Abstract

Perovskite oxide La0.6Ca0.4Fe0.8Ni0.2O3−δ (LCFN) has been used in symmetric solid oxide cells (SSOCs) to obtain good electrochemical performance in both fuel cells (SOFCs) and electrolysis cells (SOECs) modes. However, its structural stability still faces challenges and the electrocatalytic activity also needs to be further improved. Herein, tungsten-doped La0.6Ca0.4Fe0.7Ni0.2W0.1O3−δ (LCFNW) perovskite oxide material was synthesized which exhibits good structural stability under H2 and superior electrochemical performance as an electrode for SSOCs. In SOFCs mode, the cell achieved the maximum power density of 0.58 W·cm−2 with wet H2 as fuel at 850 °C. In SOECs mode, the current density can reach 1.81 A·cm−2 for pure CO2 electrolysis at 2 V. Moreover, the SSOCs exhibits outstanding long-term stability in both SOFCs and SOECs modes, proving that doping W in perovskite oxide is an effective strategy to enhance the catalytic activity and stability of the electrode. The LCFNW material developed in this work shows promising prospect as an electrode candidate for SSOCs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solid oxide cells (SOCs) can efficiently convert chemical energy into electricity in solid oxide fuel cells (SOFCs) mode, which has the special advantages of flexible fuel, high energy conversion efficiency, high power density and low environmental pollution [1, 2]. In addition, it can also operate reversely as solid oxide electrolysis cells (SOECs), using renewable energy to electrolyze H2O to produce H2 [3], electrolyze CO2 to reduce carbon emissions [4], and co-electrolyze H2O–CO2 to produce syngas for subsequent chemical production [5]. A traditional SOCs is composed of dense electrolyte, porous perovskite oxide air electrode and porous metal cermet fuel electrode. However, there is a high risk of carbon deposition and sulfur poisoning for Ni-based cermet electrode [6]. Moreover, Ni-based cermet electrodes also face the problem of redox instability, metal agglomeration and growth [7], etc. In addition, traditional perovskite oxide cathodes such as La0.8Sr0.2MnO3−δ (LSM) and La0.6Sr0.4Co0.2Fe0.8O3−δ (LSCF) still have problems such as poor activity and stability [8, 9]. Therefore, it is urgent to develop high electrocatalytic activity and stable oxide materials as SOCs air electrode and fuel electrode. If the fuel electrode and air electrode use the same material, named symmetric solid oxide cells (SSOCs), it can greatly reduce the manufacturing cost and improve the compatibility between electrolyte and electrode. Moreover, this unique symmetric structure can be flexibly switched between SOFCs mode and SOECs mode, which have attracted great attention [10,11,12].

As shown in Fig. 1, the electrode needs to meet high catalytic activity requirements towards hydrogen oxide reaction (HOR) and oxygen reduction reaction (ORR) in SOFCs mode, and carbon dioxide reduction reaction (CO2RR) and oxygen evolution reaction (OER) in SOECs mode, all of which need to be implemented on the same material, so the electrode materials are the key to the development of symmetric cells. Badding et al. [13] first proposed the concept of symmetrical cell in 2003. Since then, many new materials have been developed for SSOCs. For example, Fan et al. [14] used nanoporous Sm0.95Ce0.05FeO3−δ as electrode, the maximum power density of 130 mW·cm−2 can be achieved in pure H2 at 800 °C. Ma et al. [15] used Ni doped La0.6Sr0.4FeO3−δ (LSFN) as electrode material, and prepared symmetric cell by the impregnation method. Using C3H8 and CH4 as fuel, it was found that the electrode showed good stability in long-term test and had good catalytic activity for hydrocarbon fuel oxidation. Rath et al. [16] developed a novel double perovskite electrode Sr2ScTi1−xMoxO6, which confirmed that the electrode exhibited excellent catalytic activity for the oxidation of hydrogen and methane as well as the oxygen reduction reaction. The maximum power density of La0.8Sr0.2Ca0.8Mg0.2O3−δ (LSGM) electrolyte-supported Sr0.8Ce0.2FeO3 symmetric fuel cell reaches 482 mW·cm−2 at 800 ℃, and it also shows good structural stability [17]. Although the development of symmetric cells with these materials have seen significant progress in recent years, their electrochemical performance is still inferior to conventional cells. Therefore, it is imperative to develop novel SSOCs electrode materials with high catalytic activity and stability.

