Abstract

Glycidyl azide polymer (GAP) with tetra hydroxyl functional groups often known as tetra functional GAP or t-GAP is a potential energetic polymeric binder for high-energy composite solid rocket propellant and plastic bonded high explosive formulations. t-GAP is synthesized via azidation of the tetrafunctional precursor of poly-epichlorohydrine (t-PECH) by sodium azide in DMSO. In this article, synthesis of t-GAP is studied using IR-spectroscopy, and an attempt is made to monitor the reaction progress through characteristic IR absorption bands corresponding to C–N3 in t-GAP and C–Cl in t-PECH vibrations aiming to optimize reaction parameters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Energetic binder is one of the key ingredient used in both high-energy propellant and high explosive formulations, and always been a key research area for defence and space applications. Glycidyl azide polymer (GAP) with two or three hydroxyl groups is one among such energetic binders [1–6]. This class of energetic binders is commonly used in cast cured composite propellants, gas generating compositions, plastic bonded explosives and for coating of various high-energy materials [7–9]. GAP-based binders are more energy densed with positive heat of formation (ΔHf = +27.86 kcal/mol) and offer significantly higher specific impulse and better ballistic properties as compared to the conventional polymeric binders like hydroxyl terminated polybutadiene (HTPB) and carboxy terminated polybutadiene (CTPB).

The di-functional GAP (d-GAP) with two terminal hydroxyl group, although is well studied, suffers from detrimental issues while used in cast cure compositions. The secondary hydroxyl groups in d-GAP are relatively less reactive towards isocyantes. Thus, curing of d-GAP with di-isocyanates is carried out at relatively higher temperatures. In order to overcome the limitation of d-GAP, synthesis of t-GAP, with both primary and secondary terminal hydroxyl groups, has been conceptualized. Soman et al. [10] has reported a laboratory scale process for preparation of t-GAP. However, detailed information of the azidation process for t-GAP and its optimization are largely missing in the literature.

In this present study, the process for t-GAP (Scheme 1) has been studied at laboratory to bench scale level. Based on laboratory scale experiments, the process have been optimized with respect to time and temperature. FTIR spectroscopy is an established tool and has been widely used to study various types of reaction progress and to derive their kinetic data [11–13].

Scheme 1.

EXPERIMENTAL

Materials

The precursor material, tetrafunctional poly-epichlorohydrine (t-PECH) was obtained from commercial source (Mn ~ 1.85 × 103, OH value ~87 ± 2 mg KOH/g, viscosity ~52 ± 5 P, volatile matters (VM) ~ 0.01–0.03% and moisture content ~0.03–0.06%. The other chemicals and reagents like sodium azide (NaN3), DMSO and ethyl acetate used in the study were of GR grade (purity >95%) and obtained from Qualigen and Merck.

Experimental Set-up for t-GAP Synthesis

The bench scale process for t-GAP was carried out in HEL bench scale reactor set-up (UK). The reaction was performed in 10 L jacketed cylindrical glass reactor fitted with a double coiled reflux condenser. Agitation of reaction mass was performed with a Heidolph torque overhead agitator. The heating and cooling of reaction mixture were achieved with highly efficient Huber make Unistat-705 re-circulator. The reaction parameters like reaction temperature (Tr), jacket temperature (Tj), ttemperature gradient (ΔT), agitation (RPM), etc. were controlled and recorded through an PLC-SCADA system.

Preparation of t-GAP

A slurry of sodium azide in DMSO is prepared in a 10 L reactor at around 40–45°C under constant agitation. A solution of t-PECH in DMSO was then slowly added into the slurry. Care has been taken while addition of t-PECH solution to avoid uncontrolled rise of temperature. After completion of addition, the reaction temperature was then raised to 90°C and maintained in isothermal condition under constant agitation. During the isothermal heating of reaction mixture, samples were withdrawn periodically at an interval of 1 h and analyzed using FTIR spectrometer. At the end of the reaction, after 6 h of isothermal heating, the reaction mass was cooled to 60°C followed by quenching in ice-water mixture. The reaction mass in quencher was then added with a suitable solvent and stirred for 2–3 h and subsequently with brine solution. The organic phase was separated and solvent was distilled off under vacuum. The various stages involved in the preparation t-GAP have been depicted in Fig. 1. The physico-chemical properties of t-GAP are presented in Table 1.

Spectral Analysis

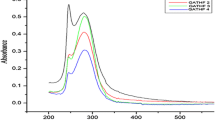

A Thermo Fisher Scientific Nicolet Summit pro table top FTIR spectrometer was used to record the IR absorption data of the reaction mixture samples. The sample collected from reaction mass was directly analyzed using single bounce Diamond ATR accessory. t‑PECH is characterized by a medium to strong IR absorption band at 747 cm–1 corresponding to C‒Cl stretching vibrations, while t-GAP can be characterized by a strong band at 2088 cm–1 corresponding to ‒N3 stretching vibrations. A comparative FTIR profile is presented in Fig. 2. Spectra were recorded for the samples withdrawn periodically at intervals of 1 h since the start of isothermal heating.

