Abstract

The valorization of marine macroalgal biomass is among the most promising international programs focusing on the sustainable exploitation of marine environment. However, macroalgal biomass remains unexploited in Tunisia, even though it represents a highly abundant renewable biomass. The excessive proliferation of several algal species causes severe environmental disorders. The objective of this work is to study the potential use of macroalgae as biofuels feedstock in the Mediterranean region and particularly in Tunisia. This study focuses on certain macroalgal species collected from Bizerte and Tunis lagoons (e.g., Chaetomorpha linum, Enteromorpha intestinalis, Gracillaria gracillis, Ulva rigida, Gracillaria verrucosa, Cystoseira brachycarpa, Laurencia obtusa, Cystoseira sedoides, and Dictyopteris polypodioides). The macroalgae’s biochemical composition was determined in a way that maximizes its valorization. To achieve this objective, a process of three steps was performed. First, the macroalgal biomass was pretreated by dilute sulfuric acid. Then, an enzymatic saccharification was performed to produce fermentable sugars. Finally, the obtained sugars were converted into bioethanol using Saccharomyces cerevisiae yeast. In fact, our experiments show that the maximum protein content of 16.22% ± 0.270 was obtained with G. verrucosa, whereas the maximum carbohydrates content of 58.46% ± 1.52% was obtained with D. polypodoies. This leads us to believe that macroalgae constitute a potential source of fiber and proteins. After a sulfuric acid pretreatment. The maximum reducing sugars and bioethanol yields were obtained, respectively, were of 324.6 mg/gDM (dry matter) and 0.24 g/gDM.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rising of the world population, the increasing massive energy consumption, the decrease of oil resources, and the atmospheric pollution by toxic gases from fossil resources combustion, which in turn causing global warming and climate change effects, are the main driving factors for developing renewable energies to strengthen the energy security (Solarte-Toro and Cardona-Alzate 2021; Tan et al. 2020; Kraan 2013; Ashokkumar et al. 2014; Sindhu et al. 2016). In this context, biofuels as biodiesel and bioethanol are considered as potential alternative biofuel sources due to their renewable nature, sustainability, and low carbon emissions (Su et al. 2015; Xu and Li 2016). However, first- and second-generation bioenergy feedstocks compete with other crops for land and water. They require large agricultural land and water reserves for their cultivation, which limits their sustainability (Boro et al. 2022; Noraini et al. 2014). Hence, to overcome those feedstocks’ limitations, fast-growing and renewable biomass sources, such as marine algae, have attracted attention as an alternative for fuels (Markou et al. 2013). In fact, algal biomass and particularly macroalgae could be a promising source for third-generation biofuels and additional high added value products such as proteins, vitamins, or trace elements. Macroalgae are rich in carbohydrates, which compose up to 76% of macroalgae’s dry weight (Leesing et al. 2022). This high carbohydrate content is critical for conversion into bio-based products. Some carbohydrate components are common among macroalgae and terrestrial crops. Other carbohydrate components are made up of monosaccharides found only in specific macroalgae species (Kraan 2013). Moreover, macroalgae have a wide spectrum of bioactive compounds (e.g., vitamins, minerals, pigments, proteins, lipids. and polyphenols), making them very attractive for feedstock, fermentation, and biorefinery, in general, that can be used in several fields such as food, cosmetics, or pharmacy industries (Jung et al. 2013). Besides, some macroalgae can produce energy with higher efficiency compared with traditional biofuels due to their high biomass productivity and important prolific growth in fouled beaches and coastal waterways.

Currently, there are over 10,000 species of macroalgae reported around the world, with only a dozen species are being cultivated commercially, while the rest of macroalgae are exploited from the wild (Ward et al. 2014).

Three main groups of macroalgae are found, namely, Chlorophyceae (green algae, 1200 species), Phaeophyceae (brown algae, 1800 species), and Rhodophyceae (red algae, 6000 species) (Hebbale et al. 2017; Person 2010). The majority of pigments of green algae are chlorophylls a and b. Marine green macroalgae, such as Ulva spp., contain between 14% and 40% carbohydrates’ dry weight (Kazir et al. 2019). These carbohydrates are made of sulfated and/or carboxylated polysaccharides and glucans, as well as floridean starch, such as amylopectin. Green algae can be grouped into two major categories based on their uronic acid content (either limited or rich), though different genera and species may have different amounts (Synytsya and Copíkova et al. 2015). Species in the genera Codium, Bryopsis, and Caulerpa are in the uronic acid-limited group and consist primarily of sulfated galactans, arabinopyranans and mannans (Jonsson et al. 2020). Species in the genera Ulva, Gayralia, Acetabularia, and Monostroma are in the uronic acid-rich group, and their primary cell wall component is ulvans (Jonsson et al. 2020).

The red macroalgae pigment is r-phycoerythrin, consisting of sulfated galactans (e.g., carrageenan, agar, and porphyrin), structural polysaccharides (cellulose, mannans, and xylans), and storage carbohydrates (floridean starch and α-1,4-glucan). Carrageenan, the main component of sulfated galactans, consists of galactose and 3,6-anhydrogalactose with alternating α-1,3- and β-1,4-linkages (Jonsson et al. 2020).

Brown macroalgae coloration is due to the predominance of xanthophyll pigments and especially fucoxanthin (Ganzon-Fortes 1991). They are rich in carbohydrates, and their cell walls are made of cellulose, hemicellulose, matrix polysaccharides (alginates and fucoidans), and laminarin. After cellulose, alginates are the second most abundant polysaccharide in the world (Leandro et al. 2020).

