Abstract

Investigation of some factors affecting the removal performance of the synthesized composite ion exchanger based on polyacrylonitrile and inorganic species is reported in this paper. The influence of pH, time, concentration of metal ions (Cs+, Co2+, Eu3+), drying temperature of the synthesized sorbent, reaction temperature on the removal percentage of cesium, cobalt, and europium ions using polyacrylonitrile–Ti(IV) tungstophosphate composite was studied. The elimination of hazardous ions—cesium, cobalt, and europium from aqueous waste was enhanced by the increase of time, pH and reduced with increasing of the concentration of metal ions, and drying of the synthesized composite. Freundlich, Langmuir, and Dubinin-Radushkevich (D–R) models were used to analyze the sorption isotherms. The experimental data fitted well with Freundlich isotherm equation. The kinetic of cesium, europium, and cobalt ions sorption on polyacrylonitrile–titanium tungstophosphate composite has been studied. Thermodynamic parameters—activation energy Ea, entropy ∆S*, and diffusion coefficients (Di) have been calculated. The particle diffusion mechanism was indicated by low activation energy values and the negativity of ∆S* refer to the stability of the exchange matrix. The reaction rate increased with increasing the sorption process temperature and with decreasing particle size and drying temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The removal of hazardous and toxic metal ions from polluted water is an important problem. Industrial processes led to formation and spread of pollutants that cause the destructive influence on the environment and dangerous effects on human health. There are different techniques used for removal process such as precipitation, liquid extraction, ion exchange, and chromatography [1, 2]. The ion exchange method is characterized by convenience, high performance, and selectivity in treatment of liquid waste. Ion exchangers are organic, inorganic, or composite organic-inorganic (hybrid) materials. Composite materials prepared by combining organic polymer with inorganic particles [3] or implantation of inorganic material into the numerous organic materials during polymerization process possess the advantages of both constituents. Using organic polymer as a binder improve the mechanical characteristics of end products which are not present in pure materials [4]. Composite ion exchangers possess better thermal and chemical properties than organic ion exchangers. They also show greater selectivity towards metal ions, and better granular properties, and better ion exchange kinetics, than pure inorganic ion exchanges. More recently, some hybrid exchanges have been developed, polyaniline–tin cerium phosphate [5], polyaniline–Sn(IV) silicate [6], polyacrylamide–ferric antimonate [7], polyacrylamide–stannic molybdophosphate [8], tin sulphosalicylomolybdate [9], polyaniline silicotitanate [10], and poly-o-toluidine–stannic molybdate [11].

Polyacrylonitrile is utilized as a binder with different inorganic materials, i.e. stannic molybdophosphate [12], copper hexacyanoferrate [13], cerium molybdate [14], magnesium oxide [15], Fe3O4 [16], and sodium titanosilicate [17].

The synthesized polyacrylonitrile–titanium tungstophosphate composite composite ion exchanger is used for removal of cesium, cobalt, and europium ions from polluted water and the effects of many factors such as time, pH, drying temperatures, and ion concentration on the removal ratio are studied in the present work. Kinetic and isotherm models were elaborated, and the thermodynamic parameters were calculated.

EXPERIMENTAL

Chemical Reagents and Instruments

The reagents were obtained from BDH (UK) and Loba Chemie (India). All reagents were of analytical reagent grade and were used without further purification. pH measurements were performed using pH meter model 601A. Inductively coupled plasma (ICP) spectrometry was made on Shimadzu instrument (Japan).

REMOVAL STUDY OF THE EXAMINED IONS

Effect of Contact Time

The equilibration time for optimum removal of cesium, cobalt, and europium using polyacrylonitrile–Ti(IV) tungstophosphate composite was determined by performing a group of adsorption experiments. A mixture is formed of 0.05 g polyacrylonitrile–Ti(IV) tungstophosphate composite with 5 mL of 10–3 M cesium, cobalt, and europium ions solutions for 15 min to 24 h. The solutions were separated and concentrations of studied ions were analyzed before and after mixing process using inductively coupled plasma (ICP) spectrometry.

The percentage of removal of ions was computed by the following formula

where Ci is the initial ion concentration and Ct is the ion concentration in mol L−1 at time t.

