Abstract

This study presents the calculation results of fuel and moderator temperature coefficients(FTC/MTC) of reactivity and also moderator density coefficient(MDC) of reactivity for the MNSR research reactor, using Low Enriched Uranium fuels (LEU—12.6%). This study uses the DRAGON5 code to calculate the cross sections of all the reactor components at different temperatures and these group constants were used then in the DONJON5 code to calculate the fuel temperature coefficient (FTC), moderator temperature coefficient (MTC), and moderator density coefficient (MDC) using 69 energy groups. Only one parameter was changed where all other parameters were kept constant. The results for the average values for both the fuel temperature coefficient (\({\text{FTC}}\)), the moderator temperature coefficient (\({\text{MTC}}\)) without water density effect, and the moderator density coefficient (MDC) for LEU were: –1.1721E–02, –3.9023E–02, and –3.1842E–01, respectively. The calculated feedback coefficients were compared with the measured data for the MNSR reactor. Good agreements were obtained. Behavior of the coefficients with rising temperature has been determined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

The nuclear reactor core reactivity depends on fuel type, enrichment, core fuel loading, amount of poison and temperature of fuel and moderator regions etc. [5]. The temperature of fuel and moderator regions are continuously changed during the reactor operation. It is [9] known that an increase in fuel temperature causes Doppler effect, which is the most important and inherent shutdown mechanism that helps to assure the safety of nuclear reactors. The individual effect of temperature change of different regions on reactivity is quantitatively different [10]. Therefore, to quantify the effect of these parameters on reactivity, the reactivity coefficients are determined. Conventionally, the reactivity coefficients are calculated independently and there seems to be a specific inaccuracy in their calculations due to the neglecting the effect of one parameter on the other, e.g. in the determination of void coefficient of reactivity, change in coolant void in moderator region also causes spectral changes in fuel region [7].

This paper discusses the effects of changing parameters; three typical reactivity coefficients for the low-power LEU core are calculated using the deterministic codes DRAGON5 and DONJON5: the fuel temperature coefficient (FTC), the moderator temperature coefficient (MTC), the moderator density coefficient (MDC) on core reactivity separate, for MNSR research reactor core. The ENDF/B.VII library was employed in these calculations.

2 DESCRIPTIONS OF MNSR REACTOR

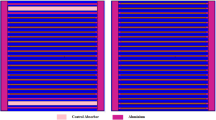

The MNS research reactor [6] is a low power research reactor with 34 kW nominal power level. It is a small, safe nuclear facility, which employs LEU (lowly enriched uranium ) as fuel, coolant and shield, light water as moderator, and beryllium as a reflector. The MNSR reactor was developed by the Chinese Institute of Atomic Energy. It is a compact research reactor designed to mimic the Canadian SLOWPOKE reactor shown in Fig. 1. The MNSR reactor consists of 347 fuel pins, four tie rods and three dummy pins concentrically arranged in ten rings [3].

The fuel assembly rests on a 50 mm block of beryllium reflector surrounded by a 100 mm thick annular beryllium reflector, and a top-shim tray which allows addition of beryllium reflector. The core has a central guide tube through which a cadmium control rod cladded in stainless steel moves to cover the core active length of 230 mm [1]. The control rod serves as a regulation for power, compensation of reactivity, and for reactor shut down during normal and abnormal operations, as shows in Fig. 1.

3 NEUTRONIC MODEL

The DRAGON5 code has a collection of models for simulating the neutronic behavior of a unit cell or a fuel lattice in a nuclear reactor [8]. The typical functionalities found in most modern lattice codes are contained in DRAGON5. These include interpolation of microscopic cross sections provided by means of standard libraries; resonance self-shielding calculations in multi-dimensional geometries; multi-group and multi-dimensional neutron flux calculations which can take into account neutron leakage; transport-transport or transport-diffusion equivalence calculations; and modules for editing condensed and homogenized nuclear properties for reactor calculations.

The neutronic analysis is of paramount importance to determine the multiplication factor, fuel temperature coefficient, moderator temperature coefficient, fuel burn-up, and power peaking factor, with the different cross sections. This calculation is typically performed in a two-step procedure. The first step involves cell calculation to obtain group constants of fuel assemblies and reflectors. We have used DRAGON5 to simulate the fuel assemblies in exact geometric details and generate its equivalent cross-sections. The generalized Stammler method for resonance treatment and collision probability method for solution of the transport equation are employed to produce 69‑groups homogenized cross-sections generation. The reflective boundary condition is used in group constants generation. In the next step, these data are used by DONJON5 to simulate the reactor core. DONJON5 is a multi-group and multi-dimensional solver of the diffusion equation [4]. The full core modeling of MNSR reactor core with reflectors around the fuel assemblies. The three-dimensional geometry of the reactor is performed by dividing the axial direction of the core into 21 layers and use of two layers for reflectors at the bottom and top of the core. The core calculation is performedwith void boundary condition.

4 REACTIVITY COEFFICIENT

Reactivity coefficients quantify the amount that the reactivity will change for a given change in the parameter. For instance, an increase in moderator temperature may cause a decrease in the reactivity of the core. Typical units for the temperature coefficient are pcm per degree temperature. In this work fuel and moderator temperature coefficient are determined [9].

4.1 Fuel Temperature Сoefficient (FTC)

It is the change in reactivity per unit change in fuel temperature. It is calculated by varying fuel temperature with an increment of 20°C or (20 K) and determining respective reactivity. The results are given in Table 1. With an increase in temperature the reactivity is decreasing but the FTC is almost constant. This can also be seen in Fig. 2.