LaFeO3 perovskite material has good structural stability and electrocatalytic activity. The well-known LSCF material is derived from it [18]. Although LSCF has achieved good electrochemical performance as a SOCs electrode, its stability still faces challenges, mainly because Sr easily segregates at high temperature and current polarization, and easily reacts with CO2 to form SrCO3 which leads to the degradation of the catalytic performance of the electrode [19]. In addition, the high thermal expansion coefficient of LSCF leads to the weak binding of the electrode–electrolyte interface [20]. In our previous work [21, 22], La0.6Ca0.4Fe0.8Ni0.2O3−δ (LCFN) was synthesized by replacing Sr and Co with Ca and Ni, respectively, to obtain higher electrical conductivity, lower thermal expansion coefficient, and higher electrochemical performance. However, whether it is LSCF or LCFN, its structural stability under H2 is insufficient. Therefore, it is urgent to improve its structural stability.

Many studies have shown that high-valence metal such as Ti, Nb, V, Sc doping perovskite oxides can effectively improve the electrocatalytic activity and structural stability of the material [23,24,25,26,27]. Herein, W was selected as the B-site doping element and the prepared La0.6Ca0.4Fe0.7Ni0.2W0.1O3−δ (LCFNW) showed excellent structural stability, high electrical conductivity, and low thermal expansion coefficient. Good electrochemical performance has also been achieved as an electrode for SSOCs. In SOFCs mode, the cell achieved the maximum power density of 0.58 W·cm−2 with wet H2 as fuel at 850 °C. In SOECs mode, the current density can reach 1.81 A·cm−2 for pure CO2 electrolysis at 2 V. The cell also shows good stability in both SOFCs and SOECs modes.

2 Experimental

2.1 Synthesis of powder

The raw material La(NO3)3, Ca(NO3)2, Fe(NO3)3, Ni(NO3)2 and H40N10O41W12·xH2O was weighed according to the stoichiometric ratio of LCFNW and were dissolved in deionized water. Then, citric acid (CA) and ethylenediaminetetraacetic acid (EDTA) were added according to the molar ratio of metal ions: CA: EDTA of 1:1:1.5. Ammonia solution was then added with continuous stirring until the pH value of the solution was 8. The gel was formed after the water evaporated and then dried at 240 °C to obtain the precursor. Finally, the precursor was fully ground in a mortar and calcined at 1200 °C in a muffle furnace to obtain the required electrode powders. LCFN powders was also prepared by the same method.

2.2 Preparation of cells

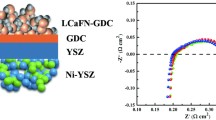

Y0.08Zr0.92O2−δ (YSZ) electrolytes with 12 mm in diameter and 0.3 mm in thickness were prepared by tape casting method. Then it was placed in a furnace and sintered at 1500 °C for 10 h to obtain the dense electrolyte. Gd0.1Ce0.9O2−δ (GDC) was used as a buffer layer to prevent phase reactions between electrode and YSZ. The GDC slurry was coated on both sides of the YSZ electrolyte and then calcined at 1300 °C for 5 h. LCFNW electrode slurry was prepared by mixing LCFNW powder with the binder at a mass ratio of 6:4. The prepared LCFNW slurry was coated on both sides of the electrolyte and calcined in air at 1000 °C for 2 h. For LCFNW-GDC composite electrode. The mass ratio of LCFNW to GDC is 6:4. Silver paste was coated on the surface of the cell as the current collector.

