Abstract

Materials of the hollandite structure in the K2O–MeO(Mе2O3)–TiO2 (Ме = Al, Ni, Mg) system, synthesized by two methods (solid-phase synthesis and pyrolysis of citrate–nitrate compositions), were studied. The pyrolysis, compared to the traditional solid-phase synthesis, yielded the materials with the more developed specific surface and, as a consequence, enhanced performance in sorption of a model dye, Methylene Blue (for K2MgTi7O16, q = 18.75 mg g–1). The K2Al2Ti6O16 sample, also prepared by pyrolysis, showed the highest catalytic performance in oxidation of СО and Н2. The hydrogen oxidation on this catalyst occurred to 95% at 355°С with the performance of ~0.21 × 10–5 mol g–1 s–1, which is two times higher compared to the sample of the same composition prepared by the solid-phase method. The hollandites show promise as sorbents and catalysts for gas treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Adsorption followed by heterogeneous photocatalysis is one of the most promising processes used in wastewater treatment to remove organic pollutants. Today titanium dioxide is one of the most actively used and studied material for this purpose. Numerous recent studies were aimed at enhancing its photocatalytic activity by varying the TiO2 synthesis conditions to obtain materials with a more developed surface [1], by doping with various elements [2, 3], and by preparing complex oxides [4–7]. These approaches allow the absorption of the electromagnetic radiation to be shifted to the visible range of the solar spectrum and the probability of electron–hole recombination to be reduced by the formation of heterotransitions.

The photocatalytic activity of complex titanates of hollandite-type structure has been studied insufficiently, despite structural features allowing wide variation of their composition. However, the published papers [8, 9] demonstrate the urgency of studying the photocatalytic and optical properties of compounds of this type. It should also be noted that particles of potassium magnesium titanate of hollandite-type structure, prepared by crystallization from molten salts, exhibit high reflection coefficient in the near-IR range, which is important for refractory materials and heat-reflecting coatings [10].

Ceramics based on a series of hollandite phases exhibit low electrical conductivity at room temperature and relatively high K-ionic conductivity in the range 700–1000°С, accompanied for some compositions by an abnormally strong increase in the dielectric permittivity [11–14]. In opinion of Gorshkov et al. [11], this combination of properties makes the ceramics based on hollandite phases promising for the development of thermoelectric thermal energy converters allowing not only generation of the electric power by absorption of heat emitted by industrial furnaces but also accumulation of the electric power for the subsequent use (ceramic supercapacitor).

The use of titanates of the hollandite group as heterogeneous catalysts is also interesting. A series of these complex oxides were tested in oxidation of С, СО, and Н2 and in reduction of NOх in the presence of hydrocarbons [15–18].

This study was aimed at revealing the relationship between the composition, synthesis method, and functional physicochemical properties of complex oxides of hollandite-type structure, crystallizing in the K2O–MeO (Me2O3)–TiO2 (Me = Al, Ni, Mg) system, to determine the prospects for using materials based on them.

EXPERIMENTAL

The samples were prepared by the (a) solid-phase method and (b) pyrolysis of citrate–nitrate compositions.

In the first case, the starting mixture was prepared from the following carbonates and oxides: K2CO3 (chemically pure grade), Al2O3 (ultrapure grade), NiCO3 (pure grade), MgCO3 (ultrapure grade), and TiO2 (ultrapure grade). The starting reactants were ground and mixed manually. The metal ratio corresponded to the stoichiometry of the desired titanate: K2MexTi8–xO16, where x = 2 at Me = Al и x = 1 at Me = Mg, Ni. The resulting charge was pressed at 100 MPa and sintered stepwise at 1000 and 1100°С. The charge for preparing the aluminum-containing hollandite was subjected to the third sintering at 1250°С. The heat treatment time in each step was 6 h.

