrant present is low.

Materials and methods

Materials

Sodium starch glycolate (SSG; Primojel, DFE Pharma, the Netherlands), crospovidone (XPVP; Kollidon CL-SF, BASF, Germany) or native maize starch (Maize Starch B, Roquette, France) was used as the disintegrant. Dicalcium phosphate dihydrate (DCP; Di-cafos D9, Budenheim, Germany), lactose (GranuLac 200, Meggle, Germany) or microcrystalline cellulose (MCC; CEOLUS PH-101, Asahi Kasei, Japan) was used as the filler. Polyvinylpyrrolidone (PVP; Plasdone K-29/32, ISP Technologies, USA) was used as the binder with MCC. Magnesium stearate (MgSt; Magnesium stearate E, Faci Asia Pacific, Singapore) was the lubricant used for DCP- and lactose-based tablets. Iron oxide (Sicovit Red 30, BASF, Germany) was the red dye used.

Methods

The manufacturing process of slugs, granules and tablets in this study is presented in Fig. 1, providing an overview of the steps involved. The methods used in each of these steps are elaborated in greater detail in the subsequent sections.

Preparation of slugs

Table 1a shows the various slugged formulations with either only filler or filler and disintegrant (SSG or XPVP). DCP or lactose was selected as the filler with different solubility. For slugs with disintegrant, the components were weighed and blended for 5 min before aliquots of 1 g (DCP-based) or 800 mg (lactose-based) were compacted at 88 MPa in a single-station tablet press (NP-RD10A, Natoli Engineering, USA) fitted with 17 mm flat-faced punches and die (Natoli Engineering, USA). External lubrication was used to prevent sticking.

Preparation of granules

The slugs were broken down using a cone mill (Quadro 197 Comil, Quadro Engineering, Canada) fitted with a grater screen of aperture size 813 μm and a teethed round impeller rotating at 1240 rpm. The granules produced were fractionated using a sieve into large (> 180 μm) and small (< 180 μm) size fractions. As each slug formulation (Table 1a) gave rise to two size fractions of granules, six types of granules were produced for each filler in this study.

Design of experiment

The proportions of the different types of granules were varied to manipulate the relative spatial distribution of disintegrant particles. A mixture design was employed to generate five tablet formulations for each combination of disintegrant and filler. The various combinations of disintegrant and filler in tablets are abbreviated as follows: SSG + DCP, XPVP + DCP, SSG + Lac and XPVP + Lac. Table 1b summarizes the compositions of the tablets studied. The concentration of SSG and XPVP in Formulations S1 to S5 and X1 to X5, respectively, was 2%, w/w. This was achieved by maintaining a 1:1 weight ratio of disintegrant-containing granules to filler granules. The weight ratio of large to small granules was also kept at 1:1 to ensure that the granule size profiles of different formulations were comparable.

Figure 2 illustrates the spatial distribution of disintegrant particles in Formulations 1, 3, and 5 (i.e., X1, X3 and X5, or S1, S3 and S5). In Formulation 1, disintegrant particles were only present in the small granules. Numerically, smaller granules are more abundant and therefore, the disintegrant particles would be expected to be better distributed across the tablet matrix. Thus, Formulation 1 would theoretically demonstrate good homogeneity (i.e., the most uniformly distributed) in terms of disintegrant particles. As the formulation number increased (i.e., X1 to X5 or S1 to S5), the proportion of large disintegrant-containing granules increased and inversely, contained less small disintegrant-containing granules. Consequently, the disintegrant particles were more restricted to the large granules, causing them to appear as being relatively clustered.

Preparation of tablets

Tablets of 800 mg (DCP-based) or 600 mg (lactose-based) with 1%, w/w of MgSt and superdisintegrant equivalent to 2%, w/w were produced. For each formulation (Table 1b), the proportions of granules were accurately weighed and hand-blended for 5 min prior to adding MgSt, and the mixture was further blended for another 1 min. The mixture was carefully weighed out and hand-filled into the tablet die. Tablets were produced at a compaction pressure of 130 MPa using a compaction simulator (STYL’One Evolution, MedelPharm, France) equipped with 14 mm flat-faced punches and die (Natoli Engineering Company, USA). The tablets were aged in a closed container for at least 24 h prior to characterization tests.

Characterization of tablets

The weight, thickness, diameter and breaking force of ten tablets from each formulation were characterized using a weighing balance (Quintix 35-1 S, Sartorius, Germany), thickness gauge (547-300 S, Mitutoyo Corporation, Japan) and hardness tester (TBF 1000, Copley Scientific, UK), respectively. The tablet tensile strength was calculated using Eq. 1.

where F, d and t are the measured breaking force, tablet diameter and tablet thickness respectively.

