Abstract

High quality and mono-dispersed ZnO nanowire and nanorod were firstly synthesized using co-precipitation method without using any organic solvents in the whole preparation process, which is consistent with the development of green chemistry and also can be used for large-scale production. The co-precipitation method is so popular with us that it is conducive to control and industrialize, which is also useful to save energy and protect our environment in part because we never utilize organic solvents and even ethanol in fabricating one-dimension (1D) ZnO. Although the focus here will be on the preparation of nanowired and nanoroded ZnO, we also explore the reaction mechanisms for semiconductor ZnO and commit to provide a prospective blueprint for how understanding growth mechanisms can be used to synthesize other one-dimensional metal oxide with environmental friendly method. As a semiconductor, it can be used in the field of the photocatalytic property, which was tested by the degradation of rhodamine B (RhB) solution. 1D ZnO nanowire products exhibit a high rate degradation of 10 mg L−1 RhB aqueous solution and achieve almost complete degradation of RhB from aqueous solution under light resource within 60 min.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

ZnO as a semiconductor and piezoelectric material have a wide band gap and a large exciton binding energy of 60 meV at room temperature [1, 2], which have been widely studied in recent years due to its outstanding properties. It has been demonstrated to have comprehensive applications in various fields such as nanosensors [3], catalysts [4], electrical and optical devices [5,6,7], nanogenerators [8], active filler for rubber [9] and UV absorber in cosmetics [10]. It is well known that one-dimensional (1D) nanosized ZnO can be synthesized by a wide range of methods, such as physical vapor deposition [11, 12], chemical vapor deposition [13, 14], sputtering [15], pulsed laser deposition [16], co-precipitation method [17], electrospinning [18], and hydrothermal method [19]. Among these methods, they have different abilities with their own advantages and disadvantages. Physical vapor deposition usually need high temperature to obtain 1D ZnO nanostructures. Chemical vapor deposition can give rise to high-quality 1D ZnO, but its use is limited due to low product yield. Sputtering and electrospinning not only require sophisticated criteria but also have less repeatability. In comparison to above methods, co-precipitation method is well received because of its low cost and flexible processes. ZnO nanostructures can be grown on a large scale which paves the way for industrialization. Up to now, there are so many methods to synthesis ZnO such as hydrothermal method, spray pyrolysis method, sputtering method and co-precipitation method. In contrast, few publications on the fabrication of 1D ZnO by co-precipitation have been reported. 1D ZnO nanoparticles can also be filled in rubber and resin to improve its mechanical properties because one dimension can be bent. Moreover, it can also be applied in gas sensors, catalysts and solar cells due to its larger ration of length to diameter. It is noted that semiconductors such as ZnO, SnS2, TiO2 could well be used in the field of photocatatalysis, and present an outstanding property [20,21,22,23,24,25].

Here in our work, we fix our attention on 1D ZnO nanostructures that are synthesized by co-precipitation method. Moreover, we introduce a new technique combining with the development of green chemistry without using any organic solvents in the process of fabrication. At the same time, the growth of 1D ZnO is carried out at room temperature. There is no high temperature and high pressure, consequently the fabrication method is cheap, non-hazardous, and thus capable of easily controlling and industrializing. In order to control the morphology and the size of ZnO nanocrystals by impeding kinetically the nucleation and growth of nanocrystals, we are supposed to vary reaction conditions such as the precursor concentrations, ligand concentrations, the speed of stirring, surfactants, reaction time etc. Under room temperature, the reactions could take place by controlling the ratio of Zn2+ and OH−, giving rise to 1D ZnO with diameter about 50 nm.

2 Experimental details

2.1 Materials

All chemicals used in this work are of analytical grade without further purification. Zn(CH3COO)2·2H2O and ZnSO4·7H2O (AR, Sinopharm Chemical Reagent Co., Ltd.) are used as zinc cation precursor. Citric acid monohydrate is used as biological ligands for metal ions. Polyvinylpyrrolidone (PVP-30K) (AR, Shanghai Lingfeng Chemical Reagent) is proposed to graft onto the ZnO nanostructures as a surfactant to reduce the grain size and decrease the aggregation. De-ionized water is used to wash glasswares, dilute the chemicals and wash the final sample for two times. All the chemicals purchased are of analytical grade without further purification.

