Abstract

A thiol-functionalized HMS mesoporous silica was synthesized with thiolsilane. FTIR characterization suggests that thiol group has been anchored on the surface of HMS. SH-HMS performs better than HMS in adsorption of lead ion from water. The adsorption ratio on SH-HMS monotonously increases with adsorption time, which is beyond 95.5% after 5 min of adsorption time and be close to the equilibrium state. It decreases with pH value while increases with adsorbent dosage. Furthermore, the increment of lead initial concentration leads to decrease the adsorption ratio while increase the adsorption quantity. Adsorption ratioof 100 % can be obtained under following conditions: pH 6, 30 min of adsorption time, 8 g L–1 of adsorbent dosage, and 40 mg L–1 of initial lead concentration. The relationship between the adsorptive quantity and equilibrium adsorption concentration is in good accordance with both of the Langmuir isotherm model and the Freundlich model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Over the past decades, we have gained much more welfare from the fast economy development, and however, we also suffer from it accordingly. Environment pollution is just one of the problems we have been subjected to. It is well known that wastewater pollution especially resulting from heavy metals has become a serious environmental problem all over the world [1]. A large amount of heavy metals with high toxicity including lead, cadmium and chromium and so on enter water bodies which leads to immeasurable risks and dangers human health and ecological systems [2]. As one of the most commonly concerned metals, lead is often detected in textile dying, petroleum refining, battery manufacture, and mining operations. It may cause mental disturbance, retardation, and semi-permanent brain damage even in relatively lower concentrations [3, 4]. Therefore, developing an efficient method or a novel agent to remove lead ions has attracted much attention of many researchers.

To remove heavy metals from wastewater, many techniques, such as ion exchange, precipitation, adsorption, membrane processes, reverse osmosis, sedimentation, and electro-dialysis, have been employed [5, 6]. The adsorption process offers flexibility and simplicity in design, convenience and ease of operation and, effective in removing heavy metal ions especially at low concentration [7]. Various adsorptive materials, such as activated carbon, silica, zeolites, clays and organic polymers are capable of capturing metal ions from dilute aqueous solutions [8]. Among them, porous silica especially mesoporous silica functionalized with various organic chelating ligands has received great interest for its large specific surface area, fast mass transferring, high selectivity and typical solid properties [9]. In the previous literatures, studies on amino, thiol, and Schiff base functionalized mesoporous silica such as MCM-41 and SBA-15 has been widely reported [2, 9–12]. However, thiol grafted on HMS mesoporous silica has been scarcely investigated up to date.

In this paper, we prepare a novel adsorbent by functionalizing the surface of HMS mesoporous silica with thiol groups and discuss its performance in removing lead ions from water solution.

EXPERIMENTAL

Preparation of the Adsorbent

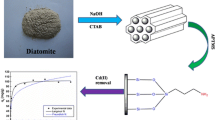

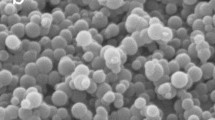

Thiol-functionalized HMS mesoporous silica was prepared following a method similar to that reported by Li [13]. A reaction solution was prepared by mixing 150 mL of n-octane and 2.6 g of 3-mercaptopropylmethyldimethoxysilane under stirring. Then 7 g of HMS mesoporous silica powder was added into the solution in a 150 mL four-necked flask. The final mixture was heated to boil and kept under stirring at 98oC (boiling point) for 2 h. Finally, the mixture was cooled, filtrated, washed using acetone and ethanol for 2 times, respectively, and the solid was dried at 50oC for 5 h. The final product was denoted as SH-HMS. For a comparative purpose, an analog named as HMS was prepared by the same procedure as SH-HMS except without silane.

Infra-red (FTIR) Characterization of the Adsorbent

The adsorbent and KBr were mixed by triturating at mass ratio of 1 : 99, and pressed into pellets, which were scanned at 4000–400 cm–1 with Thermo Nicolet 6700 Infrared spectrometer (instrument resolution of 0.4 cm–1). The data were analyzed with Omnic analysis software to determine the functional groups.