Effect of Solution pH

Investigation of pH effect is determined by mixing 5 mL 0.001 M of solutions of Cs+, Co2+, and Eu3+ which had different pH values with 0.05 g of the fabricated composite with continuous shaking, kept for 24 h to attain equilibrium. The solution was separate. The removal percentage of studying ions was determined by Eq. (1) for each pH value.

Effect of Drying of Ion Exchange

Various samples of the prepared composite were heated at different temperatures (50–500°C) for 3 h in an oven and the removal percentage of Cs+, Co2+, and Eu3+ ions were determined by the above method.

Effect of Ion Concentration

The removal of cesium, cobalt, and europium ions using polyacrylonitrile–titanium tungstophosphate composite was studied by varying initial ions concentration (0.001–0.05 M) using optimum adsorbent dose (0.05 g) at ambient temperature (25 ± 1°C) for a contact time of 24 h, neutral pH. The removal percentage of the investigated ions was determined by the above method.

Effect of Temperature

To determine the effect of temperature on the adsorption of metal ions, 0.05 g polyacrylonitrile–titanium tungstophosphate composite was equilibrated with 0.001 M of cesium, cobalt, and europium solutions at neutral pH for 24 h and different reaction temperatures 25, 45, and 65°C. The concentration of ions before and after adsorption was determined and the removal percentage was calculated as previously.

Kinetic Studies

Kinetics experiments were performed by using a batch factor of V/m equal to 100 mL g–1, and 10–2 M for cesium, cobalt and europium solutions in a shaker thermostat adjusted at the desired temperatures (25, 45, and 65 ± 1°C). After the adjusted interval period, the solid was separated immediately from the solution and the extent of sorption was determined as shown above.

RESULTS AND DISCUSSION

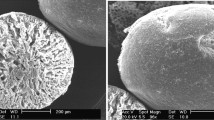

Fabrication and characterization of polyacrylonitrile–titanium tungstophosphate composite were reported earlier [18]. Polymerization of acrylonitrile was achieved by stirring a mixture of 10% acrylonitrile and 0.1 M potassium persulfate K2S2O8 (equal volumes) using a magnetic stirrer. The solutions were kept below 10°C for half an hour until a white colored polyacrylonitrile gels were formed. Titanium tungstophosphate was synthesized by mixing equal volumes of equimolar solutions of titanium chloride, and sodium tungstate (0.1 M) with orthophosphoric acid (1 M), followed by gradual addition of aqueous ammonia (NH4OH) solution until a white precipitate was formed and pH of the mixture reached 0.95. Polyacrylonitrile polymers were mixed with titanium tungstophosphate precipitate with constant stirring, then the resultant composite gels were kept for 24 h at room temperature (25 ± 1°C). The prepared gel was washed with bidistilled water several times to remove adherent particles and filtered using a centrifuge (about 104 rpm), and dried at 50 ± 1°C. The dried products were immersed in DMW to obtain small granules and converted to H+-form by treating with 1 M HNO3 for 24 h with occasional shaking intermittently replacing the supernatant liquid with fresh acid

Removal Studies

Effect of Contact Time

The effect of contact time on the removal percent of Cs+, Co2+, and Eu3+ ions from polluted water using polyacrylonitrile–titanium tungstophosphate composite ion exchange is presented in Fig. 1a. The removal percentage of the studied ions from contaminated water using the composite ion exchanger is enhanced with an increase in time until reaching equilibrium between the solid and liquid phases after 240 min.

Effect of Solution pH

The pH of the solution influences on the solution chemistry and the degree of ionization of the materials present in the solution. The surface charge and functional groups of the adsorbent is affected by pH [19]. The effect of pH on the removal of cesium, cobalt, and europium ions from aqueous solutions using the fabricated composite was achieved and presented in Fig. 1b. It was noticed that the removal percentage of the investigated ions continuously increases with increasing pH. Low removal percentage of cesium, cobalt, and europium ions in acidic environment (low pH) is due to the presence of excess of H+ ions which compete with the investigated ions and more favorably to occupy for the exchanging sites in the adsorbent [15]. At highest pH, low concentration of H+ ions then the competition effect was reduced d, so an optimum removal of the studied ions occurs [16].

