Abstract

The pyrrole electrochemical polymerization in the presence of salt and acid forms of flexible-chain sulfoacid polyelectrolytes is studied comparatively. Electrochemical and spectral methods of the synthesis control showed the polypyrrole electrosynthesis in the presence of polyelectrolytes to occur more rapidly and with lesser monomer concentration than in inorganic-anion-containing aqueous solutions. With the using of the polyelectrolytes’ Н+-form, the pyrrole polymerization rate was shown to exceed that in the Na+-salt solutions. Electrochemical, spectroelectrochemical properties in visible and near-IR spectral regions, and morphology of the obtained hybrid polypyrrole films were also studied.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Polypyrrole (PP) is one of the most thoroughly studied conducting polymers, thanks to high conductivity and stability of its conducting form. It possesses a unique combination of physico-chemical, electrochemical, and optical characteristics that make the PP perspective for using in chemical and biological sensors, as electrode material in batteries, capacitors, and electrochromic devices, as corrosion-protection materials, “artificial muscles,” etc. [1].

The principal methods of the PP synthesis are the pyrrole chemical and electrochemical polymerization. The conducting-polymer-film electrochemical synthesis is convenient because oxidant-free uniform films are formed on metal and optically transparent substrates possessing a conducting layer. By varying of charge consumed in the electrochemical synthesis, one can easily control their thickness and morphology. Thus, the electrochemical polymerization procedure solves both problems of the polymer synthesis and its depositing as thin film onto conducting substrates.

The PP synthesis is affected by its realization mode, as well as composition of the electropolymerization medium (solvent, supporting electrolyte, monomer concentration, and pH) [2]. PP can be electrochemically prepared both in organic and aqueou solutions. The PP electrosynthesis in aqueous solutions was reported to give films with larger porosity [3]; in addition, the pyrrole electropolymerization with the potential cycling onsets at less positive potentials than in acetonitrile [3] and occurs at a faster rate [4]. When having used bulky polymer anions we observed an increase in the PP synthesis rate [5]. The anions are suggested to adsorb easier at the electrode surface, and this accelerates the electropolymerization first stage. In addition, the bulky organic anions increase the PP film stability and thermal stability [5]. The polymer anion is included to the polymer film and cannot be removed from it during the dedoping [6, 7].

It is the salt forms of polyelectrolytes, such as polyvinylsulfonate [7], polystyrenesulfonate [5–9], as well as the poly-2-acrylamide-2-methyl-1-propanesulfonate acid form that were predominantly used in the pyrrole electropolymerization [10]. Moreover, the differences in the PP synthesis character in the presence of different (acid or salt) polyelectrolyte forms were mentioned only once in literature [6]. It should be noted that the majority of the studies was carried out at rather large monomer concentrations (0.1–0.05 М). It is but works [11, 12] in which the effect of monomer concentration on the pyrrole polymerization during the PP electrosynthesis in aqueous solutions of inorganic cations was studied.

Thus, the studies carried out so far are mainly restricted to mere statement of the fact that the PP electrosynthesis can be carried out in the presence of polyelectrolytes; yet, no effect of the polyelectrolyte chemical structure and its counterion nature on the PP film synthesis and properties has been analyzed.

In this work, we carried out a comparative study of the pyrrole electrochemical polymerization from aqueous solutions of flexible-chain polysulfoacid electrolytes of different structure. We also studied the effects of the polyelectrolyte’s compensating counterion nature on the PP electrochemical synthesis and properties. The PP electrosynthesis was studied by the in situ spectroscopy in UV-, visible, and NIR spectral regions, with the simultaneous control of the electrochemical parameters of the synthesis. The PP-film spectroelectrochemical properties were studied by example of the films deposited in the presence of polyelectrolytes.

