Abstract

New fieldwork and the revision of lithic collections during the past decade have renewed our interpretation of the timing and characteristics of the earliest Acheulean techno-complexes in western Europe. The lower level of the la Noira site is a crucial snapshot for evaluating the technological abilities and strategies of Middle Pleistocene hominins at 700 ka in Europe at the beginning of elaborate biface production and associated behavioural changes. The site of la Noira is located in the central part of France, where climatic conditions may have had a stronger impact on occupations than in southern Europe. New excavations between 2011 and 2018, over a surface of 100 m2, yielded a large corpus of artefacts including cores, flakes, bifaces and a large heavy-duty component. We analysed the lithic corpus composed of almost 1000 artefacts from a taphonomic perspective, identified the chaînes opératoires and all the reduction processes involved at the site, and examined the spatial distribution of the archaeological remains. The results offer a broad overview of the types of lithic management and related cognition and skills of Middle Pleistocene hominins living on a riverbank under cool conditions, at the beginning of a glacial stage. A comparison with penecontemporaneous sites indicates that a technological shift possibly occurred in western Europe between 700 and 600 ka. The technological strategies used indicate (1) common abilities in core technologies including some sporadic independence from stone shape, (2) a diversity of technical solutions and morphological results for biface shaping with evidence of a bifacial or bilateral equilibrium and a preconceived form on some tools, and (3) a large and diversified heavy-duty component. Biases related to activities, raw material types and various traditions are discussed. The chronology of the emergence of new behaviours, such as an early biface shaping ability, seems to have been identical in the northwest and south of Europe.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recent fieldwork and the revision of lithic collections over the past decade have renewed our interpretation of the timing and characteristics of the earliest Acheulean techno-complexes in western Europe. These Acheulean techno-complexes cover a large geographical area, extending from northwest Europe to the Mediterranean coast, but are limited in the east by the Rhine River and in the northeast by the Caucasus Mountains (i.e. Moncel et al. 2015; Schreve et al. 2015; Voinchet et al. 2015; Moncel and Ashton 2018). The term “Acheuleans”, rather than one uniform cultural tradition, is more appropriate for describing the puzzle of assemblages and strategies recorded in western Europe. This heterogeneity may perhaps partly be imputed to the fact that raw material constraints and diverse traditions impacted activities, as well as multiple dispersals and adaptation to local environments (Schreve et al. 2015; Moncel and Schreve 2017).

In the current state of knowledge, biface production, and more largely the ability to make large cutting tools (hereafter LCTs, i.e. bifaces, cleavers, picks) is considered in Africa as a marker of the Acheulean, alongside more complex stone management (debitage irrespective of the geometry of the stone, ability to produce large flakes, fragmentation of the reduction processes and land use management) (i.e. de la Torre 2011, 2016; de la Torre et al. 2008; de la Torre and Mora 2018). Biface shaping appears in western Europe between 1 Ma and 600 ka, associated with some innovations in core technologies in some sites and the production of large flakes (Ashton et al. 2011; Moncel et al. 2013; Vallverdu et al. 2014; Voinchet et al. 2015). This is considerably later than in east Africa, where the earliest evidence of biface shaping dates from 1.75 Ma, and later than the Levant and India, where these tools emerge around 1.5–1.2 Ma onwards (Bar-Yosef and Goren-Inbar 1993; Goren-Inbar et al. 2000; Lepré et al. 2011; Pappu et al. 2011; Beyene et al. 2013).

The earliest evidence of “Acheulean” is located in southern Europe and comes from the site of la Boella, Spain, where two crudely made LCTs (cleaver and pick) have been dated to 1 Ma–900 ka. The site of Lezignan-la-Cebe has also yielded some bifacial tools dated to around 800 ka (Mosquera et al. 2015; Bourguignon et al. 2016). These discoveries, and some other localized cases (Moncel et al. 2016), indicate an early arrival of this technology or local attempts at bifacial manufacture (Vallverdu et al. 2014; Mosquera et al. 2015). Regardless of the origin of this new behaviour (local or introduced), the la Boella site reduces the chronological gap between Africa, Asia and Europe. The sites of Cueva Negra and Solana del Zamborino seem considerably younger than firstly expected, and cannot be considered today as early evidence of LCTs (Scott and Gibert 2009; Jiménez-Arenas et al. 2011; Álvarez-Posada et al. 2017).

However, in western Europe, the earliest evidence of elaborate bifacial shaping is later than 700–650 ka, and it is associated with other behavioural changes such as the production of large flakes or a more complex debitage. For this key period, the major sites are (1) the Italian site of Notarchirico (Piperno 1999; Lefèvre et al. 2010; Pereira et al. 2015; Santagata 2016), where levels with bifaces are embedded between levels without bifaces and recently redated by 40Ar/39Ar between 661 ± 12 and 614 ± 12 ka, (2) the French sites of Moulin Quignon in the Somme Valley (to 672 ± 54 ka; Antoine et al. 2019) and (3) the French site of la Noira, in the Cher Valley, where the lower level (stratum a1) is dated by ESR of more than 665 ± 55 ka (Despriée et al. 2011; Shen et al. 2012; Moncel et al. 2013, 2015; Despriée et al. 2017). These sites are hence located under various latitudes.

The lower level of the la Noira site, dated to around 700 ka, is thus a prime example for describing the earliest key phase of biface production by European hominins (Moncel et al. 2013, 2015; Iovita et al. 2017). This key period raises questions on the origin (local or introduced) of this new behaviour in relation to current models for the onset of the Early Acheulean in east Africa (de la Torre et al. 2008; de la Torre 2011; Gallotti 2013; Gallotti and Mussi 2017; de la Torre and Mora 2018). Three hypotheses are currently advanced for the origin of these new behaviours in western Europe: (1) in situ evolution of core-and-flake industries, (2) local evolution with a mixture of external behaviours, or (3) introduction by new groups or influx of new ideas (i.e. Nicoud 2013; Moncel et al. 2013, 2015; Martínez and Garriga 2016; Mosquera et al. 2018; Méndez-Quintas et al. 2018; Moncel et al. 2018a, 2018b, c). In sum, studies either describe (1) a chronological and behavioural shift at 700 ka or (2) gradual evolutionary trends from core-and-flake-type industries to other techno-complexes (i.e. on small tool kits), with or without the introduction of new behaviours.

Recent publications on east African sites demonstrate that the onset of the Acheulean is not only related to the ability to make LCTs (on flakes over 10 cm long) (Kleindienst 1961; Clark 1969; Lepré et al. 2011; Beyene et al. 2013; de la Torre 2016) but also, in some cases, to more complex core technologies, land use, and raw material management (de la Torre 2016). For some of the European assemblages dated between 700 and 600 ka, core technologies indicate greater complexity, intensity and independence from raw material forms (Gallotti and Peretto 2015). Understanding this key period in Europe is essential for describing human strategies regarding tool kits and discussing the meaning of the diversity of lithic entities and the impact of activities on technological choices, raw material management and the presence or absence of bifaces (Parfitt et al. 2005, 2010; Moncel 2008; Baena Preysler et al. 2018).

Homo heidelbergensis has only been identified at a few sites with hominin fossils from around 600 ka (i.e. Mauer), some with a biface production. The diversity of anatomical features at that time suggests possible hominin intra- or inter-diversity in western Europe linked to multiple successful or unsuccessful arrivals, and bottle-necks over time (Stringer 1996, 2012; Stringer et al. 2007; Mounier et al. 2009; Wagner et al. 2010; Martinón-Torres et al. 2007, 2011; Bermúdez de Castro and Martinón-Torres 2013; Bermúdez de Castro et al. 2017). The scarcity of archaeological sites over such a long period suggests either poor preservation due to taphonomic processes or short-lived dispersal events with phases of depopulation and recolonization of the continent (McPherron 2006; Goren-Inbar and Sharon 2006; MacDonald et al. 2012; Dennell et al. 2011; Moncel et al. 2018d). Here, our specific period of interest is the end of the Middle Pleistocene revolution, after the Brunhes-Matuyama shift at 780 ka, a period marked by cyclical climate changes and vegetation and faunal turnovers, which could have led to the successive depopulation or extinction of small groups of hominins, and subsequent recolonization, before and between the MIS 16 and 12 cold events (Guthrie 1984; Turner 1992; Stiner 2002; Manzi 2004; Belmaker 2009; Muttoni et al. 2010, 2018; Cuenca-Bescos et al. 2011; Messager et al. 2011; Rodríguez et al. 2011; Abbate and Sagri 2012; MacDonald et al. 2012; Garcia et al. 2013; Carrión et al. 2011; Palombo 2014, 2017; Chauhan et al. 2017; Carrión and Walker 2019). MIS 12 seems to be coeval with a new shift, marked by a strong glacial event followed by a long interglacial stage (MIS 11), at the roots of the Neanderthal world (Moncel et al. 2016).

