Abstract

A BLDC motor is superior to a brushed DC motor, as it replaces the mechanical commutation unit with an electronic one; hence improving the dynamic characteristics, efficiency and reducing the noise level marginally. Maximum BLDC motor drives use PID controller to control the speed of the machine; because it is simple in structure, relatively cheaper and exhibits good performance. But the main problem associated with PID controller is adjusting its parameters during implementation. In recent works, it has been observed that Particle Swarm Optimization (PSO) technique showed good performance in tuning PID controller. For this purpose, in this article, “Grey Wolf Optimization” (GWO) algorithm is introduced; which is used to optimally tune the PID controller parameters. The objective of this article is to compare the results obtained for tuning of PID controller based on of GWO and PSO technique and a conclusion has been derived that the proposed approach yields superior dynamic performance for BLDC motor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Modern speed control techniques for variable speed drives have been changed drastically as compared to their conventional counterparts. Before evolution of power electronics, conventional (e.g. field and armature flux) control methods were being used in DC motor drives. Then power electronics-based drives gained popularity. For industrial drive applications, closed loop control techniques were introduced and PI, PID controllers were used along with power electronic converters [1]. Now-a-days for more sophisticated applications such as space craft and aeronautical engineering, biomedical instrumentation, robotic application etc.; the performance of these conventional DC motors is not up to the mark. In this work BLDC motor is selected because of their advantages [1, 2] over the other type of motors for these sophisticated applications. As a BLDC motor, does not require a commutator-brush segment so it is compact, more efficient, and generate very less noise when in operation [3, 4]. It exhibits excellent dynamic characteristics on load variation. One can note that in industrial applications more than 90% of variable speed drives use PID controllers only. Even some advanced hybrid control techniques such as Fuzzy-Neural Networks, Fuzzy-Ants Colony, Fuzzy-Genetic Algorithm, Fuzzy-Swarm, etc give better performance [5] still PID is preferred because it is cheap and has simple structure [6, 7]. For a particular application, the performance of a PID controller depends upon its parameters (KP, KI, KD). Generally, the values of these parameters are evaluated by tuning methods like Ziegler-Nichol optimization method or Cohen-Coon method, but these methods have some restrictions [8]. Advanced optimization algorithms like PSO, Genetic Algorithm etc. are more efficient and exhibit better steady state characteristics [9]. In this article, Grey Wolf Algorithm is applied to the PID controller, and the results are compared with PSO algorithm; which is a popular optimization algorithm [10]. In the later sections of this article mathematical modeling of BLDC motor and PID controller have been discussed. Third and fourth sections are describing PSO and GWO algorithms respectively. The subsequent section deals with the selection of fitness functions. In the last section authors, have given the comparative study in case of transient and steady state response in speed variations through simulated results.

2 Mathematical Modelling

2.1 BLDC Motor Modelling

Assuming the resistances of all the phase windings of a BLDC motor are equal, the phase voltages can be represented by equation-1 [11].

Assume that all the self-inductance of each phase windings are equal. Similarly, all the mutual inductances are equal.

Substituting (2) and (3) in (1):

For a balanced three phase stator winding, at any instant summation of all the phase currents is zero [13].

So,

Substituting (5) in (4) the state space form of BLDC motor is obtained as-

2.2 PID Controller Design

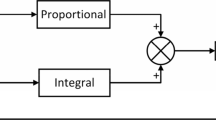

A PID controller having a parallel structure is shown in Fig. 1.

The controller processes the error signal directly. The error signal is obtained from the difference of reference speed and actual speed. When in design stage, the controller parameters Kp, Ki and Kd depend upon the closed loop feedback system which are to be chosen from a long range of values. Practically realizing an ideal PID controller is not possible. An LPF may be used to reduce noise to some extent [12]. So, by using advanced optimization algorithms, response closer to ideal can be achieved (Fig. 2).

