Abstract

Because sodium-ion batteries are relatively inexpensive, they have gained significant traction as large-scale energy storage devices instead of lithium-ion batteries in recent years. However, sodium-ion batteries have a lower energy density than lithium-ion batteries because sodium-ion batteries have not been as well developed as lithium-ion batteries. Solid-state batteries using solid electrolytes have a higher energy density than liquid batteries in regard to applications with sodium-ion batteries, making them more suitable for energy storage systems than liquid batteries. Due to their low ionic conductivity, solid electrolytes are currently unable to achieve comparable performance to liquid electrolytes at room temperature. In this review, we discuss the advancements in SSEs applied to sodium-ion batteries in recent years, including inorganic solid electrolytes, such as Na–β-Al2O3, NASICON and Na3PS4, polymer solid electrolytes based on PEO, PVDF-HFP and PAN, and plastic crystal solid electrolytes mainly composed of succinonitrile. Additionally, appropriate solutions for low ionic conductivity, a narrow electrochemical stability window and poor contact with electrodes, which are the significant flaws in current SSEs, are discussed in this review.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, renewable energy issues have been raised because of the well-known limitations of fossil fuels. Thus, it is imperative to develop green energy, especially electric energy, to replace traditional energy. However, renewable power generation energy, such as solar power, is characterized by unstable output, which results in a great deal of interest in energy storage [1,2,3,4,5]. Proton exchange membrane fuel cells (PEMFCs) are devices that convert fuel energy to electric energy smoothly and conveniently [6,7,8,9,10]. Lithium-ion batteries (LIBs) are also one of the most promising energy sustainable storage technologies because of their excellent electrochemical performance and recyclable nature, thereby maintaining a dominant position as a form of energy storage for electric vehicles (EVs) and energy storage systems (ESSs) at present [11,12,13]. These systems, however, suffer from a lack of precious metal resources and a high cost, which makes them unsuitable for use as grid energy storage systems [8, 13,14,15,16]. Alternative energy storage devices have been explored as replacements for the current devices. Sodium-ion batteries (SIBs) are the most promising alternative because of the abundance of sodium resources, the low production costs, and the similar charge/discharge principles with LIBs [17,18,19,20,21,22,23]. Although the theoretical energy density of SIBs is considered lower than that of LIBs because the relative atomic mass of sodium is much higher than that of lithium, safety and cost are primarily considered in situations such as large-scale energy storage devices, which explains the wide variety of applications of SIBs [24,25,26,27,28]. SIBs have a limited capacity for these applications, primarily due to their short development time compared with LIBs. Because LIBs have been developed for nearly 30 years, their specific capacities are close to their theoretical capacities, whereas this is not the case with SIBs [25, 27, 29]. In light of the research conducted on the positive and negative materials for SIBs, there are several potential areas for improvement in terms of capacity and cycle life. To facilitate the application of SIBs, researchers have enhanced their energy density from a variety of aspects. New “anode-free technologies” have been developed, for example, to eliminate the defect of low energy density in SIBs [30]. In this technology, the anode active material is removed from the battery, and instead, a sodium metal layer is formed on the surface of the anode side current collector through the first cycle of charge and discharge. As a result, the energy density is significantly increased. It is also likely that some new problems may arise as well, such as the formation of sodium dendrites and the reaction between the electrolyte and the sodium metal [31]. Overall, SIBs are still in need of innovation in each component of the battery to increase their capacity.

The electrolyte plays an essential role in SIBs. By transferring sodium ions between the positive and negative electrodes, it greatly influences the energy density and rate capability. Generally, electrolyte systems can be divided into three categories: water-based systems, organic solvent systems, and solid-state systems [18, 32,33,34,35]. Even though the water-based electrolyte provides SIBs with stable cycling performance, the maximum voltage typically does not exceed 2 V due to the low electrochemical window of water, which results in a low energy density. Voltages exceeding 2 V can only be achieved when the salt concentration is high, for example, 17 mol kg−1 NaClO4 [32, 36,37,38,39]. Similar to LIBs, organic liquid electrolytes, such as carbonates and ethers, are increasingly used in SIBs. The commonly used carbonate organic solvents of liquid electrolytes in SIBs, such as ethylene carbonate (EC) [17, 18, 40, 41], propylene carbonate (PC) [18, 42,43,44], and ethyl methyl carbonate (EMC) [18, 44,45,46], have a strong ability to dissolve salt. EC and PC have been gaining attention during the period of traditional liquid electrolytes because they possess a high dielectric constant and broad electrochemical window, preventing liquid electrolytes from reacting with electrodes and forming a stable solid electrolyte interface (SEI [43, 44, 47]. Due to the evolution of energy density, it is not possible to satisfy both the requirements of stability and electrochemical performance with a single kind of liquid electrolytes. To achieve higher performance, different liquid electrolytes have been mixed. There have been numerous studies utilizing EC and PC together as the electrolyte for SIBs to enhance their performance [48,49,50]. Carbonate electrolytes, however, did not form suitable binary co-intercalation compounds with sodium ions, making graphite ineligible for use in SIBs. Instead, ether electrolytes allow the effective use of graphite and other negative electrodes in SIBs, providing stable intercalation and desorption of sodium, although ethers have a lower electrochemical window [51,52,53]. Sodium metal anodes have been proposed as an effective means of improving the practical capacity of SIBs [54]. The use of organic solvent electrolytes, as described above, may cause sodium dendrites during the charging and discharging cycles, resulting in short circuits and accidents. There is a limited electrochemical window for those electrolytes as well as for sodium metal anodes [55,56,57,58]. Apart from the defects mentioned above, liquid electrolytes and organic solvents also have the well-known disadvantages of being flammable, toxic, and volatile. Liquid electrolytes are unable to be applied and developed further due to safety concerns that are either difficult or costly to overcome. It is believed that ionic liquids (ILs), which typically contain organic cations and anion ions, are a safer and stabler electrolyte than carbonate and ether liquid electrolytes [59]. The benefits of ILs include their low volatility, high boiling point, wide electrochemical window, good thermal stability, and ease with which they can be designed. They are generally preferred as an electrolyte because they can improve the safety of batteries [60,61,62,63]. Nevertheless, their high cost and high viscosity hinder the application of ILs as electrolytes [64]. Accordingly, optimizing and balancing the performance, cost, and safety of liquid electrolytes remains a major challenge. Solid-state electrolytes (SSEs) have been considered a possible alternative to liquid electrolytes in this situation [11, 21, 35, 55]. Compared with liquid electrolytes, SSEs have the advantages of good processability and good safety. As a result of the compatibility with sodium anodes, it was expected that SIBs with SSEs would have a higher energy density than those with liquid electrolytes. Some SSEs that apply polymers as the base material can have even lower costs. These remarkable characteristics of SSEs have gradually attracted the attention of researchers [56, 65,66,67]. According to a study of the number of publications related to solid electrolytes of SIBs, the number of publications has increased over the period 2010–2022, as shown in Fig. 1.

Different research groups have highlighted the following characteristics of SSE: electrochemical stability, mechanical strength, and increased energy density [68,69,70]. Specifically, Fig. 2a shows that different varieties of electrolytes have different calculated theoretical energy densities, of which the SSE has the highest [18]. This is due to the compatibility of SSEs with sodium metal anodes. A higher electrochemical window is claimed for SSEs, resulting in compatibility with high-voltage cathodes as well. Additionally, the design of the battery assembly could be simplified because the SSE serves the same purpose as the separator, which is required when using liquid electrolytes [71]. The commercialization of SSEs is, however, still hindered by some shortcomings. It has been pointed out that one of the main defects of the SSE is that its ionic conductivity is too low to meet the requirements of applications at room temperature. In Fig. 2b, the ionic conductivity of illustrative SSEs is summarized, which indicates that at room temperature, the ionic conductivity of SSEs is inferior to that of a liquid electrolyte [55]. The contact between the electrolyte and the positive and negative electrodes must also be improved, as it is difficult and complex to form a low-impedance interface [19, 55, 57, 70, 72, 73]. The solid‒solid interface between the electrodes and solid electrolytes is also a key factor that determines the electrochemical performance of solid-state batteries. Moreover, the electrochemical window and mechanical strength of SSEs play an important role in assessing the stability of the electrolyte [74,75,76]. The sodium-ion SSE system reported thus far is unable to overcome all of the shortcomings mentioned above; thus, further research is needed. Essentially, to establish a good SIB-based SSE, it is generally necessary to have a high ionic conductivity of more than 10−4 S cm−1, a low electron conductivity to prevent self-discharging, and a high electrochemical stability window to be compatible with the electrodes [77,78,79]. To supersede Li-ion technology, novel cell systems must utilize a sodium negative electrode, which can significantly increase the specific energy [57]. In addition, the SSE should also be mechanically strong enough not only to facilitate engineering processes but also to prevent dendrite formation. In this article, a review of the recent developments in the areas of the ionic conductivity, electrochemical stability window properties, interface state with electrodes, and electrochemical performance in batteries will be presented. Multiple types of solid electrolytes are included, including inorganic solid electrolytes, polymer solid electrolytes, gel polymer electrolytes, and plastic crystal electrolytes, to determine the future development direction of SSEs.

Copyright © 2017, Royal Society of Chemistry; b ionic conductivity of SSEs and liquid electrolytes at different temperatures. Reprinted with permission from Ref. [55]. Copyright © 2018, John Wiley and Sons

a Theoretical energy density of different varieties of electrolytes. Reprinted with permission from Ref. [18].