The liquid penetration test was conducted for five tablets of each formulation, using an experimental method that was published previously (Zheng et al. 2022). The liquid penetration rate constant, determined from the plot of water uptake against time, was used to compare the liquid penetration rates of different tablets.

The USP disintegration apparatus (DT2, Sotax, Switzerland) was used to determine the disintegration time of tablets. Ten tablets from each formulation were evaluated, using water at 37 \(^\circ\)C as the disintegration medium.

Comparison between SSG and maize starch on spatial distribution effect

Additional experiments were conducted to compare the effects between SSG and maize starch as both are known swelling disintegrants. SSG and maize starch were employed at working concentrations of 2 and 10%, w/w, respectively. The slug and tablet compositions are given in Table 2.

Further study on tablets with slower disintegration

The extent and significance of the disintegrant spatial distribution effect were further investigated by producing slower disintegrating tablets with MCC as filler and PVP as binder. The same design of experiment was adopted with slight adjustments in the composition of the slugs by including MCC, 2.5%, w/w PVP and 0 or 4%, w/w SSG or XPVP.

Slugs weighing 5 g each were compacted at 20 MPa using a universal testing machine (Autograph AG-100kNE, Shimadzu Corporation, Japan) fitted with 25-mm punches and die set. The slugs were subsequently comminuted using a cone mill (Quadro 197 Comil, Quadro Engineering, Canada) fitted with a grater screen of aperture size 2007 μm and a teethed round impeller rotating at 1240 rpm. The granules produced were fractionated using a 180 μm aperture size sieve as described earlier.

The proportions of granules for each tablet formulation were accurately weighed and blended for 5 min before tableting. MgSt was not added for the MCC-based formulations. Aliquots of 750 mg were carefully weighed, manually filled into the tablet die and compacted at 180 MPa using the compaction simulator (STYL’One Evolution, Medelpharm, France) fitted with 14 mm flat-faced punches and die (Natoli Engineering Company, USA). The tablet formulations were abbreviated as SSG + PVP + MCC and XPVP + PVP + MCC. Characterization of tablets was carried out as elaborated previously.

Statistical analysis

The results obtained were analysed at 5% level of significance using a statistical software (SPSS Statistics 26, IBM, USA). For comparisons between more than two independent samples (e.g., tablets with various disintegrant spatial distributions), the Kruskal-Wallis test was applied to compare the tablet properties determined. For comparisons between two independent samples (e.g., tablets containing SSG compared to those containing XPVP), the Wilcoxon rank sum test was used. In addition, Minitab 17 (Minitab Inc., State College, USA) was used for the design of experiments and OriginPro 2021b (OriginLab Corporation, Northampton, USA) to plot the experimental data.

Results and discussion

Validation of the variation in spatial distribution

A novel approach was conceptualized to introduce variability in the spatial distribution of disintegrant particles in tablets. This was achieved by altering the ratio of large to small disintegrant-containing granules to simulate various degrees of clustering of disintegrant particles. Feasibility of the method to alter the disintegrant spatial distribution was validated by using iron oxide as a red dye to mimic the presence of disintegrant particles in the tablets. Formulations 1–5 were simulated where Formulation 1 had the least while Formulation 5 had the most clustered disintegrant particles. It could be clearly observed that Formulation 1 produced tablets with minuscule but more abundant pinkish spots (Fig. 3a). From Formulation 1 to Formulation 5, it could be observed that there were progressively more large, scattered patches of red (Fig. 3b–e). This demonstrated that the method employed could produce tablets containing disintegrant particles with differences in their relative spatial distributions.

DCP or lactose tablets with superdisintegrants

Tensile strength

Figure 4a shows the plot of tensile strength against the percentage of disintegrant present in large granules. Overall, each tablet contained similar amount of disintegrant. An increase in the percentage of disintegrant present in large granules represents greater clustering of disintegrant particles. The factors known to affect tablet tensile strength, such as compaction pressure and particle size, were kept constant for all formulations. The DCP tablets (− 1.1 MPa) were clearly stronger than the lactose tablets (0.55–0.65 MPa). For DCP tablets, the spatial distribution of SSG and XPVP did not affect tensile strength (p = 0.784 and 0.916 respectively). All SSG + DCP tablets also had similar tensile strength to the corresponding XPVP + DCP tablets (p = 0.336), indicating that the disintegrant incorporated at a low concentration of 2%, w/w in the tablets did not significantly alter tablet tensile strength.