3 Particle Swarm Optimization

Inspired by some natural phenomena and animal behavior, many meta-heuristic optimization concepts like Genetic Algorithm, PSO, Ant colony algorithm etc. have been developed and proved their efficiency in solving complex optimization problems. Among those PSO is one of the most popular algorithms which was developed by Kennedy, J. and Eberhart, R.C (1995) [13]. Its structure and approach to a problem follows the behavior of birds at the time of searching food, escaping from hunters or searching of mates [14, 15].

Particles are conceptual entities similar to birds which fly through the search space [6]. Each particle has two state variables, i.e. current velocity (Vi+1) and current position (Xi+1). At the beginning the population of particles (also referred as swarm) are initialized. Similarly, the position and velocity of each particle are initialized randomly. After each iteration, the velocity and position of each particle are updated using the following equations. The position of a particle gives a trial solution for the search problem [16, 17].

Where ‘w’ is the weighted inertia which represents the degree of change of direction. C1 and C2 are positive constants. Similarly, ‘\(\phi_{1}\)’ and ‘\(\phi_{2}\)’ are two random numbers selected from a range of [0, 1]. ‘pi’ is the best position of ith particle and ‘gi’ is the best particle among the swarm [18,19,20]. The velocity of a particle is updated by using their previous velocity, distance of their current position from own best position and best position of neighbors given by (8). The new position is given by (9).

4 Grey Wolf Optimization

Grey wolf optimization is a new meta-heuristic optimization technique which is purposed by Seyedali Mirjalili, Seyed Mohammad Mirjalili, and Andrew Lewis (2014) [21]. This method follows the social hierarchy and hunting behavior of grey wolves. Their hunting strategy is followed by this algorithm to search and hunt a prey (solution). There are three main steps in hunting.

-

1.

Tracking, chasing and approaching the prey.

-

2.

Encircling and harassing the prey until it stops moving.

-

3.

Attacking the prey.

Just like the social hierarchy of grey wolves (to live in groups), in this algorithm, four groups are defined; namely Alpha (α), Beta (β), Delta (δ), and Omega (ω). During the designing stage the social hierarchy of wolves is modeled. Alpha is the fittest solution; following Beta and Delta as the second and third best solutions. The rest of the solutions are least important and considered as Omega.

4.1 Searching for Prey

According to the position of the α, β and δ, grey wolves search for prey. They diverge from each other to search the prey.

4.2 Encircling the Prey

To model the encircling behavior mathematically, following equations are proposed.

Where,

\(t\)= Current iteration.

\(\vec{A},\vec{C} \to\) Coefficient Vectors.

\(\vec{X}_{P} \to\) Position Vector of the prey.

\(\vec{X} \to\) Position vector of wolf.

The parameter ‘a’ is decreased from 2 to 0 in order to emphasize exploration and exploitation, respectively. The position of a grey wolf changes with respect to the position of prey. In this algorithm, the optimum solution (prey) is achieved with the help of the till known three best solutions (α, β, δ). To update their positions at next iteration, the following formulae are used.

4.3 Attacking the Prey

The wolves converge towards the prey, i.e. the position of prey is the final position of Alpha.

After each iteration, the GWO algorithm allows its search agents to update their position based on the location of α, β, δ and attack towards the prey.

Before starting the main objective of any meta-heuristic population-based algorithm; two basic parameters are required to be initialized. The first and foremost parameter is the “maximum number of search agents”. In GWO algorithm we recognize the search agents as “grey wolfs”. In case of PSO the search agents are called as “swarm”. The number of search agents may vary according to the application. In this application, this value is taken as 30. The second important parameter is the “number of iterations”. This also depends upon the type of application and varies in a broad range. The less the number of iterations; less the evaluation time. The maximum number of iterations indicate, that the program stops here whether the optimal solution is achieved or not. In this program this value is taken as 50. The pseudo code of this algorithm is shown below.

