Abstract

The European Union (EU) and the United States (US) determine municipal solid waste (MSW) statistics differently. The EU applies a site-specific methodology that directly measures waste whereas the US employs a materials flow methodology that estimates MSW statistics indirectly based on production and recovery data from industries. This study dissects the materials flow methodology and presents quantitative materials flow Sankey diagrams for the primary MSW materials to highlight data gaps that can be addressed to improve the methodology’s accuracy. Private industry plastics data were applied to the materials flow methodology, and the results were within 10% of the plastics statistics reported by the US Environmental Protection Agency (US EPA). Drawbacks to the methodologies include EU measurement inaccuracies due to double-counting and not accounting for residual waste in the US. The latter may partially explain why landfilling tonnages reported by the US EPA were approximately 60% less than the tonnages reported by the Waste to Energy Research and Technology Council (WTERT) in its national MSW survey that applied the EU methodology in the US. Unlike the EU, there is no US national policy that requires states to measure and report state-level waste data to the US EPA. Future improvements in US MSW statistics rely heavily on the implementation of national policies to homogenize the measurement and collection of waste data from states.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is great interest in quantitatively understanding the amount of municipal solid waste (MSW) generated and its final destination. Robust methods must be developed and verified to provide decision makers and municipal leadership with accurate data. Two of the most environmentally advanced entities, the EU and the US, have developed methodologies that are somewhat accurate but contain areas that can be improved to make them more robust. The EU methodology employs measurement of MSW but the tracking of waste must be thorough to avoid double-counting by the multiple facilities that handle the same waste stream. The materials flow methodology employed in the US does not use direct measurement of MSW, and consequently, previous studies conducted by the Waste to Energy Research and Technology Council (WTERT) and Environmental Research and Education Foundation (EREF) raised concerns regarding the accuracy of statistics generated by this methodology. WTERT and EREF applied the EU methodology in the US using state-based and facility-based national surveys, respectively, to determine US MSW statistics. The results were compared to the US Environmental Protection Agency (US EPA) statistics generated using the current materials flow methodology, leading to significant variations that are shown in Table 1.

The results of the national surveys yielded MSW generation and landfilling tonnages that were as much as 43.3% and 59.1% greater than US EPA statistics, respectively. These discrepancies provided the motivation for this study to quantitatively analyze the material flow methodology and identify potential data gaps that may explain the discrepancies. The ultimate goal of this analysis is to provide a deeper understanding of the US and EU methodologies that can be used to address their shortcomings and consequently, enhance the accuracy of MSW statistics in the US and the EU.

The US EPA for the first time attempted to quantify food waste, but those estimates do not distinguish between “food” and “inedible parts”. In food waste release, it is estimated that 17.7 million tons of food are managed by methods ranging from anaerobic digestion to donation to landfill and sewer/wastewater treatment. There are currently multiple generation estimates per sector that are then averaged to arrive at an annual amount. Except for anaerobic digestion, the management distribution use for all sectors was the same as restaurant management.

Materials and methods

Materials flow methodology Sankey diagrams

Quantitative analysis of the materials flow methodology was based on the US [11] methodology document entitled, Municipal Waste Generation, Recycling, and Disposal in the United States: Facts and Figures: A Methodology Document. Clarifications of the methodology document were provided through discussions with personnel from the US EPA. Examples of this included understanding US EPA’s definition of “Recovery” in the context of the materials flow methodology and gaining more insight into the sources that are referenced for estimating food waste data, which has the least transparent methodology explanation compared to all other primary material streams, however that was recently changed.