However, for lactose tablets, tensile strength of XPVP + Lac tablets was generally higher than that of SSG + Lac tablets (p < 0.001). Similar observations have been reported in other studies, and the difference in tensile strength was attributed to the difference in the deformation properties of SSG and XPVP (Hiew et al. 2016; Zhao et al. 2017). XPVP has good binding ability due to its plastic deformability, whereas SSG is more elastic and potentially disrupt inter-particle bonds during post-compaction elastic recovery. Shape-wise, SSG is spherical and presents less inter-particle contact area for binding as opposed to the more fibrous XPVP (Rowe et al. 2009). Consequently, the inter-particle bonds in XPVP + Lac tablets were stronger and the resultant tablets exhibited higher tensile strength. This difference in tensile strength was not observed for DCP-based tablets because DCP by itself formed strong tablets and were unaffected by the differences in binding abilities of the relatively low concentration of the disintegrants used. It was also noted that, for lactose tablets, spatial distribution of SSG did not affect tablet tensile strength (p = 0.634) but increased clustering of XPVP caused a slight decrease in tablet tensile strength (p = 0.011). With increased clustering of XPVP, the binding effect of XPVP would be more localized, resulting in less uniform bonding and tablets of lower tensile strength resulted.

Liquid penetration rate

The liquid penetration rate constant of tablets was plotted against the percentage of disintegrant present in large granules (Fig. 4b). No significant difference in liquid penetration rate was observed for XPVP + DCP tablets and SSG + Lac tablets with increased clustering of disintegrant (p = 0.057 and 0.273 respectively). The disintegrant action was triggered by water. When disintegrant particles were more dispersed, swelling or strain recovery of SSG or XPVP respectively would form numerous small pores. In comparison, increased clustering of disintegrant would result in the formation of larger but fewer pores. It has been reported that the swelling of disintegrants is primarily driven by liquid penetration, which is, in turn, strongly influenced by the change in tablet pore space due to disintegrant swelling and dissolution of the tablet matrix (Maclean et al. 2021; Soundaranathan et al. 2023). Despite increased clustering of disintegrant in these tablets, it is likely that the overall resultant pore volume from volumetric expansion of the disintegrants remained similar hence the observed liquid penetration rate was relatively unchanged.

XPVP + Lac tablets showed a slight increase in liquid penetration rate as clustering of XPVP increased (p = 0.005). This could possibly be due to the lower tensile strength of XPVP + Lac tablets with increased clustering of XPVP (Fig. 4a). For SSG + DCP tablets, liquid penetration rate increased then decreased with increased clustering of SSG (p < 0.001). As the percentage of disintegrant present in large granules increased from 0 to 50%, the clusters of SSG formed resulted in greater localized swelling that promoted liquid penetration. However, the liquid penetration rate decreased as the percentage of disintegrant present in large granules increased above 50%. While both DCP and SSG are hydrophilic, SSG has better wicking properties than DCP (Desai et al. 2012). Therefore, as the percentage of disintegrant present in large granules increased from 50 to 100%, it is likely that the increased clustering of SSG impaired the formation of a continuous network of SSG particles, causing water to traverse slower through the network of DCP particles instead.

Interestingly, the liquid penetration rate of SSG + DCP tablets was higher than that of XPVP + DCP tablets, but the opposite trend was observed for lactose tablets. It was been reported that SSG + DCP tablets underwent greater volumetric expansion than XPVP + DCP tablets (Basaleh et al. 2020). This was attributed to the omnidirectional swelling of SSG occurring over a larger range than the unidirectional strain recovery of XPVP. As a result, the larger increase in pore size would promote liquid penetration into the tablet. In contrast, for lactose tablets, the solubility of lactose impeded the effect of SSG swelling on pore size enlargement (Berardi et al. 2018). In addition, it has been reported that dissolution of lactose increased liquid viscosity (Johnson et al. 1991) while SSG interacted with water to form a gel-like mass (Rojas et al. 2012; Desai et al. 2014). The combined effects of SSG and lactose in water likely accounted for the slower liquid penetration observed for SSG + Lac tablets in comparison with SSG + DCP tablets.

Disintegration time

Figure 4c presents the plot of disintegration time against the percentage of disintegrant present in large granules. For lactose tablets, tablet disintegration time decreased with increased clustering of disintegrant for both SSG and XPVP (p < 0.001 for both disintegrants). Clustering of disintegrant particles contributed to larger cumulative volumetric expansion during swelling or strain recovery, resulting in increased local breakup force that facilitated faster tablet disintegration. In contrast, the volumetric expansion of disintegrant particles that were more homogeneously dispersed throughout the tablet exerted less cumulative expansive pressure onto the tablet matrix. As XPVP particles became more clustered in XPVP + Lac tablets, the lower tensile strength (Fig. 4a) and faster liquid penetration (Fig. 4b) also contributed to the faster disintegration observed.

