Abstract

Dunaliella salina, important source of β-carotene, was cultivated in different NaNO3 (1N = 75 mg L−1, 1.5N = 112.5 mg L−1, and 3N = 225 mg L−1) and NaH2PO4·2H2O (1P = 5.65 mg L−1, 1.5P = 8.47 mg L−1, and 3P = 16.95 mg L−1) concentrations in seawater-based f/2 medium, by semi-continuous process applying different medium feeding percentage (F = 20% and 80%). Semi-continuous process allowed the achievement of higher cell productivity (Px up to 6.7 × 104 cells mL−1 day−1; culture medium 1N:1P and F = 20%) in comparison with batch process. Maximum cell density (Xm) was not dependent on F, but the best results were obtained when using 1.5N:1.5P medium (Xm up to 5.6 × 105 cells mL−1, with F = 80%). On the other hand, β-carotene content was higher in cells grown in 1N:1P medium (up to 53.4 mg g−1 and 57.5 mg g−1, with F of 20% and 80%, respectively). The closed tubular photobioreactor employment for this microalga cultivation, under 12 h light/12 h dark cycle, contributed to successful cell growth without contamination by protozoa.

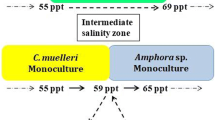

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fruits and vegetables are the main carotenoids sources, but microalgae are a promising alternative for these natural pigments production. Besides carotenoids, these photosynthetic microorganisms are rich in lipids, polyunsaturated fatty acids, carbohydrates, proteins, and vitamins. Microalgae also present cultivation advantages over higher plants such as rapid and sustainable growth (Priyadarshani and Rath 2012; Ahmed et al. 2014). Carotenoids are hydrocarbons divided in two groups: carotene containing only C and H (e.g., β-carotene and lycopene) and xanthophyll containing C, H and O (e.g., lutein, zeaxanthin, and astaxanthin) (Saini et al. 2015).

It is known that when a diet is rich in natural pigments, as carotenoids, and other compounds such as vitamins, fatty acids, and polysaccharides, diseases like obesity, cardiovascular disease, eye diseases (e.g., age-related macular degeneration), and certain cancers can be prevented (Bhosale and Bernstein 2005; De Jesus Raposo et al. 2015) due to the high antioxidant activity of some of those bioactive compounds. Carotenoids are considered key molecules for life because they can be applied to the food, as well as pharmaceutical and cosmetic industries. In fact, it is possible to find these molecules applied to dyes, functional foods and food supplements, nutraceuticals, sunscreens, and feed additives (e. g., eggs, fish, and shrimp) (Hu et al. 2008; De Jesus Raposo et al. 2015; Sathasivam and Ki 2018; Cezare-Gomes et al. 2019).

Currently, only few microalgae carotenoids are produced and marketed around the world, and countries like Australia, USA, Israel, Japan, China, and India are some of these natural pigments’ producers. As some examples, the halophilic microalga Dunaliella salina is being applied for β-carotene (pro-vitamin A) production, the freshwater Haematococcus pluvialis for astaxanthin (powerful antioxidant), and Muriellopsis sp., Chlorella protothecoides, and Scenedesmus almeriensis may be employed for the production of lutein (eye health) (Blanco et al. 2007; Borowitzka 2013). The productivity of β-carotene by carrots (traditional source) is 1.38 × 10 −1 kg ha−1 year−1, while the productivity of this same pigment by Dunaliella salina may reach 7.02 × 103 kg ha−1 year−1. The market for natural β-carotene in 2010 was about US$68 million with average price of US$300–1500 kg−1 and this is clearly a market in expansion considering the growing preference of the consumers for natural products (Cezare-Gomes et al. 2019). The induction of β-carotene synthesis (carotenogenesis) by green microalga Dunaliella salina, which can accumulate more than 10% dry weight of this orange pigment, occurs under stress conditions such as high light intensity, high salinity, low-temperature, and nutrient deprivation—mainly nitrogen and phosphorus (Mendoza et al. 1996; Guedes et al. 2011; Solovchenko 2013). It is well known that microalgal growth is influenced mainly by the sources of nitrogen, phosphorus, and carbon. Phosphorus is an essential nutrient and it plays a key-role in the conveyance of metabolic energy, for example, nucleic acid biosynthesis, phospholipid biosynthesis, and cell membranes formation (Dahmen-Ben Moussa et al. 2017; Paliwal et al. 2017). Nitrogen is extremely vital to microalgae and it is not exclusive to its role as essential building block of nucleic acids and amino acids, but it may also affect carotenoid accumulation (Del Campo et al. 2000; Carvalho et al. 2014; Ho et al. 2015).

This bio-product represents a growing market, but it can be improved by reducing its production costs. Growth optimization, genetic engineering, as well as bioreactor design and cultivation process are some algal biotechnology parameters that can be improved, making large-scale production economically viable (Matos 2017; Pires et al. 2017). Closed photobioreactors (PBR) allow the optimization and control of some parameters such as pH, light intensity, temperature, and biomass yields (Carvalho et al. 2014). Various studies show that the tubular photobioreactors are the most suitable type of culture system for the production of cyanobacteria (Matsudo et al. 2011; Ferreira et al. 2012) and microalga (Pérez-Mora et al. 2016), and that the semi-continuous process was successfully used in laboratory scale for lutein (carotenoid) production by microalga Chlorella minutissima (Dineshkumar et al. 2016) and Scenedesmus obliquus FSP-3 (Ho et al. 2015).