Effect of Drying Temperature

The removal of the studied ions was affected by heating of polyacrylonitrile–titanium tungstophosphate composite at different temperatures. It was observed that on heating the ion exchange composite from 50 to 500°C (Fig. 1c), the removal percentage of the composite for cesium, cobalt, and europium changed or reduced with increasing the heating temperatures of the fabricated sorbent.

Effect of initial concentration. The linkage between various initial concentrations of metal ions and the removal percentage of the composite was investigated at pH 4.5 at the 25°C for 24 h, presented in Fig. 1d. In general, it reveals that the removal percentage of the metal ions decreases with the increase of the initial concentrations. At low concentration the removal percentage of studying ions was enhanced due to fast movement of ions into the active site [5], also the presence of vacant active sites in the sorbent available for the metal ions. But with increasing the initial concentration of ions in solution, the removal percentage becomes lower. This behavior may be assigned to steric repulsion between solutes and available active sites become limited toward free ions in the solution [6].

Effect of adsorption temperatures. The influence of reaction temperature on the removal percentage of cesium, cobalt, and europium ions was examined, The observed results are that the removal percentage is 97, 98.3, and 99.5% for cesium ions; 69, 73, and 76.8% for cobalt ions; and 90, 94.6, 98.5% for europium ions at 25, 45, and 65°C, respectively, which indicate that the removal percentage of studied ions is considerably increased by enhancing the solution temperature from 25 to 65°C. This enhancing of removal percentage can be attributed to the fact that at higher temperatures, cations move faster. This could be due to the fact that the specific or electrostatic interactions become weaker and the ions become smaller, since solvation is reduced [20], so the reaction between cesium, cobalt, and europium ions with the prepared composite is an endothermic reaction.

Estimation of decontamination factor (DF). The decontamination factor DF can be determined by the following formula [21]

where Ai and Af are the initial and final activities (Bq/mL) of the radioactive solution, respectively.

Table 1 represents the removal percentage and decontamination factor values for 137Cs, 60Co, and 152+154Eu with polyacrylonitrile–titanium tungstophosphate composite. As shown in Table 1 the highest decontamination factor for cesium ion and the lowest decontamination factor for cobalt ion.

Equilibrium isotherm. Adsorption equilibrium isotherm is so necessary parameter to understand the behavior of adsorption process. The relationship between the amount of adsorbate on the adsorbent and the concentration of the dissolved adsorbate in the liquid at equilibrium, a fixed pH and temperature is explained through sorption isotherm studying [22]. The measured isothermal data were discussed using the most common Langmuir, Freundlich, Dubinin–Radushkevich (D–R) models.

Langmuir model. This model postulate that the sorbents surface contains specific homogenous adsorption sites. These sites are also assumed to be energetically equivalent. Each site holds only one molecule of sorbate. The sorbate form monolayer coverage of an adsorbent. and no trans-migration of adsorbate in the plane of the surface [23]. The Langmuir isotherm model suggests an estimation to the maximum sorption capacity occurred by complete monolayer sorption on the adsorbent surface. The linear form of Langmuir model is represented as the following equation (3):

where qmax (mmol/g) is the maximum adsorption, Ce (mmol/L) is the equilibrium concentration of ions, qe (mmol/g) is the adsorption amount of ions per unit weight of adsorbent at equilibrium, and b (L/mmol) is the Langmuir constant and related to affinity of sorption sites. A linear relation is deduced from the plot 1/qe with 1/Ce, the intercept and slope of this plot are used to compute qmax and b and represented in Table 2.

Freundlich Model

The Freundlich model is applicable for non-ideal sorption on heterogeneous surfaces and multilayer adsorption processes. According to the Freundlich model the logarithmic form can be written [24]:

where Kf and 1/n are Freundlich constants, indicating the adsorption capacity and the adsorption intensity, respectively. Kf and n are, respectively, determined from the intercept and slope of \(\log {{q}_{{\text{e}}}}\) vs. \(\log {{C}_{{\text{e}}}}\) plot.

The linearization of Langmuir and Freundlich models for cesium ion only for brief, is presented in Figs. 2a, 2b, respectively. Table 2 summarize the calculated Freundlich and Langmuir adsorption isotherm models parameters.