For DCP tablets, disintegration was also faster with increased clustering of XPVP (p < 0.001). As the tensile strength and liquid penetration rate remained similar (Fig. 4a, b), the faster disintegration observed could be primarily attributed to the greater stress exerted on the tablet matrix by the more localized and cumulative strain recovery by clusters of XPVP particles. In contrast, disintegration was prolonged with a higher degree of clustering of SSG (p < 0.001). As SSG interacts with water to form a gel (Rojas et al. 2012; Desai et al. 2014), greater clustering of SSG resulted in the formation of viscous gel plugs which impeded liquid penetration and caused tablets to break up slower. Disintegrated fragments were large floccules instead of fine disintegrated particles. Similar observations were reported with the use of high concentrations of SSG (Haware et al. 2008). Furthermore, as percentage of disintegrant present in large granules increased from 50 to 100%, w/w, slower liquid penetration resulted in slower activation of disintegrant particles, contributing to slower disintegration (Ekmekciyan et al. 2018). This was not observed for SSG + Lac tablets as lactose can dissolve and mitigate the swelling effects of SSG by accommodation, hampering the formation of the pressure-precipitated gel plugs.

DCP tablets were significantly more sensitive to changes in disintegrant spatial distribution compared to lactose tablets. The difference in disintegration time was up to 17% for lactose tablets and 150% for DCP tablets due mainly to the high aqueous solubility of lactose which can negate consequences of volumetric expansion by a swelling disintegrant. Therefore, it can be inferred that tablets containing insoluble fillers such as DCP would be more sensitive to changes in disintegrant spatial distribution. Consequently, it could be concluded that the disintegrant spatial distribution effect on tablet disintegration is more pronounced for tablets containing insoluble fillers.

Among the lactose tablets, the differences in disintegration time between the best dispersed and most clustered formulations were 2.35 and 4.31 s for SSG and XPVP respectively. For DCP tablets, the differences were 12.68 and 13.51 s for SSG and XPVP respectively. The significance of these differences in well-designed marketed conventional immediate release tablet would not be high but can be adverse for poorly designed or slow-disintegrating tablets. Also, for orally disintegrating tablets, expected to disintegrate within 1 min, differences in the spatial distribution of disintegrant particles could impact significantly. It should be noted that typical formulations would use XPVP at a higher concentration but for this study, the use percentage was maintained at the level for SSG. The lower concentration of XPVP employed resulted in correspondingly longer disintegration times for XPVP-based tablets, which may have muted the effects of local factors on tablet disintegration such as liquid penetration and post-compaction disintegrant swelling. Nevertheless, the spatial distribution of disintegrants have demonstrated their influences on tablet properties.

DCP tablets with SSG or native maize starch

In order to compare SSG and starch as disintegrants, DCP tablets were produced with either 2%, w/w SSG or 10%, w/w maize starch and evaluated. Tablets with maize starch had significantly lower tensile strength than the corresponding tablets containing SSG (Fig. 5a). Among the tablets containing maize starch, Formulations M4 and M5 had significantly lower tensile strength than Formulations M1 to M3 (p < 0.001). As starch is known to be elastic and poorly compressible (Shotton et al. 1972; Edge et al. 2002), greater clustering of maize starch particles in Formulations M4 and M5 likely created weakened localities within the tablet matrix and reduced the tablet tensile strength. Although SSG is also elastic in nature, this trend was not observed for tablets with SSG as it was present at only 2%, w/w and did not affect tablet tensile strength as markedly. In contrast, the presence of 10%, w/w maize starch was proportionally higher and therefore, had considerable impact on tablet tensile strength. Thus, tablets containing maize starch had lower tensile strength than tablets with SSG.

Tablets with maize starch showed significantly slower liquid penetration rates compared to tablets with SSG (Fig. 5b). Although both SSG and starch have disintegration action based on swelling, SSG swells by a greater extent (Rudnic et al. 1982). Despite being present at a lower concentration, the larger volumetric expansion of SSG particles enlarged tablet pores to a greater extent and resulted in faster liquid penetration. Although increased clustering of SSG resulted in slower liquid penetration, the spatial distribution of maize starch particles did not influence liquid penetration (p = 0.791). It was previously reported that liquid penetration rates were similar for maize starch compacts and partially pregelatinized starch compacts (Gissinger et al. 1980), as well as for partially pregelatinized starch compacts and DCP compacts (Desai et al. 2012). This implies that DCP and starch likely have similar wicking abilities. As a result, although greater clustering disrupted the continuous network of maize starch particles, water would traverse DCP particles at a similar rate.

