Abstract

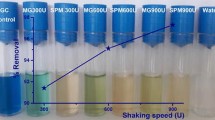

Twelve sphagnum peat moss samples were studied for removal of malachite green, as a cationic dye probe, in assessment of various pretreatment methods using three low-cost reagents, applying different approaches such as flow-through, shaking, stirring, and sonication. These sphagnum sorbents were categorized as non-treated (sorbent 1), water-treated (sorbents 2–4), hydrochloric-acid-treated (sorbents 5–8), and finally sodium-hydroxide-treated (sorbents 9–12). Foremost, the physicochemical features of these sorbents were assessed in terms of acidity, matrix emission, total dissolved salts, cation-exchange capacity, and particle morphology. As a matter of fact, different reagents and treatment methods showed dissimilar enhancement in dye removal tendency. Yet, the water and hydrochloric acid treatments by sonication (sorbents 4 and 8) and more remarkably the sodium hydroxide treatment by shaking (sorbent 10) afforded astonishing dye removal rates. Correlating the dye removal tendencies of these sorbents, with their physical properties and sorbent capacity, indicated a slight fall in their cation-exchange capacity plus a genuine change in the particle shape and substantial reduction in size. Finally, excellent reproducibility was demonstrated for the cation-exchange capacity, % removal, and the adsorption pseudo-second-order rate constant.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Sphagnum peat moss (SPM) has been reported as a low-cost sorbent for efficient removal of cationic water pollutants, which was promoted by the high porosity furnishing a high specific surface area [1, 2]. Such an efficient dye removal was also enhanced by the peculiar array of chemical functionality such as aldehyde, ketone, alcoholic, phenolic, and carboxylic groups [3, 4]. In addition, SPM was endorsed as a sorbent that required no activation, where many studies reported application of non-treated SPM in removal of water contaminants [5,6,7]. However, additional studies applied pretreated SPM using different cleanup solvents [2, 3, 8,9,10]. Thus, the treatment of sphagnum was recommended in order to lessen probable interference caused by the dissolution of matrix components such as humic substances. Hence, on the one hand, such a treatment enhanced sorbent surface adsorption by removing preadsorbed components [11]. On the other hand, a cleanup process should not harm the sorbent cation-exchange capacity (CEC), which subsequently would diminish the sorbent adsorption efficiency for cationic contaminants [11]. Actually, previous studies confirmed that carboxylic and phenolic groups in peat were behind the adsorption of cationic material [2, 12]. Not surprisingly, the sphagnum humic acids involved in dye removal were the chemically bound humic substances onto the sorbent with no contribution from the freely adsorbed ones [8]. Hence, the loss of soluble humic substances during treatment did not influence the sorbent removal efficiency [8, 11]. Namely, the sorbent-bound polar moieties of SPM enabled the efficient removal of cationic pollutants irrespective of the eluted freely adsorbed humic substances during treatment [4, 13,14,15].

Over 50 years ago, a study reported a comparison between different reagents used in sphagnum pretreatment in evaluating the elution of humic substances from SPM [16]. Equally important, another related study reported on the effect of the physical properties and the sorbent capacity of low-moor peat on the adsorption of heavy metals [17].

Undoubtedly, sphagnum peat moss has been acknowledged for good removal of a wide variety of dyes; however, the grade of dye adsorption and the adsorption equilibrium contact time depended on the type of dye and the peat origin as well. Indeed, the type of interaction between the dye and peat sorbents caused dissimilar dye removal efficiency and adsorption speed, which resulted from the different dye nature, whether cationic or anionic, and the peat composition and morphology [18]. For instance, peats collected from different places in Brunei Darussalam showed dissimilar tendency in dyes removal, where Keramut-originated peat established high removal efficiency of methyl blue and malachite green of ~ 90% [19]. Moreover, pristine-originated peat showed good removal of rhodamine B (93%) and improved that of methylene blue and crystal violet to ~ 99% [18, 20, 21]. In contrast, Panaga-originated peat showed poor removal of Congo red dye of 55% [22]. Similarly, Magellan-originated peat from Chile showed dissimilar dye removal efficiency, where the acidic black 1, acidic red 27, reactive black 5, and reactive orange 16 were poorly adsorbed concluding % removal of 29.1, 2.3, 1.3, and 15.2, respectively [23]. However, basic dyes such as orange 2, blue 3, blue 24, green 4, and violet 4 were impressively removed (99.9%) [23]. Hence, the peat originated in Brazil showed good removal of methyl blue reaching ~ 99% [13, 24]. Finally, sphagnum moss peat from Northern Ireland established high adsorption capacity for acid blue 25 (Telon blue) and basic blue 69 (Astrazone blue), where the maximum adsorption capacity was 251 and 14.4 mg/g-sorbent, respectively [5]. Regarding the removal speed, the adsorption equilibrium contact time concluded in these studies ranged between 60 and 240 min [18,19,20,21,22,23,24].

