Abstract

Water contamination, particularly by heavy metals originating from industrial processes, presents a significant threat to environmental sustainability and socio-economic development. Activated carbon (AC) has garnered considerable attention as a treatment due to its exceptional adsorption properties, characterized by a high surface area (273–827 m2/g), significant total pore volumes (0.27–0.69 ml/g), and well-defined micropores (8.2–12.4 nm), alongside tunable surface chemistry. Research efforts have focused on enhancing the synthesis, activation, and modification of AC to optimize its effectiveness in heavy metal removal from water. Studies consistently demonstrate that modified AC exhibits promising adsorption kinetics, often fitting well with Langmuir and pseudo-second-order physical adsorption models. Moreover, the economic viability of modified AC is underscored by its non-toxic nature, affordability, and sustainability. Experimental investigations reveal that AC can achieve substantial heavy metal removal efficiencies, ranging from 75 to 96%, contingent upon factors such as dosage, solution pH, surface properties, and contaminant concentrations. Despite advancements, widespread adoption of AC-based water treatment technologies remains largely confined to industrial settings. Key research priorities include the development of cost-effective and scalable synthesis methods for AC, particularly utilizing non-biodegradable feedstocks. Additionally, there is a pressing need for comprehensive studies assessing the efficacy of AC in real-world wastewater treatment scenarios. This review critically examines the role of AC in water treatment technologies, highlighting research gaps and delineating future research directions to advance sustainable and efficient water purification strategies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is essential for life, but its quality has been increasingly compromised by modern industrial activities [1, 2]. Ensuring the provision of safe and high-quality water is a paramount global concern [3, 4]. The contamination of clean water supplies by heavy metals and dyes poses significant threats to human health, animal well-being, and ecosystem integrity. Heavy metals, including cadmium (Cd), chromium (Cr), copper (Cu), nickel (Ni), lead (Pb), arsenic (As), and mercury (Hg), are among the most concerning pollutants due to their acute toxicity and adverse effects on human health and aquatic ecosystems [5, 6]. Chronic exposure to heavy metals can lead to severe toxicological consequences, including neurological damage and skin irritation, with chromium (Cr) and arsenic (As) being particularly harmful. Various wastewater treatment approaches have been developed to address heavy metal contamination [7]. These include physical, chemical, and biological methods such as adsorption, membrane filtration, ion exchange, reverse osmosis, membrane bioreactors (MBRs), and microbial remediation. However, challenges related to cost-effectiveness, efficiency, and sustainability hinder the widespread applicability of these techniques [8, 9]. Carbon compounds, such as carbon nanotubes (CNT), graphene (Gr), metal–organic frameworks (MOFs), zeolites, and activated carbon (AC), have gained attention for their ability to adsorb diverse pollutants [10]. Among these, activated carbon stands out as a highly effective adsorbent due to its substantial surface area (SSA)-to-volume ratio, porosity, durability, chemical stability, and non-toxic nature. Activated carbon is commonly synthesized from both biodegradable and non-biodegradable resources [11,12,13,14,15,16]. Recent research has shown that AC synthesized from biodegradable wastes offers advantages in terms of cost, regrowth performance, and sustainability compared to conventional methods [17]. Surface modification techniques, such as functionalization, enhance the adsorption efficiency of AC and its applicability in wastewater treatment. Modified AC could be commercialized in both granular and powdered forms. Both have been demonstrated to be useful in wastewater treatment, where AC plays a major role in decolorization, odor reduction, metal recovery, and organics adsorption. Modified AC has the potential to be marketed as a water filtration medium for removing persistent contaminants from drinking water. It is capable of removing pollutants from water due to its great potential for adsorption of these chemicals, which is attributable to its wide specific surface area (SSA) and pores.

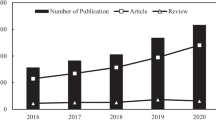

Despite the various advantages of AC as an adsorbent, there are still limitations in the manufacturing process, regrowth obstacles, recycling ability, and selectivity towards contaminants that limit its use in substantial wastewater treatment. It is important to note that there are numerous research studies that have investigated the possible uses of carbon materials, notably AC as an adsorbent against heavy metals, CO2 adsorption, and dye removal [17,18,19,20,21,22]. This review focuses on the recent trends (2019–2023) in the production and utilization of activated carbon and enhanced activated carbon as adsorbents in the removal of heavy metals from wastewater. It provides insights into the synthesis of AC from various biodegradable and non-biodegradable materials, surface modification strategies, adsorption kinetics and isotherms, and current and future challenges faced by AC adsorbents.

Production Approaches of Activated Carbon

The production of activated carbon involves several crucial steps and considerations, from the selection of suitable raw materials to the final activation process. This section explores the various approaches to producing activated carbon, with a focus on utilizing waste materials as precursors, thereby contributing to sustainability and environmental protection.

Seeking Waste Materials to Generate AC

The quest for suitable waste materials for AC production is guided by several key factors. The chosen material must be readily available, cost-effective, and non-toxic. Additionally, it should possess a high content of fixed carbon (C) and a low ash content, which are indicative of the potential to yield AC with desirable morphological and physicochemical properties.

Biodegradable waste offers a promising source for AC production. This category includes a wide range of materials such as agricultural residues, food waste, wood biomass, herbs, and various industrial biomasses. The appeal of using lignocellulosic biomass lies in its diversity, abundance, and renewability. Moreover, the process of converting this type of biomass into AC is relatively straightforward, which helps in minimizing waste disposal costs and mitigating environmental impacts [19, 22, 23].

One of the most significant benefits of using sustainable and waste materials is the ability to produce useful substances which include electrodes, catalysts, fertilizers, liming and eliminating agents, and adsorbents that eliminate particular substances and elements from both air and water [24, 25].

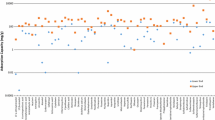

Non-biodegradable materials, such as municipal solid waste (MSW), present a different set of challenges and opportunities for AC production. MSW includes everyday items like packaging, food waste, textiles, plastics, papers, and more. The composition of MSW varies significantly across different income groups, with organic waste predominating in lower-income settings and a higher proportion of paper, metals, and glass in wealthier areas. Although less common, the utilization of MSW and sewage sludge as precursors for AC production has been explored, highlighting the potential for transforming waste into valuable adsorbents [26]. Utilizing waste materials for the production of activated carbon brings several significant advantages. It not only helps in managing waste more effectively but also contributes to the creation of value-added products such as electrodes, catalysts, fertilizers, and adsorbents. These products play critical roles in environmental remediation, including air and water purification [24, 25]. The selection of waste materials for AC production is a critical step that determines the efficiency and effectiveness of the resulting activated carbon. Figure 1 illustrates the key factors considered in choosing AC precursors, emphasizing the importance of carbon content, ash content, availability, and environmental impact.

Carbonaceous Materials Activation Procedure

The transformation of carbonaceous materials into high-quality activated carbon is primarily achieved through two methods: physical and chemical activation. Both processes begin with the carbonization of raw materials, but they diverge significantly in their subsequent steps, impacting the characteristics and applicability of the final product [27, 28].