Specifically, for plastics, industry data on production and recovery were provided by the American Chemistry Council (ACC). These data were applied to the materials flow methodology that enabled a quantitative insight and a comparison of the results to the plastics statistics reported by the US EPA. Specifically, the industry data cited were the 2016 Annual Resin Review, the 2015 National Post-Consumer Non-Bottle Rigid Plastic Recycling Report [5], the 2015 National Post-Consumer Plastic Bag & Film Recycling Report [6], and the 2015 United States National Post-Consumer Plastic Bottle Recycling Report [9]. The 2016 Annual Resin Review provided data on production and domestic consumption of all plastic resins (except for PET) from 2011 to 2015. The 2015 National Post-Consumer Non-Bottle Rigid Plastic Recycling Report provided data on the total non-bottle rigid plastics recycled in 2015. The 2015 National Post-Consumer Plastic Bag & Film Recycling Report provided data on the total plastic bags and film recycled in 2015 and the 2015 United States National Post-Consumer Plastic Bottle Recycling Report provided data on the total plastic bottles recycled in 2015. Plastics generation was estimated based on the summation of the category “Domestic Consumption by End Use” tonnages for all resins in 2015 reported in the Annual Resin Review. PET tonnages are not reported in the Annual Resin Review and instead are reported by the National Association for PET Container Resources (NAPCOR). No 2015 data were publicly available to the authors of this study for PET; therefore, PET was not included in the total tonnage estimation of plastic generation. Plastics recycling was calculated as the summation of total plastic bottles recycled, total post-consumer film recovered for recycling, and total post-consumer non-bottle rigid plastic recovered in 2015. Plastics recovery was calculated as the sum of plastics recycling and the tonnage of plastics sent to waste-to-energy (WtE). The WtE tonnage was assumed to be the same as that reported by the US EPA because this information was not provided in the plastics industry data. Plastic disposal was calculated as the difference between plastic generation and plastic recovery.

Materials flow Sankey diagrams were developed for the primary material streams in MSW—namely, plastics, paper, metals, glass, and food waste. The Sankey diagrams were based on the 2014 methodology document and discussions with the US EPA.

Materials flow methodology summary equations

Equations 1–3 are original summary equations developed by the authors of this study to determine MSW generation, recovery, and disposal based on the material flow methodology. To clarify, these equations are more detailed versions of the equations presented in the 2014 US EPA methodology document.

The “Generation” of MSW, shown in Eq. 1, is calculated in the materials flow methodology based on production data from industry association reports for the different materials found in MSW. The production data are adjusted for fabrication losses, net imports, and lifetime of durable goods. Fabrication losses refer to the materials that end up as factory scrap during the manufacturing of products. Material that creates non-MSW streams, such as construction and demolition (C&D) debris, is also accounted for and is subtracted from the total production data. Net imports refer to the net difference of manufactured products that are exported from the US and the products that are imported into the US; this difference indicates the number of export–import products that end up in the MSW. In the 2014 methodology document, the US EPA shows how it applies the materials flow methodology to specific products such as carpets and rugs and consumer electronics. Lifespan of durable goods refers to the materials that are made into products that have a lifespan of more than three years, such as toys and furniture. In general, most of these products will not enter the MSW stream in the same year that they are manufactured, and therefore, the materials flow methodology adjusts the production data to account for this time lag. The life span applied is unique to each category of product and is based on industry data for the average years of use prior to disposal.

“Recovery” of MSW in the context of the materials flow methodology is defined by the US EPA as the summation of recycling, composting, and energy recovery (in the EU, “Recovery” does not include WtE if the energy efficiency is below an accepted value). The recycling data used in the methodology come from industry association reports and are based on purchases made by recyclers. The composting data are based on the tonnages reported by composting facilities throughout the US. The composting data are provided on a volunteer basis and therefore, not all facilities in the US provide this information. Furthermore, methods of waste measurement are not standardized in the US, leading to uncertainties in reporting. Energy recovery data are based on the tonnages reported by WtE facilities throughout the US. As part of their operations, all WtE facilities measure the tonnage of waste that enters their facility, and therefore, the data that are provided to the US EPA for WtE are more robust than those for composting.

“Discards” refers to the MSW that is disposed in landfills. As seen in Eq. 3, landfilling is calculated as the difference between MSW generated and MSW recovered. The US EPA does not calculate national landfilling as the summation of state reported landfilling tonnages because the US has Subtitle D landfills, which means that non-MSW waste such as C&D debris and sewage sludge are included in the total reported tonnages. To avoid inaccuracies, the US EPA estimates landfilling via the materials flow methodology based on the difference shown in Eq. 3. The US EPA does not account for the import and export of MSW in its calculation of discards. This is largely because any transport of waste occurs at the generation and recovery stages and is accounted for in Eqs. 1 and 2. Due to the vast land in the US, the majority of the MSW that is to be landfilled remains in the US and does not need to be exported, as is the case in many countries in the EU due to limited space. However, it must be recognized that some products are exported from the US that may not be accounted for in the MSW waste stream.