2.3 Characterization and cell measurement

X-ray diffraction (XRD Shimadzu XRD-7000S, voltage: 40 kV, current: 30 mA, angle range 20°–80°, scanning speed: 10°·min−1) was used to analyze the phase structure of the material. The microstructure of the samples was analyzed by Scanning Electron Microscope (SEM Sirion 200). The LCFNW electrode powder was pressed into 24 mm × 6 mm × 2 mm bar sample by dry pressing method and sintered at 1250 °C for 5 h for subsequent thermal expansion coefficient and conductivity test. The conductivity of LCFNW bar sample was measured by Agilent B2901A Precision Source/Measurement unit using a four-probe method. The thermal expansion coefficient of the material was tested by a thermal dilatometer (NETZSCH DIL402C, Germany). The electrochemical performance of the cell was tested by Zahner IM6 Electrochemical Workstation. The SOFCs performance with wet H2 as fuel and the SOECs performance of electrolytic pure CO2 were explored through AC impedance spectroscopy, current–voltage curve test and stability test at different temperatures.

3 Results and discussion

3.1 Physicochemical properties

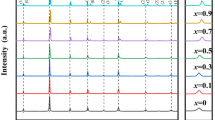

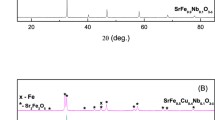

Figure 2a shows the XRD patterns of LCFN and LCFNW powders synthesized by sol–gel method. It can be seen that both samples have a good perovskite structure according to PDF card#82-1946. However, some minor unknown phase exists in LCFNW. In fact, these unknown phase does not affect the catalytic performance of the electrode material, which will be investigated later. It is worth mentioning that the crystal structure of LCFNW after treated in H2 at 800 °C for 5 h (named R-LCFNW) remains stable. However, the structure of LCFN was destroyed under the same reduction conditions. In addition, the peak at about 44° represents the exsolution of Fe–Ni alloy, indicating that the nano-alloy particles are in situ exsolved from the R-LCFNW. Moreover, when LCFNW and GDC mixed with a mass ratio of 1:1 was calcined at 1000 °C for 5 h, no impurity peaks appeared as shown in Fig. 2b, which proved that LCFNW and GDC had good chemical compatibility. Overall, W doping can effectively improve the stability of the LCFN crystal structure.

Figure 3a shows the conductivity test results of LCFNW in air. It can be seen that the conductivity increases with the increase of temperature, showing the semiconductor conductive properties. The conductivity reaches the maximum of 15 S·cm−1 at about 800 °C. With the increase of temperature, the small polaron (Fe4+, Fe3+, Ni2+, W6+)–O2−–(Fe2+, Ni+, W4+) activity induced by thermal excitation increases, resulting in the improvement of conductivity. When the temperature reaches a certain level (> 800 °C), some Fe3+, Ni2+, W6+ metal cations will undergo thermal reduction reaction, and transform into low-valence cations, resulting in the formation of oxygen vacancies. This will reduce the carrier concentration and eventually leads to the decrease of conductivity [28]. Figure 3b is the measured thermal expansion curve of LCFNW. After calculation, the average thermal expansion coefficient (TEC) is 12.77 × 10–6 K−1, which is very close to the thermal expansion coefficient of GDC (12 × 10–6 K−1) [29]. Moreover, the TEC value is also much lower than that of Co-based electrode materials such as SrCo0.9Nb0.1O3−δ (24.2 × 10–6 K−1) [30], La0.3Sr0.7Ti0.7Co0.3O3−δ (20.7 × 10–6 K−1) [31], Ba0.5Sr0.5Co0.8Fe0.2O3−δ (21.6 × 10–6 K−1) [32]. Having a TEC value close to GDC can make the electrode and GDC barrier layer well-adhered and result in decent thermal mechanical compatibility, which is beneficial to the long-term stability of the cell. It is worth noting that the TEC of LCFNW increases more significantly over 800 °C. Because the valence of metal cations changes at high temperature, resulting in the escape of lattice oxygen and the formation of oxygen vacancies, it thereby leads to a change in the slope of the thermal expansion curve. This is also consistent with the previous turning point for conductivity results.

