Abstract

Silymarin (SM) from Silybum marianum (L.) is a sum of flavolignans (silibinin, silychristin, silydianin, and isosilibinin), exhibiting a wide spectrum of biological activity and having anti-inflammatory, antitumor, hepatoprotective, immunomodulatory effects. Using a modified emulsion method with solvent evaporation, lipid nanoparticles with silymarin (LNP-SM) were obtained, the size of which was 257 ± 6 nm, and the ζ potential was –20.8 ± 1.6 mV. The efficiency of SM inclusion in the LNP-SM was 89.8%, the loading degree was 5.4%. The release of CM from the composition of the resulting nanoparticles was prolonged; after 48 h, only 68.3 ± 5.4% of the active substance was released into the dialysis medium. The dynamics of the inclusion/release of SM in the composition of LNP into the films of bacterial cellulose (BC) produced by the Gluconacetobacter hansenii GH-1/2008 strain has been studied. It was shown, that after 24 h of incubation the maximum of BC film saturation with SM reached 0.745 ± 0.038 mg/cm2, and the maximum release was 0.520 ± 0.041 mg/cm2. It was demonstrated that both LNP-SM sols and samples of BC saturated with LNP-SM exhibited low hemolytic activity, which indicates the potential biosafety of these preparations. The preparation LNP-SM, in contrast to free SM, exhibited fungistatic action against the fungi of A. niger and C. albicans. Both free SM and LNP-SM suppressed the growth of gram-positive bacteria; however, the effect of LNP-SM was much more effective. The minimum inhibitory concentration of the LNP-SM preparation for B. subtilis and B. coagulans was 105 and 210 μg/mL, respectively. The possibility of developing biocompatible coating materials based on BC saturated with LNP-SM is discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

One of the most promising and widely studied biologically active substances of natural origin are the flavolignans of silymarin (SM) contained in the Milk thistle—Silybum marianum (L.). Dry extracts obtained from Milk thistle contain about 60% of SM, the main active ingredients of which are flavolignans silibinin, silychristin, silydianin and isosilibinin [1].

Silymarin exhibits a wide spectrum of biological activity. It has the ability to suppress TNF-induced production of reactive oxygen species, trap free radicals, and prevents lipid peroxidation [2, 3]. SM also helps to reduce the concentration of low-density lipoproteins in the blood serum, promotes the utilization of these lipoproteins by the liver and thus reduces cholesterol levels [4]. The anti-inflammatory [5], antitumor [6–9], hepatoprotective [10, 11], cardioprotective [12], neuroprotective [13], and immunomodulatory [14, 15] effects of SM have been demonstrated. The antimicrobial effect of SM against gram-positive bacteria has been described [16]. SM exhibits extremely low toxicity to humans even at a daily dose exceeding 1.5 g, however, the maximum manifestation of its biological activity is hindered by its low solubility in water (<50 μg/mL) [17].

An increase in the solubility and bioavailability of the SM can be achieved by encapsulating it in liposomes or other types of nanoparticles. Thus, SM was encapsulated in liposomes [18, 19], incorporated into solid dispersions [20] and microparticles [21], amphiphilic chitosan micelles [22].

One of the promising directions for increasing the bioavailability and enhancing the effectiveness of therapeutic action is the inclusion of SM flavolignans in the composition of lipid nanoparticles stabilized by emulsifiers and existing in a solid state at human body temperature [23].

Earlier, lipid nanoparticles including SM (LNP-SM) were obtained on the basis of an ester of glycerol and fatty acid residues (“Compritol”) and a nonionic surfactant Tween 80. The resulting nanodispersions showed a higher therapeutic activity against liver damage in comparison with free flavolignan silibinin [24]. Also, solid LNPs containing silibinin were obtained based on stearic acid and nonionic detergent Brij 78 (octodecylpolyoxyethylene-78) [25]. Such nanoparticles were characterized by extremely slow release of silibinin and had a stealth effect, i.e., the ability to avoid the capture of the by macrophages of the reticuloendothelial system.

