Abstract

Safeguarding aquatic ecosystems and human health requires effective methods for removing pollutants. Mercury (Hg) is a very toxic pollutant with a global presence and is highly mobile and persistent. Here, innovative materials were prepared for separating Hg(II) from water, and the mechanisms underlying the efficient uptake of Hg species have been investigated. The sorbents include silver (Ag) nanoparticles and multilayered Ti3C2Tx MXene, both incorporated into the structure of a three-dimensional polyethyleneimine porous cryogel (PEI) that acts as a scaffold holding and exposing nano active sites involved in the removal of Hg. Specifically, Ag particles were deposited onto MXene phases, and the resulting composite was embedded in the macroporous PEI polymer (PEI/MXene@Ag cryogel). The composite has beneficial properties regarding Hg removal: 99% of Hg was separated from waste within 24 h in batch studies. The maximum removal capacity of Hg reached 875 mg/g from HgCl2, and 761 mg/g and 1280 mg/g from Hg(OAc)2 and Hg(NO3)2 salts by PEI/MXene@Ag. The Hg uptake stems from the composite’s relatively large specific surface area, layered porous channels, and highly dispersed Ag nanoparticles in the multilayered Ti3C2Tx MXene. The matrix in the water samples that were treated with the composite did not hinder the uptake of Hg by PEI/MXene@Ag. The high effectiveness achieved for the removal of Hg, combined with rapid adsorption kinetics, high efficiency, and selectivity, positions it as an efficient solution. Future work should address upscaling its preparation for increasing readiness towards mitigating Hg in surface water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Heavy metal pollution is a problem in aquatic ecosystems worldwide [1, 2]. According to the World Health Organization (WHO) and the United States Environmental Protection Agency (USEPA), the concentration of heavy metals in large bodies of water, such as the Half Park Lake (North America), the Danube River (Europe), the Nile River (Africa), the Pearl River (Asia), and the Matanza-Riachuelo (South America), exceed threshold values of toxicological concern [3]. The negative impacts of widespread heavy metal pollution in water are affecting every continent, and their bioaccumulation may affect the entire food chain [4,5,6].

Mercury (Hg) is one of the most toxic and common heavy metals, and its industry emissions threaten human health [7,8,9,10]. There are various approaches for removing Hg from water. These typically include adsorption, precipitation, electrolysis, ion exchange, membrane purification, or solvent extraction [11,12,13]. Among them, adsorption can be efficient, simple, and cost-effective; hence, it is suitable for large scale uses [14,15,16]. Activated carbon (AC), zeolites among others, have been widely used as adsorbents for Hg, although they often offer slow removal kinetics, poor adsorption capacity, and pH dependence for this metal. New composites are trying to overcome these challenges [17, 18], and there is a current technology gap for sustainable water treatment technologies with high performance that allow meeting regulations for regulated and emerging pollutants.

Composites that efficiently remove Hg and other heavy metals can rely on advantageous properties of nanomaterials [19]. For instance, a composite consisting of 2D molybdenum disulfide nanosheets (2D MoS2) in a 3D cellulose structure almost completely removed Hg(II) from aqueous solutions [20]. The incorporation of 2D MoS2 into a 3D sorbent improved the adsorption capacity offered, prevented aggregation of the nanosheets, and facilitated reusing the composite. Highly branched graphene oxide nanosheets incorporated onto a polyethyleneimine aerogel became efficient for treating Hg from freshwater (81% Hg removal at 50 µg Hg/L) thanks to its large number of oxidized functional groups and high specific surface area [21]. However, using nanomaterials in water treatment also entails limitations such as poor water dispersibility and self-aggregation, toxicity, and limited selectivity when treating pollutants [22].

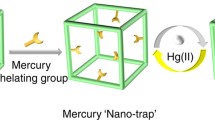

A promising family of 2D materials for water purification is MXenes. Despite that they were only discovered in 2011, MXenes can remove heavy metals from water [23,24,25]. Furthermore, there is evidence of its safety relevant to humans for some of its uses [26]. The 2D structure of MXenes, along with their abundant polar functional groups (-OH, -F, and -O), and very good dispersibility, are advantageous for the removal of both organic and metals from water [27]. Compared to other 2D structures, MXenes possess in situ reductive-adsorption capacity and can selectively remove Hg from wastewater [28,29,30,31,32]. Despite the potential safety of the nanomaterials used in this work, using nanomaterials dispersed in water for removing pollutants in the natural environment would not be a practical approach, and its risks do not outweigh the benefits [33]. Therefore, nanomaterials such as MXenes can be embedded in monoliths that would be employed to hold free nanoparticles. Cryogels are polymers with large interconnected macropores ranging in size from tens to several hundreds of micrometers, and their properties as nano-enablers are well established [34,35,36]. In this study, monolith filter cryogels will be prepared to maximize the removal of Hg as well as holding nanomaterials that would provide active sites involved in such removal. For the cryogel synthesis, the polyethyleneimine (PEI) was used as the main polymeric compound, due to the presence of primary, secondary, and tertiary amines, which are well-known metal chelating groups [37,38,39,40]. The study will focus on understanding mechanisms that drive the removal of Hg from water with Ti3C2Tx MXene doped with silver nanoparticles while embedded in cryogels. Nanosilver (Ag) can amalgamate Hg in hyperstoichiometric ratios, and this can add additional capacity for Hg removal [41]. The significance of this study is identifying the important properties that need to be preserved and maximized when upscaling the sorbent, and simplifying it, to enhance its impact and applicability.

2 Materials and methods

2.1 Materials

Dimethylacrylamide (DMAAm, 99%); N, N′-methylenebisacrylamide (BisAAm, 99%), polyethylenimine (PEI, 99%); N, N, N′, N′-tetramethylethylene-1,2-diamine (TEMED, 99%); allylamine (98%); phosphoric acid (H3PO4, ≥ 85%); sodium hydroxide (NaOH, ≥ 98%); ammonium persulfate (APS, 98%); hydrofluoric (HF, ≥ 48%); Hg(II) chloride (HgCl2, ≥ 99.5%); mercury (II) acetate (Hg(OAc)2, 97%); mercury (II) nitrate monohydrate (Hg(NO3)2 •H2O, ≥ 98.5%); and silver nitrate (AgNO3, > 99%), dimethyl sulfoxide (DMSO, ≥ 99.9%) were purchased from Sigma-Aldrich (Germany). Ti3AlC2 MAX phase (99%) was purchased from Carbon-Ukraine LTD. All experiments were performed with ultrapure water (Puris Eco RO 1600-M, South Korea).

2.2 Synthesis of PEI cryogel

PEI cryogels were prepared according to previous work [32]. Briefly, TEMED and APS acted as the catalyst and initiator, respectively. Allylamine and PEI were the monomers; BisAAm was the crosslinker, and the functional group precursor was DMAAm. Water (18.5 mL) was purged with N2 for 30 min and separated in two beakers. In one of them, 10 mL of the H2O with low air content, 260 mg of BisAAm, and 250 mg of PEI were stirred at room temperature until their full dissolution. In parallel, a second beaker, a fraction of the purged H2O (8.5 mL), and allylamine (0.3 mL) were mixed with concentrated H3PO4 (0.24 mL). Further, the solutions in both beakers were mixed, and the pH was adjusted to 7.5 by adding 5 M NaOH dropwise. TEMED (0.03 mL) was added to it, and the mixture was placed in an ice bath to reach 2–3 °C. Finally, 0.80 mL of 5% APS was added to the monomeric solution; the mixture was homogenized manually, and it was quickly transferred to plastic syringes (which had their narrow aperture sealed) placed in a refrigerated/heating circulator (F34 HE, Julabo, USA) filled with ethanol kept at − 12 °C for proceeding with the polymerization step. The mixture remained in the cryostat for 24 h to become cryogel monoliths. These were taken out from the syringes, thawed at room temperature, and washed several times in water to remove unreacted compounds. Following, they were frozen, lyophilized, and kept at room temperature and for future use.

2.3 Synthesis of MXene

Ti3AlC2 (1 g) MAX phase was gently dispersed in HF (10 mL of 48 wt%) in a plastic bottle and stirred for 24 h at room temperature as earlier reported [42]. The etched MXene was washed with 3.5 L of water via repeated centrifugation-decantation at 3500 rpm until the pH of the supernatant reached approximately ~ 6–7. To increase the interlayer spacing of multi-layer MXene, the washed Ti3C2Tx was suspended in DMSO and left stirring for 24 h. The DMSO/MXene suspension was washed via repeated (× 15) centrifugation-decantation at 3500 rpm. The obtained MXene sediment was filtered with 0.45-µm PVDF filter paper (Milli-Q, USA), vacuum dried, and preserved in a desiccator at room temperature for further studies.

