Abstract

Purpose

Nepal, with its diverse geography of flat lowlands (Terai), Hills, and Mountains, primarily focuses on rice farming, especially in the Terai and Hilly regions. This leads to varying farming patterns, inputs, and yields. This study filled the research gap in analyzing the spatial heterogeneity in energy use patterns, emissions, and the economics of rice farming in Nepal.

Methods

The study is conducted by collecting primary data through structured face-to-face interviews with 100 rice farmers. The data collected through the survey is analyzed using the literature to understand the energy, emissions, and costs associated with rice farming.

Results

The net energy, yield, productivity, and energy use efficiency were found to be 67,540 MJ ha−1, 5,720 kg ha−1, 0.47 kg MJ−1, and 6.52, respectively, for Terai, which is higher than that of the Hill, i.e., 46,932 MJ ha−1, 4,098 kg ha−1, 0.43 kg MJ−1, and 5.90 respectively. The econometric model highlighted mechanization as most impactful on paddy yield, and sensitivity analysis suggested that 1 MJ of additional machinery or seeds per ha boosts yield by 0.97 and 0.96 kg, respectively. In Terai, the profit per hectare and benefit–cost ratios were found to be USD 205 and 1.32, while in Hill, negative earnings of USD 42 ha−1 and 0.95 the benefit–cost ratios were found. Despite lower emissions, Hill had higher carbon efficiency (7.78) than Terai (5.67).

Conclusion

The study found Terai to be energy efficient and profitable but more emissive than Hill. These findings provide valuable insights for policymakers, researchers, and agricultural experts interested in the energy, economics, and emissions of rice farming in Nepal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rural Nepal heavily relies on agriculture, with rice as the main staple cereal crop. Despite the challenges of subsistence farming and poor cultivation and management practices that compromise harvests, there is a potential for significant improvement. The current situation results in a substantial (USD300 millions) annual import cost, but with the right strategies and interventions, this could be significantly reduced, leading to a more sustainable agricultural economy (Choudhary et al., 2022). Despite advancements, rice farmers in Nepal face significant challenges. Technological barriers, particularly for women farmers, further impact agricultural efficiency. Limited resources, land, and inconsistent access to quality inputs contribute to these challenges. The geographical and climatic features of Nepal's Terai and Hill areas also play a role in shaping these challenges. The Terai region, which comprises roughly 17% of Nepal's total geographical area, benefits from a subtropical to tropical temperature ideal for many kinds of agricultural activity. In contrast, the Hill area, covering over 68% of Nepal's total land area, experiences significant temperature changes with altitude, from subtropical in the lower hills to temperate at higher altitudes (Paudel et al., 2012).

From 1961–63 to 2010–15, Nepalese paddy production increased significantly by 2.2-fold, increasing from 2.1 to 4.8 million tonnes (Joshi et al., 2020). Despite a 1.8% annual growth, production doesn’t meet the demand of a growing population. Self-sufficiency in paddy declined in recent years, indicating an imbalance between demand and supply. In 2018/19, production was 5.6 million tonnes on 1.49 million hectares; in 2019/20, 5.55 million tonnes on 1.46 million hectares; and in 2020/21, 5.62 million tonnes on 1.47 million hectares, indicating increased production despite a decrease in cultivable area (MoALD, 2022). Nepalese institutions like the Ministry of Agriculture and Livestock Development (MoALD), Department of Agriculture (DoA), Nepal Agricultural Research Council (NARC), Asian Development Bank (ADB), Agriculture Knowledge Center (AKC), Prime Minister Agriculture Modernization Project (PMAMP), and cooperatives collectively drive agricultural advancements, contributing to upcoming production efforts in the country.

Nepal's agricultural landscape has evolved with technological advancements, embracing mechanization in farming. Despite increased adoption, there's an uneven distribution of mechanized practices, leading to variations in input–output ratios. Analyzing energy use in paddy fields is crucial for enhancing efficiency, reducing energy consumption, and promoting sustainable agriculture (Gadal et al., 2019).

This study compares energy use in Hill and Terai rice production, examining sources, consumption across cultivation stages, and environmental impact. It offers key insights for policymakers, farmers, and rice industry stakeholders, aiding decision-making for sustainable rice production in Nepal. Given the economic constraints of many farmers, comprehending paddy production costs and energy patterns is vital (Gairhe et al., 2018). Analyzing rice production costs involves comparing them to market prices. This study focuses on monsoon rice, exploring energy consumption trends in traditional farming methods. Environmental factors like temperature, water availability, and greenhouse gases (nitrous oxide, carbon dioxide, methane) significantly impact paddy production. Rising temperatures affect plant growth, and elevated carbon dioxide levels accelerate weed and pest growth, necessitating more pesticides and increasing greenhouse gas emissions (GHG). Rice field floods release methane (CH4) and nitrous oxide (N2O), contributing to environmental challenges (Sun et al., 2023). Reducing CH4 emissions is vital for rice production systems because of their higher global warming potential. Understanding fertilizer's impact on CH4- and N2O-emitting microorganisms in paddy soils can provide insights into agriculture's global GHG emissions (Mboyerwa et al., 2022).