In this work, LNP-SM were obtained on the basis of glycerol monostearate and phosphatidylcholine; studied their physical and chemical properties and antibacterial activity. Bacterial cellulose (BC) produced by the Gluconacetobacter hansenii GH-1/2008 strain is an elastic, biocompatible nanoporous material, the possibilities of medical application of which are being actively studied [26]. In this regard, a promising direction for using BC is the production of a coating material with antimicrobial activity on its basis, in connection with which the task was set to study the kinetics of saturation—release of LNP-SM by cellulose, as well as to study the hemolytic and antimicrobial activity of the films obtained.

EXPERIMENTAL

We used polyethylene glycol PEG 400, Tween 80, sodium dodecyl sulfate (SDS), EDTA, isopropanol, ethanol, phosphate buffered saline (PBS), glycerol monostearate, L-α-phosphatidylcholine, silymarin, Sephadex G50 (all from Sigma-Aldrich, USA). Citric acid, sucrose, Na2HPO4, NaOH were of analytical grade.

LNP-SM was obtained using a modified emulsion method with solvent evaporation [27]. The components of the particles (glycerol monostearate, phosphatidylcholine, SM) in a mass ratio of 10 : 1.5 : 1 were dissolved in a minimum volume of absolute ethanol heated to 70°C. The resulting solution was added dropwise to an aqueous phase heated to 70°C containing PEG 400 (1 wt %) and isopropanol (1 wt %), with constant stirring at a speed of 1200 rpm. After 5 h of incubation, the resulting dispersion was poured with stirring (1000 rpm) to an equal volume of an aqueous solution cooled to 4°C (hydration solution) containing Tween 80 (1 wt %) and PEG 400 (1 wt %), and incubated for 3 h. The suspension was filtered through a membrane with a pore size of 0.45 μm and additional purification of lipid particles was carried out using gel filtration on a column with a Sephadex G50. Two milliliters of a lipid dispersion containing SM was loaded onto a column equilibrated with 40 mM PBS, pH 7.4, and the preparation was eluted with the same buffer at a flow rate of 1.0 mL/min. The process was monitored with a detector at λ 300 nm.

To determine the efficiency of SM inclusion in the LNP, 50 mL of methanol was added to 1 mL of the dispersion obtained after purification on a column with Sephadex G50, filtered through a membrane filter with a pore size of 45 μm, and 100 μL of a sample was taken for HPLC analysis. The analysis was performed using an Agilent Technologies 1260 Infinity chromatograph (USA) on a C18 reverse phase column. The mobile phase consisted of a mixture of acetonitrile and water (30 : 70 vol/vol) at a flow rate of 1 mL/min. The column eluate was monitored at 300 nm. The CM concentration was determined in terms of silibinin according to a calibration graph plotted using a silibinin standard sample. The efficiency (E) of the inclusion of SM in the LNP was calculated by the formula: E = [(mass of SM in LNP, mg)/(total mass of SM, mg)] × 100%. The degree of loading (DL) of LNPs with silymarin was determined by the formula: DL = [(mass of SM in LNP, mg) / (mass of lipids, mg)] × 100%.

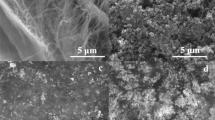

The particle size and ζ-potential were determined by dynamic light scattering (DLS) on a Zetasizer Nano ZS ζ-potential and particle size analyzer (Malvern Instruments Ltd, UK). The shapes and sizes of LNPs were studied using a JEOL JSM-6490LV scanning electron microscope (SEM) (Japan) at a magnification of ×10 000 and ×15 000. The test samples were sprayed (40 s at 40 mA) with a 20 nm platinum layer in a JEOL JFC-1600 automatic coater.