2.4 Synthesis of MXene@Ag composite

Dry MXene (200 mg) was suspended in water (170 mL), and the suspension was mixed with 30 mL of aqueous solution of AgNO3 (100 mg). The mixture was stirred for 10 min at 300 rpm and washed through centrifugation (for 5 min at 3500 rpm in 96% ethanol for three times). The sediment was washed in water twice. The solid residue (MXene@Ag flakes) was filtered with 0.45-µm PVDF filter paper (Milli-Q, USA), vacuum dried for 24 h, and used for further characterization. Freshly prepared MXene@Ag colloidal solutions (therefore where the filtration step had been omitted) were used without drying for cryogel modification.

2.5 Synthesis of PEI/MXene@Ag composite

For the superficial deposition of MXene@Ag onto the cryogel walls, the cryogel monoliths (20 mg) were immersed in 10 mL of MXene@Ag colloidal solution and left shaking for 24 h. The resulting material was washed with water to remove any MXene@Ag residues from the cryogel pores. The modified composites were freeze-dried and stored in a desiccator at room temperature for further use. The same procedure was used to modify cryogels with raw MXene.

2.6 Characterization

The surface chemistry of the dry material was characterized with IR. Specifically, an ATR-FTIR spectrophotometer (Cary 600 Series, Agilent Technologies) was used in the range of 4000–400 cm−1 with a resolution of 4 cm−1 and a scanning speed of 1 cm−1 s−1. Before the acquisition, the synthesized materials were lyophilized and ground into fine powder with a mortar. To evaluate the morphology and elemental composition of the samples, they were examined with scanning electron microscopy (SEM) (Zeiss Crossbeam 540, Germany), operating at 5–20 kV. The SEM was coupled with energy-dispersive X-ray (EDX) spectrometry. High-resolution transmission electron microscopy (HRTEM) (JEM-2100 LaB6 HRTEM, JEOL, Japan), operating at 80 kV, was used to assess pre-ground powdered samples that had been suspended in alcohol and sonicated to avoid agglomeration. A 10 µL drop of the suspension was placed on a 300-mesh carbon-coated copper grid, and the sample was dried overnight. Compositional data from bare MXenes and modified cryogel composites was obtained with X-ray diffraction (XRD), using an X-ray diffractometer (Rigaku SmartLab, Japan) with a HyPix-3000 high-energy resolution 2D HPAD detector. Materials were scanned in the range from 5 to 70° with a diffraction angle of 2θ at 40 kV and 40 mA. X-ray photoelectron spectroscopy (XPS) measurements were conducted on a VG-Microtech Mutilab 3000 device equipped with a 9 channeltrons hemispherical electron analyzer and X-ray radiation source with Mg and Al anodes. The binding energies (BE) were calibrated by a C1s core level at 284.8 eV as a reference. The analysis of the zeta potential of the samples was done as follows: briefly, each sample with a mass 10 mg was added to 10 mL aqueous solution with adjusted pH (from 1 to 10). The pH value was adjusted by adding 1 M HCl or 1 M NaOH. After 24-h shaking, the pH was measured and readjusted if needed. Upon reaching stable pH values, the surface charge of each sample was analyzed with a Malvern Zetasizer Pro model.

2.7 Mercury adsorption experiments

The performance of the prepared composites for Hg adsorption was done by mixing 10 mg of materials with various Hg concentrations and volumes. Different Hg salts were tested independently as sources of Hg. The total amount of Hg was quantified with inductively coupled plasma-mass spectrometry (ICP-MS) (iCAP RQplus, Thermo Fisher, USA). Kinetic adsorption experiments were carried out as follows: 10 mg of the synthesized material, 20 mL 10 mg/L of Hg from independent salts (HgCl2, Hg(OAc)2, or Hg(NO3)2) adjusted to pH 3. The adsorption experiments were left stirring at room temperature. For the analysis of Hg at every time point, 30 µL of solution was collected, diluted, and analyzed to record the residual concentration of Hg. For isotherm studies, like in kinetic studies, 10 mg of the composites were mixed with 20 mL of Hg in solution. Here, the levels of Hg were 100–1000 mg/L. These solutions were prepared from the above mentioned salts and left for 24 h under the stirring. To analyze the speciation of Hg ions with pH, 100 mg/L HgCl2, Hg(OAc)2, and Hg(NO3)2 solutions were used, and the study was supported with Visual MINTEQ 3.1 program. To simulate realistic conditions for the treatment of environmental samples with various co-existing ions, tap water without any purifications was spiked with 10 mg/L Hg from solutions from the salts HgCl2, Hg(OAc)2, and Hg(NO3)2 with further pH adjustment to 3 using HCl or HNO3. Hg-spiked tap water solutions (50 mL) were mixed with 10 mg of PEI, PEI/MXene, and PEI/MXene@Ag samples and left for stirring for 24 h. To compare the efficiency of synthesized materials with commercial adsorbents for the removal of Hg ions, the H+-form ion-exchange resin (Merck), NaY synthetic zeolites (Sigma-Aldrich), and activated carbon (GUNT) were used. Flow-through experiments were carried out to evaluate the effectiveness of Hg removal in dynamic mode. The synthesized samples were cut into disks (6 mm thickness, 8 mm in diameter) of ~ 14–16 mg, and these were used for filtering 5 mg Hg/L aqueous solutions filtered through the monolith with the help of a peristaltic pump. The flow rates of the filtrate solution were 2.5–5 mL/min, depending on the experiment. Every minute, the filtered solutions were collected and analyzed by ICP-MS. All experiments were performed in duplicate, and the average values with their error bars (corresponding to the standard deviation) are presented in Figs. 3, 4, 5, and 6.

2.8 Applied adsorption models

The results of isotherm experiments were used to evaluate the fitting of experimental adsorption data to widely used Langmuir and Freundlich models. The linearized equation of the Langmuir sorption isotherm [43] is given in Eq. (1):

In Eq. (1), Ceq and C0 (mg/L) are the equilibrium and initial concentration of Hg ions in solution, respectively, qeq and qm are the equilibrium and maximum adsorption capacities in mg/g wet sorbent, while KL is the Langmuir constant (L/mg). The linear form of the Freundlich sorption (Eq. 2) isotherm is as follows [44]:

In Eq. (2), Ceq (mg/L) and qeq (mg/g) are the concentration and adsorption capacity at the equilibrium, and n (dimensionless) and KF are constants (units depend on the 1/n).

In order to evaluate the behavior of the adsorption kinetics, pseudo-first order and pseudo-second order models were fit to the experimental data [45]:

In Eqs. (3) and (4), qeq and qt are the amount (mg/g) of Hg adsorbed at equilibrium and at a given time, t, in min, respectively. The pseudo-first-order constant k1 (min−1) and the calculated qe can be obtained from the slope and intercept of the ln(qe − qt) versus t graph. The pseudo-second-order constant k2 (g·mg−1·min−1) and qe can be calculated from the t/qt versus t graph.

The breakthrough curve is plotted from the normalized instantaneous Hg concentration in solution (Ct/C0), and C0 is the initial concentration of Hg ions. When designing a fixed-bed adsorption column, important parameters are the breakthrough time (tb) and exhaustion time (ts) that can be deduced from the breakthrough curve. The breakthrough time (tb) is the point at which the concentration of Hg at a given time is divided by its initial concentration (Ct/C0) = 0.05, while the exhaustion time (ts) is when Ct/C0 = 0.95. The total amount of adsorbed Hg ions (qtotal) and the maximum adsorption capacity (qm) can be calculated with Eqs. (1) and (2), respectively, as indicated elsewhere [46].

In Eqs. (5) and (6), ttotal is the total duration of the filtration, C0 and Ct (mg/L) are Hg concentrations (mg/L) at the initial and at specific time points, M is the mass of sorbent in the column, Q is the filtration flow rate (mL/min), and A is the area under the breakthrough curve. The total amount of Hg (qtotal) adsorbed by the column can be calculated from Eq. (7):

The removal of Hg from the initial solution, expressed as percentage (%), can be calculated with Eq. (8).

The efficiency of the adsorption zone in the column, so-called mass transfer zone (MTZ), was calculated with Eq. (9) [47], where, Z is the total depth of the adsorbent in the column (mm).