Before designing a optimization technique based PID controller the objective function (also called fitness function) is first defined by taking the desired specifications and constraints into consideration [22, 23]. A proper objective function is chosen to tune the controller parameters by considering entire closed loop response. There are many time domain functions which can act as objective function for different systems. These are broadly classified into two groups. (a) Criteria based on a few points in the response, (b) Criteria based on the entire response or integral criteria. The integral criteria are generally chosen because of its good performance. An extra advantage of using the integral function is that it can be easily extended to a multi-loop system. The objective function proposed for this system “integral of product between time and absolute velocity error (ITAE) of the motor” [24] is defined in (19).

GWO algorithm is implemented for optimizing the objective function and after that performance of PSO and GWO is compared.

5 Implementation and Simulation Results

The simulation model for the purposed PID controlled BLDC motor drive is shown in Fig. 3. A reference speed is set as per the requirement. The measured speed is fed to the comparator via the feedback path. The error signal is processed by the PID controller.

The different parameters of the motor are given in Table 1. The parameters (KP, KI, KD) of the PID controller are evaluated by using different algorithms. Here we use GWO algorithm to evaluate the PID controller parameters and the output response is compared with the PSO based method. For both the algorithms the numbers of search agents and iterations are shown in Table2. Similarly, the values of KP, KI and KD for both the methods are shown in Table 3.

By using the controller parameters as shown in the Table 3 the output responses are obtained for both the cases as shown in Fig. 4.

From the Fig. 4 it is clear that the peak overshoot and settling time is less in case of GWO based PID controlled system than the PSO based system. The performance of both the systems is compared in Table 4 when the motor runs at 1500 rpm. Figure 5 shows how the solution was searched in the search space using GWO (Table 5).

6 Conclusion

PID controller is a cost-effective choice for a BLDC motor drive [25]. To improve the performance of the PID controller many advanced techniques are evolving. Some techniques like PSO already proven its effectiveness in determining the parameters of the PID controller. In this article a new optimization technique (GWO) is applied which shows better results in controlling the speed of a BLDC motor than PSO technique. From results it is seen that the machine is settled down faster compared to PSO based technique. Also, the suggested method shows lesser damping. The stability analysis performance criterion viz ISE, IAE, ITAE, ITSE values are much improved in this suggested technique. Though the rise time is slightly higher than PSO technique but the other improvements in the time domain performance encourage the usage of GWO technique to tune the PID controller parameters of BLDC motor. The proposed method may give a new dimension towards the controller design field for a BLDC motor drive system.

References

Suresh Kumar B, Varun Raj D, Venkateshwara Rao D (2020) Speed control of BLDC motor with PI controller and PWM technique for antenna’s positioner. In: Hemanth D, Kumar V, Malathi S, Castillo O, Patrut B (eds) Emerging trends in computing and expert technology COMET lecture notes on data engineering and communications Technologies. Springer, Cham

Yedamale P (2003) Brushless DC (BLDC) Motor fundamentals. Microchip Technology Inc. 20:3–15

Bianchi N, Bolognani S, Jang JH, Sul SK (2006) Comparison of PM motorstructures and sensor less control techniques for zero-speed rotorposition detection. Power Electron IEEE Trans 22(6):2466–2475

Dutta P, Mahato SN (2014) Design of mathematical model and performance analysis of BLBLDC motor. IEEE Int Conf Control Instrum Energy Commun India. https://doi.org/10.1109/CIEC.2014.6959130

Fogel DB (2006) Evolutionary Computation: Toward a New Philosophy of Machine Intelligence. Press Series on Computational Intelligence IEEE, 3rd Edition: 128-138

Ziegler G, Nichols NB (1942) Optimum settings for automatic controllers. Trans ASME 64:759–768

Zhang L (2004) “Simplex method based optimal design of PID controller.” Inform Control 33:376–379

Thomas Neenu, Poongodi Dr P (2009) Position control of DC motor using genetic algorithm based PID controller. Proceedings of the World Congress on Engineering. 2