The experimental sorption isotherm data of cesium, cobalt, and europium ions on the prepared composite are presented in Fig. 2a. Table 2 indicates that the experimental isotherm data are well fitted with Freundlich model with a high correlation coefficients. The values of 1/n is, smaller than one (0 < 1/n < 1), which implies heterogeneous surface structure and favorable multilayer sorption is expected using polyacrylonitrile–titanium tungstophosphate composite Freundlich adsorption process [25]. The values of Kf also indicate the affinity and removal percentage sequence of the prepared composite with cesium, cobalt, and europium ions \({{K}_{{f{\kern 1pt} {\text{Cs}}}}}\) > \({{K}_{{f{\kern 1pt} {\text{Eu}}}}}\) > \({{K}_{{f{\kern 1pt} {\text{Co}}}}}\).

Dubinin–Radushkevich (D–R) Isotherm Model

It is known that the Langmuir and Freundlich adsorption isotherm constants do not give any idea about the adsorption mechanism. Therefore, the equilibrium data were tested with the Dubinin–Radushkevich isotherm (D–R). This model is related to the porous structure of ion exchanger. This approach was usually applied to distinguish the physical and chemical adsorption of metal ions with its mean free energy, E per molecule of adsorbate (for removing a molecule from its location sorption space to the infinity). The linear form can be as follows:

where qe is the amount of metal (mmol/g) adsorbed per unit mass of ion exchanger, qmax is the sorption capacity (mmol/g), k is a constant related to adsorption energy (mol2/kJ2), and ε is the Polanyi potential which can be calculated as follows:

where R, T, and Ce represent the gas constant (8.314 J/(mol K)), absolute temperature (K), and adsorbate equilibrium concentration (mol/L). From the slope and intercept the linear regression analysis of the plot’s ln qe against ε2, the D–R parameters qmax and K ' can be calculated and presented in Table 2. The mean free energy of adsorption (E) for transfer one mole of ions from infinity of solution to the surface of the sorbent. E can be calculated from KD–R value using the following relation [26]

The E value between 8 and 16 kJ/mol means that the adsorption process takes place chemically; values below 8 kJ/mol indicate that the adsorption process proceeds physically [27].

The value of E obtained from the slope of the D–R plot is given in Table 2. It can be noticed that the values of E are between 8–16 kJ/mol which indicate the presence chemisorption process playing an important role in the adsorption process.

Kinetic Study

Kinetic measurements were made under the conditions favoring a particle diffusion-controlled ion-exchange phenomenon for the exchange of cesium, cobalt, and europium ions. The particle diffusion-controlled phenomenon is preferred by a high metal ion concentration, relatively a large particle size of the exchange and a vigorous shaking of the exchanging mixture. For the particle diffusion-controlled kinetics, the expression developed by Boyed et al. [28] and improved by Reichenberg [29] is as shown in Eq. (6), which is used in this work. The fractional attainment of equilibrium at time t, F(t), was used and is expressed as

and

Where Bt is a mathematical function, Di is the self-diffusion coefficient of the ions undergoing exchange within the exchange, n is an integer number, and r is the radius of the particles. When the fractional attainment of equilibrium (F) is less than 0.4, Eq. (6) can be approximated in a simpler form as follows

For every calculated value of F, the corresponding values of Bt are calculated from Eq. (9). The linearity examination of Bt versus t plots (Figs. 3 and 4) is employed to find out the particle diffusion-control mechanism. At the lower concentration, the Bt versus t plots did not pass through the origin signifying the adsorption to be film diffusion, but at higher concentrations the same were linear up to a certain point and passed through the origin indicating the adsorption to be a particle diffusion in nature.

The energy of activation (Ea) for the self-diffusion of cations was determined by applying the Arrhenius equation:

where Ea is the activation energy, D0 is a preexponential constant, and R is the gas constant. The entropy of activation (ΔS*) can be calculated from D0 by substituting in the equation suggested by Barrer et al. [30]:

where K is the Boltzmann constant, T the absolute temperature, d the average distance between two successive positions in the process of diffusion, which was taken as 0.5 mm, and h is the Planck constant.

The above equations were utilized for computing of the values of D0, Di, Ea, and ΔS* for the exchanged systems and the kinetics data are presented in Table 3. ions on polyacrylonitrile–titanium tungstophosphate composite was studied at 25°C. Straight linear relationships between Bt and time passing through the origin are obtained, which gives indication for particle diffusion mechanism as presented in Fig. 3. The rate of ion exchange reaction increases with decreasing the particle diameter of the prepared composite, so the rate of the reaction is dependent on the particle size of the composite [31].