Rice cultivation's energy usage, global warming potential, and economics have been studied in diverse places. The study (Kumar et al., 2021) examined mechanical tillage's carbon intensity and efficiency in eastern India's rice-based agriculture systems and found partially mechanized tillage to be an effective energy and carbon-efficient production strategy. In Mazandaran, Iran, the study (Aghaalikhani et al., 2013) examined energy inputs in traditional and mechanized rice cultivation. In the study, diesel fuel, followed by chemical fertilizer, accounted for the highest energy inputs in traditional and mechanized cultivation. In the rice production system, the study (Eskandari & Attar, 2015) compared direct sowing and transplanting energy needs, where energy inputs were found to be completely distinct. The results recommended direct sowing over transplanting. Studies (Canakci & Akinci, 2006; Canakci et al., 2005) examined greenhouse vegetable and field crop energy use. Growing tomatoes in a greenhouse was the most economical option. Another study (Mani et al., 2007) examined energy use in Himachal Pradesh wheat–maize farming at different altitudes. The study revealed high energy consumption and high productivity in high hills compared to low hills for both wheat and maize. Additionally, a study (Kumar, 2009) examined farm size and paddy production costs in Uttar Pradesh, India, using economic analysis. Across all farm size categories, the expense of human labor accounted for the largest share of overall variable costs. The overall variable cost per farm increased as the farm size increased. However, as farm size increased, total fixed costs were reduced. Very limited research and datasets are available in the context of Nepal in relation to the rice production system. Focusing on spring rice growing in Nepal, the study (Paudel et al., 2021) calculated a global warming potential of 22,987 MJ ha−1 and 720.56 kg CO2e ha−1. Another study (Acharya et al., 2020) performed an economic comparative analysis between automated and traditional rice farms in the Terai belt of Nepal. According to the study, there are many benefits to using agricultural machinery in rice cultivation. It would cut down on production costs, boost yield, eliminate manual labor, solve the problem of a lack of workers, and make mechanized rice farms more profitable.

These aforementioned studies shows that more studies needed in the highlands. Furthermore, more research needs to be carried out in Nepal to compare rice farming in the Terai and Hill regions. This study has filled the gap by conducting a comparative study on rice cultivation in eastern Nepal's Terai and Hilly regions. First, the study assessed and compared the energy input and output, the economics of paddy production, and associated emissions. Further, the study has conducted a sensitivity analysis to understand the most influential parameters. The findings of the study could be helpful for policymakers for formulating evidence based policy to support paddy farming in Nepal.

Materials and Methods

Study Area

The eastern part of Nepal was taken as the study area comprising both Hilly and flat plain regions (Terai) as illustrated in Fig. 1. For the representation of the Hilly region, Mai municipality of Ilam district (latitude of 26°40’ North and a longitude of 87°40’ East to 88°10’ East) and Dhankuta municipality of Dhankuta district (26°53’ to 27°19’ North and 87°8’ to 88°33’ East) were chosen (HopNepal, 2021) The soil of the district is classified as a sandy loam (Khadka, 2018), with a humid to sub-humid climate and moderate to highly steep geography (Bhattarai, 2018). Although both are typical hilly zones with temperate climates, Dhankuta has less accessibility to farm mechanization and irrigation facilities than Mai municipality. For representing the plain lowlands, three sites having good practice on machinery and modern farming techniques were chosen: i.e., Kamal rural municipality and Birtamod municipality are located in Jhapa district (latitudes 26020′ to 26050′ North and longitudes 87039′ to 88012′ East) (Paudel et al., 2021), and Urlabari municipality located in Morang district (260 39′ 59.99′′ North and 870 29′ 59.99′′) (Khadka, 2021). Choosing these sites was due to accessibility, good production history, and favorable for paddy production with resourceful farms.

Data Collection and Analysis

Data was collected by administering direct questionnaires to 100 farmers via in-person interviews. The study employed a simple random sampling technique, with 50 samples collected from the Terai region and another 50 samples from the Hilly region. A well-prepared structured questionnaire encompassed data on the duration and quantities of inputs from various sources, as well as the paddy yield and weight of straw. The study specified the inputs utilized in paddy production to determine energy equivalences. Rice production encompassed the use of several inputs like human labor, animal power, machinery, diesel, chemicals, fertilizers, farmyard manure (FYM), and seed. It is important to note that solar energy, wind power, and irrigation were not considered in the study. The marketable product grain and straw were taken as output, characterizing a moisture content of around 15% (wet basis). The information on input and output parameters and the price rate of items was collected using KoboToolbox. This was then followed by data processing in the MS Excel software package; further, the Stata 13.0 and SPSS 27.0.1 were used for model fitting and regression analysis.