Recently our group reported a Latvian SPM sorbent, which was pretreated by successive refluxing in water, ethanol, and acetone. As anticipated, this sorbent established low matrix interference and ultrafast efficient removal of MG from water compared to various sorbents and peats, concluding % removal of ~ 98 and adsorption equilibrium contact time of 2 min [11]. Unfortunately, the reflux treatment was time consuming and cost-ineffective, which indicated the necessity for a substantial study to reach a time- and cost-effective method for peat sorbent conditioning while preserving high efficiency [11].

In this study, different reagents and treatment methods will be reported for preconditioning of sphagnum applying the malachite green as cationic dye probe. The physicochemical features and the dye removal tendencies of the treated SPM sorbents will be thoroughly assessed.

2 Experimental

2.1 Materials and solutions

SPM Substrate Finest Quality (Latvia) was purchased from Nord Agri. Malachite green (MG) was purchased from Sigma-Aldrich (Germany) and was used as received. Analytical-grade sodium hydroxide and hydrochloric acid were purchased from Sigma-Aldrich (Germany). Highly pure water (TDS = ~ 2.0 mg/L) was used in all experiments.

2.2 Instrumentations

A pH meter and TDS-meter were used in acidity and water purity assessment. UV–Vis spectrophotometer 1601 (Shimadzu, Japan) was used in spectroscopic analyses. Polarized light microscope was used in imaging sorbents’ particles. Centrifuge system (KOKUSAN, Japan) was used in separating sorbents from solution. A mechanical shaker (Vibromatic, Selecta) was used in dye removal experiments. A mechanical sieving machine was used in sieving peat moss mesh.

2.3 Preparation of adsorbent and adsorbate

SPM batch was dried in open air for one week before sieving. The collected mesh of 60 was treated accordingly (Table 1), where the ratio of SPM to reagent was kept constant 1 g–80 mL. Following the treatment, sorbents were rewashed with water till reaching neutral effluents. Afterward, the SPM sorbents were dried at 60 °C for 72 h. The dry SPM was grinded and stored in a desiccator for further use. The sorbents’ morphology was studied by polarized light microscope. Moreover, the CEC was determined for each sample [25]. Finally removal experiments were performed using MG as dye probe for comparison between these samples at pH 7 and temp of 25 °C. Concerning the adsorbate, a dye stock solution of 500 mg/L was prepared and all standard solutions were prepared by serial dilution.

2.4 Treatment of sphagnum peat moss

First, sorbent 1 was kept untreated as a control for comparison purposes (Table 1). Second, sorbents 2–4 were treated by water applying different cleanup approaches such as shaking, stirring, and sonication. Third, samples 5–8 were treated by 1.0 M HCl and sorbents 9–12 by 0.1 M NaOH applying flow-through, shaking, stirring, and sonication, respectively (Table 1).

2.5 Matrix pH, emission, and TDS of sorbents 1–12

After the treatment, the twelve sorbents were evaluated for SPM matrix emission in order to assess subsequent influence on their removal efficiency of MG. Applying dispersive solid-phase extraction method, a mixture of 0.1 g SPM sorbents in 10 mL of deionized water was left shaking for 20 min using a Vibromatic shaker at 900 U-speed. The pH, total dissolved salts (TDS), and absorbance (at 254 and 616 nm) of the filtrates were determined.

2.6 Assessment of cation-exchange capacity by titration

The CEC was determined following a modified protocol reported [25], where in brief all sorbents were washed by 0.1 M HCl solution (1 g-sorbent/20 mL) and dried in oven at 60 °C for 72 h. Then, each sample was treated by 0.1 M NaOH solution (0.1 g-sorbent/5 mL) by shaking for 10 min. Afterward, the filtrate collected was combined with the collected effluents from sorbents’ water wash in reaching neutral effluents. Finally, the filtrates were pH-metric titrated against standard HCl solution. The CEC was calculated by subtracting the HCl mequivalents of the sorbents’ filtrates from those of the control.