It was noticed that the rate of the reaction changed by varying the reaction temperatures. Figure 4 represent the plots of Bt, F with time for cesium, cobalt, and europium ions at 25, 45, and 65 ± 1°C in which straight lines relations between Bt and time passing through the origin, the rate of the reaction enhanced with the increase of reaction temperature from 25 to 65 ± 1°C. This trend may attribute to the enhancement of the mobility of ions with increasing the reaction temperature from 25 to 65 ± 1°C [32] or may be assigned to a higher diffusion rate of ions through the thermally enlarged interstitial positions of ion exchange matrix [33, 34]. When \(\log {{D}_{i}}\) is plotted against 1/T for the exchange of Cs+, Co2+, and Eu3+ on polyacrylonitrile–titanium tungstophosphate composite, straight lines were obtained Fig. 5. From the slope of these lines and applying Arrhenius equation, the energy of activation (Ea) and the self-diffusion coefficient (Di) were calculated. On the other hand, the entropy of activation (ΔS*) can be deduced from Di using Eq. (8). The activation energy reflects the ease with which the cation can pass through the exchanger particles. The values of activation energy are relatively low which confirm the particle diffusion mechanism [35, 36]. These data are similar with data reported with El-Naggar et al. [37], the negativity of ΔS* indicate the absence of strict hindrance and is no structural change occur in sorbent matrix when the ions pass through the channels of exchanger particles.

The influence of drying the fabricated composite (50, 200, and 400°C) on the rate of exchange of the investigated metal ions was studied. The relation between F and Bt against time is shown in Fig. 6. From this figure and Table 4, the rate of exchange decreases with increasing the drying temperature of composite from 50 to 400°C. The Di values decrease with an increase in the drying temperatures of the fabricated sorbent. It is clear that an appreciable decrease of self-diffusion of the exchange particles which hinders the diffusion of the metal ions [31, 33]. The decrease in diffusion may be attributed to the decrease in the surface area and porosity of the dried exchanger. The lower porosity means less free water inside the exchanger particles [38].

CONCLUSION

The removal of cesium, cobalt, and europium ions using polyacrylonitrile–titanium tungstophosphate composite was achieved in this paper. The removal percentage of the investigated ions increased with increasing pH, contact time, and temperature, but the removal percentage was reduced with increasing the initial concentration of ion solution, drying temperature of the composite. Equilibrium isotherm has been studied and the isotherm data are more fitted to the Freundlich model with a multilayer heterogenous surface. From kinetic studies, thermodynamic parameters Di, D0, Ea, and ΔS* has been calculated. The mechanism of the reaction between the prepared composite and investigated ions is a particle diffusion mechanism.

REFERENCES

Y. Park, Y. C. Lee, W. S. Shina, and S. J. Choi, J. Chem. Eng. 162, 685 (2010).

G. Gürboğa, H. Tel, and Y. Altas, Sep. Purif. Technol. 47, 96 (2006).

A. A. Khan, Inamuddin, and M. Mezbaaul Alam, Mater. Res. Bull. 40, 289 (2005).

Mu. Naushad, Ion Exchange Lett. 2, 1 (2009).

C. Janardanan and P. Vinisha Valsaraj, Int. J. Adv. Chem. 2, 6 (2014).

Mu. Naushad, Z. A. Al-Othman, and M. Islam, Int. J. Environ. Sci. Technol. 10, 567 (2013).

