Abstract—The thermal stability of methanol, ethanol, 2-propanol, and acetic acid, which are most suitable for depolymerization of technical lignins into low-molecular aromatic compounds, was studied under supercritical conditions. 2-Propanol was found to be most stable at 450°С. Acetic acid almost completely decomposes within 4 h, while the addition of water considerably increases its thermal stability. The chemical composition of the gaseous and liquid products of the thermal decomposition of the solvents was studied by gas chromatography–mass spectrometry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The use of biomass as a renewable source of valuable chemical products is becoming increasingly important because of the depletion of the reserves of fossil hydrocarbons and the environmental problems arising from their utilization [1–3]. Great prospects are associated with technical lignins, whose production in the pulp and paper industry alone exceeds 130 million tons. Currently, almost all lignin is subjected to oxidation under the conditions of oxygen deficiency to ensure regeneration of the reagents used in the technological cycle. At the same time, due to its chemical composition, lignin is a unique source of phenol compounds [4], which have found use in various industries.

Lignin can be converted into low-molecular products by gasification, fast pyrolysis, hydrothermal liquefaction, and depolymerization in sub- and supercritical media [5–7]. The latter method has significant advantages because it is relatively simple and environmentally safe and the process conditions can be varied to obtain the desired products.

Depolymerization of lignin in supercritical (SC) alcohols and other protic solvents is a particularly promising method. It was reported [8] that palm lignocellulose (waste from palm oil production) can be liquefied by quick pyrolysis followed by treatment of SC products with methanol and 2-propanol. The conversion of the biomass reached 78%. Lignin, along with other natural carbon materials (coal, shale, etc.), was subjected to destruction in lower aliphatic alcohols in an autoclave at temperatures exceeding the critical temperature [9].

In our preliminary experiments with alkaline lignin, methanol, ethanol, isopropanol, acetic acid, and its 50% aqueous solution were chosen as the most active depolymerizing agents. The best results on lignin conversion were obtained at 450°С. For correct interpretation of the data on the composition of the depolymerization products and understanding the process mechanisms, it is necessary to have data on the thermal stability and transformations of the solvents (depolymerizing agents) themselves. As the available data on this topic are extremely limited, the goal of this study was to investigate the stability of methanol, ethanol, 2-propanol, and acetic acid in a supercritical state at 450°С and characterization of the thermal destruction products.

EXPERIMENTAL

The experiment was performed using a TI-LabSys-100 Control laboratory reaction system (TOP Industrie, France). The unit was a 100 mL autoclave made of the chemically stable Inconel 718 alloy with a magnetic stirrer and a control unit equipped with a gas phase extraction line.

The objects of investigation were anhydrous methanol and isopropanol of HPLC grade (>99.9%), 95% ethanol, and glacial acetic acid (reagent grade).

The solvent (25 mL) was heated to 450°C at a rate of 14°C/min and kept at this temperature for 4 h. Three parallel experiments were performed for each solvent; the results of the experiments were averaged.

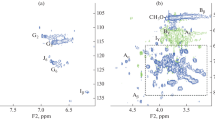

The gaseous products of destruction collected by displacement of water acidified with sulfuric acid to pH 2 and the products from the liquid phase were analyzed by gas chromatography–mass spectrometry (GC–MS) on a GC–MS QP2010 Ultra chromato-mass spectrometer (Shimadzu, Japan). An HP-5MS capillary column (30 m × 0.25 mm) with a thickness of the stationary phase of 0.25 μm was used; helium carrier gas (grade 6.0). The temperature program of the column thermostat was: initial temperature 30°C, isotherm 5 min, temperature rise to 300°С at a rate of 10°С/min, isotherm 5 min. Electron ionization was used (70 eV). The mass spectra were recorded in the range m/z = 10–500. The compounds were identified using the NIST-14 and Wiley-9 mass spectral databases.

The degree of gasification of the solvents was determined as the ratio of the mass of the liquid phase after the processing to the initial mass of the solvent.

RESULTS AND DISCUSSION

All the solvents chosen for the study (Table 1) were subjected to partial thermal destruction, which formed predominantly gaseous products.