To our knowledge, this study is the first to quantitatively compare the data obtained for MSW streams determined by the US and EU methodologies. The goal was to identify quantitative values that each methodology resulted in and highlight where data gaps existed. The intention in this publication is to inform the sustainable waste management community that methods used to arrive at precise values are inherently uncertain. In addition, researchers must scrutinize the data themselves to understand where improvements are needed to obtain high confidence information and possibly work to align methodologies.

Results and discussion

Sankey diagrams for materials flow methodology of primary MSW streams

The 2014 US EPA methodology document provides step-by-step summaries and process flow diagrams of the material flow calculations for different materials and products found in MSW. However, the process flow diagrams do not provide quantitative information that clearly indicates how the generation and recovery values of these materials are calculated from the methodology.

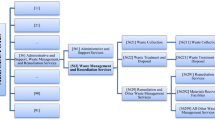

It is not possible to quantitatively analyze the materials flow methodology without access to the sources of private industry data. Through a collaboration with the ACC, the authors were able to gain quantitative insights into the materials flow calculations for plastics using reports provided by ACC that correspond to those used by the US EPA. Figure 1 is an adaptation developed by the authors of the process flow diagram for plastics from the US EPA methodology document. Unlike the original, this adaptation now incorporates quantitative information provided in each step of the methodology document as well as additional production and recovery data obtained through the ACC reports.

Figure 1 shows that the primary data sources for plastics cited by the US EPA are the ACC and NAPCOR. The US EPA cites production data from ACC’s Annual Resin Review and recycling data from recycling surveys by ACC and NAPCOR (US [11]). Domestic production includes both virgin and recovered resin, and in 2015, this was approximately 39 million tons, excluding PET (ACC [1]). These data are adjusted for net imports (the difference between imported plastics and exported plastics), and 1% fabrication scrap loss is applied as suggested by the US EPA. Products that have a useful lifetime are subtracted from the production data to account for the time lag in these products entering the waste stream. Plastics that are accounted for in the materials flow methodology of other MSW products, such as lead-acid batteries and appliances, are added to the overall amount. The end result of these calculations yields the generation of plastics in MSW that the US EPA reports.

The data in the ACC Resin Review have three different categories that are provided for plastics production: Sales & Captive Use, Production, and Domestic Consumption by End Use. The total tonnage that the US EPA reports for plastic generation is most similar to Domestic Consumption by End Use in the ACC Resin Review. In 2015, the US EPA reported 34.5 million tons of plastic generation in MSW (US EPA [10]) and the Domestic Consumption by End Use reported by ACC was 31.6 million tons (ACC [1]). The discrepancy in the tonnages can potentially be attributed to the fact that ACC does include PET in its total reported tonnages. The similarity in tonnages suggests that US EPA may reference the Domestic Consumption by End Use data from the ACC Resin Review to determine total plastics generation in the US.

The recovery of plastics is defined in the materials flow methodology as the summation of plastics recycling and plastics sent to WtE. Recycling is based on recycling data from the ACC and NAPCOR surveys. Separate recycling estimates are provided for durables, nondurables, and containers and packaging (US [11]). The US EPA methodology document does not provide specifics regarding the data for energy recovery of plastics. In 2015, the US EPA reported tonnage for plastics recycling was 3.1 million tons (ACC [1]). Based on the ACC and NAPCOR recycling survey, in 2015, the summation of recycling tonnages equated to 2.7 million tons and was specifically for post-consumer non-bottle rigid plastics, post-consumer film, and post-consumer plastic bottles. The discrepancy in the recycling tonnages between the US EPA and the industry surveys can possibly be attributed to additional plastic product categories that are not included in the recycling surveys and therefore were not included in the summation estimate conducted for this study. The total tonnage of plastic sent to WtE in 2015 as reported by the US EPA was 5.4 million tons. Since the industry data did not include WtE data, the US EPA WtE tonnage was added to the recycling estimate for this study and the US EPA’s recycling estimate to yield total plastic recovery tonnages of 8.1 million tons and 8.5 million tons, respectively, as shown in Fig. 1.