2.7 Removal of malachite green as dye probe

Sorbents 1–12 were tested for removal of MG by mixing 0.1 g of SPM with 10 mL of 50 mg/L using Vibromatic shaker for different time intervals [11]. Following extraction, the supernatant was separated from the solid and the % removal was calculated applying Eq. 1.

where Co and Ce were the MG initial and equilibrium concentrations (mg/L), respectively.

3 Results and discussion

3.1 Sorbents’ physicochemical assessment

In activating sphagnum for dye removal, various treatment approaches were designed to reduce matrix emission and save high sorbent-unoccupied surface area. Suspiciously, such a treatment might as well have eluted the adsorbed humic acids, and consequently damaged the sorbent performance in dye removal. Therefore, the treated sphagnum sorbents were evaluated for matrix pH and emission, TDS, CEC, and particles’ morphology.

3.1.1 Matrix pH, spectroscopic absorbance, and total dissolved salts

Foremost, sorbents 1–12 were washed with deionized water by shaking for 20 min next to samples’ pretreatment. Thus, the supernatant was analyzed for pH, absorbance (Fig. 1), and the total ion salts (Table 1). The supernatant of sorbent 1 was remarkably acidic (pH 4.4), while these of sorbents 2–12 varied from slightly acidic to somewhat basic. Thorough inspection of the pH values of the washouts showed that sorbents 5–8, treated by HCl, were slightly acidic. Predictably, the low solubility of matrix-adsorbed humic substances, as a result of protonation by HCl treatment, caused incomplete desorption of these humic acids that subsequently dissolved in the water washout. Furthermore, the slightly basic pH of the washouts of sorbents 2–4 and 9–12, treated by water and sodium hydroxide solution, respectively, implied a better removal of the soluble humic acids as non-protonated carboxylates. To sum up, the increase in the pH, from ~ 4 (sorbent 1) to ~ 7 (sorbents 2–12), indeed indicated good elution of humic acids from the sphagnum. Such a conclusion was supported by the lower absorbance values of the supernatants of sorbents 2–12 compared to that of sorbent 1. Furthermore, the TDS of sorbents 2–12 ranged from 19.2 to 47.9 mg/L, which was lower than that of sorbent 1 (220 mg/L) (Table 1). Apparently, the TDS values of the washouts of sorbents 2–12 were comparable indicating an almost similar desorption of metal contaminants from sphagnum in case of different treatment methods and reagents. Predictably, sorbents with different features would subsequently furnish dissimilar tendencies in dye removal [11].

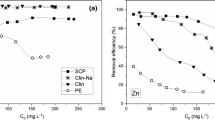

3.1.2 Sorbents’ cation-exchange capacity

The estimated values of cation-exchange capacity (CEC), presenting the adsorption active sites for sorbents 1–12, are stated in Table 2. Thus, the CEC value of sorbent 1 was ~ 242 meq/100 g-sorbent, which was relatively high compared to that of low-moor peat reported in a previous study [17]. Strangely, water treatment by different methods caused insignificant decrease in the sorbents’ CEC ranging from 239 to 240 meq/100 g-sorbent (sorbents 2–4). Furthermore, 1.0 M HCl treatment by flow-through, stirring, and sonication caused a decrease in sorbents’ CEC by < 10% (sorbents 5, 7, and 8 vs. 1), whereas shaking treatment resulted in a decrease of ~ 20% (sorbent 6 vs. 1). Finally, sorbents’ treatment by 0.1 M NaOH established dissimilar decrease in sorbents’ CEC of ~ 10% by shaking (sorbent 10 vs. 1) and ~ 20% by flow-through and stirring (sorbents 9 and 11 vs. 1). However, the CEC of sorbent 12 treated by sonication remarkably dropped to 152 meq/100 g-sorbent. Clearly, sodium hydroxide treatment resulted in extensive release of humic substances, forming the more soluble sodium salts. To sum up, sorbents 6, 9, 11, and 12 went through high loss of humic substances that was also supported by the low matrix absorbance at 254 and 616 nm (sorbents 6–12 vs. 1).