EXPERIMENTAL

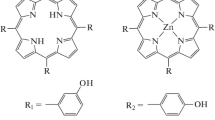

Polypyrrole was prepared by the pyrrole electrochemical polymerization in aqueous solutions of sulfoacid polyelectrolytes: poly-2-acrylamido-2-methyl-1-propanesulfonic acid (PAMPSA), polystyrenesulfonic acid (PSSA) and their salts. We used aqueous solution of PAMPSA (Aldrich, 15%, Mw ≈ 2 × 106). Its sodium salt (PAMPSNa) was prepared by the polyacid neutralization with NaOH equimolar aqueous solution. We also used aqueous solution of the PSSA sodium salt, PSSNa (Aldrich, 25%, Mw ≈ 1 × 106). PSSNa was converted to Н+-form by the using of an ion-exchange column filled with a КU-2-8 cationite. All polyelectrolytes were purified by dialysis with respect to water by using a ZelluTrans cellulose membrane, MWCO 8000–10 000.

Pyrrole was distilled in argon atmosphere; it was always used as fresh-distilled. The polyelectrolyte solutions of required concentration were prepared the day prior to the synthesis. Pyrrole was dissolved at intense 2-h-long agitation.

The pH values of the reaction solutions (Table 1) were measured by an OP-208/1 рН-meter (Radelkis). Pyrrole was polymerized in a three-electrode cell, with platinum foil as counterelectrode and a saturated silver/silver chloride reference electrode. All potentials in the paper are given against this reference electrode.

PP films were electrochemically deposited in potentiostatic (0.65 V), galvanostatic (100 μА/сm2), or potentiodynamic (over a –0.8 to 0.8 V range, at a potential scan rate of 50 mV/s) mode onto a SnO2-glass-electrode with a surface area of 2 сm2. The pyrrole/sulfoacid-group ratio was steadily maintained equal to one pyrrole molecule per two polyelectrolyte sulfoacid groups. The pyrrole concentration varied from 0.0025 to 0.015 М. For comparison, we also polymerized pyrrole electrochemically in the 0.01 М pyrrole + 0.02 М sulfuric acid/sodium sulfate and 0.05 М pyrrole + 0.1 М sodium sulfate aqueous solutions. The charge consumed in the PP-film synthesis was 50 mC/сm2. The synthesized films were washed with distilled water and dried in air. Thickness of the PP films prepared in the presence of polyelectrolytes and in inorganic electrolytes was 140 ± 10 and 80 ± 10 nm, respectively. The film thickness was measured with a МII-4 interferometer (LOMO).

In the course of pyrrole polymerization, optical absorption spectra were registered simultaneously. The electrochemical synthesis parameters were set and registered using a НА-501G potentiostat/galvanostat (Hokuto Denko, Ltd.) and a Nicolet 2090 digital storage oscilloscope (Nicolet, Inc.). The optical-absorption spectra registration over the 350–950 nm range during the PP synthesis, as well as the follow-up spectroelectrochemical film studies in 0.1 М NaClO4 aqueous solution, were performed using an Avantes 2048 single-beam scanning high-speed spectrophotometer. Electronic absorption spectra in near UV‑Vis-NIR regions were recorded using a Shimadzu UV-3101PC double-beam spectrophotometer.

The PP films deposited in the galvanostatic mode in the presence of different electrolytes were studied by the atomic force microscopy (AFM) method. Аn Enviroscope AFM-microscope with a Nanoscope V controller (Bruker) functioned in semi-contact mode. The film roughness estimate was taken as a root-mean-square deviation for the surface-profile irregularities over a (5 × 5 μm) frame. The frames were taken in the films’ different areas and averaged.

RESULTS AND DISCUSSION

Electrochemical Polymerization

The literature data mainly relate to the pyrrole electropolymerization performed at rather high concentrations of both pyrrole and electrolyte, including polyelectrolytes [5–10]. To elucidate the polyelectrolyte role in the PP synthesis, we studied effect of the monomer concentration on the synthesis rate and character at a constant monomer/sulfoacid-group mole ratio (1/2). In Fig. 1а we show that at the pyrrole concentration (0.015 М) lower than that in works [5‒10] (0.1–0.05 М) the PP potentiostatic synthesis (PS) in the presence of PAMPSA appears rather fast; moreover, it is autocatalytic in its nature. When the monomer concentration drops down to 0.005 М the electropolymerization current decreased significantly. In the case of galvanostatic synthesis (GS) (Fig. 1b) at the monomer concentrations of 0.015 and 0.01 М the polymerization occurred at the same potential; when the concentration decreased down to 0.005 М the synthesis potential begins growing in due course, and this results in the obtained polymer overoxidation. On this reason, we used the pyrrole concentration equal to 0.01 М in our subsequent studies.