García-González et al. (2005) evaluated the temperature influence on biomass yields and carotenoid productivity on Dunaliella salina cultivation in an outdoor closed tubular photobioreactor (horizontal loop), under semi-continuous process and carotenoids production in a single stage, which means that cell growth and carotenoid production were simultaneously achieved. They concluded that the closed design was successfully used for D. salina growth in comparison with open ponds (traditional systems). Prieto et al. (2011) observed higher carotenoid content when D. salina was cultivated in closed tubular photobioreactor instead of in open tanks; but they carried out cultivations in two stages. In this two-stage process, the first one was characterized by cell growth, and the second one by carotenoid accumulation, in culture medium without nitrate by D. salina harvested from the first stage.

In this study, aiming to improve the performance of D. salina for β-carotene production, cultivations were carried out in bench-scale tubular photobioreactor for evaluating different concentrations of nitrate and phosphorus and different medium feeding percentages in semi-continuous process. These cultivations were carried out in two stages, the first one dedicated to the cell growth, carried out by semi-continuous process, and the following one to carotenogenesis, which was promoted by nitrogen and phosphorus limitation and no pH control, under batch process.

Material and methods

Microalga strain, cell maintenance and inoculum production

The microalga used in this study was Dunaliella salina 19/18, obtained from the Culture Collection of Algae and Protozoa—CCAP (Scotland, UK), and maintained in test tubes containing f/2 medium solidified with 2% agar, at room temperature (25 ± 2 °C). The f/2 medium is composed of (per liter): 0.997 L of natural seawater sterilized by autoclaving at 121 °C for 20 min, 1 mL of stock solution (75 g NaNO3 and 5.65 g NaH2PO4*2H2O per liter of deionized water), 1 mL of trace elements solution and 1 mL of vitamin mix solution. The trace elements solution includes (per liter): 4.16 g Na2EDTA, 3.15 g FeCl3·6H2O, 10 mg CuSO4·5H2O, 22 mg ZnSO4·7H2O, 10 mg CoCl2·6H2O, 0.18 g MnCl2·4H2O, and 6 mg Na2MoO4·2H2O. The vitamin mix solution includes (per liter): 100 mg vitamin B1 (thiamine), 0.5 mg vitamin B12 (cyanocobalamin) and 0.5 mg biotin (Guillard 1975). Cells were grown in gradually larger flasks up to 1 L Erlenmeyer flasks containing up to 400 mL of f/2 medium. These flasks allowed the cell growth on a rotary shaker (100 rpm), under light intensity of 50 μmol of photons m−2 s−1, at 25 °C. To obtain enough biomass to achieve initial cell concentration of 2.5 × 105 cel mL−1, D. salina was further cultivated in tubular photobioreactor (described below), in the same conditions of light intensity and temperature, with the use of CO2 for maintaining pH at 7.0 (also described below).

Experimental

The microalgae cultivations were carried out in two stages. In the first stage, microalgae were grown in tubular photobioreactor, with the aim of obtaining high cell density. When cell density reached the stationary growth phase, the culture was partially discharged from the bioreactor and replaced by the same volume of fresh culture medium, starting the first cycle of the semi-continuous process. In the second stage, cells were removed from the photobioreactor to Erlenmeyer flasks, when a batch process was carried out under stressing conditions (simultaneous lack of nutrients and high pH) for carotenogenesis. Details of semi-continuous process will be given below in the section “Semi-continuous process”.

Tubular photobioreactor and growth conditions

The airlift bioreactor used in this study was developed at the Microalgal Biotechnology Laboratory at the Department of Biochemical and Pharmaceutical Technology of São Paulo University (see details in Fig. 1). It was made of 40 transparent glass tubes (1.0 cm internal diameter and 0.5 cm wall thickness) with a slope of 2% (1.15°) to facilitate the flow of culture medium; these tubes were connected with silicone hoses. Dunaliella salina was inoculated into the reactor with an initial cell density of 2.5 × 105 cells mL−1. The cultivation was submitted to 12 h light/12 h dark cycle (Guermazi et al. 2014; Xu et al. 2016), using two fluorescent lamps of 20 W with the light intensity of 50 μmol of photons m−2 s−1. The reactor was operated at 24 ± 1 °C and pH was maintained at 7.0 ± 0.2 by CO2 injection coupled to pH monitoring system (pH meter (Mettler Toledo—M300) and a solenoid valve). Cell suspension was maintained at a flow rate of 30.85 L h−1 through an air lift system, and a magnetic stirrer was used to maintain the culture homogeneity in the degasser flask. Two nylon spheres (8 mm) were incorporated to the system aiming to avoid cell adhesion to the tube wall (Pérez-Mora et al. 2016). The reactor total volume was 3.2 L and the illuminated volume was 2.0 L.