3.1.3 Sorbents’ morphology (particles’ shape and size)

The morphology of sorbents in terms of particles’ shape and size was inspected using polarized light microscope. The particles of sorbent 1 were fibrous of relatively large aggregates of ≤ 1000 × 250 µm (Table 2). Additionally, water treatments had a mild influence on the particle shape and size (sorbents 2–4). In contrast, acid treatment resulted in dissimilar sorbents’ particle shape and size, where sorbent 5 had relatively large and non-uniform aggregates, while sorbents 6–8 had smaller semi-spherical or semi-fibrous particles. Unsurprisingly, the NaOH treatment drastically changed the morphology of sorbents 9–12. Almost these sorbents donated semi-spherical particles of diameter ranging from 50 to 250 µm. Obviously, sodium hydroxide caused substantial change in the sorbent’s morphology as a result of matrix hydrolysis esp. for sorbent 12.

3.2 Sorbents’ assessment in removal of malachite green (efficiency and kinetics)

Malachite green removal from water solutions has been reported by numerous studies [11, 26,27,28,29,30,31,32,33,34,35,36,37,38] due to its high mutagenicity and toxicity [4] besides the high consumption in coloring industry [5, 39]. Thus, MG was applied as a dye probe in assessing the sorbents removal tendencies, where the % removal and the pseudo-second-order plot are overlaid in Fig. 2, applying sorbent 10 for illustrative purpose.

3.2.1 Malachite green removal efficiency

The calculated % removal indicated that sorbents 1–12 had different tendencies in the dye removal and dissimilar equilibrium contact times ranging from 1.0 to 3.0 min (Table 3). In fact, the % removal of MG by sorbents 1–12 was calculated at 0.5, 2.0, and 20 min, as adsorption patterns for preequilibrium, equilibrium, and post-equilibrium contact times, respectively (Table 4). Foremost, different adsorption tendency in dye removal was noticed at contact time of 0.5 min, always in comparison to sorbent 1 (Fig. 3). Sorbents 2–4 which was treated by water showed improvement in dye removal by 1–3%. However, sorbents treated by hydrochloric acid showed dissimilar adsorption tendency estimated by 3% drop by sorbent 5 and an improvement of 3–4% by sorbents 6–8 in dye removal. Apparently, sorbent 5 established the lowest MG % removal calculated at contact time of 0.5 min, which was contributed to the relatively large and non-uniform shaped particles that resulted in poor interaction and slower dye adsorption. Yet, its dye removal efficiency became comparable to that of other sorbents at contact times of 2.0 and 20.0 min (Fig. 3). Not surprisingly, the tendency in dye removal was improved for sorbents treated with sodium hydroxide (sorbents 9–12) by 1.5–3% compared to that of sorbent 1. In the light of the removal efficiency at 0.5 min, it was concluded that flow-through treatment (sorbents 5 and 9) demonstrated the lowest efficiency in dye removal (Fig. 3). In contrast, the sonication treatment by water or HCl and the shaking treatment by NaOH established the most efficient sorbents for dye removal (sorbents 4, 8 and 10). Finally, it was noticed that sorbents 1–12 showed comparable tendencies in dye removal of ≥ 98% at time ≥ 2 min, which changed negligibly at 20 min for all sorbents.

3.2.2 Assessment of adsorption kinetics of malachite green

Recently, it was reported that MG adsorption by SPM correlated well with pseudo-second-order plots applying Eq. 2 [11]. Likewise, the kinetics of dye adsorption was analyzed for sorbents 1–12. The linear correlation coefficient (R2) of the plotted kinetic data was regarded as the key factor to assess the kinetic design. Plotting the kinetic data was in favor of pseudo-second order, where the values of R2 ranged from 0.9997 to 0.9999 compared to ~ 0.90 for pseudo-first order.

where qt and qe are the amount of dye adsorbed at any specific time and at equilibrium (mg/g-sorbent), respectively, and k2 (g/mg min) is the rate constant pseudo-second-order model.