The use of macroalgae biomass is an interesting sustainable energy and presents several advantages, including high biomass production and high photosynthetic efficiency compared with terrestrial crops (Bruhn et al. 2011). Macroalgal biomass cultivation does not interfere with agricultural land utilization and does not require fresh water. It is easily cultivated since it does not require agricultural additives, such as fertilizers and pesticides, and has a low cost of collection without environmental damage (Ruiz et al. 2013; Singh et al. 2011). Its chemical composition characterized by the absence or the very low lignin content and the high carbohydrates level, which makes it suitable for bioethanol production (Kumar et al. 2020; Lage et al. 2018).

Bioethanol production from macroalgae involves various pretreatment steps followed by an enzymatic hydrolysis to get the monomeric sugars and a microbial fermentation process by yeast or bacteria (Abomohra et al. 2018; Azhar et al. 2017). Several fermentation methods may be used to transform reducing sugar produced from macroalgae into bioethanol. The processes are denoted as follows: (1) separate hydrolysis and fermentation (SHF), (2) simultaneous saccharification and fermentation (SSF), and (3) simultaneous saccharification and cofermentation (SSCF) (Offei et al. 2018).

For the pretreatment step, there are several possible pretreatment technologies including physical, biological, physical–chemical [e.g., liquid hot water, steam explosion ammonia fiber explosion, and instant controlled pressure drop (Sarip et al. 2011, 2014)], and chemical (acid, alkaline, wet oxidation, ozonolysis) (Tao et al. 2011). However, the dilute acid is the most widely used method for material pretreatment due to its relatively low cost, ease of use (Sannigrahi et al. 2011), and high efficiency (Sun and Cheng 2005). Indeed, chemical properties have an important role in the hydrolysis of seaweed’s polysaccharides. The high solubilization of seaweed and the subsequent high concentrations of reducing sugars have been achieved as a result of using different chemicals and thermochemical methods (Karray et al. 2015; Vanegas et al. 2014; Mazumdar et al. 2013). The chemical pretreatment is thought to hydrolyze cellulose, hemicellulose, and other storage carbohydrates such as laminarin (Vanegas et al. 2014; Schiener et al. 2016). While this pretreatment has important drawbacks related to the formation of toxic compounds (e.g., furfural and hydroxymethyl furfural) issued from sugar degradation, as inhibitors for the fermentation step. Moreover, the waste streams liberated from the dilute acid pretreatment process constitute a significant environmental hazard (Sun and Cheng 2005). More concentrated acid solutions are more effective at hydrolyzing seaweed’s cell walls to release its cell contents (Schiener et al. 2016). However, using acids has been criticized as a hazard risk (especially concentrated acid) (Schiener et al. 2016).

Tunisia is committed to international conventions to limit pollution and increase the share of renewable energies in its energy mix. However, the promising potential of energy production from algal biomass available in Tunisia is still less valued than other algal or lignocellulosic biomasses at industrial scale due to the lack of collection and absence of optimal recovery processes. Indeed, according to Shili et al. (2002), the macroalgae communities observed in the south lagoon of Tunis are characterized by the predominance of nitrophilous algae considered as important biomass: Ulva, Cladophora, and Enteromorpha (Shili et al. 2002).

Our work contributes to the field of renewable energy and marine biomass valorization. The novelty resides in highlighting the potential of an abundant, forsaken, and unexploited renewable natural resources, namely macroalgae, as an alternative raw material for bioethanol production and other value-added products in Tunisia and the Mediterranean region. This work evaluates the energetic potential of several Mediterranean macroalgae by studying their biochemical compositions and bioethanol yields. This study can help industries in Tunisia focusing on renewable energy and biomass valorization to use these studied macroalgae as alternative source for bioethanol.

Materials and methods

Macroalgae

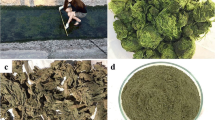

Different species of macroalgae were collected from the north of Tunisia. Chaetomorpha linum (C. linum), Enteromorpha intestinalis (E. intestinalis), and Gracillaria gracillis (G. gracillis) were collected in April 2019 from the lagoon of Tunis (GPS: 36° 48′ 6.3″ N, 10° 12′ 52.9″ E); Ulva rigida in January 2020 and Gracillaria verrucosa (G. verrucosa) in March 2020 from lagoon of Bizert; and Cystoseira brachycarpa (C. brachycarpa), Laurencia obtuse (L. obtusa), Cystoseira sedoides (C. sedoides), and Dictyopteris polypodioides (D. polypodioides) in June 2020 from lagoon of Bizert (GPS: 37° 11′ 48″ N, 9° 51′ 23). The samples were washed to dilute the salts concentration and eliminate sand and other impurities collected with the seaweed when removed from the lagoon. Then, they were dried at ambient temperature under the sun for 2 weeks to remove water that speeds up algae decay and ensure therefore long-term storage of the biomass. Once dried, algae were finally ground with a blender to obtain 15 mm length and stored until use.

Cellic CTec2 enzyme (0.43 pNPG U/mL, 61.25 CMC U/mL) from Novozymes (Denmark) was used for the algal biomass enzymatic hydrolysis.

A strain of yeast S. cerevisiae was selected as a model strain for fermentation of simple sugars. Fermentation was achieved using fresh commercial baker’s yeast S. cerevisiae (Tunisian Society of yeasts, purchased from local market) (Bouallagui et al. 2013).

Biomass productivity determination

To estimate the algal biomass productivity, the quadra sampling method was performed. Three quadrats of 50 cm × 50 cm were taken at random in Tunis lagoon with maximum of 1 m of depth. The macroalgae samples were collected, dried in the air, and then weighed (Hernandez and Koohfkan 2004).

Diluted acid pretreatment of macroalgae

A total of 10 g of each macroalgae and a mixture of G. gracillis, C. linum and E. intestinalis, collected from Tunis lagoon, were suspended in 200 mL of sulfuric acid H2SO4 (1%) at 121 °C for 30 min. The pretreated macroalgae biomasses were filtered and the solid residue washed three times by distilled water. Afterwards, the residue was dried at room temperature and used as substrate for enzymatic saccharification (Kuglarz et al. 2018).