The starting citrate–nitrate compositions for pyrolysis were prepared as described in [18]. The following chemicals were taken for preparing the starting solutions: KNO3 (ultrapure grade), Al(NO3)3·9H2O (ultrapure grade), MgO (ultrapure grade), Ni3(OH)4CO3·4H2O (chemically pure grade), and TiCl4 (ultrapure grade). The magnesium nitrate solution was prepared by the reaction of MgO with dilute HNO3 (ultrapure grade); nickel was introduced in the form of a citrate solution prepared by the reaction of basic nickel carbonate with citric acid (C6H8O7·H2O, ultrapure grade).

As in the solid-phase synthesis, the metal ratio corresponded to the synthesis stoichiometry. The required volume of citric acid was calculated from the amount of NO3 groups in the nitrate components. The following relationship should be observed to ensure complete reduction of nitrogen in nitrates:

\( n=5\left( \sum \text{N}{{\text{O}}_{3}} \right)/m, \)

where n is the number of moles of the reductant per mole of the product, and m is the number of bonds being oxidized in one molecule of the organic substance (for citric acid, m = 20).

In the course of the experiment, we prepared compositions with the reductant amount equal to the calculated value, i.e., with the nominal reductant to oxidant ratio φ = 1.0.

After dissolving the mixture in citric acid, the mixture was adjusted to pH 6.5 with a highly dilute aqueous ammonia solution. This led to the formation of a sol, which transformed into a gel in the course of evaporation at 80°С. The powders of hollandite phases were prepared by combustion followed by heat treatment of the gels at 650°С for 1–2 h.

The samples in different steps of the synthesis were analyzed by X-ray diffraction (XRD) with a DRON-3М diffractometer using CuKα radiation. The pore structure was studied by low-temperature nitrogen sorption (Quantachrome NOVA 1200e, the United States). The samples were degassed at 300°С for 0.5 h. The specific surface area (Ssp) of the samples was calculated by the Brunauer–Emmett–Teller (BET) method.

The band structure parameters of the samples obtained, including the band gap width (Eg), were determined by mathematical processing of diffuse reflection spectra recorded in the range 220–850 nm with a Shimadzu UV2600 UV spectrometer equipped with an integrating sphere. Measurements were performed using compacted powder samples. The band gap width Eg was determined by extrapolation of the linear portions of the Kubelka–Munk function F(E) to the interception with the Е-axis:

\( F\left( E \right)={{\left( 1-R \right)}^{2}}/2R, \)

where R is the diffuse reflection coefficient and E = hc/λ is the light quantum energy (eV).

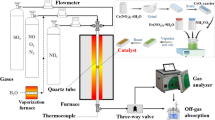

The catalytic activity of the samples in the model reactions of the СО (с0 = 2 vol %) and Н2 (с0 = 3 vol %) oxidation was studied in flow-through installations. The volume of granules (fraction 1–2 mm) prepared by pressing the starting compositions was 2–3 cm3, and the flow rate of the gas–air mixture was V = 3.3 cm3 s–1. The mixture was analyzed with a Tsvet-500 chromatograph.

The productivity in the СО (Н2) oxidation per gram of the catalyst, [mol СО (Н2)] s–1 g–1, was calculated using the equation

\( {{P}_{m}}~={{Vc}_{0}}x/22.4m, \)

where x is the conversion (volume fraction); 22.4, molar volume (dm3 mol–1); m, catalyst weight (g); с0, initial concentration of the gas being oxidized (volume fraction); and V, flow rate of the gas–air mixture (dm3 s–1).

To study the sorption capacity of the materials for organic dyes, we chose Methylene Blue as a model dye. The initial Methylene Blue solution was prepared so as to obtain the minimal light transmittance value recorded with the spectrophotometer used (PE-5400 UF); it corresponded to a concentration of 210 mg L–1. A 5-mL portion of the dye solution was transferred into a 10-mm-thick cell containing a sorbent sample (0.015 g). Immediately after that, the cell was arranged in the spectrophotometer, and the transmittance was recorded for 60 min at 2-s intervals. The data obtained were processed using the preliminarily constructed calibration plots.