Tests of Removing Lead Ion

A given mass of the adsorbent and 25 mL of lead nitrate solution (100 mg L–1) were added to a conical flask (50 mL) with cover. The conical flask was shaked for a known time to fully adsorb and remove lead ions. Herein, the adsorption time is defined as the shaking time of the solution during the test. Then the mixture was sucked and filtrated. The clear liquid was transferred to a volumetric flask to acquire a constant 100 mL of solution. The concentration of residual lead ion in the solution was determined using an atomic adsorption spectrophotometer (TEHRMO, USA). Removing efficiency was evaluated on basis of the adsorption quantity (Qe, mg g–1) and the adsorption ratio (R, %), which are calculated according to following equations:

where C0 and Ce are the initial and equilibrium concentrations of lead ion (mg L–1), and Cb is the dosage of adsorbent (g L–1), respectively.

RESULTS AND DISCUSSION

Preparation and Characterization Results

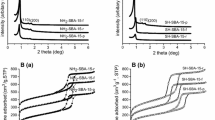

Figure 1 displays FTIR spectra of HMS and SH-HMS. Both of them have typical peaks attributed to silica-based materials. The bands at 1643 and 3431 cm–1 are ascribed to water adsorbed on Si–OH; Three bands at around 1082 and 950 cm–1 are associated to internal and external asymmetric Si–O stretching modes as well as two bands at 804 and 460 cm–1 are assigned to symmetric stretching and tetrahedral bending of Si–O bonds, respectively. As is shown in Fig. 1, SH-HMS indicates distinct differences from HMS in FTIR spectra. These bands are assigned as follows: Si–C bond “strectching” at 760 cm–1, CH3 groups “rocking” at 852 cm–1, Si–CH3 bond “stretching” at 1260 cm–1 and C–H “stretching” at 2966 cm–1 [11, 14–17]. Meanwhile, the bands at 1643 and 3431 cm–1 ascribed to water-adsorbed Si–OH significantly decrease for SH-HMS [14], suggesting that the lipophilicity of the silylated sample has been increased due to the impact of methylsilyl groups anchored on the surface of HMS. These FTIR results indicate that thiolsilyl groups of organic silanes have been really anchored on the surface of mesopores in HMS [11, 14–17].

Effect of Adsorption Time on the Efficiency of Removing Lead Ion

As is shown in Fig. 2, the adsorption time (0–100 min) has a great influence on the efficiency of removing lead under following conditions: 100 mg L–1 of initial concentration of lead ions, 8 g L–1 of adsorbent and pH 7. The result shows that the adsorption ratio increases with the adsorption time from 0 to 100 min, which includes three necessary stages. It is necessary to note that SH-HMS gives higher adsorption ratio than HMS. The three states are described as follows. Firstly, at the beginning of adsorption, the adsorption ratio dramatically increases because that the adsorption mainly occurs on the surface of adsorbent (SH-HMS). Then, at the second stage, the increasing speed of adsorption ratio becomes slow, maybe because of the decrease in the lead concentration in solution. The other reason is that during this stage the adsorption mainly works in the internal surface of adsorbent pores to decrease the mass transfer rate. Finally, the adsorption reaches an equilibrium state when the lead ions residue is much less. This law is approximately in accordance with that of the adsorption of solution on other porous materials [2, 18]. Based on the result in Fig. 2, the adsorption ratio has been beyond 95.5% after 5 min of adsorption time and be close to the equilibrium state. Accordingly, the adsorption time is set as 30 min in the following tests for a purpose of full adsorption.