Enzymatic saccharification

After algal biomass pretreatment with diluted acid, enzymatic saccharification was performed for 48 h at 55 °C and pH 5 adjusted with 5 mM sodium acetate buffer in presence of a Cellic CTec2 enzymatic preparation (1 mg of enzyme per gram of dry substrate of macroalgae) as developed in previous work (Smichi et al. 2014). These experiments were replicated three times. The estimation of total reducing sugar in the biomass’s enzymatic hydrolysate was done by the dinitro salicylic acid method (DNS method) (Miller 1959). The reducing sugars yield was determined according to the following equation: 1:

Yeast cultivation

Saccharomyces cerevisiae was used as a bioethanol fermentation strain. The yeast strain was maintained on agar plates made from 5 g/L yeast extract, 5 g/L of peptone, 20 g/L of d-glucose, and 20 g/L of agar. Inoculation flasks were prepared by autoclaving 100 mL of 50 g/L glucose, 1 g/L of KH2PO4, 1 g/L of MgSO4 7H2O, 5 g/L of peptone, and 5 g/L of yeast extract. The medium was incubated for 24 h at 30 °C and shaken at 150 rpm prior to use (Pasha et al. 2007).

Fermentation

Batch fermentation experiments have been carried out in 100 mL flasks under anaerobic conditions with working volumes of 20 mL. The fermentation medium had a pH of 5.5. The solid fraction hydrolysates (15 mL) resulting from macroalgae pretreatment was used as substrates with 2 mL of YPX10 (200 g/L of yeast extract and 400 g/L of peptone) and 2 mL of the yeast suspension. The fermentation medium was incubated for 24 h at 37 °C with shaking (100 rpm) (Pasha et al. 2007). These experiments were replicated three times.

Analytic methods

The estimation of total reducing sugar in the enzymatic hydrolysate of biomass was done by the DNS method (Miller 1959). Dry matter and ash content were determined according to the Association of Official Analytical Chemists (AOAC) standard 950.46 and 920.153, respectively, by drying the macroalgae biomass at 105 °C (24 h) followed by incineration at 550 °C (5 h) (Sarip and Allaf 2014). Total fiber contents were determined according to the analytical method described by Van Soest that gives not only an estimation of total cell wall content in the biomass [neutral detergent fiber (NDF)] but also its main constituants [acid detergent fiber (ADF) or lignocellulose fraction and acid detergent lignin (lignin fraction)] (Juliano 1985; AOAC 1984).

The lipid contents were determined using the protocol described by Folch et al. (1957). The Folch method (Folch et al. 1957) uses chloroform–methanol (2:1 by volume) to extract lipids from cells. The homogenized cells are equilibrated with one-fourth volume of saline solution and mixed well. The resulting mixture is then allowed to separate into two layers. The lipid fraction was obtained and weighted after a distillation with the rotary evaporator.

Kjeldahl nitrogen (TKN) was carried out using the normalized Kjeldahl method 928.08 (Helrich 1995). The conversion factor 6.25 was used to estimate the crude protein according to the following Eq. 2 (Helrich 1995).

With:

-

V: volume (mL) of hydrochloric acid (0.1 N) used for titration.

-

6.25: Kjeldahl factor.

-

N: normality of hydrochloric acid.

-

m: mass (mg) of sample.

An Agilent gas chromatograph was used with a capillary column type (CP-Wax-57, 50 mm × 0.32 mm chrompack). Oven initial temperature was 50 °C and raised after injection to 180 °C at a rate of 10 °C/min. The total analysis time was around 13 min. The carrier gas (He) had a flow rate of 1 mL/min. The injector’s temperature was 220 °C and that of the flame ionization detector was 280 °C (Wang et al. 2003). The bioethanol yield was determined according to the following Eq. 3:

Results and discussion

This work aims to produce bioethanol from macroalgal biomass issued from Tunisian lagoons in Mediterranean region. In this work, we determined the biochemical composition of studied macroalgae and performed an enzymatic hydrolysis and an alcoholic fermentation to determine their bioethanol yields.

Biochemical composition

The results of the organic, mineral, lipid, fiber, and protein contents of macroalgae species collected from Tunisian lagoons (Table 1).

Carbohydrate content was determined according to the Van Soest and Wine method. This method is based on the successive extraction of the macroalgae’s main constituents by detergents. After each extraction, the product retained on the filter was dried and weighed.

Macroalgae with high carbohydrate contents are promising candidates for bioethanol production, as presented in Table 1, such as: D. polypodoides (58.46% ± 1.52%), C. brachycarpa (42.94% ± 0.28%), C. linum (41.21% ± 2%), E. intestinalis, U. rigida, C. sedoides, and Laurencia obtusa (up to 40%). Macroalgae carbohydrate contents vary widely among species and cultivar. The present results agree with previous studies on various locations where macroalgae demonstrated great potential as fibers source (Dave et al. 2019). In fact, Laminaria Japonica, E. intestinalis, and Palmaria palmata contain 54.5%, 42.8%, and 39.4% of carbohydrate, respectively (Jang et al. 2012; Kim et al. 2014; Kostas et al. 2016). Therefore, these biomasses could be considered as adequate substrates for bioethanol production.