The adsorption rate for sorbents 1–12 was compared based on values of k2 (g/mg.min) (Fig. 4, Table 3). Thus, sorbents 2 and 3 demonstrated comparable k2 values, which were almost fourfold that of sorbent 1. However, sorbent 4 as water-sonicated established faster removal with k2 value of ~ 26-fold of sorbents 1, i.e., ~ sevenfold these of sorbents 2 and 3. Surprisingly, sorbent 5 had an almost equal k2 value to that of sorbents 1, which was due to the relatively large particles of non-uniform aggregates that slowed down dye adsorption. In addition, sorbents 6 and 7 had comparable k2 values of 102 and 135, which were almost sixfold to eightfold that of sorbent 1, respectively. Not surprisingly, HCl-sonication (sorbent 8) highly enhanced dye removal efficiency reaching k2 value of 812.1 g/mg min. Again, flow-through treatment by NaOH afforded sorbent 9 with relatively low k2 value, of only twice that of sorbent 1. Hence, Sorbent 10, treated by shaking in NaOH, established the highest dye removal rate with k2 of 1032.3, as > 60-fold that of sorbent 1. Such a remarkable adsorption removal rate, in shortest equilibrium contact time of < 1.0 min, was correlated with the relatively high CEC and the small particle size concluded, which was not the case for sorbent 5 having the slowest removal rate despite the identical CEC value for these two sorbents because sorbent 5 had a large non-uniform particle aggregates. Furthermore, sorbent 11 treated by stirring in sodium hydroxide solution had a k2 value of ~ 12-fold that of sorbent 1. Finally, as anticipated the relatively low value of k2 of sorbent 12 (~ 82 g/mg.min, ~ fivefold of sorbent 1) presented a discrepancy in the rate of dye removal for the sorbents treated by sonication, where the dye removal rate was ~ 5 and ~ 10 times lower than these of the corresponding sorbents 4 and 8. This was correlated with the highly damaged sorbent's CEC regardless of the smallest particle size among treated sorbents (Table 2). Finally, sorbents required different times to reach equilibrium, as sorbents 3, 4, 6, 8, 10, and 11 that had comparatively high k2 values demonstrated a 1-min adsorption equilibrium contact time (Fig. 5, Table 3), whereas the other sorbents of relatively low k2 values had an adsorption equilibrium contact time ranging from 1.5 to 3.0 min.

3.3 The dye adsorption thermodynamics

Thermodynamically, the dye adsorption equilibrium constant Kd ranged from 4.31 to 13.42 for sorbents 1–12 (Table 3). Moreover, the Gibbs free energy (ΔG°) for dye adsorption equilibrium ranged between − 3.62 and − 6.43 kJ/mol, for sorbents 1–12. Hence, the adsorption spontaneity and the low activation energy of the system were depicted from the negative values of ΔG° [11]. In addition, the adsorption of MG by SPM sorbents was merely a physisorption since the ΔG° values calculated were < − 80 kJ/mol [17].

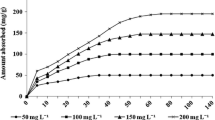

3.4 Adsorption maximum and equilibrium capacities

The malachite green adsorption maximum (qm) and equilibrium (qe) sorbent capacities were calculated for sorbents 1–12, from the kinetic plots (t/qe vs. time) and from Eq. 3, respectively.

where Co and Ce are the initial and equilibrium concentrations of MG (mg/L), and V is the solution volume (L), and m is the SPM mass (g).

Obviously, reasonable values of qm were concluded for all sorbents ranging between 4.909 to 4.980 mg/g-sorbent (Fig. 6, Table 3). In parallel, the values of qe were also comparable for sorbents 1–12, ranging from 4.888 to 4.963 mg/g-sorbent (Fig. 6, Table 3). In fact, the slightly high values of qm and qe were noticed for sorbents 7, 8, and 12, which were characterized by either small particle size or by high CEC.

3.5 Comparison of pretreatment reagents and methods

Sonication using water and HCl resulted in better sorbents with respect to CEC and the rate of dye removal, which had in fact furnished sorbents of competitive characteristics for ultrafast removal of MG from water solution. In contrary, sonication using NaOH turned out to be a poor treatment process since it highly damaged the sorbent CEC, which in turn deteriorated the rate of dye adsorption. However, the shaking treatment of sorbent in NaOH afforded the highest removal rate of MG, which was ~ 20-fold and ~ tenfold of these of corresponding treated sorbents by shaking in water and HCl, respectively (sorbent 10 vs. 2 and 6). Moreover, the stirring treatment method in water, HCl, and NaOH (sorbents 3, 7 and 11) enhanced the dye removal rate for the three solvents where the adsorption rate was fourfold, eightfold, and 12-fold that of sorbent 1, respectively. Finally, the flow-through treatment established the poorest removal efficiency inferred from the lowest k2 values among sorbents 2–12 (sorbents 5 and 9).