The dynamics of the release of SM from the LNP was studied using the dialysis method with some modifications [28]. Before use, the dialysis bags were boiled in water for 10 min with the addition of ethylenediamine tetraacetic acid, washed and left in deionized water for 12 h. Ten milliliters of the LNP-SM dispersion in a dialysis bag was dialyzed for 48 h at 37°C on a VXR basic Vibrax shaker (IKA) with stirring (50 rpm) against 500 mL of PBS, pH 7.4, containing 1% methanol. Free SM was used as a control, which was dialyzed under similar conditions. Aliquots of the experimental and control samples of the dialyzed solution were taken for analysis at regular intervals by adding the same volume of fresh buffer to this solution. The content of SM in the dialysate was determined using HPLC.

The Gluconacetobacter hansenii GH-1/2008 strain VKPM B-10547 was used. To obtain BC films, the G. hansenii strain was cultivated in a stationary culture on a medium containing 2% sucrose, 0.5% peptone, 0.5% yeast extract, 0.27% Na2HPO4, and 0.12% citric acid. The G. hansenii inoculum was grown on this medium at 30°C using a rotary shaker for 3 days. To obtain BC films, the producer was cultivated in a stationary culture on a medium for 15 days at a temperature of 26 ± 2°C in cuvettes 25 × 50 cm in size. The thickness of the obtained films was ~150 μm. After the completion of cultivation, the films were separated from the culture liquid, washed with distilled water to remove medium components, and treated with 1.0 M NaOH solution at 80°C for 2 h to remove contamination and producer cells immobilized on the film. At the final stage, the BC films were washed from alkali with distilled water. Washing was stopped when the pH of the washing liquid reached neutral values.

To study the sorption of LNP-SM on BC, hydrated films 4 cm2 in size were incubated in the LNP-SM ash for certain periods of time (from 10 min to 24 h) with shaking at room temperature. The SM concentration in the LNP-SM sol was 0.842 mg/mL. After the incubation time elapsed, the films were removed from the incubation medium and the concentration of the SM remaining in the incubation medium was determined using HPLC, as described above, at a wavelength of λ 300 nm after the destruction of the LNP by adding 96% ethanol. The amount of SM adsorbed on the BC was calculated from the difference in concentrations in the initial suspension and in the suspension after removing the film.

Further, the dynamics of release of SM from films of bacterial cellulose with adsorbed LNP-SM was studied. Wet BC films with LNP-SM adsorbed on them, obtained as described above, were placed in a container with PBS, pH 7.4, and incubated with shaking. At certain time intervals, samples of the incubation medium were taken and the concentration of SM released from the films was estimated using HPLC. Based on the results of the experiment, a graph of the dynamics of the release of SM from BC films was plotted.

The hemolytic activity of LNP-SM was determined according to the method [29] with some modifications. Whole blood of outbred sexually mature female ICR (CD-I) mice collected by decapitation was used in the experiments. The maintenance of animals and all procedures were carried out in accordance with the requirements of the legislation of the Russian Federation, the provisions of “European Convention for the protection of vertebrate animals used for experimental and other scientific purposes” (ETC 123), the provisions of the Guide for the Care and Use of Laboratory Animals (Washington D.C., 2011) and other rules of international law regulating the content and use of laboratory (experimental) animals. To 1 mL of LNP-SM sol in PBS (pH 7.4), 100 μL of mouse blood was added, and the mixture was incubated for 1 h at 37°C. The solution was centrifuged for 10 min at 5000 rpm. The hemoglobin released during lysis was recorded photometrically in the supernatants at a wavelength of 540 nm. PBS, pH 7.4 was used as a negative control (no hemolysis), and 1.5 wt % SDS solution was used as a positive control with 100% hemolytic activity. The control preparations were subjected to the same procedure as the experimental samples. The hemolytic activity (H) of LNP-SM in percent was calculated by the formula: H = [(ALNP – APBS)/ASDS] × 100%, where ALNP is the optical density of the supernatant in preparations containing LNP-SM, APBS, ASDS are the optical densities of the supernatants of negative and positive controls.