2 Inorganic Solid Electrolyte

Inorganic solid electrolytes (ISEs) have the advantages of being nonflammable, chemically stable, and mechanically strong [1, 80, 81]. In an earlier study by Famprikis et al. [80], it was concluded that the ion diffusion mechanism of an ISE can be divided into four categories: vacancy migration, interstitial migration, correlated migration, and concerted diffusion. It was found that sodium-ion diffusion was closely related to the activation energy of the material and the number of defects in the vacancies, which indicated that the ion conductivity of the ISE can be enhanced by ion doping. The general electrochemical window of different sodium-based inorganic compounds was studied by Lacivita et al. [82]. Based on density functional theory (DFT) calculations, a wide range of Na SSE chemistries were investigated in terms of their electrochemical stability and chemical reactivity. Sodium compounds exhibit lower reduction limits, as shown in Fig. 3, indicating their increased cathodic stability and the ability to cycle sodium against a variety of oxides with increased stability. In addition to oxidation and reduction reactions against Na metal, some reduction reactions are also depicted in the figure. In general, solid electrolytes can be classified by the anion or anion group, namely oxide-based solid electrolytes, sulfide-based solid electrolytes, and other inorganic solid electrolytes. Below are a few examples of different types of ISEs.

Calculated electrochemical stability windows of Na inorganic SSEs [82]

3 Oxide-Based Solid Electrolyte

3.1 Na–β-Al2O3

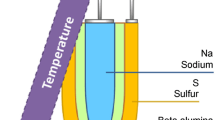

β-Al2O3 is a kind of alternate layered accumulation compound. The layered compound of the conductive plane and the spinel block corresponds to two different crystal structures, namely β-Al2O3 (the hexagonal crystal system, Na2O·(8–11)Al2O3) and β″-Al2O3 (rhombus, Na2O·(5–7)Al2O3) [83, 84]. The microstructures of β-Al2O3 and β″-Al2O3 are shown in Fig. 4 [85]. Due to a higher percentage of sodium ions in the crystal lattice and a weaker ionic bond between sodium and oxygen, the ion conductivity of β″-Al2O3 is consequently higher [86]. The Na–β-Al2O3 SSE was first discovered by Yung Fang et al. in 1967 [87]. It was reported that the diffusion coefficient of sodium ions was up to 1 × 10−5 cm2 s−1 at 593 K and 4.0 × 10−7 cm2 s−1 at room temperature, indicating a high ionic conductivity and thermal stability at high temperature. Commercialized cell systems utilizing sodium as the negative electrode and Na–β-Al2O3 as the solid electrolyte have been developed. A well-known example of these batteries is the Na–S battery, which operates at temperatures of 350 °C [88].

Microstructure of β-Al2O3 and β″-Al2O3. Reprinted with permission from Ref. [85].

Many studies have been conducted to improve the ionic conductivity of Na–β-Al2O3 SSE. The methods mainly used in the past are ion doping with other metal ions [89] and adjusting the rate between β-Al2O3 and β″-Al2O3 [90]. Recently, it has been reported that a high β″-Al2O3 content Na–β-Al2O3 SSE was synthesized by using boehmite as an alumina source [91]. In this study, the effects of sodium oxide on the SSE were examined from the perspective of phase constituents and ionic conductivity to the point of application. By increasing the content of β″-Al2O3 to 95 wt% (wt% means the weight percentage), the newly synthesized Na–β-Al2O3 SSE showed a high ionic conductivity of 6.30 × 10−4 S cm−1 at room temperature and 1.16 × 10−2 S cm−1 at 350 °C. Using the Na3V2(PO4)3 cathode and Na metal anode materials, the battery exhibited an initial discharge capacity of 80.5 mAh g−1 at 0.5C. The optimized Na–Al2O3 SSE displayed excellent electrochemical stability against sodium metal. According to Fig. 3, the electrochemical stability window of Na–β-Al2O3 is between 3 and 4 V, and the reduction limit vs. Na/Na+ is nearly 0 V, indicating that Na–β-Al2O3 is suitable for sodium metal anodes.

Ion doping is an effective way to improve the performance of ionic conductivity. Hua et al. [92] reported a novel Na–β-Al2O3 SSE composed of β″-Al2O3 and an ethylenediaminetetraacetic acid (EDTA)-zirconium(IV)/yttrium(III) complex. The manufacture and modification process of the SSE is depicted in Fig. 5. Different characteristics, such as microstructure, were also studied. With the outcome that 5 wt% nano 33 mol% (mol% means the molar percentage) yttrium partial stabilized zirconia (3YSZ) offered a high performance in terms of density and microstructure, the ionic conductivity reached 7.1 × 10−2 S cm−1 at 300 °C and 0.33 S cm−1 at 600 °C. Although the ionic conductivity of Na–β-Al2O3 SSE has been optimized to over 10−2 S cm−1, it is the high temperature to which SSEs can only be applied. It is not only the ionic conductivity but also the contact surface with the electrode that produces a high resistance at room temperature.

a synthetic route; b SEM microstructure and c ionic conductivity of SSEs. Adapted with permission from Ref. [92].

Substantial effort has been made to apply Na–β-Al2O3 SSEs at room temperature to the Na–S battery. Electrochemical cells operated at room temperature do not inevitably prevent dendrite growth when sodium-beta alumina is used since dendrite formation is not solely dependent on the Na–β-Al2O3 SSE itself. It is also crucial to consider the properties of the sodium metal negative electrode, in which the solid state and liquid state are different [93]. Spencer et al. [94] investigated the surface between a Na–β-Al2O3 SSE and a sodium metal anode at room temperature to understand the failure mechanism of a Na–β-Al2O3 SSE at ambient temperature. Using three electrodes and tomographic imaging, it was found that voids form within the Na metal at the interface during stripping and accumulate during cycling, resulting in an increase in interfacial current density, dendritic formation on plating, short circuits, and failures of the batteries, as shown in Fig. 6. It was also investigated that above 9 MPa is required to prevent the formation of dendrites when cycled at current densities lower than 2.5 mA cm–2 at room temperature. Clearly, the conditions for stable cycling at room temperature are harsh and impede progress towards commercialization of the Na–β-Al2O3 SSE. Currently, optimization of the surface of SSEs is required to be compatible with sodium metal anodes and to apply a lower temperature, such as 60 °C [95].

An illustration of the mechanism that results in the voiding of the cell and subsequent development of dendrites. Grey represents the sodium anode, and blue represents the Na–β-Al2O3 SSE. Reprinted with permission from Ref. [94].

Although the Na–β-Al2O3 SSE exhibits a high ionic conductivity at both high and room temperatures, it still has low kinetics owing to both its thickness and its interfacial properties. Due to the formation of solid polysulfides with slow electrochemical reactivity, reducing the operation temperature of Na–S batteries limits their electrochemical performance as well [96]. Therefore, researchers are focusing on optimizing the interface between Na–β-Al2O3 SSEs and electrodes to obtain usable batteries at lower temperatures. The use of ILs with good chemical stability and performance has been, for example, demonstrated. In their study, Wang et al. [97] investigated a dual electrolyte comprising a Na–β-Al2O3 SSE and an inorganic IL Na[OTf]–Cs[TFSA] that possesses a high ionic conductivity and a wide electrochemical stability window of 5.1 V, where [OTf]− is trifluoromethanesulfonate and [TFSA]− is bis(trifluoromethanesulfonyl)amide. At an operation temperature of 150 °C, the Na–S battery achieves a high reversible capacity of 795 mAh (g-S)−1. Figure 7 shows the electrochemical performance and a schematic illustration of this dual-electrolyte Na–S battery. During a 1 000 cycle test, an average capacity of 381 mAh (g-S)−1 was achieved with an average 100% coulombic efficiency. It was also investigated that the usage of an electrolyte based on Na[OTf] is employed as a method of improving the kinetics of inert polysulfides through Na+ conduction. The presence of a large number of [OTf]− donors causes polysulfides to dissolve more readily into the electrolytes, thereby improving the electrochemical performance. Efforts should be made to optimize the cell structure and the IL composition to achieve significant improvements in performance. With improved polysulfide reaction kinetics and sodium dendrites at room temperature, Na–S cells with Na–β-Al2O3 SSEs are promising for high practical capacity and safety.

a-e Electrochemical performance of a Na–S cell with IL/Na–β-Al2O3 electrolytes; f Na–S battery operation mechanism diagram with IL/Na–β-Al2O3 electrolytes. Adapted with permission from Ref. [97].

3.2 NASICON

NASICON (Na superion conductor) is different from Na–β-Al2O3 SSEs, as NASICON has 3D channels for sodium-ion transportation, whereas Na–β-Al2O3 SSEs can only transport sodium ions in plane. NASICON was first discovered by Goodenough and Hong in 1976 and consists of Na1+xZr2SixP3−xO12 (0 < x < 3) (NZSP) [98, 99]. NZSP is composed of NaZr2(PO4)3 and Na4Zr2(SiO4)3. The crystal structure of NZSP at 1400 K has been studied and is shown in Fig. 8 [100]. The transport path of sodium ions marked as yellow stripes is simulated by comparison of neutron powder diffraction data, the maximum entropy method (MEM), the bond valence energy landscape (BVEL) approach, and DFT computations.