Energy Input–output Analysis

Agricultural systems encompass energies from direct sources of energy or indirect energy, similarly renewable or non-renewable energy. Direct energy is derived from diesel fuel, animal power, and human labor. In contrast, indirect energy sources are machinery, chemical fertilizers, fertilizers, FYM, and seeds. Renewable energy comprises human labor, animal power, FYM, and seeds, whereas non-renewable energy includes machinery, diesel, chemical fertilizer, and herbicides. To get the energy value of output and input per hectare, their respective amounts were multiplied by the energy equivalent coefficient collected from different literature tabulated in Table 2.

Then, several energy indices were calculated based on the studies (Mondal et al., 2021; Rafiee et al., 2010).

where, NE is net energy (MJ ha−1), EUE is energy use efficiency, EP is energy productivity (Kg MJ−1), SE is specific energy (MJ Kg−1), HEP is human energy profitability, Eo is energy output (MJ ha−1), Ei is energy input (MJ ha−1), Yp is paddy yield (kg ha−1), and E1 is energy derived from human labor (MJ ha−1).

To establish a relation between input energies and the yield of a mathematical function, the Cobb–Douglas production function has been determined to be the best mathematical function for this use due to its statistical significance. Numerous researchers have already explored the association between input energy and output yield utilizing the Cobb–Douglas function (Mobtaker et al., 2010; Rafiee et al., 2010; Firouzi et al., 2016). The following is the expression for the Cobb–Douglas production function, Eq. (7), which further re-written as Eq. (8)

where, Yi represents the farmer's yield in ith, Xij represents the production process's input vector, α represents the constant term, αj stands for the estimated coefficients for each input obtained by the model and ei is the error term.

While yield is a result of input energies, then Eq. (8) can be extended as Eq. (9). The ordinary least squares approach was used to estimate Eq. (9).

where, Xi is energies equivalent to X1, human labor, X2 is animal power, X3 is for machinery, X4 is for diesel, X5 is for herbicides, X6 is Nitrogen, X7 is for Phosphorous, X8 is for FYM, and X9 is for seed.

Based on the inputs response coefficients, the Marginal Physical Product (MPP) approach was used to analyze the sensitivity of energy inputs on paddy yield. When a factor's value changes by one unit, the MPP displays how the output varies for that particular input factor while keeping the other factors constant at their geometric mean levels. Using the αj of the various energy inputs, the MPP of the various inputs was calculated as (Singh et al., 2004).

where MPPxj is the marginal-physical productivity of the jth input, αj is the regression coefficient value of the jth input, GM(Y) is the geometric mean of yield, and GM (Xj) is the geometric mean of jth input energy per hectare.

If a particular factor's MPP is positive, then adding more units of that factor's input boosts production; if it's negative, then adding more units of that factor's input reduces production. Therefore, instead of using the variable resource as a fixed resource, it is preferable to maintain a surplus of it (Singh et al., 2004).

The analysis concluded with the calculation of returns to scale of production. The output increases proportionately because of this proportional change when all inputs are raised by a constant factor. This phenomenon is known as returns to scale in manufacturing. The total of the elasticities obtained from regression coefficients indicates returns to scale in the Cobb–Douglas production function. This denotes that the returns to scale are rising, constant, or falling if the total is greater than, equal to, or less than one (Rafiee et al., 2010).

Economic Analysis

The economic evaluation of rice outputs includes several factors, including production costs, gross returns, and net returns. The price of cultivation included the amount spent on human labor, animal power, machinery, diesel, chemical fertilizers, herbicides, farmyard manure, and seed. All financial data were first converted into US dollars using a conversion rate of 1 USD = 132 Nepalese Rupees.

Environmental Analysis

Studying the environmental impact of different agricultural inputs is done alongside estimating the potential for global warming and other environmental indicators. One way to quantify the impact of GHG emissions on climate change is by looking at their global warming potential (GWP). Methane (CH4), nitrous oxide (N2O), and carbon dioxide (CO2) are the three GHGs most often linked to agricultural production systems. The GHG emissions from paddy production were determined by multiplying the input values of diesel, nitrogen, and phosphorus by their respective emission factors adapted from (Paudel et al., 2021) where they compiled factors from different pieces of literature.

Considering a 100-year time horizon, the GWP coefficients for N2O and CH4 are 298 and 25, respectively, while the GWP value for CO2 is 1. The GWP from the GHG emissions of different inputs and Greenhouse gas intensity (GHGI) were found using the Eq. (15) and Eq. (16) (IPCC, 2007).

The carbon equivalent emission (CEE) and carbon efficiency ratio (CER) of the inputs were calculated using the Eq. (17) and Eq. (18) (Bhatia et al., 2005).

where C is the concentration in rice grain that was measured at 43%.

Results and Discussion

Socioeconomic Condition of the Farmers and Farms

The socioeconomic structures of the farms that produced paddy and the farmers of those farms were determined and presented in Table 1. The farm size surveyed for paddy production was of various sizes, with an average of 0.70 ha overall; the study covered average landholdings of 0.46 ha in the Hilly region and 0.95 ha in the Terai region. Comparatively, in the overall survey, questioned to 49% of male-headed households and the rest 51% were female, with a greater concentration of males in the Terai region (64%) as opposed to the Hilly region (34%). There is a significant regional disparity in the caste distribution, with 50% belonging to the upper caste in highland regions and 88% in the lowland regions.