Heat Atomization (Pyrolysis)/Carbonization

Heat atomization, commonly referred to as pyrolysis or carbonization, is a critical precursor step in the production of activated carbon. During this process, carbonaceous substances undergo thermal decomposition at elevated temperatures, typically ranging from 600 to 900 °C, in an inert atmosphere [23]. The primary objective of pyrolysis is to drive off volatile components, such as water vapor, methane, carbon monoxide, and carbon dioxide, leaving behind a carbon-rich residue known as char. The success of the pyrolysis process depends on various parameters, with temperature being the most influential factor. Higher temperatures generally result in increased carbonization efficiency, minimizing the formation of undesired by-products such as tar and volatile organic compounds [29]. Additionally, the heating rate, atmosphere composition, and duration of the pyrolysis process play significant roles in determining the quality and characteristics of the resulting char. Upon completion of pyrolysis, the carbonaceous material undergoes structural transformation, with the expulsion of volatiles leading to the development of a porous network within the char matrix. This porous structure serves as the foundation for the subsequent activation process, where the surface area and adsorption capacity of the activated carbon are further enhanced.

Physical Stimulation (Activation)

Physical stimulation, commonly known as activation, represents the second phase in the production of activated carbon. Unlike chemical activation, which involves the use of activating agents, physical stimulation relies on the controlled exposure of carbonized material to elevated temperatures and oxidizing gases. During physical activation, the carbonized precursor material is subjected to temperatures typically ranging from 800 to 1100 °C in the presence of oxidizing gases such as steam, carbon dioxide, or a combination of gases. These gases react with the carbonized material, promoting the formation of additional pores and increasing the surface area of the activated carbon. The physical activation process is characterized by its simplicity, cost-effectiveness, and environmentally friendly nature, as it does not require the use of chemical agents. Moreover, physical activation offers greater control over pore structure and distribution, resulting in activated carbon with tailored adsorption properties suited for specific applications. In summary, physical stimulation plays a crucial role in enhancing the porosity and surface area of activated carbon, thereby improving its adsorption capacity and effectiveness in various environmental and industrial applications [19, 30] (Table 1).

Chemical Stimulation (Activation)

Chemical stimulation, also known as chemical activation, represents a versatile and widely employed method for the production of activated carbon. In contrast to physical activation, which relies on elevated temperatures and oxidizing gases, chemical activation involves the use of chemical compounds as activators to initiate the formation of pores and enhance the adsorption properties of the precursor material.

Chemical Activators and Mechanisms

Chemical activators play a pivotal role in initiating the activation process by modifying the thermal decomposition of the precursor material. Various classes of compounds serve as effective activators, including alkaline, acidic, and transition metal salts. Alkaline compounds such as sodium hydroxide (NaOH), potassium carbonate (K2CO3), and potassium hydroxide (KOH) are commonly used due to their ability to promote char formation and pore development. Acidic agents like nitric acid (HNO3), phosphoric acid (H3PO4), and sulfuric acid (H2SO4) also contribute to pore formation through chemical reactions with the precursor material. Transition metal salts such as zinc chloride (ZnCl2) and iron chloride (FeCl3) act as catalysts, facilitating the decomposition of organic compounds and the formation of activated carbon [19].

Process Parameters and Optimization

Several parameters govern the efficiency and effectiveness of the chemical activation process. The ratio of chemical activator to precursor material, temperature–time profile, impregnation agent, and mixing method are critical factors that influence the final properties of the activated carbon. Optimal conditions must be carefully determined through experimental optimization to achieve the desired pore structure, surface area, and adsorption capacity [19].

Thermal Treatment and Activation

The precursor material, impregnated with the chemical activator, undergoes thermal treatment in a controlled environment, typically within a furnace. Temperatures ranging from 400 to 900 °C are employed to induce the activation process while minimizing undesired side reactions. During thermal treatment, the chemical activator promotes the decomposition of the precursor material, resulting in the formation of char with an interconnected network of pores [20, 39].

Post-treatment and Washing

Following thermal treatment, the activated carbon undergoes several washing steps to remove residual impurities and activator residues. This post-treatment process is crucial for ensuring the purity and quality of the activated carbon product. Multiple washing cycles may be employed to achieve the desired level of cleanliness and reduce the presence of impurities that could affect the performance of the activated carbon in practical applications [39].

Chemical stimulation offers several advantages, including versatility, cost-effectiveness, and the ability to tailor the properties of the activated carbon to specific applications. Activated carbon produced via chemical activation exhibits enhanced adsorption characteristics, making it suitable for a wide range of applications, including water treatment, air purification, gas separation, and industrial processes. Table 2 summarizes the effects of different chemical activating compounds on the porosity and surface area of activated carbon, providing valuable insights into their impact on the final product.

Approaches for Enhancing AC Heavy Metal Removal Efficiency

Activated Carbon Surface Modification

Surface modification stands as a crucial aspect in augmenting the adsorption capabilities of activated carbon (AC), particularly in the realm of heavy metal removal from aqueous environments. Post-activation, surface modification techniques are employed to tailor the physicochemical properties of AC, thereby enhancing its adsorption capacity and selectivity [46].

Physical Modification

Physical modification techniques offer precise control over the surface morphology and chemistry of AC, thereby influencing its adsorption characteristics. One such method is microwave-assisted surface chemistry modification, which has gained prominence due to its ability to induce rapid and uniform heating. Microwave irradiation enables controlled surface functionalization with minimal energy consumption, making it an attractive option for modifying AC surfaces [47]. During microwave-assisted surface chemistry modification, AC is exposed to microwave radiation in the presence of appropriate reactants or precursors. The electromagnetic radiation penetrates the AC matrix, causing localized heating and promoting chemical reactions at the surface. This results in the selective introduction of desired functional groups onto the AC surface, such as hydroxyl (–OH), carbonyl (C = O), and carboxyl (–COOH) groups. These functional groups enhance the surface polarity of AC and promote interactions with heavy metal ions in aqueous solutions.

Another physical modification strategy is plasma treatment, which involves the exposure of AC to plasma under controlled atmospheric or vacuum conditions. Plasma, often referred to as the fourth state of matter, is a highly energetic and ionized gas composed of electrons, ions, and neutral species. Plasma treatment induces surface modifications by bombarding the AC surface with reactive species, leading to alterations in surface chemistry and morphology [48]. During plasma treatment, the AC surface undergoes physical and chemical changes due to interactions with plasma species. These changes include the creation of oxygen-containing functional groups, such as carbonyl and carboxyl groups, as well as the generation of defects and surface roughness. Plasma-induced surface modifications enhance the surface area and porosity of AC, thereby increasing its adsorption capacity for heavy metal ions. Both microwave-assisted surface chemistry modification and plasma treatment offer advantages such as precise control over surface functionalization, rapid reaction kinetics, and the ability to induce specific surface modifications. These physical modification techniques have the potential to enhance the efficiency of AC in heavy metal removal applications, making them promising strategies for the development of advanced adsorbents.

Chemical Modification

Chemical modification methods involve the selective introduction of functional groups onto the AC surface through reactions with reagents such as acids, bases, and organic solvents. These methods enable precise control over the surface chemistry of AC, thereby enhancing its adsorption affinity for heavy metal ions.

