Abstract—

n-Type Bi2Te3–Bi2Se3 solid solutions containing 6, 8, and 10 mol % Bi2Se3 and doped with hexabromobenzene (C6Br6) and excess tellurium have been prepared by extruding granules produced by melt solidification in a liquid. The solid solutions have been characterized by X-ray microanalysis and microstructural analysis using a scanning electron and an optical microscope, and their mechanical and thermoelectric properties have been studied. Their ultimate strength, fracture strain, and elastic coefficient have been evaluated from room-temperature compression test results. The electrical conductivity, Seebeck coefficient, and thermal conductivity of the solid solutions have been measured in the temperature range 100–700 K. The temperature behavior of the Seebeck coefficient and electrical conductivity in the temperature range 150–300 K has been shown to differ from that predicted theoretically. The highest thermoelectric figure of merit of the solid solutions, (ZT)max, is ~0.9 at temperatures from 320 to 390 K.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The subject of this study is materials based on an n‑type bismuth chalcogenide solid solution, which are used in thermoelectric devices for various applications. The carrier concentration in this solid solution is usually varied by adding very small amounts of halogen-containing compounds (CdCl2, Hg2Cl2, and SbI3). However, these compounds are hygroscopic, and it is sometimes difficult to optimize the amount of the dopant and, hence, obtain materials with stable properties. The organic compound hexabromobenzene (C6Br6) is environmentally safe, sufficiently stable, and water-insoluble, and the use of this compound is expected to enable the fabrication of high-performance materials based on the above-mentioned solid solution, with well-reproducible thermoelectric characteristics.

In a previous study [1], we investigated the thermoelectric and mechanical properties of n-type Bi2Te3–Bi2Se3 solid solutions containing 8 and 20 mol % Bi2Se3 and doped with excess tellurium, cadmium chloride, and antimony iodide, which were prepared by hot-pressing and extruding granules produced through melt solidification in a liquid. In this paper, we describe Bi2Te3–Bi2Se3 solid solutions containing 6, 8, and 10 mol % Bi2Se3 and doped with hexabromobenzene (0.05 wt % C6Br6), which were prepared by extruding granules produced through melt solidification in water at room temperature and were then ground in a planetary mill.

The objectives of this work were to assess the feasibility of controlling carrier concentration in C6Br6-doped Bi2Te3–Bi2Se3 solid solutions by varying their composition and achieve high thermoelectric performance and strength using a previously developed process for the preparation of materials through rapid melt solidification [2].

EXPERIMENTAL

Extruded samples were prepared from granules produced by water-quenching Bi2Te2.82Se0.18, Bi2Te2.76Se0.24, and Bi2Te2.7Se0.3 melts containing 0.049 wt % C6Br6 and 0.05 wt % excess Te.

The starting materials were loaded directly into the container of a casting system in the following order: C6Br6, Se, Te, and Bi. The mixture was melted and stirred via high-frequency heating for 2 min. The melt flowed to water at a speed of ~5 m/s. Under such conditions, the cooling rate of the melt reached ~105 K/s. The resultant granules were comminuted in a planetary mill under a nitrogen atmosphere for 40–45 min at a rotation rate of 340 rpm and then cold-pressed into compacts in an inert (nitrogen) atmosphere at a load of 300 kN for 2 min and then in air at a load of 600 kN for another 2 min. The compacts were annealed for 10 h in an argon atmosphere at 763 K and extruded at 640 K into rectangular bars 5 × 5 mm in cross-sectional dimensions and up to 200 mm in length, which were then annealed for 24 h at a temperature of 613 K.

The ultimate strength, fracture strain, and elastic modulus of the solid solutions were determined at room temperature in compression tests on a Model 5800 Instron Universal Testing Machine at a crosshead speed of ~1 mm/min.

Using a LEO 1420 scanning electron microscope (SEM), we determined the phase composition of the samples in terms of their major components (tellurium, selenium, and bismuth) in different areas of the samples and examined fracture surfaces. In addition, the microstructure of the fracture surfaces was examined on a Polivar-Met-66 metallurgical optical microscope after etching polished sections for 10 s in an aqueous 50% HNO3 solution.

