Abstract

The existing methods of fabricating low-field cathodes do not permit the development of device structures that comply with the requirements of developers of systems. In this work, large-area field-emission cathodes with homogeneous emission properties of the working surface and low working voltages (<1 kV) are considered. A Spindt cathode with a number of silicon microtips up to 6000 and a packing density of ~1 × 105 cm–2 is investigated. Titanium nitride and carbon films are deposited onto microtips using the electric-arc method. It is shown that the cathode has low emission homogeneity due to the problem of reproducing microtips of the same shape and size. A cathode based on a microchannel plate with channels 6 μm in diameter, inside which graphite-like nanostructures are formed by the electric-arc method, is fabricated. It is found that an increase in the electron flux in the channels of a microchannel plate can result in a considerable decrease in the operating voltage (<1 kV) and attain high emission homogeneity at the highest admissible output current.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The results of systemic investigations of the field-emission properties of various conductors show the prospects of their use in microwave devices, X-ray tubes, and light sources as cathodes. The electric field, at which insignificant emission appears, is very high (about 107 V/cm) for the smooth surfaces of conductors with an electron work function from 2 to 5 eV, which causes definite limitations for the application of cathode formation methods.

Graphite-like nanostructures (graphene, carbon nanotubes, nanographites, and nanodiamonds) have a low work function (<1 eV), which makes them widely applicable as emission media [1–3]. For example, the authors of [4] showed that emission is excited on carbon nanoclusters under reduced fields (104–105 V/cm). The formation technology of emission centers based on nanocluster structures in carbon films formed by the pyrolysis of heptane is urgent [5]. To synthesize carbon nanocluster structures, the well-studied electric-arc method is also used [6]. The authors of [7] proposed an alternative formation method of low-field cathodes, in which the effect of topographic enhancement of the electric field at microtips is applied. However, despite the large number of publications, device structures that comply with the requirements of developers of systems have still not been developed.

The goal of our work is the development and investigation of an alternative method for the fabrication of large-area field-emission cathodes with homogeneous emission properties of the surface and acceptable threshold voltages.

FORMATION OF A LARGE-AREA SPINDT CATHODE BASED ON A MICROCHANNEL PLATE

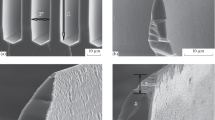

The emission of a Spindt matrix field-emission cathode with a number of silicon microtips up to 6000 and a packing density of ~1 × 105 cm–2 is investigated. Methods of planar technology are used to form the microtips. Barrier and emitting films of titanium nitride and carbon, respectively, were sequentially deposited onto the microtips by the electric-arc method. The deposition technology of these coatings using a UVNIPA installation is described in [8, 9]. To deposit carbon films, an electric-arc evaporator with a cathode consisting of three parts, notably, a water-cooled base made of titanium of the VT1-0 brand, a graphite holder made of carbon material of the MPG-6 brand and shaped as a truncated cone, and graphite insert (expendable material). A graphite insert 4 mm in diameter is placed into an aperture at the graphite cone center so that its upper plane turns out to be 8 mm above the cone surface. Graphite is sputtered on the insert end. The installation includes a system for the magnetic separation of continuous carbon plasma, which makes it possible to form an almost smooth film surface without carbon microparticles.

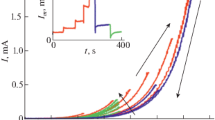

The Spindt cathode (Fig. 1) was investigated in a diode circuit (Fig. 2). A field-emission matrix was used as the cathode, and a glass screen with a phosphor coating was used as an anode. The distance between the cathode and anode is 250 μm, the operating voltage is 3 kV, and the current is ~1 μA. The tests were performed at a rarefaction of 1 × 10–6 torr. The cathode was supplied from a pulsed power unit (100 μs, 50 Hz).

The matrix of emitters (silicon “wells”) with tips inside is arranged at the center of a silicon wafer 7 × 18 × 0.47 mm in size (Fig. 3). The inhomogeneity of the anode (the screen) cathodoluminescence pattern allows us to assume that the arrays of tips of the Spindt cells are not identical. One method of solving this problem can be the proposed alternative method of the formation of large-area field-emission cathodes based on a microchannel plate (MCP), which fulfills the function of an amplifier of the electron flux in electro-optical converters and consists of numerous channels identical in geometry and secondary emission properties.