Acidic Treatment

Acidic treatments utilize strong acids such as sulfuric acid (H2SO4) and nitric acid (HNO3) to introduce oxygen-containing functional groups onto the AC surface. During acidic treatment, the AC surface undergoes oxidative reactions, leading to the formation of surface functionalities such as hydroxyl (–OH), carbonyl (C = O), and carboxyl (–COOH) groups [49]. These functional groups enhance the surface polarity of AC and promote interactions with heavy metal ions through mechanisms such as ion exchange and complexation.

Alkaline Treatment

Alkaline treatments involve the use of bases such as potassium hydroxide (KOH) and sodium hydroxide (NaOH) to increase the surface basicity of AC. During alkaline treatment, the AC surface is deprotonated, leading to the formation of basic functional groups such as amino (–NH2) and hydroxyl (–OH) groups. These basic functionalities enhance the adsorption affinity of AC for acidic pollutants, facilitating the removal of heavy metal ions through mechanisms such as chemisorption and precipitation [49, 50].

Impregnation Techniques

Impregnation techniques involve the deposition of metallic or polymeric precursors onto the AC surface, resulting in the formation of catalytic sites for pollutant oxidation reactions. Metal impregnation, utilizing compounds such as silver nitrate (AgNO3) and copper chloride (CuCl2), introduces metal nanoparticles onto the AC surface, which can catalyze the oxidation of organic pollutants and enhance overall pollutant removal efficiency [51, 52]. Similarly, polymeric impregnation involves the deposition of polymer precursors onto the AC surface, leading to the formation of polymer coatings that can enhance the surface area and porosity of AC, thereby increasing its adsorption capacity for heavy metal ions. Chemical modification methods offer versatile approaches to tailor the surface chemistry of activated carbon, thereby enhancing its adsorption affinity for heavy metal ions. By selectively introducing functional groups onto the AC surface, these methods enable precise control over the adsorption properties of AC, making it an effective adsorbent for heavy metal removal from aqueous solutions.

Biological Modification

Biological modification methods involve the utilization of microorganisms to enhance the adsorption properties of activated carbon for heavy metal ions. These methods leverage the metabolic activities of microorganisms to promote pollutant oxidation and biodegradation, thereby improving the overall pollutant removal efficiency of AC.

Microbial Immobilization

Microbial immobilization techniques entail the entrapment or attachment of microorganisms onto the surface of activated carbon particles. This immobilization process can be achieved through physical adsorption, covalent bonding, or encapsulation within polymeric matrices. Once immobilized, the microorganisms colonize the AC surface and form biofilms, which are structured communities of microorganisms embedded within an extracellular matrix [53, 54].

Biofilm Formation

Biofilm formation plays a crucial role in enhancing the pollutant removal efficiency of activated carbon. The biofilm matrix provides a protective environment for microorganisms, allowing them to thrive and metabolize pollutants effectively. Within the biofilm, microorganisms undergo metabolic processes such as pollutant oxidation, reduction, and biodegradation, leading to the transformation of toxic pollutants into less harmful byproducts [53, 54].

Enhanced Pollutant Degradation

Microorganisms immobilized on activated carbon surfaces possess enzymatic capabilities that facilitate the degradation of organic pollutants and the transformation of heavy metal ions. These enzymatic activities include oxidoreductases, hydrolases, and dehalogenases, which catalyze pollutant oxidation reactions and promote the biodegradation of complex organic compounds. Additionally, microbial metabolism can promote the precipitation or sequestration of heavy metal ions through biomineralization processes, further enhancing pollutant removal efficiency [53, 54].

Synergistic Effects

Biological modification of activated carbon can lead to synergistic effects between microorganisms and the adsorbent material. The presence of microorganisms on the AC surface can enhance the adsorption capacity of AC by providing additional binding sites for heavy metal ions. Furthermore, microbial metabolism can regenerate spent activated carbon by desorbing adsorbed pollutants and promoting the biodegradation of organic contaminants [54].

Biologically modified activated carbon has shown promising applications in wastewater treatment, particularly in the removal of heavy metal ions and organic pollutants. Biofilters incorporating activated carbon as a support matrix for microbial growth have demonstrated high pollutant removal efficiencies in various wastewater treatment applications, including industrial effluent treatment and decentralized water treatment systems [55]. Biological modification methods offer innovative approaches to enhance the adsorption properties of activated carbon for heavy metal removal. By leveraging the metabolic activities of microorganisms, these methods can improve the overall pollutant removal efficiency of activated carbon and expand its applicability in wastewater treatment [56].

Magnetization of Activated Carbon

In exploring the advancements in water purification technologies, the magnetization of AC stands out as a transformative approach, particularly with the incorporation of magnetic (Fe3O4) adsorbents. This method has garnered considerable attention for its innovative use in enhancing the efficacy and efficiency of water purification processes [57]. The principal allure of magnetic AC lies in its operational simplicity and the regeneration capability it offers post-adsorption. The use of an external magnetic field for separation means that the process of isolating, washing, and dispersing the sample becomes straightforward. This method not only streamlines the purification process but also introduces a level of reliability and effectiveness that is hard to achieve with traditional non-magnetic AC [57]. Magnetic separation using an external field, often through a magnetic separator, revolutionizes the way materials are isolated from treated water. This technology sidesteps the limitations typically encountered with non-magnetic AC, such as the need for filtration or centrifugation, which can be time-consuming and costly. Moreover, the issue of secondary turbidity arising from incomplete isolation of non-magnetic AC is effectively mitigated with magnetic AC, presenting a clear advantage in maintaining water clarity and quality. However, the integration of magnetite (Fe3O4) or similar nanoparticles into AC is not without its challenges. Research indicates that the presence of these iron-based nanoparticles can lead to the blockage of sorbent pores, potentially decreasing the specific surface area (SSA) available for adsorption. This occupancy of sorption sites by magnetic particles could theoretically reduce the efficiency of the AC [58]. Yet, paradoxically, the introduction of magnetic nanoparticles has also been shown to create new adsorption sites, thereby increasing the overall surface area available for purification processes. This duality suggests that while there may be some initial reduction in SSA, the net effect of magnetization can enhance the adsorption capacity of AC. Given these characteristics, the appeal of magnetic AC extends beyond its practical benefits to include potential improvements in wastewater treatment applications. The balance between the drawbacks and benefits indicates a promising future for magnetic AC in environmental management and industrial applications. The efficiency of magnetic AC in adsorbing pollutants, coupled with the ease of its recovery and reuse, presents a compelling case for its adoption in comprehensive wastewater treatment strategies [59]. As the research community continues to explore and refine the application of magnetic AC, the integration of this technology in industrial settings seems increasingly feasible. The unique properties of magnetic AC, as highlighted in Table 3, underscore its potential to revolutionize wastewater treatment facilities, offering a more efficient, cost-effective, and environmentally friendly solution to water purification challenges.