3.2 Electrochemical performance in SOFCs mode

Figure 4a shows the I–V–P curves and b Electrochemical impedance spectrum (EIS) of the symmetric cell with pure LCFNW electrode at different temperatures when using wet H2 as fuel. The open circuit voltage (OCV) is basically consistent with the theoretical OCV calculated by the Nernst equation, indicating the good tightness of YSZ electrolyte and well sealing of the cell. Figure 4a shows the maximum power density (MPD) of the symmetric cell at 750, 800 and 850 °C, which is 0.110, 0.211, 0.327 W·cm−2, respectively. Moreover, the I–V–P curve did not show noticeable concentration polarization phenomenon. For EIS as shown in Fig. 4b, the ohmic resistance (Rs) of symmetric cell at 750, 800 and 850 °C is 1.65, 0.86 and 0.58 Ω·cm2; and the polarization resistance (Rp) are 1.06, 0.46 and 0.32 Ω·cm2, respectively. It can be seen that Rs and Rp decrease greatly with the increase of temperature. Increasing the temperature is beneficial to the ion transport of the electrolyte and the improvement of the electrochemical activity.

In order to further enhance the electrocatalytic activity of the electrode, LCFNW-GDC composite electrode was prepared and the I–V–P curves of LCFNW-GDC symmetric cell at different temperatures were shown in Fig. 4c. The MPD of the symmetrical cell at 700, 750, 800 and 850 °C is 0.11, 0.25, 0.38 and 0.58 W·cm−2, respectively. Compared with pure LCFNW electrodes, the power density has been significantly improved. Moreover, compared with previous studies as listed in Table 1, The performance is also good, suggesting that the W doping LCFN can reinforce the electrocatalytic performance of electrode materials. Figure 4d shows the EIS of LCFNW-GDC symmetric cell at different temperatures. The Rs and Rp of the cell at 700, 750, 800 and 850 °C is 1.07, 0.56, 0.38, 0.26 Ω·cm2 and 0.77, 0.36, 0.25 and 0.18 Ω·cm2, respectively. And the Rp is also lower than pure LCFNW electrode and other electrodes such as the SmBaMn2O5+δ (1.23 Ω·cm2) [40], Sr2ScTi0.9Mo0.1O6 (0.29 Ω·cm2) at 800 °C [16]. In brief, higher MPD and lower Rp demonstrate the good HOR and ORR catalytic activity of LCFNW.

3.3 Electrochemical performance in SOECs mode

Figure 5a is the I–V curves of LCFNW-GDC symmetric cell for pure CO2 electrolysis at different temperatures. It can be seen that the current density gradually rises with the increase of applied voltage. When the electrolysis voltage is greater than 1 V, the electrolysis current density increases rapidly with the increase of voltage, indicating the electrolysis process of CO2 begins. With the increase of temperature, the maximum current densities of 0.88, 1.34 and 1.8 A·cm−2 at 750, 800 and 850 °C can be achieved at 2.0 V, respectively. Figure 5b is EIS of LCFNW-GDC cell at different temperatures. It is found that the Rs and Rp of the cell decrease with the increase of temperature. At 750, 800 and 850 °C, the Rs and Rp of the cell were 1.60, 1.26, 1.11 Ω·cm2 and 3.40, 1.93, 1.27 Ω·cm2, respectively. The electrolysis performance is also better than other symmetric cells such as La0.3Sr0.7Fe0.7Ti0.3O3 (0.521 A·cm−2) [41], La0.3Sr0.7Fe0.7Cr0.3O3−δ (0.41A·cm−2@1.5 V) [42], La0.6Sr0.4Fe0.9Mn0.1O3−δ (1.107 A·cm−2@2.0 V) [43] at 800 °C, etc. In short, the LCFNW electrode has good CO2RR catalytic activity and OER catalytic activity.