The electrophysical properties, including the imaginary and real parts of the complex resistance (Z '', Z ') and the total electrical conductivity σ, were determined with a Z-2000 impedance meter using a two-electrode scheme in the frequency range from 1 Hz to 2 MHz with the measuring signal amplitude of 125 mV in the temperature interval 600–700°C. The contacts were deposited onto the ceramic samples in the form of a conducting silver paste (produced by Elma Pasta) and annealed at 700°C for 4 h.

RESULTS AND DISCUSSION

When using materials in sorption, catalysis, and some electrochemical processes, the specific surface area is one of the key factors associated with the heterogeneous character of the processes. In this study, the pyrolysis of the citrate–nitrate compositions as the synthesis procedure allowed the specific surface area to be increased only to ~10 m2 g–1 (Table 1).

Nevertheless, the hollandite structure, which is a framework of metal–oxygen octahedra, pierced in one of the directions by “tunnels” accommodating large mono- or bivalent cations, allows these compounds to be considered as a kind of molecular sieves. At low specific surface areas, the surface phenomena will largely depend on the physicochemical state of the surface, in particular, on the crystal lattice defectiveness, presence of coordination-unsaturated cations, and acid–base properties. These factors influence the dye sorption. The Mg- and Al-containing ceramic materials prepared by the citrate–nitrate method exhibit approximately 2 times higher sorption activity compared to the samples prepared by solid-phase reactions (Fig. 2, curves 2 and 3 compared to 5 and 6, respectively). In the case of the nickel hollandite, however, the use of pyrolysis of citrate–nitrate compositions does not lead to an increase in the sorption capacity. It should be noted that the use of this method decreases the sorption rate in the initial period (Fig. 2, curves 1 and 4).

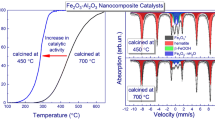

Trials of the catalysts in the model processes have shown (Fig. 3) that the СО oxidation on all the hollandites occurs at moderately high temperatures, 250–540°С, and the hydrogen oxidation occurs at temperatures from 60 to 350°С. The use of pyrolysis of citrate–nitrate compositions for preparing the samples appreciably (by approximately 100°C) decreases the initial temperature of the СО oxidation (Fig. 3a), whereas in Н2 oxidation such effect is not observed (Fig. 3b). Because the oxidation of hydrogen and СО occurs by different mechanisms, it can be assumed that the pyrolysis of citrate–nitrate compositions leads to an increase in the amount of catalytically active surface sites ensuring activated adsorption of a larger amount of СО. Hence, the samples prepared by pyrolysis of citrate–nitrate compositions may be promising for use in catalytic processes, including photocatalytic wastewater treatment to remove toxic components. The aluminum-containing sample prepared by pyrolysis showed the highest catalytic activity in both model reactions (Fig. 3, curves 6). In particular, 95% oxidation of hydrogen on this catalyst occurred at 355°С and corresponded to the performance of ~0.21 × 10–5 mol g–1 s–1, which is 2 times higher than with the catalyst of the same composition prepared by the solid-phase method (Fig. 3b, curve 3).

The electrotransport properties of ceramic samples prepared by the solid-phase synthesis were studied by impedance spectroscopy. Typical impedance hodographs of the compounds under consideration are shown in Fig. 4. They can be approximated by two partially overlapping hemi circles with the center lying below the abscissa. This distortion is particularly noticeable in the low-frequency part of the impedance, which is probably associated with the presence of a limited diffusion layer. In the equivalent circuit, it is described most frequently by a constant-phase element, CPE.Footnote 1 Magnesium hollandite has the lowest electrical conductivity at 650°С, σ ≈ 1.29 × 10–5 S cm–1; for the nickel and aluminum compounds, the corresponding values are 1.91 × 10–4 and 1.92 × 10–4 S cm–1. The activation energy of the charge transfer, calculated from the dependences obtained at different temperatures, is as follows: K2NiTi7O16 1.12, K2MgTi7O16 1.65, and K2Al2Ti6O16 0.82 eV; it reasonably agrees with the published data [14].