Tablets with maize starch showed significantly slower disintegration compared to tablets with SSG (Fig. 5c). This can be attributed to the slower water uptake and smaller magnitude of swelling of starch (Rudnic et al. 1982). Among the maize starch formulations, Formulations M4 and M5 showed faster disintegration than Formulations M1 to M3 (p < 0.001). As Formulations M4 and M5 were observed to have lower tensile strengths (Fig. 5a), the tablet matrix was likely to be broken up more easily. In addition, the more localized swelling due to clusters of maize starch particles contributed to the faster disintegration observed. Despite having a similar mechanism of action, different trends were observed when the spatial distribution of SSG and maize starch were varied. It can be inferred that the concentration of the disintegrant played an important role. At a concentration of 10%, w/w, clustering of maize starch particles significantly reduced tablet tensile strength and disintegration time. In contrast, SSG at a lower concentration of 2%, w/w had minimal effect on tensile strength but clustering of SSG increased disintegration time via the formation of SSG gel plugs.

Interestingly, the variability in disintegration time decreased from Formulations M3 to M5 (Fig. 5c). This was likely due to the clusters of maize starch particles contributing to more effective and consistent local disintegrant action. This indicates that clustering of disintegrant particles could aid in the formulation of tablets with more predictable and consistent disintegration times. This effect was likely not as easily observed with superdisintegrants due to the short disintegration times of the test tablets formulated.

MCC tablets with superdisintegrants

In order to investigate the extent and significance of the spatial distribution effect, tablets with slower disintegration were also produced. MCC was used as the filler and PVP was included as a binder to produce stronger but slower disintegrating tablets. Figure 6a shows the plot of tablet tensile strength against the percentage of disintegrant present in large granules. Similar to previous findings (Fig. 4a), the spatial distribution of SSG and XPVP did not affect tablet tensile strength markedly (p = 0.215 and 0.230 respectively). Tablets with XPVP had significantly higher tensile strength compared to those with SSG (p < 0.001), and this finding concurred with the results for lactose tablets as previously discussed, due to the better binding ability of XPVP.

Compared with the DCP and lactose tablets with SSG or XPVP (Fig. 4b), liquid penetration was generally lower for all the MCC tablet formulations (Fig. 6b). Previous studies have shown that water uptake in MCC-based tablets largely takes place via the inter-particle pore space (Nogami et al. 1969; Al-Sharabi et al. 2020; Skelbæk-Pedersen et al. 2020) and MCC undergoes plastic deformation during compaction to produce tablets with low porosity which hindered liquid uptake (Bolhuis et al. 2006; Thoorens et al. 2014). Tablets with SSG exhibited significantly faster liquid penetration when compared to those with XPVP (Fig. 6b, p < 0.001). As discussed previously, this was attributed to stronger capillary action and swelling effects of SSG when compared with XPVP (Zhao et al. 2005; Desai et al. 2012; Rojas et al. 2012). A similar trend was also obtained with DCP tablets, indicating that the disintegrants promoted liquid penetration in a similar manner for tablets made with insoluble fillers.

For the MCC tablets with XPVP, the liquid penetration rate increased slightly with increased clustering of XPVP (p = 0.013). With XPVP + Lac tablets, the increased liquid penetration rate observed with increased clustering of XPVP particles which was associated with decreased tablet tensile strength (Fig. 4a, b). As the tensile strength of the MCC tablets with different extents of XPVP clustering was relatively constant, it could be inferred that the clusters of XPVP particles promoted stronger wicking compared to when XPVP was more dispersed throughout the tablet, resulting in faster liquid penetration.

For MCC tablets with SSG, the liquid penetration rates were rather similar when SSG was better distributed but decreased with increased clustering of SSG (p < 0.001). This observation is different from that for DCP tablets where faster liquid penetration was observed when the percentage of disintegrant present in large granules increased from 0 to 50% (Fig. 4b). As the MCC tablets produced had low porosity, the localized swelling loci of better distributed SSG particles were likely unable to enlarge the tablet pores to effectively percolate through the matrix and promote liquid penetration, hence the liquid penetration rate remained similar when the percentage of SSG present in large granules increased from 0 to 50%. As discussed previously, SSG can form a viscous gel with water (Rojas et al. 2012; Desai et al. 2014), and the formation of pressure-precipitated gel plugs would be more marked in MCC tablets with low porosity. As a result, as the percentage of large disintegrant granules increased from 50 to 100%, the increased clustering of SSG promoted the formation of viscous gel plugs which impeded liquid penetration.