The crude protein (CP) content of macroalgae was determined using the “Kjeldahl method” by measuring the nitrogen they contain. According to the results enumerated in Table 1, the macroalgae species collected from Tunisian lagoons show considerably high crude protein contents (> 9% relative to the dry matter) (Marfaing and Lerat 2007). Indeed, for green macroalgae, the crude protein contents were 19.03%, 9.84%, and 11.28 ± 0.3%, for E. intestinalis, C. linum, and U. rigida, respectively. Protein contents of 16.22 ± 0.27%, 10.17%, and 9.19 ± 0.05% were observed in red macroalgae G. verrucosa, L. obtusa, and G. gracillis biomasses, respectively. For brown macroalgae, the protein contents range from 3% to 15% for C. brachycarpa (5.35 ± 1.06) and C. sedoides (3.55 ± 1.09%). According to literature, the protein fraction in brown macroalgae is low (from 3% to 15%, relative to the dry matter) when compared with the green and red macroalgae (from 10% to 47%), which confirms our obtained results (Fleurence 1999). It is reported that the protein content of marine macroalgae varies significantly between species and depends on seasons and environmental conditions (Dawczynski et al. 2007). These contents can sometimes exceed those of fabaceae, which can make it an interesting source for human and animal food (Marfaing and Lerat 2007; Zitouni et al. 2014).

The lipid contents of the studied macroalgae species are lower than 2% relative to the dry matter. This agrees with the results of Ivanova et al., asserting that the lipid content in macroalgae varies between 1% and 5% (Ivanova et al. 2013). It was reported that macroalgae have low lipid contents, but their polyunsaturated fatty acids can be as high as those of terrestrial plants, which explains their dietary and even pharmacological benefits (Darcy-Vrillon 1993). It is important to note that macroalgae’s chemical composition presents a great variability related to several abiotic factors, mainly environmental ones such as salinity, water, temperature, light, and seasonal variation of nutrients (Dave et al. 2019). Commonly, these ecological parameters fluctuate with reference to the locality and the seasonal effects. Additionally, the tidal periods can also indirectly affect the macroalgal biomass availability and biochemical composition (Dave et al. 2019).

Finally, the obtained results demonstrate that the studied macroalgae from Tunisia having high carbohydrate and protein contents and are promising candidates for bioethanol production and animal feed industries.

Bioethanol production from Tunisian macroalgae biomass

Enzymatic saccharification of pretreated macroalgae biomass

The nontreated biomasses and the solid residue obtained after dilute acid pretreatment were utilized as substrates for the enzymatic saccharification to recover fermentable sugars. Enzymatic hydrolysis was carried out under mild conditions (55 °C and pH 5) for 48 h using a commercial enzymatic preparation (Cellic C-Tec2). The reducing sugars yields obtained after an enzymatic saccharification of nontreated C. linum and E. intestinalis were, respectively, 23.86 ± 0.34 mg/gDM and 10.27 ± 0.25 mg/gDM.

Figure 1 shows reducing sugars yields obtained after an enzymatic saccharification of macroalgae collected from Tunisia northern lagoon and pretreated by dilute acid.

Compared with the reducing sugars yields of nontreated C. linum and E. intestinalis (preliminary tests), the results show that the best reducing sugars yields were obtained after a sulfuric acid pretreatment. Consequently, we choose to perform all the experiments with the pretreatment step to ameliorate the reducing sugars yields.

The results in Fig. 1 show that maximum reducing sugars yields obtained after an enzymatic hydrolysis were 325 ± 0.2 mg/g and 280.8 ± 0.35 mg/g dry biomass from C. linum and E. intestinalis, respectively. We obtained a reducing sugars yield of 170.9 ± 0.02 mg/g after an enzymatic hydrolysis of pretreated U. rigida. These results were compared with the results described by Korzen et al. (2015). In fact, the authors obtained 196. ± 2.5 mg/gDM after hydrolysis catalyzed by Amylo-glucosidase, α-amylase, and cellulase enzymes of U. rigida biomass pretreated by milling and sonication (40 kHz frequency and power 120 W) (Korzen et al. 2015).

In previous work, enzymatic hydrolysis of Ulva lactuca biomass pretreated by liquid hot water or air-drying, size reduction using centrifugal and vibratory ball mill gave, respectively, 97.5 mg/g DM and 131 mg/g of reducing sugars yields (Jmel et al. 2018; Amamou et al. 2018). Moreover, a yield of 345 mg/g was obtained following an enzymatic hydrolysis with CMCase enzyme of 3% NaOH pretreated Ulva sp. (Ben Yahmed et al. 2018). For red macroalgae, our results demonstrate that maximum reducing sugars yields were obtained with G. gracillis (277.2 ± 0.06 mg/g) and G. verrucosa (175.2 ± 0.05 mg/g), respectively. Other studies found lower sugars yields for the same kind of Gracillaria, as Saravanan et al. observed 140.6 mg/g of yield following an enzymatic hydrolysis using cellulase and β-glucosidase of Gracillaria sp. biomass pretreated by 4% of H2SO4 (Saravanan et al. 2018).

When using brown macroalgae as raw material, the maximum sugar yield was obtained with C. sedoides biomass at 175 ± 0.12 mg/g. According to data reported by literature, Borines et al. found 120 mg/g yield with Sargassum sp. pretreated by sulfuric acid and hydrolyzed by cellulase and cellobiase (Borines et al. 2013). In addition, yields of 127 ± 0.05 mg/g and 44 ± 0.05 mg/g were obtained with Ascophyllum nodosum biomass pretreated by microwave-assisted acid hydrolysis or microwave-assisted thermochemical treatment (Yuan and Macquarrie 2015). In the present work, reducing sugars yields after pretreatment followed by saccharification are comparable with even higher than yields reported in literature. This can be explained on the one hand by the efficiency of the applied chemical pretreatment with sulfuric acid and on the other hand by the richness of our macroalgae in carbohydrates as depicted in Table 1. In fact, the chemical pretreatment method with sulfuric acid is widely accepted and involves various steps such as cellulose depolymerization, hemicellulose-solvation, and structural modification using mild alkali or dilute-acid treatment (Kostas et al. 2016). Dilute-acid pretreatment demonstrated its efficiency and is mainly used in several macroalgae biomass pretreatment (Kostas et al. 2016). When followed by enzymatic hydrolysis, it seems to be economically viable method for bioethanol production. Therefore, through dilute-acid treatment, the holocellulose content can be broken down into monomeric sugars (e.g., glucose, xylose, etc.) while further saccharification efficiency can be increased using enzymatic hydrolysis.