The total effluent volume (Vs) and breakthrough volume (Vb) can be obtained by Eqs. (10) and (11), respectively.

Three models, namely Adam-Bohart’s, Thomas’s, and Yoon-Nelson’s, were used to adjust the experimental data of flow-through experiments. The Adams-Bohart model assumes that the rate of adsorption is proportional to both the concentration of the adsorbing species and the residual capacity of the adsorbent. The Adams-Bohart model is only used for the description of the initial part of the breakthrough curve and is expressed as linear Eq. (12) [48]:

where kAB (mL/mg/min) is the rate constant of the Adams-Bohart model, H (cm) is the bed depth, N0 (mg/L) is the maximum ion adsorption capacity per unit volume of adsorbent column, and U0 (cm/min) is the linear velocity of influent solution. A linear relationship between C/C0 and time is obtained for the relative concentration up to C/C0 = 0.5, and thus, the values of N0 and kAB were calculated as intercept and slope of the line.

Thomas’s model is one of the most widely used column performance models which allows predicting the relationship between concentration and time. It is presented in Eq. (13) [49]:

where C0 is the initial concentration of metal ions, C is that concentration at time t (mg/L), Q0 is the maximum adsorption capacity of the adsorbent (mg/g), qm is the amount of adsorbent (g), F is the flow rate (mL/min), t is the time of the experiment (min), and kTH is the Thomas’ model constant (mL/mg/min). Yoon-Nelson’s model (Eq. (14)) does not require detailed data about the characteristics of the adsorbate or from the physical proportions of the adsorption bed [50].

where kYN is Yoon-Nelson’s model constant (min−1), and τ is the time (min) required for 50% adsorbate breakthrough.

3 Results and discussion

The structure and composition of the material will affect the efficiency of Hg removal. The design of future approaches for Hg removal from environmental samples will be informed by research aiming at finding fundamental information such as the work presented here.

3.1 Morphology and structure of synthesized materials

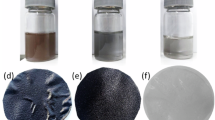

The morphology of the PEI/MXene@Ag cryogel composite is presented in Fig. 1. The SEM micrographs display a macroporous 3D channeled network for both the pure cryogel and the composite (Fig. 1A–E). Both the MXene and modified sorbent MXene@Ag presented multi-layer structure with typical accordion-like morphology of the MXenes (Fig. 1B, C), indicating that the etching of Al from the initial MAX phase was successful. After the modification of the composite, the MXene@Ag particles were found in the interior of the porous structure of the cryogel as well as on the surface (Supplementary, Figure S1). The composite had aggregates of Ag particles on the surface and between the MXene layers (Supplementary, Figure S2) as confirmed by EDX.

The amorphous cryogel structure from PEI/MXene can be appreciated with TEM in Fig. 2A. TEM is especially important for observing the distribution and size of metal nanoparticles. For the PEI/MXene@Ag composite, the particles on the surface of the cryogel were 10 to 30 nm; a representative detail of the composite is given in Fig. 2B. The composites were also examined with XRD before and after modification with Ag and MXene nanoparticles (Fig. 2C). The X-ray patterns obtained for Ti3C2Tx MXene had characteristic peaks for (004) and (008) at 2θ 21.16° and 27.68°, respectively [51] (Fig. 2C), and the MXene@Ag composite has four major diffraction peaks which can be indexed to the (111), (200), (220), and (311) planes of the face-centered-cubic Ag single crystal [52]. The composites’ surface chemistry was examined with high-resolution XPS (Fig. 2D). A comparative analysis of the XPS spectra from PEI/MXene@Ag composite and pristine PEI helps to observe characteristic peaks in the PEI/MXene@Ag composite attributed to the elements Ti, C, O, and Ag (Fig. 2E). For example, in the Ag 3d region, two peaks are observed at 367.3 eV and 373.3 eV from the presence of Ag 3d5/2 and 3d3/2 spin–orbit pairs, respectively [53]. The presence of MXene in the composite is indicated by peaks in the Ti 2p region characteristic of the Ti-C bond at 455.03 eV and Ti-C-F/O at 456.04 eV, also in the C1s region (Supplementary, Figure S3). A peak at 281.95 eV corresponds to a single C-Ti bond [54]. On the other hand, a peak at 529.75 eV in the O 1 s region indicates vacant O positions in defective TiO2 [55]. Thus, the analysis of the spectra obtained for the PEI/MXene@Ag composite and pristine PEI indicates successful modification, while for PEI, all peaks in the C1s and O1s regions are attributed to the presence of carbon bonds and the presence of oxygen functional groups, which is in good agreement with the literature [56]. The analysis of the surface charge of the PEI, PEI/MXene, and PEI/MXene@Ag samples by measuring zeta potential was performed, and results are presented in Figure S4 (in Supplementary). The zeta potential measurements for all samples measured from pH 1 to 10 show positive potential values. This is due to the presence of PEI, where amine groups are protonated [57]. Despite that MXene has a negative surface charge due to the presence of the O−, OH, and F− groups [58], the MXene content in PEI/MXene composite did not exceed 10 wt%, which did not show an impactful decrease of zeta potential values of composites. At the acidic pH 1–2, the zeta potential values from PEI/MXene (17.1 and 20.9 mV, respectively) were higher than bare PEI (11.8 and 15.9 mV) due to the protonation of the PEI amino groups and MXene OH groups, which in good agreement with previous works [59]. Further increase of the pH decreased the zeta potential values for all samples, reaching 5–8 mV at pH 10.

3.2 Mercury sorption studies

3.2.1 Mercury speciation

The occurrence of Hg species prepared from various salts, namely HgCl2, Hg(OAc)2, and Hg(NO3)2, at different pH, was predicted with Visual MINTEQ 3.1 (Fig. 3a–c). An outcome is that, to avoid the precipitation of Hg in the form of insoluble Hg(OH)2 onto adsorbents, it is necessary to carry out experiments at pH values < 5 when the starting salt is HgCl2, while for Hg(OAc)2 and Hg(NO3)2, the pH to mitigate precipitation should be < 3.

3.2.2 Sorption isotherms

Sorption isotherms with initial concentrations 100–1000 mg Hg/L using HgCl2, Hg(OAc)2, and Hg(NO3)2, independently, at pH 3, were performed to determine the maximum adsorption capacities of pristine PEI, and PEI/MXene, and PEI/MXene@Ag composites. The pH conditions of this study were chosen to avoid precipitation of insoluble Hg species and to determine the adsorption capacities of the prepared materials. The adsorption isotherms using HgCl2 presented a synergistic effect attributed to the modification of the pristine PEI with MXene and AgNPs on (Fig. 4A). At the initial concertation (C0) of Hg of 100 mg/L, PEI reached 145 mg/g maximum removal capacity (qmax), where both MXene-modified sorbents uptook Hg ions reaching ~ 200 mg/g capacity. With the increase of C0 from 200 to 1000 mg Hg/L prepared from HgCl2 salt, the qmax also increased to a maximum of 340 mg of Hg per g of PEI cryogel. For the PEI/MXene and PEI/MXene@Ag composites, both showed similar removal capacities until C0 = 500 mg/L with qmax values ~ 690 mg/g, which is > 3 times superior to what was achieved for the bare polymer PEI. With the increase of C0 to 800–1000 mg/L, just 10% difference in qmax values of the PEI/MXene (805 mg/g) and PEI/MXene@Ag (875 mg/g) were observed. Hence, a main factor of Hg uptake is MXene, but there is still improvement with the MXene modified with AgNPs. The adsorption isotherms (Fig. 4B) of Hg onto PEI, modified PEI/MXene, and PEI/MXene@Ag in solutions of Hg(OAc)2 at lower concentrations (C0 < 300 mg/L) show a similar pattern than that for the removal from HgCl2 solutions, where all Hg ions were removed by the composites. However, with the increase of initial Hg concentrations and using Hg(OAc)2 as starting salt, qmax reached 912 mg/g for PEI/MXene while it was 761 mg/g for PEI/MXene@Ag. Like for the study with HgCl2, MXene appears to have the key active sites for the removal of Hg.