Semi-continuous process

Dunaliella. salina was cultivated by semi-continuous process in tubular photobioreactor. The cultivation started as a batch process, and when the cell growth reached the stationary phase (considering 8.4% of error in the determination of this parameter), a previous defined portion of microalgae culture was harvested and the same volume of fresh medium was replenished to start the first cycle of the semi-continuous process. This procedure was repeated until the third cycle. Medium feeding percentages of 20% and 80% were tested. Also, different initial concentrations of NaNO3 (1 N = 75 mg L−1; 1.5 N = 112.5 mg L−1; and 3 N = 225 mg L−1) and NaH2PO4*2H2O (1P = 5.65 mg L−1; 1.5P = 8.47 mg L−1; and 3P = 16.95 mg L−1) were evaluated. At the end of each cycle, cell-free supernatant was submitted to analysis of nitrogen and phosphorus.

Carotenogenesis

As mentioned before, carotenogenesis is induced in the cell by its stress conditions. This step was carried out immediately after each culture harvesting from the photobioreactor, at the end of the initial batch process and each subsequent semi-continuous cycle. 600 mL of microalgae culture collected from the bioreactor was submitted to carotenogenesis induced by increasing light intensity (150 μmol of photons m−2 s−1), nitrogen starvation, and lack of pH control. Carotenogenesis was performed in 3 Erlenmeyer flasks by batch process, containing 200 mL (in each flask), in a rotary shaker at 110 rpm and 24 ± 1 °C. Cell morphology and β-carotene accumulation was optically monitored under a BX 51 microscope (Olympus, Japan). Cells were harvested approximately 3 days after the onset of carotenogenesis, when at least 90% of them turned orange, according to section below. Besides the pH measurement, at the end of carotenogenesis, biomass was harvested for analysis of β-carotene content by HPLC, and cell-free supernatant was submitted to quantification of nitrate and phosphorus according to the sections “Residual Nitrate concentration” and “Residual Phosphorus concentration”, respectively. Additionally, at the end of the third cycle, the remaining cells were kept in the bioreactor and the carotenogenesis took place by continuous illumination, lack of pH control, and lack of the respective fresh medium feeding percentage.

Determination of cell density

Daily or every other day, cell density (cells mL−1) was measured by direct counting the number of cells in a Neubauer chamber using a BX 51 microscope, after fixing Dunaliella salina with Lugol’s iodine solution (ca.0.5%). Before counting cells, the microalgae were observed under the microscope equipped with SC-30 digital camera (Olympus, Japan). The analysis in the microscope was performed to monitor any possible contamination, as well as cell percentage in green phase and in the phase corresponding to carotenoids accumulation.

Analysis in cell-free supernatant

Samples of 50 mL were centrifuged at 2934 g and 10 °C for 20 min and the supernatant was submitted to measurement of nitrate and phosphorus.

Concentration of residual nitrate in the culture medium was determined by indirect colorimetric technique using salicylic acid, in which nitrate is reduced to nitrite (Cataldo et al. 1975). For determination of nitrate, a calibration curve correlating the absorbance (λ = 410 nm) with the sodium nitrate concentration in mM was obtained.

Dissolved inorganic phosphate concentration (mg L−1) was determined by the molybdenum blue phosphorus colorimetric method at λ = 885 nm (Carmouze 1994) using a spectrophotometer, model 700 Plus (Femto, Brazil) and a calibration curve with potassium monobasic phosphate.

Determination of β-carotene concentration

Samples of cell suspension were centrifuged at 3419 g, at 10 °C for 20 min. Cell pellet was washed twice with ammonium formate 1.5 M to remove the salts (Fachet et al. 2016). The wet biomass pellet was stored at –18 °C before β-carotene content analysis. This procedure was carried out at the end of the stress phase in the Erlenmeyer flasks and at the end of the bioreactor culture.

For the ultra-sound carotenoid extraction, 10 mg samples of wet biomass pellet obtained after centrifugation, were mixed with 6 mL of 15% acetone (Cezare-Gomes 2018) and let to extract for 20 min of ultra-sound bath. In this step, cell lysis was confirmed by microscopic observations. Afterwards, 1 mL of the lysate was collected, 6 ml of the extractor solvent (benzene) was added and it was maintained in ultra-sound bath for additional 5 min. The organic phase was separated by centrifugation (10 min at 717 g) at 20 °C, 5 mL of supernatant (organic phase) was collected and evaporated under the flow of nitrogen gas, and dry material was resuspended with chloroform and methanol (1:1). Samples were filtered with syringe filter (0.45 µm) before HPLC analysis. In addition, extractions were performed at 20 °C, under low light conditions.

The β-carotene was quantified by High Performance Liquid Chromatography (HPLC), with the use of a Shimadzu HPLC system and injection volume of 20 µL. The reverse phase chromatographic method was developed using an YMC-Pack Pro C-4 (4.6 mm × 250, 5.0 µm) (YMC, USA) with isocratic elution. The mobile phase consisted of methanol/water (95:5, v/v) at a flow rate of 1 mL min−1. The β-carotene concentration was determined by comparing the peak area (measured at 450 nm) with that of standard (Sigma Aldrich, USA). Calibration curve was constructed for quantification of carotenoid in samples. For the calculation of β-carotene content (Yp/x), biomass dry weight of all harvested samples was determined. In this case, part of wet biomass harvested from the cultivation was dried at 60 °C for 12 h in an oven with air circulation (Arias et al. 2021).

Kinetic parameter

Cell productivity (Px) was calculated using the Eq. (1):

where, Xi and Xm represent the cell density of microalga (cells mL−1) at the beginning of each cycle and maximum cell density, respectively, and tc represents the time correspondent to this variation of cell density.