Bioethanol production from Tunisian macroalgae

The hydrolysate obtained from the enzymatic hydrolyze of dilute acid pretreated macroalgae collected from Tunisian lagoons were fermented with S. cerevisiae under anaerobic conditions. Figure 2 shows the obtained bioethanol yields for several species of Tunisian macroalgae after a fermentation.

The maximum obtained bioethanol yield for green macroalgae was 0.21 g/gDM with C. linum. The alcoholic fermentation of G. gracillis gave a 0.12 g/gDM. To avoid a sorting step for the macroalgae collected from Tunis Lagoon, a mixture was considered and used as a substrate for bioethanol production. This macro algae mixture (C. linum + E. intestinalis + G. gracillis) was pretreated with sulfuric acid, hydrolyzed by a commercial enzyme and converted by S. cerevisiae into bioethanol with a yield of 0.23%. Thus, it constitutes an advantage for the bioenergy industry since it reduces the process’s cost by avoiding an expensive sorting step and by improving of the bioethanol yield and, therefore, the biomass productivity. For D. polypodioides, C. brachycarpa, and C. sedoides, the bioethanol yields were reached to 0.24 g/g DM, 0.21 g/g DM, and 0.19 g/g DM, respectively.

The bioethanol yields obtained in this study are comparable to previous results for first-generation biomasses, which were, respectively, 0.25 g/g and 0.21 g /g from sorghum (Salvi et al. 2009) and from sweet potato (Wang et al. 2016).

For the second-generation biomasses, the bioethanol yields obtained were 0.3 g/g for wheat straw and 0.3 g/g for corn stover (Yanagisawa et al. 2013). Our results are in accordance with others reported for example by Borines et al. (2013). In fact, the authors obtained 0.13 g/g of bioethanol yield for Sargassum sp. collected from the coastal region of Bolinao (Dave et al. 2019). The alcoholic fermentation of C. linum that was collected from coastal region of Monastir, Tunisia, resulted in a 0.28 g/g of bioethanol yield (Fleurence 1999) and was even higher than the obtained bioethanol yields for U. lactuca (0.06 g/g), U. rigida (0.12 g/g), and Padina tetrastromatica (0.16 g/g), using S. cerevisiae as fermenter microorganism (Amamou et al. 2018; Harchi et al. 2018; Ashokkumar et al. 2017).

Nevertheless, other studies have found higher bioethanol yields than our work. In fact, Kumar et al. obtained 0.43 g/g of bioethanol yield from G. verrucosa pretreated by alkaline solution (5% of NaOH) at 80 °C for 2 h, followed by an enzymatic saccharification and an alcoholic fermentation with Saccharomyces cerevisiae (Kumar et al. 2013). Our results can be explained by the presence of some inhibitors in dilute acid hydrolysate inhibiting the alcoholic fermentation. In fact, the acid pretreatment (H2SO4 (Nguyen et al. 1999; Nguyen et al. 2000), HCl (Springer 1966), HF (Franz et al. 1982), or CH3COOH) (Conner and Lorenz 1986) used as catalysts at severe conditions leads to sugar degradation. Therefore, the pretreatment consists on the releasing of proton that break the heterocyclic ether bonds between momoneric sugars of hemicelluloses and cellulose to release xylose, glucose, and arabinose and other molecules (furfural and acetic acid), which are considered as unwanted products (David et al. 1985; Grethlein and Converse 1991). Aliphatic acids, furfural, and HMF compounds are formed from the degradation of sugars (DamH 1986). These compounds can inhibit enzymatic hydrolysis by at least 50% (Cantarella et al. 2004).

The results show that macroalgae collected from Tunisian lagoons constitute a potential feedstock for bioenergy. This macroalgal biomass is abundant in nature and can compete favorably with other classical biomasses for biofuel production. Therefore, we believe it can be considered as a promising substrate for bioethanol production.

Feasibility assessment of bioethanol production from marine macroalgal biomass: case study: macroalgae collected from Tunis lagoon, Tunisia

The bioethanol production process proposed in this work was experimented on Tunisian macroalgae to demonstrate its feasibility and potential. We used a macroalgae mix collected from a Tunis lagoon, and it composed of G. gracillis, C. linum, and E. intestinalis. To achieve this objective, three steps of process were performed. First, the macroalgal biomass was treated by dilute sulfuric acid. Then, an enzymatic saccharification was performed by a commercial enzyme (Cellic C-tech2) at 55 °C to produce fermentable sugars. Finally, the latter was converted into bioethanol using S. cerevisiae yeast at 37 °C (Fig. 3).

The obtained results show that the estimated bioethanol yield was 0.23 g/g of dry matter macroalgae. The lagoon can have a maximum biomass productivity of 344 ± 48.5 g of dry matter per m2 in the period from April to September. Since the total area of the lagoon is 4000 hectares, the projected estimate is 13,760 tons of dry matter for the entire lake. The estimated maximum productivity of bioethanol, therefore, is 791.2 kg per hectare per year.

Tunisia has several coastal regions and lagoons that can be exploited to collect larger macroalgae quantities for conversion into bioethanol. This may amplify yields and to demonstrate the project’s feasibility in the Mediterranean regions.

Conclusions

Biofuels have become a very important alternative energy source to combat the global climate change and increasing fuel prices. The macroalgal biomass has shown a great potential as feedstock for bioethanol production negates food versus fuel concerns and serves as an alternative energy source. In this study, we proposed a valorization perspective of the abundant and unexploited macroalgal biomass into third generation bioethanol. The study focuses on macroalgae collected from Tunisian lagoons in the Mediterranean region (i.e., Bizert lagoon and north lagoon of Tunis).