Kinetic curves for the charge and current (а) recorded during the PP potentiostatic synthesis (0.65 V) and for the potential (b) during the galvanostatic PP synthesis in the PAMPSA aqueous solutions with the pyrrole different concentrations: (1) 0.015, (2) 0.01, (3) 0.005, (4) 0.0025 М. The pyrrole/sulfoacid-group molar ratio was 1 : 2 mol/g-equivalent.

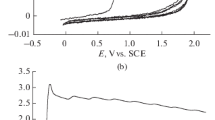

To elucidate the influence of the chemical structure of polyacid and its counterion, we carried out the PP electrochemical syntheses in aqueous solutions of flexible-chain polyacids: PSSA and PAMPSA, as well as their Na+-salts; for comparison, the syntheses were also carried out in H2SO4 and Na2SO4 solutions. In Fig. 2 we show cyclic voltammograms recorded during the PP synthesis in the presence of PSSA in potentiodynamic mode (PD) over the potential range from ‒0.8 to 0.8 V. Their shape is characteristic of the PP potentiodynamic synthesis in aqueous medium [3]; it is practically independent of the polyacid chemical structure. Table 1 shows that the monomer oxidation onset potentials determined from the potentiodynamic-synthesis first cycle are practically identical for the syntheses in the presence of PAMPSA and PSSA; in the presence of their salts, the potentials are slightly higher, however.

For PS, we see (Fig. 3а) that the duration of the pyrrole-polymerization induction period (calculated from kinetic curves of the charge variation, Fig. 3а), which corresponds to the radical-cation dimerization stage [12], depends on the chemical structure of both polyelectrolyte and its counterion (Table 1). When the polymer acids are used, the pyrrole electrochemical polymerization begins earlier (Fig. 3b, curves 1, 2) and proceeds faster than in the presence of their salts (Fig. 3b, curves 1*, 2*). At that, in the presence of PSSA the PP synthesis in PS mode proceeds at a higher current than in the presence of PAMPSA (Fig. 3b, curves 1, 2). The longest induction period was observed in the presence of the PAMPSNa (Fig. 3а). During the GS (Fig. 3c), pyrrole is polymerized at the same potential in the presence of both PSSA and PAMPSA and their salts.

The increase in the pyrrole oxidation potential and the induction period duration for the PP electrosynthesis in the polyelectrolytes’ salt forms, that is, in the high-pH-media, correlates with the data of work [13] demonstrated the role of H+ ion and pyrrole protonation in its polymerization process. Indeed, at larger degree of PAMPSA neutralization (up to pH 5.5) the potentiostatic synthesis proceeds still slower; the galvanostatic one, at a higher potential (Table 1).

It should be noted that the PP synthesis is slowed down significantly when the pyrrole electropolymerization occurs in sulfuric acid at similar conditions and concentrations (Figs. 3а, 3b). Yet, the monomer oxidation potential remained nearly the same as it is in the polyelectrolytes; the PS induction period increased by a factor of 2–6. The GS potential in sulfuric acid is somewhat higher than in the polyelectrolytes. The pyrrole PS polymerization in the presence of Na2SO4 at the same reactants’ concentrations is autocatalytic as well, but proceeds much slower and has much longer induction period than in the polymer electrolytes and sulfuric acid (Table 1). In GS mode we observed potential growth (Fig. 3c); the monomer oxidation potential in the first cycle of potentiodynamic synthesis in the presence of Na2SO4 (0.8 V) is higher than that measured in the presence of the polyelectrolytes (Table 1). With the increasing of the monomer and Na2SO4 concentration by a factor of 5 the monomer oxidation potential decreased, and the PP potentiostatic electrosynthesis proceeds at a higher rate; the galvanostatic one, at a lower potential.