The lithic component of the lower level of the open-air site of la Noira is thus a crucial snapshot for evaluating the technological abilities and strategies of Middle Pleistocene hominins at around 700 ka in Europe, at the starting point of elaborate biface production and behavioural changes. The site is located in the centre of France, beyond the 45th parallel, in areas where climatic conditions may have had a stronger impact on occupations than in southern Europe. New excavations carried out between 2011 and 2018 on a preserved surface of 100 m2, on the western part of the quarry, yielded a large corpus of artefacts. We conducted a taphonomic assessment of the lithic corpus composed of almost 1000 artefacts, the study of chaînes opératoires and all the on-site reduction processes, and the spatial distribution of archaeological remains. Results offer a large overview of the types of lithic management and related cognition and skills of Middle Pleistocene hominins living on a riverbank under cool climatic conditions, at the very beginning of a glacial stage.

The la Noira Site

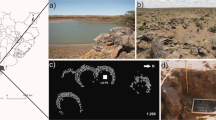

The la Noira site is located on the township of Brinay, about 10 km south of Vierzon (Cher department). Jean Dépont discovered the site in 1972 during sand and gravel extraction from a fluvial formation, called the Fougères formation (Dépont 1984). The site is located in the middle of the west slope of the Cher Valley, beneath the sheet D of the stepped Cher system (at a relative altitude of 13/+ 21 m above the present-day base layer) (Despriée et al. 2017) (Figs. 1 and 2). Geological and geochronological research has been conducted at the site since 2003 as part of prospecting authorized by the Ministry of Culture–Regional Service of Archaeology for the Centre of France. The sedimentary sequence of la Noira was deposited in an alluvial plain context and includes four units named from the base to the top units a, b, c and d. The lower archaeological level is associated with stratum a1, which is the first coarse layer of unit a deposited in discordance on the Eocene-Oligocene lacustrine clay and limestone bedrock after the end of river incision, during a transition stage between interglacial and glacial phases.

a Theoretical model of the fluviatile system of the middle valley of the Cher and ESR ages of the fluviatile formations. The relative position of the Fougères fluviatile formation and the site of la Noira are indicated by a star. b North and south stratigraphic logs from the west section of the la Noira quarry and position of the dating samples

This deposit, which reaches a maximum thickness of about 50 cm, corresponds to a diamicton and lies downslope from the tertiary deposits, which overlie the plateau. It contains blocks, cobbles, pebbles and gravels of diverse endogenous rocks and Jurassic silicifications embedded in a sandy-clayey matrix. It also comprises numerous broken lacustrine silicified slabs (millstone slabs), uncovered by the erosion of the lacustrine limestone slope. Hominins gathered these millstone slabs. These solifluction deposits and human workshops corresponding to the anthropic raw material use were then cryoturbated on several places during the following glacial phase. A part of the archaeological level (stratum a1), previously covered by a second slope deposit level (stratum a2), was not disturbed (Despriée et al. 2011, 2017; Despriee et al. 2016).

Unit a was covered by about 5 m thick organized fluvial sand layers (unit b), deposited in low-energy contexts. Then, after a standstill phase in terms of sedimentation and erosion, a gravel layer (unit c) deposited in unconformity and was itself covered by a sandy-silty slope deposit (unit d). ESR data obtained on optically bleached sand from unit b gave a weighted average age of 655 ± 55 ka (Voinchet et al. 2010; Despriee et al. 2016; Despriée et al. 2017; Moncel et al. 2013), while the top of unit c was dated to 449 ± 45 ka (Iovita et al. 2017). The stratum a1 is thus earlier than 655 ± 55 ka.

Material and Methods

During surveys, sampling or test pits on the northern and central parts of the quarry, bifaces, cores and flakes in lacustrine millstone were systematically recorded in association with coarse elements in the diamicton located below the fluvial formation, generally in cryoturbation cells (Moncel et al. 2013). An undisturbed in situ archaeological level was identified on the southern part of the quarry, at the top of the diamicton, below the alluvial formation. Excavations carried out from 2011 to 2018 uncovered this level over a surface of 100 m2. It appears to be the only preserved level after extraction works (Moncel et al. 2013; Despriee et al. 2016; Despriée et al. 2017).

This paper presents the stone tool assemblage of the lower level (stratum a1) collected during extended excavations from 2010 to 2014, with additional sporadic fieldwork from 2015 to 2018. The archaeological level located at the bottom of Cher sheet D was studied along a 25-m long section on the top of the clayey and limestone lacustrine floor. Then, an area of 100 m2 was opened and excavated. A north to south drainage channel was hence uncovered between two platforms. Three 10 to 20 cm thick sub-circular heaps with a diameter of about five metres were studied on the platforms. These heaps were identified as solifluction lobes and contained cobbles of endogenous rocks, Jurassic siliceous nodules, and numerous broken millstone slabs associated with artefacts (Despriee et al. 2016; Despriée et al. 2017).

A total of 6495 lithic objects were systematically recorded by overhead photography during successive dismantling within the metric grid. The photographs were printed at a scale of 1/10 and used for recording all the characteristics of the lithic objects (raw materials and dimensions), spatial position (orientation and dip) and visible alterations (physical, chemical, climatic). These data were checked in the laboratory before being entered into the database. A total of 918 pieces were considered as anthropogenic.

Material

Taphonomy and Raw Materials in Stratum a1

A detailed analysis of the lithic component demonstrates that varied rock types are present in the three concentrations excavated in stratum a1. Petrographic identification was carried out on fresh breaks for the non-anthropogenic items. The knapped materials were observed with a broad view magnifying lamp (170 mm) with magnifications of × 3 and × 12 dioptres (Despriee et al. 2016). The materials are endogenous rocks, such as granite and quartz (13.4%), and more varied sedimentary rocks, such as sandstones (3.8%), Jurassic silicifications (17.1%), lacustrine millstone slabs and fragments (48.2%), quincite (18.2%) and iron ore (Despriee et al. 2016).

Among the endogenous rocks and Jurassic silicifications, irregular polyhedral volumes with numerous fractures and wear marks are abundant. All these marks indicate that the rocks underwent repeated high-energy fluvial-type transport. Thirty-five percent of them present chemical alterations characteristic of tropical climates, with enrichments in iron and aluminium, and significant recrystallizations. Those allochthonous materials were spread on the plateau from southern areas, over distances ranging from 60 to 120 km, during the Cenozoic era and were strongly lateritized. During the Pleistocene, some of them were frost-shattered (29.5%) during successive cold phases before solifluction transportation on the incision floor.

During the excavation of stratum a1, 3127 fragments of millstone slabs were recorded (48.2% of the raw material assemblage). Lacustrine millstone is a local siliceous material. The bank with slabs was uncovered on the western slope during Pleistocene river incision of the local lacustrine limestone. Slabs were then mixed with coarse materials, which were carried from the plateau by solifluction. These millstone slabs do not bear the transport marks observed on the other rocks, but 41.7% of them bear frost-shattering marks, such as multidirectional cracks and cusps. The presence of diverse categories of frost marks implies that several periods of gelifraction occurred before the slabs were transported to the site (Despriee et al. 2016; Despriée et al. 2017) (Fig. 3).