3.4 Stability test in SOFCs and SOECs mode

To test the stability of the LCFNW-GDC symmetric cell in SOFCs mode, both the short-term and long-term durability tests at 0.7 V were measured as shown in Fig. 6a, b. It can be seen the performance of the cell keeps all stable in short-term and long-term tests at 750 °C and 700 °C. Moreover, the EIS of the cell before and after the stability test was measured as shown in Fig. 6c. It can be seen that the Rs and Rp of the cell are slightly reduced after stability test. The reason may be due to the exsolution of a large number of Fe–Ni alloy nanoparticles on the surface of LCFNW under high temperature and reducing atmosphere, which is beneficial to the electrocatalytic and conductivity of LCFNW electrode. It is also confirmed by the XRD results mentioned before.

Figure 7a is the EIS of the symmetric cell measured at 1.4 V for pure CO2 electrolysis at different temperatures. At 750, 800 and 850 °C, the Rs and Rp of the cell were 1.32, 0.87, 0.59 Ω·cm2 and 2.57, 1.62, 0.50 Ω·cm2, respectively. It can be found that the higher the temperature, the smaller the Rs and Rp. At the same time, the durability tests under different voltages were also carried out as shown in Fig. 7b. It can be seen that the cell performance is relatively stable at low voltage, but with the increase of the electrolysis voltage, the cell performance is slightly attenuated, the reason may be that the lack of CO2 in the cathode gas and the slow oxygen evolution reaction (OER) of the cell at high voltage cause the cell performance degradation [44]. Therefore, LCFNW symmetric cell is suitable for operation under 1.4 V. Figure 7c shows the stability test of LCFNW-GDC symmetric cell for pure CO2 electrolysis at 750 °C for 40 h at 1.4 V. The current density gradually decreased in the first 10 h, then it remained steady at around 100 mA·cm−2. Overall, the LCFNW electrode has good stability for pure CO2 electrolysis.

The microstructure of the symmetric cell after the stability test is shown in Fig. 8. As can be seen from Fig. 8a, c, both the cathode and anode were tightly bound to the GDC layer. There is still existing a good electrode/electrolyte interface with no signs of cracking and delamination after SOFCs and SOECs stability test. The thickness of the electrodes and the GDC barrier is about 20 μm and 5 μm, respectively. The electrodes had porous microstructure and uniform particle size distribution as shown in Fig. 8b, d, which provides more electrocatalytic active sites for the electrochemical reaction. The nanoparticles can be found on the surface of the cathode side after reduction, which is beneficial to the electrocatalytic activity of the electrode.

4 Conclusion

In this work, the LCFNW electrode powder was synthesized by the sol–gel method, and the LCFNW-GDC|GDC|YSZ|GDC|LCFNW-GDC symmetric cell was prepared and showed good electrochemical performance both in SOFCs and SOECs modes. The LCFNW can maintain a stable perovskite structure both in air and hydrogen atmosphere. In SOFCs mode, the symmetric cell based on LCFNW-GDC composite electrode can achieve a maximum power density of 0.38 W·cm−2 and a Rp of 0.24 Ω·cm2 at 800 °C. In SOECs mode, the maximum current density of the symmetric cell for pure CO2 electrolysis at 800 °C can reach 1.34 A·cm−2. Both Rs and Rp decrease with increasing applied voltage and temperature. In addition, the cell shows good stability in both SOFCs and SOECs modes, and the cell microstructure also remains decent after the stability test. The results show that LCFNW has good electrocatalytic activity and stability, which confirms that doping tungsten is indeed beneficial to improve the electrocatalytic activity of perovskite oxide. Tungsten doping strategy can also be extended to other electrocatalytic fields such as metal-air batteries, ammonia synthesis, etc.

Data availability

The raw/processed data can be provided on the reasonable request.

References

Xu Q, Guo Z, Xia L, He Q, Li Z, Bello IT, Zheng K, Ni M. A comprehensive review of solid oxide fuel cells operating on various promising alternative fuels. Energy Convers Manag. 2022;253:115175.

Ndubuisi A, Abouali S, Singh K, Thangadurai V. Recent advances, practical challenges, and perspectives of intermediate temperature solid oxide fuel cell cathodes. J Mater Chem A. 2022;10(5):2196.