Statistical analysis

All growth experiments in photobioreactor were performed in duplicate and data were statistically analyzed by analysis of variance (ANOVA), considering them significant when p < 0.05 (confidence level of 95%), with the use of MINITAB 17 software (Minitab Inc., USA).

Results and discussion

Cell growth of Dunaliella salina CCAP 19/18 and its β-carotene production were studied using different fresh medium feeding percentages (20% and 80%) and different concentrations of nitrate and phosphorus in the culture medium in tubular photobioreactor. The cultivations were carried out in two stages: the first one was characterized by cell growth (green phase) in the photobioreactor and the second one (carotenogenesis) was performed in a rotary shaker with the increase of light intensity under nutrient starvation and lack of pH control to induce β-carotene production. The carotenogenesis was also induced at the end of the last cycle of semi-continuous process in the photobioreactor. This induction was performed in the absence of light/dark cycle and by the lack of pH control as well, since higher pH values (8.5–9.0) favor the carotenoids production by D. salina (Dhaka and Singh 2018). Before that, it was not possible to apply such stress, since it is necessary to, first, maintain the best conditions to promote cell growth inside the photobioreactor (first stage).

As pointed out before, D. salina produces β carotene when it is submitted to a stress condition at the end of the cultivation, which was confirmed by our results (Table 1 and microscopic observations). In fact, after about 3 days under stress conditions, more than 90% of the cells presented orange color, irrespective of bioreactor configuration (tubular photobioreactor or Erlenmeyer flask). Although nutrient starvation, high light intensity, and/or high salinity are the most common stressing conditions applied, the lack of pH control is also a critical variable for this phenomenon, especially when environmental issues are considered. It is important to mention that the high salinity stress condition can be achieved by the culture medium reuse, particularly from D. salina culture medium, since in addition to the little information in the literature, the environment will be preserved if the culture medium is not discharged in soil or water bodies increasing their salinity.

During photosynthetic microorganisms’ growth, there is a natural increase in the pH as a consequence of the inorganic carbon source cells consumption (Moheimani 2013). This pH increase is related to the decrease of CO2 and bicarbonate, and increase of carbonate (proportionally) that negatively affect the carbon source assimilation during the microalga green phase (Markou et al. 2014). Therefore, it is important to maintain optimal pH values by, for instance, the CO2 addition, which can be easily dissolved in the culture medium and it is also the preferable source of carbon to photosynthetic organisms (Moheimani 2013). For this reason, in this work, during the cultivation green phase (growth phase), pH was maintained at 7.0 ± 0.2 by adding CO2.

On the other hand, in the second stage, the lack of pH control and consequent pH increase was useful for promoting the carotenoid production. In fact, as it can be seen in Table 1, the pH increased up to values above 9.0 during carotenogenesis. Concerning environmental aspects, at the end of carotenogenesis, the culture medium could be reused after pH adjustment by CO2 addition, which is much easier than desalinization in the case of carotenogenesis induced by high salinity.

Figure 2 (F = 20%; 1 N:1P) and Fig. 3 (F = 80%; 1.5 N:1.5P) show D. salina growth curves from cultivations carried out in different concentrations of nitrogen and phosphorus in f/2 medium and different medium feeding percentages in semi-continuous mode. Although the cells used as inoculum had previously grown in photobioreactor using the cultivation medium 1N:1P, a lag phase was observed for cultivations carried out with medium 1N:1P (initial batch step in Fig. 2), but not with medium 1.5N:1.5P (Fig. 3). D. salina cells were centrifuged prior to inoculation in the photobioreactor. The centrifugation step is likely to damage the cells, thus influencing their growth. Nevertheless, this deleterious effect may be minimized by the use of enriched culture medium (1.5N:1.5P medium).

In fact, this microalga has a fragile membrane, which leads to a low resistance to mechanical forces (García-González et al. 2005) and it could be affected by centrifugal compaction, as it can occur in bacterial cells (Peterson et al. 2012). Regardless the experimental conditions, the absence of lag phases was provided by avoiding centrifugation procedure when preparing the inoculum at the beginning or subsequent cycles in the semi-continuous process (Figs. 2 and 3).

Maximum cell density (Xm) is an important parameter of the process, because besides influencing cell productivity it also directly affects the cost of biomass harvesting. By the values of this parameter showed in Table 2 and Figs. 2 and 3, it is possible to conclude that there was no difference between results of Xm in the first stage: initial batch and semi-continuous processes for a given N:P condition (1N:1P or 1.5 N:1.5P). Xm values are between 3.8 × 105 cells mL−1 and 4.4 × 105 cells mL−1, in runs with 1N:1P, and between 4.8 × 105 cells mL−1 and 5.6 × 105 cells mL−1 in runs with 1.5N:1.5P (Table 2).

For the cultivations carried out as semi-continuous process, there was no variation on cell density independently of the medium feeding percentage (F) (Table 2), even with a high culture withdraw (F = 80%, Fig. 3) and consequent high variation on cell density at each new cycle of cultivation, if compared with F = 20% (Fig. 2). On the other hand, the increase in nutrients’ concentration in the cultivation medium from 1N:1P to 1.5N1.5P allowed an overall increase in cell growth (Table 2).