A simulation of Na3Zr2Si2PO12 at 1 400 K. a Unit cell; b 2a*1b*2c cells. Adapted with permission from Ref. [100].

Zhou et al. indicated that for NZSP without modification, Na3Zr2Si2PO12, which retains a monoclinic structure, shows the highest performance in terms of ionic conductivity and physical and chemical stability [1]. NZSP was reported to reach an ionic conductivity of 6.7 × 10−4 S cm−1 at room temperature and 2.0 × 10−1 S cm−1 at 300 °C. An electrochemical stability window of up to 6 V is typically observed when applying cyclic voltammetry to NASICON-type electrolytes. Despite this, low values have been obtained experimentally due to the restricted electrode/electrolyte contact area [101]. Figure 3 shows that by calculation, the NASICON reduction limit is approximately 1.1 V, while the NASICON oxidation limit is approximately 3.6 V, indicating a stable electrochemical window of 2.5 V. According to Schwietert et al. [102], the electrochemical stability window of solid electrolytes is significantly larger than predicted for direct decomposition, which rationalizes the observed stability window. The electrochemical stability window depends on the oxidation and reduction potentials of the solid electrolyte, not on the stability of the decomposition products. As a result of this indirect thermodynamic pathway, the electrochemical stability window is generally wider than that based solely on decomposition product stability.

It is possible to increase the ionic conductivity of NASICON from two dimensions. One method involves increasing the concentration of sodium ions. An increased sodium-ion concentration results in an increase in charge carriers. The other method involves the introduction of appropriate substituents. By increasing the size of the bottleneck, substituents can reduce the energy barrier as well as the activation energy [103]. Recently, Sun et al. [104] studied in detail the mechanism of the augmentation of ionic conductivity of scandium doping in sodium-rich NASICON SSEs of Na3+xScxZr2−xSi2PO12 (x = 0, 0.1, 0.2, 0.3, 0.4, 0.5, and 0.6) (NSZSPx). The microstructure of the general NZSP and X-ray diffraction (XRD) of NSZSPx are shown in Fig. 9. It has been discovered that Sc ions are doped into the crystal lattice in place of Zr, which leads to a structural change, enhancing ionic conductivity. According to the results, the highest ionic conductivity of Sc-doped NASICON was Na3.3Sc0.3Zr1.7Si2PO12, which presented an ionic conductivity of 1.9 × 10−3 S cm−1 at room temperature. It was also investigated that with x < 0.3, the ionic conductivity was increased by an acceleration of the transference of sodium ions, while for x > 0.3, the crystal form of NASICON changed from monoclinic to rhombohedral, which resulted in sluggish sodium-ion transportation. The detailed ion transport mechanism of ion-doped NZSP is still under development, which may result in the progress on a series on NASICON-type SSE materials.

a General microstructure of NZSP; b XRD patterns of NZSP and NSZSPx; c&d amplified view of the selected area. Reprinted with permission from Ref. [104].

Zhang et al. [105] reported a newly designed NASICON containing lanthanum ions. NASICON was synthesized by La(CH3COO)3 and NASICON precursors consisting of NaNO3, ZrO(NO3)2, and NH4H2PO4. Scanning transmission electron microscopy (STEM) and electrochemical impedance spectroscopy (EIS) revealed that lanthanum doping enhanced ion transport at grain boundaries, generating new Na3La(PO4)2, La2O3, and LaPO4 phases. With this perfection, the ion conductivity of NASICON reached 3.4 × 10−3 S cm−1 at room temperature. According to the authors, the interface impedance between electrodes and SSEs was high due to a relatively low effective contact. Different organic liquid electrolytes (EC–DMC) and ILs (PP13FSI) were then added between the electrolyte and Na3V2(PO4)3 (NVP) cathode to adjust the interface contact. The interfacial resistance decreases by dozens of ohm after liquid is added, as shown from Fig. 10e–g, which presents the resistance of NVP/SSE/Na, NVP/LE/SSE/Na, and NVP/IL/SSE/Na, respectively. Through its wetting properties, IL facilitates favorable interface kinetics in SSBs. As shown in Fig. 10d, when IL was introduced between the cathode and SSE, the cell exhibited fantastic electrochemical performance under 10 C at room temperature. When compared to the cycling curve of NVP/LE/SSE/Na in Fig. 10b, the IL is far stabler due to the possible decomposition of the organic liquid electrolyte during cycling. The introduction of ionic liquids may be a new feasible method for ISEs to optimize the interface [106].

a, b and d Charge/discharge cycling curves of the marked cell; c rate performance of NVP/IL/SSE/Na from 0.2 C to 10 C at 25 °C; e to g interfacial resistance curve of the cells mentioned in the text. Adapted with permission from Ref. [105].

It is the electrode/electrolyte interfaces, electrochemical stability windows, and electrolyte variations during long cycling that determine the electrochemical stability of batteries. For enhanced battery performance, intimate contact interfaces with large surface areas and electrode compatibility are the most important factors.

4 Sulfide-Based Solid Electrolyte

The electronegativity of sulfur is smaller than that of oxygen, which reduces the attraction to sodium ions. Under a similar crystal lattice, sulfide-based SSEs have a higher ionic conductivity performance than oxide-based SSEs, which helps form an appropriate transportation channel for sodium ions [81]. Due to their high ionic conductivity, good ability to combine with electrodes, isotropic ionic conduction without grain boundary resistances, and variable composition over a wide range, sulfide-based SSEs have attracted much attention [79]. Sulfide-based SSEs, however, have the drawback of easily becoming bibulous and reacting with airborne water, which increases the difficulty of the product process [107]. Additionally, it should be noted that sulfide-based SSEs have high reduction limits and narrow electrochemical stability windows, as shown in Fig. 3.

4.1 Na3PS4

Na3PS4 was first synthesized in 1992 and possesses a tetragonal crystal lattice; however, the ionic conductivity was only 4.17 × 10−6 S cm−1 at 323 K [108]. Performance in terms of ionic conductivity did not meet the requirements of SSEs. It was then reported by Hayashi et al. in 2012 that a cubic crystal Na3PS4 glass–ceramic electrolyte was synthesized [109]. The Na3PS4 electrolyte was synthesized by powder compression at room temperature, and the ionic conductivity was 2.3 × 10−4 S cm−1, which revealed the possibility of application.

Ion doping will expand the ionic conductivity of sulfide-based electrolytes, which is the same as oxide-based electrolytes, as the transport channel will be enlarged, and more sodium vacancies will be introduced. Moon et al. reported the synthesis of a new Ca-doped Na3PS4 electrolyte (Na3–2xCaxPS4 (0 < x \(\leqslant\) 0.375)).[110]. According to the XRD spectra, the crystal lattice of the electrolyte changed from tetragonal to cubic with the addition of Ca, and this transformation enhanced the ionic conductivity. The microstructures of the normal Na3PS4 crystal and Na3–2xCaxPS4 crystal are shown in Fig. 11. According to the complementary analysis thus far, it is rational to conclude that overall conductivity is determined by the interaction between the Na+ vacancy concentration enhancement caused by Ca doping and the energy barrier impediment caused by Ca2+ together. As a result, the impact of vacancies is higher than that of the energy barrier, thereby enhancing the ionic conductivity. The ionic conductivity of the Ca-doped Na3PS4 electrolyte reached a maximum of 1 × 10−3 S cm−1 at room temperature. Applying the Ca-doped Na3PS4 electrolyte to TiS2/Na–Sn SIBs, the cycling stability performance was significantly improved. The capacity retention of TiS2/Ca-doped Na3PS4/Na–Sn, which was 91.0% after 100 cycles, was higher than that employing the cubic Na3PS4 electrolyte of 78.6%. Within the negative (0.0–2.0 V (vs. Na/Na+)) and positive (1.5–5.0 V (vs. Na/Na+)) voltage ranges, a cyclic voltammetry test was applied to the Ca-doped and original Na3PS4 electrolytes, as shown in Fig. 11b. The performance of Ca-doped Na3PS4 is slightly worse than that of the original Na3PS4 in terms of cathodic stability but better in terms of anodic stability. The electrochemical stability window of Ca-doped Na3PS4 is still narrow when applied to other electrode systems that possess a high voltage. The method of cation doping displayed an enhancement in ionic conductivity with increasing vacancies, which indicated a technique optimization. Electrochemical stability is still a barrier to the development of high-voltage and high-capacity SIBs.

a Microstructure of Na3PS4 and Na3–2xCaxPS4 with vacancy shown; b first two cyclic voltammetry curves for cells in the negative potential range (0.0–2.0 V (vs. Na/Na+)) and in the positive potential range (1.5–5.0 V (vs. Na/Na+)) at 303 K. Adapted with permission from Ref. [110].