Thus, by using polymeric electrolytes for the pyrrole polymerization, we accelerated the electrochemical synthesis; moreover, the application of polymeric electrolytes allows using reactants in lower concentrations. In addition, thus obtained PP films are highly uniform and well adhesive to substrates. It is essential to note that PP films prepared in H2SO4 and Na2SO4 are less uniform; they were exfoliated from electrodes after spectroelectrochemical measurements connected with changes in the film volume upon the potential variation.

To summarize our data on the synthesis of conducting polymers (polyaniline and poly-3,4-etylenedioxythiophene (PEDOT)) in polyelectrolytes [14, 15] allows concluding that the using polyelectrolytes in the pyrrole electropolymerization for the purpose of PP synthesis also promotes local ordering of positively charged radical-cations near the negatively charged sulfoacid groups. This accelerates the polymerization and allows obtaining high-quality films under the conditions described.

In Fig. 4, we give optical absorption spectra recorded in the course of the PP films galvanostatic synthesis. For salt forms of the polyelectrolytes, H2SO4, and Na2SO4 (0.1 M), we observed the optical absorption monotonic growth with a well pronounced maximum at 730 nm; this wavelength corresponds to the PP bipolaron form [16, 17] (Fig. 4а). For acidic forms of the polyelectrolytes, we observed a wider absorption band extended toward NIR spectral region (Fig. 4b). Moreover, PP films synthesized in the presence of acid forms demonstrated a better pronounced absorption growth near 500 nm, which corresponds to PP radical-cations [17]. When the polymerization proceeds in the presence of the polyelectrolyte salt form, this absorption band is likely to shift toward short-wave spectral region. A shift of the radical-cation absorption toward 400 nm with the increasing of the synthesis-solution pH was also observed in work [13], along with a decrease in the PP film conductivity.

In Fig. 5 we give optical absorption spectra for dry PP films synthesized in GS mode. It should be noted that under the same conditions and the same charge consumed in the film deposition (50 mC/cm2) the films obtained in sulfuric acid are thinner and absorbed less light. This may evidence a lesser PP yield under the above-discussed conditions. We see that the using the polyelectrolytes in their acid forms leads to the formation of wide absorption band extended toward NIR spectral region, which points to the fact that the films are fully oxidized (to their bipolaron form) [17]. In the spectra of PP films prepared in the presence of the polyelectrolytes’ salt forms and H2SO4 the absorption bands are shifted toward a short-wave spectral region; also, their IR-absorption dropped down. A decrease in the bipolaron form content in the PP can lead to a decrease in the film conductivity.

Spectroelectrochemistry

Thus obtained hybrid polypyrrole films were characterized in a monomer-free NaClO4 aqueous solution. Prior to spectroelectrochemical measurements, the PP films were continuously cycled in 0.1 М NaClO4 aqueous solution over the potential range from –0.6 to 0.6 V, up to formation of a stable cyclic voltammogram. In Fig. 6, we give a cyclic voltammogram characteristic of the entire PP films under study.

The effect of the synthesis-medium pH, hence, the polyelectrolyte-counterion nature manifests itself also in the spectroelectrochemical properties of the obtained PP films. In Fig. 7, we present spectra of PP films synthesized in the presence of the PSSA acid and salt forms recorded at different constant potential values. It should be noted that the spectra shape is characteristic of PP films prepared in inorganic electrolytes [17]. At lower potentials we observed a band near 400 nm, which is due to π–π*-transitions and characterizes a PP reduced form. With the increasing of potential (that is, during film oxidation) the band intensity decreased; at the same time, a new weak band appears near 500 nm, which is ascribed to radical-cations (the polarons), and the absorption near 800 nm (the bipolaron form) [16, 17] strengthens. The polaron absorption is poorly pronounced in the case of PP prepared with the polyelectrolytes’ acid form. When, however, the polyelectrolyte is used in its salt form no such band can be observed; however, here all PP films demonstrate isobestic points that evidence that the reduced form transforms into the polaron one (i.p.1); the polaron form, into bipolaron one (i.p.2). The absence of any visible polaron absorption peak is likely to be caused by its shift toward short-wave part of the spectrum [17]. Indeed, we see from Table 2 that for PP films deposited in the presence of sodium forms the reduced-form absorption maximums are shifted to the short-wave region by 9–10 nm; the isosbestic points, by 20–30 nm. Similar differences manifested themselves for the PP films obtained in the presence of PAMPSA and PAMPSNa. A better pronounced peak of radical-cation absorption of PP films synthesized in the presence of the polyelectrolytes’ acid forms can be due to the presence in the film bulk of isolated regions with different degree of protonation because of the presence of trapped polyacid molecules therein. Their protons are not able to exchange with the electrolyte during the doping/dedoping cycles. However, this supposition requires further experimental verification by using structural methods (e.g., in situ Raman spectroscopy). Moreover, it was often reported on the heterogeneous structure of conducting polymers, PP, in particular. The very presence of differently conducting regions in PP films was shown [18] by using conductive-AFM method, the difference in the conductivity being caused by differences in the doping level.