Activated Carbon Implementation

The threat posed by heavy metals in water sources is a growing concern, given their persistence and bioaccumulation tendencies. Industrial activities persistently release these toxicants into the environment, posing significant risks to both ecological and human health. Activated carbon (AC), with its high surface area and porosity, emerges as a critical player in addressing this issue. Exploration the mechanisms, enhancements, and real-world applications of AC in the removal of heavy metals, highlighting recent advances and the potential for scalable solutions, could be discussed as follows:

Heavy Metal Pollution

Heavy metals, such as lead, mercury, arsenic, and cadmium, find their way into water bodies from various industrial processes. Once in the environment, they can migrate across ecosystems and enter human bodies, where they pose severe health risks. The complexity of heavy metal ions, existing in different states influenced by environmental pH, organic matter, and oxygen levels, complicates their removal. Activated carbon’s versatility in adsorbing these ions makes it an invaluable tool in environmental remediation efforts. Heavy metals enter water sources through multiple pathways, including industrial discharge, agricultural runoff, and atmospheric deposition. Industrial processes such as mining and metal plating contribute substantial amounts of heavy metals to water bodies, often in the form of dissolved ions or particulate matter. Agricultural activities involving the use of fertilizers and pesticides can also lead to metal contamination of water sources through runoff and leaching [60, 61]. Additionally, atmospheric deposition of heavy metals from industrial emissions and vehicular exhaust further exacerbates the problem, particularly in urban areas. The presence of heavy metals in water bodies can have severe environmental and health consequences. These metals are toxic to aquatic organisms, causing detrimental effects on aquatic ecosystems and biodiversity. Bioaccumulation of heavy metals in aquatic organisms can lead to biomagnification up the food chain, posing risks to human consumers who rely on fish and shellfish as dietary staples. From a human health perspective, exposure to heavy metals, even at low concentrations, can result in a range of adverse effects. Chronic exposure to metals such as lead and mercury has been linked to neurological disorders, developmental delays in children, and cardiovascular diseases. Arsenic contamination in drinking water is a significant concern in many regions, with long-term exposure increasing the risk of cancer and other serious health conditions [62].

Challenges in Remediation

Remediating heavy metal contamination in water sources presents significant challenges due to the persistence and complex behavior of these pollutants. Conventional treatment methods, such as precipitation, coagulation, and filtration, are often ineffective or impractical for removing heavy metals at low concentrations or in complex matrices. Activated carbon (AC) emerges as a promising solution for heavy metal removal due to its high surface area, porosity, and adsorption capacity. By adsorbing heavy metal ions onto its surface, AC can effectively reduce metal concentrations in water, mitigating the environmental and health risks associated with heavy metal contamination [63]. Understanding the sources, pathways, and impacts of heavy metal pollution is essential for developing effective remediation strategies. As a versatile adsorbent, activated carbon plays a crucial role in addressing heavy metal contamination in water sources, offering a sustainable and efficient solution to this pressing environmental challenge. Continued research and innovation in AC technology holds promise for advancing heavy metal remediation efforts and safeguarding water quality for future generations [60,61,62, 64].

Mechanisms and Factors Influencing Heavy Metal Adsorption

pH-Dependent Mechanisms

The adsorption capacity of AC is significantly influenced by the pH of the aqueous solution, with acidic conditions generally enhancing metal ion capture. This enhancement is attributed to the increased availability of adsorption sites and the electrostatic attraction between the positively charged metal ions and the negatively charged surface of the AC. Studies have shown varied adsorption efficacies across different pH levels, indicating the need for pH optimization in treatment processes [61, 62].

Surface Modification for Enhanced Performance

Advancements in surface chemistry have led to the development of modified ACs with improved adsorptive properties. By integrating functional groups or nanoparticles, such as magnetite (Fe3O4) or zirconium oxide (ZrO2), into the AC structure, researchers have significantly increased its affinity for specific heavy metals. These modifications not only enhance the adsorption capacity but also introduce selectivity towards certain pollutants, offering a tailored approach to water treatment [64, 65].

Innovations in Activated Carbon Technology

The incorporation of nanotechnology into AC structures represents a leap forward in adsorption technology. Magnetite nanoparticles, for instance, provide a dual function of enhancing adsorption through increased surface area and facilitating easy separation from the treated water through magnetic retrieval. This innovation extends the applicability of AC to more complex treatment scenarios, where efficiency and ease of recovery are paramount [64]. Developing composite materials, such as those combining AC with chitosan or specific metal oxides, has opened new avenues for the selective removal of heavy metals. These composites leverage the unique properties of their constituent materials, such as the biocompatibility of chitosan and the adsorptive power of AC, to create synergistic effects in heavy metal removal. Such composites have shown remarkable efficacy and recyclability, indicating their potential for long-term use in industrial applications [64,65,66]. The practical application of these advanced AC materials in real-world scenarios underscores their potential to revolutionize water treatment processes. Pilot studies and industrial-scale implementations have demonstrated the effectiveness of modified AC in removing heavy metals from wastewater, offering a viable solution to a pressing environmental challenge. The scalability of these technologies, coupled with their operational efficiencies, positions them as frontrunners in the quest for sustainable water treatment methodologies. The advancements in activated carbon technology, particularly through nanotechnology and chemical modification, have significantly broadened its applicability in environmental remediation, especially for heavy metal removal. These innovations not only enhance the intrinsic adsorptive properties of AC but also introduce new functionalities, making it a versatile and powerful tool in water treatment processes. As research progresses, the potential for AC in providing scalable, efficient, and sustainable solutions to heavy metal pollution becomes increasingly tangible, offering hope for the preservation of water quality and public health.

Exploring Adsorption Techniques for Environmental Remediation

Various practical methods used to address heavy metal pollution have been explored through adsorption techniques, highlighting effective strategies for environmental remediation. Adsorption serves as a fundamental and efficient method for removing both organic and inorganic contaminants from liquid solutions, particularly at low concentrations. Defined as a surface phenomenon, adsorption involves the concentration of chemical compounds at the surface of a solid material through mass transfer processes. The efficacy of adsorption hinges on the interaction between the sorbent material and the sorbate, with the physical form and chemical composition of the sorbent being pivotal determinants of overall adsorption performance [67]. Within the paradox of adsorption mechanisms, various approaches have been elucidated to understand and optimize contaminant removal processes. These mechanisms encompass a spectrum of interactions, each contributing to the overall efficacy of adsorption.

Physical Adsorption

Physical adsorption, also known as physisorption, involves the non-specific attraction of molecules or ions to the surface of the adsorbent material. This mechanism occurs due to van der Waals forces between the adsorbate and the adsorbent surface. In the context of heavy metal removal, the adsorbate molecules or ions are physically trapped within the micropores and mesopores of the adsorbent material. The extent of physical adsorption depends on factors such as the surface area, pore size distribution, and surface chemistry of the adsorbent. Materials with high surface area and abundant micropores, such as activated carbon, exhibit enhanced physical adsorption capacity. The process is influenced by parameters like temperature, pressure, and the concentration of the adsorbate in the solution. Physical adsorption is reversible, and desorption can occur under suitable conditions, making it suitable for regeneration and reuse of the adsorbent [68].