It has been suggested that the ionic conductivity of tetragonal Na3PS4 is much lower than that of cubic Na3PS4 [109]. However, it was reported recently by Feng et al. [111] that Cl-doped tetragonal Na3PS4 (Na3−xPS4−xClx) was produced through a solid-state reaction, which had a persuasive performance. It was demonstrated by the authors that the accelerated and enhanced transportation of sodium ions in Na3−xPS4−xClx was due to functional defects that produced two more sodium transportation channels according to solid-state nuclear magnetic resonance (NMR). As a result, a high ionic conductivity was observed for Na2.9PS3.9Cl0.1, which was 1.96 × 10−3 S cm−1 at room temperature. According to Fig. 12a, the cyclic voltammetry test of Na|Na3.0PS3.8Cl0.2| in cells from − 0.5 to 10 V (vs. Na/Na+) showed only sodium deposition at 0 V. No decomposition was found in the electrolyte even when the voltage was as high as 10 V. It was suggested that the low electron conductivity of Na3.0PS3.8Cl0.2 hindered the decomposition. It should be noted that the LSV experiments produce very small currents and large overpotentials due to the slow reaction kinetics of the oxidation reaction, leading to a difference between the experimental oxidation limit and the reality limit [112]. As shown in Fig. 12b, a decrease in specific capacity was observed when the electrolyte was applied to the Na|Na3.0PS3.8Cl0.2|Na3V2(PO4)3 full cell. Possible explanations include interfacial stability during electrochemical cycling. As illustrated in Fig. 12c, impedance measurements before and after cycling provide evidence of this hypothesis. The total interfacial resistance is only 80 Ω before cycling and 1 300 Ω after cycling, resulting from undesirable side reactions between the electrodes and Na3.0PS3.8Cl0.2. The anion-doped Na3PS4 electrolyte created abundant sodium vacancies in the crystal, which consequently enhanced the ionic conductivity performance. The electrochemical stability window was enhanced due to a high electronic impedance. However, the interfacial resistance during cycling still needs to be solved.

a Cyclic voltammetry test from the 1st to 3rd rounds of the In|Na3.0PS3.8Cl0.2|Na cell; b charge/discharge curve from the 1st to 10th cycles of the Na|Na3.0PS3.8Cl0.2|Na3V2(PO4)3 full cell; c interfacial resistance of the Na|Na3.0PS3.8Cl0.2|Na3V2(PO4)3 full cell before and after cycling. Adapted with permission from Ref. [111].

4.2 Na3SbS4

Na3SbS4 is similar to Na3PS4 in that both have tetragonal and cubic crystal lattices, and the ionic conductivity of cubic Na3SbS4 is higher than that of tetragonal Na3SbS4. Wang et al. [113] first reported that cubic Na3SbS4 synthesized based on soft–hard acid-base (SHAB) theory had application prospects for SSEs. Air-conditioning resistance was tested on the product, which overcame the hygroscopicity of Na3PS4. The microstructure of cubic Na3SbS4 is shown in Fig. 13. It was stated by the authors that this type of SSE has a notable ionic conductivity of 1 × 10−3 S cm−1.

Microstructure of cubic Na3SbS4. Reprinted with permission from Ref. [113].

Gamo et al. [114] recently prepared tetragonal Na3SbS4 using the liquid phase method. The SSE showed an attractive high ionic conductivity of 3.0 × 10−4 S cm−1 at room temperature. Notably, the ionic conductivity of the SSE was enhanced to 3.1 × 10−3 S cm−1 at room temperature with ball milling, which proved that the crystal lattice of Na3SbS4 changed partially from tetragonal to cubic, forming a multiphase Na3SbS4 SSE. An experiment with a TiS2–Na3SbS4|Na3SbS4|Na–Sn cell was conducted to evaluate the electrochemical characteristics of the prepared Na3SbS4. The cell was cycled between 2.50 and 1.50 V at room temperature with a specific capacity of 125 mAh g−1 and an average coulombic efficiency of 97%. It was indicated that there were no side reactions between the prepared Na3SbS4 and TiS2.

Ion doping also helps enhance the ionic conductivity of Na3SbS4, which has the same purpose of enlarging the transport channel. Yubuchi et al. [115] investigated the use of tungsten instead of antimony, showing that the liquid-phase-synthesized Na3SbS4 electrolyte upsurged the ionic conductivity from 1.2 × 10−3 to 4.28 × 10−3 S cm−1 with the chemical formula of Na2.88Sb0.88W0.12S4. It was suggested that the enhancement of ionic conductivity was due to sodium-ion vacancies from ion doping, which indicated that by introducing doped ions, the ionic conductivity was expanded with the formation of sodium-ion vacancies. Recently, Tsuji et al. investigated the ionic conductivity of cation-doped Na3SbS4 with extra sodium, namely Na3+xSb1–xMxS4 (M = Si, Ge, Sn), which had lower ionic conductivity than Na3SbS4 at room temperature [116]. However, with partial replacement of molybdenum, forming sodium vacancies, Na3–xSb1–xMoxS4 showed attractive ionic conductivity. In particular, Na2.88Sb0.88Mo0.12S4 exhibited an ionic conductivity of 3.9 × 10−3 S cm−1 at room temperature. The ionic conductivity at different temperatures is shown in Fig. 14. Accordingly, the author suggests that sodium vacancies, rather than sodium ions, enhance ionic conductivity.

Temperature dependence of Na3SbS4, Na3+xSb1–xMxS4 (x = 0.06) and Na3–xSb1–xMoxS4 (x = 0.06). Reprinted with permission from Ref. [116].

Although Na3SbS4 has exhibited exciting ionic conductivity at room temperature and high air stability, its electrochemical stability with sodium metal anodes remains a problem. Na2S and Na3Sb can be formed on the interface between Na3SbS4 and Na metal [117]. It is likely that a percolating electronic conduction path forms at the interface due to the large fraction of metallic Na3Sb in the decomposition products, indicating that further decomposition of the Na3SbS4 electrolyte will occur. Thus, Tian et al. designed hydration covers on the surface by first-principles computational tools to form an h-Na3SbS4 electrolyte [118]. With an acceptable level of ionic conductivity, the hydrated surface (Na3SbS4·8H2O) formed NaH and Na2O, which slowed the reaction of the Na3SbS4 electrolyte with Na metal compared with the nonhydrated Na3SbS4 electrolyte. The formation of the hydrated surface is easy. In ambient air, the Na3SbS4 electrolyte was subjected to a humidity of approximately 68% for 10 min. Two different symmetric cells consisting of Na|Na3SbS4|Na and Na|h-Na3SbS4|Na were cycled at a constant current (0.1 mA cm−2) to evaluate the stability with the Na metal electrode. The result was that the h-Na3SbS4 electrolyte showed a stable interface during 25 h of cycling, as shown in Fig. 15a. In contrast, the voltage of the nonhydrated Na3SbS4 cell increased continuously due to the polarization of the unstable interface. The synchrotron X-ray diffraction (SXRD) spectra shown in Fig. 15b also show that the reaction product is determined to be NaS of the nonhydrated Na3SbS4 electrolyte. The schematic diagram shows a contrast interface between the nonhydrated and hydrated Na3SbS4 electrolytes, as shown in Fig. 15c.

a Symmetric cells consisting of Na|Na3SbS4|Na and Na|h-Na3SbS4|Na cycled at a constant current (0.1 mA cm−2); b SXRD pattern of Na3SbS4/Na interface products; c schematic diagram of the solid electrolyte-Na metal interface before (left) and after (right) electrochemical cycling. Adapted with permission from Ref. [118].

Although sulfide-based SSEs show higher performance than oxygen-based SSEs, problems remain. Sulfide-based compounds, especially Na3PS4, have the shortcoming of sensitivity to water, which easily forms hydrogen sulfide, causing the collapse of crystals and emission of toxic gases. In addition, elements of high valence, such as phosphorus and antimony, are easily reduced, which leads to a narrow electrochemical stability window. Optimization may focus on the modification of the surface of sulfide-based SSEs to prevent the reactions between the SSEs.

5 Other Inorganic Solid Electrolytes

In addition to oxide- and sulfide-based inorganic solid electrolytes, other inorganic solid electrolytes have also been investigated, such as Na(BH4)x(NH2)1−x, NaI, NaCB9H10, and Na3OBH4 [119,120,121]. Composite hydroborate solid electrolytes have unique physical chemistry properties, such as high ionic conductivity, a wide electrochemical stability window, good flexibility, and low density. Sun et al. [121] recently reported that synthesized Na3OBH4 demonstrated a high ionic conductivity of 4.4 × 10−3 S cm−1 at room temperature. This SSE showed a cubic antiperovskite microstructure, and the BH4 cluster anion was rotated, which created a fast sodium ion transportation channel. This work revealed the mechanism of cluster anion-based sodium-ion conductors, indicating a new kind of sodium ion super conductor at room temperature.