3.6 Reproducibility and errors

In order to check the reproducibility and to weigh the errors of the experimental measurements, three replicates were performed for each sorbent in determining the CEC, the % removal of MG, and k2 for sorbents 1–12. The average values are plotted and reported in Tables 3 and 4. Obviously, excellent reproducibility were concluded as the RSD values ranged from ± 0.5 to 9.1%, from ± 0.1 to 4.4%, and from ± 0.12 to 10.5% for the CEC, % removal, and k2, respectively.

4 Conclusion

Three treated sphagnum sorbents were concluded for the foremost highest dye removal rate that would suit for treatment of real contaminated water samples. Different reagents and treatment methods caused alteration of the physicochemical features of the SPM sorbents and subsequently dissimilar dye removal tendencies. The water and hydrochloric acid treatment by sonication afforded efficient sorbents for dye removal with relatively high adsorption rates. The most fruitful treatment was the NaOH by shaking furnishing a sorbent with the highest rate of dye adsorption of ~ 70 times that of non-treated sorbent. The values of the adsorption rate correlated well with the sorbents’ CEC and their morphology.

References

McLelland JK, Rock CA (1988) Pretreating landfill leachate with peat to remove metals. Water Air Soil Pollut 37:203–215. https://doi.org/10.1007/BF00226492

Gupta BS, Curran M, Hasan S, Ghosh TK (2009) Adsorption characteristics of Cu and Ni on Irish peat moss. J Eviron Manag 90:954–960. https://doi.org/10.1016/j.jenvman.2008.02.012

Gonzales APS, Firmino MA, Nomura CS, Rocha FRP, Oliveira PV, Gaubeur I (2009) Peat as a natural solid-phase for copper preconcentration and determination in a multicommuted flow system coupled to flame atomic absorption spectrometry. Anal Chim Acta 636:198–204. https://doi.org/10.1016/j.aca.2009.01.047

Ali I, Asim M, Khan TA (2012) Low cost adsorbents for the removal of organic pollutants from wastewater. J Environ Manag 113:170–183. https://doi.org/10.1016/j.jenvman.2012.08.028

Ho YS, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem Eng J 70:115–124. https://doi.org/10.1016/S0923-0467(98)00076-1

Henryk K, Jaroslaw C, Witold Z (2016) Peat and coconut fiber as biofilters for chromium adsorption from contaminated wastewaters. Environ Sci Pollut Res 23:527–534. https://doi.org/10.1007/s11356-015-5285-

Girardello F, Rovani S, Giovanela M, Fernandes SN (2016) Removal of pyrene from aqueous solutions by adsorption onto Brazilian peat samples. Adsorpt Sci Technol 34(9–10):538–551. https://doi.org/10.1177/0263617416670168

Kyziol J, Twardowska I, Schmitt-Kopplin Ph (2006) The role of humic substances in chromium sorption onto natural organic matter (peat). Chemosphere 63:1974–1982. https://doi.org/10.1016/j.chemosphere.2005.09.042

Batista APS, Romao LPC, Arguelho MLPM, Garcia CAB, Alves JPH, Passosa EA, Rosa AH (2009) Biosorption of Cr(III) using in natural and chemically treated tropical peats. J Hazard Mater 163:517–523. https://doi.org/10.1016/j.jhazmat.2008.06.129

Caramalau C, Bulgariu L, Macoveanu M (2009) Cobalt(II) removal from aqueous solutions by adsorption on modified peat moss. Chem Bull “POLITEHNICA” Univ (Timisoara) 54(68):13–17. http://www.chemicalbulletin.ro/admin/articole/21548art_3(13-17).pdf

Lubbad SH, Abu-Saqer KK, Kodeh FS (2018) Ultrafast and highly efficient removal of malachite green from aqueous solution by Latvia-originated sphagnum peat moss sorbent applying dispersive solid-phase extraction. Int J Environ Res 12(3):279–288. https://doi.org/10.1007/s41742-018-0090-2

Ringqvist L, Oborn I (2002) Copper and zinc adsorption onto poorly humidified Sphagnum and Carex peat. Water Res 36:2233–2242. https://doi.org/10.1016/S0043-1354(01)00431-6