4.2 Moderator Temperature Coefficient (MTC)

MTC is the change in reactivity per unit change in moderator temperature. It is calculated by varying moderator temperature with an increment of 20°C or (20 K) and determining respective reactivity. The results are given in Table 2. It is clear from the results that with an increase in moderator temperature MTC becomes more and more negative. This is inherent safety feature of light water moderated reactors. Figure 3 shows the variation of reactivity with moderator temperature.

4.3 Moderator density coefficient (MDC)

The moderator density coefficient is defined the change in reactivity (\(\rho \)) per unit change in moderator density. The reactivity effect in MDC is calculated by varying moderator density with an increment of 20 K. And, as the increase in the density of moderator is the effect of a positive reactivity. The range of the moderator density coefficient from beginning of life to end of life. The results are shown in Table 3 and Fig. 4.

The results obtained from this study indicate that the MNSR reactor will be safe to operate between the temperature ranges of 293–393 K. Table 4 shows the average values for both the fuel temperature coefficient (\({\text{FTC}}\)), the moderator temperature coefficient (\({\text{MTC}}\)) without water density effect, and the moderator density coefficient (\({\text{MDC}}\)) for LEU. Using coupled neutronics/thermal-hydraulics codes, the overall temperature coefficient of reactivity for the transient conditions can be evaluated.

5 CONCLUSIONS

The feedback reactivity coefficients is one of the very important parameters to evaluate the inherent safety of a nuclear reactor. The results obtained from this work indicate that the MNSR will be safe to operate between the temperature range of 293–393 K. It is found that the dominant reactivity coefficient for all types of fuel is the Moderator Density Coefficient. The average values of the FTC for LEU (UO2) was observed to be –1.1721E–02 mk/K. The average values of the MTC (without water density effect) for the LEU was observed to be –3.9023E–02 mk/K. Finally, the average values of the MDC for LEU was found to be 3.1842E–01 mk/g/cm3.

The overall temperature coefficient (OTC) for transient conditions can be evaluated utilizing a coupled neutronics/thermal hydraulics code.

REFERENCES

J. Al Zain, O. El Hajjaji, T. El Bardouni, H. Boukhal, and O. Jaï, “Validation of DRAGON4/DONJON4 simulation methodology for a typical MNSR by calculating reactivity feedback coefficient and neutron flux,” Res. Phys. 9, 1155–1160 (2018). https://doi.org/10.1016/j.rinp.2018.04.033

S. Dawahra, K. Khattab, and G. Saba, “Reactivity temperature coefficients for the HEU and LEU fuel of the MNSR reactor,” Prog. Nucl. Energy 88, 28–32 (2016). https://doi.org/10.1016/j.pnucene.2015.11.012

S. Dawahra, K. Khattab, and G. Saba, “A comparative study of the neutron flux spectra in the MNSR irradiation sites for the HEU and LEU cores using the MCNP4C code,” Appl. Radiat. Isotopes 104, 67–73 (2015). https://doi.org/10.1016/j.apradiso.2015.06.006

A. Hébert, D. Sekki, and R. Chambon, A User Guide for DONJON, Vers. 5. http://www.polymtl.ca/merlin/downloads/IGE344.pdf. Accessed October 9, 2018.

A. Hussain and C. Xinrong, “Reactivity feedback calculation of a conceptual TRISO fueled compact PWR core,” Prog. Nucl. Energy 53, 76–79 (2011). https://doi.org/10.1016/j.pnucene.2010.08.006

I. Khamis and K. Khattab, “Neutronics-design modification of the Syrian miniature neutron source reactor,” Prog. Nucl. Energy 36, 91–96 (2000). https://doi.org/10.1016/S0149-1970(00)00009-3

R. Khan, T. Hamid, and S. Bakhtyar, “Feedback reactivity coefficients and their coupling,” Nucl. Eng. Des. 237, 972–977 (2007). https://doi.org/10.1016/j.nucengdes.2006.10.009

G. Marleau, A. Hebert, and R. Roy, A User Guide for Dragon, Vers. 5.340. https://www.polymtl.ca/merlin/downloads/IGE335.pdf. Accessed 2018.

F. Muhammad, “Reactivity feedback coefficients of a low enriched uranium fuelled material test research reactor at end-of-life,” Ann. Nucl. Energy 38, 2836–2839 (2011). https://doi.org/10.1016/j.anucene.2011.08.012

R. M. G. do P. Souza and A. Z. Mesquita, “Reactivity balance in the IPR-R1 TRIGA reactor,” in Proceedings of the International Nuclear Atlantic Conference INAC, 2009, Prog. Nucl. Energy 53, 1132–1135 (2011). https://doi.org/10.1016/j.pnucene.2011.06.011

ACKNOWLEDGMENTS

Special thanks should be given to Prof. Otman El Hajjaji, my research project supervisor for his scientific and professional guidance and his valuable support and to Prof. Tarek El Bardouni for his useful and constructive recommendations on this work.

The authors are grateful to the staff of the laboratory of Radiation and Nuclear Systems (RNS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al Zain, J., El Hajjaji, O. & El Bardouni, T. Calculation of the Reactivity Feedback Coefficients for the LEU Fuel of the MNSR Reactor Using DRAGON5/DONJON5 Codes. Phys. Part. Nuclei Lett. 18, 687–690 (2021). https://doi.org/10.1134/S154747712106011X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S154747712106011X