To develop all-solid-state batteries with high energy and power density, solid electrolytes with a wide electrochemical window and high ionic conductivity are essential. Large cage-like BnHn2− anions, namely closo-borates, provide salts with excellent electrochemical performance. However, closo-borates have proven to exhibit an electrochemical stability window in the 3.0–4.0 V range, which is difficult to apply with high-voltage cathodes [122]. Furthermore, according to calculations, hydroborates appear to be reactive with certain oxide-based cathodes, but those results have not yet been demonstrated experimentally [82]. Therefore, it was investigated that the oxidation compound of B10H102−, namely B20H182−, exhibited promising electrochemical stability up to 5.1 V versus Na/Na+ [75]. However, the ionic conductivity of Na2B20H18 has been measured as 2.5 × 10−6 S cm−1 at room temperature, which does not meet the requirement of the electrolyte for SIBs. A mixed anion electrolyte was then investigated, namely Na2B20H18–4Na2B12H12, which exhibited excellent electrochemical performance. The ionic conductivity was improved due to the disordering of the bulk starting materials Na2B20H18 and Na2B12H12. The sodium-ion transference number of this mixed electrolyte was calculated to be 0.976, indicating cation migration for the major proportion. As shown in Fig. 16b, the oxidation limit of Na2B20H18/4Na2B12H12 was measured to be 4.8 V versus Na/Na+, allowing its application to electrodes of high voltage. The electrochemical performance and stability for the studied closo-borates are listed in Fig. 16c, indicating a balanced high performance of the Na2B20H18/4Na2B12H12 electrolyte. To investigate the long-term stability and chemical compatibility of electrolytes to metallic sodium, constant-current cycling measurements were taken on the symmetric cell Na|Na2B20H18–4Na2B12H12|Na, which is charged and discharged at a certain current density of 0.1 mA cm−2. An inconspicuous increase in overpotential was observed after 100 h of testing, indicating that a slow parasitic reaction may occur between the electrolyte and sodium metal. An all-solid-state Na|Na2B20H18–4Na2B12H12|TiS2 cell was established and tested between 1.5 and 2.7 V at 0.1 C. At 25 °C, the cell displayed a reversible charge capacity of 65.2 mAh g−1 and a discharge capacity of 64.8 mAh g−1. Unfortunately, the critical current density was shown to be 0.8 mA cm−2, which is possibly due to the formation of sodium dendrites.

a Current–time curves for Na|Na2B20H18–4Na2B12H12|Na at a polarization voltage of 10 mV. The inset shows the impedance spectra before and after polarization; b linear sweep voltammograms (LSVs) of Na2B20H18-4Na2B12H12 measured at a scan rate of 10 μV s−1; c summary of the room temperature ionic conductivity and electrochemical stability window of various sodium hydroborate electrolytes; d stepped current density galvanostatic cycling of the symmetric Na|Na2B20H18–4Na2B12H12|Na cell; e galvanostatic cycling of the symmetric Na|Na2B20H18–4Na2B12H12|Na cell at a current density of 0.1 mA cm−2 for 100 h. Reprinted with permission from Ref. [75].

A summary of the temperature dependence of the ionic conductivity of some ISEs at approximately room temperature is shown in Fig. 17. Many ISEs have been developed with preferable ionic conductivity at room temperature. Among the above-mentioned sodium ISEs, Na–β-Al2O3 is mainly aimed at high-temperature Na–S batteries, and the application of Na–β-Al2O3 to lower-temperature Na–S batteries still has problems with the interface with the cathode and dendrites with the anode. Therefore, the optimization of the performance of Na–β-Al2O3 at low temperatures should be the focus of future research, especially on surface modification. The ion-doped NASICON shows convincing ionic conductivity at ambient temperature. However, the interface contacts between those sodium ISEs and electrodes remain an urgent problem, which prominently increases the internal resistance of the battery, leading to a reduction in energy density. Thus, the surface needs to be optimized to reduce the resistance by a higher effective contact area. Improving the surface contact can be performed by introducing additives, such as ionic liquids and liquid electrolytes, and high-temperature eutectics. However, a high-temperature eutectic will increase the opportunity for diffusion of elements. In addition to ionic liquids, conductive agents with good electrical conductivity can be considered to increase the contact efficiency between the electrolyte and electrodes [123]. Sulfide-based electrolytes have the obvious problem of a narrow electrochemical stability window in general, which results in limited application to electrodes with low voltage, such as TiS2/Na–Sn. Regarding hydroborate solid electrolytes, research has been limited to date. The results of tests with SIBs have not been as good as those of the other tests. The issue of how to solve the problem with the principle of thermodynamics remains unresolved. Forming an artificial stabilized SEI may help enhance the electrochemical stability. Consequently, the constituent of the SEI that can prevent the decomposition of ISEs and improve the conduction of sodium ions still needs to be certified for each ISE.

7 Solid Polymer Electrolytes

Solid polymer electrolytes (SPEs) consist of a type of base polymer and an electrolyte salt. It consists of a polymer matrix and alkali metal salts dissolved in the polymer matrix. In comparison with ISEs, SPEs have the advantage of mechanical flexibility, which makes them easier to process, reduces the interface impedance, and eases the expansion of the electrode [125]. In the investigation of SPEs, the ionic conductivity of this material is generally achieved by the movement of chains of base polymer [124]. To date, most research on SPEs has focused on lithium-ion batteries, which provided some guidance in developing SPEs of SIBs.

7.1 PEO-Based SPEs

The polymer poly(ethylene oxide) (PEO) has been an important component of solid electrolytes for a long time. It was first reported by Wright et al. that the compound of NaSCN/PEO and NaI/PEO had the ability for ion conduction, which was deemed to be the beginning of the research on PEO-based solid electrolytes [126]. Xue et al. [127] demonstrated that the mechanism of lithium transportation in the PEO matrix was that the cation was delivered by interchain or intrachain oxygen atoms. In the PEO matrix, sodium behaves in a similar manner to lithium [128]. Occasionally, the electrolyte molecule can assist the cation in being hooped, as shown in Fig. 18.

Mechanism of ion transportation of PEO-based electrolytes. Reprinted with permission from Ref. [127].

The ionic conductivity of the PEO-based electrolytes (< 10−6 S cm−1 at R.T.) is typically lower than that of ISEs, which is due to the high crystallinity of PEO at room temperature. Despite the extensive studies that have been conducted on the solid electrolytes of PEO in solid-state lithium batteries, their ionic conductivity at room temperature is too low, so a higher operating temperature of 50–60 °C is necessary [127, 129]. Based on the ion transport mechanism above, the main strategy to increase conductivity is to reduce the crystallinity of PEO through copolymerization, plasticization, and filler addition. Recently, Devi et al. [128] reported a novel SPE that was synthesized by PEO and polyvinylpyrrolidone (PVP) blended with a sodium hexafluorophosphate (NaPF6) electrolyte in the presence of InAs nanowires. They showed that due to the introduction of InAs, the crystallinity of the copolymer decreased, and the number of flexible chains in the amorphous phase increased. The ionic conductivity was measured to be 1.5 × 10−4 S cm−1 at a maximum of 40 °C with 1 wt% InAs. The synthesized PEO–PVP–NaPF6–InAs SPE also showed potential application for lightweight materials. According to the linear sweep voltammetry (LSV) data, the electrochemical stability window was identified as 4.1 V at 40 °C. Although a test with SIBs was not mentioned by the authors, it is convincing that with the addition of InAs nanowires, the PEO-based SPE showed an enhanced electrochemical performance at 40 °C. Similarly, Shenbagavalli et al. [130] reported that SPEs for SIBs based on PEO/PVP and sodium nitrate (NaNO3) with Al2O3 added were successfully synthesized. According to the characterization, the PEO–PVP–NaNO3–Al2O3 SPE showed a maximum ionic conductivity of 1 × 10−5 S cm−1 at room temperature and an electrochemical stability window of approximately 2.69 V, which indicated poor application potential for energy storage devices. The increase in the amorphous phase of PEO was monitored by XRD with the addition of filler concentration. The complexation between the polymer, salts, and filler was observed and detected by Fourier transform infrared spectroscopy (FTIR). The electrochemical performance of the PEO–PVP–NaNO3–Al2O3 SPE showed that the enhancement of the electrochemical stability window was also significant.

The use of ISEs as a filler is also possible in addition to the use of inorganic compound fillers for PEO-based SPEs. Yao et al. [131] demonstrated that a PEO-based SPE with the addition of sodium conductive beta-alumina (β″-Al2O3) nanoparticles showed promising chemical and electrochemical performance. As shown in Fig. 19a–d, the SPE composed of PEO, NaClO4 and 0–15 wt% beta-alumina was assembled as a Na3V2(PO4)3/SPE/Na system to evaluate the electrochemical performance at 60 °C. With the addition of beta-alumina, the initial capacity, rate performance, and cycling stability of the SPE were better than those without beta-alumina. According to the thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) results shown in Fig. 19e, f, the thermal stability was enhanced by the addition of beta-alumina, and the glass transition temperature was decreased due to the decreasing crystallinity of the polymer matrix. The ionic conductivity was found to increase with the addition of beta-alumni due to the reduced crystallinity and quick transition of sodium ions at the interface between the active filler and polymer. In addition, SPEs have a stable electrochemical window above 5 V, as determined by LSV measurements, which indicates that the process is stable enough to be used in a practical environment.

a Cyclic performance; b charge/discharge profile; c rate performance; d charge/discharge curve of different rates of Na3V2(PO4)3/SPEs/Na batteries at 60 °C; e TGA curve; f DSC curve of PEO-based SPEs; g temperature dependence of ion conductivity; h LSV curve of synthesized PEO-based SPEs. Adapted with permission from Ref. [131].