Fernandes AN, Almeida CAP, Menezes CTB, Debacher NA, Sierra MMD (2007) Removal of methylene blue from aqueous solution by peat. J Hazard Mater 144:412–419. https://doi.org/10.1016/j.jhazmat.2006.10.053

Fine P, Scagnossi A, Chen Y, Mingelgrin U (2005) Practical and mechanistic aspects of the removal of cadmium from aqueous systems using peat. Environ Pollut 138:358–367. https://doi.org/10.1016/j.envpol.2005.03.003

Hemmati F, Norouzbeigi R, Sarbisheh F, Shayesteh H (2016) Malachite green removal using modified sphagnum peat moss as a low-cost biosorbent: kinetic, equilibrium and thermodynamic studies. J Taiwan Inst Chem Eng 58:482–489. https://doi.org/10.1016/j.jtice.2015.07.004

Smith DG, Lorimer JW (1964) An examination of the humic acids of sphagnum peat. Can J Soil Sci 44:74–87. http://www.nrcresearchpress.com/doi/pdf/10.4141/cjss64-011

Kyziol J (2002) Effect of physical properties and cation-exchange capacity on sorption of heavy metals on peats. Pol J Environ Stud 11(6):713–718. http://www.pjoes.com/pdf/11.6/713-718.pdf

Chieng HI, Lim LBL, Priyantha N (2015) Sorption characteristics of peat from Brunei Darussalam for the removal of rhodamine B dye from aqueous solution: adsorption isotherms, thermodynamics, kinetics and regeneration studies. Desalin Water Treat 55(3):664–677. https://doi.org/10.1080/19443994.2014.919609

Chieng HI, Zehra T, Lim LBL (2014) Sorption characteristics of peat of Brunei Darussalam IV: equilibrium, thermodynamics and kinetics of adsorption of methylene blue and malachite green dyes from aqueous solution. Environ Earth Sci 72(7):2263–2277. https://doi.org/10.1007/s12665-014-3135-7

Lim LBL, Priyantha N, Tennakoon DTB, Chieng HI, Chandima B (2013) Sorption characteristics of peat of Brunei Darussalam I: characterization of peat and adsorption equilibrium studies of methylene blue—peat interactions. Cey J Sci (Phys Sci) 17:41–51. http://www.pdn.ac.lk/research/journal/cjsps/pdf/abstract%2017_5.pdf

Chieng HI, Lim LBL, Priyantha N, Tennakoon DTB (2013) Sorption characteristics of peat of Brunei Darussalam III: equilibrium and kinetics studies on adsorption of crystal violet (CV). Int J Earth Sci Eng 6(4):791–801. https://www.researchgate.net/publication/286530218

Zehra T, Priyantha N, Lim Lim LBL, Iqbal E (2015) Sorption characteristics of peat of Brunei Darussalam V: removal of Congo red dye from aqueous solution by peat. Desalin Water Treat 54(9):2592–2600. https://doi.org/10.1080/19443994.2014.899929

Sepulveda L, Fernandez K, Contreras E, Palma C (2004) Adsorption of dyes using peat: equilibrium and kinetic studies. Environ Technol 25:987–996. https://doi.org/10.1080/09593332508618390

Fernandes AN, Almeida CAP, Debacher NA, de Souza Sierra MM (2010) Isotherm and thermodynamic data of adsorption of methylene blue from aqueous solution onto peat. J Mol Struct 982:62–65. https://doi.org/10.1016/j.molstruc.2010.08.006

Alemdaroglu T (2001) Determination methods for the acidity of solid surfaces. Commun Fac Sci Univ Ank Ser B 47:27–35. http://dergiler.ankara.edu.tr/dergiler/31/1386/15752.pdf

Garg VK, Kumar R, Gupta R (2004) Removal of malachite green dye from aqueous solution by adsorption using agro-industry waste: a case study of Prosopis cineraria. Dyes Pigments 62:1–10. https://doi.org/10.1016/j.dyepig.2003.10.016

Khattri SD, Singh MK (2009) Removal of malachite green from dye wastewater using neem sawdust by adsorption. J Hazard Mater 167:1089–1094. https://doi.org/10.1016/j.jhazmat.2009.01.101