2.2 Synthesis of 1D ZnO nanostructures

The 1D ZnO nanostructures is synthesized in de-ionized water in room temperature. In a typical experiment, 0.25 g Zn(CH3COO)2·2H2O for nanorod (0.327 g ZnSO4·7H2O for nanowire) is dissolved in 50 ml water, respectively. 0.25 g or 0.327 g of citric acid is added to the above aqueous. 0.28 g of PVP is dissolved in 20 ml de-ionized water and added into the above solution drop by drop. Finally, 0.8 g of NaOH is dissolved in 10 ml de-ionized water and added into the above solution drop by drop. The mixture is stirred magnificently at room temperature. A white precipitate is obtained after 1 h. The obtained precipitate is washed by de-ionized water to remove impurities and then the final product is dried into powder at around 160 °C.

2.3 Materials characterization

X-ray diffraction (XRD) patterns were characterized by Panalytical diffractometer (X’PERT) using Cu target at a scanning rate of 0.1° s−1. Raman spectra were measured by Renishaw inVia with 532 nm laser excitation. The morphologies of MoS2 were investigated by the scanning electron microscope (SEM; S-4700) and transmission electron microscopy (TEM, Tecnai G2-F30) with 300 kV accelerating voltage. Photocatalytic characterization was tested by the UV–Vis (UV-3150).

3 Results and discussion

3.1 Morphological study

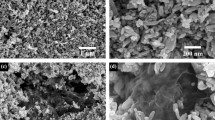

Figure 1 shows the SEM images of 1D ZnO nanostructures. ZnO, as an amphoteric oxide, which has an isoelectric point value of about 9.5 [26]. Generally speaking, ZnO can be formed using strong or weak alkalis owing to the hydrolysis of Zn salts in a basic solution. From the Fig. 1a, b, there is a little aggregation and the shape of the ZnO nanoparticles is nanowire structure. Each nanowire has a uniform diameter along its growth orientation, and the typical diameters of the nanowires are in the range of 50 to 80 nm. No purities were observed at the ends of the nanowires, which indicates that the obtained 1D ZnO nanoparticles are high quality. From the Fig. 1c, d, ZnO nanorod was obtained. TEM image furthermore indicates ZnO nanowire structure as shown in Fig. 2.

3.2 Structural study

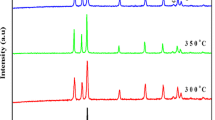

The structure of the obtained 1D ZnO nanostructures is characterized by X-ray diffraction, which is shown in Fig. 3a. The diffraction peaks show that sample is in single phase, which can be indexed as (100), (002), (101), (102), (110), (103) and (112) planes of hexagonal wurtzite structure that matched well with the standard JCPDS values (JCPDS Card No. 89-7102). From the figure, all the observed wide diffraction peaks are in good accordance with those of wurtzite structure ZnO, which clearly indicated the nature of the well-dispersed nanoparticles. No other diffraction peaks of any other impurities are observed by adding complex agent and surfactant, which indicates that high quality and mono-dispersed 1D ZnO nanostructures were obtained.

3.3 Raman study

The Raman spectra is recorded with the excitation wavelength set at 532 nm as shown in Fig. 3b. As we know, we can get information about the crystal structure on the scale of a few lattice constants from Raman spectra. Obviously, any distortion of the lattice, crystal defect, surface bonding and surface adsorption, will exert an influence on crystal structure and vibration modes. As a consequence, the characteristic Raman frequency will be altered from its ideal value. ZnO is one of the simplest uniaxial crystals, which belongs to hexagonal wurtzite crystal with C6v4 symmetry. The optical phonos at the center of the Brillouin zone are just involved in first-order Raman scattering. In group theory, there are eight sets of phonon modes: 2E2, 2A1, 2E1 and 2B1. Among them, A1 and E1 modes are split into transverse and longitudinal optical (TO and LO) components because they are polar. The two modes are not only Raman active but also infrared active. The E2 modes are Raman active merely. In contrast, B1 modes are infrared and Raman inactive [27]. From Fig. 3, E2 (high), A1(LO) and A1(TO) phonon modes were observed clearly at 436, 577 and 382 cm−1, respectively. Although each ZnO nanowire is c-axis oriented, the whole nanowires are randomly arrayed when the samples were synthesized by co-precipitation method [28, 29].