The operating voltage and gain of the electron flux for the MCP are on the order of 400–1000 V and 102–103, respectively. We note that when increasing the MCP input current, the output current increases and reaches the limiting value (the effect of MCP deep saturation). The authors of [10] proposed a method for fabricating a MCP-based field-emission cathode with channels filled by graphite-like nanostructures. Thus, there is no necessity to form a regular structure in the form of periodic tips.

To fabricate cathodes with a MCP-based reference structure we used samples 24.8 mm in diameter with channels 6 μm in diameter fabricated at OOO “Microchannel Systems” (Gatchina). Emitters regularly arranged according to the scheme presented in Fig. 4 were formed inside the MCP channels by the electric-arc method. A carbon film was deposited on the end MCP surface into the channels by the simultaneous electric-arc sputtering of graphite and a catalyst (nichrome). Then a contact electrode was sequentially deposited onto a carbon layer without leak-in of the vacuum chamber by the thermal evaporation of the electroconductive material (copper). The copper layer was deposited onto the opposite end MCP surface and fulfilled the function of an accelerating electrode for secondary electrons of MCP channels. The anode was formed in the form of a cathodoluminescence screen.

The results of our investigations showed that the high homogeneity of field emission from a large-area surface (~3 cm2) is observed for samples of field-emission diodes fabricated by the described method. A limiting output current of ~1 mA/cm2 is attained at Uoper ~ 400 V. A considerable decrease in the operating voltages is attained due to enhancement of the electron flux in the MCP channels.

Thus, the lowered operating voltages (<1 kV) and high emission homogeneity at the highest acceptable output current (up to 1 A) evidences the efficiency of applying MCPs with channels filled by graphite-like nanostructures for fabricating field-emission cathodes. The emission inhomogeneity of the Spindt cathodes is due to the problem of reproducing microtips of identical shapes and sizes.

REFERENCES

V. Zhigalov, V. Petukhov, A. Emelianov, et al., in Proceedings of the IEEE Young Researches in Electrical and Electronic Engineering ELConRus,2017, p. 1449.

R. V. Konakova, O. B. Okhrimenko, A. M. Svetlichnyi, O. A. Ageev, E. Yu. Volkov, A. S. Kolomiytsev, I. L. Jityaev, and O. B. Spiridonov, Semiconductors 49, 1242 (2015).

G. G. Sominskii and T. A. Tumareva, Izv. Vyssh. Uchebn. Zaved., PND 17 (3), 17 (2009).

G. N. Fursei, M. A. Polyakov, A. A. Kantonistov, A. M. Yafyasov, B. S. Pavlov, and V. B. Bozhevol’nov, Tech. Phys. 58, 845 (2013).

S. G. Savel’ev, N. I. Sinitsyn, G. V. Torgashov, and Yu. A. Grigor’ev, in Proceedings of the International Interschool Conference on Modern Problems of Microwave Electronics and Radiophysics, Saratov,2001, p. 138.

E. Z. Khamdokhov, Z. M. Khamdokhov, V. S. Kulikauskas, et al., J. Surf. Invest.: X-ray, Synchrotr. Neutron Tech. 8, 12997 (2014).

C. A. Spindt, I. Brodie, L. Humphry, and E. R. Westerberg, J. Appl. Phys. 47, 5248 (1976).

A. Z. Khamdokhov and E. Z. Khamdokhov, RF Patent No. 2497977, Byull. Izobret., No. 31 (2013).

E. Z. Khamdohov, R. Sh. Teshev, Z. M. Khamdohov, A. Z. Khamdohov, Z. H. Kalajokov, and H. H. Kalajokov, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 8, 1306 (2014).

E. Z. Khamdokhov and Z. M. Khamdokhov, RF Patent No. 2640355 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Korovin

Rights and permissions

About this article

Cite this article

Khamdokhov, Z.M., Margushev, Z.C., Khamdokhov, E.Z. et al. Field-Emission Cathodes Based on Microchannel Plates. Semiconductors 53, 2037–2039 (2019). https://doi.org/10.1134/S1063782619150090

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063782619150090