Spectroscopic measurements (Fig. 5a) have shown that the reflection intensity of the hollandites K2MgTi7O16 and K2Al2Ti6O16 in the visible and near-IR range (>400 nm) is 84 and 91%, respectively. The hollandite K2NiTi7O16 exhibits two diffuse reflection peaks irrespective of the synthesis method. The dependence of the Kubelka–Munk function on the photon energy shows that the value of F(R) is higher for the magnesium- and nickel-containing samples prepared by the citrate–nitrate method (Fig. 5b). This may be due to smaller particle size and, as a consequence, to stronger scattering of the incident radiation. The absorption band edges were determined for all the hollandites by the graphical method. These values can be assumed to be close to the energy of the electron transition from the valence band to the conduction band, i.e., to the band gap width (Eg). The presented plots show that Eg for the samples containing aluminum and magnesium is in the interval 3.55–3.70 eV. Only for nickel hollandite, the absorption band edge is shifted to the visible region and corresponds to the band gap width of 2.65 eV for the sample synthesized by the solid-phase method and 2.48 eV for the sample prepared by pyrolysis of citrate–nitrate compositions. Therefore, this hollandite shows promise as a photocatalyst activated with visible light.

CONCLUSIONS

The advantage of the pyrolysis of citrate–nitrate compositions over the solid-phase procedure for preparing materials of hollandite structure with the general formula K2MexTi8–xO16 (Me = Mg, Ni, Al) was demonstrated. The materials prepared by pyrolysis have more developed surface and show promise as sorbents and catalysts for gas treatment. Furthermore, the K2NiTi7O16 sample, also prepared by the citrate–nitrate method, has the band gap width of 2.48 eV and is therefore promising as a photocatalyst activated with visible light.

Notes

Impedance Spectroscopy. Theory, Experiment, and Applications, Barsoukov, E. and Ross Macdonald, J., Eds., Hoboken, New Jersey: Wiley, 2005, 2nd ed., pp. 14–128.

REFERENCES

Zhang, Y., Jiang, Z., Huang, J., Lim, L.Y., Li, W., Deng, J., Gong, D., Tang, Y., Lai, Y., and Chen, Z., RSC Adv., 2015, vol. 97, pp. 79479–79510. https://doi.org/10.1039/C5RA11298B

Chen, J., Ding, T., Cai, J., Wang, Y., Wu, M., Zhang, H., Zhao, W., Tian, Y., Wang, X., and Li, X., Appl. Surf. Sci., 2018, vol. 453, pp. 101–109. https://doi.org/10.1016/j.apsusc.2018.04.189

Zdravkov, A.V., Gorbunova, V.A., Volkova, A.V., and Khimich, N.N., Russ. J. Gen. Chem., 2018, vol. 88, no. 3, pp. 528–531. https://doi.org/10.1134/S1070363218030210

Wang, Q., Guo, Q., and Li, B., RSC Adv., 2015, vol. 5, pp. 66086–66095. https://doi.org/10.1039/c5ra10640k

Garay-Rodríguez, L.F., Yoshida, H., and Torres-Martínez, L.M., Dalton Trans., 2019, vol. 48, pp. 12105–12115. https://doi.org/10.1039/C9DT01452G

Li, Q., Kako, T., and Ye, J., Appl. Catal. A: General, 2010, vol. 375, pp. 85–91. https://doi.org/10.1016/j.apcata.2009.12.020

Phoon, B.L., Lai, C.W., Juan, J.C., Show, P.-L., and Pan, G.-T., Int. J. Hydrogen Energy, 2019, vol. 44, no. 28, pp. 14316–14340. https://doi.org/10.1016/j.ijhydene.2019.01.166