Effect of pH Value on the Efficiency of Removing Lead Ion

pH value of the lead-containing solution was adjusted in the range of 2.5–11 by HCl and NaOH solutions. The adsorption test on the pH value was conducted under a condition of 100 mg L–1 of initial concentration of lead ion, 8 g L–1 of adsorbent dosage and 30 min of adsorption time. The result in Fig. 3 shows that the adsorption ratio monotonically increases with pH of solution and SH-HMS displays higher adsorption ratio than HMS. More importantly, the adsorption performance of SH-HMS is dramatically improved (R = 89–98%) compared with HMS in the range of pH less than 7. It also suggests that thiol in SH-HMS is resistant to dissolution of lead in acidic condition. It is much valuable because that most of adsorption treatments in industries perform in acidic condition. Both of SH-HMS and HMS indicate much higher adsorption ratio in the range of pH more than 7 because that Pb(OH)2 precipitate may be formed in alkaline condition. pH value of 6 was fixed in the following tests, considering that adsorption in industries works in acidic condition and SH-HMS may be dissolved in condition of pH more than 8. On the hand, the adsorption ratio on SH-HMS reaches 96.9% when pH value is 6, which is enough for removing lead ion.

Effect of Adsorbent Dosage on the Efficiency of Removing Lead Ion

Figure 4 shows the effect of adsorbent dosage (1–12 g L–1) on the efficiency of removing lead ions under conditions including 100 mg L–1 initial concentration of lead ions, pH 6 and 30 min adsorption time. Obviously, HMS performs not effective in adsorption compared with SH-HMS. The adsorption on SH-HMS quickly increases with the adsorbent dosage to reach a high number of 96.4% at 7 g L–1 of dosage and almost keeps unchangeable with increasing the dosage from 7 to 12 g L–1. It suggests that it is enough for the adsorption process when 7 g L–1 of adsorbent dosage was used. However, 8 g L–1 adsorbent dosage is utilized in the subsequent test for the purpose of full adsorption. Non-increment of the adsorption ratio with more adsorbent dosage could result from a too low concentration of the left lead ion in solution after adsorption ratio of 96.4% has been obtained. It also indicates adsorption equilibrium has reached.

Based on the above results, SH-HMS gives notable superiority in adsorption compared with HMS. It is because that SH-HMS possesses porous property as well as the chelating property from thiol, both of which are beneficial for adsorption lead. Accordingly, it is valuable to note that thiol-functionalizing is really an effective means to enhance adsorption performance for HMS materials.

Effect of Initial Lead Ion Concentration on the Removing Efficiency

Under conditions of 8 g L–1 SH-HMS dosage, pH 6 and 30 min adsorption time, the effect of lead ion initial concentration on removing efficiency was carried out. It could be observed from Fig. 5 that the adsorption ratio decreases while the adsorption quantity increases with the initial concentration of lead ion. Obviously, the removing ratio can mostly reach the optimum value of 100% at the ion initial concentration of 40 mg L–1. The results may be interpreted as follows. Firstly, adsorption quantity on adsorbent will be a constant when a given mass of adsorbent is used. Then the amount of residual lead ion can be increased at a higher initial concentration, which leads to a decrease of the removing efficiency. The above-mentioned reasons are also described as follows. The absolute amount of removed lead ion is increased while the removing ratio is decreased with the initial concentration of lead ion before the adsorption process does not still attain an equilibrium state. As a result, the adsorption ratio is increased while the adsorption quantity is decreased.

Isotherms of the Removing Lead Ion Process

The two most commonly used isotherms, namely Langmuir and Freundlich, were adopted to further describe the removing laws between equilibrium concentration (Ce) and adsorption quantity (Qe) during removal of lead ion using SH-HMS, From the linear form of these two isotherms, equations can be written as follows:

As shown in Figs. 6 and 7, the adsorption law accords well with both of the Langmuir isotherm model (r = 0.99995, here r stands for the linear correlation coefficient) and the Freundlich model (r = 0.99989).