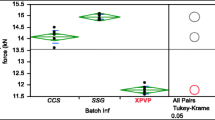

Figure 6c presents the plot of tablet disintegration time against the percentage of disintegrant present in large granules. The disintegration time of the MCC tablets decreased with increased clustering of XPVP (p = 0.003) but increased exponentially when SSG particles became increasingly clustered (p < 0.001). Similar trends were observed with the DCP tablets (Fig. 4c). As discussed previously, when XPVP was used as the disintegrant, increased clustering of XPVP exerted greater localized stress on the tablet matrix, hastening tablet disintegration. However, with SSG as the disintegrant, greater clustering of SSG formed viscous gel plugs which impeded liquid penetration and caused tablets to break into large floccules instead of disintegrating completely. Furthermore, as the percentage of SSG present in large granules increased from 50 to 100%, w/w, slower liquid penetration was observed, resulting in slower activation of disintegrant which contributed to slower disintegration.

Comparing SSG and XPVP, tablets with SSG exhibited significantly faster disintegration than those with XPVP. As previously discussed, the liquid penetration rate of tablets with SSG was significantly higher and it enabled faster activation of disintegrant action. In addition, the inherently smaller volumetric expansion of XPVP compared to SSG translates to XPVP being less effective than SSG in breaking up the tablet matrix (Rojas et al. 2012; Sacchetti et al. 2017; Bauhuber et al. 2021). In contrast, the strong swelling of SSG coupled with fast liquid penetration allowed faster disintegration of tablets with SSG.

Among the MCC tablets, the differences in disintegration time for the least and most clustered formulations were 2.07 min and 1.19 min for SSG and XPVP respectively. The percentage difference in disintegration time was 5% for XPVP and 16% for SSG, which was less than that for DCP tablets where up to 150% difference was observed. It can be inferred that the effect of disintegrant spatial distribution on tablet disintegration was less pronounced for stronger tablets. The disintegration time of the MCC tablets with SSG ranged from 12 min to more than 15 min, suggesting that a difference in spatial distribution of SSG in MCC tablets could impact whether the tablets pass or fail the pharmacopeial requirements for tablet disintegration test. The spatial distribution of disintegrant particles could be part of the reason for variations in tablet disintegration time, especially for formulations with high tendency to segregate within the die prior to compaction.

Conclusion

This study examined the effect of disintegrant spatial distribution in tablets on their disintegratability by the use of a novel experimental design to simulate varied spatial distribution of disintegrant particles within tablets. This involved distributing the same amount of disintegrant particles in granules of different sizes. It was observed that the spatial distribution of the disintegrants at low concentrations generally had no significant effect on tensile strength. Increased clustering of disintegrant particles promoted tablet disintegration through more localized swelling and strain recovery of SSG and XPVP, respectively. Exceptions were observed for tablets with insoluble fillers and SSG as the disintegrant, with increased clustering of SSG prolonging tablet disintegration. This was due to the formation of SSG gel plugs which restricted liquid penetration and prolonged tablet disintegration. Tablets containing insoluble fillers were also found to be more sensitive to changes in disintegrant spatial distribution compared to those containing soluble fillers. Overall, the effects of disintegrant spatial distribution varied with the type of disintegrant and filler used. The spatial distribution of disintegrant particles has the potential to affect tablet disintegratability to a large extent, especially for tablets with insoluble fillers, and improved understanding of this effect would enable judicious choice of materials in tablet formulation. Formulators would need to exercise extra caution when using SSG as the disintegrant in an insoluble tablet matrix. As disintegrant clusters facilitated disintegration through more local cumulative disintegrant action, this could potentially be harnessed to promote disintegration. Further investigations can explore the application of specifically designed granules as clustered disintegrant loci to improve tablet disintegratability.

References

Al-Sharabi M, Markl D, Mudley T, Bawuah P, Karttunen AP et al (2020) Simultaneous investigation of the Liquid Transport and Swelling Performance during Tablet Disintegration. Int J Pharm 584:119380

Alderborn G (2013) Tablets and compaction. In: Michael E, Aulton (eds) Pharmaceutics: the Science of Dosage Form Design, 4th edn. Churchill Livingstone, Edinburgh/New York, pp 397–440

Augsburger LL, Brzeczko AW, Shah U, Hahm HA (2007) Super disintegrants: characterization and function. In: James Swarbrick (ed) Encyclopedia of Pharmaceutical Technology, 3rd edn. Informa Healthcare, New York, pp 3553–3567