Morphology

The obtained PP films were characterized by the atomic-force microscopy method (Fig. 8). However, no significant differences in surface morphology were observed. The film surface shows regular globular structure that is characteristic of PP [6, 18]. PP films obtained in the presence of the polyelectrolyte acid forms are somewhat more rough than those deposited from salt-form solutions. This may be due to faster synthesis reaction in the first case as compared with the second one.

CONCLUSIONS

To summarize, we performed comparative study on the pyrrole electrochemical polymerization in the presence of salt and acid forms of flexible-chain sulfoacid polyelectrolytes. By using electrochemical methods combined with the process monitoring by means of in situ UV-, Vis-, and NIR-spectroscopy the polymer electrolyte application in the pyrrole electrochemical polymerization was shown to accelerate the synthesis. In addition, lower reactant concentrations, as compared with the electrosynthesis in the electrolytes with inorganic anions, can be used. It was shown that in the presence of the polyelectrolytes’ acid forms the PP films are deposited at higher rates, their surfaces are rougher, and their spectroelectrochemical properties are characteristic of PP films prepared in inorganic-anion-containing electrolytes. Spectra of PP films synthesized in the presence of the polyelectrolytes’ acid forms demonstrated a better pronounced peak of the radical-cation absorption near 500 nm, which can be connected with the presence in the film bulk of isolated regions containing trapped polyacid molecules whose protons are not able leaving the films during the doping/dedoping cycles. However, this supposition requires additional experimental verification; it will be an object of further studies.

REFERENCES

Handbook of Conducting Polymers, Conjugated Polymers. Processing and Applications, 3rd ed., Skotheim, T.A. and Reynolds J.R., Eds. London, New York: Taylor & Francis Group, 2007.

Vernitskaya, T.V. and Efimov, O.N., Polypyrrole: a conducting polymer; its synthesis, properties and applications, Russ. Chem. Rev., 1997, vol. 66, no. 5, p. 443.

Ko, J. M., Rhee, H. W., Park, S.-M., and Kim, C. Y., Morphology and Electrochemical Properties of Polypyrrole Films Prepared in Aqueous and Nonaqueous Solvents, J. Electrochem. Soc., 1990, vol. 137, no. 3, p. 905.

Lim, J.Y., Paik, W., and Yeo, I.-H., A Study on Ion Transports and Growth of Conducting Polypyrrole with Electrochemical Quartz Crystal Microbalance, Synth. Met., 1995. vol. 69, p. 451.

Kupila, E.-L. and Kankare, J., Electropolymerization of pyrrole: effects of pH and anions on the conductivity and growth kinetics of polypyrrole, Synth. Met., 1993, vol. 55, p. 1402.

Qu, L.-T., Shi, G.-Q., Liu, C., Yuan, J.-Y., and Qian, W.-B., Preparation, characterization and electrochemical properties of polypyrrole-polystyrene sulfonic acid composite film, Chinese J. Polymer Sci., 2005, vol. 23, no. 1, p. 37.

Shimidzu, T., Ohtani, A., Iyoda, T., and Honda, K., Charge-controllable polypyrrole/polyelectrolyte composite membranes Part II. Effect of incorporated anion size, J. Electroanal. Chem., 1987, vol. 224, p. 123.