CONCLUSIONS

FTIR characterization result suggests SH-HMS has been successfully synthesized by thiol group being anchored on the surface of HMS. SH-HMS performs better than HMS in adsorption of lead ion from water. The adsorption ratio on SH-HMS monotonously increases with adsorption time, which is beyond 95.5% after 5 min of adsorption time and be close to the equilibrium state. It decreases with pH value while increases with adsorbent dosage. Furthermore, the increment of lead initial concentration leads decreasing the adsorption ratio while increasing the adsorption quantity. 100% of adsorption ratio can be obtained under a condition including 6 of pH, 30 min of adsorption time, 8 g L–1 of adsorbent dosage, and 40 mg L–1 of initial lead concentration. The relationship between the adsorption quantity and equilibrium adsorption concentration is in good accordance with both of the Langmuir isotherm model and the Freundlich model.

REFERENCES

Y. Xie, J. Wang, M. Wang, and X. Ge, J. Hazard. Mater. 297, 66 (2015).

Q. Wang, W. Gao, Y. Liu, J. Yuan, Z. Xu, Q. Zeng, Y. Li, and M. Schröder, Chem. Eng. J. 250, 55 (2014).

O. M. M. Freitas, R. J. E. Martins, C. M. Delerue-Matos, and R. A. R. Boaventura, J. Hazard. Mater. 153, 493 (2008).

A. T. Paulino, L. B. Santos, and J. Nozaki, React. Funct. Polym. 68, 634 (2008).

D. Pérez-Quintanilla, A. Sánchez, I. del Hierro, M. Fajardo, and I. Sierra, J. Colloid Interface Sci. 313, 551 (2007).

M. Amini, H. Younesi, and N. Bahramifar, Colloids Surf. A 337, 67 (2009).

A. Bhatnagar and M. Sillanpää, Chem. Eng. J. 168, 493 (2011).

H.-T. Fan, J.-B. Wu, X.-L. Fan, D.-S. Zhang, Z.-J. Su, F. Yan, and T. Sun, Chem. Eng. J. 198– 199, 355 (2012).

J. Aguado, J. M. Arsuaga, A. Arencibia, M. Lindo, and V. Gascón, J. Hazard. Mater. 163, 213 (2009).

S. J. L. Billinge, E. J. McKimmy, M. Shatnawi, H. Kim, V. Petkov, D. Wermeille, and T. J. Pinnavaia, J. Am. Chem. Soc. 127, 8492 (2005).

J. Aguado, J. M. Arsuaga, and A. Arencibia, Ind. Eng. Chem. Res. 44, 3665 (2005).

X. Li, J. Sol-Gel Sci. Technol. 76, 476 (2015).

M. A. Arain, F. H. Wattoo, M. H. S. Wattoo, A. B. Ghanghro, S. A. Iqbal, J. Tirmizi, and S. A. Arain, Arab. J. Chem. 2, 25 (2009).

R. R. Sever, R. Alcala, J. A. Dumesic, and T. W. Root, Micropor. Mesopor. Mater. 66, 53 (2003).

M. L. Peña, V. Dellarocca, F. Rey, A. Corma, S. Coluccia, and L. Marchese, Micropor. Mesopor. Mater. 44–45, 345 (2001).

K. F. Lin, L. F. Wang, F. Y. Meng, Z. H. Sun, Q. Yang, Y. M. Cui, D. Z. Jiang, and F. S. Xiao, Micropor. Mesopor. Mater. 235, 423 (2005).

J. M. R. Gallo, H. O. Pastore, and U. Schuchardt, J. Catal. 243, 57 (2006).

S. Hao, Y. Zhong, F. Pepe, and W. Zhu, Chem. Eng. J. 189–190, 160 (2012).

ACKNOWLEDGMENTS

This work was supported by the Natural Science Foundation of Education Department of Henan Province in China (12B530004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xuefeng Li, Like Zhang Removing Pb2+ by Adsorption over Thiol-Functionalized Mesoporous Silica. Russ. J. Phys. Chem. 93, 1804–1808 (2019). https://doi.org/10.1134/S0036024419090310

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024419090310