To determine the hemolytic activity of phosphatidylcholine and Tween 80, their solutions (1 and 0.625%, respectively) were prepared in PBS, pH 7.4. Before determining the hemolytic activity of phosphatidylcholine, its solution was subjected to ultrasonic treatment. To determine the hemolytic activity of free SM, its suspension was prepared (0.842 mg in 1 mL PBS, pH 7.4). Determination of the hemolytic activity of BC was carried out in PBS containing a film fragment (230 mg per 1 mL) (control sample); the experimental sample contained 230 mg of cellulose saturated with LNP-SM in 1 mL of PBS.

The antimicrobial activity of LNP-SM was assessed by the agar diffusion method [30] using test cultures of opportunistic fungi and bacteria: Aspergillus niger INA 00760, Candida albicans ATCC 2091, Bacillus subtilis ATCC 6633, B. coagulans 429, Escherichia coli ATCC 8739. Disks cut from the BC film, on which 420 µg of SM included in LNP was preliminarily applied, were placed on the agar surface; BC disks 6 mm in diameter containing 420 μg of free SM were used as control samples. The sensitivity of the test organism was controlled by standard discs with nystatin (40 µg/mL) and co-amoxiclav (10 µg/mL) (both—Pasteur Research Institute, Russia).

The minimum inhibitory concentration (MIC) of LNP-SM was determined by the method of successive dilutions on strains of gram-positive bacteria B. subtilis ATCC 6633, B. coagulans 429 and gram-negative bacteria E. coli ATCC 8739. Experiments were carried out in liquid media: meat-peptone broth with glucose (for Bacillus) or Kessler’s medium (for E. coli). The inoculum suspension of test organisms was diluted in sterile saline to an optical density of 0.5 according to the McFarland Standard, and then diluted 100 times with a nutrient medium. An inoculum in a volume of 1 mL was added to sterile test tubes, each containing 1 mL of the drug dilution on a nutrient medium. The final concentration of the drug in test tubes ranged from 420 to 26.25 μg/mL. One milliliter of pure culture medium and inoculum were added to the control tube. The tubes were incubated for 24 h at 37°C, after which the MIC was determined as the minimum concentration of the drug that completely prevents the visible growth of the test organism [30].

The obtained data were processed using the Microsoft Excel 2010 and Microcal Origin 8.0 computer programs (OriginLab Corporation). All data are presented as arithmetic means (M) and standard deviations (±SD). To identify the statistical significance of differences, one-way analysis of variance (ANOVA) was used; differences were considered significant at p < 0.05.

RESULTS AND DISCUSSION

Using the emulsion method with solvent evaporation at a high temperature followed by solidification of particles at a low temperature, an LNP-SM preparation was obtained, the average size of which, according to DLS data, was 257.0 ± 6.3 nm (Fig. 1). The ζ-potential is an important parameter, the value of which makes it possible to evaluate the stability of colloidal solutions [31]. In the case of LNPs, the ζ-potential depends on the nature of the particles, the composition of the buffer medium, the nature of the arrangement of lipid molecules on the particle surface, the nature and localization of surfactant molecules at the interface, and other parameters. The ζ-potential of the obtained LNP-SM was –20.8 ± 1.6 mV, while the sol remained stable at 4°С for at least two weeks. During this period, the parameters characterizing the stability of the sol (the formation of aggregates, the particle size distribution, the efficiency of the inclusion of the SM) remained practically unchanged (data not shown). The efficiency of SM inclusion in the LNP was quite high and amounted to 89.8%; loading degree—5.4%.