The thermoelectric properties of the solid solutions were studied using samples 5 × 5 × 12 mm in dimensions, cut from the extruded bars. The Seebeck coefficient (α), electrical conductivity (σ), and thermal conductivity (κ) of the solid solutions were measured at room temperature and in the ranges 100–300 and 300–700 K. The temperature dependences of α and σ in the temperature range 100–300 K were obtained in a liquid-nitrogen-cooled cryostat. The temperature and Seebeck coefficient were determined using copper–constantan thermocouples located on the end faces of the sample. Voltage leads were soldered to the lateral surface of the sample. The high-temperature measurements were made in an argon atmosphere at a pressure of 0.7 × 105 Pa. The temperature and Seebeck coefficient were then determined using Chromel–Alumel thermocouples, which were inserted in holes drilled in the sample. The thermocouples were used in addition as voltage leads in electrical conductivity measurements.

To follow the variation in the thermoelectric efficiency coefficient Z = α2σ/κ in the temperature range 100–700 K, the lattice thermal conductivity κl (or κl + κph) was evaluated as the difference between the total thermal conductivity κ and the electron contribution κel to the thermal conductivity using the relation κl = κ – κel, where κel = LσT (L is the Lorenz number and T is the ambient temperature). To calculate κl(T), we used κl values evaluated from the total thermal conductivity measured at room temperature, a κl ~ T–0.5 relation at temperatures below 300 K, and a (κl + κph) ~ T0.9 relation at T > 300 K, that is, above the inflection in the α(T) and σ(T) curves in the intrinsic conductivity region, where an additional contribution to thermal conductivity, κph, emerges due to ambipolar diffusion of electrons and holes.

RESULTS AND DISCUSSION

Table 1 summarizes X-ray microanalysis data illustrating the concentrations of major components in different areas of the extruded samples. The samples were found to be similar in composition to the starting mixture used for melt granulation. According to the X-ray analysis data, the scatter in the Bi and Te contents of the samples did not exceed 2% and that in the Se content was within ~20%. The Bi, Te, and Se contents of the samples differed from those of the starting mixture by no more than 0.5–1.5, 0.9–2.0, and 5.0–9.0%, respectively.

The strength data obtained for the samples with different compositions in the room-temperature compression tests demonstrate that stress is a linear function of strain, pointing to elastic deformation. Figure 1 shows the 300-K stress–strain (σ–ε) diagrams for these samples. They exhibit brittle fracture at a strain of 0.7–1.4%. Table 2 presents the ultimate strength, fracture strain, and elastic modulus of the materials studied. These quantities were calculated with allowance for the nonlinear stress–strain behavior in the initial stage of loading. Increasing the percentage of bismuth selenide in the solid solutions was found to increase their ultimate strength. The highest strength was offered by the materials prepared by extruding the Bi2Te3–Bi2Se3 solid solution containing 10 mol % Bi2Se3 and doped with C6Br6: they had an ultimate strength of ~250 MPa.

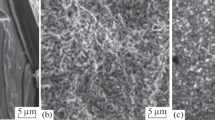

Microstructural analysis of fracture surfaces under an optical microscope showed that all of the samples had a fine-grain structure with a grain size no greater than a few microns (Figs. 2a–2c). SEM examination of fractographs of fracture surfaces of the samples (Figs. 2d–2f) showed that they had a “fibrous” structure formed by grains elongated in the plastic flow direction and having a (100) and (110) deformation texture. The (001) cleavage planes are basal slip planes. Under compression, the materials under study fracture along both grain boundaries and basal (cleavage) planes, with the main deformation mechanism being basal dislocation slip. The samples prepared by extrusion contain the highest density of dislocation networks, both basal and tilted to the basal planes, which hinder dislocation motion, impeding the propagation of compression-induced cracks in these materials, so they have high ultimate strength.

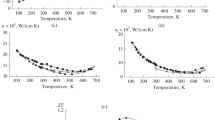

Table 3 summarizes the room-temperature thermoelectric properties of our samples. Figure 3 shows temperature dependences of the Seebeck coefficient, electrical conductivity, and thermal conductivity in the range 100–700 K for the samples containing 6, 8, and 10 mol % Bi2Se3. The highest electron concentration and, accordingly, a lower Seebeck coefficient and higher electrical conductivity and thermal conductivity were obtained in the Bi2Te3–Bi2Se3 solid solution with the lowest Bi2Se3 content (6 mol %, sample 1). Raising the percentage of bismuth selenide in the Bi2Te3–Bi2Se3 solid solutions reduces the carrier concentration and shifts the inflection in the α(T), σ(T), κ(T), and ZT(T) curves to lower temperatures. The (ZT)max of the solid solutions is essentially independent of their composition and reaches ~0.9 in the range 320–390 K (Table 4).