Shimada H, Yamaguchi T, Kishimoto H, Sumi H, Yamaguchi Y, Nomura K, Fujishiro Y. Nanocomposite electrodes for high current density over 3 A·cm-2 in solid oxide electrolysis cells. Nat Commun. 2019;10:1.

Song Y, Zhang X, Xie K, Wang G, Bao X. High-temperature CO2 electrolysis in solid oxide electrolysis cells: developments, challenges, and prospects. Adv Mater. 2019;31(50):1902033.

Bian L, Duan C, Wang L, Chen Z, Hou Y, Peng J, Song X, An S, O’Hayre R. An all-oxide electrolysis cells for syngas production with tunable H2/CO yield via co-electrolysis of H2O and CO2. J Power Sources. 2021;482:228887.

Qiu P, Sun S, Yang X, Chen F, Xiong C, Jia L, Li J. A review on anode on-cell catalyst reforming layer for direct methane solid oxide fuel cells. Int J Hydrogen Energy. 2021;46(49):25208.

Pan J, Ye Y, Zhou M, Sun X, Ling Y, Yashiro K, Chen Y. Improving the activity and stability of Ni-based electrodes for solid oxide cells through surface engineering: recent progress and future perspectives. Mater Rep Energy. 2021;1(2):100025.

Mosiałek M, Zimowska M, Kharytonau D, Komenda A, Górski M, Krzan M. Improvement of La0.8Sr0.2MnO3−δ cathode material for solid oxide fuel cells by addition of YFe0.5Co0.5O3. Materials. 2022;15(2):642.

Zhuang Z, Li Y, Yu R, Xia L, Yang J, Lang Z, Zhu J, Huang J, Wang J, Wang Y. Reversely trapping atoms from a perovskite surface for high-performance and durable fuel cell cathodes. Nat Catal. 2022;5:300.

Zhu K, Luo B, Liu Z, Wen X. Recent advances and prospects of symmetrical solid oxide fuel cells. Ceram Int. 2022;48(7):8972.

Tian Y, Abhishek N, Yang C, Yang R, Choi S, Chi B, Pu J, Ling Y, Irvine JT, Kim G. Progress and potential for symmetrical solid oxide electrolysis cells. Matter. 2022;5(2):482.

Tian Y, Zheng H, Zhang L, Chi B, Pu J, Li J. Direct electrolysis of CO2 in symmetrical solid oxide electrolysis cell based on La0.6Sr0.4Fe0.8Ni0.2O3−δ electrode. J Electrochem Soc. 2018;165:F17.

Badding ME, Brown JL, Ketcham TD, Julien DJS. Solid oxide fuel cells with symmetric composite electrodes. US Patents: US6630267B2; 2003.

Fan W, Sun Z, Wang J, Zhou J, Wu K, Cheng Y. A new family of Ce-doped SmFeO3 perovskite for application in symmetrical solid oxide fuel cells. J Power Sources. 2016;312:223.

Ma Z, Sun C, Ma C, Wu H, Zhan Z, Chen L. Ni doped La0.6Sr0.4FeO3−δ symmetrical electrode for solid oxide fuel cells. Chin J Catal. 2016;37(8):1347.

Rath MK, Kossenko A, Zinigrad M, Kalashnikov A. In-operando gas switching to suppress the degradation of symmetrical solid oxide fuel cells. J Power Sources. 2020;476:228630.

Li B, He S, Li J, Yue X, Irvine JT, Xie D, Ni J, Ni C. A Ce/Ru codoped SrFeO3−δ perovskite for a coke-resistant anode of a symmetrical solid oxide fuel cell. ACS Catal. 2020;10:14398.

Petric A, Huang P, Tietz F. Evaluation of La–Sr–Co–Fe–O perovskites for solid oxide fuel cells and gas separation membranes. Solid State Ionics. 2000;135(1–4):719.

Zhang Y, Nicholas JD. Evidence that surface-segregated Sr phases can be removed in LSCF via ceria pre-infiltration, are less apt to form in SSC. J Electrochem Soc. 2021;168:024522.