Cheng W, Wang SG, Lu L, Gong WX, Liu XW, Gao BY, Zhang HY (2008) Removal of malachite green (MG) from aqueous solutions by native and heat-treated anaerobic granular sludge. Biochem Eng J 39:538–546. https://doi.org/10.1016/j.bej.2007.10.016

Sharma UYC (2013) Removal of malachite green from aqueous solutions by adsorption on to timber waste. IJEEM 4(6):631–638. http://www.ripublication.com/ijeem.htm

Mall ID, Srivastava VC, Agarwal NK, Mishra IM (2005) Adsorptive removal of malachite green dye from aqueous solution by bagasse fly ash and activated carbon-kinetic study and equilibrium isotherm analyses. Colloids Surf A 264:17–28. https://doi.org/10.1016/j.colsurfa.2005.03.027

Ahmad MA, Laozi R (2011) Removal of malachite green dye from aqueous solution using rambutan peel-based activated carbon: equilibrium, kinetic and thermodynamic studies. Chem Eng J 171:510–516. https://doi.org/10.1016/j.cej.2011.04.018

Zhang L, Zhang H, Guo W, Tian Y (2014) Removal of malachite green and crystal violet cationic dyes from aqueous solution using activated sintering process red mud. Appl Clay Sci 93–94:85–93. https://doi.org/10.1016/j.clay.2014.03.004

Dahri MK, Kooh MRR, Lim LBL (2014) Water remediation using low cost adsorbent wal-nut shell for removal of malachite green: equilibrium, kinetics, thermodynamic and regeneration studies. J Environ Chem Eng 2:1434–1444. https://doi.org/10.1016/j.jece.2014.07.008

Baek MH, Ijagbemi CO, Se-Jin O, Kim DS (2010) Removal of malachite green from aqueous solution using degreased coffee bean. J Hazard Mater 176:820–828. https://doi.org/10.1016/j.jhazmat.2009.11.110

Banerjee S, Sharma GC, Gautam RK, Chattopadhyaya MC, Upadhyay SN, Sharma YC (2016) Removal of malachite green, a hazardous dye from aqueous solutions using Avena sativa (oat) hull as a potential adsorbent. J Mol Liq 213:162–172. https://doi.org/10.1016/j.molliq.2015.11.011

Sartape AS, Mandhare AM, Jadhav VV, Raut PD, Anuse MA, Kolekar SS (2017) Removal of malachite green dye from aqueous solution with adsorption technique using Limonia acidissima (wood apple) shell as low cost adsorbent. Arab J Chem 10:S3229–S3238. https://doi.org/10.1016/j.arabjc.2013.12.019

Bouaziza F, Koubaab M, Kallela F, Ghorbel RE, Chaabouni SE (2017) Adsorptive removal of malachite green from aqueous solutions by almond gum: kinetic study and equilibrium isotherms. Int J Biol Macromol 105:56–65. https://doi.org/10.1016/j.ijbiomac.2017.06.106

Naseeruteen F, Abdul Hamid NS, Suah FBM, Ngah WSW, Mehamod FS (2018) Adsorption of malachite green from aqueous solution by using novel chitosan ionic liquid beads. Int J Biol Macromol 107:1270–1277. https://doi.org/10.1016/j.ijbiomac.2017.09.111

Allen SJ, Poots VJP, McKay G, Healy JJ (1976) The removal of acid dye from effluent using natural adsorbents—I. Peat. Water Res 10:1061–1066. https://doi.org/10.1016/0043-1354(76)90036-1

Acknowledgements

The authors would like to thank Mr. Ahmad O. Ashour and Mr. Ibrahim Saad for their invaluable assistance throughout this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors of this manuscript have seen and approved the final version of the manuscript being submitted. They warrant that the article is the authors’ original work, has not received prior publication and is not under consideration for publication elsewhere. Moreover, the authors confirm that the validity of research and that there is no financial or personal interest or belief that could affect their objectivity. This research was self-sponsored, and no grants were received. The authors state explicitly that no potential conflicts exist.

Rights and permissions

About this article

Cite this article

Abu-Saqer, K.K., Lubbad, S.H. Assessment of various treatment methods and reagents for cleanup and conditioning of sphagnum peat moss as sorbents in removal of malachite green as a cationic organic dye probe from water. SN Appl. Sci. 1, 20 (2019). https://doi.org/10.1007/s42452-018-0021-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-018-0021-z