The study of the dynamics of the release of SM from the composition of the obtained LNP was carried out at pH 7.4, which can simulate the release of the drug when it enters the human blood plasma after intravenous administration. As seen in Fig. 2, in the first hours of incubation, free SM is rather quickly released into the dialysis medium, practically reaching a half-maximum (47.05%) accumulation in it in a little more than 1 h. Subsequently, the release rate gradually decreased; after 24 h, 92.7 ± 8.34% of the total amount of free SM was found in the dialysis medium, and after 48 h—94.1 ± 8.46% of the total amount of free SM. At the same time, the release of the SM, which is in the composition of the LNP, is of a prolonged nature; after 1 h of incubation, only 11.8 ± 0.94% CM is released; after 24 h—61.8 ± 4.97%, and after 48 h—68.3 ± 5.44%. Thus, LNP-SM sols can be considered as a therapeutic vehicle that can be used for the delivery and prolonged release of SM.

The antioxidant, membrane-protective, anti-inflammatory, antitumor effect of SM described in the literature [1] suggests that it is promising for its use in the composition of covering materials for the treatment of skin and burn injuries, psoriasis, autoimmune diseases, etc. In this regard, it seems important to find ways to solve the problem of the possibility of using the LNP-SM in the composition of cover materials and transdermal systems for medical purposes. In this work, we investigated the possibility of obtaining such a material based on BC films produced by the Gluconacetobacter hansenii GH-1/2008 strain. Bacterial cellulose is a biocompatible nanoporous material, the fields of application of which are being actively studied [26].

The results of the experiment on the saturation of cellulose with the LNP-SM preparation are shown in Fig. 3. Cellulose saturation with LNP-SM was exponential. The half-maximum saturation of the BC film was achieved after 4 h of incubation and was 0.579 ± 0.029 mg/cm2; the maximum saturation, after 24 h, was 0.745 ± 0.038 mg/cm2. Thus, 89.1% of the SM contained in the LNP-SM in the incubation medium was included in the BC, which may indicate its rather high porosity and capacity. As seen in Fig. 4, LNP-SM actively interact with BC fibrils, creating a rather dense nanocoating on its surface.

The results of investigating the release of SM from BC films saturated with LNP-SM are shown in Fig. 5. The release of SM was delayed; after 1 h of incubation, 0.162 ± 0.013 mg/cm2 SM was released (21.6% of the total mass of SM adsorbed on the BC); after 2 h—0.248 ± 0.019 mg/cm2 (33.1%). The maximum release of SM from the BC film was observed after 24 h of incubation and amounted to 0.520 ± 0.041 mg/cm2 (69.3%). Thus, the practical application of LNP-SM in the composition of dosage forms based on BC films can have significant advantages as a result of prolonged release of SM, provided both by the delayed release of nanoparticles themselves from the composition of the film, and by delayed release of SM from the composition of nanoparticles.

It was previously shown that SM can be used in the treatment of eczema, psoriasis, skin cancer, and other diseases [32, 33]. The immunosuppressive effect of silibinin (the main flavolignan of SM) has also been described. The suppression of proliferation along with the induction of T-lymphocyte apoptosis by silibinin against the background of suppression of the expression of pro-inflammatory cytokines led to a decrease in the body’s immune response to healthy tissues, which may be important in the treatment of autoimmune diseases [34]. Thus, the development of biocompatible coating materials based on BC saturated with LNP-SM seems to be an urgent direction of expanding the arsenal of means for treating wound and burn injuries, skin pathologies and autoimmune diseases.

A test for hemolytic activity was used to assess the safety level of LNP-SM, bacterial cellulose saturated with nanoparticles, and key components of LNP. As seen in Fig. 6, the highest hemolytic activity (16.8 ± 1.4%) was possessed by the hydrating solution Tween 80, which was used to prepare LNP-SM. Obviously, after purification of the LNP-SM, carried out using gel filtration, the Tween 80 content in the sol should have significantly decreased and did not make a significant contribution to the hemolytic activity of the preparation. Indeed, the purified sol LNP-SM exhibited very low hemolytic activity (8.7 ± 0.7%). At the same time, the free SM preparation showed practically no hemolytic activity (0.4 ± 0.1%), while phosphatidylcholine exhibited extremely low activity (0.8 ± 0.1%). The control sample of BC without LNP-SM showed slightly higher hemolytic activity (12.8 ± 1.0%) in comparison with the sample of BC saturated with LNP-SM (10.1 ± 0.9%), which confirms the data on the antihemolytic effect of SM [35].