More effective and efficient farming techniques have traditionally been associated with households from higher castes because of their greater access to resources, education, and social networks. Some regions, like the Terai region, have a higher share of upper caste farmers, which may explain why their farms tend to be larger and their farmers tend to have more expertise. On the flip side, farmers from lower castes may encounter structural obstacles that restrict their acquisition of land, funds, and other resources, which could result in smaller farms and less effective agricultural methods. The gender distribution of household heads may also be impacted by this imbalance, as traditional caste roles frequently shape family dynamics and decision-making.

Crop Yields and Energy Input–output Relationships

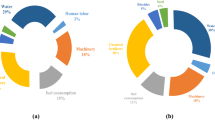

The results revealed that around 1,329 h of human labor and 16 h of machinery per hectare were needed to produce paddy in the Hilly region (Table 2). In contrast, lower hours (580 h) of human labor and higher hours (34 h) of machinery were used in the Terai region. The total energy input was computed as 9,576 MJ ha−1 in the Hilly region, while the Terai region accounted for significantly higher energy input (12,242 MJ ha−1). These data reveal how agricultural energy dynamics vary by geography, including human labor, machinery, and fuel sources. The average input energy consumption was highest for human labor (27.2%), followed by diesel fuel (21.4%) in the Hilly area. In contrast, diesel fuel (36.94%) contributed the highest in the Terai region, followed by Nitrogen (18.88%). The average yield of paddy was calculated to be 56,508 MJ ha−1 in the Hilly region and 79,782 MJ ha−1 in the Terai region. The paddy grain yield in terai is found 3,762 kg ha−1, which is about 1.5 times than that of the Hill. Straw is produced as a byproduct, mostly used in conventional ways as animal feed and kitchen fuel, but it can be converted to clean fuel (Paudel et al., 2024; Kafle et al., 2024). The research shows that agricultural policy should consider regional inequalities and maximize resource utilization for sustainable and effective farming in the assessed areas. The Hilly region's higher dependence on human labor suggests a need for further mechanization to increase output and lower labor costs. On the other hand, the more mechanized approach suggested by the Terai region's more significant energy inputs results in better yields but also increased energy consumption. The development of sustainable agriculture policy adapted to regional needs depends on the equilibrium between labor and mechanization.

The energy value of machinery and diesel ranges widely from below 2,000 MJ ha−1 to above 8,000 MJ ha−1 in the Hilly region and above 10,000 MJ ha−1 in the Terai region. Similarly, inputs of labor, nitrogen, and FYM also reached above 4,000 MJ ha−1 in the maximum range (Fig. 2). Herbicides and phosphorus are used in constant ratios in both regions.

Terai regions had 12,242 MJ ha−1 of energy inputs, compared to 9,576 MJ ha−1 in Hilly regions (Table 2), suggesting greater agricultural operations. The energy output in Terai is 79,782 MJ ha−1, compared to 56,508in the Hilly regions, resulting in greater yields (5,720 kg ha−1). Thus, Terai has 67,540 MJ ha−1 Net Energy, compared to 46,932 in Hills. Energy Use Efficiency in the Terai rice production system is slightly greater (6.52) than in the Hilly regions (5.90), demonstrating its efficiency. Terai has better Energy Productivity (0.47 kg MJ−1) than Hilly regions (0.43 kg MJ−1), indicating more effective energy conversion into agricultural output. Hilly areas have 2.34 MJ kg−1 Specific Energy, somewhat more significant than Terai's 2.14, suggesting agricultural product energy requirements vary. The Terai region's flatter topography helps profit from economies of scale by allowing wider application of technology. By contrast, the higher specific energy of the Hilly region highlights inefficiencies in human work and less mechanized farming since it represents more energy consumption per unit of output.

Terai regions have a higher contribution in Indirect Energy (53.57%) than in Direct Energy (46.43%), indicating increased mechanization and cultivation. However, Direct Energy is leading in Hilly areas (56.67%). Terai heavily uses non-renewable energy (76.94%), while Hilly regions use 46.84% of total input energy. This shows that Terai needs a balanced and sustainable energy policy. Human Energy Profitability is higher in Terai (70.15) than in Hilly areas (21.69), indicating more efficient human labor use (Table 2).

The point plot indicates that most farms are small, holding below the 1-hectare area with a greater concentration in smaller farm size; the trendlines plotted with the interval farm size data indicate that a polynomial of degree two fits the trendline more accurately (Fig. 3). The value of R2 is slightly lower, indicating that it cannot be used for further prediction. Only their correlation on the trendline shows that in the Terai region, there is an increasing pattern in energy use efficiency up to a certain inflection point concerning increasing farm area. In contrast, the efficiency of the Hilly region presents a declining trend with increasing farm area. This indicates that farms in the Terai region may profit somewhat from economies of scale, probably due to mechanization and other technologies that work well in bigger agricultural settings. The efficiency gains, however, eventually stagnate or even decrease after this inflection point, suggesting that the advantages of growing farm size are limited. On the other hand, the area's topographical features are responsible for the reduction in the hilly region, which probably leads to a higher dependence on manual labor and a less effective use of mechanization. Larger farms may have difficulties in this type of terrain that reduce overall productivity.