Electrostatic Interactions

Electrostatic interactions play a crucial role in the adsorption of charged species onto solid surfaces. In the case of heavy metal ions, which often carry positive charges, electrostatic attraction occurs between these ions and the charged sites on the surface of the adsorbent material. The surface charge of the adsorbent can be influenced by pH, with pH-dependent charging affecting the distribution of charges on the surface. At the point of zero charge (pHZC), the surface charge of the adsorbent is neutral, and electrostatic interactions are minimal. However, deviations from the pHZC result in surface charging, leading to electrostatic attraction or repulsion between the adsorbent and the metal ions in the solution. This mechanism is particularly relevant for materials with functional groups capable of ion exchange or surface complexation reactions, such as activated carbon modified with specific moieties [69].

Ion Exchange

Ion exchange involves the replacement of ions adsorbed onto the surface of the adsorbent with ions from the solution phase. In the context of heavy metal removal, functional groups present on the surface of the adsorbent material, such as carboxyl (–COOH) and hydroxyl (–OH) groups, serve as exchange sites for metal ions. The selectivity and efficiency of ion exchange depend on factors such as the concentration and nature of the competing ions in the solution, the pH of the solution, and the affinity of the metal ions for the exchange sites. The process follows principles akin to those observed in traditional ion exchange resins, with metal ions adsorbed onto the adsorbent surface being displaced by ions present in the solution phase [69, 70].

Surface Complexation

Surface complexation involves the formation of chemical complexes between metal ions in solution and functional groups present on the surface of the adsorbent material. The interaction occurs through coordination chemistry, with Lewis acid–base interactions playing a crucial role. Functional groups such as hydroxyl (–OH), carboxyl (–COOH), and amino (–NH2) groups act as ligands, binding metal ions through coordination bonds. The formation of surface complexes depends on factors such as the nature and density of functional groups, the concentration of metal ions in solution, and the pH of the solution. Surface complexation reactions are reversible, and the stability of the formed complexes determines the efficacy of heavy metal removal [69, 70].

Coprecipitation/Precipitation

Coprecipitation and precipitation involve the incorporation or removal of metal ions from solution through the formation of insoluble precipitates. In coprecipitation, metal ions are incorporated into the solid phase during the precipitation of a sparingly soluble compound. Precipitation, on the other hand, entails the formation of insoluble metal hydroxides, oxides, or sulfides due to changes in solution conditions such as pH, temperature, or addition of precipitating agents. The formed precipitates can adsorb onto the surface of the adsorbent material or settle out of solution, leading to the removal of metal ions from the aqueous phase. Coprecipitation and precipitation mechanisms are particularly effective for removing metal ions present at low concentrations or as trace contaminants in solution. Figure 2 illustrates the coprecipitation/precipitation mechanism along with other adsorption ways, highlighting the formation of insoluble metal complexes on the adsorbent surface [22].

Understanding the mechanisms and factors influencing heavy metal adsorption is paramount for devising effective strategies to mitigate environmental pollution. Heavy metals, pervasive in industrial effluents, pose significant threats to ecological balance and human health due to their inherent toxicity, even at minimal concentrations (Table 4). These contaminants exhibit diverse chemical forms in water, influenced by intricate environmental variables such as pH, dissolved oxygen levels, and organic matter content [46, 59, 60]. Given the imperative to curb their deleterious impacts, substantial research endeavors have been dedicated to elucidating adsorption processes, with activated carbon (AC) emerging as a beacon of hope in this modality. The preceding discussion underscores the critical role of pH in heavy metal adsorption onto AC, where acidic conditions typically facilitate enhanced adsorption owing to favorable electrostatic interactions. Expanding upon this fundamental understanding, recent investigations have ventured into innovative approaches aimed at augmenting AC’s adsorptive prowess, leveraging breakthroughs in surface modification and nanotechnology integration. By incorporating advanced materials like magnetite (Fe3O4) nanoparticles and chitosan into AC matrices, researchers have achieved remarkable enhancements in heavy metal removal efficiency. These composite structures exhibit bespoke adsorption capabilities, characterized by favorable kinetics and recyclability, thereby positioning them as promising candidates for real-world applications [64]. Furthermore, activities exploring the modification of AC with zirconium oxide to enhance cadmium (II) adsorption, and the development of AC doped with iron and zirconium sourced from Tectona grandis sawdust for arsenic (III) removal, serve as poignant examples of the strides made in environmental remediation. These pioneering advancements not only expand the utility of AC but also underscore its potential as a sustainable solution for combating heavy metal pollution across diverse industrial landscapes [65, 66]. Illustrative of one example of these advancements, Fig. 3 depicts the adsorption of As(III) onto Fe@AC and Fe-Zr@AC via a possible method, highlighting the efficacy of modified AC in heavy metal removal processes. Thus, by unraveling the intricate mechanisms underpinning heavy metal adsorption and harnessing cutting-edge technologies and materials, AC provides a solution in the efforts that aim at preserving environmental integrity and conserving public health. It could be seen as a potential tool in the ongoing struggle against the scourge of heavy metal pollution, offering a ray of optimism for a cleaner and healthier future.

Each of these mechanisms offers unique advantages and challenges for the removal of heavy metal contaminants from aqueous solutions. Realizing these mechanisms is essential for the design and optimization of adsorption processes tailored to specific environmental remediation needs.

Critical Analysis of AC Applications in Wastewater Treatment by Performed Case Studies

Numerous case studies have investigated AC for its effectiveness in treating wastewater, especially in dye removal. In this section, we will briefly summarize three case studies which focused on the capacity of AC and delivering unique insights into its application and efficiency.

Dye Removal Case Studies

-

Streit et al. (2019): Worked on the removal of dyes using high-quality activated carbon developed from biological sludge. Streit et al. found that AC could effectively remove various dyes from aqueous solutions, achieving high removal efficiencies. They reported that the adsorption capacity of the AC for dyes was of a big significance, with maximum removal rates up to 95%. However, they also noted that the effectiveness varied depending on the type of dye and the specific properties of the AC used. The work concluded that AC derived from biological sludge is a promising material for dye removal, but its performance can be influenced by the initial dye concentration and the presence of competing substances in the wastewater [2].

-

Saratale et al. (2016): In that research work, the authors prepared activated carbons from peach stones using H4P2O7 and applied them for the removal of Acid Red dye. The produced AC showed high adsorption capacity for the dye, with removal efficiencies exceeding 90%. The study highlighted the importance of activation methods and surface modification in the enhancing course of AC adsorption performance. The authors observed how the porosity and surface area of the AC were critical and could be limiting factors that influenced the dye removal efficiency. Finally, the study highlighted the economic viability of using agricultural waste materials for AC production, making it a sustainable and cost-effective option for wastewater treatment [15].

-

Aljeboree et al. (2017): In their research study, they have investigated the adsorption capacities of textile dyes on coconut shell activated carbon. The work reported that AC was highly effective in removing dyes from aqueous solutions, with removal efficiencies ranging from 85 to 98% depending on the dye and specific experimental conditions. The study emphasized the role of surface area and pore structure in the adsorption process, noting that the AC’s high surface area contributed to its high adsorption capacity. The researchers also pointed out that the adsorption process followed a pseudo-second-order kinetic model, indicating chemisorption as the dominant mechanism in the dye removal [10].