Liu, X., Xu, L., Huang, Y., Qin, C., and Seo, H.J., J. Taiwan Inst. Chem. Eng., 2017, vol. 76, pp. 126–131. https://doi.org/10.1016/j.jtice.2017.03.036

Sanford, S., Misture, S.T., and Edwards, D.D., J. Solid State Chem., 2013, vol. 200, pp. 189–196. https://doi.org/10.1016/j.jssc.2012.12.036

Chen, M., Wang, Z., Liu, H., Wang, X., Ma, Y., and Liu, J., Mater. Lett., 2017, vol. 202, pp. 59–61. https://doi.org/10.1016/j.matlet.2017.05.072

Gorshkov, N.V., Goffman, V.G., Khoryukov, A.S., Sevryugin, A.V., Burmistrov, I.N., and Gorokhovskii, A.V., Refract. Ind. Ceram., 2016, vol. 57, no. 4, pp. 413–416. https://doi.org/10.1007/s11148-016-9995-5

Gorokhovsky, A.V., Tretyachenko, E.V., Goffman, V.G., Gorshkov, N.V., Fedorov, F.S., and Sevryugin, A.V., Inorg. Mater., 2016, vol. 52, no. 6, pp. 587–592. https://doi.org/10.1134/S0020168516060042

Khanna, S.K., Griiner, G., Orbach, R., and Beyeler, H.U., Phys. Rev. Lett., 1981, vol. 47, no. 4, pp. 255–257. https://doi.org/10.1103/PhysRevLett.47.255

Reau, J.-M., Moali, J., and Hagenmuller, P., J. Phys. Chem. Solids, 1977, vol. 38, no. 12, pp. 1395–1398. https://doi.org/10.1016/0022-3697(77)90014-2

Liu, T., Li, Q., Xin, Y., Zhang, Z., Tang, X., Zheng, L., and Gao, P.-X., Appl. Catal. B: Environmental, 2018, vol. 232, pp. 108–116. https://doi.org/10.1016/j.apcatb.2018.03.049

Watanabe, M., Mori, T., Yamauchi, S., and Yamamura, H., Solid States Ionics, 1995, vol. 79, pp. 376–381. https://doi.org/10.1016/0167-2738(95)00091-J

Sinelshchikova, O.Y., Kuchaeva, S.K., Drozdova, I.A., Ugolkov, V.L., Petrov, S.A., and Vlasov, E.A., Glass Phys. Chem., 2011, vol. 37, no. 4, pp. 433–440. https://doi.org/10.1134/S1087659611040146

Sinelshchikova, O.Yu., Petrov, S.A., Besprozvannykh, N.V., Kuchaeva, S.K., and Vlasov, E.A., J. Sol–Gel Sci. Technol., 2013, vol. 68, no. 3, pp. 495–499. https://doi.org/10.1007/s10971-013-2988-7

ACKNOWLEDGMENTS

The authors are grateful to Researcher N.Yu. Ul’yanova and Junior Researcher E.Yu. Brazovskaya for the assistance in studying the textural and optical characteristics of the samples (Institute of Silicate Chemistry, Russian Academy of Sciences), and also to T.A. Vishnevskaya and G.A. Galkina, who performed trials of the samples in oxidation of СО and Н2 [engineers of the St. Petersburg State Institute of Technology (Technical University), Chair of General Chemical Technology and Catalysis].

Funding

The study was performed within the framework of the government assignment for the Institute of Silicate Chemistry, Russian Academy of Sciences in accordance with the Basic Research Program of State Academies of Sciences for 2019–2021 (theme no. 0097-2019-0012).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Besprozvannykh, N.V., Sinel’shchikova, O.Y., Morozov, N.A. et al. Synthesis and Physicochemical Properties of Complex Oxides K2MexTi8–xO16 (Me = Mg, Ni, Al) of Hollandite Structure. Russ J Appl Chem 93, 1132–1138 (2020). https://doi.org/10.1134/S1070427220080042

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427220080042