The discarding of plastics is calculated in the materials flow methodology as the difference between the total plastics generated and the total plastics recovered. In 2015, the US EPA reported that 26.0 million tons of plastics were landfilled (US EPA [10]). The difference calculated based on the industry report data for generation and recovery yielded a tonnage of approximately 23.5 million tons. Analysis of the materials flow methodology using industry data for plastics yielded results that were within 10% of the US EPA reported estimates. This indicates that the material flow calculations are not completely transparent but that with access to the raw industry data, it is possible to gain quantitative insights into how the US EPA MSW statistics are determined from the methodology.

A crucial insight into the materials flow methodology that is highlighted in Fig. 1 and all adaptations of the process flow diagrams are that residues of waste treatment are not accounted for in this methodology. Residual waste from recovery operations such as recycling and energy recovery are not accounted for in the discards of material streams. This is an inherent error due to the top-down approach of the materials flow methodology and can potentially explain the discrepancies in landfilling tonnages reported by the US EPA compared to WTERT and EREF, as shown previously in Table 1. Specifically, the US EPA may underestimate landfilling because the materials flow methodology does not account for disposal of residual waste, and simultaneously, the surveys of WTERT and EREF may have overestimated landfilling since measured landfill tonnages include non-MSW.

Figures 2, 3, 4, 5 show the adapted material flow process flow diagrams for paper, metals, glass, and food waste in MSW. Only the US EPA reported estimates could be included for these material streams since their industry data were not publicly available to verify the material flow calculations.

Data gaps in the materials flow methodology

Analysis of the US EPA methodology document revealed that there are inconsistencies in the material flow calculations for different material streams in MSW. The agency is currently developing efforts to improve the accuracy of waste data collection in the US, starting with food waste, yet these values here are considered sufficient for this comparison.

Paper, generation and recovery tonnages are based on data from the American Forest and Paper Association (AF&PA). Production data are adjusted for loss from scraps due to fabrication using conversion factors from a 1992 Recycling Advisory Council report. An inconsistency with paper, compared to all other material streams, is that only imports are accounted for in the materials flow calculation, as opposed to net imports (which is the difference between imports and exports of paper product). Furthermore, this is the only material stream that solely relies on packaging to represent imports and does not account for paper products. Most other material streams use products to account for imports and exports. The generation of paper is calculated as the production data with the addition of paper packaging imports and the removal of fabrication scrap loss. Paper recovery is defined as the summation of paper that is recycled and that is sent to WtE. Paper recycling is determined from recycling surveys by the AF&PA based on purchases by US paper mills and is adjusted to remove pre-consumer recycling. The recycling data include the exports of recycled paper, thus, per-consumer exports are not measured, similar to the plastic stream, and the amount of paper sent to WtE is not specified (US [11]).

Metals include steel and aluminum containers and packaging. Production data are based on domestic shipments of virgin materials from the American Iron and Steel Institute and The Aluminum Association. The amount of metals in MSW is calculated as the addition of domestic shipments and net imports and the subtraction of fabrication losses. The losses are based on estimates from the manufacturing industry for cans, foils, and other products and packaging. However, net imports are only specified for aluminum in the methodology document and not for steel. Therefore, net imports may not be applied to steel production data in the materials flow methodology. The recycling of steel is based on data provided from the Steel Recycling Institute, and the recycling of aluminum cans is based on the number of cans melted by domestic end users plus exported used beverage cans (UBCs) minus imported UBCs. The recycling of aluminum foil and closures is assumed to be 0% (US [11]).