AC capabilities in water treatment have been reported as we have mentioned by many research groups through different case studies. As any other tool, it has its own advantages and disadvantages. The pros of AC usage in water treatment could be mainly due to its wide versatility and high adsorption capacity via the high surface area and well-developed porosity, which provides numerous active sites for the adsorption of wide range of contaminants that include organic compounds, dyes, and heavy metals. AC can be seen as a sustainable and environment friendly option since it can be produced from renewable and agricultural wastes material. Yet, its cons lies on the relatively high cost of producing and regenerating high-quality activated carbon and this could be a major limitation for their usage. Also, in real situation of waste water treatment, natural organic materials may compete with the target pollutants for the adsorption on AC which affects its efficacy. Nevertheless, the efficiency of AC relies on the production characteristics, operations conditions, and pollutant type rendering some complexity in the optimization procedures for certain AC applications.

Conclusion and Future Prospects

The utilization of adsorption technology in wastewater treatment is gaining momentum, driven by the remarkable attributes of activated carbon (AC) such as its high surface-area-to-volume ratio, cost-effectiveness, efficiency, environmental friendliness, and ease of synthesis from abundant waste materials. However, despite these advantages, there is a scarcity of literature on AC synthesis from non-biodegradable waste sources due to constraints such as excessive cross-linking, impermeable structural compositions, costly treatments, and challenges in downstream processing. Additionally, the regenerability of AC poses hurdles to its widespread pilot and commercial applications. Efforts have been made to address these limitations through research on AC magnetization, which enhances its recyclability, reduces waste generation, and improves its economic viability. Concerns have been raised regarding the potential pore-blocking effects of iron nanoparticles, but strategies involving pre-treatment with magnetization agents may mitigate this issue. The chemical composition of the target contaminant influences AC activation and modification, with surface functionalization using acidic compounds like –COOH and –CO showing promise in enhancing electrostatic interactions with adsorbates. However, there is a need for caution as excessive functionalization can lead to site blockage or electrostatic repulsion.

Challenges remain in scaling up AC applications due to concerns related to durability, efficacy, and affordability. Moreover, much of the research has focused on synthetic wastewater systems rather than real-world water matrices. The exploration of advanced nanomaterials, including modified activated carbon with diverse functional groups, holds promise for addressing these challenges and enhancing pollutant removal efficiency. Future research should focus on developing simpler and more efficient methods for AC synthesis and exploring innovative approaches to overcome existing limitations in adsorption technology, as well as improving the cost-effectiveness and scalability of AC production from sustainable materials, and conducting comprehensive studies on its performance in real-world scenarios.

In addition to technological advancements, interdisciplinary collaboration and knowledge exchange between academia, industry, and policymakers will be crucial in driving the adoption of adsorption technology in wastewater treatment. Public–private partnerships and funding initiatives can facilitate the translation of research findings into practical solutions, ultimately contributing to the development of sustainable and cost-effective strategies for water quality management.

Data Availability

No datasets were generated or analysed during the current study.

References

Rahimpour M, Taghvaei H, Zafarnak S, Rahimpour MR, Raeissi S (2019) Post-discharge DBD plasma treatment for degradation of organic dye in water: a comparison with different plasma operation methods. J Environ Chem Eng 7:103220

Streit AF, Côrtes LN, Druzian SP, Godinho M, Collazzo GC, Perondi D, Dotto GL (2019) Development of high quality activated carbon from biological sludge and its application for dyes removal from aqueous solutions. Sci Total Environ 660:277–87

Fan X, Ding S, Chen M, Gao S, Fu Z, Gong M, Tsang DC, Wang Y, Zhang C (2019) Peak chromium pollution in summer and winter caused by high mobility of chromium in sediment of a Eutrophic Lake: in situ evidence from high spatiotemporal sampling. Environ Sci Technol. 53:4755–4764

Mydin, N.M., Mubarak, N., Nizamuddin, S., Siddiqui, M., Baloch, H.A., Abdullah, E., Khalid, M., 2019. Multiwall carbon nanotube promising route for removal of chromium from wastewater via batch column mechanism, IOP Conference Series: Materials Science and Engineering. IOP Publishing, p. 012061.

Jaiswal, A., Verma, A., Jaiswal, P.P., Toxicology, Oncology, 2018. Detrimental effects of heavy metals in soil, plants, and aquatic ecosystems and in humans. 37.

Pandey, G., Madhuri, S.A., Veterinary, Sciences, F., 2014. Heavy metals causing toxicity in animals and fishes. 2, 17–23.

Sweetman, M., May, S., Mebberson, N., Pendleton, P., Vasilev, K., Plush, S., Hayball, J., 2017. Activated carbon, carbon nanotubes and graphene: materials and composites for advanced water purification. C 3, 18.

Bharagava RN, Mishra S (2018) Hexavalent chromium reduction potential of Cellulosimicrobium sp. isolated from common effluent treatment plant of tannery industries. Ecotoxicol. Environ. Saf. 147:102–109

Sepehri, A., Sarrafzadeh, M.E., Intensification, P.-P., 2018. Effect of nitrifiers community on fouling mitigation and nitrification efficiency in a membrane bioreactor. 128, 10–18

Aljeboree AM, Alshirifi AN, Alkaim AF (2017) Kinetics and equilibrium study for the adsorption of textile dyes on coconut shell activated carbon. Arab J Chem 10:S3381–S3393

Gul A, Khaligh NG, Julkapli NM (2021) Surface modification of carbon-based nanoadsorbents for the advanced wastewater treatment. J Mol Struct 1235:130148

Hoslett J, Ghazal H, Ahmad D, Jouhara H (2019) Removal of copper ions from aqueous solution using low temperature biochar derived from the pyrolysis of municipal solid waste. Sci Total Environ 673:777–789

Özsin G, Kılıç M, Apaydın-Varol E, Pütün AE (2019) Chemically activated carbon production from agricultural waste of chickpea and its application for heavy metal adsorption: equilibrium, kinetic, and thermodynamic studies. Appl Water Sci 9:56

Rai M, Shahi G, Meena V, Meena R, Chakraborty S, Singh R, Rai B (2016) Removal of hexavalent chromium Cr (VI) using activated carbon prepared from mango kernel activated with H3PO4. Resour Effic Technol 2:S63–S70

Saratale RG, Sivapathan SS, Jung WJ, Kim HY, Saratale GD, Kim DS (2016) Preparation of activated carbons from peach stone by H4P2O7 activation and its application for the removal of Acid Red 18 and dye containing wastewater. J Environ Sci Health Part A 51:164–177

Silva-Medeiros FV, Consolin-Filho N, Xavier de Lima M, Bazzo FP, Barros MAS, Bergamasco R, Tavares CR (2016) Kinetics and thermodynamics studies of silver ions adsorption onto coconut shell activated carbon. Environ Technol 37:3087–3093

Hamad HN, Idrus S (2022) Recent developments in the application of bio-waste-derived adsorbents for the removal of methylene blue from wastewater: a review. Polymers 14:783

Demirbas A (2009) Agricultural based activated carbons for the removal of dyes from aqueous solutions: a review. J Hazard Mater 167:1–9

González-García P (2018) Activated carbon from lignocellulosics precursors: a review of the synthesis methods, characterization techniques and applications. Renew Sustain Energy Rev 82:1393–1414

Shafeeyan MS, Daud WW, Houshmand A, Shamiri AA (2010) A review on surface modification of activated carbon for carbon dioxide adsorption. J Anal Appl Pyrol 89:143–151

Sultana, M., Rownok, M.H., Sabrin, M., Rahaman, M.H., Alam, S.E., 2022. Technology A review on experimental chemically modified activated carbon to enhance dye and heavy metals adsorption. 6, 100382.