Three concentrations of slabs and fragments of slabs have been identified on two sub-horizontal areas separated by a north-south oriented channel (Despriée et al. 2017) (Fig. 4). In the three excavated concentrations, slabs and fragments of slabs are mixed with allochthonous rocks and accumulated over a thickness of around 40–50 cm. The taphonomic analysis of these accumulations indicates that all the millstone slabs and slab fragments present similar distributions, whether or not they are frost-shattered. Millstone pieces were generally in a sub-horizontal position without preferential orientation, suggesting a selection and displacement of raw materials by hominins. Moreover, among this mixture of slabs and slab fragments, bearing the marks of several phases of gelifraction, only non-frost-fractured siliceous slabs were selected (Despriee et al. 2016; Despriée et al. 2017). Experiments demonstrated that frost-fractured slabs are not suitable for knapping or shaping. Hominins only collected non-frost-fractured siliceous slabs and fragments. Some of the broken fragments, debris and artefacts, located on the top of heaps have millimetric frozen cup marks on their upper cortical surface. After the human occupations, the three accumulations and the artefacts abandoned by hominins were overlaid by a second slope deposit, called stratum a2. During the next Pleniglacial deterioration, the thickness of stratum a2 protected the millstone from frost, so that only the superficial cortex was slightly affected.

Available Non-frost-Fractured Limestone Slabs in Stratum a1

Around the three concentrations, five fragmented slabs or slab fragments measuring several decimetres and up to a metre were unearthed at the excavation. The cortical perimeter of these slabs has totally disappeared, replaced by a polygonal perimeter with orthogonal sides displaying homogeneous silicification, with no patina or alteration. On the edges, traces of shocks are observed at the top of the sharp or inverted angles on the perimeter. The ridges do not bear blunting or crushing marks. No fragments refitting onto these slabs were found in situ or in the immediate vicinity. However, several slab fragments were found in connection and cortex crushing is clearly visible on the centre of two broken edges (Despriee et al. 2016, 2017).

In the three concentrations, a total of 567 whole and partial slabs, millstone slab fragments and debris were examined. First, 241 decimetric-sized whole or partial slabs bear patinated edges, shocks on the surfaces, considerable blunting of the ridges, crushing of the sharp-angled edges and splintering of the sides. This shows that these breaks occurred before the slabs were transported to the site. These pieces do not bear anthropogenic marks. Secondly, in close association, 173 large slab fragments (L ≥ 10 cm) and 153 smaller slab fragments (L < 10 cm) with fresh orthogonal sides, on which the siliceous material is clearly visible, do not bear patina or transport marks or traces of blunting or crushing of the ridges. The position of these fresh or cortical edges on the perimeter indicates that the fragments and debris result from intentional breaking of the slabs, as described above. Many potential marks were observed on the edges of these slab fragments and debris: crushing marks, generally on the opposite cortical zones, with fissures, and characteristic angular breaking. These marks were reproduced by experiments, using pounding hammers similar to those unearthed near the concentrations or near the metric-sized slabs (Despriee et al. 2016). As a result of the irregular thickness of the original silicifications, these slab fragments are shaped like parallelepipeds with sub-vertical sides with angles of 80–90°, sub-trapezoidal or sub-rectangular sections, and sub-triangular or trapezoidal cross-sections.

The lengths of virtually all of the slab fragments and debris (98.2%) range between 50 and 260 mm. However, for 77% of the pieces, lengths range from 100 to 150 mm. The average length is 143 mm. Width ranges from 40 to 200 mm (96.6%), with an average width of 106 mm, and for 79% of the pieces, width varies from 100 to 150 mm. Average elongation (L/W) is 1.3 (Despriee et al. 2016). Thickness varies between 20 and 100 mm (97.9%). Average thickness is 51 mm and for 79% of the fragments, thickness ranges from 30 to 70 mm. The elongation index (L/W) for most of the pieces (315/329 or 95.7%) varies between 1 and 2, indicating the near-exclusive presence of wide, thick and quite thick modules.

In conclusion, a total of 567 elements without frost alteration marks in the mass of the piece were apt for knapping and shaping, despite a cortical surface. Their average and higher dimensions match the average dimensions of the cores and heavy-duty tools found on site.

The Archaeological Material-Archaeological Corpus of Stratum a1

After the study of all the material collected from excavations, the archaeological corpus totals 918 elements, including cortical and knapped slab fragments, cores, unretouched or retouched flakes, and bifaces, bifacial tools and cleavers (3.1% or 7.4% if we include the entire heavy-duty component) (Table 1). The only siliceous raw material used in the archaeological level is the lacustrine millstone recovered in situ and three oolitic Jurassic silicifications (Moncel et al. 2013; Despriee et al. 2016; Iovita et al. 2017; Hardy et al. 2018). Marks similar to impact marks, crushing, fissures and breaks were observed on the ridges or on the surfaces of the lacustrine millstone slabs. We also observed cortical removals, and removal scars on these slabs.

Physical Aspects of the Archaeological Corpus

Marks potentially related to intentional breaks and use, and to post-depositional processes, were systematically recorded and characterized for each piece in the archaeological corpus using macroscopic and microscopic methods (see Despriee et al. 2016). These observations reveal the total absence of blunting marks on the ridges of removals and of crushing scars on the edges of the pieces of the assemblage. This fresh aspect of the anthropogenic surfaces confirms the taphonomic observations made for stratum a1. It suggests that artefacts did not move before or during the deposition of the colluviums of stratum a2 on the archaeological remains. Only 17 pieces with smooth and crushed edges are considered as intrusive and probably moved during solifluction deposits in stratum a1 (Despriée et al. 2017). Our study did not take these 17 pieces into account. The other artefacts are cortical and Kombewa flakes, cores (unifacial and bifacial) and fragments of cores. Only 13 artefacts have small frost cup marks on the upper surface, which also confirms the rapid burial of the archaeological remains.

A significant proportion of cutting edges, i.e. 186 (44.9%) flakes and fragments of flakes show a fresh edge, without modification or use marks. A total of 63 cutting edges (39.4%) are modified and 65 (15.7%) are partially retouched. Among the modified cutting edges, most of the traces are located on one edge (lateral or transversal), two edges, or the flake periphery (Supp. Material Fig. 1ASM). Three types of marks have been observed. Some of the cutting edges are totally or partially nibbled (35.6%), characterized by micro-denticulated areas. Others are splintered (31.9%), with irregular micro-removals or only rubbed (10.4%), with abraded zones on the tops of ridges of the edges. The nibbling and splintering marks can occur together on a same flake and are sometimes associated with rubbing. Some of these modified flakes are broken, and could have snapped during use. During our experiments, these types of damage were observed after cutting, sawing and scraping soft and hard materials (wood or bones). These types are similar to damage described in Despriee et al. (2016).

Among the bifaces, we also note five splintered pieces, four with crushing marks and two with use-wear marks. For the cleavers and bifacial cleavers, we observed eight splintered pieces, five with use marks, one with nibbled marks and one with frost cup marks. For the other heavy-duty tools, the main identified marks are splintering and use marks. Finally, for the cores, except for the fresh pieces, we observe pieces with occasional crushed and splintered marks suggesting possible use despite the lack of residues and polish. Post-depositional frost cup marks observed on the upper surface of 13 pieces indicate that the geoarchaeological level was protected during the following Pleniglacial stage (Despriée et al. 2017).

Methods: Identification of Reduction Processes and Tool Categories

Our aim was to identify all the chaînes opératoires of the lithic assemblage (i.e. Boëda 1993, 2001; Roche 2005; Geneste 1989, 1991), through the analysis of the sequence of gestures and technical choices for the manufacturing and the techno-economic process, in order to describe the cognitive skills. The hierarchy of flaking surfaces and reading of removal sequences on cores (bipolar or freehand technology) (Isaac 1977; Boëda 1993) allow for the identification of knapping methods and techniques. Each artefact was attributed first to a general technological category, distinguishing small artefacts from debitage from the heavy-duty component. Slabs are measured according to the slab bedding when broken or with some removals. For the heavy-duty tools, they are oriented technologically. Large flakes are distinguished from small flakes on the basis of length > 10 cm (identification of the LCTs) (Moncel 1995; de la Torre et al., 2008; de la Torre de la, 2011; Beyene et al. 2013). For the heavy-duty component, the definitions of bifaces, cleavers, LCTs and heavy-duty tools are based on those of Leakey (1951), Kleindienst (1961), de la Torre de la (2011), Barsky et al. (2018), de la Torre and Mora (2018) and Baena Preysler et al. (2018). We identified the volumetric processes, sizes, relation to stone geometry and morphological results according to Bordes (1961), Roe 1964, 1981), Mourre (2003), Goren-Inbar and Sharon (2006), McPherron (2006), Lycett et al. (2016), Shipton and Clarkson (2015), Key et al. (2016) and Herzlinger et al. (2017).