A similar declining pattern seemed for both energy input and output in both regions, but the diminishing rate is faster in larger farms in the Hilly region. This suggests that the Terai region's medium-sized farms can attain the highest levels of energy use efficiency. There is a limit to how much technology and mechanization can improve efficiency; after that, increasing farm size will not result in the same gains in efficiency. The decreasing efficiency in the hilly area highlights the difficulties larger farms confront in this type of terrain. Larger farms in mountainous regions are inefficient due to their reliance on human labor, emphasizing the necessity for agricultural strategies and technologies specifically designed to work within the limited geographic limits.

Econometric Model Estimation and Sensitivity Analysis of Inputs for Paddy Production

Using the Ordinary Least Squares estimate approach, the Cobb–Douglas production function was created and computed in the study of the relationship between energy inputs and paddy yield. This implies that the paddy yield, considered the endogenous variable, is determined by factors such as human labor, animal power, machinery, diesel, herbicides, nitrogen, phosphorous, FYM, and seed, which are treated as exogenous variables. The Durbin-Watson method was employed to assess autocorrelation in the data employed for this research (Hatirli et al., 2005; Mobtaker et al., 2010). For Eq. (7), the Durbin-Watson statistic yielded a value of 1.37, indicating the absence of autocorrelation in the model estimation at the 1% significance level. Furthermore, this equation's R2 value was found to be 0.99, meaning that the linear regression model explained around 99% of the variability in energy inputs.

Variations in the influence of individual inputs on yield composition are shown by evaluating the Cobb–Douglas function for each input used in paddy production. The result showed that at a 1% significance level, machinery had the most significant influence (0.67) when compared to other inputs and contributed considerably to yield. This suggests that, in these circumstances, a 1% increase in equipment input resulted in a 0.67% increase in yield. With an elasticity of 0.62, seed was shown to be the second most influential input. Diesel and FYM came in second and third, with elasticity values of 0.17 and 0.03, respectively. On the other hand, Paddy yield was negatively impacted by animal power and phosphorus. The regression coefficients were added together to calculate the return to scale value for Model 1, which came out to be 1.52. Increased return to scale is implied by a return to scale value greater than unity.

Significantly, machinery energy had the largest marginal physical productivity (0.97), closely followed by seed energy (0.96). This implies a 0.97 kg increase in yield for machinery and a 0.96 kg increase for seeds for every 1 MJ of additional energy input. As a result, the state variable is greatly influenced by parameters with high sensitivity coefficients. This emphasizes how crucial it is to pinpoint these variables, keep a careful eye on them, and evaluate the state of the ecological system in order to determine which environmental components should be addressed first (Drechsler, 1998). The marginal physical productivity (MPP) for phosphorus and animal power was -0.056 and -0.032, respectively. A negative MPP value means that adding more of these inputs has a negative impact on production; in other words, adding inputs results in lower output. Diesel and FYM energy were found to be other significant variables influencing paddy production, with MPP values of 0.213 and 0.051, respectively (Table 3).

A radar plot drawn with the MPP value to know the sensitivity of inputs parameter to the paddy production in two regions (Fig. 4). However, both regions are most sensitive to the machinery and seed input parameters, with the Hilly region being more sensitive than the Terai region.

The result from the Terai region shows that farm size is favorably correlated with paddy production; however, the Hilly region shows the opposite relation (Table 4). This may be due to scattered small plots of land in sloppy areas where more human labor is required. A negative farm size squared coefficient indicates that the rate of increase or decrease diminishes even more beyond a certain farm size. Since our farming system is more labor-intensive and less mechanized, the negative association with farm size squared is not unexpected. Systematic development and implementation of mechanization can reverse the association with farm size squared.

The inflection point was calculated to be around 0.34 ha in the Hilly region and around 1.85 ha in the Terai region (Table 4).

Economic Analysis

The study revealed that paddy production in the Terai region was more profitable than in the Hilly region, where net profit was negative (Fig. 5). This is due to the higher requirement of human labor and animals rather than machinery. The total cost of cultivation was extremely higher in the Hilly region (USD852 ha−1) than in the Terai region (USD642 ha−1). The average total output cost was observed at USD810 ha−1 for the Hilly region, while in the Terai region, it was observed at USD848 ha−1. Hence, an estimated profit of USD205 ha−1 was calculated in the Terai region. However, a loss of USD42 ha−1 was found in the Hilly region. It was also found that the net return per kg grain production in the Hilly region is negative, 0.06 USD kg−1, and positive, 0.05 USD kg−1 in Terai.

The result showed that human labor cost was the major input in both regions (Fig. 5). The cost of human labor in the Terai region is about USD 346 ha−1; in the Hilly region, the cost is doubled (USD 704 ha−1). Since loss in the Hilly region is due to high investment in human labor and minimum or no use of machinery, it can be clearly concluded that farm mechanization is necessary in the Hilly region to ensure profit in the paddy production system. Similarly, there is a scope for improvement in mechanization in the Terai region. This result demonstrated that paddy production is economically viable when the farm is well-managed and mechanized.