Kumar RV, Khandale A. A review on recent progress and selection of cobalt-based cathode materials for low temperature-solid oxide fuel cells. Renew Sustain Energy Rev. 2022;156:111985.

Wang W, Tian Y, Liu Y, Abhishek N, Li Y, Chi B, Pu J. Tailored Sr–Co-free perovskite oxide as an air electrode for high-performance reversible solid oxide cells. Sci China Mater. 2021;64:1621.

Tian Y, Liu Y, Jia L, Naden A, Chen J, Chi B, Pu J, Irvine JT, Li J. A novel electrode with multifunction and regeneration for highly efficient and stable symmetrical solid oxide cell. J Power Sources. 2020;475:228620.

Su T, Zhang T, Xie H, Zhong J, Xia C. Investigation into structure and property of W and Ti co-doped SrFeO3 perovskite as electrode of symmetrical solid oxide fuel cell. Int J Hydrog Energy. 2022;47(36):16272.

Song J, Zhu T, Chen X, Ni W, Zhong Q. Cobalt and titanium substituted SrFeO3 based perovskite as efficient symmetrical electrode for solid oxide fuel cell. J Mater. 2020;6(2):377.

Gou M, Ren R, Sun W, Xu C, Meng X, Wang Z, Qiao J, Sun K. Nb-doped Sr2Fe1.5Mo0.5O6−δ electrode with enhanced stability and electrochemical performance for symmetrical solid oxide fuel cells. Ceram Int. 2019;45(12):15696

Arrive C, Delahaye T, Joubert O, Gauthier GH. Study of (La, Sr)(Ti, Ni)O3−δ materials for symmetrical Solid oxide cell electrode—part a: synthesis and structure analysis in air. Ceram Int. 2019;45(14):17969.

Tian Y, Yang C, Li Y, He S, Wang X, Ling Y, Li W, Chi B, Pu J. A Simple Sc doping strategy to enhance electrocatalytic activity and stability in symmetrical solid oxide cells. J Electrochem Soc. 2021;168:104515.

Tian Y, Wang W, Liu Y, Zhang L, Jia L, Yang J, Chi B, Pu J, Li J. Cobalt-free perovskite oxide La0.6Sr0.4Fe0.8Ni0.2O3−δ as active and robust oxygen electrode for reversible solid oxide cells. ACS Appl Energy Mater. 2019;2(5):3297.

Shi H, Su C, Ran R, Cao J, Shao Z. Electrolyte materials for intermediate-temperature solid oxide fuel cells. Prog Nat Sci Mater Int. 2020;30(6):764.

Wang F, Zhou Q, He T, Li G, Ding H. Novel SrCo1−yNbyO3−δ cathodes for intermediate-temperature solid oxide fuel cells. J Power Sources. 2010;195(12):3772.

Du Z, Zhao H, Shen Y, Wang L, Fang M, Świerczek K, Zheng K. Evaluation of La0.3Sr0.7Ti1−xCoxO3 as a potential cathode material for solid oxide fuel cells. J Mater Chem A. 2014;2(26):10290.

Wei B, Lü Z, Li S, Liu Y, Liu K, Su W. Thermal and electrical properties of new cathode material Ba0.5Sr0.5Co0.8Fe0.2O3−δ for solid oxide fuel cells. Electrochem Solid State Lett. 2005;8:A428.

Gu Y, Zhang Y, Ge L, Zheng Y, Chen H, Guo L. YSZ electrolyte support with novel symmetric structure by phase inversion process for solid oxide fuel cells. Energy Convers Manag. 2018;177:11.

Bastidas DM, Tao S, Irvine JT. A symmetrical solid oxide fuel cell demonstrating redox stable perovskite electrodes. J Mater Chem. 2006;16(17):1603.

Guo Y, Guo T, Zhou S, Wu Y, Chen H, Ou X, Ling Y. Characterization of Sr2Fe1.5Mo0.5O6−δ–Gd0.1Ce0.9O1.95 symmetrical electrode for reversible solid oxide cells. Ceram Int. 2019;45(8):10969.