Kim Dong Hwa, Jin Ill Park (2005) Intelligent PID controller tuning of AVR system using GA and PSO. Springer-Verlag Berlin Heidelberg: ICIC, Part II, LNCS 3645: 366-375. https://doi.org/10.1007/1153835638

Rubaai A, Kotaru R (2000) Online identification and control of a DC motor using learning adaptation of neural networks. Ind Appl IEEE Trans 36(3):935–942

Shyam A, Daya FJL (2013) A comparative study on the speed response of BLDC motor using conventional PI controller, anti-windup PI controller and fuzzy controller, International Conference onControl Communication and Computing (ICCC): https://doi.org/10.1109/ICCC.2013.6731626

K Ang, G Chong, Y Li (2005) PID control system analysis, design, and technology. Control System Technology IEEE Transaction on, 13(4): 559 576

Kennedy J, Eberhart RC (1995) Particle swarm optimization. Proc. IEEE International Conference on Neural Networks,Perth, Australia, IEEE Service Center, Piscataway, NJ: 1942- 1948. https://doi.org/10.1109/ICNN.1995.488968

Shi Y, Eberhart RC (1998) A modified particle swarm optimizer. IEEE International Conference on Evolutionary Computation, Anchorage, Alaska. https://doi.org/10.1109/ICEC.1998.699146

Shi, Y, Eberhart RC (1999) “Empirical Study of Particle Swarm Optimization.” Proceedings IEEE: 1945 –1950. https://doi.org/10.1109/CEC.1999.785511

Kennedy J. (2006). Swarm Intelligence. In: Zomaya A.Y. (eds) Handbook of Nature-Inspired and Innovative Computing. Springer, Boston, MA. https://doi.org/10.1007/0-387-27705-6_6

Eberhart R, Shi Y, Kennedy J (2001) Swarm intelligence. Elsevier. https://doi.org/10.1016/B978-1-55860-595-4.X5000-1

Gaing ZL (2004) A particle swarm optimization approach for optimum design of PID controller in AVR system. Energy Convers IEEE Trans 19(2):384–391

Panda S, Padhy N (2008) Comparison of particle swarm optimization and genetic algorithm for FACTS-based controller design. Int J Appl Soft Comput 8(4):1418–1427

Zarringhalami M, Hakimi S, Javadi M (2010) Optimal regulation of STATCOM controllers and PSS parameters using hybrid particle swarm optimization, IEEE conference. https://doi.org/10.1109/ICHQP.2010.5625436

Mirjalili Seyedali, Mirjalili Seyed Mohammad, Lewis Andrew (2014) Grey wolf optimizer. Adv Eng Softw. https://doi.org/10.1016/j.advengsoft.2013.12.007

Potnuru D, Tummala ASLV (2019) Grey wolf optimization-based improved closed-loop speed control for a BLDC motor drive. In: Satapathy S, Bhateja V, Das S (eds) Smart intelligent computing and applications smart innovation, systems and technologies. Springer, Singapore

Muniraj M, Arulmozhiyal R, Kesavan D (2020) An improved self-tuning control mechanism for BLDC motor using grey wolf optimization algorithm. In: Bindhu V, Chen J, Tavares J (eds) International conference on communication, computing and electronics systems lecture notes in electrical engineering. Springer, Singapore

Zitzler Eckart, Simon Künzli (2004) Indicator-based selection in multiobjective search parallel problem solving from nature-PPSN VIII. Springer, Berlin Heidelbergss

Shamseldin MA, EL-Samahy, AA (2014) Speed control of BLDC motor by using PID control and self-tuning fuzzy PID controller," 15th International workshop on research and education in mechatronics (REM), El Gouna pp. 1-9, https://doi.org/10.1109/REM.2014.6920443

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dutta, P., Nayak, S.K. Grey Wolf Optimizer Based PID Controller for Speed Control of BLDC Motor. J. Electr. Eng. Technol. 16, 955–961 (2021). https://doi.org/10.1007/s42835-021-00660-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42835-021-00660-5