On average, sampled farmers cultivated paddy on 0.58 ha of land in the study area (Table 5). The data are evaluated by categorizing the territory into two regions: Hilly and Terai. Terai region farms were assigned a much larger land area for farming (0.7 ha) than the Hilly region (0.46 ha). The average land preparation cost is approximately USD 196 ha−1 for overall scenarios. Farms in Hilly regions, on the other hand, pay significantly more for land preparation than those in Terai regions, possibly due to the use of human labor and bullocks as well as smaller and more fragmented land holdings. Weeding, harvesting, and threshing costs are significantly greater for Hilly region farms than for Terai region farms. In the Terai region, people used herbicides for weeding, which reduced labor costs. In the Hilly region, farmers still rely on traditional methods, investing more money and time rather than welcoming mechanization on the farm.

The average total input cost for paddy production in the study area is around USD 747 ha−1. The Hilly region farmers are paying higher input costs (USD 852 ha−1) than the Terai region farmers (USD 642 ha−1). This suggests that Hilly region farmers rely more on manpower than machinery, which may represent the low level of acceptance of mechanization. The average paddy productivity in the study area is around 4.81 kg USD−1 year−1. The Hilly region farms have reduced paddy productivity (3.51 kg USD−1) than the Terai region farms (6.12 kg USD−1). The benefit–cost ratio of paddy in the study area is 1.11 on average. However, due to the high cost and low yield in Hilly region farms, the benefit–cost ratio is significantly lower in Hilly region farms (Table 5).

Environmental Analysis

Among the various input factors in the study, diesel, nitrogen, and phosphorus are mainly considered as the sources of GHG production. The results of global warming contribution (GWC) clearly depict the dominant production of CO2 followed by CH4 and N2O being the least among three in both the Terai and Hilly regions (Table 6). In the case of contributions to global warming, N2O seems least responsible in both the Terai and Hilly regions. The overall gas production and global warming effect is found to be higher in the Terai region; this is contributed by the higher use of fertilizers and farm machinery.

The GWP for the Hilly region was calculated to be 209 kg CO2e ha−1, while the Terai region’s GWP was 450 kg CO2e ha−1. The highest CEE of 123 kg ha−1 was recorded in the Terai region, while a low of 57.10 kg ha−1 was noticed in the Hilly region. The Hilly region has the greatest CER (7.78), which is the amount of carbon fixed in rice grains per unit of carbon emitted. The Terai region has the lowest CER, suggesting that more carbon was emitted and less carbon was fixed. In the Hilly region, however, carbon emissions were far lower than fixed carbon emissions. This shows that Hilly regions are more efficient, contributing less to emissions than the Terai region. This emphasizes the requirement of well-balanced measures supporting environmental sustainability as well as output. While ensuring great output, sustainable agricultural methods and precision agriculture could help reduce the environmental impact.

Conclusions

This study has uncovered significant variations in energy consumption, cost factors, and greenhouse emissions between the Terai and Hilly regions through meticulous data collection, field survey, and analysis. The energy consumption patterns in rice production differ significantly across these two regions. Compared to the Hilly region, energy efficiency, yield, and net return are satisfactory in rice farming in the Terai region; however, it consumes more energy, especially non-renewable energy like machinery, petroleum, chemicals, and fertilizers. Although agriculture in Hill is energy inefficient and cost-ineffective, it is eco-friendly, emits lower GHGs, and uses renewable energy sources like human and animal power.

Intensification in energy efficiency, yield, and net returns are indeed in both regions, while the region-specific measures should imply enhanced sustainable agriculture and guaranteeing food security. In Terai, shifting to green practices, such as promoting renewable sources like FYM, green manure, renewable power-operated machinery, integrated pest management, and conservation agriculture, is recommended. Conversely, in the hilly region, topography-friendly mechanization and farming technologies are recommended for consideration while making policies and implementing projects.

Data Availability

Data will be made available on request.

References

Acharya, P., Regmi, P. P., Gauchan, D., KC, D. B., & KC, G. B. (2020). Comparative analysis of cost, return, profitability and labor use in mechanized and traditional rice farms in Nepal. Food & Agribusiness Management, 2(1), 17–22. https://doi.org/10.26480/fabm.01.2021.17.22

Aghaalikhani, M., Kazemi-Poshtmasari, H., & Habibzadeh, F. (2013). Energy use pattern in rice production: A case study from Mazandaran province, Iran. Energy Conversion and Management, 69, 157–162. https://doi.org/10.1016/j.enconman.2013.01.034

Bhatia, A., Pathak, H., Jain, N., Singh, P. K., & Singh, A. K. (2005). Global warming potential of manure amended soils under rice–wheat system in the Indo-Gangetic plains. Atmospheric Environment, 39(37), 6976–6984. https://doi.org/10.1016/J.ATMOSENV.2005.07.052