Results: Reduction Processes During Hominin Occupations of Stratum a1

Fragmentation of Non-frost-Fractured Millstone Slabs for Size Reduction

The presence of impacts (n = 48) on fragments of slabs indicates a fragmentation process with hard hammers. Slab fragments were mainly broken into two parts (Despriee et al. 2016). On the perimeter of the crushed surfaces, the fracture line is rectilinear (angle = 170–190°: 37.4%), or presents at the impact mark an internal angle (angle < 170°: 21.9%), or more generally an outer angle (angle > 190°: 40.6%) The angles between the surfaces and the obtained edges range between 80 and 100° and indicate surfaces orthogonal to the original slab surfaces. As possible hammers, used blocks or quartz and granite pebbles, as well as fragments of Jurassic siliceous nodules and lateritized millstone, were recovered in the immediate vicinity of each of these accumulations (n = 48) (Suppl. Material Fig. 1BSM). All these materials are characterized by their extreme hardness (weighing more than 2 kg and up to 3, 4 and 5 kg, with an average length of 180 mm, an average width of 140 mm and a thickness of 100 mm).

Flaking Processes

Flaking of Whole Slabs and Fragments of Slabs: Giant and Middle-Sized Cores (n = 83)

On millstone whole slabs (n = 68) or fragments of slabs (n = 14), we observe some discontinuous or continuous removal scars (Suppl. Material Table 1SM). Most of the pieces measure between 100 and 200 mm long and are slightly elongated. The largest piece is 265 mm long. Thickness varies (mostly between 30 and 70 mm), from thin (20 mm) to thick (100 mm) (Suppl. Material Fig. 2SM, 3SM, 4SM, 5SM). These pieces and the whole slabs and fragments of slabs with traces of impacts are similar in size, suggesting that initial breakage was a preliminary action to flaking (Fig. 5). Only 10 slab fragments bear traces of impacts from breaking the slab.

These giant and middle-sized cores bear between one and six invasive unipolar or centripetal removal scars, mostly dispersed on the cortical surfaces, with no evidence of slab preparation. Scars are located on a short part of the periphery, on one or both parallel or orthogonal surfaces, and on one edge, if the slab is thick (Supp. Material Fig. 3SM). The common trend is one or more large removals on one cortical surface. Abrupt scars are rare and truncate the slab edge, resulting in “slices”, with one to three cortical backs. Blank production systematically uses the natural angles of the edges as platforms to produce large and cortical flakes with a thick cortical or patinated platform. The percussion impact is generally located far from the slab edge. Flaking is face-by-face or alternate. The intensity of flaking does not depend on the potential surfaces. The slab is systematically abandoned before being depleted. It is important to mention six pieces with crushing or micro-retouch on one natural edge, suggesting the dual use of the slab, as a core and a tool.

To conclude, management is non-standardized and unorganized. The flaking surface is never re-prepared. Natural surfaces are used to produce some large and thick products, with one or several backs, in some cases. Despite the plane cortical surfaces of the slabs, scars are rarely hinged, suggesting good control of the best slab angles for knapping. We can describe this behaviour as an opportunistic strategy dependent on slab shape.

Cores with “Structured Debitage” (n = 47)

We include pieces with organized flaking with or without platform preparation, regardless of the number of removals. Flaking can take advantage of the slab shape or be carried out independently of the geometry of the blank. A total of 18 cores bear crushing marks, mainly on one edge and some with retouch, indicating reuse after flaking (Suppl. Material Table 2SM). Debitage only occurs by direct percussion with a hard hammer.

Most of the blanks used for flaking are slab fragments. In addition to slabs, there are two nodules (round shape) and two flakes. The thickness of the slab was measured when two opposite cortical surfaces are preserved and is mainly 30–40 mm, which is less than the thickness of the large cores with some removals (Fig. 6). Most of the cores measure between 50 and 120 mm long. Small cortical patches are frequently preserved on both faces, more rarely only on one (slab edge or one face) and on three or multiple faces (on whole slabs). The slab or slab fragment is frequently worked from the plane surface but it is not rare to observe flaking on the slab edge of thick slabs obliquely broken beforehand (more than 100 mm thick).

Several types of cores were identified based on the number of flaking surfaces and the organization of removals (Table 2). Transitional types reflect the flexibility of core technology and probable adaptation to slab shape. The main category consists of bifacial cores with two secant surfaces (hierarchical reduction or not) with a total or partial peripheral cutting edge. Simple cores, with one flaking surface on the largest cortical face or on the slab edge, are the second most frequent category. Unifacial or bifacial debitage is frequently initiated on natural slab planes with limited preparation. When bifacial flaking becomes more invasive, the shape of the blank no longer affects core management, and scars are used as striking platforms for the following removals.

Blank production is mainly centripetal, with partial convergent and invasive removals. The number of removals is low and generally consists of a single series for each surface. Scars are sometimes hinged due to badly controlled angles and plane surfaces. For bifacial cores, the two faces are often asymmetrical, opposing a plane face to a face with abrupt removals. One face sometimes shows a pyramidal form and the final removals exploit the available scars of this face as striking platforms. The core thus gradually becomes multidirectional. The frequent dissymmetry of the cross-section of the cores suggests that one face could be considered as a striking platform from the beginning of or during debitage. The other alternative is that the abrupt face is the remnant surface of the first opening of the slab (preparation of oblique planes for starting the flaking on the opposite cortical face). Core surface exploitation is mainly face-by-face but can also be alternate if angles are suitable. In some cases, a third flaking surface, orthogonal to the two secant surfaces, is created by breaking the core side or by using the preserved natural back of the fragment. Debitage then becomes orthogonal, and the final core is trifacial.

For unifacial cores, debitage is also centripetal or unipolar, with more or less invasive removals. The striking platform is always partial and rarely prepared (cortical or patinated). This mode of flaking is applied to two cores on flakes. The centripetal removals partially cover the inferior face of the flake and a partial striking platform was prepared by short and abrupt removals. The orthogonal cores (with two flaking surfaces) cannot be described as related to “Clactonian technology” like at High Lodge (Ashton and White 2003). There is no alternate management of the two surfaces but independent debitage of each face of the slab, as for unifacial cores. The number of removals is low. Two cores are peripheral or “semi-tournant” type cores with peripheral removals (one or two striking platforms with abrupt angles between faces) on the entire thickness of the slab. This type of flaking starts with removals perpendicular to the largest cortical surfaces and continues all around the slab fragment.

Cores or Heavy-Duty Tools (n = 8)

These artefacts are minimal cores or minimally prepared heavy-duty tools on account of the location, the profile and the limited extension of removals. These are among the largest pieces of the series, ranging from 50 to 200 mm long, and 35 to 70 mm thick. Removals are unifacial unipolar or centripetal removals, orbifacial centripetal. Two of these pieces show a final series of shorter removals or retouch partially covering the removals. They measure 120 mm long and 38–40 mm thick. This type of management is considered as (1) limited preparation of the piece by some large removals before retouching the functional cutting edge, (2) re-cycling a minimal core as a tool. If this is a heavy-duty component, these pieces could be described as chopping tools, “rabot” opposite a back, and large tools with a partial functional edge (rounded or rectilinear).

Large and Small Flakes, Fragments of Flakes and Debris (n = 445)

The series totals 445 pieces, mainly in limestone, except three Jurassic silicifications, one quincite and one quartz. The rare products in other raw materials share similar features with the millstone products and they are thus studied together. Two main population sizes were observed for flakes, one centred on 40–50 mm long pieces and the second one on 80–90 mm long pieces (Fig. 7). Flakes longer than 10 cm, considered as large flakes (see Kleindienst, 1961), total 74 items, representing 16% of the series (Suppl. Material Fig. 6SM, 7SM, 8SM). Since scars on cores and minimally flaked slabs generally measure less than 10 cm long, we assume that large flakes (> 10 cm) are from giant cores that were not found in the excavated area. The ratio of small flakes/cores is low (2.1) and could indicate that flakes were exported. The lack of refitting suggests the exportation of products or flake displacement to activity areas along the river.