Basaleh S, Bisharat L, Cespi M, Berardi A (2020) Temperature: an overlooked factor in Tablet Disintegration. Eur J Pharm Sci 151:105388

Bauhuber S, Warnke G, Berardi A (2021) Disintegrant selection in Hydrophobic Tablet formulations. J Pharm Sci 110:2028–2037

Berardi A, Bisharat L, Blaibleh A, Pavoni L, Cespi M (2018) A simple and inexpensive image analysis technique to Study the Effect of disintegrants Concentration and diluents type on disintegration. J Pharm Sci 107:2643–2652

Bolhuis GK, Armstrong NA (2006) Excipients for direct Compaction-An update. Pharm Dev Technol 11:111–124

Curlin LC (1955) A note on Tablet Disintegration with Starch. J Am Pharm Assoc 44:16

Desai PM, Liew CV, Heng PWS (2012) Understanding disintegrant action by visualization. J Pharm Sci 101:2155–2164

Desai PM, Er PX, Liew CV, Heng PWS (2014) Functionality of disintegrants and their mixtures in enabling fast disintegration of tablets by a quality by Design Approach. AAPS PharmSciTech 15:1093–1104

Edge S, Steele DF, Staniforth JN, Chen A, Woodcock PM (2002) Powder Compaction Properties of Sodium Starch Glycolate disintegrants. Drug Dev Ind Pharm 28:989–999

Ekmekciyan N, Tuglu T, El-Saleh F, Muehlenfeld C, Stoyanov E et al (2018) Competing for water: a New Approach to Understand Disintegrant performance. Int J Pharm 548:491–499

Faroongsarng D, Peck GE (1994) The Swelling & Water Uptake of tablets III: moisture sorption behavior of Tablet disintegrants. Drug Dev Ind Pharm 20:779–798

Gissinger D, Stamm A (1980) A comparative evaluation of the properties of some Tablet disintegrants. Drug Dev Ind Pharm 6:511–536

Haware RV, Chaudhari PD, Parakh SR, Bauer-Brandl A (2008) Development of a Melting Tablet containing promethazine HCl against Motion Sickness. AAPS PharmSciTech 9:1006–1015

Hiew TN, Johan NB, Desai PM, Chua SM, Loh ZH et al (2016) Effect of moisture sorption on the performance of Crospovidone. Int J Pharm 514:322–331

Johnson JR, Wang LH, Gordon MS, Chowhan ZT (1991) Effect of Formulation Solubility and Hygroscopicity on Disintegrant Efficiency in tablets prepared by Wet Granulation, in terms of dissolution. J Pharm Sci 80:469–471

Khan KA, Rhodes CT (1975) Water-Sorption properties of Tablet Disintegrants. J Pharm Sci 64:447–451

Kissa E (1996) Wetting and Wicking. Text Res J 66:660–668

Kondo A, Koide T, Fukami T (2023) Evaluation of the effect of disintegrant distribution on the dissolution behavior of Pharmaceutical tablets using Raman Chemical Imaging. Chem Pharm Bull (Tokyo) 71:454–458

Lendlein A, Kelch S (2002) Shape-memory polymers. Angew Chem Int Ed 41:2034–2057

Lewis EN, Carroll JE, Clarke F (2001) A Near Infrared View of Pharmaceutical Formulation Analysis. NIR News 12:16–18

Maclean N, Walsh E, Soundaranathan M, Khadra I, Mann J et al (2021) Exploring the performance-controlling Tablet Disintegration mechanisms for Direct Compression formulations. Int J Pharm 599:120221

Markl D, Maclean N, Mann J, Williams H, Abbott A et al (2021) Tablet Disintegration performance: Effect of Compression pressure and storage conditions on Surface Liquid absorption and swelling kinetics. Int J Pharm 601:120382

Moreton RC (2008) Disintegrants in Tableting. In: Larry L, Augsburger, Hoag SW (eds) Pharmaceutical Dosage forms: tablets. CRC Press, New York, pp 217–249

Nogami H, Hasegawa J, Miyamoto M (1967) Studies on Powdered preparations. XX. Disintegration of the aspirin tablets containing starches as Disintegrating Agent. Chem Pharm Bull (Tokyo) 15:279–289

Nogami H, Nagai T, Fukuoka E, Sonobe T (1969) Disintegration of the aspirin tablets containing Potato Starch and Microcrystalline Cellulose in various concentrations. Chem Pharm Bull (Tokyo) 17:1450–1455

Patel NR, Hopponent RE (1966) Mechanism of action of Starch as a disintegrating Agent in Aspirin tablets. J Pharm Sci 55:1065–1068