ILs are nonflammable and nonvolatile and are safe to apply to batteries, especially electrolytes. ILs can also act as plasticizers of SPEs to reduce the interaction between chains of base polymers so that the crystallinity is reduced, leading to enhancement of ionic conductivity. Chen et al. claimed that a novel PEO-based SPE was synthesized by using sodium perchlorate (NaClO4) and N-methyl-N-propylpyrrolidinium bis(fluorosulfonyl)imide IL (Pyr13FSI) [132]. The composition of this PEO–NaClO4–Pyr13FSI SPE is shown in Fig. 20a, b. As shown in the figure, it was believed that the FSI− anion was combined with the PEO chain by hydrogen bonding. The combination not only decreased the crystallinity of the base polymer, but more sodium ions were associated with the base polymer. As a result, the SPE with 40 wt% PEO exhibited an improved ionic conductivity of 6.8 × 10−5 S cm−1 at room temperature compared with that of ~ 10−7 S cm−1 for the pure PEO-based SPE. The jumps in ionic conductivity displayed in Fig. 20c indicated that phase transformation occurred between 50 and 60 °C, which was then corroborated by DSC characterization. The electrochemical stability window was also investigated by LSV, and the curve demonstrated that with the addition of Pyr13FSI, the electrochemical stability window grew from 3.70 to 4.44 V, as shown in Fig. 20d. The enhanced electrochemical stability of the synthesized SPE made it a viable candidate for use as a solid electrolyte for high-voltage SIBs. Na3V2(PO4)3/SPE/Na solid-state batteries were assembled to evaluate the electrochemical performance. After activation, the enhanced reversibility of the battery was analyzed by using the charge–discharge curve from the first cycle to the tenth, as shown in Fig. 20e. Additionally, from Fig. 20f, a comparison of the retention rate within 70 cycles between the SPEs with IL and without IL showed an influence of the limited ionic conductivity and electrochemical stability window. Finally, the rate performance of the SPE with IL, especially at 1 C and 2 C, was found to show significant progress compared to that of the SPE without IL. The electrochemical performance of the optimized SPE exhibited great potential for application in high-voltage SIBs.

a Composition of PEO-NaClO4-Pyr13FSI; b schematic illustration of hydrogen bonds between PEO and Pyr13FSI; c temperature dependence ionic conductivity of SPEs; d LSV curves of SPEs with different ILs; e charge–discharge curves; f cycling performance; g rate performance of the Na3V2(PO4)3/SPE/Na cell at 0.1 C and 60 °C. Adapted with permission from Ref. [132].

In addition to ILs, liquid crystals (LCs) have been identified as another plasticizer for base polymers because LCs can form a continuous phase with low viscosity for metal ions among the polymer matrices [133]. The characteristics of intermediate crystallization and isotropy can also enhance the transportation ability of metal ions. Koduru et al. [134] claimed that a PEO/E8 LC-based SPE containing sodium meta periodate (NaIO4) was successfully synthesized. According to the results of XRD and micro-Raman spectroscopy, the crystallinity was inhibited by the addition of LCs. The LC-based SPE with 10 wt% NaClO4 showed an ionic conductivity of 1.05 × 10−7 S cm−1 at room temperature. Furthermore, the ion transfer number of cations (0.384) was lower than that of anions (0.513), indicating an incompatibility of NaClO4 with the LC-based SPE system. Despite the fact that the ionic conductivity and ion transfer number of LC-based SPEs were not excellent, a new method of enhancing ionic conductivity was developed.

In the field of nanotechnology, metal–organic frameworks (MOFs) are nanoporous materials with high specific surface areas, ordered channels, and stable structures. PEO segment movement can be improved, and salt dissociation can be increased [135, 136]. Similarly, Ge et al. [137] synthesized a flexible PEO–NaCF3SO3–MIL-53(Al) SPE (PNM–SPE) by the solution casting method. MIL-53(Al) was synthesized by treating aluminum nitrate nonahydrate and 1,4-benzenedicarboxylic acid. Figure 21a illustrates the excellent flexibility of the PNM–SPE, indicating its potential use in flexible foldable batteries. The SPE consisting of 3.24 wt% MIL-53(Al) and an EO 20:Na 1 ratio exhibited the highest ionic conductivity of 6.87 × 10−5 S cm−1 at 60 °C. The sodium ion transference number of PNM–SPE was found to be 0.40, which was much higher than that of the SPE without the addition of MIL-53(Al). This is due to the Lewis acidity of MIL-53(Al), which helped to attract the anions of sodium salt. The electrochemical stability window was determined to be 4.0 V at 60 °C, according to Fig. 21c. There is an electrochemical deposition of sodium on the PNM–SPE electrode at a voltage of 0.07 V and a temperature of 60 °C, which indicates a reversible process of Na plating/stripping. The rate performance of the ASSBs assembled with the PNM–SPE and PN–SPE at 60 °C is shown in Fig. 21d, and the cycling performance is shown in Fig. 21e. A higher capacity and stability were achieved by the application of MIL-53(Al).

a Photograph of the flexible PNM–SPE; b temperature dependence of ionic conductivity of the PNM–SPE with different percentages of MIL-53(Al); c cyclic voltammograms curve; d rate performance from 0.1 to 0.5 C at 60 °C; e cycling performance of the PNM-SPE and PN-SPE at 60 °C. Adapted with permission from Ref. [137].

7.2 PVDF-Based SPEs

Poly(vinylidene fluoride) (PVDF) is believed to be a fictional material that possesses great chemical and physical properties and has become a kind of commercial product [138]. Bristi et al. [139] reported a novel PVDF, PVP polymer binder, and NaPF6 salt-based SPE. PVDF-based SPEs for SIBs were examined under different NaPF6 salt concentrations, as well as with the SiO2 nanofiller and PVP binder. For convenience, SPEs of PVDF/NaPF6 (4:1) + PVP (11 wt% of PVDF), PVDF/NaPF6 (9:1) + PVP (11 wt% of PVDF) and PVDF/NaPF6 (17:1) + PVP (11 wt% of PVDF) were recognized as SPE-1, SPE-2, and SPE-3, respectively. The ionic conductivity performance, as shown in Fig. 22a, indicated that SPE-2 possessed the highest ionic conductivity at room and higher temperatures. Most likely, the difference was due to the easier possibility of ion hopping in SPE-2 than in SPE-1 and SPE-3 when NaPF6 salt was present in the amorphous PVDF. In symmetric cell configurations of Na|LE/C|SPE-2|LE/C|Na, where LE was composed of 20 μL of 1 M (1 M = 1 mol L−1) NaClO4 in EC/PC (1:1), Na plating–stripping experiments were conducted to determine the compatibility and stability of the SPE with a Na metal anode. As shown in Fig. 22b, during the 400 cycles of 800 h, good electrochemical stability was achieved for the Na plating-stripping performance. A maximum specific capacity of 105.5 mAh g–1 was achieved (Fig. 22c) when assembled as the NVP|LE/C|SPE-2|LE/C|Na battery. With a discharge capacity of 93.20 mAh g–1, a 3.3 V discharge plateau was observed at the same rate for the first cycle, indicating a reduction of NaV2(IV)(PO4)3 to Na3V2(III)(PO4)3. The NVP electrode showed excellent cycling performance after 100 consecutive charge–discharge cycles at a 0.5 C rate, retaining 86% of its capacity after 100 cycles. It was concluded that PVP binders can contribute significantly to fast Na ion conductivity and excellent Na plating-stripping performance in PVDF-based composite systems.

a Temperature dependence of ionic conductivity from SPE-1 to SPE-3; b galvanostatic cycling profiles of the symmetric cell Na|LE/C|SPE-2|LE/C|Na; c charge–discharge curve of the NVP|LE/C|SPE-2|LE/C|Na battery at 0.1 C; d cycling performance of the NVP|LE/C|SPE-2|LE/C|Na battery at 0.5 C. Adapted with permission from Ref. [139].

Bag et al. reported the synthesis and characterization of a novel PVDF-based composite polymer electrolyte (CPE) with the NaCF3SO3 salt and SiO2 filler [140]. The CPE was synthesized by casting a slurry of PVDF solution ball milled with SiO2 powder, as shown in Fig. 23a. Compared to the PVDF–NaCF3SO3 electrolyte, the ionic conductivity was improved from 2.1 × 10−6 to 6.3 × 10−5 S cm−1. The symmetric sodium cell in Fig. 23c indicated that the synthesized CPE was compatible with sodium. The electrochemical profile of the NVP|CPE|Na cell at 2–4 V and a 0.5 C rate is shown in Fig. 23e, f. A liquid electrolyte of 5 µL was applied to both sides of the CPE. With 86% capacity retention after 250 cycles, the NVP electrode demonstrated outstanding cycling performance. A symmetric NVP full cell was fabricated by using the NVP electrode and the CPE as the electrolyte, as shown in Fig. 23d. It was found to be able to deliver a high specific capacity of 76 mAh g−1 with an energy density of 126 Wh kg−1 at 0.5 C. As a result, its specific capacity retained 70% of its original value after 100 cycles.

a Schematic illustration of the synthesis process of CPEs; b Arrhenius plot for PVDF-NaCF3SO3 and CPEs; c cycling performance of the sodium symmetric cell with CPEs; d schematic illustration of the NVP symmetric cell; e charging-discharging curve; f cycling performance; g rate performance; h rate charging-discharging curve of the NVP|CPE|Na cell; i charging–discharging curve; j cycling performance; k rate performance; l rate charging-discharging curve of the NVP|CPE|NVP symmetric cell. Adapted with permission from Ref. [140].

Wang et al. [141] reported the synthesis of an organic ionic plastic crystal (OIPC)-modified PVDF using the electrospinning method. It was demonstrated that the electrolyte of pure PVDF by electrospinning had two phases: an electroactive β phase and a nonactive α phase. With the OIPC added, which was N-ethyl-N-methylpyrrolidinium tetrafluoroborate [C2mpyr][BF4], the prepared composite SPE showed no α phase. The ionic conductivity of the synthesized SPE in different weight percentages of OIPC is shown in Fig. 24. The ionic conductivity of this SPE is detected to be 1.2 × 10−6 S cm−1 at room temperature, measured with a single fiber.