Characterization

Average molecular weights were determined using a Thermo Scientific Ultimate 3000 Gel Permeation Chromatography (GPC) instrument. OH value in the form of ‘mg of KOH per gram of analyte’ was determined by acetylation method. Viscosity was measured using RV Brookefield viscometer. Karl fisher titration method was employed to determine moisture content while volatile matter (VM, %) was measured using IR heated balance.

FTIR Profiling Data of t-GAP

For reaction monitoring, periodic sampling of the reaction mixture was done at an interval of 1 h from the time of attaining reaction temperature, 90°C. Then samples were subjected to FTIR analysis without any prior treatment. Single bounce diamond ATR accessory has been employed for the subject study. Formation of t-GAP is indicated by gradual growth of the peak attributed by –N3 vibration of sodium azide, while consumption of t-PECH in the reaction is depicted by disappearance of the peak indicating C-Cl bond. Area under the curves of the respective absorption peaks is considered as proportional to the concentration of product and the reactants in the reaction. The spectroscopic data thus generated is plotted to create a concentration-time profiling of the reactant t-PECH as well as product t-GAP.

RESULTS AND DISCUSSION

Optimization of Reaction

Lab level experiments were carried out at different reaction temperature starting from 80 to 100°C. After completion of the process, t-GAP was isolated and characterized using FTIR spectroscopy to assess if the reaction was completed or not. The absence of band at 747 cm–1 corresponding to C–Cl bond indicates that the reaction is complete. Table 2 depicts the completion of the reaction at different temperature/time intervals. During the lab level experiments at 95 and 100°C, significant evaporation of DMSO solvent vapour was observed. Therefore, reaction temperature of 90°C was considered as optimum temperature with reaction time of 6 h.

Spectroscopic Study of t-GAP

Azidation of the t-PECH by sodium azide is carried out in an aprotic solvent medium like DMSO. The reaction is believed to be a nucleophilic substitution reaction whereby the –Cl of PECH is substituted by –N3. Organic chlorides usually show IR absorption band in a very wide wavenumber range 600 to 800 cm–1. However, for t-PECH, due to polymeric structure of the aliphatic chain and presence of adjacent C–O–C, the C–Cl vibration is observed relatively towards the high energy region of about 747 cm–1. Effective substitution by –N3 will exhibit complete disappearance of C‒Cl vibrational band. The said feature has thus been considered to map the reaction progress for conversion of t-PECH to t-GAP.

Periodic collection of IR absorption data thus would exhibit gradual decrease in the intensity of C–Cl stretching signature. From the Fig. 3, it can be observed that, a band corresponding to 747 cm–1 disappeared almost after 5 h. The relative absorbance of C–Cl vibration in pure t-PECH is about 0.28. While, the area under the curve C–Cl vibrational band in reaction mixture at starting of reaction, i.e., T0 is around 0.69 which gradually decreases, and the spectrum collected at around 330 min, i.e., T5 shows almost no intensity at 747 cm–1. The subsequent spectrum collected after 6 h, i.e., T6 also shows no significant change in the specific spectra features with respect to the normalized baseline intensity. This suggests the substitution reaction has reached to the maximum conversion and almost all the C–Cl functional group are converted to C–N3 function, indicating completion of the reaction. It is also interesting to note that, the maximum conversion takes place during the first one hour where the C–Cl absorbance is brought down from to nearly 0.09. This is in-line with reaction progression of SN2 type, where the rate is maximum owing to highest concentration of limiting reagent and such reaction is of nearly second order.

The reaction progress is also been studied in terms of change in the intensity of C–N3 vibrational band appearing at around 2080 cm–1. The –N3 stretching vibration in NaN3 appears at 2010 cm–1. In the spectrum of reaction mixture at T0, a strong band is observed at 2010 cm–1 with a small intensity for C–N3 at 2088 cm–1. It is to be noted that, the spectrum is collected when the reaction mixture reached the process temperature of 90°C. This is because, while heating the reaction mixture from room temperature to 90°C, some part of C–Cl is replaced as C–N3. This shows the extreme reactivity of metal azides towards t-PECH.

In the subsequent spectra collected through T1 to T6, the NaN3 vibrational band intensity at 2010 cm–1 reduces periodically and C–N3 vibrational band intensity gradually raises with maximum relative IR absorption of about 0.22. In this case, the maximum rise in C–N3 intensity is observed while transiting from T0 to T1, i.e., during the first one hour of the reaction at 90°C. The spectrums collected at 5th and 6th hour i.e., T5 and T6 show almost same absorbance level indicating completion of the reaction. Table 2 shows the relative concentrations of t-PECH and t‑GAP obtained from the FTIR spectrum collected during the progression of the reaction.