The originality of this work resides in highlighting the potential of an unexploited renewable natural resources, namely macroalgae, as an alternative for bioethanol production and other value-added products in Tunisia and the Mediterranean region.

The results revealed that the studied marine macroalgae, particularly the carbohydrates-rich ones, from Tunisian lagoons constitute an interesting biomass for bioenergy and high added value molecules. In our experiments, the maximum bioethanol yield of 0.24 g/gDM, obtained with D. polypodioides, demonstrates the value of our proposal leading to more sustainable bioenergies without the compromises of first and second generations biomasses.

Improving the conversion and the valorization processes will be vital in establishing this emerging source of bioenergy for commercial utilization. The optimization of some steps in the proposed integrated process in addition to a complete techno-economical study are therefore necessary to scale it up. If these technologies are further optimized, the production of bioethanol and other value-added molecules from macroalgae could lead to a new sustainable industry in the near future.

References

Abomohra AEF, Hamed El-Naggar A, Baeshen AA (2018) Potential of macroalgae for biodiesel production: screening and evaluation studies. J Biosci Bioeng 125(2):231–237

Amamou S, Sambusiti C, Monlau F, Edubreucq E, Barakat A (2018) Mechano-enzymatic deconstruction with a new enzymatic cocktail to enhance enzymatic hydrolysis and bioethanol fermentation of two macroalgae species. Molecules 23(1):174

AOAC (1984) Official methods of analysis. Association of Official Analytical Chemists, 14th edn. AOAC, Arlington

Ashokkumar V, Agila E, Salam Z, Ponraj M, Fadhil M, Ani FN (2014) A study on largescale cultivation of Microcystis aeruginosa under open raceway pond at semicontinuous mode for biodiesel production. Bioresour Technol 172:186–193

Ashokkumar V et al (2017) Production of liquid biofuels (biodiesel and bioethanol) from brown marine macroalgae Padina tetrastromatica. Energy Convers Manage 135:351–361

Azhar SHM et al (2017) Yeasts in sustainable bioethanol production: a review. Biochem Biophys Reports 10:52–61

Ben Yahmed N, Berrejeb N, Jml MA, Jazar S, Marzouki MN, Smaali I (2018) Efficient biocatalytic conversion of stranded green macroalgal biomass using a specific cellulases-based cocktail. Waste Biomass Valoriz 11:211–222

Borines MG, de Leon RL, Cuello JL (2013) Bioethanol production from the macroalgae Sargassum spp. Biores Technol 138:22–29

Boro M, Verma AK, Chettri D, Yata VK, Verma AK (2022) Strategies involved in biofuel production from agro-based lignocellulose biomass. Environ Technol Innov 28:102679

Bouallagui H, Touhami Y, Hanafi N, Ghariani A, Hamdi M (2013) Performance comparison between three technologies for continuous ethanol production from molasses. Biomass Bioenergy 48:25–32

Bruhn A, Dahl J, Nielsen HB, Nikolaisen L, Rasmussen MB, Markager S, Olesen B, Arias C, Jensen PD (2011) Bioenergy potential of Ulva lactuca: biomass yield, methane production and combustion. Bioresour Technol 102:2595–2604

Cantarella M, Cantarella L, Gallifuoco A, Spera A, Alfani F (2004) Subsequent enzymatic hydrolysis and SSF. Biotechnol Prog 20:200–206

Conner AH, Lorenz LF (1986) Kinetic modelling of hardwood prehydrolysis. Part III: water and dilute acetic acid of prehydrolysis southern red oak. Wood Fiber Sci 18:248–263

Darcy-Vrillon B (1993) Nutritional aspects of the developing use of marine macroalgae for the human food industry. Int J Food Sci Nutr 44

Dave N, Selvaraj R, Varadavenkatesan T, Vinayagama R (2019) A critical review on production of bioethanol from macroalgal biomass. Algal Res 42:101–606

David C, Fornasier R, Greindl-Fallon C, Vanlautem N (1985) Enzymatic hydrolysis and bacterian hydrolysis-fermentation of Eucalyptus wood pretreated with sodium hypochlorite. Biotechnol Bioeng 27(11):1591–1595

Dawczynski C, Schubert R, Jahreis G (2007) Amino acids, fatty acids, and dietary fiber in edible seaweed products. Food Chem 103:891–899

El Harchi M, Kachkach FZF, El Mtili N (2018) Optimization of thermal acid hydrolysis for bioethanol production from Ulva rigida with yeast Pachysolen tannophilus, South African. J Bot 115:161–169

Fleurence J (1999) Seaweed proteins: biochemical, nutritional aspects and potential uses. Trends Food Sci Technol 10:25–28

Folch J, Lees MBC, Stanley GHS (1957) A simple method for the isolation and purification of total lipides from animal tissues. J Biol Chem 226:497–509

Franz R, Erckel R, Riehm T, Woernle R, Deger HM (1982) Lignocellulose saccharification by HF. Energy from biomass. Appl Sci Publishers, London, pp 873–878

Ganzon-Fortes ET (1991) Characteristics and economic importance of seaweeds. In: Proceedings of the seaweed research training and workshop for project leaders. Philippine Council for Aquatic and Marine Research and Development

Grethlein HE, Converse AO (1991) Common aspects of acid prehydrolysis and steam explosion for pretreating wood. Bioresour Technol 36(1):77–82

Hebbale D, Chandran MDS, Joshi NV, Ramachandra TV (2017) Energy and food security from macroalgae. J Biodivers 8(1):1–11

Helrich K (1995) Association of Official Analytical Communities. Volume 2, Edition 16. The Association, Arlington