In fact, in experiments carried out with F = 20%, for medium 1N:1P, the mean value of the three cycles was 4.3 × 105 cells mL−1, whereas for medium 1.5N:1.5P the mean value was 5.3 × 105 cells mL−1. The same behavior under different nutrient concentrations was found when medium feeding percentage of 80% was applied, thus evidencing that the nutrients concentration of 1.5N:1.5P is the best condition for cell growth (p = 0.034, ANOVA). Such results indicate that cultivations carried out with the standard medium (1N:1P) were limited by nutrient. This fact evidence that the standard medium for cultivation of photosynthetic microorganisms, although being properly developed for their growth, may require an increase in some nutrients amount in order to support cell growth in tubular photobioreactor. Such additional demand of nutrient is a consequence of the high cell growth that occurs when closed photobioreactors are used for these microorganisms´ cultivation (Del Campo et al. 2007).

Considering the elemental cell composition and, consequently, nutrient demand, the carbon represents about half of dry cell mass. This demand could be partially supplied by salts (bicarbonate, for example), especially in cultivation that require higher pH values in the cultivation medium, but it is usually supplied by CO2, as it was done in this work. Other essential nutrients, nitrogen and phosphorus, represent about 7% and 1% of dry biomass, respectively, and they need to be added in higher concentrations in the cultivation medium at the beginning of the cultivation process in experiments carried out under batch or semi-continuous processes (Martínez et al. 2000).

In this way, aiming to improve cell growth, experiments were carried out with further addition of nitrogen and phosphorus (medium 3N:3P). In this condition, nitrogen and phosphorus concentrations were equivalent to 2.64 mM and 0.11 mM, respectively. However, no cell growth was observed in such condition, with a clear drop in cell density after 7–8 days of cultivation. Considering that this microorganism grows in high salinity medium (f/2 medium), composed of mainly sea water, this decrease in cell growth was not expected, since the increase in salinity would be negligible, i.e., would increase the f/2 medium salinity from 42.64 to 42.80 g L−1 (Pérez-Mora 2014). In fact, even microalgae that are sensitive to salinity, as Botryococcus braunii, tolerate nitrogen and phosphorus concentrations up to 6.0 mM and 0.30 mM, respectively, without suffering clear inhibition effects (Pérez-Mora et al. 2016) as occurred with D. salina in lower concentrations of these nutrients. These findings point out to the need of a restricted control to find the best condition of nitrogen and phosphorus concentrations for D. salina cultivation.

It can be observed in Table 2 that the residual nitrate concentration is in the range of 0.5–0.7 mM, irrespective of the cultivation medium used for cell growth. This could indicate that D. salina is not able to uptake nitrate from the cultivation medium at concentrations lower than 0.5 mM. This threshold is attained more rapidly for the cultivations carried out with 1N:1P medium, if compared with the runs with 1.5N:1.5P, thus limiting the cell growth that, as previously mentioned, was lower with the use of the former medium. Consequently, because the cell growth for 1N:1P runs was nitrogen limited, the residual phosphorus quantity in these cultivations is higher than in 1.5N:1.5P runs (Table 2).

A well-known advantage of the semi-continuous process is the absence of lag phases at the beginning of every cycle, which results in higher productivities when compared to batch process. In fact, as it can be observed in Table 2, irrespective of the medium composition and medium feeding percentage, there is a sharp increase in cell productivity with the semi-continuous process (p = 0.010, ANOVA) that, in general, is maintained throughout the three cycles of cultivation. An exception is the third cycle of experiments carried out with medium 1N:1P in which, although the maximum cell density had achieved about the same value as those obtained in previous cycles, the time to achieve such values was higher.

For semi-continuous process, in both medium feeding percentage experiments (20% and 80%), it is not possible to state that cell productivity was affected by increasing the quantity of nitrogen and phosphorus in cultivation medium, because despite the higher cell density in this condition, there was an increment in the cultivation time. On the other hand, medium feeding percentage of 20% led to higher cell productivities. This fact is probably a consequence of the low dilution of cell density at each new cycle of semi-continuous cultivation in this condition.

It is also worth mentioning that f/2 medium showed to be adequate for the growth of D. salina. Several studies have already used this medium for culturing this photosynthetic microorganism (Borowitzka 1990; López-Elías et al. 2013; Maadane et al. 2015; Wang et al. 2021). In fact it is a simple and low-cost culture medium (Charioui et al. 2015; Colusse et al. 2020) and seems to be adequate for inducing synthesis and accumulation of carotenoids (Abu-Rezq et al. 2010; Charioui et al. 2015). Another advantage of f/2 medium over higher salinity medium is the possibility of causing lower environmental impact of this technology, in the cases the medium is discharged instead of reused (Morocho-Jácome et al. 2015). Employing this medium, it was possible to naturally and satisfactorily induce the carotenogenesis by lack of nutrients, high pH, and high light intensity, as presented in this study, which makes this procedure an eco-friendly technology. However, higher salinity media could also be employed for this goal, associated with a process in which the medium is recirculated, which could be the subject of further studies.