The difference observed with the uptake of Hg with composites with or without Ag could be attributed to the speciation of Hg ions in solution, where positively charged Hg2+ and HgOH+ are the main species (50 and 18.5%, respectively). It is already reported in the literature that O− and F− negatively charged functional endings of MXene may attract various positively charged ions [60]. For PEI/MXene@Ag, some negatively charged groups of MXene were occupied with Ag during the modification step, which in turn decreases the removal capability of Hg cations. This observation also agrees with the removal performance of Hg from Hg(NO3)2 in solution (Fig. 4C), where 75% of Hg species are positively charged (60% for Hg2+ and 15% for HgOH+). The increase of positively charged Hg ions content in solution increased the maximum removal capacity of composites, where PEI/MXene@Ag reached ~ 840 mg/g, while PEI/MXene was able to remove up to 1280 mg/g of Hg. The experiments with distinct Hg salts highlight that the charge of the adsorbate plays an important role in the removal performance of Hg(II) by MXene-containing adsorbents and are aligned with previously published work that used the oxygen-containing MXene for the removal of Hg from nitrate and chloride salts [61]. In this research, Hu et al. reported that their synthesized adsorbents reached the maximum removal capacity of 1057 mg/g from Hg(NO3)2 and 773 mg/g from HgCl2 which supports the statement that MXene plays a significant role in adsorption performance [61]. In our recent experimental study of single-layered PEI/MXene@Ag composites for adsorption of Hg ions from water, ~ 98% removal efficiency was achieved with a maximum adsorption capacity of 156.2 mg/g [32]. However, the use of multi-layer MXene particles in current research increased the removal capacity of the composites possibly due to the increased number of available functional groups in both the MXene and in the polymer carrier. Exceptional removal capacities exceeding 5400 mg of Hg per g of single-layer MXene nanosheets were reported by Shahzad et al. [62], study that attributed the high removal capacity of Hg to the attraction an interaction between Hg(II) and OH groups, which led to sorption-electrochemical reduction [48].

Langmuir and Freundlich’s models were fitted to adsorption isotherms to explain the adsorption behavior (Table 1). The adsorption of Hg from HgCl2 and Hg(NO3)3 by PEI, PEI/MXene, and PEI/MXene@Ag fit better a Langmuir model (R2 values are in the range 0.9065–0.9925). The obtained model results propose that a monolayer adsorption on homogeneous sites of samples is predominant for these adsorbents. Nevertheless, the Langmuir model presented low R2 0.7122 for the pristine PEI. The Freundlich model, on the other hand, does not fit the sorption of most of the samples under study, and the corresponding R2 is showing low values (Table 1). However, for adsorption isotherms conducted with PEI and PEI/MXene using Hg(NO3)2, it had a good fit with the experimental values, demonstrating a possible multi-layer adsorption behavior on heterogeneous sites. A recent study on PEI-grafted carbon nanofibers for remediation of Hg2+ from solution reached an adsorption capacity of 19.2 mg/g, and it adjusted to a Langmuir model of isotherm [63]. Another study of a PEI composite (starch/PEI surface modified with mesoporous silica) by Yang et al. [64] achieved 97.9% removal of Hg with a capacity of 244.9 mg/g in 150 min and also had a good fit to the Langmuir model.

3.2.3 Kinetics

The kinetics studies of Hg adsorption using PEI, PEI/MXene, and PEI/MXene@Ag composites from three different Hg aqueous solutions (HgCl2, Hg(OAc)2, and Hg(NO3)2) at pH 3 were effective and fast. Most of the removal was < 10 h (Fig. 5A–C). Regarding the solutions spiked with HgCl2, > 50% of Hg2+ was removed in 5 h by the three sorbents, wherein the maximum Hg removal was reached with PEI/MXene (99%) and PEI/MXene@Ag (99%) within 48 h. In contrast, pristine PEI had an average removal of ~ 60% from that same starting salt within 48 h. Similar adsorption kinetic profiles were observed from Hg(NO3)2 solution, with the composites presenting the highest removal (99%) within 48 h. In contrast, the pristine PEI removed around 62% within 48 h under the same conditions. The removal performance of Hg by PEI, PEI/MXene, and PEI/MXene@Ag from Hg(OAc)2 solution was similar to that from HgCl2, wherein the half-fraction was removed within initial 5 h, while the remaining adsorption was reached in 48 h, achieving 99% Hg removal with PEI/MXene and PEI/MXene@Ag. The maximum adsorption of Hg from Hg(OAc)2 by PEI was similar in magnitude to that from the salts HgCl2 and Hg(NO3)2; it reached ~ 70% removal within 48 h. Such removal was lower than what was achieved with an adsorbent made of graphene oxide and PEI (GOPEI) [21]. The adsorption of Hg2+ from natural waters under conditions close to real environmental concentrations (50 µg/L) had the highest removal efficiency of 91% [21].

Kinetics models, pseudo-first order and pseudo-second order, were fitted to explain the removal dynamics under the study experimental conditions (presented in Table 2). The modeling results demonstrate that the rate-limiting mechanism of Hg removal in all studied samples is most probably chemisorption, based on the correlation coefficients (R) achieved. The latter hypothesis fits well with all sorbents PEI, PEI/MXene, and PEI/MXene@Ag as the removal process in all of them is attributed to chemical sorption involving interaction with superficial functional groups in all of them, in addition to Hg-Ag reactions in the case of PEI/MXene@Ag. The modeling results here are in agreement with the recent studies by Gou et al. [65] on PEI based polymer sponge developed by a cryopolymerization and PEI-modified carboxymethylcellulose beads by Yoo et al. [66].

3.3 Removal of Hg ions from ultrapure and tap water with the derivatized PEI materials and commercial adsorbents

To evaluate the performance of Hg removal, the sorption of the new material PEI and its modifications (PEI/MXene and PEI/MXene@Ag samples) was compared with that from commercially available adsorbents, e.g., ion-exchange resin (IER), zeolite (ZEO), and activated carbon (AC). This was done with Hg2+ from three different counter ions as it is well known that these can affect Hg sorption [67]. The adsorption characteristics were further assessed in ultrapure water and tap water (Fig. 6A, B). According to the findings, from Hg spiked in ultrapure water, PEI showed a comparable or slightly higher removal (between 8 and 27%) than the commercial adsorbents, where the Hg removal for IER and Zeo was < 10%. The sorption was indeed affected by the nature of the counter-ion. The modified PEI composites displayed a substantially improved removal that ranged from 55 to 95% in all three counter-ion solutions of Hg2+. In contrast, the removal capacity of Hg in solution (pH 3) with the commercial adsorbents was < 30% in tap water using three different Hg-solutions (HgCl2, Hg(OAc)2, Hg(NO3)2) and 10 mg Hg/L as initial concentration. There were comparable values of Hg adsorption with all the salts used. PEI presented an adsorption value of 10–20%, while the modified PEI/MXene and PEI/MXene@Ag had higher removal (45–87%). The different adsorption behavior of PEI/MXene and PEI/MXene@Ag samples was in agreement with the speciation studies of various Hg salts used: it was dependent on the surface charge of the sorbent and the active surface area of MXene involved in attracting more Hg2+ from the solution to enhance the adsorption performance. Similar studies on Hg2+ removal from water using natural and synthetic zeolites were performed by Inglezakis et al. [68] and Tauanov et al. [69]. They emphasized a crucial role of impregnating sorbents with Ag+, Ag, and Ag2O nanoparticles to enhance Hg removal [68]. Further research on the influence of Cl− and NO3− counter ions on Hg2 uptake concluded that the adsorption of Hg2+ from solution using silver-modified zeolites depended on the pH, the initial concentration of Hg, and the counter ions present (acetate, chloride, or nitrate) [68, 69]. Here, we add that the adsorption of Hg is also affected by surface charge with the PEI/MXene@Ag composites. The modified PEI/MXene and PEI/MXene@Ag demonstrated a significant improvement (3–9 times better) over commercial adsorbents (IER, zeolites, AC), and this can be because of the availability of the abundant number of available functional groups (e.g., OH) and the interaction of Ag with Hg.