Glass generation is based on domestic shipments of glass reported by the Glass Packaging Institute (GPI). The US EPA has determined that it needs to adjust the data upward using factors based on comparisons of 2008 census data and 2008 GPI data, and these factors are applied to beer bottles and three other categories of glass containers that are not specified in the methodology document. Net imports are added to the production data for both empty and filled glass containers. Based on the unit conversions shown in Fig. 4, filled glass container data are adjusted so that the tonnages account for only the glass container and not the contents. The summation of the domestic shipment data and net imports equates to the total glass generation reported by the US EPA. Recycling of glass is based on recycling surveys from GPI and state environmental agency recycling data. The difference in the two data sets is assumed to equal the quantity of recycled glass going to low-end markets (US [11]).

Food waste is calculated differently from other material streams since it is not based on pre-consumer production data. The primary data sources that the US EPA cites for food waste generation and recovery are the BioCycle survey and state environmental agencies. Food waste in MSW is the summation of residential and commercial food waste. Residential food waste is estimated based on an average food waste per capita generation rate that is based on the results of curbside sampling studies from eight states and Canada. These states are: Arizona, California, Illinois, Minnesota, Missouri, Vermont, Washington, and Wisconsin. The data range covered is from 0.07 kg to 0.30 kg per person per day and therefore very variable. The tonnage of residential food waste generated is calculated as the product of the average per capita food waste generation rate, i.e., 0.36 pounds per person per day, and the national population. Commercial food waste generation is estimated using factors based on data from sampling studies and demographic data on population, grocery store sales, restaurant sales, number of employees, and number of students, patients, and prisoners in institutions. Recovery of food waste is the summation of data reported by BioCycle and state environmental agencies for mixed MSW composting and food waste composting, respectively (US [11]).

The US EPA acknowledges that there are data gaps in the materials flow methodology, especially with regard to food waste. All primary material streams that were analyzed had a limitation in updated or accurate data on recovery. Food waste has one of the least robust material flow calculations because its data set is limited since it is reliant on state agencies that are not needed by law to measure and report food waste generation and recovery. Food waste generation is based on a small sample size of per capita food generation in only eight states. Recovery tonnages may be inaccurate because non-food waste organics may be included in the total composting tonnages. Furthermore, the US EPA reports in the methodology document that state agency data on composting were found for only 33 states, and the data were between three and six years old (US [11]). The US EPA currently has a dedicated concerted effort to improve food waste management data collection and reporting. In 2020, a revised measurement methodology that includes more generators and management pathways and the industrial sector is now included in a separate report.

EU methodology for MSW statistics

The EU employs a site-specific methodology to determine its MSW statistics that is based on the measurement of MSW at waste treatment facilities. In the EU, member states are required to submit waste data to Eurostat in accordance with the Waste Statistics Regulation (WStatR). WStatR provides guidelines on how member states should collect data on waste generation, waste treatment, and waste infrastructure.

In the EU, waste type is categorized by economic activity and waste category. Specifically, there are 19 statistical classifications of economic activities in the European Community (NACE) categories and 51 European Waste Characterization (EWC-Stat) classifications based on material type in the waste stream. Waste treatment residues of waste treatment facilities are considered a secondary waste according to WStatR, but they are included in the overall estimate of waste generation [3].

The EU and the US define MSW similarly, however, in the context of WStatR, MSW is not explicitly identified. Instead, MSW is the conglomeration of household waste and items under the categories for metals, glass, and plastics that would be found in the MSW. Specifically, household waste is the 19th classification of the NACE codes and is EWC-Stat classification 10.1, Item 34 [3].

Waste treatment is classified by WStatR, and energy recovery is classified in the EU based on the R1 energy efficiency formula. The R1 energy efficiency formula is applied to determine whether an energy recovery facility is considered WtE or incineration on the basis of efficiency in energy capture.

In addition to waste generation and waste treatment, the third data set that must be submitted to Eurostat is on waste treatment infrastructure. This includes the number of waste treatment facilities and their maximum capacities and information on the percentage of population covered by collection schemes for household and similar waste [3].