3.4 Optical study

Figure 3c shows that the UV images of 1D ZnO nanoparticles. The band gap of 1D ZnO nanostructure is studied by UV–Vis diffuse reflection spectra (DRS) in the range of 200–700 nm. Generally, the band gap of semiconductor nanoparticles is calculated simply by the wave energy equation (E = hc/λ) [19, 22] and the band gap value for ZnO nanowire is 2.72 eV, indicating its narrower band gap when compared to ZnO nanorod which the band gap is 2.90 eV. In comparison with a majority of ZnO nanoparticles [10], the absorption peak of our 1D ZnO nanostructures is more red shifted owing to the quantum size effects, and it is in consistent with the small size and uniformity of nanosized ZnO. Thus, the above results suggest that ZnO nanowire exhibit excellent photocatalytic performance.

3.5 Photocatalytic property

The Photocatalytic properties of 1D ZnO were investigated by degrading RhB solution (10 mg L−1), using a Xe lamp (PLS-SXE300-300UV). The characteristic UV–Vis adsorption spectra of degradation of RhB solution was shown in Fig. 4a. The photocatalytic performance of ZnO nanowire is better than ZnO nanorod (Fig. 4b). The linear fitting curve of the equation of ZnO nanowire is ln(C0/C) = 0.017 tmin + 0.06, and the linear fitting degree R2 = 0.988 is high (Fig. 4c), indicating that the photocatalytic reaction is similar to the pseudo-first-order reaction. Furthermore, ZnO nanowire also possess outstanding cycling ability as shown in Fig. 4d.

The schematic of the reaction mechanism of 1D nanowire for the photocatalytic degradation of RhB dye was shown in Scheme 1. We can found that ZnO nanowire products exhibit good activity, which can be attributed to the 1D nanowire generating more carriers and 1D nanowire are good for electron transport. The intermediate band gap of ZnO nanowire between valence band and conduction band becomes more active owing to the increase of carrier concentration. H+ and ·OH can be generated because of the influence of hole (h+) on water. Furthermore, electron (e−) can generate O2 to be superoxide anion radicals ·O2−. RhB dye can be then decomposed by the generated radicals. The reaction mechanism of major initial steps under visible light source is listed on the above equations [30].

4 Conclusion

In summary, high quality and uniform 1D ZnO structures were prepared by a co-precipitation method without using any organic solvents in the fabrication process, which is in consistent with the development of green chemistry. In addition, it is easy to control and industrialize. The Raman study means that each 1D ZnO is c-axis oriented, the whole nanorods and nanowires are randomly arrayed when the products were synthesized by co-precipitation method. Moreover, ZnO nanowire have better photoexcitation of charge carriers and exhibit outstanding photocatalytic activity. This work paves a new way for the design of 1D materials and offers profound insights into the fabrication of 1D materials.

References

Özgür Ü, Alivov YI, Liu C et al (2005) A comprehensive review of ZnO materials and devices. J Appl Phys 98(4):041301

Hu H, Huang X, Deng C et al (2007) Hydrothermal synthesis of ZnO nanowires and nanobelts on a large scale. Mater Chem Phys 106(1):58–62

Wang ZL (2008) Oxide nanobelts and nanowires—growth, properties and applications. J Nanosci Nanotechnol 8(1):27–55

Li Y, Meng GW, Zhang LD et al (2000) Ordered semiconductor ZnO nanowire arrays and their photoluminescence properties. Appl Phys Lett 76(15):2011–2013

Bagnall DM, Chen YF, Zhu Z et al (1997) Optically pumped lasing of ZnO at room temperature. Appl Phys Lett 70(17):2230–2232

Tang ZK, Wong GKL, Yu P et al (1998) Room-temperature ultraviolet laser emission from self-assembled ZnO microcrystallite thin films. Appl Phys Lett 72(25):3270–3272

Wan Q, Li QH, Chen YJ et al (2004) Fabrication and ethanol sensing characteristics of ZnO nanowire gas sensors. Appl Phys Lett 84(18):3654–3656

Wang ZL (2006) Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312(5771):242–246

Hu Z, Oskam G, Searson PC (2003) Influence of solvent on the growth of ZnO nanoparticles. J Colloid Interface Sci 263(2):454–460

Yu ZJ, Kumar MR, Sun DL et al (2016) Large scale production of hexagonal ZnO nanoparticles using PVP as a surfactant. Mater Lett 166:284–287

Huang MH, Wu Y, Feick H et al (2001) Catalytic growth of zinc oxide nanowires by vapor transport. Adv Mater 13(2):113–116