Removal of Hg from different salts from A ultrapure water and B tap water with synthesized and commercial adsorbents. IER refers to H.+-form ion-exchange resin, Zeo refers to NaY synthetic zeolites, and AC corresponds to activated carbon. The material mass was 10 mg; volume of solution, 50 mL; concentration of Hg ions, 10 mg/L; pH 3

To further understand the Hg adsorption mechanisms onto PEI composites from real water matrices, adsorption profiles of the prepared composites and commercial adsorbents were compared. This was carried out by treating spiked tap water spiked with Hg from salts with different counter ions. In addition, the concentrations of other cations were quantified (before and after the removal of Hg) in water. The initial Hg2+ aqueous solution mainly contained > 10 mg/L of Hg, high concentrations of the following metal ions Na ≥ Ca > Mg > > K, and a trace amount of Ba, Fe, and Zn (see results in Table 3). Post-adsorption measurements demonstrated that metal ions changed in the IER and Zeo samples, which may be because of ion exchange that can take place with these adsorbents. The water tested with commercial AC had an increase of Ca2+ after Hg adsorption, most probably related to ion exchange of the Ca ions from the surface of AC. It was confirmed by EDX analysis that bare AC has > 4% in mass of Ca2+ (Supplementary Figure S5). The same statement could be applied for Fe ions in AC, where the initial Fe content in the AC of 1.21 ± 0.002% could be leached into the solution. The increase of the iron content in water samples after the Hg removal was observed for all Hg salt solutions after the AC treatment. Other metals such as Na+, Mg2+, and K+ decreased their concentration in real water samples after interactions with adsorbent. This is possibly due to the non-selectivity of the composites when uptaking Hg. In contrast, the MXene-modified samples showed comparatively higher adsorption of Hg species across the studied counter ions of Hg2+ in solution, demonstrating a degree of selectivity for the removal of Hg regardless of the counter ion present.

3.4 Analysis of breakthrough parameters in filtration studies

The effectiveness of monolithic adsorbents in fixed-bed columns can be evaluated by assessing the breakthrough curves presented in Fig. 7. These were achieved under flow rates, expressed with liquid hourly space velocity (LHSV), of 0.42, 0.94, and 1.37 h−1 for PEI, PEI/MXene, and PEI/MXene@Ag; these are comparable to the conditions in water treatment plants [70]. The breakthrough from unmodified PEI cryogel reached saturation faster (~ 1 h) than its composites. The PEI/MXene filtration media reached saturation after 82 min, while PEI/MXene@Ag was fully loaded with Hg ions from 100 min. All the three sorbents tested sorbed Hg very fast given the concentrations of Hg < limit of detection (0.01 mg/L) at the start of the water filtration. The fast saturation of the PEI cryogel indicates that the number of active sites on the polymer adsorb is limited, while MXene composites took longer to reach saturation and removed more Hg ions, mainly due to MXenes which were estimated to adsorbed up to 5473 mg of Hg/g of MXene [62]. The assessment of the breakthrough curves from Hg removal from water samples is in Table 4. The breakthrough time (tb) for PEI was 33 min, 16 min for PEI/MXene, and 24 min for PEI/MXene@Ag composite. The exhaustion time ts reached 58, 78, and 98 min, respectively. The maximum removal capacity qmax was estimated at 52, 63, and 114 mg/g of Hg ions for PEI, PEI/MXene, and PEI/MXene@Ag, respectively. The increasing trend of qmax by composites corresponds to the results of isotherm studies.

The breakthrough experiment results were analyzed by applying the Thomas, Adam-Bohart, and Yoon-Nelson adsorption models [48,49,50]. The parameters from these models extracted from the filtration experiments are presented in Table 5. According to the Thomas model, kTH values for PEI and PEI/MXene@Ag are almost similar (0.0032 and 0.0039 mL/mg/min), while the PEI/MXene had > 2 increase in kTH value. The values of q0 also follow the same trend, where the PEI and PEI/MXene@Ag reached 120.6 and 173.8 mg/g of Hg removal, respectively, while PEI/MXene reached only 76.4 mg/g. However, the R2 value for PEI/MXene was found to be close to 1 (0.9925) while the rest of the sorbents had lower R2 values. In this regard, it can be concluded that the removal of Hg ions by PEI/MXene sample fits well the Thomas model, while for PEI and PEI/MXene@Ag, the external and internal diffusion was a limiting step.

The Adam-Bohart model predicts a linear relationship between adsorbent bed depth and time required for the breakthrough. According to the obtained results, kAB rate coefficient for PEI/MXene was the highest (0.022 mL/mg/min), followed by PEI/MXene@Ag and PEI cryogel. The N0, values which are the maximum adsorption capacity of the materials per unit of fixed-bed volume, took place following the order PEI > PEI/MXene > PEI/MXene@Ag. The values of the constant rate (kYN), time needed for 50% breakthrough (τ), and q0 estimated from the slope and intercept of the Yoon-Nelson plot, are collected in Table 5. The kYN values were 0.2511 min−1 for PEI, 0.0584 min−1 for PEI/MXene, and 0.0438 min−1 for PEI/MXene@Ag. The experimental data were also found to be well fitted with the Yoon-Nelson model with correlation coefficients in the range 0.9151–0.9833. This means that the study modifications of PEI reduced the speed of Hg uptake, possibly because the active sites are not immediately used.

3.5 Removal mechanism

For the understanding of Hg removal mechanisms with the PEI/MXene@Ag composite, examining the Hg uptake mechanisms with 2D MXene and 3D cryogels separately is necessary. In this context, understanding the removal mechanisms for each material individually and collectively will lead to a comprehensive understanding of the Hg adsorption process. Surface functional groups of the composites (before and after Hg adsorption) were examined using XPS (Supplementary, Figure S3 and S8). New characteristic peaks of Hg appeared post-adsorption in all materials, confirming the removal of Hg ions from aqueous solution. For instance, the Hg 4f spectrum exhibited two peaks, 4f7/2 and 4f5/2, at binding energies of 100.5 eV and 104.6 eV, respectively, with a ~ 4.1 eV separation, indicating different oxidation states of Hg. Relatively weak doublet peaks at 101.6 eV and 105.5 eV correspond to Hg(II) 4f7/2 and Hg(II) 4f5/2, respectively. These findings are in agreement with earlier work [29], where the removal of Hg(II) from aqueous environments occurred via adsorption combined with catalytic reduction. HgClOH preferably interacts with open positive {001}-Ti due to strong O-Ti atom interactions, leading to immediate homolytic cleavage, forming •OH and •HgCl radicals [29]. Both doublets are separated by ~ 4.1 eV between Hg 4f7/2 and Hg 4f5/2 peaks. Based on the proposed mechanism, the contribution of the catalytic reduction reaction to maximum removal capacity outweighs adsorption, demonstrating the significance of this new removal mechanism [29]. Moreover, Ti 2p spectra analysis also indicates the adsorption process of Hg ions, evident from the energy peak shift from 463.3 to 458.4 eV. This shift can be explained by the adsorption of Hg(II) on the MXene surface. In the case of interaction of Ag with Hg in PEI/MXene@Ag composite, it was found that silver before the interaction with Hg has doublet peak for3d5/2 and 3d3/2 binding energy values of 367.3 and 373.3 eV while after the formation of AgHg amalgam, the Ag peaks shifted for the higher region (Supplementary, Figure S8). Moreover, the spectrum of the Hg 4f after AgHg formation shows two peaks at the binding energy values of 100.5 and 104.6 eV for 4f7/2 and 4f5/2, with the difference between peaks of 4.1 eV which indicate the presence of Hg in the Hg0 state. These observations strongly match with the literature data and suggest the formation of AgHg amalgam [71].

The XRD characterization of the materials post-sorption was also carried out to understand mechanisms of Hg(II) removal from the three Hg salt solutions. Figure 8A presents XRD data for the PEI/MXene@Ag composite after sorption for Hg chloride, which is characterized by Hg2Cl2 peaks at 2θ = 21.4, 28.2, and 32.8°, which confirms the reduction of HgCl2 to Hg2Cl2. In this case, peaks are observed at 2θ 32.3°, 52.9°, 54.8°, 57.4°, and 67.4° which can be attributed to Ag2Hg3 and the cubic phase of AgCl phases [61, 72]. The X-ray diffraction pattern demonstrates the reduction of Hg(II) to Hg0 due to the formation of bonds with reactive atoms of silver nanoparticles, which also confirms the proposed mechanism, where the contribution of the catalytic reduction outweighs adsorption of Hg chloride, demonstrating the significance of this new removal mechanism. On the other hand, the removal mechanism of Hg(NO3)2 and Hg(OAc)2 solutions using PEI/MXene@Ag composite was found to have significant differences compared to HgCl2. Thus, the XRD spectra after the adsorption of solutions of Hg(II) from nitrate and acetate salts show a characteristic peak at 37.4°, indicating the formation of HgO (Fig. 8C). However, this peak is not observed for studies including HgCl2, which also confirms the proposed removal mechanism involving reduction. At the same time, the X-ray diffraction patterns for PEI/MXene@Ag after the adsorption of Hg from solutions of Hg(II) nitrate and Hg(II) acetate have similar peaks, for example, at 2θ 32.8°, 40.3°, 43.8°, 52.9°, 57.4°, and 67.4° which refer to Ag2Hg3 and the cubic phase of the AgCl phase. The formation of such compounds occurs regardless of the type of salt, which is confirmed by several studies and indicates the high reactivity of Ag nanoparticles. However, there is a difference in the X-ray diffraction patterns for pure PEI cryogel (Fig. 8B and C, black line). In this regard, for Hg(NO3)2 and Hg(OAc)2, the mechanism of adsorption of Hg ions is electrostatic interaction and surface complexation, which is consistent with many works [28, 73].