Hernandez RP, Koohfkan P, Antoine J (2004) Assessing carbon stocks and modelling win–win scenarios of carbon sequestration through land use changes. Food and Agriculture Organization of the United Nations, Rome

Ivanova V, Stancheva M, Petrova D (2013) Fatty acid composition of black sea Ulva rigida and Cystoseira crinita. Bulg J Agric Sci 1:42–47

Jang S, Shirai Y, Uchida M, Wakisaka M (2012) Production of mono sugar from acid hydrolysis of seaweed. Afr J Biotechnol 11(8):1953–1963

Jmel MA et al (2018) Variations I physicochemical properties and bioconversion of Ulva lactuca polysaccharides after different biomass pretreatment techniques. Appl Biochem Biotechnol 184(3):777–793

Jonsson M, Allahgholi L, Sardari RRR, Hreggviosson GO, Karlsson EN (2020) Extraction and modification of macroalgal polysaccharides for current and nextgeneration applications. Molecules 25:930

Juliano BO (ed) (1985) Rice: chemistry and technology, 2nd edn. American Association of Cereal Chemists, St. Paul, p 69

Jung KA, Lim SR, Kim Y, Park JM (2013) Potentials of macroalgae as feedstocks for biorefinery. Bioresour Technol 135:182–190

Karray R, Hamza M, Sayadi S (2015) Evaluation of ultrasonic, acid, thermo-alkaline and enzymatic pre-treatments on anaerobic digestion of Ulva rigida for biogas production. Bioresour Technol 187:205–213

Kazir M, Abuhassira Y, Robin A, Nahor O, Luo J, Israel A, Golberg A, Livney YD (2019) Extraction of proteins from two marine macroalgae, Ulva sp. and Gracilaria sp., for food application, and evaluating digestibility, amino acid composition and antioxidant properties of the protein concentrates. Food Hydrocoll 87:194–203

Kim DH, Lee SB, Jeong GT (2014) Production of reducing sugar from Enteromorpha intestinalis by hydrothermal and enzymatic hydrolysis. Bioresour Technol 161:348–353

Korzen L, Pulidindi IN, Israel A, Abelson A, Gedanken A (2015) Single step production of bioethanol from the seaweed Ulva rigida using sonication. RSC Adv 5(21):16223–16229

Kostas ET, Wilkinson SJ, White DA, Du CY, Cook DJ (2016) Optimization of a total acid hydrolysis-based protocol for the quantification of carbohydrate in macroalgae. J Algal Biomass Util 7(1):21–36

Kraan S (2013) Mass-cultivation of carbohydrate rich macroalgae, a possible solution for sustainable biofuel production. Mitig Adapt Strateg Glob Chang 18:27–46

Kuglarz M, Alvarado-Morales A, Dąbkowska K, Angelidaki I (2018) Integrated production of cellulosic bioethanol and succinic acid from rapeseed straw after dilute-acid pretreatment. Biores Technol 265:191–199

Kumar S, Gupta R, Kumar G, Sahoo D, Kuhad RC (2013) Bioethanol production from Gracilaria verrucosa, a red alga, in a biorefinery approach. Biores Technol 135:150–156

Kumar M, Sun Y, Rathour R, Pandey A, Thakur IS, Tsang DC (2020) Algae as potential feedstock for the production of biofuels and value-added products: opportunities and challenges. Sci Total Environ 716:137116

Lage S, Gojkovic Z, Funk C, Gentil FG (2018) Algal biomass from waste and flue gases as a source of bioenergy. Energies 11(3):664

Leandro A, Pereira L, Gonçalves AMM (2020) Diverse applications of marine macroalgae. Mar Drugs 18:17

Leesing R, Somdee T, Siwina S, Ngernyen Y, Fiala K (2022) Production of 2G and 3G biodiesel, yeast oil, and sulfonated carbon catalyst from waste coconut meal: an integrated cascade biorefinery approach. Renew Energy 199:1093–1104

Marfaing H, Lerat Y (2007) Les algues dans notre alimentation: interet nutritionnel et utilisations. Cent. D’étude Valoris. Algues CEVA

Markou G, Angelidaki I, Nerantzis E, Georgakakis D (2013) Bioethanol production by carbohydrate-enriched biomass of Arthrospira (Spirulina) platensis. Energies 6:3937–3950

Mazumdar S, Lee J, Oh MK (2013) Microbial production of 2,3 butanediol from seaweed hydrolysate using metabolically engineered Escherichia coli. Bioresour Technol 136:329–336

Miller GL (1959) Use of dinitrosaliclyic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Neifar M, Chatter R, Chouchane H, Genouiz R, Jaouani A, Masmoudi AS, Cherif A (2016) Optimization of enzymatic saccharification of Chaetomorpha linum biomass for the production of macroalgae-based third generation bioethanol. AIMS Eng 3(3):400–411

Nguyen QA, Tucker MP, Keller FA, Beaty DA, Connors KM, Eddy FP (1999) Dilute acid hydrolysis of softwoods. Appl Biochem Biotech 77(79):133–142

Nguyen QA, Tucker MP, Keller FA, Eddy FP (2000) Two-stage dilute-acid pretreatment of softwoods. Appl Biochem Biotech 84(86):561–576

Noraini MY, Ong HC, Badrul MJ, Chong WT (2014) A review on potential enzymatic reaction for biofuel production from algae. Renew Sust Energ Rev 39:24–34

Offei F, Mensah M, Thygesen A, Kemausuor F (2018) Seaweed bioethanol production: a process selection review on hydrolysis and fermentation. Fermentation 4:99

Pasha C, Valli N, Rao LV (2007) Lantana camara for fuel ethanol production using thermotolerant yeast. Lett Appl Microbiol 44:666–672

Person J (2010) Livre turquoise: algues, filiere du future. Adebiotech-Romainville, p 163