Tian D, Lin B, Yang Y, Chen Y, Lu X, Wang Z, Liu W, Traversa E. Enhanced performance of symmetrical solid oxide fuel cells using a doped ceria buffer layer. Electrochim Acta. 2016;208:318.

Ruiz-Morales JC, Canales-Vazquez J, Pena-Martmez J, Lopez DM, Nunez P. On the simultaneous use of La0.75Sr0.25Cr0.5Mn0.5O3−δ as both anode and cathode material with improved microstructure in solid oxide fuel cells. Electrochim Acta. 2006;52(1):278.

Luo X, Yang Y, Yang Y, Tian D, Lu X, Chen Y, Huang Q, Lin B. Reduced-temperature redox-stable LSM as a novel symmetrical electrode material for SOFCs. Electrochim Acta. 2018;260:121.

dos Santos-Gómez L, Porras-Vázquez JM, Losilla ER, Marrero-López D, Slater PR. Investigation of PO43− oxyanion-doping on the properties of CaFe0.4Ti0.6O3−δ for potential application as symmetrical electrodes for SOFCs. J Alloys Compd. 2020;835:155437.

Zhang Y, Zhao H, Du Z, Świerczek K, Li Y. High-performance SmBaMn2O5+δ electrode for symmetrical solid oxide fuel cell. Chem Mater. 2019;31(10):3784.

Cao Z, Wei B, Miao J, Wang Z, Lü Z, Li W, Zhang Y, Huang X, Zhu X, Feng Q. Efficient electrolysis of CO2 in symmetrical solid oxide electrolysis cell with highly active La0.3Sr0.7Fe0.7Ti0.3O3 electrode material. Electrochem Commun. 2016;69:80.

Torrell M, Garcia-Rodriguez S, Morata A, Penelas G, Tarancon A. Co-electrolysis of steam and CO2 in full-ceramic symmetrical SOECs: a strategy for avoiding the use of hydrogen as a safe gas. Faraday Discuss. 2015;182:241.

Peng X, Tian Y, Liu Y, Wang, Jia L, Pu J, Chi B, Li J. An efficient symmetrical solid oxide electrolysis cell with LSFM-based electrodes for direct electrolysis of pure CO2. J CO2 Util. 2020;36:18.

Li Y, Li Y, Wan Y, Xie Y, Zhu J, Pan H, Zheng X, Xia C. Perovskite oxyfluoride electrode enabling direct electrolyzing carbon dioxide with excellent electrochemical performances. Adv Energy Mater. 2019;9(3):1803156.

Acknowledgements

We gratefully appreciate for financial support from National Key R&D Program for Young Scientists (2021YFA1501900), National Natural Science Foundation of China (52272257), Material Science and Engineering Discipline Guidance Fund of China University of Mining and Technology (CUMTMS202203), Foundation of State Key Laboratory of Clean and Efficient Coal Utilization, Taiyuan University of Technology (Grant No. SKL2022008), the Jiangsu Provincial Shuangchuang Doctor Program (JSSCBS20211224), Young Elite Scientists Sponsorship Program by (CAST2022QNRC001) and the Open Sharing Fund for the Large-scale Instruments (DYGX-2021-026) and Equipments of China University of Mining and Technology (CUMT) Analytical for sample characterizations assistance.

Author information

Authors and Affiliations

Contributions

XJ: conceptualization, investigation, writing—original draft. AG: investigation, validation. YX: formal analysis, investigation. XW: funding acquisition, investigation. FJ: methodology, investigation. YL: investigation, data curation. YT: supervision, data curation, review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiao, XY., Geng, AY., Xue, YY. et al. Tungsten doping La0.6Ca0.4Fe0.8Ni0.2O3−δ as electrode for highly efficient and stable symmetric solid oxide cells. Tungsten 5, 598–606 (2023). https://doi.org/10.1007/s42864-023-00217-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-023-00217-1