Thus, the adsorption mechanisms of heavy metal ions on MXene-based adsorbents may differ depending on the adsorbent used and surface charge of the heavy metal ion being removed. These mechanisms can take several forms, primarily including electrostatic interactions, ion exchange, surface complexation, and catalytic reduction. Further research into the mechanisms of adsorption of Hg when in the presence of other heavy metal ions onto MXene will be key to the effective use of this material in water treatment and other applications. Future work will also need to include a variety of water matrices although the sorbent will not be used in environmental remediation soon. This is because nano-enabled water purification devices, like this one, will also need some sustainable considerations regarding their life cycle before their use in the real scenario; these are impacts of the extraction of the precursors of the material, manufacturing, use, and end-of-life [74].

4 Conclusion

The composite made of PEI cryogel modified by Ti3C2Tx MXene with AgNPs has been prepared, and it presents high efficiency for removing Hg from aqueous solutions at pH 3. The use of three different Hg salts, namely HgCl2, Hg(OAc)2, and Hg(NO3)2, gave an opportunity to evaluate the effect of co-existing anions and surface charge of Hg species to identify the mechanism of adsorption. Bare PEI cryogel enabled reaching the maximum removal capacity of Hg: 340 mg Hg/g by bare PEI when the source of Hg was HgCl2, while MXene modification increased the removal twofolds. The use of Hg(OAc)2 and Hg(NO3)2 resulted in the formation of positively charged Hg2+ species, which in turn increased Hg removal capabilities. The qmax for PEI/MXene reached 912 mg/g and ~ 840 mg/g from Hg(OAc)2 and Hg(NO3)2 salts, respectively, while PEI/MXene@Ag sorbed 761 mg Hg/g and 1280 mg Hg/g from these same salts. Hence, Ag was not essential for boosting Hg removal. The analysis of PEI/MXene@Ag composite and individual MXene and cryogels unveils diverse Hg removal mechanisms: confirmation of effective Hg(II) adsorption with catalytic reduction, evident through distinct Hg peaks in XPS, emphasizing varied pathways for heavy metal ion adsorption contingent upon the adsorbent and metal type. These results can serve as a starting point for further research and development in the field of materials and technologies for water decontamination, contributing to the improvement of the environment and ensuring the safety of water resources for future generations.

Data availability

No datasets were generated or analysed during the current study.

References

Zhang H, Wang Z, Zhao Y, Cui W, Zhang X, Wang S, Walter ED, Sassi MJ, Pearce CI, Clark SB, Rosso KM (2023) Metal ion (Cr3+, Eu3+, UO22+) adsorption on gibbsite nanoplates. Eng Sci:. https://doi.org/10.30919/es896

Zhang H, Ding X, Wang S, Huang Y, Zeng X-F, Maganti S, Jiang Q, Huang M, Guo Z, Cao D (2022) Heavy metal removal from wastewater by a polypyrrole-derived N-doped carbon nanotube decorated with fish scale-like molybdenum disulfide nanosheets. Eng Sci:. https://doi.org/10.30919/es8d649

World Health Organization. Regional Office for Europe & Joint WHO/Convention Task Force on the Health Aspects of Air Pollution. (2007). Health risks of heavy metals from long-range transboundary air pollution. World Health Organization. Regional Office for Europe. https://iris.who.int/handle/10665/107872

Tchounwou PB, Yedjou CG, Patlolla AK, Sutton DJ (2012) Heavy metal toxicity and the environment, In: Luch A (Ed.), Molecular, Clinical and Environmental Toxicology, Springer Basel, Basel: pp 133–164. https://doi.org/10.1007/978-3-7643-8340-4_6

Un Environment ed. (2019) Global environment outlook – GEO-6: healthy planet, healthy people:, 1st ed., Cambridge University Press. https://doi.org/10.1017/9781108627146

Kumar A, Singh MV, Bhatt N, Jayaswal P, Sethi M, Burcar E, Wang Z (2024) The perils of heavy metal contamination in groundwater: impacts on human health in the northeastern region of Jhunjhunu, Rajasthan, ES Food Agrofor. https://doi.org/10.30919/esfaf1079

Streets DG, Horowitz HM, Jacob DJ, Lu Z, Levin L, ter Schure AFH, Sunderland EM (2017) total mercury released to the environment by human activities. Environ Sci Technol 51:5969–5977. https://doi.org/10.1021/acs.est.7b00451

Renberg I, Persson MW, Emteryd O (1994) Pre-industrial atmospheric lead contamination detected in Swedish lake sediments. Nature 368:323–326. https://doi.org/10.1038/368323a0

Bluhm RE, Bobbitt RG, Welch LW, Wood AJJ, Bonfiglio JF, Sarzen C, Heath AJ, Branch RA (1992) Elemental mercury vapour toxicity, treatment, and prognosis after acute, intensive exposure in chloralkali plant workers. Part I: History Neuropsychol Find Chelator Effects Human Exp Toxicol 11:201–210. https://doi.org/10.1177/096032719201100308

Minamata Convention on Mercury (2023) Minamata convention on mercury - text and annexes. https://minamataconvention.org/en/resources/minamata-convention-mercury-text-and-annexes

Yu J-G, Yue B-Y, Wu X-W, Liu Q, Jiao F-P, Jiang X-Y, Chen X-Q (2016) Removal of mercury by adsorption: a review. Environ Sci Pollut Res 23:5056–5076. https://doi.org/10.1007/s11356-015-5880-x

Li Y, Yu J, Liu Y, Huang R, Wang Z, Zhao Y (2022) A review on removal of mercury from flue gas utilizing existing air pollutant control devices (APCDs). J Hazard Mater 427:128132. https://doi.org/10.1016/j.jhazmat.2021.128132

Liu Z, Liu D, Zhao B, Feng L, Ni M, Jin J (2020) Mercury removal based on adsorption and oxidation by fly ash: a review. Energy Fuels 34:11840–11866. https://doi.org/10.1021/acs.energyfuels.0c02209

Cheng M, Yao C, Su Y, Liu J, Xu L, Bu J, Wang H, Hou S (2021) Cyclodextrin modified graphene membrane for highly selective adsorption of organic dyes and copper (II) ions. Eng Sci:. https://doi.org/10.30919/es8d603

Wu Q, Gao L, Huang M, Mersal GAM, Ibrahim MM, El-Bahy ZM, Shi X, Jiang Q (2022) Aminated lignin by ultrasonic method with enhanced arsenic (V) adsorption from polluted water. Adv Compos Hybrid Mater 5:1044–1053. https://doi.org/10.1007/s42114-022-00492-5

Hou K, Xu X, Xiang Y, Chen X, Lam SS, Naushad M, Sonne C, Ge S (2023) Rapid uptake of gold ions by sulfonated humic acid modified phenolic resin with high adsorption capacity and selectivity. Adv Compos Hybrid Mater 6:77. https://doi.org/10.1007/s42114-023-00647-y

Velarde L, Nabavi MS, Escalera E, Antti M-L, Akhtar F (2023) Adsorption of heavy metals on natural zeolites: a review. Chemosphere 328:138508. https://doi.org/10.1016/j.chemosphere.2023.138508

Muliwa AM, Oyewo OA, Maity A (2023) Recent progress on the removal of aqueous mercury by carbon-based adsorbents: a review. Inorg Chem Commun 156:111207. https://doi.org/10.1016/j.inoche.2023.111207

Whitby RLD, Busquets R (2013) Nanomaterials and the environment: global impact of tiny materials, Nanomaterials and the. Environment 1:1–2. https://doi.org/10.2478/nanome-2012-0001

Fang Y, Lu A, Zhao D, Su K, Li Z, Wang Y, Shen XC, Liu K, Ruan C (2022) Facile synthesis of widened MoS2 nanosheets vertically anchored on natural cellulose fibers for efficient removal of mercury ions from aquatic systems. J Environ Chem Eng 10:108229. https://doi.org/10.1016/J.JECE.2022.108229