Patel S, Kaushal AM, Bansal AK (2007) Effect of particle size and Compression Force on Compaction Behavior and Derived Mathematical parameters of Compressibility. Pharm Res 24:111–124

Quodbach J, Kleinebudde P (2016) A critical review on Tablet Disintegration. Pharm Dev Technol 21:763–774

Quodbach J, Moussavi A, Tammer R, Frahm J, Kleinebudde P (2014) Tablet Disintegration studied by high-resolution real-time magnetic resonance imaging. J Pharm Sci 103:249–255

Rigby SP, Van Der Walle CF, Raistrick JH (2004) Determining drug spatial distribution within controlled delivery tablets using MFX Imaging. J Control Release 96:97–100

Rojas J, Guisao S, Ruge V (2012) Functional Assessment of four types of disintegrants and their effect on the Spironolactone Release Properties. AAPS PharmSciTech 13:1054–1062

Rowe RC, Sheskey PJ, Quinn ME, American Pharmacists A (2009) Handbook of Pharmaceutical excipients. Pharmaceutical Press, London

Rudnic EM, Rhodes CT, Welch S, Bernardo P (1982) Evaluations of the mechanism of Disintegrant Action. Drug Dev Ind Pharm 8:87–109

Sacchetti M, Teerakapibal R, Kim K, Elder EJ Jr (2017) Role of Water Sorption in Tablet Crushing Strength, Disintegration, and dissolution. AAPS PharmSciTech 18:2214–2226

Shotton E, Leonard GS (1972) The Effect of Intra- and Extragranular Maize Starch on the disintegration of compressed tablets. J Pharm Pharmacol 24:798–803

Skelbæk-Pedersen AL, Al-Sharabi M, Vilhelmsen TK, Rantanen J, Zeitler JA (2020) Effect of particle size and deformation behaviour on Water Ingress into tablets. Int J Pharm 587:119645

So C, Narang AS, Mao C (2021) Modeling the tablet disintegration process using the Finite Difference Method. J Pharm Sci 110:3614–3622

Soundaranathan M, Al-Sharabi M, Sweijen T, Bawuah P, Zeitler JA et al (2023) Modelling the evolution of Pore structure during the disintegration of Pharmaceutical tablets. Pharmaceutics 15:489

Thoorens G, Krier F, Leclercq B, Carlin B, Evrard B (2014) Microcrystalline Cellulose, a Direct Compression Binder in a quality by Design Environment-A Review. Int J Pharm 473:64–72

Turkoglu M, Sakr A (2009) Tablet Dosage forms. In: Alexander T, Florence, Juergen, Siepmann (eds) Modern pharmaceutics, 5th edn. Informa Healthcare USA, New York, pp 481–497

Twitchell AM (2013) Mixing. In: Michael E, Aulton (eds) Pharmaceutics: the Science of Dosage Form Design, 4th edn. Churchill Livingstone, Edinburgh/New York, pp 170–186

Young PM, Edge S, Staniforth JN, Steele DF, Price R (2005) Dynamic Vapor Sorption properties of Sodium Starch Glycolate disintegrants. Pharm Dev Technol 10:249–259

Zhao N, Augsburger LL (2005) The influence of swelling capacity of superdisintegrants in different pH media on the dissolution of Hydrochlorothiazide from directly compressed tablets. AAPS PharmSciTech 6:E120–E126

Zhao J, Koo O, Pan D, Wu Y, Morkhade D et al (2017) The impact of disintegrant type, surfactant, and API properties on the processability and performance of Roller compacted formulations of Acetaminophen and Aspirin. AAPS J 19:1387–1395

Zheng AY, Heng PWS, Chan LW (2022) Tablet Disintegratability: sensitivity of superdisintegrants to temperature and Compaction pressure. Pharmaceutics 14:2725

Acknowledgements

The authors acknowledge the financial support provided by GEA-NUS PPRL fund (N-148-000-008-001). Audrey Yi Zheng is a recipient of the National University of Singapore Graduate Research Scholarship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors (A.Y. Zheng, W.W. Huang, L.Y.J. Poon, E.S. Wong, P.W.S. Heng and L.W. Chan) declare that they have no conflict of interest.

Research involving human or animal participants

This article does not contain any studies with human and animal subjects performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, A.Y., Huang, W.W., Poon, L.Y.J. et al. Examining the effect of spatial distribution of disintegrant particles on tablet disintegratability. J. Pharm. Investig. 54, 195–207 (2024). https://doi.org/10.1007/s40005-023-00639-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40005-023-00639-6