Ionic conductivity of PVDF/OIPC (5–20 wt%) fibers at different temperatures. Reprinted with permission from Ref. [141].

Recently, it was stated by Makhlooghiazad et al. [142] that an original electrolyte of PVDF and triisobutyl(methyl)phosphonium bis(fluorosulfonyl)imide ([P1i444][FSI]) OIPC was prepared with sodium bis(fluorosulfonyl)amide (NaFSI) or sodium bis(trifluoromethanesulfonyl)amide (NaTFSI). The synthesized composite electrolytes showed excellent performance of ionic conductivity of 20 mol% NaFSI of 2.1 × 10−3 S cm−1 and 20 mol% NaTFSI of 2.5 × 10−3 S cm−1. The reason for the difference between the NaFSI-based and NaTFSI-based SPEs was that the TFSI− anion had stronger interactions with PVDF so that a layer possessing higher conductivity for sodium ions formed on the PVDF fibers. Figure 25a, c together introduces the performance of a symmetric Na|SPE|Na cell based on NaFSI and NaTFSI, respectively. For the NaTFSI-based system, a short circuit occurred after two cycles when the current density was increased to 0.5 mA cm−2. It is unclear what caused this behavior, but it is being investigated. In addition, both cells exhibit a very similar high-frequency impedance, which indicates similar ionic conductivity, because high-frequency impedance corresponds to bulk electrolyte resistance, as shown in Fig. 25b, d. Assembled as NVP|SPE|Na solid-state batteries, the electrochemical performance at 50 °C was investigated, as shown from Fig. 25e–h. A remarkable rate capability of the batteries, delivering reversible capacity from 1/20 C to 1 C, was demonstrated for both NaFSI-based and NaTFSI-based systems. Both systems exhibited excellent cycling performance with reversible rates of 98.0% and 98.5% for NaFSI and NaTFSI, respectively. Accordingly, the specific capacity of the NaTFSI-based system was higher than that of the NaFSI-based system. Moreover, the polarization of the mixed anion-based composite cell was lower (20 mV) than that of the cell containing NaTFSI (40 mV), reflecting the higher ionic conductivity of the NaTFSI-based system, as shown in Fig. 25g, h. The combination of PVDF and OIPC provided a new idea to improve the ionic conductivity of SPEs. Further development can be focused on improving the compatibility of polymers with OIPC and reducing the costs of both polymers and OIPC.

a and c Na symmetric cell cycling of NaFSI- and NaTFSI-based SPEs at various current densities; b and d Nyquist plots of the cell in a & c every 5 cycles; e rate performance from 0.05 to 1 C; f cycling performance of NVP|SPE|Na of NaFSI- and NaTFSI-based SPEs; g and h the cell charge–discharge curve of NaFSI- and NaTFSI-based SPEs at 0.1 C [142]

Fang et al. [143] reported the synthesis of an ultrathin composite polymer electrolyte consisting of PVDF/sodium β-alumina ceramic electrolyte (SBACE)/NaPF6. The sodium beta-alumina ceramic particles were screened before synthesis to ensure the thickness of the membrane, as shown in Fig. 26a. The highest ionic conductivity of the ultrathin single particle layer (ULSPL) membrane, namely ULSPL-35SBACE, which indicated 35 wt% SBACE of the electrolyte, was tested to be 0.19 mS cm−1. The symmetric Na/Na cells were cycled with different electrolytes to evaluate their compatibility with the sodium anode and to calculate the Na+ transference number. Similarly, the UTSPL-35SBACE membrane showed a high Na+ transference number of 0.91, indicating free Na+ ions in the UTSPL-35SBACE membrane. According to Fig. 26d–f, the ULSPL-35SBACE membrane also showed the best stability at higher current density. An evaluation of the cycling stability and rate performance of cells with the UTSPL-35SBACE membrane was conducted by using potassium manganese hexacyanoferrate (KMHCF) cathodes. With a capacity retention of 95.5% after 100 cycles, Na/KMHCF@CNTs/CNFs cells with the UTSPL-35SBACE membrane displayed good cycling performance.

a Schematic illustration of the UTSPL-xSBACE membrane structure; b ionic conductivity of UTSPL membranes at room temperature; c Na+ transference number test of the UTSPL-35SBACE membrane; d–f cycling performance of the sodium symmetric cell applying UT-35SBACE, UT-35ACE and UTSPL-35SBACE, separately; g Nyquist plot; h charging-discharging curves from 0.5 to 5 C; i cycling performance at 1 C; j rate performance of Na/KMHCF@CNTs/CNF cells applying UT-35SBACE and UTSPL-35SBACE. Adapted with permission from Ref. [143].

Although additives and inorganic fillers have been applied to SPEs to increase the performance of ionic conductivity, there is still a giant gap between actual and required performances. The most important part is to determine how to establish a sodium-ion transport channel. In addition, the principle of additives and inactive inorganic fillers is still in doubt, which prevents us from finding a shortcut to select a suitable combination of polymers and additives. A high interfacial resistance is also indicative of difficulties at the interface between SPEs and electrodes.

7.3 Other SPEs

Considering the inspiration from the natural world and the cost, carboxymethyl cellulose (CMC) has been considered a proper polymer to form SPEs. Shetty et al. [144] investigated the biodegradable SPE of poly(vinyl alcohol) (PVA)/sodium salt carboxymethyl cellulose (NaCMC) (PVA/NaCMC with a ratio of 70:30) doped with sodium bromide (NaBr) metal salt. The SEM images of the SPEs based on different mass ratios of NaBr, which were 0 wt%, 5 wt%, 10 wt%, and 15 wt%, indicated that free volumes or voids existed when NaBr was added, as shown in Fig. 27a. In addition, the amorphous phase was enhanced by the increasing free volume. Thus, the ionic conductivity at room temperature of the SPEs based on different ratios of NaBr showed a positive correlation with mass scores, as shown in Fig. 27b.

a SEM images and b ionic conductivity of pure and NaBr-doped PVA/CMC SPEs. Adapted with permission from Ref. [144].

Similarly, Cyriac et al. [145] studied the effect of the NaNO3 salt concentration (0, 5, 10, 15, 20, 25, and 30 wt%) on the structural, electrical, and mechanical properties of Na-CMC/PVA SPE films. The potential mechanism of the transportation of sodium ions was studied. Na-CMC and PVA were considered to be connected by hydrogen bonds between the –OH group of Na-CMC and the C=O group of PVA. The formation of hydrogen bonds decreased the crystallinity of the polymer matrix. With the addition and dissociation of NaNO3 salt, the NO3− anion was combined with the formation of hydrogen bonds with the Na-CMC chain so that sodium ions could freely transport, as shown in Fig. 28a. Therefore, the ionic conductivity was increased by the addition of NaNO3 salt, which can be observed in Fig. 28b. In the test of the electrochemical stability window, the SPE was tested to have an electrochemical stability window of 3.29 V.

a Schematic illustration of the microstructure of NaCMC/PVA SPEs after the addition of NaNO3 salt; b Nyquist plot of SPEs with different mass ratios of NaNO3 salt; c electrochemical stability window of SPEs with 20 wt% NaNO3 salt. Adapted with permission from Ref. [145].

In addition to drug delivery, poly(ethylene glycol) diacrylate (PEGDA) can be used for tissue engineering and tissue regeneration as a derivative of PEO. Xingwen et al. [146] reported the incorporation of ceramic Na3Zr2Si2PO12 nanopowders into a PEGDA polymer matrix to form a novel polymer-ceramic electrolyte. Succinonitrile (SCN) was also utilized to enhance the Na+ conductivity as a plasticizer. In this work, an investigation of the ionic conductivity of PEGDA/NaClO4 electrolytes with different weight ratios of SCN and Na3Zr2Si2PO12 nanopowders was conducted. The composition of the polymer phase of the SSE was selected to be PEGDA:NaClO4:SCN = 52.5:17.5:30. With 30 wt% Na3Zr2Si2PO12 nanopowder blended, the ionic conductivity was 4.5 × 10−5 S cm−1. Testing between the sodium working electrode and stainless-steel (SS) counter electrode, the electrochemical stability window was determined to be 5 V. In addition, the sodium-ion transference number was calculated to be 0.41. The reasonable rate capability and high cycling stability performance of Na|PEGDA/NaClO4/SCN/Na3Zr2Si2PO12 | Na2MnFe(CN)6 all-solid-state coin cells were systematically examined and analyzed at ambient temperature.

In addition to NASICONs, sulfide-based ISEs have also been studied in combination with inorganic and organic electrolytes. Ren et al. reported a novel hybrid electrolyte film consisting of pentaerythritol tetraacrylate (PETEA) and Na3SbS4 [147]. The cross-linking of liquid PETEA monomer was initiated by Na3SbS4 particles, as shown in Fig. 29a. The ionic conductivity of the hybrid solid electrolyte, which was 0.047 mS cm–1 at room temperature, was slightly lower than that of the Na3SbS4 pellet. However, with the test of sodium symmetric cells, the compatibility of hybrid solid electrolytes with sodium electrodes was found to be much better than that of the Na3SbS4 pellet, as demonstrated in Fig. 29c, d. Additionally, the hybrid electrolytes served as an effective barrier between soluble sodium polysulfides (NaPS) in the sulfur cathode and sodium metal, which is critical to the viability of Na-S batteries.

a Schematic illustration of the initiation of PETEA by Na3SbS4 particles; b comparison of ionic conductivity between hybrid solid electrolytes and Na3SbS4 pellets; c and d comparison of the compatibility with sodium between hybrid solid electrolytes and Na3SbS4 pellets. Adapted with permission from Ref. [147].