Seven technological groups of flakes were distinguished depending on their position in the reduction process (Suppl. Material Table 3SM). They are classified according to their location on the slab: (1) on cortical surfaces or edges and (2) from the first phases to the full debitage phase. Since the slabs present flat surfaces, unlike for blanks with convex surfaces, the first phases require preparation or the use of the best angles for starting platform preparation or knapping (use of slab edges). These are classified as (1) cortical flakes (starting phase on slab surfaces); (2) first phases on slab surfaces: flakes with large cortical patches and a cortical or non-cortical back, flakes with large cortical patches and a cortical platform back, or flakes with large cortical patches; (3) first phases on slab edges, perpendicular or longitudinal to the slab plane: flakes with large natural surfaces, flakes with cortical patches (centripetal mode), flakes with cortical patches (orthogonal mode); (4) flakes truncating the core (with or without cortex); (5) flakes without cortex with a back (cortical or not); (6) flakes without cortex (full debitage phase) and (7) Kombewa flakes.

Products from the whole flaking reduction process are present in the series, indicating complete management of the raw materials (slabs and some large flakes) in situ. Product size (length, width and thickness) remains globally similar regardless of their position in the reduction sequence. The first cortical flakes are frequently backed flakes, with a simple or double back, as a result of the use of the slab edge for starting the debitage. The platform of the product is cortical (or natural) or part of a previously broken surface. However, there are also some flat, dihedral and facetted platforms indicating preparation of the striking platform as soon as flaking started (Figs. 7 and 14).

Flakes with large cortical patches are technologically similar to the first cortical flakes, but with higher variability for backs which are sometimes already flaked (core edge). During flaking, management seems to obey the same rules, systematically using the slab edge or the core edge as a striking platform. This platform can be prepared or not. Some flakes with a thick and distal cortical back indicate the creation of an oblique striking platform to start the debitage of the slab surface.

Slab management preserved cortical surfaces or slab edges for a long time. Striking platforms are sometimes prepared (flat, dihedral and punctiform platforms). The platforms are 32% on cortical or natural surfaces, and 30% flat, followed by punctiform (21%), dihedral (4%) and facetted (2%; n = 6) (Suppl. Material Table 4SM). The ratio of cortical platforms is proportional to the extension of the cortical surface on the flakes. However, the few facetted platforms can belong to any flaking phase, in the same way as the few blades with a cortical or flat platform. Butts are thick or thin, large or small, with a centred or lateralized impact point, always located close to a guiding axis. Sometimes, a crushed area is observed on the edge of the platform, providing evidence of repetitive impacts due to a bad exterior platform angle. However, the rarity of hinged or overrun products suggests good management of platform angles. This may explain the range of angle values from 49 to 90° for cortical and flat platforms. Facetted platforms show angles ranging between 70 and 80° while dihedral platform angles vary between 60 and 80°.

For the whole series, 17% of the flakes are partially broken (distal, multiple or Siret fractures). There is no relationship between the fracture and the position of the flake in the reduction process. Some cortical pieces also bear an impact point on the fracture. This may be voluntary or accidental. The few Kombewa flakes indicate that the taking of flakes from the inferior flake face is limited, as observed on the cores.

The main organization of scars on the upper face of flakes is consistent with core removals: longitudinal unipolar (28.5%), then centripetal (27.1%), crossed (25.6%), perpendicular to the technical axis (2.8%) and longitudinal bipolar (2.1%). These patterns are not related to the type of flake, suggesting regular use of the same method throughout the process. The large flakes (> 10 cm) are technologically similar, apart from a higher ratio of cortical products. The proportion of centripetal and crossed scars (38.3% and 25%) on the larger flakes (> 10 cm) indicates that the largest cores (giant cores) were often turned in the hands to find the most suitable platform. Cortical and flat platforms are the most common categories, while punctiform, dihedral and facetted platforms are mainly found on smaller products. Giant cores could have been minimally flaked. In the same way, slabs with few removals indicate a short series of cortical flakes (Supp. Material Tables 5SM, 6SM, 7SM).

Retouched Flakes (n = 104)

The assemblage contains a total of 104 retouched pieces (23.4% of the series of flakes) (Table 3). The proportion of retouched pieces is 20% for the small flakes and 40% for the large flakes (n = 33) (Fig. 13, Supp. Material Fig. 7SM). Most of the tools are flakes with continuous retouch on the whole or part of the cutting edge (“scrapers”), regardless of flake size. There is no clear selection of specific types of products. Retouch is more or less abrupt, rarely denticulate, invasive or inverse according to the cross-section. They do not profoundly modify the cross-section of the piece (Supp. Material Fig. 8SM). The longest edge is more retouched than the shorter edges. When there are double or multiple retouched edges, retouch types vary between or along the edges depending on the cross-section. When retouch is on a backed flake, it is systematically opposite the back. Some backs are also retouched, by direct or inverse retouch, opposite a sharp cutting edge (rabot-type if retouch is invasive). The rare “becs” are on non-cortical flakes and are made by two notches or a retouched edge.

The denticulates are made by small retouched and/or Clactonian notches, as the notches. The convergent scrapers and the points (tip angle inferior to 70°) are on cortical flakes or “non-cortical déjeté” flakes. They are mainly made by partial marginal, abrupt or ordinary retouch (located on the tip). Some show a small retouched tip with the aspect of a nosed end scraper. The composite tools associate continuous retouch, notches and some invasive retouch/thin removals (direct, inverse, alternate) on the proximal part or one cutting edge. The result is an end scraper, a point or a peripheral scraper. They can be considered as specific rather than opportunistic tools as they are not the result of the association of different tools over time (see Hayden 1979).

To sum up, the diversity of the type of retouch, retouch location and angles suggest a corpus composed of tools with various statuses: simple tools on specific or unspecific blank types, composite tools, and additional tools (made together or at different times). The angles of the retouched area are similar for all tool types with higher diversity for “scrapers”.

Production of the Heavy-Duty Component: Shaping Processes

Preforms or Crudely Made Bifacial Tools (n = 4)

Four additional slab fragments could be considered as preforms due to the presence of short peripheral removals forming two convergent edges or by one or two transversal edges made by flat and invasive removals (cleaver-like with angles of 50–60° for the transversal edge) (Fig. 8). They measure between 130 and 160 mm in length and 25–55 mm in thickness. Two are on poor-quality millstone, which may possibly explain their abandonment during the process. All these pieces appear to have been made by a hard hammer.

Bifacial Tools (n = 11)

This category is composed of partial bifacial tools made by peripheral removals that do not aim to manage the general volume and shape of the slab fragment. The aim is to prepare convergent cutting edges. One tool is on a 130-mm-long flake. The others are on slab fragments among the thinnest slabs, in comparison to cores, and among the largest pieces in comparison to bifaces (Fig. 9). The general form of these pieces is irregular, triangular or oval due to the fact that partial shaping leaves (proximal or lateral) natural backs on the slab fragments. Shaping is face-by-face and produces plano-convex cross-sections and regular cutting edges. All the pieces bear final retouch, which can be (1) unifacial and unilateral or (2) unifacial on one side and bifacial on the opposite side (see the description of the three categories in Suppl. Material). The tip is pointed or oval and tip shaping is part of shaping the lateral edges. A hard hammer makes the first series of removals. Final retouch is short, and is either made by a hard or soft hammer.

Bifaces (n = 8)

Eight tools on millstone slabs or slab fragments attest to general bifacial volume and shape management. Cortex residues are visible in places, illustrating very slight reductions in slab thickness. The selected slabs are among the thinnest of the series. This also suggests specific processes for the initial phases (preparation of striking platforms and alternate shaping to maintain platforms for the symmetrical tools). Plano-convex and symmetrical bifaces do not seem to be formed by a long and intense reduction process (and resharpening) but by different shaping modes aiming to prepare various forms and volumes on slab fragments. The tip and base are generally equally shaped and retouched. The lateral and proximal cutting edges are rectilinear with regular angles, which are higher than the tip angle. A hard (heavy stone) hammer makes the first series of large and medium-sized removals. For the final retouch and some very flat and invasive removals, it is possible that a soft (organic or soft stone) hammer was used occasionally to regularize the edges and the tip. The tools are cordiform or lanceolate, sometimes with a back (Bordes 1961) (Figs. 10a, b, 11a, c, d and 12a, b, c). A detailed description is given in the Suppl. Material.