Dunaliella salina was able to produce β-carotene irrespective of the experimental conditions for cell growth and carotenogenesis induction. However, it was possible to observe differences in the amount of pigment production depending on the nutrient conditions (Figs. 4A and B). In experiments carried out with medium 1N:1P there was a higher variation in the content of β-carotene in dry cell mass (Yp/x), tending to increase this content from the 2nd cycle of process. Therefore, higher values of Yp/x may be obtained when medium 1N:1P is used, because in such condition the cells have remained longer time under nitrogen source starvation. These results were obtained in shaker flasks, as mentioned in “Material and Methods” section.

In this work, cells behavior during β-carotene production in the photobioreactor was also verified. In general, β-carotene production in shaker flasks and in photobioreactor are very similar (Table 1, data corresponding to S3 and bioreactor), thus indicating that both were adequate to promote carotenogenesis. The results of Yp/x obtained in this work are in agreement with results from Garcia-Gonzáles et al. (2003) who obtained values ranging from 34 to 78 mg g−1, depending on the strain of D. salina.

Dunaliella salina cells morphology and behavior, in green and orange phases, were microscopically examined. During the green phase, most of the cells presented mobility (biflagellate) and ellipsoidal shape, but spherical shape was also observed (Fig. 5).

Similar cell behavior was observed in 1.5N:1.5P runs in the green phase. However, in 3N:3P runs, cells did not present morphological differences if compared to those grown in media with lower nutrient concentrations, and from 7to 8 days of culture a process of cell lysis started.

When the culture was submitted to the conditions that led to carotenogenesis, the cells presented predominantly spherical morphology, with loss of mobility and, in some cases, an increase in volume was also noticed. This same behavior was found by Solovchenko et al. (2015). In the carotenogenesis phase, there was a gradual change from green to orange color, so that, as previously commented, more than 90% of the cells presented this characteristic after 3 days.

During the green phase in photobioreactor, no contamination by protozoa was observed, likely because its closed shape helps to prevent contamination (Del Campo et al. 2007). As the cells were aseptically collected from photobioreactor and transferred to Erlenmeyer flasks, even in carotenogenesis phase, no contamination by protozoa was observed.

Conclusions

Dunaliella salina cultivation by semi-continuous process is feasible for β-carotene production. In comparison with initial batch process, semi-continuous process provided higher cell productivities (Px up to 6.7 × 104 cells mL−1 d−1). Regardless of medium feeding percentage, the best results of maximum cell density were achieved when using cultivation medium 1.5N:1.5P (Xm = 5.6 × 105 cells mL−1). β-carotene content was, instead, higher in cells grown in medium 1N:1P (Yp/x = 57.5 mg g−1). The closed tubular photobioreactor, under 12 h light/12 h dark cycle, contributed to successfully cultivate D. salina without protozoa contamination. Moreover, high pH and light intensity as stress conditions showed to be an excellent protocol for carotenogenesis.

Code availability

Not applicable.

References

Abu-Rezq TS, Al-Hooti S, Jacob D et al (2010) Induction and extraction of β-carotene from the locally isolated Dunaliella salina. J Algal Biomass Util 1:58–83

Ahmed F, Fanning K, Netzel M et al (2014) Profiling of carotenoids and antioxidant capacity of microalgae from subtropical coastal and brackish waters. Food Chem 165:300–306. https://doi.org/10.1016/j.foodchem.2014.05.107

Arias CAD, Matsudo MC, Ferreira-Camargo LS et al (2021) Semicontinuous system for the production of recombinant mCherry protein in Chlamydomonas reinhardtii. Biotechnol Prog 37:1–7. https://doi.org/10.1002/btpr.3101

Bhosale P, Bernstein PS (2005) Microbial xanthophylls. Appl Microbiol Biotechnol 68:445–455. https://doi.org/10.1007/s00253-005-0032-8

Blanco AM, Moreno J, Del Campo JA et al (2007) Outdoor cultivation of lutein-rich cells of Muriellopsis sp. in open ponds. Appl Microbiol Biotechnol 73:1259–1266. https://doi.org/10.1007/s00253-006-0598-9

Borowitzka MA (1990) The mass culture of Dunaliella salina. In: Tech Resour Pap Reg Work Cult Util Seaweeds 2 Reg Seafar Dev Demonstr Proj FAO Netw Aquac Centres, pp 63–80

Borowitzka MA (2013) High-value products from microalgae-their development and commercialisation. J Appl Phycol 25:743–756. https://doi.org/10.1007/s10811-013-9983-9

Carmouze JP (1994) O metabolismo dos ecossistemas aquáticos : fundamentos teóricos, métodos de estudo e análises químicas. Edgard Blucher, Brazil

Carvalho JCM, Matsudo MC, Bezerra RP et al (2014) Microalgae bioreactors. In: Bajpai R, Prokop A, Zappi M (eds) Algal biorefineries cultivation of cells and products, vol 1. Springer, Dordrecht, pp 83–126

Cataldo DA, Maroon M, Schrader LE, Youngs VL (1975) Rapid colorimetric determination of nitrate in plant tissue by nitration of salicylic acid1. Commun Soil Sci Plant Anal 6:71–80. https://doi.org/10.1080/00103627509366547

Cezare-Gomes E (2018) Evaluation of Dunaliella salina growth and corresponding β-carotene production in tubular photobioreactor. In: University of Sao Paulo

Cezare-Gomes EA, Mejia-da-Silva LC, Pérez-Mora LS et al (2019) Potential of microalgae carotenoids for industrial application. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-018-02945-4