EU member states collect MSW data via a combination of surveys, administrative and other sources, and statistical estimation procedures. In terms of waste generation data, surveys are most effective for businesses because they are identified with NACE codes through business registration. Meanwhile, surveys for household waste are more challenging since there is no household registry. As a result, in the EU, MSW generation is generally estimated based on measurements from waste treatment facilities [3].

MSW treatment data in the EU are based on surveys of waste treatment facilities. The facilities are requested by Eurostat to report the final tonnage of waste treated. Facilities should not report MSW that is processed at the facility as an intermediate of multi-step processing; they should only report waste that leaves the facility in its final form. For example, the temporary storage of waste at a facility is not accounted for as a final tonnage if it is to be shredded and processed in another location for final use as refuse derived fuel. This WStatR guideline in waste treatment facility reporting helps to reduce double-counting in the site-specific methodology for MSW statistics [3]. In general, the EU data collected for waste treatment are the total quantities of waste that are recycled, recovered, and exported for recycling or recovery. The tracking of the import and export of waste in the EU is associated with the tracking of consignment notes associated with the shipment of waste.

Waste collectors and transporters may also be surveyed in the collection of waste, however, it can be challenging to confirm which tonnages that are reported are MSW since waste collectors often pick up waste from different types of waste generators [3]. The data in the collection surveys can be correlated with data provided in waste treatment surveys to avoid double-counting in the site-specific methodology.

The site-specific methodology can be employed in the EU because there is a legislative framework that helps standardize and homogenize data collection and reporting from its member states, unlike in the US. Each EU member state is required to report a national quality data report on MSW management in their respective country to Eurostat every second year. Each member state has freedom within the WStatR guidelines of how to collect data and several countries with advanced waste infrastructures have implemented computerized data collection systems such as WasteDataFlow of the UK and the Waste Data System of Denmark. The municipal agencies within each member state work with the national environmental agencies to collect waste data.

Discrepancies in MSW methodologies in the EU and the US

The US and EU methodologies for MSW statistics both have inherent data gaps and inaccuracies that are acknowledged by Eurostat and the US EPA, respectively. The primary issue with the EU methodology is double-counting, and the primary issue with the materials flow methodology is not accounting for residues of waste treatment operations. Double-counting can occur if waste collectors and waste treatment facilities both report the same waste and if intermediate facilities, i.e., storage facilities, mechanical biological treatment (MBT) facilities include waste that has not yet reached its final waste treatment facility in its total tonnages. Since the US EPA does not measure waste streams in the materials flow methodology, the residue of recovery operations is not accounted for and may contribute to the discrepancies in the landfilling tonnages reported by the US EPA compared to WTERT-US and EREF.

Eurostat acknowledges that there are data gaps in the EU MSW statistics reported in the Eurostat database, specifically with regard to the reported tonnages of MSW generated compared to MSW treated. Eurostat refers to this difference as the “Other treatment” category and explains that it arises because some member states have to estimate waste generation in areas that are not covered by MSW collection schemes. As a result, these member states report a higher waste generation tonnage than waste treatment tonnage. The “Other treatment” category also accounts for imports and exports, weight losses, double-counting of secondary waste (e.g., landfilling and recycling of residues from incineration), differences due to time lags, temporary storage, and, increasingly, the use of pre-treatment, such as MBT [4].

Similar to Eurostat, the US EPA acknowledges that there are data gaps in the materials flow methodology and identifies them in the 2014 methodology document for specific material streams in MSW. For paper and paperboard, there are no current data available for adjustments to account for the packaging of imported goods, and there are no current data available for conversion scrap. For metals, there is no scrap loss data available for non-steel can containers, and therefore, it is currently assumed to be the same as for steel cans for the material flow calculations. Also, other aluminum packaging recovery estimates are not available, so they are currently estimated to be 0%. For glass, the domestic shipment data do not represent the entire glass industry, there are missing imports of food and other products in glass containers, and there may be an issue of double counting in using the state level recovery data since bottles can be imported between states. For plastics, the net import adjustment generation factors for products made with plastics do not cover all products, the recovery data for durable goods are limited, and the fabrication loss may be underestimated for some products. Last, with food waste, the major issue is that mixed MSW composting surveys that are cited may include non-food waste in its tonnages. Furthermore, not all commercial sources are accounted for due to a lack of sampling studies, and the basis of sampling studies from the state agencies that are reviewed are from different years (US [11]).