Cleavers on Flake (n = 2)

Two cleavers on large millstone flakes (Fig. 13) are not simple flake tools (lateral scrapers), on account of the abrupt angle of the lateral retouched area and the linear aspect of the transversal unretouched cutting edge. They measure 85 and 145 mm long with a thickness of 20 and 43 mm, respectively. The unretouched transversal cutting edge is the side of the flake with a sharp angle varying between 43 and 50°. The upper face of the smaller flake bears a patinated surface and some convergent removals indicating a primary flaking phase. The platform is small. The second flake is a non-cortical flake with invasive and convergent scars. The section is asymmetrical (pseudo-back on a side). These pieces are extremely rare and their role in the assemblage is unclear. The knapping of large flakes was planned, but they were rarely used for bifacial technology and for making cleavers. This choice can perhaps be explained by the widespread availability of slabs and slab fragments on site or by the fact that this tool type is not part of the usual routine and tool kit, and is not a target tool. These partially retouched large flakes may actually only be scrapers.

Bifacial Tools with a Transversal Cutting Edge (Bifacial Cleaver or Cleaver-like Tool?) (n = 8)

Eight tools, including two broken extremities, are bifacial tools with a transversal cutting edge shaped by bifacial and transversal removals (Fig. 14). This shaping produces a transversal cutting edge. The blanks are thin slabs or slab fragments, ranging between 30 and 50 mm thick (Fig. 15). They measure between 100 and 178 mm long. The cleavers on flakes are smaller than these bifacial tools. The shaping mode and the location of removals indicate (1) shaping of several sides of rectangular slab fragments by bifacial removals, without really modifying the natural form of the fragment, and (2) the creation of an elongated tool with a transversal cutting edge by a bifacial management of the volume of a slab fragment (Suppl. Material for the detailed description). Shaping is always bifacial, invasive or limited to the lateral and/or transversal cutting edges. When the removals cover both surfaces, series of alternate removals or series of large removals are followed by smaller removals and final retouch. The cross-section of these tools is either plano-convex or symmetrical. The cutting edges are often retouched by unifacial retouch on the transversal or lateral cutting edges. The angle of the transversal cutting edge of these bifacial tools ranges from 40 to 85°, which is more diversified than for cleavers on flakes.

Heavy-Duty Tools (n = 39)

The heavy-duty component is the most diversified category (Suppl. Material Table 8SM, 9SM and Fig. 16), on irregular slab fragments, small whole slabs, nodules or large flakes (> 10 cm). Only a small area of the blank is modified. All the blanks are cortical and one uniface shows double patina, indicating possible evidence of reuse and recurrent occupations of the site. Size is as diversified as the typological and technological features, with the use of large and small blanks. The general shape of the blank seems to be of little importance, except for one bifacial nosed end scraper, with unifacial retouch on the plano-convex nose. The only objective appears to be the partial shaping of an active cutting edge, regardless of size. Removals are always located on the most appropriate zone of the blank for optimal management, starting by using a natural cutting edge or the slab edge. The active cutting edge angles range from 50 to 90° and vary along the edge. Almost all the pieces present unifacial traces of crushing on the edges (rabot, scrapers, end scrapers and sometimes associated on the same piece) or bifacial micro-retouch.

a Heavy-duty tools. Convex transversal edge by unifacial (n°1) and bifacial (n°2) removals, Retouched edge on the slab slice (n°3), quadrangular bifacial tool (n°4). Dotted lines (retouches or removals). b Heavy-duty tools. Bifacial tool (n°1), rabot-type (n°2), Abrupt removals on the slab slice (n°3), peripheral composite bifacial tool (n°4)

Products from LCT Production (n = 16)

The number of products related to the shaping process is low considering the quantity of shaped tools. Only 15 unretouched flakes were identified from the last shaping phases (Fig. 17). The first cortical flakes issued from the shaping process cannot be distinguished from flakes produced by cores, as they are identical. The recognition of flakes from the following phases is based on the profile, the thin bulb and the presence of a lip near the thin platform. Flakes are mainly cortical. Scars are unipolar or unipolar convergent. The platform is flat, punctiform, cortical and in two cases facetted. Platform angles vary from 40 to 90°. There is also one “coup de tranchet” and one truncated edge of a bifacial tool. The corresponding tools were reshaped or exported.

Discussion: the la Noira Occupations in the Western European Framework at 700–600 kyrs

Technological Processes at la Noira Stratum a1 and Middle Pleistocene Hominin Skills

Techno-Economic Patterns

The most recent excavations in the southern part of the quarry yielded a lithic series similar to those previously found in the northern and central parts of the quarry (Moncel et al. 2013). Hominins recovered millstone slabs in situ for flaking or shaping, which are available in huge quantities on the riverbank. Hominins focused on this raw material despite the presence of some other stones in situ. The best quality stones were not systematically selected, but slabs affected by frost were not flaked. However, both poor and good quality stones were used for some heavy-duty tools on slab fragments. Cores and bifaces are always on good quality stone suggesting that stone selection depended on production and management aims. Good quality materials were not required for partial tools whereas tools and cores with management of the whole volume required good quality stone. The selection of the thickness and the shape of the slab or slab fragment was also a priority for bifaces and structured cores (suitability of natural angles and surfaces). This was not the case for the partial heavy-duty tools, which just required one suitable angle or a limited available flat surface for shaping. This selection indicates the flexibility and adaptability of hominins to the diversity of available slabs. They used the most suitable slabs, broke them when necessary and displayed varying degrees of exigence depending on the final purpose.

The ratio of flakes to cores (0.6 for the largest cores and flakes, 2.1 for the small flakes and structured cores) indicates that the whole production sequence was not recovered. Apart from some limestone slabs broken in situ, few core and flake refits were found. No flakes were refitted to LCTs, perhaps due to the small quantity of flakes from biface shaping identified at the site, and no broken LCTs were refitted. Despite the considerable extension of the excavated area, it is plausible that the different activity areas covered a large occupation surface and that pieces were moved across these areas. The hypothesis of higher mobility for some LCTs (for instance, bifaces) cannot be retained despite the small quantity of flakes from the shaping process. Only one bifacial tool can be considered as a reshaped broken tool. This is not due to fluvial disturbance (see the taphonomy of the archaeological layer above), but probably due to the spatial fragmentation of the chaîne opératoire (in situ?), regardless of the number and duration of occupations. This fragmentation is also observed for the debitage where flakes are missing from giant and smaller cores (for instance, cortical flakes). However, as only one raw material was used, we assume that all the processes took place on site.

Skill and Cognition

Core technology is the predominant activity at the site, with two main chaînes opératoires: one devoted to the production of small flakes and the other to large flakes (Fig. 18). The whole assemblage shows mental and technical templates and the ability to adapt to stone availability. The production of small flakes is more structured and productive than that of large flakes, for which unstructured giant and medium-sized cores were used. These latter cores were occasionally used as blanks for shaping sequences. They show varying degrees of investment and complexity depending on reduction processes. The assemblage combines two groups of artefacts: one with high levels of investment and complexity (bifaces, small flakes), and one showing less complex, opportunistic and expedient behaviour (partial tools, cleavers, heavy-duty tools, large flakes). However, both large and small flakes were selected for retouch.

Numerous large slabs present a limited number of invasive removals or were broken by direct percussion with hard hammers. Thickness was a major criterion for slab selection, and the thickest slabs were used for the production of flakes. Varied panoplies of opportunistic or structured methods using direct hard hammer percussion were applied for core technology. Small cores show clear crushing marks on their edges and some large quartz and metamorphic rock pebbles found in situ could also have been used for percussion activities. They are considered as a set of potential hard hammers. Overall, the cores indicate good knowledge of millstone slab properties and show the relatively minor role of natural slab shape, except at the beginning of the reduction sequence. Several centripetal and bifacial cores provide further evidence of the limited influence of stone geometry.