Yao BD, Chan YF, Wang N (2002) Formation of ZnO nanostructures by a simple way of thermal evaporation. Appl Phys Lett 81(4):757–759

Park WI, Kim DH, Jung SW et al (2002) Metalorganic vapor-phase epitaxial growth of vertically well-aligned ZnO nanorods. Appl Phys Lett 80(22):4232–4234

Park WI, Yi GC, Kim M et al (2002) ZnO nanoneedles grown vertically on Si substrates by non‐catalytic vapor‐phase epitaxy. Adv Mater 14(24):1841–1843

Chiou WT, Wu WY, Ting JM (2003) Growth of single crystal ZnO nanowires using sputter deposition. Diam Relat Mater 12(10):1841–1844

Sun Y, Fuge GM, Ashfold MNR (2004) Growth of aligned ZnO nanorod arrays by catalyst-free pulsed laser deposition methods. Chem Phys Lett 396(1):21–26

Yu ZJ, Kumar MR, Sun DL et al (2016) Large scale production of hexagonal ZnO nanoparticles using PVP as a surfactant. Mater Lett 166(1):284–287

Sui XM, Shao CL, Liu YC (2005) White-light emission of polyvinyl alcohol/ZnO hybrid nanofibers prepared by electrospinning. Appl Phys Lett 87(11):113115

Yu ZJ, Kumar MR, Chu Y et al (2018) Photocatalytic decomposition of RhB by newly designed and highly effective CF@ ZnO/CdS hierarchical heterostructures. ACS Sustain Chem Eng 6(1):155–164

Wang H, Zhang Y, Wang G et al (2019) A molecular-based design of RGO/TiO2-PAM composite flocculant with photocatalytic self-degrading characteristics and the application of the oil sand tailings flocculant. ACS Sustain Chem Eng 7(7):6758–6768

Zhang X, Wang Y, Hou C et al (2018) Fabrication of unique and green tin(IV) sulfide/moss photocatalyst for highly effective photocatalytic reduction of Cr(VI). Nano 13(03):1850030

Zhong Y, Qiu X, Chen D et al (2016) Flexible electrospun carbon nanofiber/tin(IV) sulfide core/sheath membranes for photocatalytically treating chromium(VI)-containing wastewater. ACS Appl Mater Interfaces 8(42):28671–28677

Kumar S, Rao K (2017) Comparison of modification strategies towards enhanced charge carrier separation and photocatalytic degradation activity of metal oxide semiconductors (TiO2, WO3 and ZnO). Appl Surf Sci 391:124–148

Guerrero de León JA, Pérez-Centeno A, Gómez-Rosas G et al (2019) Influence of the Zn plasma kinetics on the structural and optical properties of ZnO thin films grown by PLD. SN Appl Sci 1(5):475

Honarmand MM, Mehr ME, Yarahmadi M et al (2019) Effects of different surfactants on morphology of TiO2 and Zr-doped TiO2 nanoparticles and their applications in MB dye photocatalytic degradation. SN Appl Sci 1(5):505

Zang JF, Li CM, Cui XQ, Wang JX, Sun XW, Dong H, Sun CQ (2007) Tailoring zinc oxide nanowires for high performance amperometric glucose sensor. Electroanalysis 19:1008–1014

Decremps F, Pellicer-Porres J, Saitta AM, Chervin JC, Polian A (2002) High-pressure Raman spectroscopy study of wurtzite ZnO. Phys Rev B 65:092101

Huang Y, Liu M, Li Z et al (2003) Raman spectroscopy study of ZnO-based ceramic films fabricated by novel sol–gel process. Mater Sci Eng B 97(2):111–116

Tong Y, Liu Y, Shao C et al (2006) Highly active TiO2N photocatalysts prepared by treating TiO2 precursors in NH3/ethanol fluid under supercritical conditions. J Phys Chem B 110(30):14714–14718

Bramhaiah K, Singh VN, John NS (2016) Hybrid materials of ZnO nanostructures with reduced graphene oxide and gold nanoparticles: enhanced photodegradation rates in relation to their composition and morphology. Phys Chem Chem Phys 18:1478–1486

Funding

This study was funded by the national natural fund corpus 31370575-1 and the national natural fund 21501130.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Hou, C., Lin, X. et al. Photocatalytic decomposition of rhodamine B by newly designed one-dimension ZnO using chemical method. SN Appl. Sci. 1, 743 (2019). https://doi.org/10.1007/s42452-019-0741-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0741-8