Bessa A, Henriques B, Gonçalves G, Irurueta G, Pereira E, Marques PAAP (2020) Graphene oxide/polyethyleneimine aerogel for high-performance mercury sorption from natural waters. Chem Eng J 398:125587. https://doi.org/10.1016/J.CEJ.2020.125587

Baimenov A, Montagnaro F, Inglezakis VJ, Balsamo M (2022) Experimental and modeling studies of Sr 2+ and Cs + sorption on cryogels and comparison to commercial adsorbents. Ind Eng Chem Res 61:8204–8219. https://doi.org/10.1021/acs.iecr.2c00531

Anasori B, Lukatskaya MR, Gogotsi Y (2017) 2D metal carbides and nitrides (MXenes) for energy storage. Nat Rev Mater 2:16098. https://doi.org/10.1038/natrevmats.2016.98

Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, Hultman L, Gogotsi Y, Barsoum MW (2011) Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv Mater 23:4248–4253. https://doi.org/10.1002/adma.201102306

Bhat A, Anwer S, Bhat KS, Mohideen MI, Liao K, Qurashi A (2021) Prospects challenges and stability of 2D MXenes for clean energy conversion and storage applications. npj 2D Mater Appl 5: 61. https://doi.org/10.1038/s41699-021-00239-8

Ward EJ, Lacey J, Crua C, Dymond MK, Maleski K, Hantanasirisakul K, Gogotsi Y, Sandeman S (2020) 2D Titanium carbide (Ti 3 C 2 T x ) in accommodating intraocular lens design. Adv Funct Materials 30:2000841. https://doi.org/10.1002/adfm.202000841

Zheng W, Yang Z, Chen J, Zhang M, Zu H, Qin R, Qu W, Yang J, Leng L, Li H (2023) Universal pathway towards metal sulfides decorated 3D porous Ti3C2Tx MXene aerogel for vapor-phase mercury removal. Chem Eng J 146402. https://doi.org/10.1016/j.cej.2023.146402

Isfahani AP, Shamsabadi AA, Alimohammadi F, Soroush M (2022) Efficient mercury removal from aqueous solutions using carboxylated Ti3C2Tx MXene. J Hazard Mater 434:128780. https://doi.org/10.1016/j.jhazmat.2022.128780

Fu K, Liu X, Yu D, Luo J, Wang Z, Crittenden JC (2020) Highly efficient and selective Hg(II) removal from water using multilayered Ti3C2Ox MXene via adsorption coupled with catalytic reduction mechanism. Environ Sci Technol 54:16212–16220. https://doi.org/10.1021/acs.est.0c05532

Shahzad A, Nawaz M, Moztahida M, Jang J, Tahir K, Kim J, Lim Y, Vassiliadis VS, Woo SH, Lee DS (2019) Ti3C2Tx MXene core-shell spheres for ultrahigh removal of mercuric ions. Chem Eng J 368:400–408. https://doi.org/10.1016/j.cej.2019.02.160

Solangi NH, Karri RR, Mubarak NM, Mazari SA, Jatoi AS, Koduru JR (2023) Emerging 2D MXene -based adsorbents for hazardous pollutants removal. Desalination 549:116314. https://doi.org/10.1016/j.desal.2022.116314

Megbenu HK, Daulbayev C, Nursharip A, Tauanov Z, Poulopoulos S, Busquets R, Baimenov A (2023) Photocatalytic and adsorption performance of MXene@Ag/cryogel composites for sulfamethoxazole and mercury removal from water matrices. Environ Technol Innov 32:103350. https://doi.org/10.1016/j.eti.2023.103350

Gilbertson LM, Zimmerman JB, Plata DL, Hutchison JE, Anastas PT (2015) Designing nanomaterials to maximize performance and minimize undesirable implications guided by the Principles of Green Chemistry. Chem Soc Rev 44:5758–5777. https://doi.org/10.1039/C4CS00445K

Ayatzhan A, Tashenov A, Nurgeldi A, Zhanar O, Zhexenbek T, Kaldibek A, Nuraje N (2021) P(DADMAAC-co-DMAA): synthesis, thermal stability, and kinetics. Polym Adv Techs 32:2669–2675. https://doi.org/10.1002/pat.4999

Akhmetzhan A, Myrzakhmetova N, Amangeldi N, Kuanyshova Z, Akimbayeva N, Dosmaganbetova S, Toktarbay Z, Nik S (2021) Longinos A short review on the N, N-dimethylacrylamide-based hydrogels. Gels 7:234. https://doi.org/10.3390/gels7040234

Baimenov A, Berillo D, Abylgazina L, Poulopoulos SG, Inglezakis VJ (2018) Novel amphoteric cryogels for Cd2+ ions removal from aqueous solutions. KEM 775:376–382. https://doi.org/10.4028/www.scientific.net/KEM.775.376

Xie X, Gao H, Luo X, Zhang Y, Qin Z, Ji H (2022) Polyethyleneimine-modified magnetic starch microspheres for Cd(II) adsorption in aqueous solutions. Adv Compos Hybrid Mater 5:2772–2786. https://doi.org/10.1007/s42114-022-00422-5

Hou C, Xie H, Qu Y, Tian H, Jiang J, Lu H, Yang S, Ma Y (2023) Rigid-flexible double coating silicon oxide composed of pitch pyrolytic carbon and polyvinyl alcohol/polyethyleneimine/carbon nanotubes as high-performance anode material for lithium-ion battery. Adv Compos Hybrid Mater 6:143. https://doi.org/10.1007/s42114-023-00715-3

Li X, Chen P, Sun X, AlMasoud N, Wang C, Alomar TS, Algadi H, Sun B, Lian Z, Guo X (2023) Electrophoretically deposited “rigid-flexible” hybrid graphene oxide-polyethyleneimine on carbon fibers for synergistically reinforced epoxy nanocomposites. Adv Compos Hybrid Mater 6:152. https://doi.org/10.1007/s42114-023-00726-0

Song J, Wang Y, Qiu J (2018) High adsorption performance of methyl blue from aqueous solution using hyperbranched polyethyleneimine grafted MWCNTs as an adsorbent. ES Mater Manuf:. https://doi.org/10.30919/esmm5f193

Katok KV, Whitby RLD, Fukuda T, Maekawa T, Bezverkhyy I, Mikhalovsky SV, Cundy AB (2012) Hyperstoichiometric interaction between silver and mercury at the nanoscale. Angew Chem Int Ed 51:2632–2635. https://doi.org/10.1002/anie.201106776

Mathis TS, Maleski K, Goad A, Sarycheva A, Anayee M, Foucher AC, Hantanasirisakul K, Shuck CE, Stach EA, Gogotsi Y (2021) Modified MAX phase synthesis for environmentally stable and highly conductive Ti 3 C 2 MXene. ACS Nano 15:6420–6429. https://doi.org/10.1021/acsnano.0c08357

Langmuir I (1916) The constitution and fundamental properties of solids and liquids. PART I. SOLIDS. J Am Chem Soc 38: 2221–2295. https://doi.org/10.1021/ja02268a002

HRP (1911) Kapillarchemie Eine Darstellung der Chemie der Kolloide und verwandter Gebiete. Nature 85:534–535. https://doi.org/10.1038/085534a0

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Talat M, Mohan S, Dixit V, Singh DK, Hasan SH, Srivastava ON (2018) Effective removal of fluoride from water by coconut husk activated carbon in fixed bed column: experimental and breakthrough curves analysis, Groundwater for. Sustain Dev 7:48–55. https://doi.org/10.1016/j.gsd.2018.03.001

Chatterjee S, Mondal S, De S (2018) Design and scaling up of fixed bed adsorption columns for lead removal by treated laterite. J Clean Prod 177:760–774. https://doi.org/10.1016/j.jclepro.2017.12.249

Bohart GS, Adams EQ (1920) Some aspects of the behavior of charcoal with respect to chlorine. J Am Chem Soc 42:523–544. https://doi.org/10.1021/ja01448a018

Thomas HC (1948) Chromatography: a problem in kinetics. Ann N Y Acad Sci 49:161–182. https://doi.org/10.1111/j.1749-6632.1948.tb35248.x

Yoon YH, Nelson JH (1984) Application of gas adsorption kinetics I A theoretical model for respirator cartridge service life. Am Ind Hygiene Assoc J 45:509–516. https://doi.org/10.1080/15298668491400197

Mashtalir O, Naguib M, Mochalin VN, Dall’Agnese Y, Heon M, Barsoum MW, Gogotsi Y (2013) Intercalation and delamination of layered carbides and carbonitrides. Nat Commun 4: 1716. https://doi.org/10.1038/ncomms2664