Thin and elongated slabs were selected or occasionally broken for shaping. They can be considered as partly predetermined, with an appropriate shape, and oriented for minimal preliminary shaping, preparation of the peripheral platforms and the first removals (beginning of the initial equilibrium of tool shape and a 3D mental image). Suitable parts of naturally or deliberately broken slabs were used for making other heavy-duty tools. Shaping technology produces tools with varied shapes and more or less invasive removals. The material indicates the ability to manage the contour and biconvex symmetry and shows that standardized and structured rules were applied even though the morphological results are diverse (Iovita et al. 2017). The tools are made by a high number of flake removals, with bifacially and bilaterally regularized edges. One to three series of removals have been identified on the bifaces sensu stricto and these sometimes entirely cover both surfaces. When several series occur, the first consists of deep hard hammer removals and the second of thin and invasive removals in order to finish shaping. The shape of the second series of removals may possibly indicate the occasional use of a soft hammer (some thin and invasive removals). Other bifacial tools show limited and/or peripheral shaping, suggesting the prime importance of a bifacial pointed tip. The first shaping phases are partly related to the slab cross-section. Cross-sections are plano-convex or symmetric, whatever the categories and the final morphological result. They attest to the limited role of slab morphology. Some bifaces are twisted. Cutting edge angles generally vary from 50 to 80°. When the blank is a flake, the ventral surface displays fewer scars than the dorsal surface and the tool is minimally shaped. Lastly, on most of the tools, unifacial retouch rectifies some areas of the edges and the tip and does not systematically produce regular cutting edges (around 40% of the edges are sinusoidal). This final retouch could represent resharpening in some cases and confirms the control of tool edge management. Tips are often thinned by additional short removals. Bases are mainly worked by general shaping removals or else remain cortical (with a natural slab edge). The thickest part of the tools is either the bottom or the central part of the tool, depending on the aim and intensity of shaping (remains of large cortical slab surfaces). They are generally asymmetrical in shape except for bifaces sensu stricto with a bifacial or bilateral equilibrium and a preconceived form.

Technological Behaviour, Function of the Tool Kit and Spatial Distribution

Hardy et al. (2018) presented around 100 artefacts with residues and micro-wear traces. Results indicate diverse domestic activities, in addition to knapping workshops (Supp. Material Fig. 9-13SM).

Three complete plano-convex or symmetrical bifaces with final retouch revealed patterned residues and use-wear. The tools measure 120–176 mm long and 30–40 mm thick. Plants are the most common residues on tool edges with angles between 40 and 82°. The whole perimeter of one biface was used while the base and part of a lateral cutting edge were used on the others. No evidence of use was identified on the tips.

Six bifacial tools or crudely made bifaces bear residues. The cross-sections are all plano-convex except for one, which is twisted. The edges are often sinusoidal. Residues are located on the two convergent edges (woodworking, 66–70°), on the surface of the upper part of the tool (plant, hair, 68–80°), on the base (hard material), on the edge opposed to a back (cutting bird, 70°), on the two convergent edges and the tip (butchery, 66°), and on one edge (plant, 55–69–76°). All tool parts bear residues but rarely the tip. A variety of angles were used. These pieces were used for the same actions as fully shaped bifaces, implying that the degree and complexity of shaping are not necessarily related to function. Six pieces with bifacial transversal tips (cleaver-like), measuring between 107 and 180 mm long, with an average thickness of around 35 mm, present used areas on both the transversal tip and one or two lateral edges, sometimes with final retouch. Used angles are around 50° for most of the pieces. Residues were preserved on the two cleavers on large millstone flakes. The lateral zone or the middle zone of the transversal cutting edge were used either for butchery, or woodworking. The angle is sharp, between 43 and 50°. Some residues were also found on the retouched lateral edge of one piece used for the same task.

Micro-wear and residues indicate that for the large flakes, the retouched or unretouched cutting edge is more important than the general shape for use while for small flakes, retouch often results in a more structured tool (Suppl. Material Tables 10SM, 11SM). Flakes with preserved residues are from all the phases of the reduction process. Cores did not bear use-wear or residues, apart from crushing macro-marks on some of them. No specific types of flake could be correlated with a specific action or type of worked material. Each part of the flake seems to have been used independently. Flakes used for butchery are often thinner (10–20 mm) than flakes used for working wood and plants (20–40 mm). For butchery, angles vary between 40–50° and 60–70°. For plant working, 40–50° angles were preferentially used. For woodworking, 30–40° cutting edges were clearly selected while multiple activities were associated with angles of 60–70°. Residues on flake tools show that unretouched flakes and retouched flakes were used indistinguishably. No particular criteria seem to have been applied to angles and retouched edges. Some notches were used for woodworking, as were natural notches on some unretouched flakes.

The geological analysis of unit a (or stratum a) indicates that the sand covering the archaeological layer was deposited in a low-energy context. The spatial distribution could thus be tested, and the position of the pieces can be considered as reliable, as attested by the in situ geological connection of the different fragments of some broken slabs. The small quantity of small flakes (less than 10 mm long) may be due to some disturbances during the deposition of the sandy layer. The lack of refitting between flakes and cores, and between heavy-duty tools and shaping products suggests the displacement of material during the occupations of the site by hominins (to unexcavated areas suggesting extended occupations). We also note the presence of broken slabs where missing fragments were probably moved around the occupation.

The artefacts are concentrated in the three concentrations as described above. The bifaces and structured cores were found in groups of twos or threes, or were dispersed. Flakes and flake tools are also dispersed on the excavated areas and more concentrated in some squares (SW part of the excavation). The distribution of pieces issued from shaping is more concentrated in the eastern part of the excavated area, close to some bifaces. Finally, the sample of flakes and heavy-duty tools studied for use-wear and residues indicate dispersion of the different tasks (Suppl. Material Fig. 2SM to 6SM).

What About the Technological Features in Western Europe Before 600 kyrs

Early Evidence of Biface Production?

In southern Europe, La Boella (Spain, 1.00 Ma ± 0.068 minimum age) has yielded the earliest evidence of large bifacial tools (Vallverdu et al. 2014; Mosquera et al. 2015). With Lezignan-la-Cebe (800 ka), it currently represents the best example for discussing the early arrival of biface production in Europe on a local substratum or as a local development (Bourguignon et al. 2016). The core technology does not indicate behavioural changes compared to, for instance, the penecontemporaneous lithic series of level TD6 at Gran Dolina (Atapuerca, Spain, ~ 0.8 Ma; Parés and Pérez-Gonzalez 1999; Parés et al. 2013; Mosquera et al. 2018). Cueva Negra del Estrecho del Quípar (southern Spain) yielded a lithic series with bifacially shaped tools and small flakes showing centripetal exploitation (Scott and Gibert 2009). However, Jiménez-Arenas et al. (2011) have proposed a younger Middle Pleistocene age for this site. Bifacially shaped tools were discovered recently at Solana del Zamborino (Guadix Basin, Southern Spain, ~ 0.76 Ma), but no data are currently available for the whole lithic series and the chronostratigraphy of the site has been questioned (Álvarez-Posada et al. 2017). The sites of Pradayrol (900 ka based on biostratigraphy), Soleilhac (700–500 ka tephra dating) or the assemblages from the Upper Roussillon and Rhône terraces in France, or the site of Bogatyri (1.4–1.1 Ma) in Russia, record some unclear attempts at bifacially worked pieces (Bourdier 1958; Tavoso 1986; Shchelinsky et al. 2010; Guadelli et al. 2012). No transitional industries are currently known between the core-and-flake industries and series with “elaborate” biface shaping.

Technological Features from 700 to 600 ka

From 700 to 600 ka, the lithic record indicates a technological shift with more widespread biface production and some other innovations. In the northwest of Europe, the technical features of the flint industry identified in the Cromer Forest bed formation at Pakefield (Great Britain, ~ 700 ka) are difficult to evaluate due to the limited number of lithic pieces in local flint (Parfitt et al. 2005, 2010). At Moulin Quignon, France, in the Somme Valley, a total of 244 flakes, 13 cores and five bifaces were recently discovered in situ in the lower part of alluvial deposits of the Somme Valley dated to 672 ± 54 ka (Antoine et al. 2019). The complete flake reduction process mainly consists of large flakes (mostly between 40 and 80 mm long). Cortical flakes attest to the use of nodule sides or core edges for eliminating the cortex and initiating the flaking process. Flakes without cortex show that the debitage continued by unipolar, centripetal and/or crossed removals. The thick and large platforms display an open angle (50–60°). Less than 30 pieces bear retouch (end scraper, convergent tools (point) and some scrapers). The cores indicate either crude and opportunistic flaking, or unipolar/centripetal debitage on one, two (orthogonal or bifacial) or multiple surfaces. Some series of removals on orthogonal cores and bifacial cores show no links with nodule shape and thus indicate the limited constraints of blanks and a degree of independence from the raw material. The five bifaces show wide diversity in shape and shaping modes. They range from a crudely worked biface to a triangular elongated biface with no cortex, a triangular and symmetrical biface with a thick cortical base, an oval and symmetrical biface with cortical patches on one face and a back.