Bhattarai, K. R. (2018). Ethnobotanical study of plants used by Thami community in Ilam District, eastern Nepal. Our Nature, 16(1), 55–67. https://doi.org/10.3126/on.v16i1.22123

Canakci, M., & Akinci, I. (2006). Energy use pattern analyses of greenhouse vegetable production. Energy, 31(8–9), 1243–1256. https://doi.org/10.1016/j.energy.2005.05.021

Canakci, M., Topakci, M., Akinci, I., & Ozmerzi, A. (2005). Energy use pattern of some field crops and vegetable production: Case study for Antalya Region, Turkey. Energy Conversion and Management, 46(4), 655–666. https://doi.org/10.1016/J.ENCONMAN.2004.04.008

Chaudhary, V. P., Gangwar, B., Pandey, D. K., & Gangwar, K. S. (2009). Energy auditing of diversified rice–wheat cropping systems in Indo-gangetic plains. Energy, 34(9), 1091–1096. https://doi.org/10.1016/J.ENERGY.2009.04.017

Choudhary, D., Banskota, K., Khanal, N. P., McDonald, A. J., Krupnik, T. J., & Erenstein, O. (2022). Rice subsector development and farmer efficiency in Nepal: Implications for further transformation and food security. Frontiers in Sustainable Food Systems, 5, 740546. https://doi.org/10.3389/FSUFS.2021.740546/BIBTEX

Drechsler, M. (1998). Sensitivity analysis of complex models. Biological Conservation, 86(3), 401–412. https://doi.org/10.1016/S0006-3207(98)00021-4

Erdal, G., Esengün, K., Erdal, H., & Gündüz, O. (2007). Energy use and economical analysis of sugar beet production in Tokat province of Turkey. Energy, 32(1), 35–41. https://doi.org/10.1016/j.energy.2006.01.007

Eskandari, H., & Attar, S. (2015). Energy comparison of two rice cultivation systems. Renewable and Sustainable Energy Reviews, 42, 666–671. https://doi.org/10.1016/J.RSER.2014.10.050

Firouzi, S., Nikkhah, A., Khojastehpour, M., Holden, M., & N. (2016). Energy use efficiency, GHG emissions, and carbon efficiency of paddy rice production in Iran. Energy Equipment and Systems, 4(2), 169–176. https://doi.org/10.22059/EES.2016.23035

Gadal, N., Shrestha, J., Poudel, M. N., & Pokharel, B. (2019). A review on production status and growing environments of rice in Nepal and in the world. Archives of Agriculture and Environmental Science, 4(1), 83–87. https://doi.org/10.26832/24566632.2019.0401013

Gairhe, S., Yadaw, R. B., & Timsina, K. (2018). Status of rice after NARC establishment in Nepal. Proceedings of 29th national summer crops workshop. In: D. Bhandari, H. K. Upreti, R. Shrestha, J. Tripati, H. K. Shrestha, K. K. Mishra, B. K. Joshi, A. R. Ansari, B. P. Tripathi, S. Baidya, J. Shrestha, M. Tripati, & P. Paneru (Eds.), Held On, January, 17–18. https://doi.org/10.13140/RG.2.2.16756.30080

Hatirli, S. A., Ozkan, B., & Fert, C. (2005). An econometric analysis of energy input–output in Turkish agriculture. Renewable and Sustainable Energy Reviews, 9(6), 608–623. https://doi.org/10.1016/J.RSER.2004.07.001

HopNepal. (2021). Dhankuta - A District and Municipality of Nepal. Hop Nepal. https://www.hopnepal.com/blog/dhankuta-district-municipality-nepal. Accessed 5 May 2024

IPCC. (2007). Climate change 2007: The physical science basis, Working group I. Intergovernmental Panel on Climate Change (IPCC).

Joshi, K. D., Upadhyay, S., Chaudhary, P., Shrestha, S., Bhattarai, K., & Tripathi, B. P. (2020). The rice processing industry in Nepal: Constraints and opportunities. Agricultural Sciences, 11(11), 1060–1080. https://doi.org/10.4236/AS.2020.1111069

Kafle, S., Gyawali, M., Adhikari, S., Kropp, J. P., & Pradhan, P. (2024). Possibilities and challenges for converting waste biomass into fuel, feed, and fertilizer in Nepal. Regional Environmental Change, 24(3), 1-13. https://doi.org/10.1007/s10113-024-02285-6

Khadka, D. (2018). Soil fertility assessment and mapping of chungbang farm, Pakhribas, Dhankuta, Nepal. Advances in Plants & Agriculture Research, 8(3), 219–227. https://doi.org/10.15406/apar.2018.08.00317

Khadka, S. (2021). Effect of aggregate extracted from different sources on compressive strength of concrete for Urlabari Municipality of Morang, Nepal. In School of energy, faculty of science and technology, Madan Bhandari Memorial Academy Nepal. (Issue October). https://doi.org/10.5281/zenodo.6539504

Kumar, V. (2009). An economic analysis of cost of production of paddy in different farm size groups. Plant Archives, 9(1), 197–198.