Zou G, Zhang Z, Guo J, Liu B, Zhang Q, Fernandez C, Peng Q (2016) Synthesis of MXene/Ag composites for extraordinary long cycle lifetime lithium storage at high rates. ACS Appl Mater Interfaces 8:22280–22286. https://doi.org/10.1021/acsami.6b08089

Satheeshkumar E, Makaryan T, Melikyan A, Minassian H, Gogotsi Y, Yoshimura M (2016) One-step solution processing of Ag, Au and Pd@MXene hybrids for SERS. Sci Rep 6:32049. https://doi.org/10.1038/srep32049

Näslund L-Å, Persson POÅ, Rosen J (2020) X-ray photoelectron spectroscopy of Ti 3 AlC 2, Ti 3 C 2 T z, and TiC provides evidence for the electrostatic interaction between laminated layers in MAX-phase materials. J Phys Chem C 124:27732–27742. https://doi.org/10.1021/acs.jpcc.0c07413

Yamamoto S, Bluhm H, Andersson K, Ketteler G, Ogasawara H, Salmeron M, Nilsson A (2008) In situ x-ray photoelectron spectroscopy studies of water on metals and oxides at ambient conditions. J Phys Condensed Matter 20. https://doi.org/10.1088/0953-8984/20/18/184025

Louette P, Bodino F, Pireaux J-J (2005) Poly(ethylene imine) (PEI) XPS reference core level and energy loss spectra. Surf Sci Spectra 12:54–58. https://doi.org/10.1116/11.20050911

Geng J, Yin Y, Liang Q, Zhu Z, Luo H (2019) Polyethyleneimine cross-linked graphene oxide for removing hazardous hexavalent chromium: adsorption performance and mechanism. Chem Eng J 361:1497–1510. https://doi.org/10.1016/j.cej.2018.10.141

Szuplewska A, Kulpińska D, Dybko A, Jastrzębska AM, Wojciechowski T, Rozmysłowska A, Chudy M, Grabowska-Jadach I, Ziemkowska W, Brzózka Z, Olszyna A (2019) 2D Ti2C (MXene) as a novel highly efficient and selective agent for photothermal therapy. Mater Sci Eng, C 98:874–886. https://doi.org/10.1016/j.msec.2019.01.021

Mu W, Du S, Yu Q, Li X, Wei H, Yang Y (2018) Improving barium ion adsorption on two-dimensional titanium carbide by surface modification. Dalton Trans 47:8375–8381. https://doi.org/10.1039/C8DT00917A

Othman Z, Mackey HR, Mahmoud KA (2022) A critical overview of MXenes adsorption behavior toward heavy metals. Chemosphere 295:133849. https://doi.org/10.1016/j.chemosphere.2022.133849

Hu X, Chen C, Zhang D, Xue Y (2021) Kinetics, isotherm and chemical speciation analysis of Hg(II) adsorption over oxygen-containing MXene adsorbent. Chemosphere 278:130206. https://doi.org/10.1016/j.chemosphere.2021.130206

Shahzad A, Rasool K, Iqbal J, Jang J, Lim Y, Kim B, Oh J-M, Lee DS (2022) MXsorption of mercury: Exceptional reductive behavior of titanium carbide/carbonitride MXenes. Environ Res 205:112532. https://doi.org/10.1016/j.envres.2021.112532

Al-Yaari M, Saleh TA, Saber O (2021) Removal of mercury from polluted water by a novel composite of polymer carbon nanofiber: kinetic, isotherm, and thermodynamic studies. RSC Adv 11:380–389. https://doi.org/10.1039/D0RA08882J

Yang C, Jiang J, Wu Y, Fu Y, Sun Y, Chen F, Yan G, Hu J (2021) High removal rate and selectivity of Hg(II) ions using the magnetic composite adsorbent based on starch/polyethyleneimine. J Mol Liq 337:116418. https://doi.org/10.1016/j.molliq.2021.116418

Gou X, Li Y, Ahmad Z, Zhu X, Chen J (2021) Thiolated polyethyleneimine-based polymer sponge for selective removal of Hg 2+ from aqueous solution. ACS Omega 6:31955–31963. https://doi.org/10.1021/acsomega.1c04729

Yoo S-H, Lee S-C, Ko M, Yoon S, Lee J, Park J-A, Kim S-B (2023) Adsorption of Hg(II) on polyethyleneimine-functionalized carboxymethylcellulose beads: characterization, toxicity tests, and adsorption experiments. Int J Biol Macromol 241:124516. https://doi.org/10.1016/j.ijbiomac.2023.124516

Boutsika LG, Karapanagioti HK, Manariotis ID (2017) Effect of chloride and nitrate salts on Hg( II ) sorption by raw and pyrolyzed malt spent rootlets. J Chem Tech Biotech 92:1912–1918. https://doi.org/10.1002/jctb.5215

Inglezakis VJ, Kudarova A, Guney A, Kinayat N, Tauanov Z (2023) Efficient mercury removal from water by using modified natural zeolites and comparison to commercial adsorbents. Sustain Chem Pharm 32:101017. https://doi.org/10.1016/j.scp.2023.101017

Suleimenova M, Zharylkan S, Mekenova M, Mutushev A, Azat S, Tolepova A, Baimenov A, Satayeva A, Tauanov Z (2023) Fusion-assisted hydrothermal synthesis of technogenic-waste-derived zeolites and nanocomposites: synthesis, characterization, and mercury (II) adsorption. IJMS 24:11317. https://doi.org/10.3390/ijms241411317

Žula M, Grilc M, Likozar B (2022) Hydrocracking, hydrogenation and hydro-deoxygenation of fatty acids, esters and glycerides: mechanisms, kinetics and transport phenomena. Chem Eng J 444:136564. https://doi.org/10.1016/j.cej.2022.136564

ZangenehKamali K, Pandikumar A, Jayabal S, Ramaraj R, Lim HN, Ong BH, Bien CS, Kee YY, Huang NM (2016) Amalgamation based optical and colorimetric sensing of mercury(II) ions with silver@graphene oxide nanocomposite materials. Microchim Acta 183:369–377. https://doi.org/10.1007/s00604-015-1658-6

Khunphonoi R, Khamdahsag P, Chiarakorn S, Grisdanurak N, Paerungruang A, Predapitakkun S (2015) Enhancement of elemental mercury adsorption by silver supported material. J Environ Sci 32:207–216. https://doi.org/10.1016/j.jes.2015.01.008

Fausey CL, Zucker I, Lee DE, Shaulsky E, Zimmerman JB, Elimelech M (2020) Tunable molybdenum disulfide-enabled fiber mats for high-efficiency removal of mercury from water. ACS Appl Mater Interfaces 12:18446–18456. https://doi.org/10.1021/acsami.9b22823

Falinski MM, Turley RS, Kidd J, Lounsbury AW, Lanzarini-Lopes M, Backhaus A, Rudel HE, Lane MKM, Fausey CL, Barrios AC, Loyo-Rosales JE, Perreault F, Walker WS, Stadler LB, Elimelech M, Gardea-Torresdey JL, Westerhoff P, Zimmerman JB (2020) Doing nano-enabled water treatment right: sustainability considerations from design and research through development and implementation. Environ Sci: Nano 7:3255–3278. https://doi.org/10.1039/D0EN00584C

Funding

This research was funded by the Ministry of Science and Higher Education of the Republic of Kazakhstan through the project AP13067739. The Marie Skłodowska-Curie Actions Staff exchanges project 101131382– CLEANWATER, funded by the European Union under Horizon-Europe Programme, and UK Research and Innovation, is also acknowledged for partially funding the research. Views and opinions expressed are however those of the authors only and do not necessarily reflect those of the European Union or Research Executive Agency (REA). Neither the European Union nor the REA can be held responsible for them.

Author information

Authors and Affiliations

Contributions

Chingis Daulbayev wrote the main manuscript text and did some characterization; Armanbek Nursharip performed experiments; Zhandos Tauanov wrote some part of the manuscript text and revised the draft; Rosa Busquets revised the manuscript; Alzhan Baimenov did experiments conceptualization, general management, and manuscript revision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Daulbayev, C., Nursharip, A., Tauanov, Z. et al. Mechanisms of mercury removal from water with highly efficient MXene and silver-modified polyethyleneimine cryogel composite filters. Adv Compos Hybrid Mater 7, 139 (2024). https://doi.org/10.1007/s42114-024-00945-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-024-00945-z