Conclusions

Data gaps exist in both the EU and US MSW methodologies such as double-counting and lack of available industry data, respectively. However, analysis of the materials flow methodology shows that it may leave room for major inaccuracies. Independent national surveys performed by WTERT-US and EREF yielded data on the generation and landfilling of US MSW that varied as much as 40% and 60% from the US EPA reported tonnages, respectively. Table 2 summarizes a comparison of the EU and US MSW methodologies.

In this study, plastics industry data were applied to the materials flow methodology and results were within 10% of the US EPA plastics statistics. The industry data provided insights into what type of data the US EPA cites from industry reports but the data did not enable the authors to demonstrate exactly how the materials flow calculations are applied to determine recovery from production data. Nonetheless, this analysis was the first step toward providing quantitative insights into the methodology.

Legislation is key to improving the accuracy of US MSW statistics in the future. Similar to WStatR in the EU, the US needs to establish a standardized national guideline for waste data collection and reporting that would enable the US EPA to determine MSW trends based on measured state data and consequently, facilitate more targeted and effective ways that the US can sustainably manage its waste.

In addition to the discrepancies just discussed, there may be other possible sources that could lead to significant differences between US and EU information. For example, in The 2017 Waste Characterization Study by the US EPA, data were obtained during the spring, summer and fall seasons. It is likely that waste composition differs in the winter months due to holidays and changes in consumer habits. Thus, the data may not reflect an average sampling of waste composition. Depending on when data are obtained in the EU, a similar bias may occur.

In the US, waste characterization studies are conducted through a hand-sorting process that relies on the presence of the recycling symbol and polymer number on the individual plastic item. In 2017, a large portion (24% and 23,303 tons) of plastics collected in MGP were characterized as “Other/Unlabeled”. However, the ability of a human to properly categorize a plastic type does not necessarily reflect how the material will be sorted by the optical scanners at MRFs. For example, an unusual, unlabeled PET container would be sorted in the 2017 Waste Characterization Study as “Other/Unlabeled”, but the NIR technology at the MRF may still be able to identify the item as PET and sort it. Here again, a similar situation may occur in the EU.

Data availability

Data of these analyses are avaialable upon request to the corresponding author.

References

American Chemistry Council. 2016. ACC Resin Review 2016: Thermoplastic Resins.

EREF. 2016. Municipal Solid Waste Management in the US: 2010 & 2013.

Eurostat. 2013. Manual on Waste Statistics: A handbook for data collection waste generation and treatment, 3rd edition.

Eurostat. 2017. Municipal Waste by Waste Management Operations, November 2017 https://ec.europa.eu/eurostat/cache/metadata/en/env_wasmun_esms.htm

Moore Recycling Associates. 2017. 2015 National Post-Consumer Non-Bottle Rigid Plastic Recycling Report.

Moore Recycling Associates. 2017. 2015 National Post-Consumer Plastic Bag & Film Recycling Report.

NAPCOR. 2018. Report on Postconsumer PET Container Recycling Activity in 2017.

Shin Dolly. 2014. Generation and Disposition of Municipal Solid Waste (MSW) in the United States – A National Survey, WTERT-Columbia University.

The Association of Plastics Recyclers. 2015 United States National Postconsumer Plastic Bottle Recycling Report.

US EPA. 2015. Advancing Sustainable Materials Management: Facts and Figures 2013.

US EPA. 2014. Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures: A Methodology Document.

Acknowledgements

The authors of this study would like to thank the United States Environmental Protection Agency team for their valuable insights and the American Chemistry Council for sharing industry data on plastics.

Funding

The authors received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tsiamis, D., Poretti, F., Consonni, S. et al. A quantitative analysis of the US materials flow methodology and comparison to the EU methodology for MSW statistics. Waste Dispos. Sustain. Energy 6, 85–94 (2024). https://doi.org/10.1007/s42768-023-00171-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-023-00171-1