According to [36], drugs with hemolysis values exceeding 25% are considered high risk factors; drugs that cause hemolysis not exceeding 10% are considered non-hemolytic. Thus, in accordance with the data obtained in this work, the LNP-SM preparation and samples of bacterial cellulose saturated with it can be considered as safe enough from the point of view of manifestation of hemolytic activity.

Taking into account that free SM exhibits antimicrobial activity [37], we carried out a comparative study of the antimicrobial activity of free SM and LNP-SM against strains of conditionally pathogenic fungus of A. niger, yeast C. albicans, gram-positive bacteria B. subtilis and B. coagulans, as well as gram-negative bacteria E. coli (Table 1). Free SM exhibited a weak inhibitory effect against gram-positive bacteria, while LNP-SM preparation had an inhibitory effect against microorganisms of all studied strains.

According to [38], the effect of free silibinin (one of the SM flavolignans) on C. albicans leads to a change in the permeability of cell membranes, a decrease in the metabolic activity of cells, suppression of biofilm formation, and induction of apoptosis. As seen from the Table 1, the LNP-SM preparation, in contrast to free SM, exhibits a fungistatic effect against A. niger and C. albicans, less pronounced in comparison with nystatin. In contrast to free SM, the presence of an antifungal effect in LNP-SM can be associated with the effective interaction of LNP with the surface of a bacterial cell, followed by the release of SM flavolignans directly on the surface of the target cell.

As is known, free SM does not exhibit antibacterial activity against the gram-negative bacteria E. coli. In this case, the absence of an antibacterial effect can be explained by the stimulating effect of SM on DNA synthesis in E. coli cells, as well as the absence of its effect on the level of synthesis of cellular proteins and RNA [39]. In the experiment carried out, in contrast to free SM, the LNP-SM preparation exhibited bacteriostatic activity, which is extremely low in comparison with the activity of co-amoxiclav (Table 1).

Gram-positive bacteria are more sensitive to the action of free SM, since it inhibits the intracellular synthesis of proteins and RNA [39]. As seen in Table 1, both free SM and LNP-SM inhibit the growth of bacteria B. subtilis and B. coagulans. At the same time, the effect of the LNP-SM preparation is more effective—its MIC for B. subtilis and B. coagulans is 105 and 210 μg/mL, respectively. The preparation of free SM has a weak bacteriostatic effect (in the range of investigated concentrations from 420 to 26.25 μg/mL, the MIC was not achieved).

Thus, the LNP-SM preparation exhibits a higher antimicrobial activity compared to free SM, which may be due to the specific binding of LNP-SM to the surface of microbial cells. The highest activity of LNP-SM is observed against gram-positive bacteria B. subtilis and B. coagulans; in relation to fungi of A. niger and C. albicans, LNP-SM has a fungistatic effect. Apparently, LNP-SM do not have broad prospects for use as effective antimicrobial agents due to their low toxicity. However, both free SM and LNP-SM can be considered as promising agents that complement the action of antibiotics [37].

CONCLUSIONS

In contrast to free SM, which is poorly soluble in biological fluids, LNP-SM form stable aqueous sols, the presence of which can significantly expand the spectrum of the therapeutic use of SM based on the development of new dosage forms. In addition, flavolignans SM as part of a lipid nanoparticle are reliably protected from an aggressive environment. Prolonged release of SM from LNP creates additional advantages when considering the routes of administration and the possibilities of its therapeutic use. The practical absence of hemolytic activity in LNP-SM and their components, along with the literature data on the extremely low toxicity of SM, its high antioxidative, antiviral, anti-inflammatory, antiangiogenic and antitumor activity, clearly indicates the relevance of the development of new anti-burn and wound healing dressings and transdermal delivery systems based on these nanoparticles and biocompatible BC material.