Ruiz HA, Rodríguez-Jasso RM, Fernandes BD, Vicente AA, Teixeira JA (2013) Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: a review. Renew Sust Energ Rev 21:35–51

Salvi DA, Aita GM, Robert D, Bazan V (2009) Ethanol production from sorghum by a dilute ammonia pretreatment. J Ind Microbiol Biotechnol 37(1):27

Sannigrahi P, Kim D, Jung H, Ragauskas A (2011) Pseudo-lignin and pretreatment chemistry. Energy Environ Sci 4:1306–1310

Saravanan K, Duraisamy S, Ramasamy G, Kumarasamy A, Balakrishnan S (2018) Evaluation of the saccharification and fermentation process of two different seaweeds for an ecofriendly bioethanol production. Biocatal Agric Biotechnol 14:444–449

Sarip H, Allaf K, Mohd Noor MA (2011) Pure cellulose conversion to glucose with instant pressure drop (DIC) technology. IJEIT 8:36–41

Sarip H, Allaf K, Noor MAM (2014) A patent: Procede d'hydrolyse de polysaccharides

Schiener P, Stanley MS, Black KD, Green DH (2016) Assessment of saccharification and fermentation of brown seaweeds to identify the seasonal effect on bioethanol production. J Appl Phycol 28:3009–3020

Shili A, Trabelsi EB, Ben Maiz N (2002) Seasonal dynamics of macro-algae in the South Lake of Tunis. J Coast Conserv 8:127

Sindhu R, Binod P, Pandey A (2016) A novel sono-assisted acid pretreatment of chili postharvest residue for bioethanol production. Bioresour Technol 213:58–63

Singh A, Nigam PS, Murphy JD (2011) Renewable fuels from algae: an answer to debatable land based fuels. Bioresour Technol 102:10–16

Smichi N, Messaoudi Y, Ksouri R, Abdelly C, Gargouri M (2014) Pretreatment and enzymatic saccharification of new phytoresource for bioethanol production from halophyte species. Renew Energy 63:544–549

Solarte-Toro JC, Cardona-Alzate CA (2021) Biorefineries as the base for accomplishing the sustainable development goals (SDGs) and the transition to bioeconomy: technical aspects, challenges and perspectives. Bioresour Technol 340:125626

Springer EL (1966) Hydrolysis of aspen wood xylan with aqueous solutions of hydrochloric acid. TAPPI 49:102–106

Su Y, Zhang P, Su Y (2015) An overview of biofuels policies and industrialization in the major biofuel producing countries. Renew Sust Energ Rev 50:991–1003

Sun Y, Cheng J (2005) Dilute acid pretreatment of rye straw and bermuda grass for ethanol production. Bioresour Technol 96(14):1599–1606

Synytsya A, Copíkova J, Kim WJ, Park YI (2015) Cell wall polysaccharides of marine algae. In: Kim SK (ed) Springer handbook of marine biotechnology. Springer handbooks. Springer, Berlin

Tan IS, Lam MK, Foo HCY, Lim S, Lee KT (2020) Advances of macroalgae biomass for the third generation of bioethanol production. Chin J Chem Eng 28(2):502–517

Tao L, Aden A, Elander R, Pallapolu V, Lee Y, Garlock R, Balan V, Dale B, Kim Y, Mosier N, Ladisch M, Falls M, Holtzapple M, Sierra R, Shi J, Ebrik M, Red-mond B, Yang T, Wyman C, Hames B, Thomas S, Warner R (2011) Process and techno-economic analysis of leading pretreatment technologies for lignocellulosic ethanol production using switchgrass. Bioresour Technol 102:11105–11114

Van Dam H, Kieboom A, Van Bekkum H (1986) The conversion of fructose and glucose in acidic media: formation of hydroxymethyl furfural. Starch-Stärke 3:95–101

Vanegas C, Hernon A, Bartlett J (2014) Influence of chemical, mechanical, and thermal pretreatment on the release of macromolecules from two Irish seaweed species. Sep Sci Technol 49:30–38

Wang ML, Choong YM, Su NW, Lee MH (2003) A rapid method for determination of ethanol in alcoholic beverages using capillary gas chromatography. JFDA 11(2):133–140

Wang F et al (2016) An environmentally friendly and productive process for bioethanol production from potato waste. Biotechnol Biofuels 9(1):50

Ward AJ, Lewis DM, Green FB (2014) Anaerobic digestion of algae biomass: a review. Algal Res 5:204–214

Xu J, Li M (2016) Innovative technological paradigm-based approach towards biofuel feedstock. Energy Convers Manage 141:48

Yanagisawa M, Kawai S, Murata K (2013) Strategies for the production of high concentrations of bioethanol from seaweeds: production of high concentrations of bioethanol from seaweeds. Bioengineered 4(4):224–235

Yuan Y, Macquarrie DJ (2015) Microwave assisted acid hydrolysis of brown seaweed Ascophyllum nodosum for bioethanol production and characterization of alga residue. ACS Sustain Chem Eng 3(7):1359–1365

Zitouni H, Arhab R, Boudry C, Bousseboua H (2014) Chemical and biological evaluation of the nutritive value of Algerian green seaweed Ulva lactuca using in vitro gas production technique fiber ruminant animals. Int J Adv Res 2(4):916–925

Acknowledgements

The authors thank the National Agency for the Promotion of Scientific Research for the funding and the Tunis Lake Promotion Company for technical assistance and access to the Tunis Lake resources.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest and give their informed consent. No financial or other interests influenced the outcome of the research.

Additional information

Responsible Editor: Philippe Michaud.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Smichi, N., Messaoudi, Y., Moujahed, N. et al. Bioethanol production from Tunisian macroalgal biomass. Euro-Mediterr J Environ Integr 9, 1459–1469 (2024). https://doi.org/10.1007/s41207-024-00482-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41207-024-00482-7