For SPEs, low ionic conductivity at room temperature is still relatively common. Although methods such as copolymerization, adding active inorganic fillers, and adding ionic liquids have been employed to improve the ionic conductivity and electrochemical properties, it is still difficult to meet practical applications. In the presence of low ionic conductivity, both cycling performance and rate performance can be affected. It is not sufficient to reduce the crystallinity of the polymer to improve ionic conductivity. Polymer chains themselves have a slow ion transport rate, making it necessary to add other active inorganic substances or ionic liquids to improve the ion transport rate. For further development, additives can also be considered metal organic frameworks (MOFs). MOFs are a class of compounds consisting of metal ions or clusters coordinated to organic ligands to form dimensional structures [148]. With the metal ions of MOFs introduced, the anion dissociation of sodium salts can easily be attracted and fixed. In addition, the host material of ion transport can be changed from polymers to additives such as extractants. The extractants that may have the ability to transport sodium can be selected or created to construct SPEs. Under the mechanism of ion extraction and transportation, the sodium ions may be transported through SPEs driven by the voltage or the concentration difference.

Not only ion conductivity but also the interface between SPEs and electrodes need attention. Most studies on SPEs have used Na3V2(PO4)3 cathode materials due to the high ionic conductivity of NVP, a NASICON-type material. However, cathode materials, such as Na1.92Fe[Fe(CN)6] and Na2/3[Ni1/3Mn1/2Ti1/6]O2, have not been adapted for SPEs. The best solution is in situ polymerization, where electrodes are infiltrated while SPEs are still liquid and then polymerized to form the SPEs. This approach has been used in the upcoming gel polymer electrolytes (GPEs), but it is still less used in SPEs and may be a future development trend.

8 Gel Polymer Electrolytes

In addition to SPEs, GPEs have also been investigated in recent years. GPEs consist of base polymers, sodium salts, and liquid solvents [149, 150]. GPEs can be regarded as an intermediate state between solid electrolytes and liquid electrolytes. In 1975, Feuillde et al. [151] investigated GPEs with lithium salts. GPEs were prepared by immersing the synthesized solid electrolytes into liquid electrolytes containing sodium salt. Overall, the electrochemical performance of GPEs was better than that of SPEs because a portion of the safety concern was sacrificed to improve the performance.

8.1 PEO-Based GPEs

Apart from SPEs, PEO is also one of the most commonly used polymers in GPEs. For the development of PEO-based GPEs, Yu et al. [152] reported a newly designed cross-linked poly(ethylene glycol) diglycidyl ether (PEGDE)- and diamino-poly(propylene oxide (DPPO)-based electrolyte. The formed electrolyte consisted of PEO and poly (propylene oxide) (PPO) chains. The electrolyte combined with the supporting glass fiber (GF) material exhibited a high performance in terms of mechanical strength and flexibility. By using compact GF-GPEs, electrolyte solvents can be immobilized tightly during cycling to reduce side reactions with electrodes. The ionic conductivity was confirmed to be 2.18 × 10−3 S cm−1 at room temperature, according to Fig. 30a. The electrochemical stability window of the GF–GPE was 4.8 V versus Na+/Na according to the LSV curves in Fig. 30b, showing the high purity of the GF–GPE. Because SSEs usually show a lower ionic conductivity, the performance at a high rate will obviously decrease. However, this was not observed for GF–GPEs, as shown in Fig. 30c. The cycling performance of GF–GPEs at a rate of 5 C was almost the same as that of GF–LEs. The cycling performance was determined with the assembled NVP|GF–GPE|Na and NVP|GF–LE|Na cells. As a result, the NVP|GF–GPE|Na cell exhibited a discharge capacity of 93.4 mAh g−1 after 2 000 cycles at 1 C, retaining its capacity by 96.7%, which was significantly better than that of the NVP|GF–LE|Na cell. The results shown in Fig. 30i illustrate that the GF–LE/Na interface was unstable during cycling in the NVP/GF–LE/Na cell with increased polarization, whereas GF–GPEs promoted the formation of a stable GF-GPE/Na interface. With this robust and compact GF-GPE, Na plating/stripping can be uniformly carried out without Na dendrite penetration, ensuring a very stable Na/GF-GPE interface during cycling.

a Temperature dependence of ionic conductivity; b LSV curves of GF-GPEs and GF-LEs; c rate performance from 0.1 to 5 C; d charge–discharge curve of the first cycle; e & h cycling performance at 25 °C and 60 °C, respectively; f and g Nyquist plots after cycles of NVP|GF-GPE|Na & NVP|GF-LE|Na cells; i cycling performance of the Na-symmetric cell. Adapted with permission from Ref. [152].

Menisha et al. also recently showed that EC-, PC-, NaClO4-, PEO-, and NaClO4-based GPEs can be optimized under conditions of immobilization of the rate of EC and PC at 40 wt% for both [150]. It was discovered that the highest ionic conductivity, which pertained to 13 wt% NaClO4 and 7 wt% PEO, was 9.8 × 10−3 S cm−1. The PEO-based GPEs can achieve electrochemical performance similar to liquid electrolytes at room temperature, which is far ahead of PEO-based SPEs. GPEs can be a feasible alternative to liquid electrolytes before the further development of SPEs.

8.2 PVDF-HFP-Based GPEs

Poly(vinylidene fluoride-cohexafluoro-propylene (PVDF-HFP) has been considered a proper material for GPEs because it has the characteristics of high flexibility and dielectric constant [153]. The percentage of amorphous phase in PVDF-HFP is higher, which leads to a higher performance on ionic conductivity. Research on PVDF-HFP-based GPEs has been popular in recent years. Vo et al. [154] synthesized a PVDF-HFP-based GPE consisting of PC and fluoroethylene carbonate (FEC) in a mixture of 98:2. The prepared GPE exhibited a high ionic conductivity performance with NaClO4 or NaPF6 as the sodium salt. The electrolyte of NaClO4 1 M – PC:2%FEC/PVdF-HFP presented the highest ionic conductivity of 1.91 × 10−3 S cm−1. In addition, the synthesized GPE showed a wide range of electrochemical windows of ~ 4 V, indicating a probable application with a high-voltage electrode pair. A sodium cell with a configuration of Na/GPE/Na0.44MnO2 was evaluated under a constant current density of 0.1 C at room temperature. It was found that PVdF-HFP/NaClO4 PC:2%FEC exhibited nearly no increase in polarization after 20 cycles.

Janakiraman et al. also reported an electrospun PVDF-HFP-based GPE [155]. The liquid electrolyte was selected to be 0.6 M NaPF6 dissolved in EC/PC (1:1). According to the XRD results, PVDF-HFP formed an amorphous electroactive β phase, which indicated an interaction among the base polymer, salt, and liquid solvent. The microstructure of the novel GPE was characterized by field emission scanning microscopy (FESEM), as shown in Fig. 31b, giving evidence of the amorphous structure. The ionic conductivity of the synthesized GPE was as high as 1.28 × 10−3 S cm−1 at room temperature. The high porosity, amorphicity, and electroactive properties of PVDF-HFP mats were cited as contributing factors to ionic conductivity. Based on Fig. 31c, the PP Celgard membrane was less stable below 4.0 V and started decomposing at 4.0 V, as indicated by an increase in the background current. In contrast, the electrospun GPE with a shallow background current had a stable voltage up to 4.6 V. The performance of the PVDF-HFP gel electrolyte after 30 cycles demonstrated excellent capacity retention of sodium-ion cells, as shown in Fig. 31d.

FESEM image of electrospun a PVDF-HFP and b GPE. c The performance of PP Celgard membrane. d The performance of the PVDF-HFP gel electrolyte after 30 cycles Reprinted with permission from Ref. [155].

Chauhan et al. reported a high-performance porous PVDF-HFP-based GPE filled with sodium aluminate (NaAlO2) powder [156]. The composition of the liquid electrolyte applied to the newly prepared GPE was 1 M NaClO4 dissolved in EC/PC (1:1). The NaAlO2 particles initially settled on the PVDF-HFP network, which led to the formation of an amorphous phase. Then, the absorbed liquid electrolyte was also fixed by the NaAlO2 particles, causing multiple pathways for ion transportation. The ion transportation principles of the PVDF-HFP/NaAlO2 GPE are demonstrated in Fig. 32. The ionic conductivity was 6.8 × 10−4 S cm−1 maximum at room temperature. The discharge capacity was found to decrease from the first to fourth cycles. At increased discharge currents, the discharge capacity may decrease as a result of a voltage drop caused by a combination of internal resistance and reduced recovery rates as well as a reduction in the active mass contributing to electrochemical reactions at high current densities. The insertion of inorganic particles can also increase the mechanical strength of GPEs, which makes up for some shortcomings.

Illustration of the addition of NaAlO2 particles and ion transport paths in GPEs. Reprinted with permission from Ref. [156].