REFERENCES

R. Gazák, D. Walterová, and V. Kren, Curr. Med. Chem. 14, 315 (2007). https://doi.org/10.2174/092986707779941159

S. K. Manna, A. Mukhopadhyay, N. T. Van, and B. B. Aggarwal, J. Immunol. 163, 6800 (1999).

H. Basaga, G. Poli, C. Tekkaya, and I. Aras, Cell Biochem. Funct. 15, 27 (1997). https://doi.org/10.1002/(SICI)1099-0844(199703)15:1<27::AID-CBF714>3.0.CO;2-W

N. Skottová and V. Krecman, Acta Univ. Palacki. Olomuc. Fac. Med. 141, 39 (1998).

C. H. Wu, S. M. Huang, and G. C. Yen, Antioxid. Redox Signal. 14, 353 (2011). https://doi.org/10.1089/ars.2010.3134

Y. X. Wang, H. Cai, G. Jiang, et al., Asian Pacif. J. Cancer Prev. 15, 6791 (2014). https://doi.org/10.7314/apjcp.2014.15.16.6791

S. M. Woo, K. J. Min, S. Kim, et al., Chem.-Biol. Interact. 211, 36 (2014). https://doi.org/10.1016/j.cbi.2014.01.004

M. B. Pirouzpanah, M. Sabzichi, S. Pirouzpanah, et al., Asian Pacif. J. Cancer Prev. 16, 2087 (2015). https://doi.org/10.7314/apjcp.2015.16.5.2087

A. Tyagi, C. Agarwal, G. Harrison, et al., Carcinogenesis 25, 1711 (2004). https://doi.org/10.1093/carcin/bgh180

J. Féher and G. Lengyel, Curr. Pharm. Biotechnol. 13, 210 (2012). https://doi.org/10.2174/138920112798868818

N. Vargas-Mendoza, E. Madrigal-Santillán, A. Morales-González, et al., World J. Hepatol. 6, 144 (2014). https://doi.org/10.4254/wjh.v6.i3.144

P. R. Rao and R. K. Viswanath, Exp. Clin. Cardiol. 12, 179 (2007).

A. Borah, R. Paul, S. Choudhury, et al., CNS Neurosci. Ther. 19, 847 (2013). https://doi.org/10.1111/cns.12175

M. Gharagozloo, M. Karimi, and Z. Amirghofran, Int. Immunopharmacol. 16, 243 (2013). https://doi.org/10.1016/j.intimp.2013.04.016

N. Esmaeil, S. B. Anaraki, M. Gharagozloo, and B. Moayedi, Int. Immunopharmacol. 50, 194 (2017). https://doi.org/10.1016/j.intimp.2017.06.030

D. G. Lee, H. K. Kim, Y. Park, et al., Arch. Pharm. Res. 26, 597 (2003). https://doi.org/10.1007/BF02976707

A. di Costanzo and R. Angelico, Molecules 24, 2155 (2019). https://doi.org/10.3390/molecules24112155

M. S. El-Samaligy, N. N. Afifi, and E. A. Mahmoud, Int. J. Pharm. 308, 140 (2006). https://doi.org/10.1016/j.ijpharm.2005.11.006

N. B. Feldman, T. I. Gromovykh, N. E. Sedyakina, et al., BioNanoSci. 8, 971 (2018). https://doi.org/10.1007/s12668-018-0556-x