Mamma, T., Ken, N., Osaka, T., Kondo, N., and Nakamura, S., Electrochemical Properties of a Polypyrrole/Polystyrenesulfonate Composite Film and Its Application to Rechargeable Lithium Battery Cathodes, J. Electrochem. Soc., 1994, vol. 141, no. 9, p. 2326.

Prezyna, L.A., Qiu, Y.-J., Reynolds, J.R., and Wnek, G.E., Interaction of Cationic Polypeptides with Electroactive Polypyrrole/Poly(styrenesulfonate) and Poly(N-methylpyrrole) / Poly(styrenesu1fonate) Films, Macromolecules, 1991, vol. 24, p. 5283.

Ignatova, M., Labaye, D., Lenoir, S., Strivay, D., Jerome, R., and Jerome, C., Immobilization of Silver in Polypyrrole/Polyanion Composite Coatings: Preparation, Characterization, and Antibacterial Activity, Langmuir, 2003, vol. 19, p. 8971.

Asavapiriyanont, S., Chandler, G.K., Gunawardena, G.A., and Pletcher, D., The electrodeposition of polypyrrole films from aqueous solutions, J. Electroanal. Chem., 1984, vol. 117, p. 229.

Qiu, Y.-J. and Reynolds, J.R., Electrochemically Initiated Chain Polymerization of Pyrrole in Aqueous Media, J. Polymer Sci.: Part A, Polymer Chem., 1992, vol. 30, p. 1315.

Qian, R., Pei, Q., and Huang, Z., The role of H+ ions in the electrochemical polymerization of pyrrole, Makromol. Chem., 1991, vol. 192, p. 1263.

Gribkova, O.L., Nekrasov, A.A., Ivanov, V.F., Zolotarevsky, V.I., and Vannikov, A.V., Templating effect of polymeric sulfonic acids on electropolymerization of aniline, Electrochim. Acta, 2013, vol. 122, p. 150.

Iakobson, O.D., Gribkova, O.L., Nekrasov, A.A., and Vannikov, A.V., The Effect of Counterion in Polymer Sulfonates on the Synthesis and Properties of Poly-3,4-ethylenedioxythiophene, Russ. J. Electrochem., 2016, vol. 52, no. 12, p. 1191.

Breads, J.L., Scott, J.C., Yakushi, K., and Street, G.B., Polarons and bipolarons in polypyrrole: Evolution of the band structure and optical spectrum upon doping, Phys. Rev. B, 1983, vol. 30, p. 1023.

Arjomandi, J., Shah, A.-H. A., Bilal, S., Hoang, H.V., and Holze, R., In situ Raman and UV–vis spectroscopic studies of polypyrrole and poly(pyrrole-2,6-dimethyl-β-cyclodextrin), Spectrochim. Acta Part A, 2011, vol. 78, p. 1.

Lee, H.J. and Park, S.-M., Electrochemistry of Conductive Polymers. 30. Nanoscale Measurements of Doping Distributions and Current–Voltage Characteristics of Electrochemically Deposited Polypyrrole Films, J. Phys. Chem. B, 2004, vol. 108, p. 1590.

ACKNOWLEDGMENTS

Spectral studies and surface AFM-studies were performed using equipment of Center for the Collective Use of Physical Methods of Investigation of IPCE RAS.

Funding

This work was supported by the Russian Foundation for Basic Research (project no. 18-53-18009 Bolg_а) and the Ministry of Education and Sciences of RF (the development of the procedure of polypyrrole synthesis in the presence of polyelectrolytes).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by Yu. Pleskov

This paper is dedicated to the 80th anniversary of Professor V.V. Malev who has made a considerable contribution into modern directions of electrochemistry.

Rights and permissions

About this article

Cite this article

Gribkova, O.L., Kabanova, V.A. & Nekrasov, A.A. Electrochemical Polymerization of Pyrrole in the Presence of Sulfoacid Polyelectrolytes. Russ J Electrochem 55, 1110–1117 (2019). https://doi.org/10.1134/S1023193519110065

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193519110065