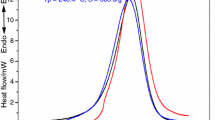

Concentration Profiling from FTIR Spectrum

The relative concentrations are obtained by comparing the C–Cl (~747 cm–1) and C–N3 (~2088 cm–1) band’s intensities with a common and almost constant vibrational band intensity of C–O–C at 1040 cm–1, which remains unaltered during conversion of t‑PECH to t-GAP. From, spectra collected periodically, the area under these three peaks at distinct time is taken for further calculation. Where, A1 corresponds to area under band 747 cm–1, A2 corresponds to area under band 2088 cm–1 and a 3rd peak area, A3, corresponding to band at 1040 cm–1 (–C–O–C– bond) common to both t-PECH and t-GAP that remains almost constant throughout the reaction. The ratio of A1/A3 and A2/A3 give effectively corrected area under the bands that can be considered as proportionate concentration of t-PECH and t-GAP. These proportionate concentrations were then normalized to scale of 1, as shown in Table 3.

Based on the normalized area under the IR absorption bands data obtained from FTIR probing, a concentration profile for consumption of t-PECH and followed formation of t-GAP is derived using relative intensities of C–Cl band at 747 cm–1 and C–N3 band at 2088 cm–1, respectively, Fig. 4.

The derived concentration profile of t-PECH and t-GAP shows the initial reaction to be relatively faster with about 70% conversion within the first 90 min. The reaction then slowed down and approached a nearly plateau region approximately after 210 min. The comparative FTIR spectral profiles as shown in Fig. 3 also clearly validate the observation. This relates to the fact that, the azidation reaction is relatively faster during the initial phase and therefore, maximum mass transfer is expected in this phase. The spectroscopic data thus obtained shall therefore be useful for designing an optimized process flow and equipment sizing for a scaled-up plant facility for bulk scale manufacture.

CONCLUSIONS

The azidation process of t-PECH to t-GAP is probed using FTIR spectroscopy in ATR mode. The relative peak intensities measured as area under the curve were used to derive the concentration data of reactant t-PECH and the product t-GAP against reaction time at 90°C. The periodic probing with FTIR spectroscopy suggested the t-GAP reaction to be complete within 5 h from the instance of achieving the desired reaction temperature. The reaction profiling suggested that, the rate of conversion of t-PECH to T-GAP is high during the initial 100 min and after about 150 min it gradually became slow and reached completion at about 300 min. The profiling has been validated with both the C–Cl and C–N3 vibrational intensities. Thus FTIR spectroscopy has been used as an effective tool to monitor the progress and to optimize the temperature and time required for completion of azidation process while preparing t-GAP from its precursor, t-PECH.

REFERENCES

E. J. Vandenburg, US Patent No. 3645917 (1972).

M. B. Frankel and J. E. Ranagan, US Patent No. 4268450 (1981).

J. P. Agrawal, High Energy Materials, Propellants Explosives and Pyrotechnics (Wiley-VCH, Weinheim, Germany, 2010).

T. Urbanski, Chemistry and Technology of Explosives, Vol. 2 (Pergamon Press, Oxford, 1964).

A. N. Nazare, S. N. Asthana, and H. Singh, J. Energetic Mater. 10, 43 (1992).

M. B. Frankel, L. R. Grant, and J. E. Flanagan, J. Propulsion Power 8, 550 (1992).

V. Gettwert, M. A. Bohn, S. Fischer, and V. Weiser, in Proceedings of Insensitive Munitions and Energetic Materials Technology Symposium (IMEMTS), Rome, Italy, 2015.

A. K. Hussein, A. Elbeih, and S. Zeman, RSC Adv. 8, 17272 (2018).

C. Nguyen, F. Morin, F. Hiernard, and Y. Guengant, in Proceedings of IM Results, Insensitive Munitions and Energetic Materials Technology Symposium, Munich, Germany, 2010.

R. R. Soman, J. Athar, N. T. Agawane, S. Shee, G. M. Gore, and A. K. Sikder, Polym. Bull. 73, 449 (2016).

A. Pintar, J. Batista, and J. Levec, Analyst 127, 1535 (2002).

S. Ye, S. Yang, L. Ni, W. Qiu, and Q. Xu, Spectrochim. Acta, Part A 264, 120280 (2022).

K. Skotnicki, S. Ostrowski, J. C. Dobrowolski, J. R. De la Fuente, A. Cañete, and K. Bobrowski, Int. J. Mol. Sci. 22, 633 (2021).

ACKNOWLEDGMENTS

The authors of this manuscript are highly obliged to the Director, HEMRL for his valuable support and for giving us the opportunity to carry out this work.

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct this particular research were obtained.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception, design data collection, and analysis. The first draft of the manuscript was written by MG, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Adak, P.K., Ghosh, M., Meena, A.K. et al. Reaction Profiling and Process Optimization for the Azidation of Tetrafunctional Glycidyl Azide Polymer Using FTIR Spectroscopy. Polym. Sci. Ser. B (2024). https://doi.org/10.1134/S1560090424600918

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1134/S1560090424600918