Okpara, O.G., Ogbeide, O.M., Nworu, J.N., Chukwuekeh, J.I., Igoche, S.A., Alichi, F.S. and Orinya, O.E. Enhanced removal of Pb(II), Cd(II), and Zn(II) ions from aqueous solutions using EDTA-synthesized activated carbon derived from sawdust. Open Access Library Journal, 10, 1–15.

Ioannidou O, Zabaniotou A (2007) Agricultural residues as precursors for activated carbon production—a review. Renew Sustain Energy Rev 11:1966–2005

Ali I, Asim M, Khan TA (2012) Low cost adsorbents for the removal of organic pollutants from wastewater. J Environ Manage 113:170–83

Foo, K., Hameed, B.J., Coconut husk derived activated carbon via microwave induced activation: effects of activation agents, preparation parameters and adsorption performance. 184, 57–65.

Periyasamy, S., Kumar, I.A., Viswanathan, N., 2020. Activated carbon from different waste materials for the removal of toxic metals. Green Materials for Wastewater Treatment. Springer, pp. 47–68.

Foo KY, Hameed BH (2012) Coconut husk derived activated carbon via microwave induced activation: effects of activation agents, preparation parameters and adsorption performance. Chem Eng J. 184:57–65

Zhao, Y., Fang, F., Xiao, H.-M., Feng, Q.-P., Xiong, L.-Y., Fu, S., 2015. Preparation of pore-size controllable activated carbon fibers from bamboo fibers with superior performance for xenon storage. 270, 528–534.

Czajczyńska D, Anguilano L, Ghazal H, Krzyżyńska R, Reynolds AJ, Spencer N, Jouhara H (2017) Potential of pyrolysis processes in the waste management sector. Therma Sci Eng Prog 3:171–97

Din MI, Ashraf S, Intisar A (2017) Comparative study of different activation treatments for the preparation of activated carbon: a mini-review. Sci Prog 100:299–312

Bazan-Wozniak A, Nowicki P, Pietrzak R (2021) Removal of NO2 from gas stream by activated bio-carbons from physical activation of residue of supercritical extraction of hops. Chem Eng Res Des 166:67–73

Mai NT, Nguyen MN, Tsubota T, Nguyen PL, Nguyen NH (2021) Evolution of physico-chemical properties of Dicranopteris linearis-derived activated carbon under various physical activation atmospheres. Sci Rep 11:14430

Abbas Q, Mirzaeian M, Ogwu AA, Mazur M, Gibson D (2020) Effect of physical activation/surface functional groups on wettability and electrochemical performance of carbon/activated carbon aerogels based electrode materials for electrochemical capacitors. Int J Hydrogen Energy. 45:13586–95

Adan-Mas A, Alcaraz L, Arévalo-Cid P, López-Gómez FA, Montemor F (2021) Coffee-derived activated carbon from second biowaste for supercapacitor applications. Waste Management. 120:280–9

Jiang C, Yakaboylu GA, Yumak T, Zondlo JW, Sabolsky EM, Wang J (2020) Activated carbons prepared by indirect and direct CO2 activation of lignocellulosic biomass for supercapacitor electrodes. Renew Energy. 155:38–52

Hagemann N, Schmidt HP, Kägi R, Böhler M, Sigmund G, Maccagnan A, McArdell CS, Bucheli TD (2020) Wood-based activated biochar to eliminate organic micropollutants from biologically treated wastewater. Sci Total Environ 730:138417

Attia NF, Jung M, Park J, Jang H, Lee K, Oh H (2020) Flexible nanoporous activated carbon cloth for achieving high H2, CH4, and CO2 storage capacities and selective CO2/CH4 separation. Chem Eng J 379:122367

Pena J, Villot A, Gerente C (2020) Pyrolysis chars and physically activated carbons prepared from buckwheat husks for catalytic purification of syngas. Biomass Bioenergy 132:105435

Yahya MA, Al-Qodah Z, Ngah CZ (2015) Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Ren Sustain Energy Rev 46:218–35

Wei H, Wang H, Li A, Li H, Cui D, Dong M, Lin J, Fan J, Zhang J, Hou H, Shi Y (2020) advanced porous hierarchical activated carbon derived from agricultural wastes toward high performance supercapacitors. J Alloys Compd 820:153111

Baig MM, Gul IH (2021) Conversion of wheat husk to high surface area activated carbon for energy storage in high-performance supercapacitors. Biomass and Bioenergy 144:105909

Jain D, Kanungo J, Tripathi SK (2020) Enhancement in performance of supercapacitor using eucalyptus leaves derived activated carbon electrode with CH3COONa and HQ electrolytes: a step towards environment benign supercapacitor. J Alloys Compd. 832:154956

Pandey, L., Sarkar, S., Arya, A., Sharma, A., Panwar, A., Kotnala, R., Gaur, A.C., 2021. Biorefinery Fabrication of activated carbon electrodes derived from peanut shell for high-performance supercapacitors. 1–10.

Hu SC, Cheng J, Wang WP, Sun GT, Hu LL, Zhu MQ, Huang XH (2021) Structural changes and electrochemical properties of lacquer wood activated carbon prepared by phosphoric acid-chemical activation for supercapacitor applications. Renew Energy 177:82–94

Mitravinda T, Anandan S, Sharma CS, Rao TS (2021) Design and development of honeycomb structured nitrogen-rich cork derived nanoporous activated carbon for high-performance supercapacitors. J Energy Storage 34:102017

Kinoshita, K., 1988. Carbon: electrochemical and physicochemical properties. Lakherwal, D., Development, 2014. Adsorption of heavy metals: a review. 4, 41–48

Ania CO, Parra JB, Menéndez JA, Pis JJ (2005) Effect of microwave and conventional regeneration on the microporous and mesoporous network and on the adsorptive capacity of activated carbons. Micropor Mesopor Mat 85:7–15

Dehdashti, A., Khavanin, A., Rezaee, A., Assilian, H., Motalebi, M., Application of microwave irradiation for the treatment of adsorbed volatile organic compounds on granular activated carbon.

Wu, S., Chen, J.P., 2001. Modification of a commercial activated carbon for metal adsorption by several approaches, Proceedings of the 2001 International Containment & Remediation Technology Conference and Exhibition. Citeseer, p. 13.

Shen, W., Li, Z., Liu, Y.E., 2008. Surface chemical functional groups modification of porous carbon. 1, 27–40.