Charioui I, Chikhaoui M, El FF et al (2015) Effect of the medium culture on cells growth and accumulation of carotenoids in microalgae hypersaline Dunaliella sp. isolated from salt ponds of the region of Essaouira in Morocco. Appl J Environ Eng Sci 2:85–91

Colusse GA, Mendes CRB, Duarte MER et al (2020) Effects of different culture media on physiological features and laboratory scale production cost of Dunaliella salina. Biotechnol Rep 27:e00508. https://doi.org/10.1016/j.btre.2020.e00508

Dahmen-Ben Moussa I, Chtourou H, Karray F et al (2017) Nitrogen or phosphorus repletion strategies for enhancing lipid or carotenoid production from Tetraselmis marina. Bioresour Technol 238:325–332. https://doi.org/10.1016/j.biortech.2017.04.008

De Jesus Raposo MF, De Morais AMMB, De Morais RMSC (2015) Carotenoids from marine microalgae: a valuable natural source for the prevention of chronic diseases. Mar Drugs 13:5128–5155. https://doi.org/10.3390/md13085128

Del Campo JA, Moreno J, Rodríguez H et al (2000) Carotenoid content of chlorophycean microalgae: factors determining lutein accumulation in Muriellopsis sp. (Chlorophyta). J Biotechnol 76:51–59. https://doi.org/10.1016/S0168-1656(99)00178-9

Del Campo JA, García-González M, Guerrero MG (2007) Outdoor cultivation of microalgae for carotenoid production: current state and perspectives. Appl Microbiol Biotechnol 74:1163–1174. https://doi.org/10.1007/s00253-007-0844-9

Dhaka P, Singh GP (2018) Effect of pH on growth and biopigment accumulation of green alga Dunaliella salina. Int J Pharm Sci Res 9:271–276. https://doi.org/10.13040/IJPSR.0975-8232.9(1).271-76

Dineshkumar R, Subramanian G, Dash SK, Sen R (2016) Development of an optimal light-feeding strategy coupled with semi-continuous reactor operation for simultaneous improvement of microalgal photosynthetic efficiency, lutein production and CO2 sequestration. Biochem Eng J 113:47–56. https://doi.org/10.1016/j.bej.2016.05.011

Fachet M, Hermsdorf D, Rihko-Struckmann L, Sundmacher K (2016) Flow cytometry enables dynamic tracking of algal stress response: a case study using carotenogenesis in Dunaliella salina. Algal Res 13:227–234. https://doi.org/10.1016/j.algal.2015.11.014

Ferreira LS, Rodrigues MS, Converti A et al (2012) Arthrospira (Spirulina) platensis cultivation in tubular photobioreactor: use of no-cost CO2 from ethanol fermentation. Appl Energy 92:379–385. https://doi.org/10.1016/j.apenergy.2011.11.019

García-González M, Moreno J, Cañavate JP et al (2003) Conditions for open-air outdoor culture of Dunaliella salina in southern Spain. J Appl Phycol 15:177–184. https://doi.org/10.1023/A:1023892520443

García-González M, Moreno J, Manzano JC et al (2005) Production of Dunaliella salina biomass rich in 9-cis-β-carotene and lutein in a closed tubular photobioreactor. J Biotechnol 115:81–90. https://doi.org/10.1016/j.jbiotec.2004.07.010

Guedes AC, Amaro HM, Malcata FX (2011) Microalgae as sources of carotenoids. Mar Drugs 9:625–644. https://doi.org/10.3390/md9040625

Guermazi W, Masmoudi S, Boukhris S et al (2014) Under low irradiation, the light regime modifies growth and metabolite production in various species of microalgae. J Appl Phycol 26:2283–2293. https://doi.org/10.1007/s10811-014-0260-3

Guillard RRL (1975) Culture of phytoplankton for feeding marine invertebrates. In: Smith WL, Chanley MH (eds) Culture of marine invertebrates animals, 1st edn. Plenum Press, New York, pp 29–60

Ho SH, Xie Y, Chan MC et al (2015) Effects of nitrogen source availability and bioreactor operating strategies on lutein production with Scenedesmus obliquus FSP-3. Bioresour Technol 184:131–138. https://doi.org/10.1016/j.biortech.2014.10.062

Hu CC, Lin JT, Lu FJ et al (2008) Determination of carotenoids in Dunaliella salina cultivated in Taiwan and antioxidant capacity of the algal carotenoid extract. Food Chem 109:439–446. https://doi.org/10.1016/j.foodchem.2007.12.043

López-Elías JA, Fimbres-Olivarría D, Medina-Juárez LA et al (2013) Production of biomass and carotenoids of dunaliella tertiolecta in nitrogen-limited cultures. Phyton (b Aires) 82:23–30. https://doi.org/10.32604/phyton.2013.82.023

Maadane A, Merghoub N, Ainane T et al (2015) Antioxidant activity of some Moroccan marine microalgae: Pufa profiles, carotenoids and phenolic content. J Biotechnol 215:13–19. https://doi.org/10.1016/j.jbiotec.2015.06.400

Markou G, Vandamme D, Muylaert K (2014) Microalgal and cyanobacterial cultivation: the supply of nutrients. Water Res 65:186–202. https://doi.org/10.1016/j.watres.2014.07.025