N. Sun, X. Wei, B. Wu, et al., Powder Technol. 182, 72 (2008). https://doi.org/10.1016/j.powtec.2007.05.029

S. Abrol, A. Trehan, and O. P. Katare, Drug Deliv. 11, 185 (2004). https://doi.org/10.1080/10717540490433958

Y. P. Wu, M. R. Huo, and J. P. Zhou, Yaoxue Xuebao 44, 651 (2009).

S. Bhatt, J. Sharma, M. Singh, and V. Saini, Acta Pharm. Sci. 56 (3), 27 (2018). https://doi.org/10.23893/1307-2080.APS.05616

M. Cengiz, H. M. Kutlu, D. D. Burukoglu, and A. Ayhancı, Food Chem. Toxicol. 77, 93 (2015). https://doi.org/10.1016/j.fct.2014.12.011

J. Q. Zhang, J. Liu, X. L. Li, and B. R. Jasti, Drug Deliv. 14, 381 (2007). https://doi.org/10.1080/10717540701203034

T. I. Gromovykh, V. S. Sadykova, S. V. Lutsenko, A. S. Dmitrenok, N. B. Feldman, T. N. Danilchuk, and V. V. Kashirin, Appl. Biochem. Microbiol. 53, 60 (2017). https://doi.org/10.1134/S0003683817010094

K. Liu, J. Sun, Y. Wang, et al., Drug Dev. Ind. Pharm. 34, 465 (2008). https://doi.org/10.1080/03639040701662230

X. Zhang, S. Lu, J. Han, et al., Pharmazie 66, 404 (2011). https://doi.org/10.1691/ph.2011.0350

M. Elmowafy, T. Viitala, H. M. Ibrahim, et al., Eur. J. Pharm. Sci. 50, 161 (2013). https://doi.org/10.1016/j.ejps.2013.06.012

M. Balouiri, M. Sadiki, and S. K. Ibnsouda, J. Pharm. Anal. 6, 71 (2016). https://doi.org/10.1016/j.jpha.2015.11.005

R. L. Garcia and A. G. Rondero, J. Chem. Dermatol. Sci. Appl. 5, 62 (2015). https://doi.org/10.4236/jcdsa.2015.52008

P. Corchete, in Bioactive Nolecules and Nedicinal Plants, Ed. by K. Ramawat and J. Merillon (Springer, Berlin, 2008), p. 123. https://doi.org/10.1007/978-3-540-74603-4_6

A. Q. Khan, R. Khan, M. Tahir, et al., Nutr. Cancer. 66, 249 (2014). https://doi.org/10.1080/01635581.2014.863365

M. L. Dupuis, F. Conti, A. Maselli, et al., Front. Immunol. 9, 1903 (2018). https://doi.org/10.3389/fimmu.2018.01903

A. Valenzuela, T. Barría, R. Guerra, and A. Garrido, Biochem. Biophys. Res. Commun. 126, 712 (1985). https://doi.org/10.1016/0006-291x(85)90243-8

K. Amin and R. M. Dannenfelser, J. Pharm. Sci. 95, 1173 (2006). https://doi.org/10.1002/jps.20627

D. R. de Oliveira, S. R. Tintino, M. F. Braga, et al., BioMed Res. Int., No. 292797 (2015). https://doi.org/10.1155/2015/292797

D. G. Yun and D. G. Lee, IUBMB Life 69, 631 (2017). https://doi.org/10.1002/iub.1647

D. G. Lee, H. K. Kim, and Y. Park, Arch. Pharm. Res. 26, 597 (2003). https://doi.org/10.1007/BF02976707

Funding

This work was supported by a project to improve the competitiveness of leading Russian universities among the world's leading research and educational centers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bahman, M.R., Feldman, N.B., Orekhov, S.N. et al. Saturation of Bacterial Cellulose with Silymarin Flavolignans in the Composition of Lipid Nanoparticles. Nanotechnol Russia 16, 239–245 (2021). https://doi.org/10.1134/S2635167621020038

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2635167621020038