For the materials studied, we evaluated the exponent (r) in the relation between log σ and log T and the slope (A) of the plot of α against ln T in the range from their Debye characteristic temperature (155 K) to a temperature 50 K below the temperature corresponding to αmax (Table 4). The behavior of the temperature dependences of the Seebeck coefficient and electrical conductivity in the range 150–300 K differs from that in the case of a parabolic band structure and an acoustic carrier scattering mechanism in materials, when the carrier effective mass is temperature-independent, with r = –1.5 and A = 129 μV/K [3]. For the materials studied here, we obtained r ~ –1 and A ~ 110 μV/K. The same values were obtained for Bi2Te2.7Se0.3 solid solution samples prepared by hot-pressing melt-spun powder [4] and CdCl2-doped Bi2Te2.76Se0.24 and Bi2Te2.4Se0.6 samples prepared by extruding granules produced by liquid quenching at 180 K and ground in a planetary mill [1].

CONCLUSIONS

The composition of n-type hexabromobenzene-doped Bi2Te3–Bi2Se3 solid solutions has been further optimized. The solid solutions have been prepared by extruding granules produced by liquid quenching in water and ground in a planetary mill. These samples have been shown to be sufficiently homogeneous in terms of their major components, whose composition was similar to that of the starting mixture.

The ultimate strength of the samples increases from 100 to 250 MPa as Bi2Se3 content increases from 6 to 10 mol %. The highest thermoelectric figure of merit of the solid solutions, (ZT)max ~ 0.9, is essentially independent of their composition, whereas the peak in ZT shifts from 320 to 390 K with decreasing Bi2Se3 content.

REFERENCES

Ivanova, L.D., Granatkina, Yu.V., Mal’chev, A.G., Nikhezina, I.Yu., Emel’yanov, M.V., and Nikulin, D.S., Mechanical and thermoelectric properties of bismuth chalcogenide solid solutions prepared through melt solidification in a liquid, Inorg. Mater., 2018, vol. 54, no. 12, pp. 1193–1198. https://doi.org/10.1134/S0002337X18120072

Ivanova, L.D., Petrova, L.I., Granatkina, Yu.V., Nikulin, D.S., and Raikina, O.A., Crystallization and mechanical properties of solid solutions between bismuth and antimony chalcogenides, Inorg. Mater., 2016, vol. 52, no. 3, pp. 248–255. https://doi.org/10.1134/S0020168516030043

Gol’tsman, B.M., Kudinov, V.A., and Smirnov, I.A., Poluprovodnikovye termoelektricheskie materialy na osnove Bi 2 Te 3 (Bi2Te3-Based Thermoelectric Semiconductor Materials), Moscow: Nauka, 1972.

Ivanova, L.D., Petrova, L.I., Granatkina, Yu.V., Kichik, S.A., Marakushev, I.S., and Mel’nikov, A.A., Melt-spun materials based on an n-type Bi2Te2.7Se0.3 solid solution, Inorg. Mater., 2015, vol. 51, no. 7, pp. 741–745. https://doi.org/10.1134/S0020168515070067

ACKNOWLEDGMENTS

This work was supported by the Russian Federation Ministry of Education and Science (state research target no. 007-00129-18-00) and the Russian Foundation for Basic Research (project no. 16-08-00033a).

We are grateful to N.A. Alad’ev for his assistance in the scanning electron microscopic characterization of the samples and A.S. Baikin for testing the samples in compression on an Instron Machine.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Ivanova, L.D., Granatkina, Y.V., Mal’chev, A.G. et al. Hexabromobenzene-Doped Bismuth Chalcogenide Solid Solutions Prepared through Melt Solidification in a Liquid. Inorg Mater 55, 432–436 (2019). https://doi.org/10.1134/S0020168519050078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519050078