Among the aliphatic alcohols, methanol was least stable; half of its mass was converted into carbon oxide and methane. A similar degree of gasification was also characteristic of ethanol, which gave a mixture of ethane and ethylene during the decomposition. Isopropanol had significantly higher thermal stability. It transformed mainly into propylene and small amounts of other gaseous hydrocarbons.

At a first glance, the balance of carbon and hydrogen in the gaseous products of alcohol decomposition implies the release of molecular hydrogen, which cannot be determined by GC–MS under the chosen conditions. Nevertheless, the relatively small amounts of liberated gases suggest that hydrogen is not released in substantial amounts. It is obviously present in the form of water in the liquid phase.

The behavior of acetic acid under SC conditions seems very interesting. In pure form, it undergoes the destruction almost completely, forming mainly carbon oxide and small amounts of dimethylbutane. As the process occurs at high pressures, the result is in contrast with the literature data on the thermal decomposition of CH3COOH in the gas phase, which occurs as decarboxylation (CO2 + CH4) or dehydrogenation to form ketene [10]. In addition to the liquid phase, the residue contains a large amount of carbided solids (up to 60 wt %). At the same time, addition of water to acetic acid in an equal amount radically increases the thermal stability of the solvent, CO being again the main product of destruction. The effect of water is determined by its active participation in the destruction and formation of bonds in the transition states, changing the activation barriers for pyrolysis of carboxylic acids occurring along a definite route [11].

The liquid phase that remains after the treatment of the solvents under SC conditions mainly consists of the starting solvents and contains small amounts of water and impurities (1–2%) of the decomposition products such as hydrocarbons, aliphatic alcohols, aldehydes, and ketones (Table 2). An exception is acetic acid, which also forms aromatic hydrocarbons and tert-butyl acetate and is characterized by a significant proportion of decomposition products in the liquid phase (32 wt %).

Therefore, 2-propanol and aqueous acetic acid are SC media most preferable from the viewpoint of stability for lignin depolymerization at temperatures of up to 450°C. When performing depolymerization, it is necessary to take into account the gaseous products that form during the thermal decomposition of the solvents.

REFERENCES

A. Peterson, E. Vogel, R. Lachance, and M. Fröling, Energy Environ. Sci. 1, 32 (2008).

M. F. Demirbas, Appl. Energy 86, 151 (2009).

H. An, W. E. Wilhelm, and S. W. Searcy, Biomass Bioenergy 35, 3763 (2011).

H. Wang, M. Tucker, and Y. Ji, J. Appl. Chem. 10, 9 (2013).

R. C. Brown and T. R. Brown, Biorenewable Resources (Wiley, New York, 2014).

Q. Dang, Z. Luo, J. Zhang, J. Wang, W. Chen, and Y. Yang, Fuel 103, 683 (2013).

D. S. Kosyakov, E. V. Ipatova, S. M. Krutov, N. V. Ul’yanovskii, and I. I. Pikovskoi, J. Anal. Chem. 72, 1396 (2017).

H. Jo, V. Prajitno, H. Zeb, and J. Kim, Energy Convers. Manage. 148, 197 (2017).

S. P. Gubin and E. Yu. Buslaeva, Russ. J. Phys. Chem. B 3, 1172 (2009).

M. T. Nguyen, D. Sengupta, G. Raspoet, and L. G. Vanquickenborne, J. Phys. Chem. 99, 11883 (1995).

N. Akiya and P. E. Savage, AIChE J. 44, 405 (1998).

Funding

This study was performed using the equipment of the Arktika Multiaccess Center, Northern (Arctic) Federal University, and financially supported by the Ministry of Education and Science of the Russian Federation (project ID no. RFMEFI59417X0013) and Russian Foundation for Basic Research (grant no. 17-43-290657).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by L. Smolina

Rights and permissions

About this article

Cite this article

Ivakhnov, A.D., Ul’yanovskii, N.V., Pokryshkin, S.A. et al. Promising Solvents for Lignin Depolymerization: Stability under Supercritical Conditions. Russ. J. Phys. Chem. B 13, 1147–1149 (2019). https://doi.org/10.1134/S1990793119070108

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1990793119070108