Adhoum N, Monser L (2004) Removal of phthalate on modified activated carbon: application to the treatment of industrial wastewater. Sep Purif Technol 38(3):233–9

Monser L, Adhoum N (2002) Modified activated carbon for the removal of copper, zinc, chromium and cyanide from wastewater. Sep Purif Technol 26:137–46

Wilcox DP, Chang E, Dickson KL, Johansson KR (1983) Microbial growth associated with granular activated carbon in a pilot water treatment facility. Appl Environ Microbiol. 46:406–16

Srivastava A, Gupta B, Majumder A, Gupta AK, Nimbhorkar SK (2021) A comprehensive review on the synthesis, performance, modifications, and regeneration of activated carbon for the adsorptive removal of various water pollutants. J Environ Chem Eng. 9:106177

Sharaf A, Liu Y (2021) Mechanisms and kinetics of greywater treatment using biologically active granular activated carbon. Chemosphere 263:128113

Bhatnagar A, Hogland W, Marques M, Sillanpää M (2013) An overview of the modification methods of activated carbon for its water treatment applications. Chem Eng J 219:499–511

Moosavi S, Lai CW, Gan S, Zamiri G, Akbarzadeh Pivehzhani O, Johan MR (2020) Application of efficient magnetic particles and activated carbon for dye removal from wastewater. ACS omega 5:20684–97

Rocha LS, Pereira D, Sousa É, Otero M, Esteves VI, Calisto V (2020) Recent advances on the development and application of magnetic activated carbon and char for the removal of pharmaceutical compounds from waters: a review. Sci Total Environ 718:137272

Dai, S.P., Beijing, China, Environmental chemistry.

Zhu Y, Fan W, Zhou T, Li X (2019) Removal of chelated heavy metals from aqueous solution: a review of current methods and mechanisms. Sci Total Environ 678:253–266

Dai Y, Wang W, Lu L, Yan L, Yu D (2020) Utilization of biochar for the removal of nitrogen and phosphorus. J Clean Prod 257

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) A review of potentially low-cost sorbents for heavy metals. Water Res 33:2469–79

Ghorbani M, Seyedin O, Aghamohammadhassan M (2020) Adsorptive removal of lead (II) ion from water and wastewater media using carbon-based nanomaterials as unique sorbents: a review. J Environ Manag 254:109814

Bahador F, Foroutan R, Esmaeili H, Ramavandi B (2021) Enhancement of the chromium removal behavior of Moringa oleifera activated carbon by chitosan and iron oxide nanoparticles from water. Carbohydr Polym. 251:117085

Sharma G, Naushad M (2020) Adsorptive removal of noxious cadmium ions from aqueous medium using activated carbon/zirconium oxide composite: Isotherm and kinetic modelling. J Mol Liq 310:113025

Sahu N, Singh J, Koduru JR (2021) Removal of arsenic from aqueous solution by novel iron and iron–zirconium modified activated carbon derived from chemical carbonization of Tectona grandis sawdust: isotherm, kinetic, thermodynamic and breakthrough curve modelling. Environ Res 200:111431

Dai Y, Zhang N, Xing C, Cui Q, Sun Q (2019) The adsorption, regeneration and engineering applications of biochar for removal organic pollutants: a review. Chemosphere. 223:12–27

Yang X, Wan Y, Zheng Y, He F, Yu Z, Huang J, Wang H, Ok YS, Jiang Y, Gao B (2019) Surface functional groups of carbon-based adsorbents and their roles in the removal of heavy metals from aqueous solutions: a critical review. Chem Eng J 366:608–21

Duan C, Ma T, Wang J, Zhou Y (2020) Removal of heavy metals from aqueous solution using carbon-based adsorbents: A review. Journal Water Process Eng 37:101339

Li H, Dong X, da Silva EB, de Oliveira LM, Chen Y, Ma LC (2017) Mechanisms of metal sorption by biochars: biochar characteristics and modifications. Chemosphere 178:466–478

Genchi G, Carocci A, Lauria G, Sinicropi MS, Catalano A (2020) Nickel: human health and environmental toxicology. Int J Environ Res Public Health. 17:679

Zulaikhah ST, Wahyuwibowo J, Pratama AA (2020) Mercury and its effect on human health: a review of the literature. Int J Public Health Sci 9:103–14

Rajput V, Minkina T, Sushkova S, Behal A, Maksimov A, Blicharska E, Ghazaryan K, Movsesyan H, Barsova N (2020) ZnO and CuO nanoparticles: a threat to soil organisms, plants, and human health. Environ Geochem Health. 42:147–58

Moreno-Rodríguez V, Del Rio-Salas R, Loredo-Portales R, Briseño-Beltrán A, Romo-Morales D, Zepeda J, Peña-Ortega M, Espinoza-Maldonado IG, del la O-Villanuevade la O-Villanueva M MM (2020) Abandoned agricultural lands as a source of arsenic in semi-arid regions: influence on human exposure and health risk assessment in vulnerable rural areas. J South Am Earth Sci 104:102829

Fu Z, Xi S (2020) The effects of heavy metals on human metabolism. Methods 30:167–176

Andjelkovic M, Buha Djordjevic A, Antonijevic E, Antonijevic B, Stanic M, Kotur-Stevuljevic J, Spasojevic-Kalimanovska V, Jovanovic M, Boricic N, Wallace D, Bulat Z (2019) Toxic effect of acute cadmium and lead exposure in rat blood, liver, and kidney. Int J Environ Res Public Health. 16:274

Manoj S, RamyaPriya R, Elango L (2021) Long-term exposure to chromium contaminated waters and the associated human health risk in a highly contaminated industrialised region. Environ Sci Pollut Res. 28:4276–88

Acknowledgements

The authors are thankful to the Deanship of Graduate studies and scientific research at University of Bisha for supporting this work through the Fast-Track research support program.

Funding

The APC is paid by the Faculty of Bioengineering of Animal Resources, University of Life Science”King Mihai I” Timisoara, Romania.

Author information

Authors and Affiliations

Contributions

Author Contributions: Conceptualization, I.P., M.S., M.F., and M.E.; methodology, A.E., M.S.A., and A.I.; software, I.P., M.S., M.F., and M.E.; validation, I.P., M.S., M.F., M.E., A.E.; formal analysis, I.P., M.S., M.F., M.E., A.E., and M.S.A.; investigation, I.P., M.S., M.F., M.E., A.E., M.S.A., and A.I.; resources, M.S., M.F., and M.E.; data curation, I.P., M.S., M.F., and M.E.; writ-ing—original draft preparation, I.P., M.S., M.F., M.E., A.E., M.S.A., R.A., and A.I.; writing—review and editing, I.P., M.S., M.F., M.E., A.E., M.S.A., R.A,and A.I.; visualization, I.P., M.S., M.F., and M.S.A.;. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Pet, I., Sanad, M.N., Farouz, M. et al. Review: Recent Developments in the Implementation of Activated Carbon as Heavy Metal Removal Management. Water Conserv Sci Eng 9, 62 (2024). https://doi.org/10.1007/s41101-024-00287-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41101-024-00287-3