Martínez M, Sanchez S, Jimenez JM et al (2000) Nitrogen and phosphorus removal from urban wastewater by the microalga Scenedesmus obliquus. Bioresour Technol 73:263–272. https://doi.org/10.1016/S0960-8524(99)00121-2

Matos ÂP (2017) The impact of microalgae in food science and technology. JAOCS J Am Oil Chem Soc 94:1333–1350. https://doi.org/10.1007/s11746-017-3050-7

Matsudo MC, Bezerra RP, Converti A et al (2011) CO2 from alcoholic fermentation for continuous cultivation of Arthrospira (Spirulina) platensis in tubular photobioreactor using urea as nitrogen source. Biotechnol Prog. https://doi.org/10.1002/btpr.581

Mendoza H, Jiménez Del Río M, García Reina G, Ramazanov Z (1996) Low-temperature-induced β-carotene and fatty acid synthesis, and ultrastructural reorganization of the chloroplast in Dunaliella salina (chlorophyta). Eur J Phycol 31:329–331. https://doi.org/10.1080/09670269600651551

Moheimani NR (2013) Inorganic carbon and pH effect on growth and lipid productivity of Tetraselmis suecica and Chlorella sp (Chlorophyta) grown outdoors in bag photobioreactors. J Appl Phycol 25:387–398. https://doi.org/10.1007/s10811-012-9873-6

Morocho-Jácome AL, Mascioli GF, Carvalho JCM (2015) Continuous cultivation of Arthrospira platensis using exhausted medium treated with granular activated carbon. J Hydrol 522:467–474. https://doi.org/10.1016/j.jhydrol.2015.01.001

Paliwal C, Mitra M, Bhayani K et al (2017) Abiotic stresses as tools for metabolites in microalgae. Bioresour Technol 244:1216–1226. https://doi.org/10.1016/j.biortech.2017.05.058

Pérez-Mora LS (2014) Avaliação do crescimento de Botryococcus braunii em reator tubular empregando diferentes concentrações de fontes de nitrogênio e fósforo. In: University of Sao Paulo

Pérez-Mora LS, Matsudo MC, Cezare-Gomes EA, Carvalho JCM (2016) An investigation into producing Botryococcus braunii in a tubular photobioreactor. J Chem Technol Biotechnol 91:3053–3060. https://doi.org/10.1002/jctb.4934

Peterson BW, Sharma PK, van der Mei HC, Busscher HJ (2012) Bacterial cell surface damage due to centrifugal compaction. Appl Environ Microbiol 78:120–125. https://doi.org/10.1128/AEM.06780-11

Pires JCM, Alvim-Ferraz MCM, Martins FG (2017) Photobioreactor design for microalgae production through computational fluid dynamics: a review. Renew Sustain Energy Rev 79:248–254. https://doi.org/10.1016/j.rser.2017.05.064

Prieto A, Pedro Cañavate J, García-González M (2011) Assessment of carotenoid production by Dunaliella salina in different culture systems and operation regimes. J Biotechnol 151:180–185. https://doi.org/10.1016/j.jbiotec.2010.11.011

Priyadarshani I, Rath B (2012) Commercial and industrial applications of micro algae—a review. J Algal Biomass Ulit 3:89–100

Saini RK, Nile SH, Park SW (2015) Carotenoids from fruits and vegetables: chemistry, analysis, occurrence, bioavailability and biological activities. Food Res Int 76:735–750. https://doi.org/10.1016/j.foodres.2015.07.047

Sathasivam R, Ki JS (2018) A review of the biological activities of microalgal carotenoids and their potential use in healthcare and cosmetic industries. Mar Drugs. https://doi.org/10.3390/md16010026

Solovchenko AE (2013) Physiology and adaptive significance of secondary carotenogenesis in green microalgae. Russ J Plant Physiol 60:1–13. https://doi.org/10.1134/S1021443713010081

Solovchenko AE, Selivanova EA, Chekanov KA et al (2015) Induction of secondary carotenogenesis in new halophile microalgae from the genus Dunaliella (Chlorophyceae). Biochemistry 80:1508–1513. https://doi.org/10.1134/S0006297915110139

Wang X, Zhang MM, Liu SF et al (2021) Synergistic bioconversion of lipids and carotenoids from food waste by Dunaliella salina with fulvic acid via a two-stage cultivation strategy. Energy Convers Manag 234:113908. https://doi.org/10.1016/j.enconman.2021.113908

Xu Y, Ibrahim IM, Harvey PJ (2016) The influence of photoperiod and light intensity on the growth and photosynthesis of Dunaliella salina (chlorophyta) CCAP 19/30. Plant Physiol Biochem 106:305–315. https://doi.org/10.1016/j.plaphy.2016.05.021

Acknowledgements

The authors acknowledge CAPES – Brazil (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Finance Code 001) and Engineer Lucas Cezere Vidal for drawing Figure 1.

Funding

Capes (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Brazil), finance code 001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cezare-Gomes, E.A., Lousada, M.E.G., Matsudo, M.C. et al. Two-stage semi-continuous cultivation of Dunaliella salina for β-carotene production. Braz. J. Chem. Eng. 40, 367–378 (2023). https://doi.org/10.1007/s43153-022-00246-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-022-00246-2