In Italy, the site of Notarchirico is a 7-m-thick fluvial-derived sedimentary sequence rich in volcanic materials from the Monte Vulture stratovolcano. New studies of 40Ar/39Ar and ESR ages constrain the occupation period of this site to between 670 ± 4 and 614 ± 4 ka, spanning MIS 16 (Pereira et al. 2015). The site documents one of the earliest occurrences (levels B, D, F) of bifacial technology in southern Europe (Piperno 1999; Lefèvre et al. 2010; Santagata 2016; Moncel et al. 2019). Raw material procurement and core technology are globally similar throughout the sequence and focus on the production of small flint end-products by freehand or bipolar debitage of small flint nodules or pebbles. One or multiple surfaces display simple unipolar or convergent removals. Some cores are discoid-like with alternate debitage. Platforms are not prepared. Cores on limestone resemble chopper-cores, with invasive removals. Raw material shape strongly impacts core technology for limestone whereas flint cores are more depleted and ultimately broken. The end-products and cores (20–40 mm) are small. Retouch, on quartz, quartzite, limestone and flint flakes or pebbles modifies the initial shape of the blank (pointed pebble tools, scrapers, notches, denticulates, Tayac points). The diversified heavy-duty component displays little standardization and includes numerous pointed chopping tools and rare pseudo-cleavers on limestone pebbles. Hominins used local pebbles from the lakeshore. Some bifaces on quartzite limestone and flint pebbles or flakes are bifacially shaped by more or less invasive series of deep removals, and then, in some cases, rectified by a second series of small removals on the tip. Cutting edges are irregular and the cross-section of bifaces is asymmetrical. Others are bifacial tools made by peripheral shaping. They are rather small in size (on average, 100–120 mm long).

The assemblages of Isernia-la-Pineta, level 3c, considered to date to 600–650 ka, and recently dated to 585 ± 1 ka by 39Ar/40Ar (Peretto et al. 2015; Pereira 2017), did not yield bifaces but contains an abundant heavy-duty component on pebbles and evidence of more complex debitage management (Gallotti and Peretto 2015; Peretto et al. 2015; Lugli et al. 2017). Hominins mainly used discoid methods, regardless of the geometry of the stones, to produce medium-sized flakes that could be transformed into small tools.

Common Technological Behaviours and Skills at 700–600 kyrs in Western Europe?

The comparison of the lithic assemblage from stratum a1 at la Noira with contemporaneous sites shows shared behavioural traits despite very different geographical locations and mineral environments. This tends to suggest a common cultural background throughout western Europe, whatever the climatic conditions, and points towards a sort of metapopulation with connected or a few connected small human groups. Well-dated sites now provide a reliable overview of the main features of toolkits and reduction processes between 700 and 600 ka: (1) predominant use of local raw materials and no evidence of the debitage of stones brought to sites from distant outcrops, (2) occasional complex large and small flake production (core technologies), (3) low ratio of bifaces, when present, and association of elaborate bifaces and partial bifacial tools, (4) diversity of shaping modes and forms for bifaces and bifacial tools (non-standardization) with some evidence of soft percussion, (5) lack of cleavers on flakes in north-western territories, and (6) rare use of large flakes for making the heavy-duty component or for debitage (little evidence of fragmentation of the reduction processes) (Moncel and Ashton 2018). Raw material procurement is mainly local and may perhaps be related to the type of site (along water areas) or to the lack of detailed analysis of the origin of stones. Flint is mainly used in the north whereas various stones were exploited in the south. Only the P-Q series from Caune de l’Arago at around 550 ka documents stone procurement from a wider perimeter. Some tools present bifacial volume management with one or several series of removals to obtain well-balanced surfaces. These pieces are made by diverse shaping modes and the resulting morphologies are also varied. Tools are not systemically symmetrical in form and cross-section (McNabb et al. 2018). The diversity and lack of standardization of the bifacial tools and the heavy-duty component also characterize the series, although some are more homogeneous due to the raw materials. Flaking modes are opportunistic (unifacial and multifacial), bipolar or discoid-type but they cannot always be considered as expedient. Some reduction sequences are more structured and more independent of blank shape and fully managed on good quality stones, as clearly observed at la Noira and the slightly younger site of Isernia-la-Pineta (590 ka) (Peretto et al. 2004; Coltorti et al. 2005; Parfitt et al. 2005, 2010; Carbonell et al. 2010; Pereira 2017). These innovations occur in techno-complexes with or without the presence of bifacial heavy-duty tools and could reveal a threshold in skills dated to the late Lower/early Middle Pleistocene, between 800 and 600 ka (Carbonell et al. 1999; Rodríguez et al. 2011; Mosquera et al. 2018). This threshold is connected to the ability to produce large flakes in association with reduction processes producing small flakes.

The impact of activities on the diversity of technological strategies and tool kits remains open to discussion. Occupations are in open-air habitats beside rivers, lakes or swamps (Isernia-La-Pineta, Notarchirico in Italy, la Noira in France) (Piperno 1999; Gallotti and Peretto 2015). Cut marks and fragmented bones demonstrate meat processing, butchery and scavenging on herbivore carcasses of different sizes, including megaherbivores. Sites seem to be either multi-activity sites (la Noira) or specialized sites (possibly scavenging sites at Isernia-La-Pineta (Longo et al. 1997)). They suggest mobile groups using local raw materials with little evidence of semi-local stone procurement (Ollé et al. 2013; Gallotti and Peretto 2015; Mosquera et al. 2015; Leroyer 2016). Isotopes of strontium on a human tooth at Isernia-La-Pineta confirm the relatively limited mobility of these hominins (Lugli et al. 2017).

Preliminary functional results from la Noira suggest that the site was not only a tool manufacture area but that domestic activities were also carried out there. Flakes and heavy-duty tools were used for similar functions (Hardy et al. 2018). No correlations have been established between types of pieces and function, and crudely made bifacial tools appear to have been used in the same way as bifaces. This suggests that the lithic series represents above all a cultural package. Butchery sites for large herbivores of the same age indicate that small flakes were widely used and were possibly as invaluable as heavy-duty tools for these activities (for instance Isernia-La-Pineta in Italy). Moreover, the few micro-wear studies point to multifunctional LCTs destined for butchery activities or plant cutting and gathering (for instance Aridos I-II, Hoxne, Boxgrove, Soucy; J Key and Lycett 2017). Preliminary evidence is consistent with the forms and technological processes observed on bifaces. Series contain tools with irregular cutting edges, which are poorly adapted to cutting or scraping but used for their volume/weight or pointed shape, associated with tools with rectilinear cutting edges.

Is la Noira Lithic Assemblage Evidence of the Introduction of the Acheulean(s) in Western Europe or Evidence of Isolated and Local Evolutions?

Different mental templates in some sites from 700 to 600 ka suggest a technological shift with new cognitive and skills requirements. Since the first identification of the Acheulean by Gabriel de Mortillet in 1872 and the first use of the term biface by Vayson de Pradennes in 1920 in the Somme Valley in France, many definitions and classifications have been advanced, leading to contradictory debates (e.g. Commont 1908; Breuil Abbé and Kelley 1954; Bordes 1961; Clark 1969; Kleindienst 1961; McPherron 2006). A large diversity of assemblages and “know-how” exists over long periods of apparent stasis during the Middle Pleistocene (Leakey 1951, 1971; Kleindienst 1961; Roe 1964; Clark 1969; Isaac 1977; Delagnes et al. 2006; Semaw et al. 2009; de laTorre et al., 2008; de la Torre and Mora 2018). Recent studies in Africa show that new techno-complexes described as Early Acheulean from 1.75 Ma onwards are not only identified by the manufacture of LCTs (always in small proportions until 1 Ma), requiring specific and common skills (for instance the ability to produce a balanced bilateral shape, the maintenance of symmetry in cross-section and plan view and the final shaping of the tip and cutting edge), or the production of large flakes produced by various methods. New behavioural criteria appear sporadically from 1.5 Ma onwards, and above all from 1 Ma to 800 ka: higher mobility, increased selection of raw materials, different site locations, variable ecological settings, mobile LCTs and curated tools on pebbles destined for diverse functions (e.g. McNabb et al. 2004; Harmand 2009; McHenry and de la Torre 2018; de la Torre and Mora 2018).