Kumar, R., Sarkar, B., Bhatt, B. P., Mali, S. S., Mondal, S., Mishra, J. S., Jat, R. K., Meena, R. S., Anurag, A. P., & Raman, R. K. (2021). Comparative assessment of energy flow, carbon auditing and eco-efficiency of diverse tillage systems for cleaner and sustainable crop production in eastern India. Journal of Cleaner Production, 293, 126162. https://doi.org/10.1016/J.JCLEPRO.2021.126162

Mani, I., Kumar, P., Panwar, J. S., & Kant, K. (2007). Variation in energy consumption in production of wheat-maize with varying altitudes in hilly regions of Himachal Pradesh, India. Energy, 32(12), 2336–2339. https://doi.org/10.1016/j.energy.2007.07.004

Mboyerwa, P. A., Kibret, K., Mtakwa, P., & Aschalew, A. (2022). Greenhouse gas emissions in irrigated paddy rice as influenced by crop management practices and nitrogen fertilization rates in eastern Tanzania. Frontiers in Sustainable Food Systems, 6, 868479. https://doi.org/10.3389/FSUFS.2022.868479/BIBTEX

MoALD. (2022). Statistical information on Nepalese agriculture 2077/78 (2021/22). Ministry of Agriculture and Livestock Development, Government of Nepal, Kathmandu, Nepal, 73, 1–26. https://moald.gov.np/wp-content/uploads/2023/08/Statistical-Information-on-Nepalese-Agriculture-2078-79-2021-22.pdf

Mobtaker, H. G., Keyhani, A., Mohammadi, A., Rafiee, S., & Akram, A. (2010). Sensitivity analysis of energy inputs for barley production in Hamedan Province of Iran. Agriculture, Ecosystems & Environment, 137(3–4), 367–372. https://doi.org/10.1016/J.AGEE.2010.03.011

Mondal, M., Garai, S., Banerjee, H., Sarkar, S., & Kundu, R. (2021). Mulching and nitrogen management in peanut cultivation: An evaluation of productivity, energy trade-off, carbon footprint and profitability. Energy, Ecology and Environment, 6(2), 133–147. https://doi.org/10.1007/S40974-020-00189-9/METRICS

Nassiri, S. M., & Singh, S. (2009). Study on energy use efficiency for paddy crop using data envelopment analysis (DEA) technique. Applied Energy, 86(7–8), 1320–1325. https://doi.org/10.1016/j.apenergy.2008.10.007

Paudel, P. K., Bhattarai, B. P., Kindlmann, P. (2012). An overview of the biodiversity in Nepal. In: Kindlmann, P. (eds), Himalayan Biodiversity in the Changing World. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-1802-9_1

Paudel, P. P., Pokhrel, D. R., Koirala, S., Baitha, L., Kim, D. H., & Kafle, S. (2021). How profitable and energy-efficient Is Nepal’s crop production? A case study of spring rice production in Jhapa District. Journal of Biosystems Engineering, 46(1), 26–35.

Paudel, P. P., Kafle, S., Park, S., Kim, S. J., Cho, L., & Kim, D. H. (2024). Advancements in sustainable thermochemical conversion of agricultural crop residues: A systematic review of technical progress, applications, perspectives, and challenges. Renewable and Sustainable Energy Reviews, 202(March), 114723. https://doi.org/10.1016/j.rser.2024.114723

Powar, R. V., Shahare, P. U., Aware, V. V., & Deogirikar, A. A. (2017). Energy audit of paddy cultivation practices in Kokan region of Maharashtra. International Journal of Agricultural Engineering, 10(2), 1–9. https://doi.org/10.15740/has/ijae/10.2/647-654

Rafiee, S., Mousavi Avval, S. H., & Mohammadi, A. (2010). Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy. https://doi.org/10.1016/j.energy.2010.04.015

Singh, G., Singh, S., & Singh, J. (2004). Optimization of energy inputs for wheat crop in Punjab. Energy Conversion and Management, 45(3), 453–465. https://doi.org/10.1016/S0196-8904(03)00155-9

Sun, J., Chen, L., Ogle, S., Cheng, K., Xu, X., Li, Y., & Pan, G. (2023). Future climate change may pose pressures on greenhouse gas emission reduction in China’s rice production. Geoderma, 440, 116732. https://doi.org/10.1016/J.GEODERMA.2023.116732

Yilmaz, I., Akcaoz, H., & Ozkan, B. (2005). An analysis of energy use and input costs for cotton production in Turkey. Renewable Energy, 30(2), 145–155. https://doi.org/10.1016/J.RENENE.2004.06.001

Acknowledgements

This work is an undergraduate thesis and is supported by Purwanchal Campus, Institute of Engineering, Tribhuvan University, Nepal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bashyal, S., Paudyal, B., Pandey, D. et al. Comparative Assessment of Energy, Economics, and Emission (3E) of Rice Production in Plain and Hilly Areas in Nepal. J. Biosyst. Eng. 49, 313–325 (2024). https://doi.org/10.1007/s42853-024-00235-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-024-00235-y