I. M. El-Naggar, E. A. Mowafy, Y. F. El-Aryan, and M. G. Abd El-Wahed, Sci. Res. Essay 9, 162 (2014).

I. M. El-Naggar, E. A. Mowafy, E. A. Abdel-Galil, and M. F. El-Shahat, Glob. J. Chem. 1, 91 (2010).

P. Vinisha Valsaraj and C. Janardanan, Int. J. Adv. Sci. Tech. Res. Iss., No. 4, 3 (2014).

I. M. El-Naggar, K. A. Hebash, E. Sheneshen, and E. A. Abdel-Galil, Inorg. Chem. Indian J. 9, 1 (2014).

S. A. Nabi, R. Bushra, Mu. Naushad, and A. M. Khan, Chem. Eng. J. 165, 529 (2010).

R. Yavari, S. J. Ahmadi, F. Farkhondehru, V. Gholipoor, and L. Kamel, Int. J. Environ. Sci. Technol. 11, 1073 (2014).

A. Nilchi, R. Saberia, M. Moradi, H. Azizpour, and R. Zarghami, Chem. Eng. J. 172, 572 (2011).

S. J. Ahmadi, R. Yavari, P. Ashtari, V. Gholipour, L. Kamel, and F. Rakhshandehru, Chin. J. Chem. 30, 177 (2012).

A. Nilchi, M. R. Hadjmohammadi, S. Rasouli Garmarodi, and R. Saberi, J. Hazard. Mater. 167, 531 (2009).

M. M. Hamed, M. Holiel, and I. M. Ahmed, Radiochim. Acta 104, 873 (2016); Q. Liu, Lu-Bin Zhong, Q. Bao Zhao, C. Frear, and Yu-Ming Zheng, Appl. Mater. Interfaces 7, 14573 (2015).

R. Saberi, A. Nilchi, S. Rasouli Garmarodi, and R. Zarghami, J. Radioanal. Nucl. Chem. 284, 461 (2010).

Y. F. El-Aryan, E. A. Abdel-Galil, and G. E. Sharaf El-deen, Russ. J. Appl. Chem. 88, 516 (2015).

G. Crini, H. N. Peindy, F. Gimbert, and C. Robert, Sep. Purif. Technol. 53, 97 (2007).

M. M. Abd El-Latif and M. F. Elkady, Desalination 255, 21 (2010).

T. Valsala, S. Roy, J. G. Shah, J. Gabriel, K. Raj, and V. Venugopal, J. Hazard. Mater. 166, 1148 (2009).

J. Peric, M. Trgo, and N. V. Medvidovic, Water Res. 38, 1839 (2004).

I. Langmuir, J. Am. Chem. Soc. 40, 1361 (1918).

S. S. Dubey and B. S. Rao, J. Hazard. Mater. 186, 1028 (2011).

H. M. Freundlich, J. Phys. Chem. 57, 385 (1906).

L. V. Radushkevich, Zh. Fiz. Khim. 23, 1410 (1949).

L. Cheng, S. Yu, S. Zha, Y. Yao, and X. Pan, Chem. Eng. J. 213, 22 (2012).

G. E. Boyed, A. W. Adamson, and L. S. Myers, J. Am. Chem. Soc. 69, 2836 (1947).

D. Reichenberg, J. Am. Chem. Soc. 75, 5897 (1953).

R. M. Barrer, R. F. Bartholomew, and L. V. C. Rees, J. Phys. Chem. Solids 24, 51 (1963).

S. A. Shady, A. B. El-Deeb, and I. M. El-Naggar, Sci. Res. Essays 7, 1962 (2012).

P. Patel and U. Shudasama, Ind. J. Chem. 49, 1318 (2010).

I. M. El-Naggar, E. A. Mowafy, E. A. Abdel-Galil, and M. F. El-Shahat, Glob. J. Phys. Chem. 2, 164 (2011).

M. M. El-Shorbagy and A. A. El-Sadek, Sci. Res. Essays 7, 1954 (2012).

Z. A. Al-Othman, Inamuddin, and M. Naushad, Chem. Eng. J. 171, 456 (2011).

Z. A. Al-Othman, M. M. Alam, and M. Naushad, J. Ind. Eng. Chem. Mater. 5, 2874 (2012).

I. M. El-Naggar, E. S. Sheneshen, and E. A. Abdel-Galil, Partic. Sci. Technol. 1 (2015).

E. A. Abdel-Galil, M. Khalil, and Y. F. El-Aryan, Radiochemistry 57, 87 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Aryan, Y.F., El-Kenany, W.M., Amin, M. et al. Sorption of Some Radionuclides onto Polyacrylonitrile–Ti(IV) Tungstophosphate Composite. Russ. J. Phys. Chem. 95 (Suppl 1), S171–S178 (2021). https://doi.org/10.1134/S0036024421140028

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024421140028